torque YAMAHA YZF-R7 1999 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 1999, Model line: YZF-R7, Model: YAMAHA YZF-R7 1999Pages: 381, PDF Size: 18.88 MB

Page 7 of 381

EB004000

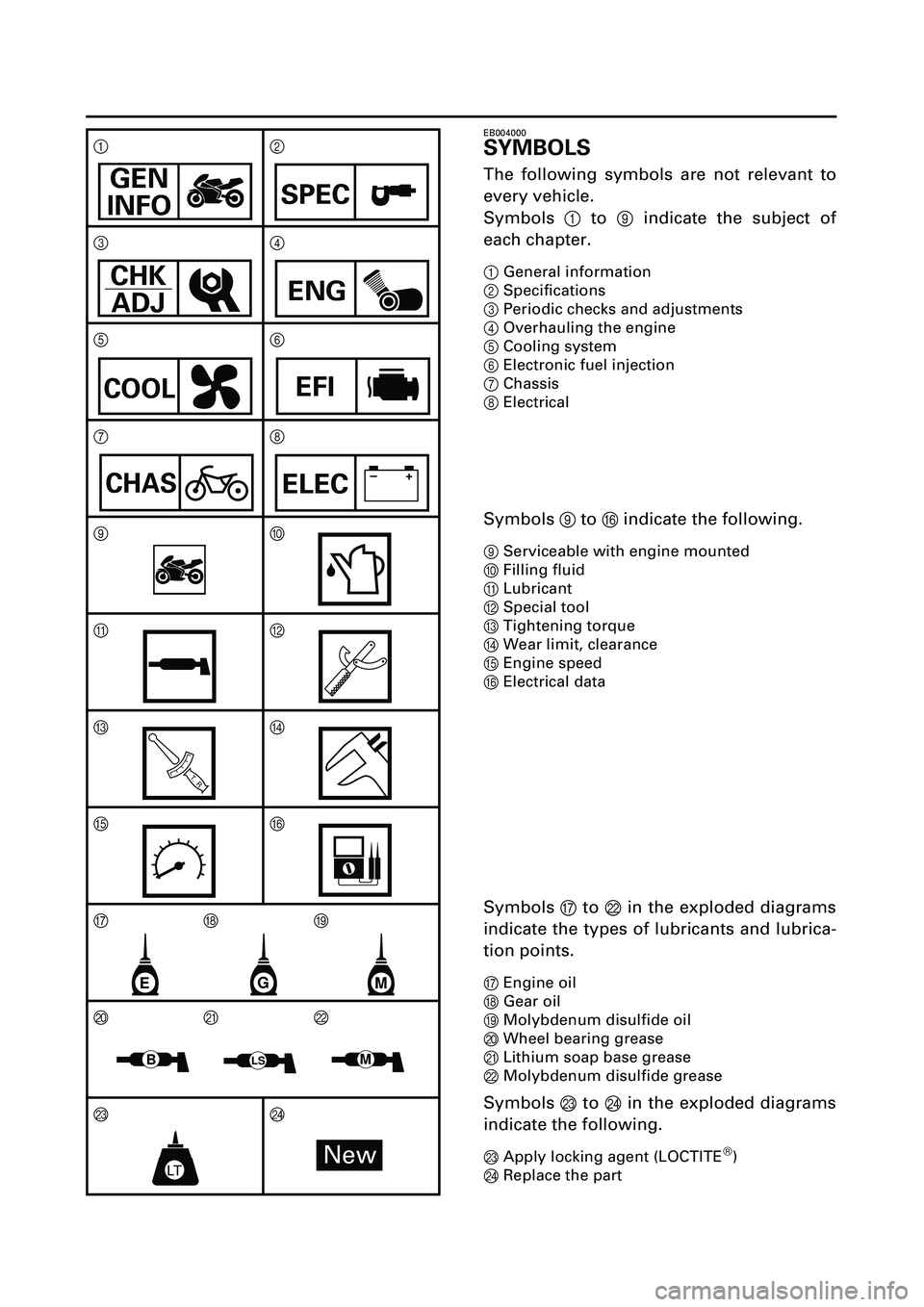

SYMBOLS

The following symbols are not relevant to

every vehicle.

Symbols

1

to

9

indicate the subject of

each chapter.

1

General information

2

Specifications

3

Periodic checks and adjustments

4

Overhauling the engine

5

Cooling system

6

Electronic fuel injection

7

Chassis

8

Electrical

Symbols

9

to

F

indicate the following.

9

Serviceable with engine mounted

0

Filling fluid

A

Lubricant

B

Special tool

C

Tightening torque

D

Wear limit, clearance

E

Engine speed

F

Electrical data

Symbols

G

to

L

in the exploded diagrams

indicate the types of lubricants and lubrica-

tion points.

