wheel YAMAHA YZF600 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZF600, Model: YAMAHA YZF600 2000Pages: 109, PDF Size: 5.01 MB

Page 86 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-36

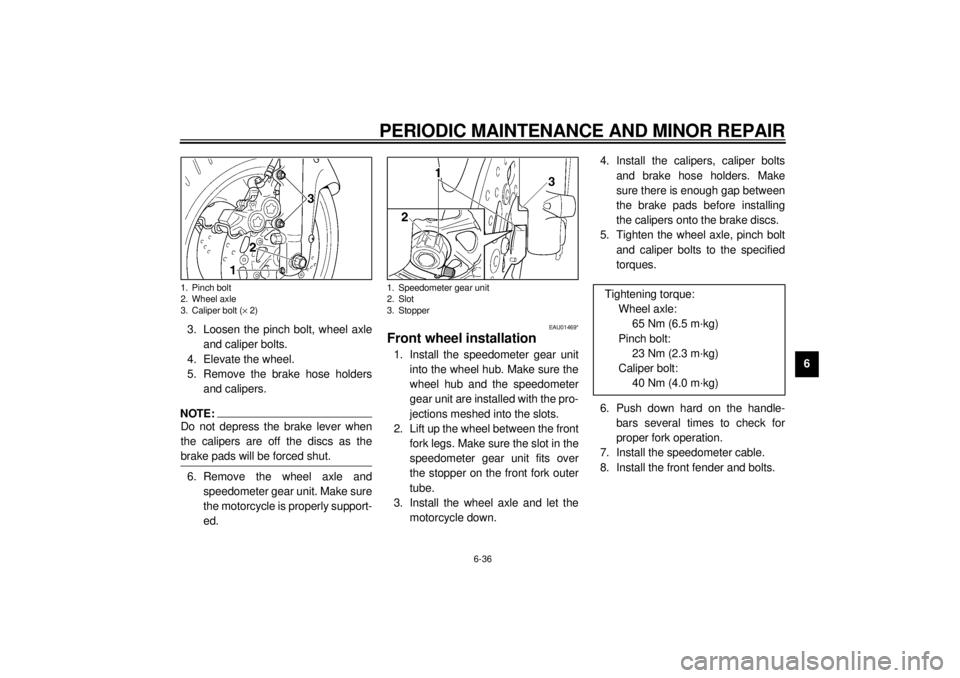

6 3. Loosen the pinch bolt, wheel axle

and caliper bolts.

4. Elevate the wheel.

5. Remove the brake hose holders

and calipers.

NOTE:@ Do not depress the brake lever when

the calipers are off the discs as the

brake pads will be forced shut. @6. Remove the wheel axle and

speedometer gear unit. Make sure

the motorcycle is properly support-

ed.

EAU01469*

Front wheel installation1. Install the speedometer gear unit

into the wheel hub. Make sure the

wheel hub and the speedometer

gear unit are installed with the pro-

jections meshed into the slots.

2. Lift up the wheel between the front

fork legs. Make sure the slot in the

speedometer gear unit fits over

the stopper on the front fork outer

tube.

3. Install the wheel axle and let the

motorcycle down.4. Install the calipers, caliper bolts

and brake hose holders. Make

sure there is enough gap between

the brake pads before installing

the calipers onto the brake discs.

5. Tighten the wheel axle, pinch bolt

and caliper bolts to the specified

torques.

6. Push down hard on the handle-

bars several times to check for

proper fork operation.

7. Install the speedometer cable.

8. Install the front fender and bolts.

1. Pinch bolt

2. Wheel axle

3. Caliper bolt (´ 2)

1. Speedometer gear unit

2. Slot

3. Stopper

Tightening torque:

Wheel axle:

65 Nm (6.5 m·kg)

Pinch bolt:

23 Nm (2.3 m·kg)

Caliper bolt:

40 Nm (4.0 m·kg)

E_4tv_Periodic.fm Page 36 Wednesday, September 1, 1999 11:12 AM

Page 87 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-37

6

EAU01247*

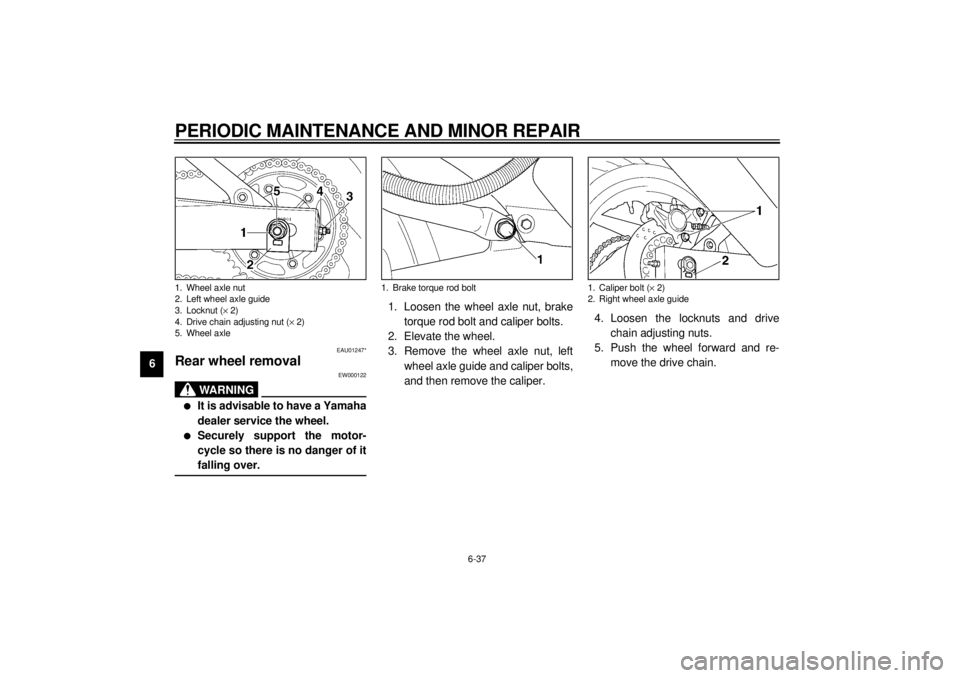

Rear wheel removal

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so there is no danger of it

falling over.

@

1. Loosen the wheel axle nut, brake

torque rod bolt and caliper bolts.

2. Elevate the wheel.

3. Remove the wheel axle nut, left

wheel axle guide and caliper bolts,

and then remove the caliper.4. Loosen the locknuts and drive

chain adjusting nuts.

5. Push the wheel forward and re-

move the drive chain.

