torque YAMAHA YZF600 2000 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZF600, Model: YAMAHA YZF600 2000Pages: 109, PDF Size: 5.01 MB

Page 51 of 109

6-1

6

EAU00462

6-PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00464

Periodic inspection, adjustment and lu-

brication will keep your motorcycle in

the safest and most efficient condition

possible. Safety is an obligation of the

motorcycle owner. The maintenance

and lubrication schedule chart should

be considered strictly as a guide to

general maintenance and lubrication

intervals. YOU MUST TAKE INTO

CONSIDERATION THAT WEATHER,

TERRAIN, GEOGRAPHICAL LOCA-

TIONS, AND A VARIETY OF INDIVID-

UAL USES ALL TEND TO DEMAND

THAT EACH OWNER ALTER THIS

TIME SCHEDULE TO SHORTER IN-

TERVALS TO MATCH THE ENVI-

RONMENT. The most important points

of motorcycle inspection, adjustment,

and lubrication are explained in the fol-

lowing pages.

EW000060

WARNING

@ If you are not familiar with motor-

cycle service, this work should be

done by a Yamaha dealer. @

EAU00469

Tool kitThe service information included in this

manual is intended to provide you, the

owner, with the necessary information

for completing some of your own pre-

ventive maintenance and minor re-

pairs. The tools provided in the owner’s

tool kit are to assist you in the perfor-

mance of periodic maintenance. How-

ever, some other tools such as a torque

wrench are also necessary to perform

the maintenance correctly.

NOTE:@ If you do not have necessary tools re-

quired during a service operation, take

your motorcycle to a Yamaha dealer for

service. @

EW000063

WA R N I N G

@ Modifications to this motorcycle not

approved by Yamaha may cause

loss of performance, and render it

unsafe for use. Consult a Yamaha

dealer before attempting any chang-

es. @

1. Tool kit

E_4tv_Periodic.fm Page 1 Wednesday, September 1, 1999 11:12 AM

Page 59 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-9

6Installation

1. Measure the electrode gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifica-

tion.

2. Clean the gasket surface. Wipe off

any grime from the threads.

3. Install the spark plug and tighten it

to the specified torque.

NOTE:@ If a torque wrench is not available when

you are installing a spark plug, a good

estimate of the correct torque is 1/4 to

1/2 turn past finger tight. Have the

spark plug tightened to the specified

torque as soon as possible. @4. Install the spark plug caps.

EAU01765*

Engine oilOil level inspection

1. Place the motorcycle on a level

place and hold it in an upright posi-

tion. Warm up the engine for sev-

eral minutes.NOTE:@ Be sure the motorcycle is positioned

straight up when checking the oil level.