G

Engine oil

H

Gear oil

I

Molybdenum disulfide oil

J

Wheel bearing grease

K

Lithium soap base grease

L

Molybdenum disulfide grease

Symbols

M

to

N

in the exploded diagrams

indicate the following.

MApply locking agent (LOCTITE

â)

NReplace the part 12

34

56

78

90

AB

CD

E F

GHI

JKL

M N

SPEC

CHK

ADJENG

COOLEFI

CHAS–+ELEC

T R..

GME

BLSM

LTNew

Page 10 of 381

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

GIVE SAFETY THE RIGHT OF WAY ........ 1-1

DESCRIPTION ........................................... 1-2

INSTRUMENT AND CONTROL

FUNCTIONS .............................................. 1-4

OPERATION AND IMPORTANT

RIDING POINTS ...................................... 1-12

INCLUDED ACCESSORIES ..................... 1-14

MOTORCYCLE CARE AND

STORAGE ................................................ 1-15

CONSUMER INFORMATION ................. 1-17

TROUBLESHOOTING .............................. 1-18

IMPORTANT INFORMATION ................. 1-20

CHECKING THE CONNECTIONS ........... 1-22

SPECIAL TOOLS ..................................... 1-23

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS .................... 2-1

ENGINE SPECIFICATIONS ....................... 2-2

CHASSIS SPECIFICATIONS ................... 2-11

ELECTRICAL SPECIFICATIONS ............. 2-15

TIGHTENING TORQUES ........................ 2-17

LUBRICATION POINTS AND

LUBRICANT TYPES ................................ 2-22

OIL FLOW CHART ................................... 2-24

COOLANT FLOW CHART ....................... 2-25

CABLE ROUTING .................................... 2-26

Page 26 of 381

1 - 14

OPERATION AND IMPORTANT RIDING POINTS/

INCLUDED ACCESSORIES

EAU01128

Engine break-in

There is never a more important period

in the life of your motorcycle than the

period between zero and 1,600 km. For

this reason we ask that you carefully

read the following material. Because

the engine is brand new, you must not

put an excessive load on it for the first

1,600 km. The various parts in the en-

gine wear and polish themselves to the

correct operating clearances. During

this period, prolonged full throttle oper-

ation, or any condition which might re-

sult in excessive heating of the engine,

must be avoided.

EAU013290 ~ 1,000 km

Avoid operation above 5,500 r/min.

1,000 ~ 1,600 km

Avoid cruising speeds in excess of

7,000 r/min.

EC000052

CAUTION:

After 1,000 km of operation, be sure

to replace the engine oil and oil fil-

ter.

1,600 km and beyond

Proceed with normal riding.

EC000053

CAUTION:

lNever let engine speeds enter

the red zone.

lIf any engine trouble should oc-

cur during the break-in period,

consult a Yamaha dealer imme-

diately.

EAU00460

Parking

When parking the motorcycle, stop the

engine and remove the ignition key.

EW000058

WARNING

The exhaust system is hot. Park the

motorcycle in a place where pedes-

trians or children are not likely to

touch the motorcycle. Do not park

the motorcycle on a slope or soft

ground; the motorcycle may over-

turn.

INCLUDED ACCESSORIES

EAU01575

Tool kit

The tools provided in the owner’s tool

kit are to assist you in the performance

of periodic maintenance. However,

some other tools such as a torque

wrench are also necessary to perform

the maintenance correctly.

The service information included in this

manual is intended to provide you, the

owner, with the necessary information

for completing some of your own pre-

ventive maintenance and minor re-

pairs.

NOTE:

If you do not have necessary tools re-

quired during a service operation, take

your motorcycle to a Yamaha dealer

for service.

EW000063

WARNING

Modifications to this motorcycle not

approved by Yamaha may cause

loss of performance, and render it

unsafe for use. Consult a Yamaha

dealer before attempting any chang-

es.

Page 55 of 381

2 - 17

SPEC

EB202001

TIGHTENING TORQUES

GENERAL TIGHTENING TORQUES

This chart specifies tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifica-

tions for special components or assemblies

are provided for each chapter of this man-

ual. To avoid warpage, tighten multi-fas-

tener assemblies in a crisscross pattern and

progressive stages until the specified tight-

ening torque is reached. Unless otherwise

specified, tightening torque specifications

require clean, dry threads. Components

should be at room temperature.

