YAMAHA YZF1000 2021 Owner's Manual

Manufacturer: YAMAHA, Model Year: 2021, Model line: YZF1000, Model: YAMAHA YZF1000 2021Pages: 108, PDF Size: 11.75 MB

Page 21 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-6

3

EAU03889

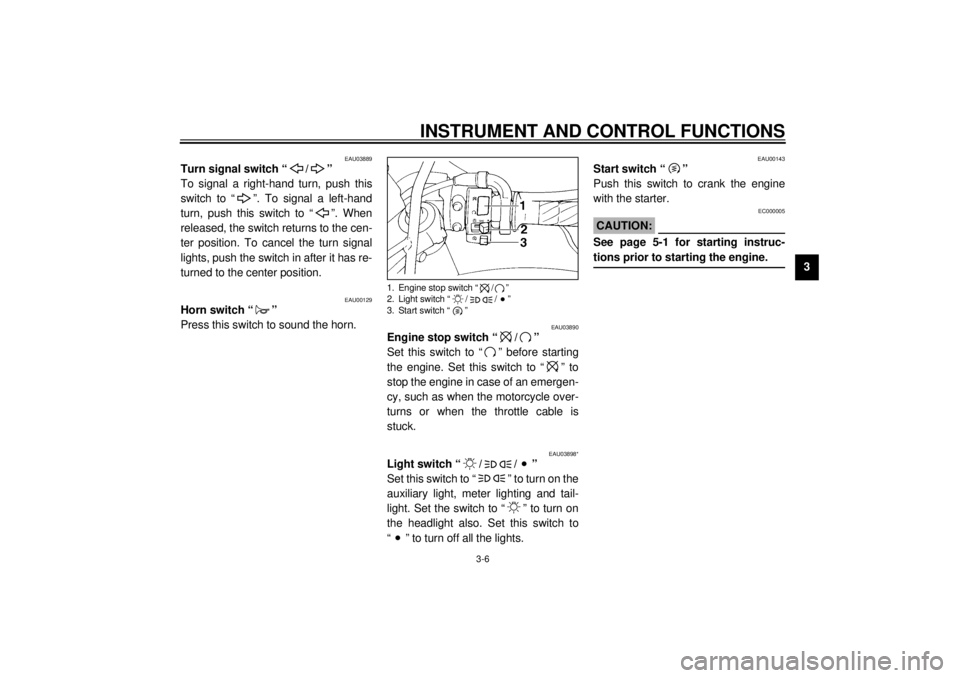

Turn signal switch “ / ”

To signal a right-hand turn, push this

switch to “ ”. To signal a left-hand

turn, push this switch to “ ”. When

released, the switch returns to the cen-

ter position. To cancel the turn signal

lights, push the switch in after it has re-

turned to the center position.

EAU00129

Horn switch “ ”

Press this switch to sound the horn.

EAU03890

Engine stop switch “ / ”

Set this switch to “ ” before starting

the engine. Set this switch to “ ” to

stop the engine in case of an emergen-

cy, such as when the motorcycle over-

turns or when the throttle cable is

stuck.

EAU03898*

Light switch “ / / ”

Set this switch to “ ” to turn on the

auxiliary light, meter lighting and tail-

light. Set the switch to “ ” to turn on

the headlight also. Set this switch to

“ ” to turn off all the lights.

EAU00143

Start switch “ ”

Push this switch to crank the engine

with the starter.

