Periodic maintenance and adjustment

6-6

6

11*Wheel bearings • Check bearing for looseness or

damage. √√√√

12 *Swingarm pivot

bearings • Check operation and for exces-

sive play. √√√√

• Lubricate with lithium-soap- based grease. Every 50000 km (30000 mi)

13 Drive chain • Check chain slack, alignment and

condition.

• Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 1000 km (600 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

14 *Steering bearings • Check bearing assemblies for

looseness. √√

√

• Moderately repack with lithium- soap-based grease. √√

15 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened. √√√√√

16 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

17 Brake pedal pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Clutch lever pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

19 Shift pedal pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)UBEBE0E0.book Page 6 Monday, July 5, 2021 2:26 PM

Periodic maintenance and adjustment

6-25

6

EAU59921

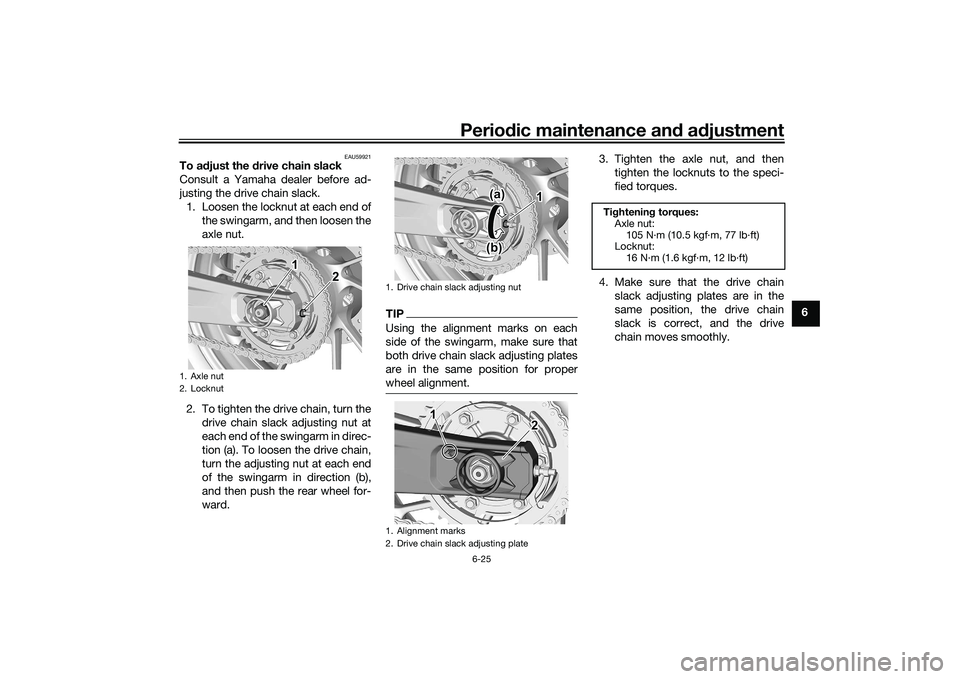

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

2. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

3. Tighten the axle nut, and thentighten the locknuts to the speci-

fied torques.

4. Make sure that the drive chain slack adjusting plates are in the

same position, the drive chain

slack is correct, and the drive

chain moves smoothly.

1. Axle nut

2. Locknut

1 1 1 2 2

1. Drive chain slack adjusting nut

1. Alignment marks

2. Drive chain slack adjusting plate

1 1 1

(a) (a) (a)

(b) (b) (b)

1 1 1 2 2

Tightening torques:

Axle nut: 105 N·m (10.5 kgf·m, 77 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

UBEBE0E0.book Page 25 Monday, July 5, 2021 2:26 PM