1. Wheel axle nut

2. Left wheel axle guide

3. Locknut (´ 2)

4. Drive chain adjusting nut (´ 2)

5. Wheel axle

1. Brake torque rod bolt

1. Caliper bolt (´ 2)

2. Right wheel axle guide

E_4tv_Periodic.fm Page 37 Wednesday, September 1, 1999 11:12 AM

Page 88 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-38

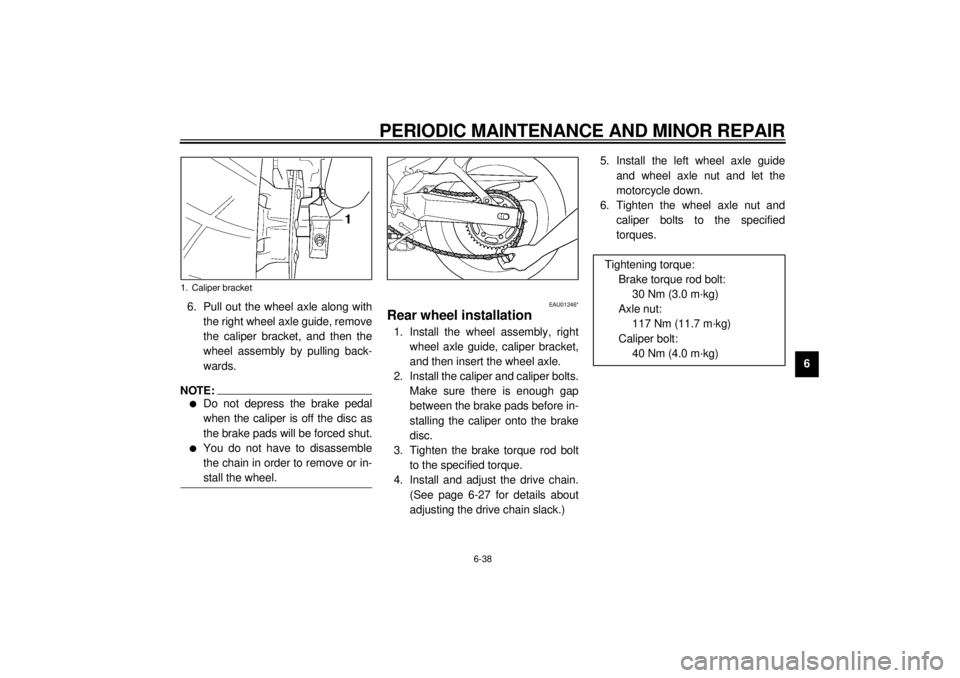

6 6. Pull out the wheel axle along with

the right wheel axle guide, remove

the caliper bracket, and then the

wheel assembly by pulling back-

wards.

NOTE:@ l

Do not depress the brake pedal

when the caliper is off the disc as

the brake pads will be forced shut.

l

You do not have to disassemble

the chain in order to remove or in-

stall the wheel.

@

EAU01246*

Rear wheel installation1. Install the wheel assembly, right

wheel axle guide, caliper bracket,

and then insert the wheel axle.

2. Install the caliper and caliper bolts.

Make sure there is enough gap

between the brake pads before in-

stalling the caliper onto the brake

disc.

3. Tighten the brake torque rod bolt

to the specified torque.

4. Install and adjust the drive chain.

(See page 6-27 for details about

adjusting the drive chain slack.)5. Install the left wheel axle guide

and wheel axle nut and let the

motorcycle down.

6. Tighten the wheel axle nut and

caliper bolts to the specified

torques.

1. Caliper bracket

Tightening torque:

Brake torque rod bolt:

30 Nm (3.0 m·kg)

Axle nut:

117 Nm (11.7 m·kg)

Caliper bolt:

40 Nm (4.0 m·kg)

E_4tv_Periodic.fm Page 38 Wednesday, September 1, 1999 11:12 AM

Page 93 of 109

7-1

7

EAU01516

7-MOTORCYCLE CARE AND STORAGECareThe exposure of its technology makes

a motorcycle charming but also vulner-

able. Although high-quality compo-

nents are used, they are not all rust-

resistant. While a rusty exhaust pipe

may remain unnoticed on a car, it does

look unattractive on a motorcycle. Fre-

quent and proper care, however, will

keep your motorcycle looking good, ex-

tend its life and maintain its perfor-

mance. Moreover, the warranty states

that the vehicle must be properly taken

care of. For all these reasons, it is rec-

ommended that you observe the fol-

lowing cleaning and storing

precautions.Before cleaning

1. Cover up the muffler outlet with a

plastic bag.

2. Make sure that all caps and covers

as well as all electrical couplers

and connectors, including the

spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-

ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.Cleaning

After normal use

Remove dirt with warm water, a neutral

detergent and a soft clean sponge,

then rinse with plenty of clean water.

Use a tooth or bottle brush for hard-to-

reach parts. Tougher dirt and insects

will come off more easily if the area is

covered with a wet cloth for a few min-

utes before cleaning.

E_4tv_Cleaning.fm Page 1 Wednesday, September 1, 1999 11:13 AM

Page 94 of 109

MOTORCYCLE CARE AND STORAGE

7-2

7

ECA00010

CAUTION:@ l

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If you do use such

products for hard-to-remove

dirt, do not leave it on any long-

er than instructed, then thor-

oughly rinse it off with water,

immediately dry the area and

apply a corrosion protection

spray.

l

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

l

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

l

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel bearings,

swingarm bearings, forks and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

l

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure they do not

leave any marks. If the wind-

shield is scratched, use a quali-

ty plastic polishing compound

after washing.

@After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on the

roads in the winter are extremely corro-

sive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads. (Salt sprayed in the

winter may remain on the roads well

into spring.)

E_4tv_Cleaning.fm Page 2 Wednesday, September 1, 1999 11:13 AM

Page 97 of 109

MOTORCYCLE CARE AND STORAGE

7-5

7a. Remove the spark plug caps and

spark plugs.

b. Pour a teaspoonful of engine oil

into each spark plug bore.

c. Install the spark plug caps onto the

spark plugs and place the spark

plugs on the cylinder head so that

the electrodes are grounded. (This

will limit sparking during the next

step.)

d. Turn the engine over several times

with the starter. (This will coat the

cylinder walls with oil.)

e. Remove the spark plug caps from

the spark plugs, install the spark

plugs and then the spark plug

caps.