EC000005

CAUTION:_ See page 5-1 for starting instruc-

tions prior to starting the engine. _

1. Engine stop switch “ / ”

2. Light switch “ / / ”

3. Start switch “ ”

E_4sv.book Page 6 Friday, November 10, 2000 3:03 PM

Page 22 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-7

3

EAU00153

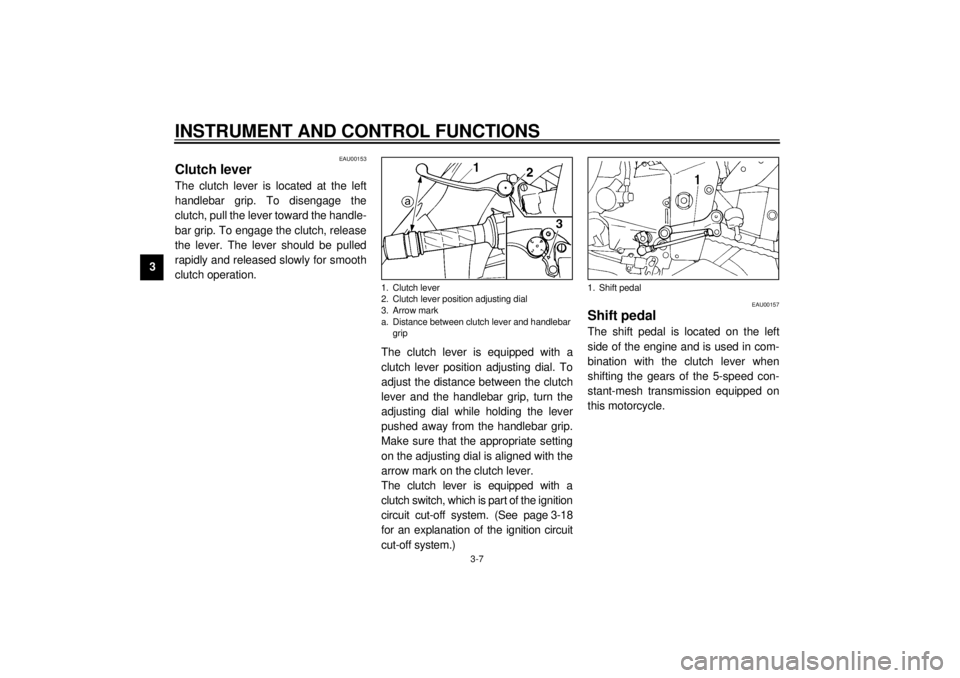

Clutch lever The clutch lever is located at the left

handlebar grip. To disengage the

clutch, pull the lever toward the handle-

bar grip. To engage the clutch, release

the lever. The lever should be pulled

rapidly and released slowly for smooth

clutch operation.

The clutch lever is equipped with a

clutch lever position adjusting dial. To

adjust the distance between the clutch

lever and the handlebar grip, turn the

adjusting dial while holding the lever

pushed away from the handlebar grip.

Make sure that the appropriate setting

on the adjusting dial is aligned with the

arrow mark on the clutch lever.

The clutch lever is equipped with a

clutch switch, which is part of the ignition

circuit cut-off system. (See page 3-18

for an explanation of the ignition circuit

cut-off system.)

EAU00157

Shift pedal The shift pedal is located on the left

side of the engine and is used in com-

bination with the clutch lever when

shifting the gears of the 5-speed con-

stant-mesh transmission equipped on

this motorcycle.