A: Width across flats

B: Thread diameter

A

(nut)B

(bolt)General tightening

torques

Nm m•kg ft•lb

10 mm 6 mm 6 0.6 4.3

12 mm 8 mm 15 1.5 11

14 mm 10 mm 30 3.0 22

17 mm 12 mm 55 5.5 40

19 mm 14 mm 85 8.5 61

22 mm 16 mm 130 13.0 94

TIGHTENING TORQUES

Page 56 of 381

2 - 18

SPEC

ENGINE TIGHTENING TORQUES

Item Fastener Thread size Q’tyTightening torque

Remarks

Nm m·kgf ft·lb

Spark plugs – M10 4 13 1.3 9.4

Cylinder head Nut M10 8 50 5.0 36

E

Cylinder head Cap nut M10 2 50 5.0 36E

Cylinder head Bolt M6 2 12 1.2 8.7

Camshaft caps Bolt M6 28 10 1.0 7.2

E

Cylinder head cover Bolt M6 6 12 1.2 8.7

Oil passage check bolt Bolt M8 1 20 2.0 14

Cap bolt (timing chain tensioner) Bolt M6 1 10 1.0 7.2

Camshaft sprocket Bolt M7 4 24 2.4 17

Generator rotor Bolt M10 1 65 6.5 47

E

Pickup coil rotor Bolt M10 1 45 4.5 32E

Water pump inlet pipe Bolt M6 1 10 1.0 7.2LT

Water pump outlet pipe Bolt M6 1 10 1.0 7.2LT

Oil/water pump assembly

driven sprocketBolt M6 1 15 1.5 11LT

Oil pump Bolt M6 1 12 1.2 8.7

Oil cooler Bolt M20 1 63 6.3 45

E

Engine oil drain bolt – M14 1 43 4.3 31

Oil strainer housing Bolt M6 2 10 1.0 7.2

LT

Oil/water pump assembly

driven sprocket coverBolt M6 1 12 1.2 8.7LT

Oil delivery pipe Bolt M6 1 10 1.0 7.2LT

Oil filter bolt Bolt M20 1 70 7.0 50

Oil filter cartridge – M20 1 17 1.7 12

E

Exhaust pipe joints Bolt M8 8 20 2.0 14

Exhaust pipe Bolt M8 1 20 2.0 14

Exhaust pipe bracket Bolt M8 1 24 2.4 17

Exhaust pipe emission check

boltsBolt M6 4 10 1.0 7.2

Muffler clamp Bolt M8 1 20 2.0 14

Muffler Bolt M10 1 38 3.8 27

Muffler bracket Bolt M8 2 28 2.8 20

Crankcase (cylinder head) Stud bolt M10 10 10 1.0 7.2

E

Crankcase Bolt M9 10 32 3.2 23E

Crankcase Bolt M6 2 14 1.4 10E

Crankcase Bolt M6 14 12 1.2 8.7E

Crankcase Bolt M8 2 24 2.4 17E

Generator rotor cover Bolt M6 9 12 1.2 8.7

Clutch cover Bolt M6 9 12 1.2 8.7

Pickup coil rotor cover Bolt M6 7 12 1.2 8.7

TIGHTENING TORQUES

Page 57 of 381

2 - 19

SPEC

Shift shaft cover Bolt M6 6 12 1.2 8.7

Oil baffle plate Bolt M6 5 10 1.0 7.2

LT

Timing mark accessing screw – M8 1 15 1.5 11

Starter clutch Bolt M6 3 12 1.2 8.7

LT

Clutch boss Nut M20 1 70 7.0 50Use a lock

washer.

Clutch spring Bolt M6 6 8 0.8 5.8

Drive sprocket Nut M18 1 70 7.0 50Use a lock

washer.

Main axle bearing housing Screw M6 3 12 1.2 8.7

LT

Shift drum retainer Bolt M6 2 10 1.0 7.2LT

Shift shaft spring stopper Bolt M8 1 22 2.2 16LT

Shift rod locknut Nut M6 2 7 0.7 5.1

Shift arm Bolt M6 1 10 1.0 7.2

Stator coil Bolt M6 3 10 1.0 7.2

LT

Neutral switch – M10 1 20 2.0 14

Pickup coil Screw M5 2 4 0.4 2.9

LT

Thermo switch – M16 1 23 2.3 17

Camshaft sensor Bolt M6 1 10 1.0 7.2

LT

Speed sensor Bolt M6 1 10 1.0 7.2LT

Coolant temperature sensor – M12 1 18 1.8 13

Intake air temperature sensor – M12 1 18 1.8 13

Intake air pressure sensor Screw M5 2 5 0.5 3.6

LT

Atmospheric pressure sensor Screw M5 2 5 0.5 3.6LT

Air funnel Bolt M6 8 10 1.0 7.2LT

Throttle body assembly Bolt M6 16 10 1.0 7.2

Injector 2 cover Bolt M5 8 8 0.8 5.8

LT

Fuel distributor Bolt M6 6 10 1.0 7.2LT

Injector fuel pipe 1,3 and 4 Union bolt M12 3 30 3.0 22

Injector fuel pipe 2 – M12 1 30 3.0 22

Fuel hose joint pipe Bolt M5 1 6 0.6 4.3

LT

Pressure sensor bracket Bolt M5 2 8 0.8 5.8LT

Item Fastener Thread size Q’tyTightening torque

Remarks

Nm m·kgf ft·lb

TIGHTENING TORQUES

Page 58 of 381

2 - 20

SPEC

Crankcase tightening sequence:

TIGHTENING TORQUES

Page 59 of 381

2 - 21

SPEC

CHASSIS TIGHTENING TORQUES

HINWEIS:NOTE:

1.First, tighten the ring nut to approximately 18 Nm (1.8 m • kg, 13 ft • lb) with a torque

wrench, then loosen the ring nut completely.

2.Retighten the ring nut to specification.Item Thread sizeTightening torque

Remarks

Nm m·kgf ft·lb

Upper bracket pinch bolts M8 26 2.6 19

Steering stem nut M28 115 11.5 85

Handlebar pinch bolts M6 13 1.3 9.4

Lower ring nut M30 9 0.9 6.5 See NOTE.

Lower bracket pinch bolts M6 11 1.1 8.0

Front brake hose union bolts M10 30 3.0 22

Front brake master cylinder M6 13 1.3 9.4

Engine mounting

Spacer bolts M16 18 1.8 13

Left front mounting bolts M10 40 4.0 29

Right front mounting bolts M10 40 4.0 29

Rear mounting bolts M10 55 5.5 40

Pinch bolts M8 17 1.7 12

Exhaust pipe bracket M8 24 2.4 17

Pivot shaft nut M18 125 12.5 90

Connecting arms M10 40 4.0 29

Relay arm and connecting arms M10 40 4.0 29

Relay arm M10 40 4.0 29

Rear shock absorber and relay arm M10 40 4.0 29

Rear shock absorber assembly M10 40 4.0 29

Fuel pump and fuel tank M5 4 0.4 2.9

Coolant reservoir and radiator M6 5 0.5 3.6

Rider footrest bracket M8 28 2.8 20

Rear master cylinder M8 23 2.3 17

Rear brake hose union bolts M10 30 3.0 22

Sidestand bracket M8 26 2.6 19

Front wheel axle M20 79 7.9 57

Rear wheel axle M24 150 15.0 110

Rear wheel axle nut M24 45 4.5 32

Front brake caliper and front fork M10 40 4.0 29

Rear brake caliper and bracket M10 40 4.0 29

Brake disc and wheel M6 18 1.8 13

Rear wheel sprocket and rear wheel

drive hubM10 69 6.9 50

Brake caliper and bleed screw M8 6 0.6 4.3

Pinch bolt (front wheel axle) M8 23 2.3 17

TIGHTENING TORQUES

Page 62 of 381

2 - 24

SPEC

OIL FLOW CHART

Pressure feed

Timing chain area camshaft

Valve lifter Check bolt

Piston

Connecting rod

Big end bearing

Nozzle

Nozzle

Back torque limiter clutch

Starter clutch Main axleMain gallery

Drive axle

Oil filter cartridge

Oil cooler

Relief valve

Oil pump

Oil strainer

Oil pan

Drain bolt Main axle gears

Drive axle gearsCrankshaft journal (#2, #4)

Crankshaft journal (#3, #5)Crankshaft journal (#1)

OIL FLOW CHART

Page 99 of 381

3 - 30

CHK

ADJCHECKING THE CRANKCASE BREATHER HOSE/

CHECKING THE EXHAUST SYSTEM

3. Install:

• fuel tank

Refer to “FUEL TANK AND AIR FIL-

TER”.

EB303200

CHECKING THE EXHAUST SYSTEM

The following procedure applies to all of

the exhaust pipes and gaskets.

1. Remove:

• radiator assembly

Refer to “RADIATOR AND THERMO-

STAT” in chapter 5.

2. Check:

• exhaust pipe joint 1

• exhaust pipe 2

• muffler 3

Cracks/damage ® Replace.

• gasket 4

Exhaust gas leaks ® Replace.

3. Measure:

• tightening torque

4. Install:

• radiator assembly

Refer to “RADIATOR AND THERMO-

STAT” in chapter 5.

T R..

Exhaust pipe joint bolt 5

20 Nm (2.0 m • kg, 14 ft • lb)

Muffler clamp bolt 6

20 Nm (2.0 m • kg, 14 ft • lb)

Exhaust pipe bolt 7

20 Nm (2.0 m • kg, 14 ft • lb)

Muffler bolt 8

38 Nm (3.8 m • kg, 27 ft • lb)

1

6 3

74

5

2 8