A slight tilt toward the side can result in

false readings. @

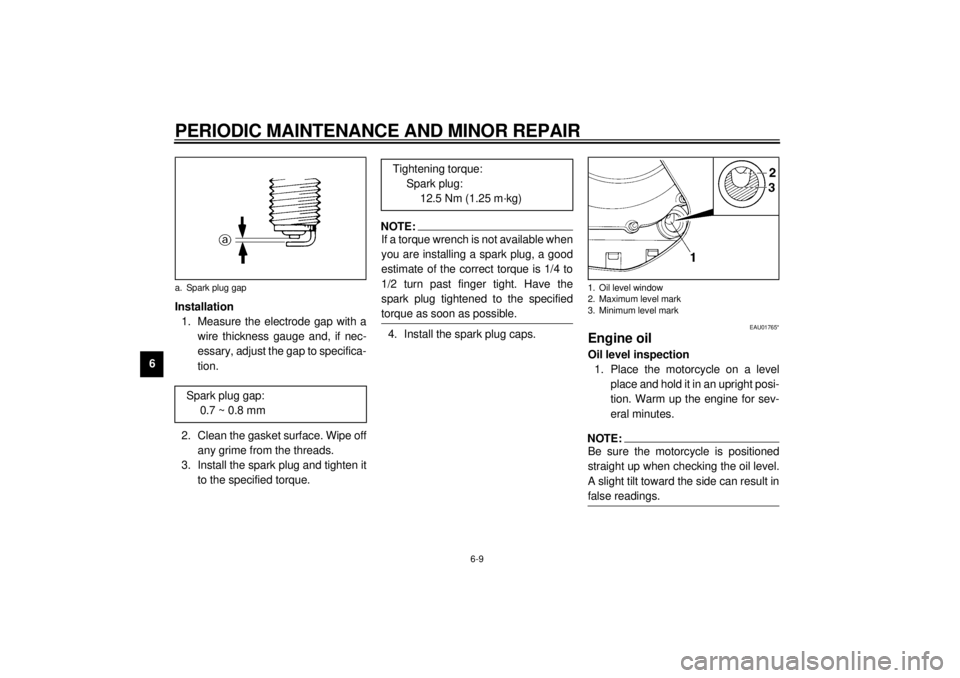

a. Spark plug gap

Spark plug gap:

0.7 ~ 0.8 mm

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kg)

1. Oil level window

2. Maximum level mark

3. Minimum level mark

E_4tv_Periodic.fm Page 9 Wednesday, September 1, 1999 11:12 AM

Page 60 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-10

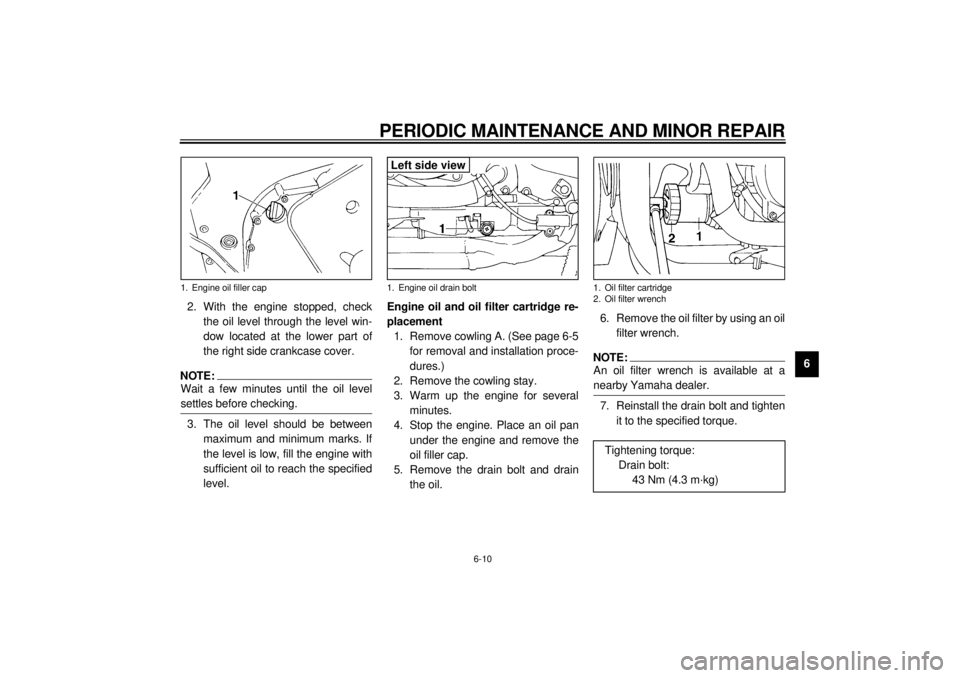

6 2. With the engine stopped, check

the oil level through the level win-

dow located at the lower part of

the right side crankcase cover.

NOTE:@ Wait a few minutes until the oil level

settles before checking. @3. The oil level should be between

maximum and minimum marks. If

the level is low, fill the engine with

sufficient oil to reach the specified

level.Engine oil and oil filter cartridge re-

placement

1. Remove cowling A. (See page 6-5

for removal and installation proce-

dures.)