1. Clutch lever

2. Clutch lever position adjusting dial

3. Arrow mark

a. Distance between clutch lever and handlebar

grip

1. Shift pedal

E_4sv.book Page 7 Friday, November 10, 2000 3:03 PM

Page 23 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-8

3

EAU00161

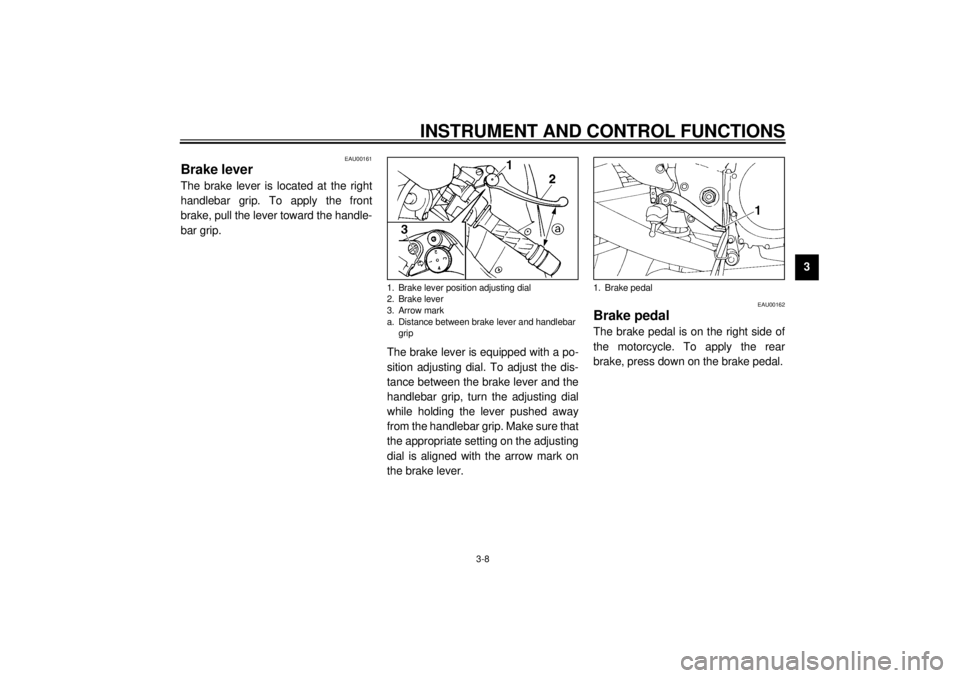

Brake lever The brake lever is located at the right

handlebar grip. To apply the front

brake, pull the lever toward the handle-

bar grip.

The brake lever is equipped with a po-

sition adjusting dial. To adjust the dis-

tance between the brake lever and the

handlebar grip, turn the adjusting dial

while holding the lever pushed away

from the handlebar grip. Make sure that

the appropriate setting on the adjusting

dial is aligned with the arrow mark on

the brake lever.

EAU00162

Brake pedal The brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.

1. Brake lever position adjusting dial

2. Brake lever

3. Arrow mark

a. Distance between brake lever and handlebar

grip

1. Brake pedal

E_4sv.book Page 8 Friday, November 10, 2000 3:03 PM

Page 24 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-9

3

EAU02935

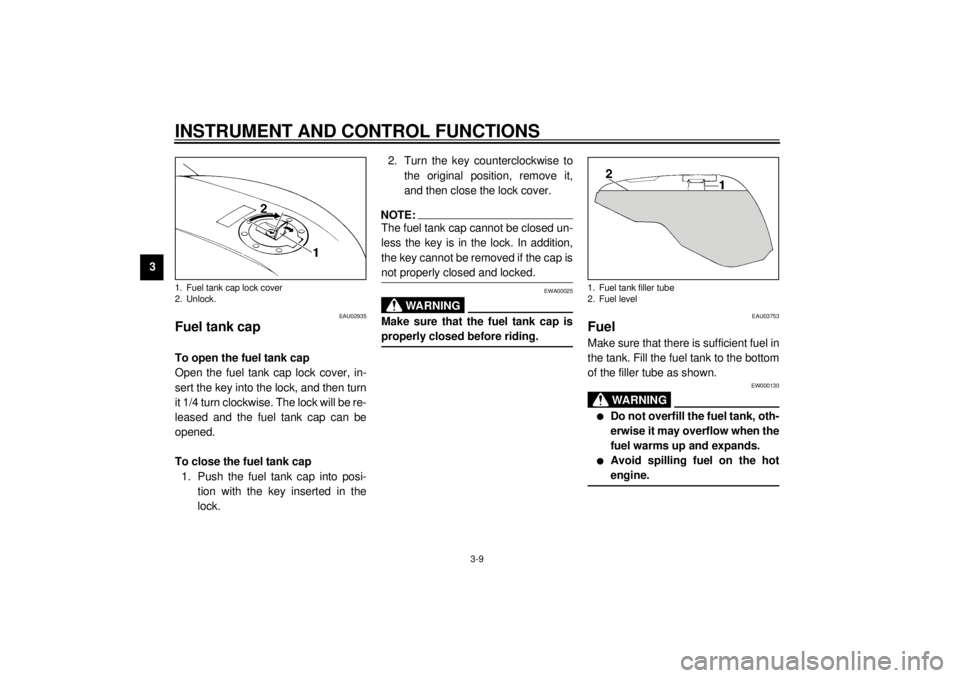

Fuel tank cap To open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be re-

leased and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into posi-

tion with the key inserted in the

lock. 2. Turn the key counterclockwise to

the original position, remove it,

and then close the lock cover.