EWA00003

WARNING

@ When turning the engine over, be

sure to ground the spark plug elec-

trodes to prevent damage or injury

from sparking. @

6. Lubricate all control cables and

the pivoting points of all levers and

pedals as well as of the sidestand/

centerstand.

7. Check and, if necessary, correct

the tire air pressure, then raise the

motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

8. Cover up the muffler outlet with a

plastic bag to prevent moisture

from entering.9. Remove the battery and fully

charge it. Store it in a cool, dry

place and recharge it once a

month. Do not store the battery in

an excessively cold or warm place

(less than 0 °C or more than

30 °C). For more information, see

“Battery storage” in the chapter

“PERIODIC MAINTENANCE AND

MINOR REPAIRS”.

NOTE:@ Make any necessary repairs before

storing the motorcycle. @

E_4tv_Cleaning.fm Page 5 Wednesday, September 1, 1999 11:13 AM

Page 99 of 109

8-1

8

EAU01038

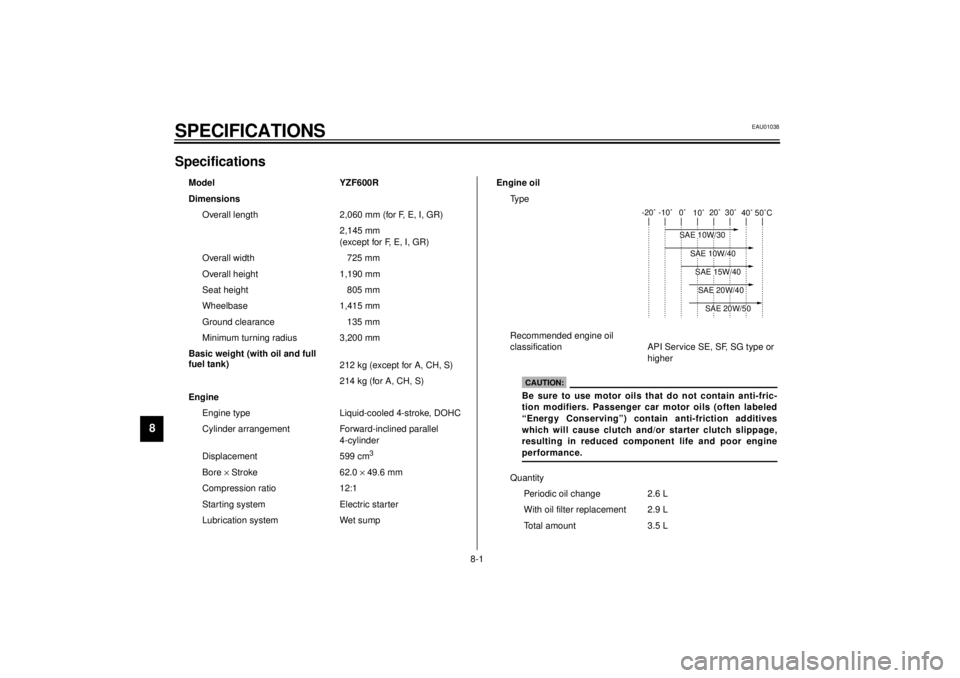

8-SPECIFICATIONSSpecifications01E

Model YZF600R

Dimensions

Overall length 2,060 mm (for F, E, I, GR)

2,145 mm

(except for F, E, I, GR)

Overall width 725 mm

Overall height 1,190 mm

Seat height 805 mm

Wheelbase 1,415 mm

Ground clearance 135 mm

Minimum turning radius 3,200 mm

Basic weight (with oil and full

fuel tank)

212 kg (except for A, CH, S)

214 kg (for A, CH, S)

Engine

Engine type Liquid-cooled 4-stroke, DOHC

Cylinder arrangement Forward-inclined parallel

4-cylinder

Displacement 599 cm

3

Bore ´ Stroke 62.0 ´ 49.6 mm

Compression ratio 12:1

Starting system Electric starter

Lubrication system Wet sumpEngine oil

Ty p e

Recommended engine oil

classification API Service SE, SF, SG type or

higher

Quantity

Periodic oil change 2.6 L

With oil filter replacement 2.9 L

Total amount 3.5 L

-20˚ -10˚ 0˚

10˚20˚ 30˚

40˚50˚C

SAE 10W/30

SAE 15W/40SAE 20W/40SAE 20W/50

SAE 10W/40

CAUTION:Be sure to use motor oils that do not contain anti-fric-

tion modifiers. Passenger car motor oils (often labeled

“Energy Conserving”) contain anti-friction additives

which will cause clutch and/or starter clutch slippage,

resulting in reduced component life and poor engine

performance.