2. Remove the cowling stay.

3. Warm up the engine for several

minutes.

4. Stop the engine. Place an oil pan

under the engine and remove the

oil filler cap.

5. Remove the drain bolt and drain

the oil.6. Remove the oil filter by using an oil

filter wrench.

NOTE:@ An oil filter wrench is available at a

nearby Yamaha dealer. @7. Reinstall the drain bolt and tighten

it to the specified torque.

1. Engine oil filler cap

1. Engine oil drain boltLeft side view

1. Oil filter cartridge

2. Oil filter wrenchTightening torque:

Drain bolt:

43 Nm (4.3 m·kg)

E_4tv_Periodic.fm Page 10 Wednesday, September 1, 1999 11:12 AM

Page 61 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-11

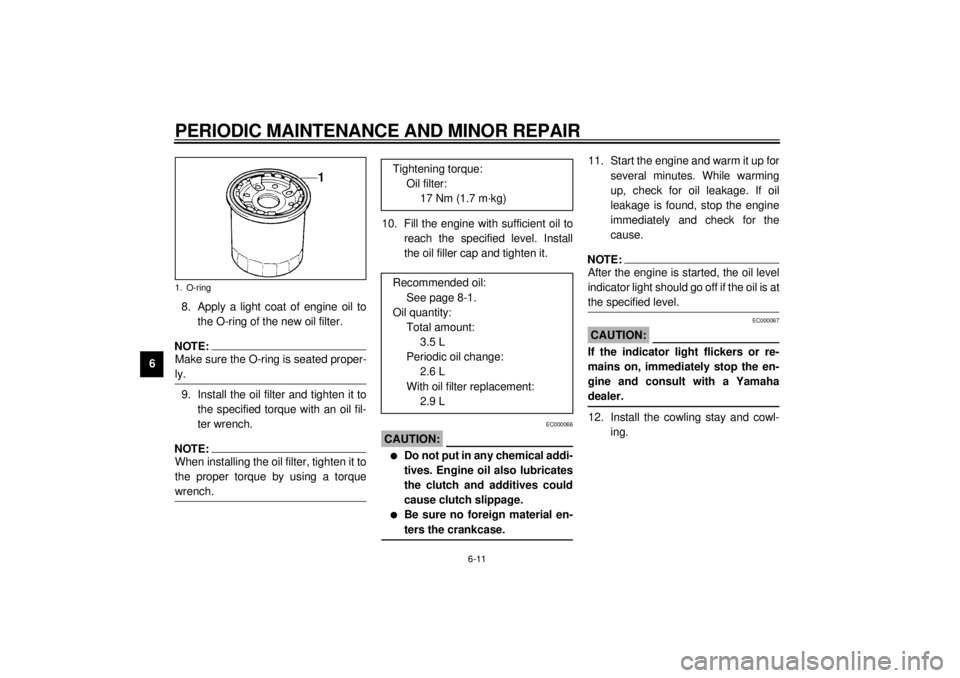

68. Apply a light coat of engine oil to

the O-ring of the new oil filter.

NOTE:@ Make sure the O-ring is seated proper-

ly. @9. Install the oil filter and tighten it to

the specified torque with an oil fil-

ter wrench.NOTE:When installing the oil filter, tighten it to

the proper torque by using a torque

wrench.

10. Fill the engine with sufficient oil to

reach the specified level. Install

the oil filler cap and tighten it.

EC000066

CAUTION:@ l

Do not put in any chemical addi-

tives. Engine oil also lubricates

the clutch and additives could

cause clutch slippage.

l

Be sure no foreign material en-

ters the crankcase.