NOTE:_ The fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked. _

EWA00025

WARNING

_ Make sure that the fuel tank cap is

properly closed before riding. _

EAU03753

Fuel Make sure that there is sufficient fuel in

the tank. Fill the fuel tank to the bottom

of the filler tube as shown.

EW000130

WARNING

_ l

Do not overfill the fuel tank, oth-

erwise it may overflow when the

fuel warms up and expands.

l

Avoid spilling fuel on the hot

engine.

_

1. Fuel tank cap lock cover

2. Unlock.

1. Fuel tank filler tube

2. Fuel level

E_4sv.book Page 9 Friday, November 10, 2000 3:03 PM

Page 25 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-10

3

EAU00186

CAUTION:_ l

Immediately wipe off spilled fuel

with a clean, dry, soft cloth,

since fuel may deteriorate paint-

ed surfaces or plastic parts.

l

For Germany only: Whenever

replacement is necessary, use a

fuel tank cap of the same spe-

cial design as the original.

_

EAU00191

NOTE:_ If knocking (or pinging) occurs, use

gasoline of a different brand or with a

higher octane grade. _

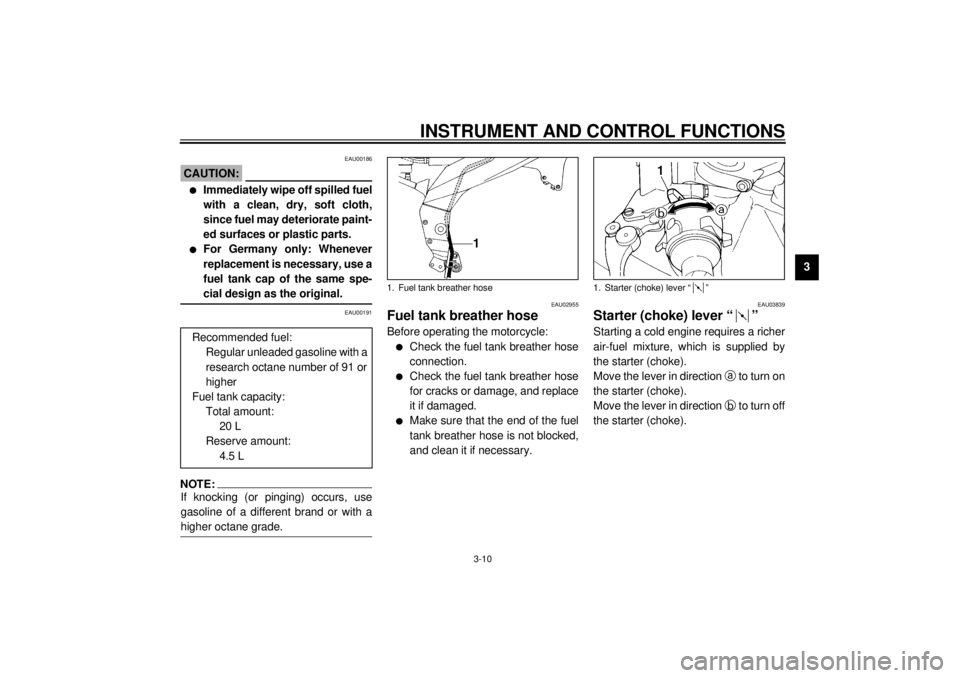

EAU02955

Fuel tank breather hose Before operating the motorcycle:l

Check the fuel tank breather hose

connection.

l

Check the fuel tank breather hose

for cracks or damage, and replace

it if damaged.

l

Make sure that the end of the fuel

tank breather hose is not blocked,

and clean it if necessary.

EAU03839

Starter (choke) lever “ ” Starting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the lever in direction

a to turn on

the starter (choke).