E_4tv_Spec.fm Page 1 Wednesday, September 1, 1999 11:14 AM

Page 101 of 109

SPECIFICATIONS

8-3

8

Rear

Ty p e Tu b e l e s s

Size 160/60 ZR17 (69 W)

Manufacturer/model Bridgestone / BT57

Dunlop / D204

Metzeler / MEZ1

Michelin / MACADAM 90X

Maximum load* 180 kg (except for A, CH, S)

178 kg (for A, CH, S)

Air pressure (cold tire)

Up to 90 kg load*

Front 225 kPa (2.25 kg/cm

2, 2.25 bar)

Rear 250 kPa (2.50 kg/cm2, 2.50 bar)

90 kg load ~ maximum

load*

Front 250 kPa (2.50 kg/cm2, 2.50 bar)

Rear 290 kPa (2.90 kg/cm2, 2.90 bar)

High speed riding

Front 250 kPa (2.50 kg/cm2, 2.50 bar)

Rear 290 kPa (2.90 kg/cm2, 2.90 bar)

* Load is total weight of cargo, rider, passenger and accessories.Wheels

Fr on t

Ty p e C a s t

Size 17 ´ MT 3.50

Rear

Ty p e C a s t

Size 17 ´ MT 5.00

Brakes

Fr on t

Type Dual disc brake

Operation Right hand operation

Fluid DOT 4

Rear

Type Single disc brake

Operation Right foot operation

Fluid DOT 4

Suspension

Fr on t

Ty p e Te l e s c o p i c f o r k

Rear

Type Swingarm (link suspension)

Shock absorbers

Front Coil spring / oil damper

Rear Coil spring / gas-oil damper

E_4tv_Spec.fm Page 3 Wednesday, September 1, 1999 11:14 AM

Page 102 of 109

SPECIFICATIONS

8-4

8

Wheel travel

Front 130 mm

Rear 120 mm

Electrical system

Ignition system T.C.I. (digital)

Charging system

Type A.C. magneto

Standard output 14 V, 18.5 A @ 5,000 r/min

Battery

Type YTX12-BS

Voltage, capacity 12 V, 10 AH

Headlight type

Quartz bulb (halogen)