@

11. Start the engine and warm it up for

several minutes. While warming

up, check for oil leakage. If oil

leakage is found, stop the engine

immediately and check for the

cause.NOTE:@ After the engine is started, the oil level

indicator light should go off if the oil is at

the specified level. @

EC000067

CAUTION:@ If the indicator light flickers or re-

mains on, immediately stop the en-

gine and consult with a Yamaha

dealer. @12. Install the cowling stay and cowl-

ing.

1. O-ring

Tightening torque:

Oil filter:

17 Nm (1.7 m·kg)

Recommended oil:

See page 8-1.

Oil quantity:

Total amount:

3.5 L

Periodic oil change:

2.6 L

With oil filter replacement:

2.9 L

E_4tv_Periodic.fm Page 11 Wednesday, September 1, 1999 11:12 AM

Page 64 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-14

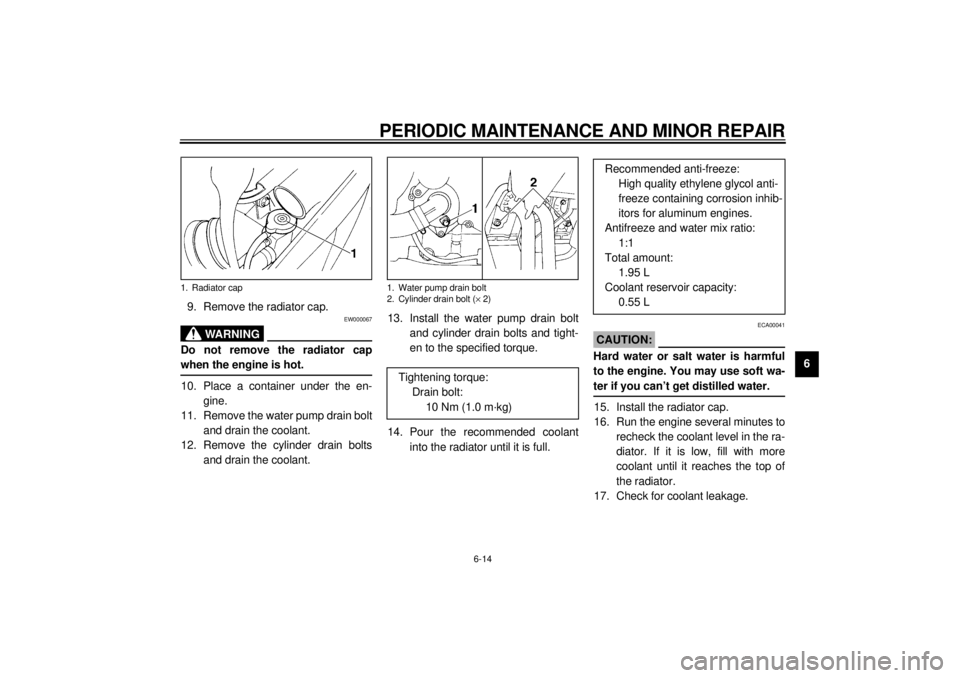

6 9. Remove the radiator cap.

EW000067

WARNING

@ Do not remove the radiator cap

when the engine is hot. @10. Place a container under the en-

gine.

11. Remove the water pump drain bolt

and drain the coolant.

12. Remove the cylinder drain bolts

and drain the coolant.13. Install the water pump drain bolt

and cylinder drain bolts and tight-

en to the specified torque.

14. Pour the recommended coolant

into the radiator until it is full.

ECA00041

CAUTION:@ Hard water or salt water is harmful

to the engine. You may use soft wa-

ter if you can’t get distilled water. @15. Install the radiator cap.

16. Run the engine several minutes to

recheck the coolant level in the ra-

diator. If it is low, fill with more

coolant until it reaches the top of

the radiator.

17. Check for coolant leakage.

1. Radiator cap

1. Water pump drain bolt

2. Cylinder drain bolt (´ 2)

Tightening torque:

Drain bolt:

10 Nm (1.0 m·kg)

Recommended anti-freeze:

High quality ethylene glycol anti-

freeze containing corrosion inhib-

itors for aluminum engines.