Move the lever in direction

b to turn off

the starter (choke). Recommended fuel:

Regular unleaded gasoline with a

research octane number of 91 or

higher

Fuel tank capacity:

Total amount:

20 L

Reserve amount:

4.5 L

1. Fuel tank breather hose

1. Starter (choke) lever “ ”

E_4sv.book Page 10 Friday, November 10, 2000 3:03 PM

Page 26 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-11

3

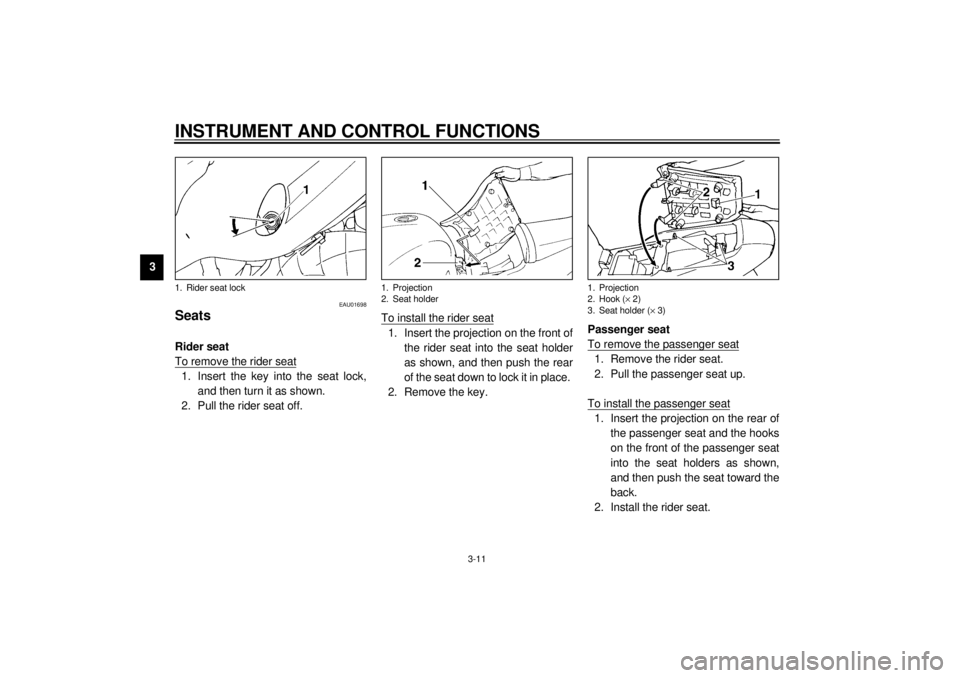

EAU01698

Seats Rider seat

To remove the rider seat1. Insert the key into the seat lock,

and then turn it as shown.

2. Pull the rider seat off.To install the rider seat

1. Insert the projection on the front of

the rider seat into the seat holder

as shown, and then push the rear

of the seat down to lock it in place.

2. Remove the key.Passenger seat

To remove the passenger seat

1. Remove the rider seat.

2. Pull the passenger seat up.

To install the passenger seat1. Insert the projection on the rear of

the passenger seat and the hooks

on the front of the passenger seat

into the seat holders as shown,

and then push the seat toward the

back.