Bulb voltage, wattage

´ quantity

Headlight 12 V, 60/55 W ´ 1

Tail/brake light 12 V, 5/21 W ´ 1

Auxiliary light 12 V, 4 W ´ 1

Turn signal light 12 V, 21 W ´ 4

Meter light 12 V, 1.7 W ´ 4

Neutral indicator light 12 V, 3.4 W ´ 1

High beam indicator light 12 V, 3.4 W ´ 1

Oil level indicator light 12 V, 3.4 W ´ 1

Turn indicator light 12 V, 3.4 W ´ 1

Fuel indicator light 12 V, 3.4 W ´ 1Fuses

Main fuse 30 A

Headlight fuse 20 A

Signaling system fuse 15 A

Fan fuse 7.5 A

Ignition fuse 7.5 A

E_4tv_Spec.fm Page 4 Wednesday, September 1, 1999 11:14 AM

Page 107 of 109

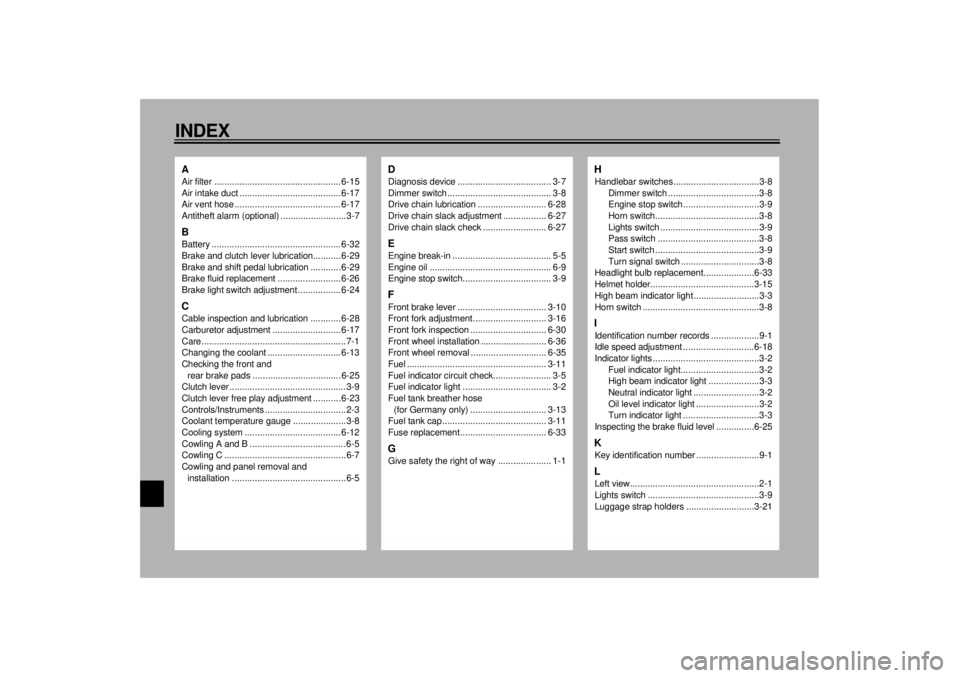

10-INDEXAAir filter ..................................................6-15

Air intake duct ........................................6-17

Air vent hose .......................................... 6-17

Antitheft alarm (optional) .......................... 3-7BBattery ................................................... 6-32

Brake and clutch lever lubrication........... 6-29

Brake and shift pedal lubrication ............ 6-29

Brake fluid replacement ......................... 6-26

Brake light switch adjustment ................. 6-24CCable inspection and lubrication ............ 6-28

Carburetor adjustment ...........................6-17

Care.........................................................7-1

Changing the coolant ............................. 6-13

Checking the front and

rear brake pads ................................... 6-25

Clutch lever .............................................. 3-9

Clutch lever free play adjustment ........... 6-23

Controls/Instruments ................................2-3

Coolant temperature gauge ..................... 3-8

Cooling system ...................................... 6-12

Cowling A and B ......................................6-5

Cowling C ................................................6-7

Cowling and panel removal and

installation .............................................6-5

DDiagnosis device ..................................... 3-7

Dimmer switch ......................................... 3-8

Drive chain lubrication ........................... 6-28

Drive chain slack adjustment ................. 6-27

Drive chain slack check ......................... 6-27EEngine break-in ....................................... 5-5

Engine oil ................................................ 6-9

Engine stop switch................................... 3-9FFront brake lever ................................... 3-10

Front fork adjustment............................. 3-16

Front fork inspection .............................. 6-30

Front wheel installation .......................... 6-36

Front wheel removal .............................. 6-35

Fuel ....................................................... 3-11

Fuel indicator circuit check....................... 3-5

Fuel indicator light ................................... 3-2

Fuel tank breather hose

(for Germany only) .............................. 3-13

Fuel tank cap ......................................... 3-11

Fuse replacement.................................. 6-33GGive safety the right of way ..................... 1-1

HHandlebar switches ..................................3-8

Dimmer switch ....................................3-8

Engine stop switch..............................3-9

Horn switch.........................................3-8

Lights switch .......................................3-9

Pass switch ........................................3-8

Start switch .........................................3-9

Turn signal switch ...............................3-8

Headlight bulb replacement....................6-33

Helmet holder.........................................3-15

High beam indicator light ..........................3-3

Horn switch ..............................................3-8IIdentification number records ...................9-1

Idle speed adjustment ............................6-18

Indicator lights ..........................................3-2

Fuel indicator light...............................3-2

High beam indicator light ....................3-3

Neutral indicator light ..........................3-2

Oil level indicator light .........................3-2

Turn indicator light ..............................3-3

Inspecting the brake fluid level ...............6-25KKey identification number .........................9-1LLeft view...................................................2-1

Lights switch ............................................3-9

Luggage strap holders ...........................3-21

E_4tvIX.fm Page 1 Wednesday, September 1, 1999 11:15 AM