Antifreeze and water mix ratio:

1:1

Total amount:

1.95 L

Coolant reservoir capacity:

0.55 L

E_4tv_Periodic.fm Page 14 Wednesday, September 1, 1999 11:12 AM

Page 77 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

6

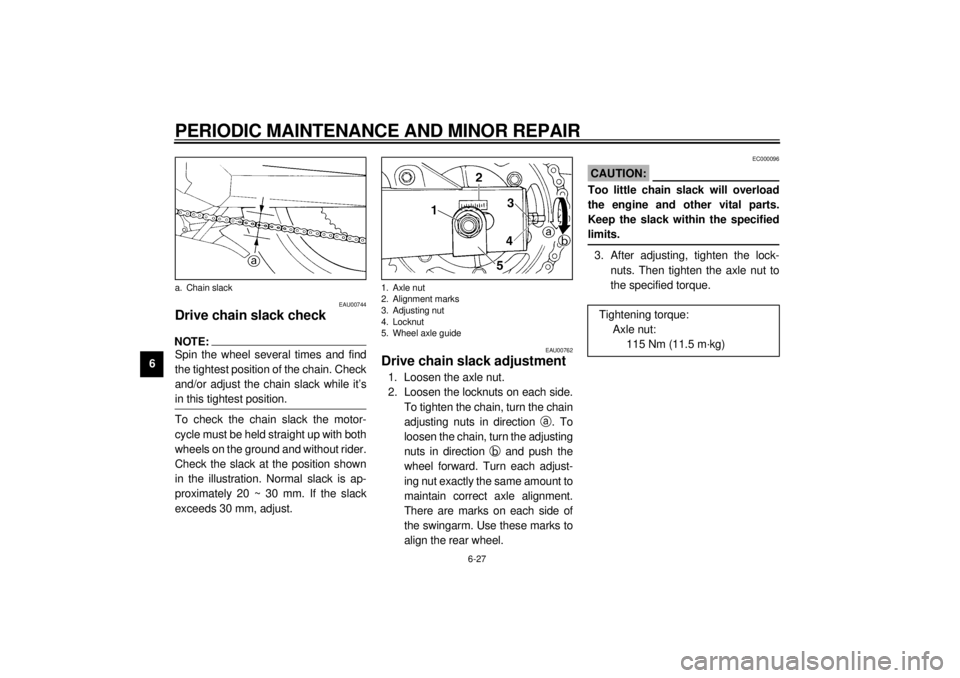

EAU00744

Drive chain slack checkNOTE:@ Spin the wheel several times and find

the tightest position of the chain. Check

and/or adjust the chain slack while it’s

in this tightest position. @To check the chain slack the motor-

cycle must be held straight up with both

wheels on the ground and without rider.

Check the slack at the position shown

in the illustration. Normal slack is ap-

proximately 20 ~ 30 mm. If the slack

exceeds 30 mm, adjust.

EAU00762

Drive chain slack adjustment1. Loosen the axle nut.

2. Loosen the locknuts on each side.

To tighten the chain, turn the chain

adjusting nuts in direction a

. To

loosen the chain, turn the adjusting

nuts in direction b

and push the

wheel forward. Turn each adjust-

ing nut exactly the same amount to

maintain correct axle alignment.

There are marks on each side of

the swingarm. Use these marks to

align the rear wheel.