2. Install the rider seat.

1. Rider seat lock

1. Projection

2. Seat holder

1. Projection

2. Hook (´ 2)

3. Seat holder (´ 3)

E_4sv.book Page 11 Friday, November 10, 2000 3:03 PM

Page 27 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

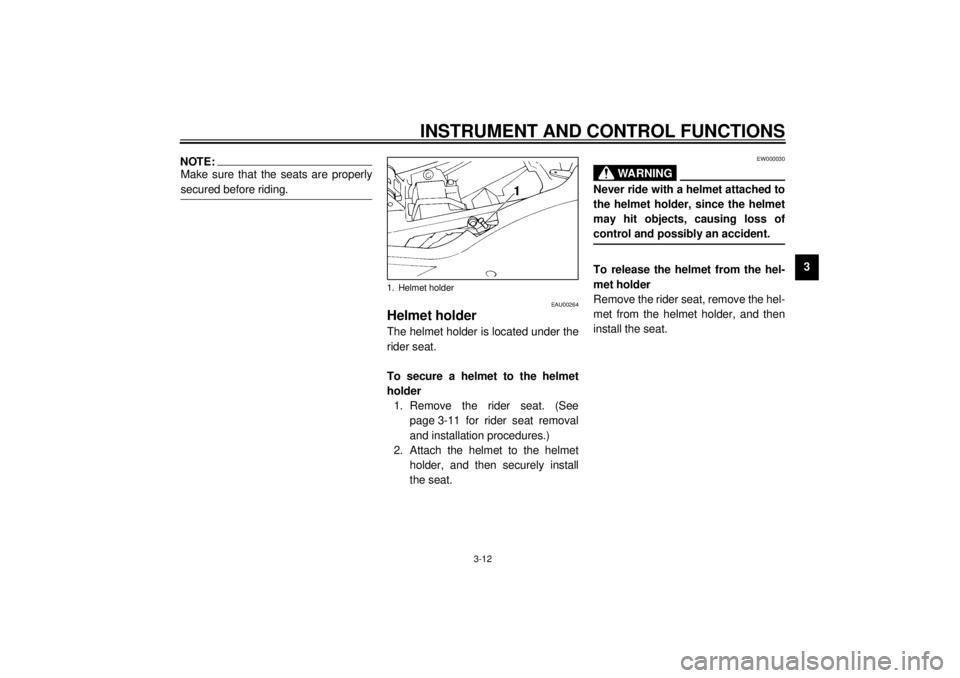

NOTE:_ Make sure that the seats are properly

secured before riding. _

EAU00264

Helmet holder The helmet holder is located under the

rider seat.

To secure a helmet to the helmet

holder

1. Remove the rider seat. (See

page 3-11 for rider seat removal

and installation procedures.)

2. Attach the helmet to the helmet

holder, and then securely install

the seat.

EW000030

WARNING

_ Never ride with a helmet attached to

the helmet holder, since the helmet

may hit objects, causing loss of

control and possibly an accident. _To release the helmet from the hel-

met holder

Remove the rider seat, remove the hel-

met from the helmet holder, and then

install the seat.

1. Helmet holder

E_4sv.book Page 12 Friday, November 10, 2000 3:03 PM

Page 28 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-13

3

EAU01688

Storage compartment This storage compartment is designed

to hold a genuine Yamaha U-LOCK.

(Other locks may not fit.) When placing

a U-LOCK in the storage compartment,

securely fasten it with the straps. When

the U-LOCK is not in the storage com-

partment, be sure to secure the straps

to prevent losing them.

When storing the owner’s manual or

other documents in the storage com-

partment, be sure to wrap them in a

plastic bag so that they will not get wet.

When washing the motorcycle, be

careful not to let any water enter the

storage compartment.

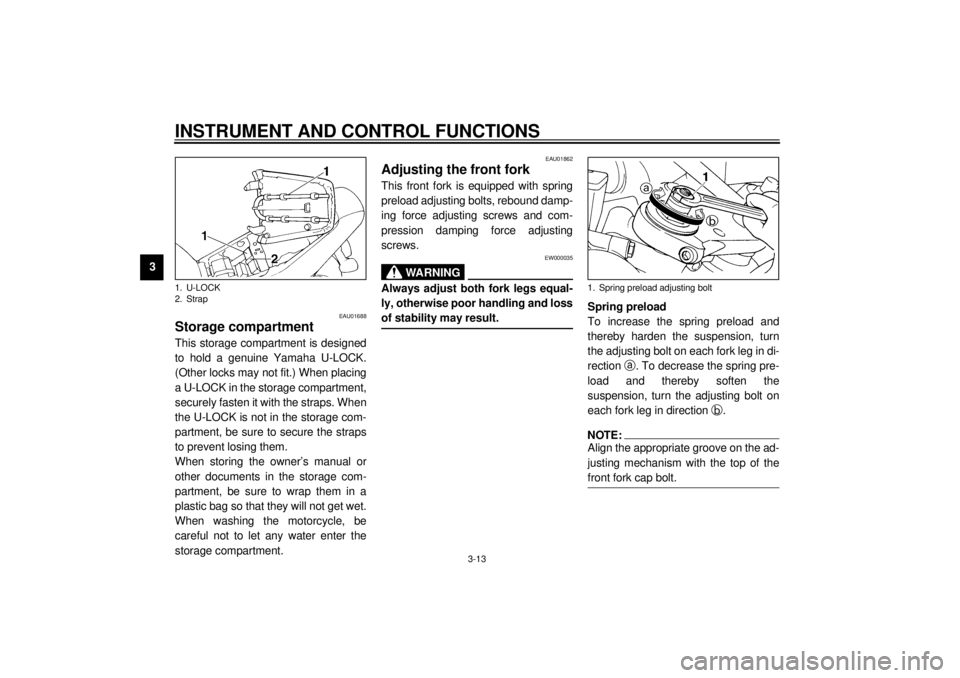

EAU01862

Adjusting the front fork This front fork is equipped with spring

preload adjusting bolts, rebound damp-

ing force adjusting screws and com-

pression damping force adjusting

screws.

EW000035

WARNING

_ Always adjust both fork legs equal-

ly, otherwise poor handling and loss

of stability may result. _

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection

a. To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction

b.NOTE:_ Align the appropriate groove on the ad-

justing mechanism with the top of the

front fork cap bolt. _

1. U-LOCK

2. Strap

1. Spring preload adjusting bolt

E_4sv.book Page 13 Friday, November 10, 2000 3:03 PM

Page 29 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3

CI-10E

Rebound damping force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw on

each fork leg in direction

a. To de-

crease the rebound damping force and

thereby soften the rebound damping,

turn the adjusting screw on each fork

leg in direction

b.CI-02E

Compression damping force

To increase the compression damping

force and thereby harden the compres-

sion damping, turn the adjusting screw

on each fork leg in direction

a. To de-

crease the compression damping force

and thereby soften the compression

damping, turn the adjusting screw on

each fork leg in direction

b.CI-02E

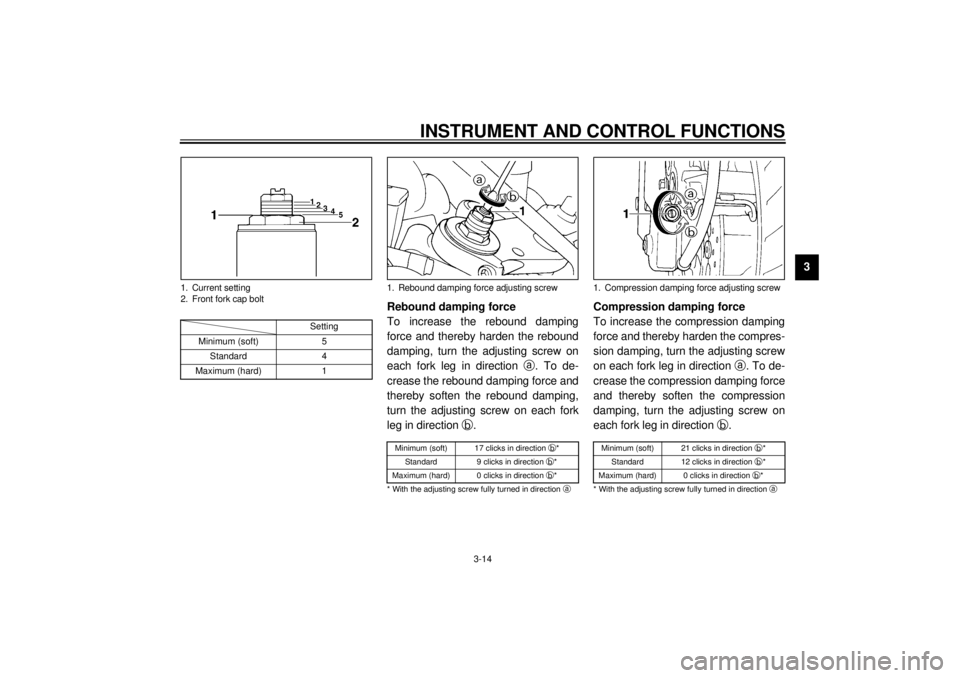

1. Current setting

2. Front fork cap bolt

Setting

Minimum (soft) 5

Standard 4

Maximum (hard) 1

1. Rebound damping force adjusting screwMinimum (soft) 17 clicks in direction

b*

Standard 9 clicks in direction

b*

Maximum (hard) 0 clicks in direction

b*

* With the adjusting screw fully turned in direction

a

1. Compression damping force adjusting screwMinimum (soft) 21 clicks in direction

b*

Standard 12 clicks in direction

b*

Maximum (hard) 0 clicks in direction

b*

* With the adjusting screw fully turned in direction

a

E_4sv.book Page 14 Friday, November 10, 2000 3:03 PM

Page 30 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

EC000015

CAUTION:_ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. _NOTE:_ Although the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above spec-

ifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting

range. To obtain a precise adjustment,

it would be advisable to check the num-

ber of clicks of each damping force ad-

justing mechanism and to modify the

specifications as necessary. _

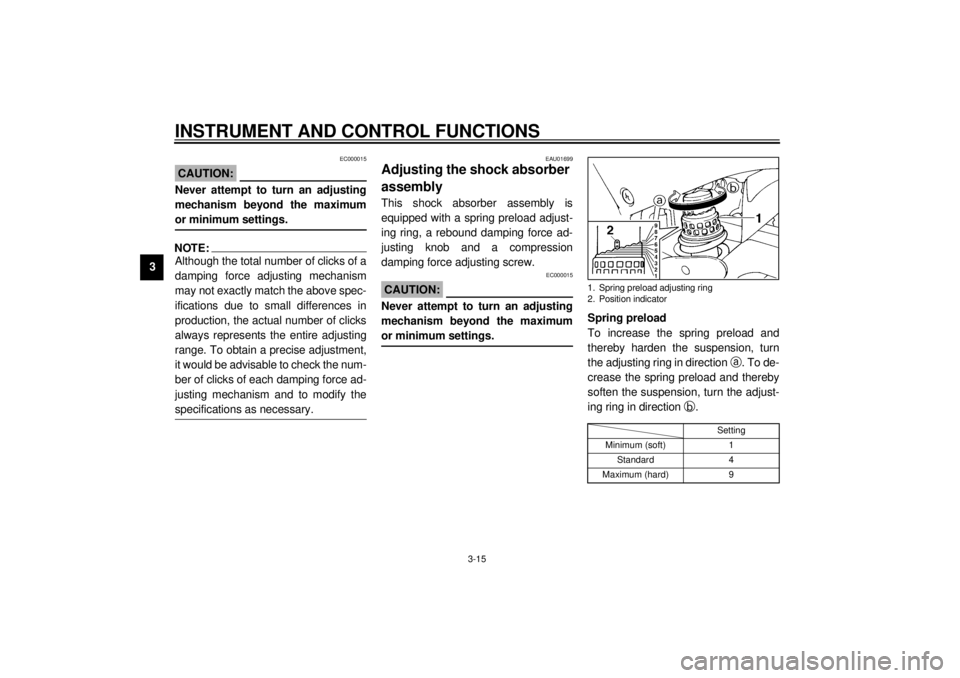

EAU01699

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing ring, a rebound damping force ad-

justing knob and a compression

damping force adjusting screw.

EC000015

CAUTION:_ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. _

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction

a. To de-

crease the spring preload and thereby

soften the suspension, turn the adjust-

ing ring in direction

b.CI-10E1. Spring preload adjusting ring

2. Position indicator

Setting

Minimum (soft) 1

Standard 4

Maximum (hard) 9

E_4sv.book Page 15 Friday, November 10, 2000 3:03 PM