EC000096

CAUTION:@ Too little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits. @3. After adjusting, tighten the lock-

nuts. Then tighten the axle nut to

the specified torque.

a. Chain slack

1. Axle nut

2. Alignment marks

3. Adjusting nut

4. Locknut

5. Wheel axle guide

Tightening torque:

Axle nut:

115 Nm (11.5 m·kg)

E_4tv_Periodic.fm Page 27 Wednesday, September 1, 1999 11:12 AM

Page 86 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-36

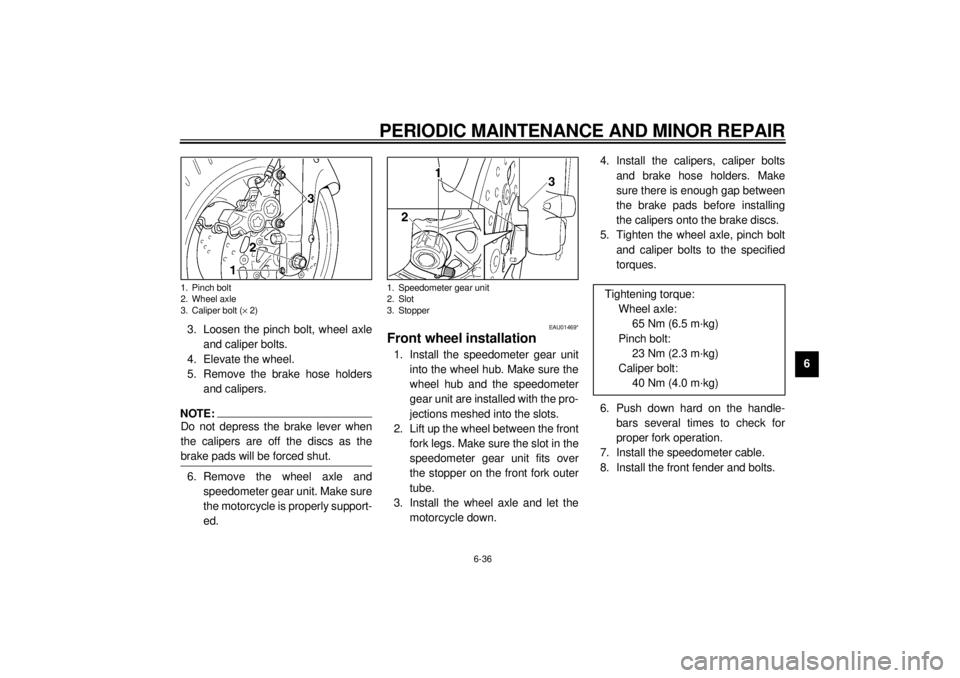

6 3. Loosen the pinch bolt, wheel axle

and caliper bolts.

4. Elevate the wheel.

5. Remove the brake hose holders

and calipers.

NOTE:@ Do not depress the brake lever when

the calipers are off the discs as the

brake pads will be forced shut. @6. Remove the wheel axle and

speedometer gear unit. Make sure

the motorcycle is properly support-

ed.

EAU01469*

Front wheel installation1. Install the speedometer gear unit

into the wheel hub. Make sure the

wheel hub and the speedometer

gear unit are installed with the pro-

jections meshed into the slots.

2. Lift up the wheel between the front

fork legs. Make sure the slot in the

speedometer gear unit fits over

the stopper on the front fork outer

tube.

3. Install the wheel axle and let the

motorcycle down.4. Install the calipers, caliper bolts

and brake hose holders. Make

sure there is enough gap between

the brake pads before installing

the calipers onto the brake discs.

5. Tighten the wheel axle, pinch bolt

and caliper bolts to the specified

torques.

6. Push down hard on the handle-

bars several times to check for

proper fork operation.

7. Install the speedometer cable.

8. Install the front fender and bolts.

1. Pinch bolt

2. Wheel axle

3. Caliper bolt (´ 2)

1. Speedometer gear unit

2. Slot

3. Stopper

Tightening torque:

Wheel axle:

65 Nm (6.5 m·kg)

Pinch bolt:

23 Nm (2.3 m·kg)

Caliper bolt:

40 Nm (4.0 m·kg)

E_4tv_Periodic.fm Page 36 Wednesday, September 1, 1999 11:12 AM

Page 87 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-37

6

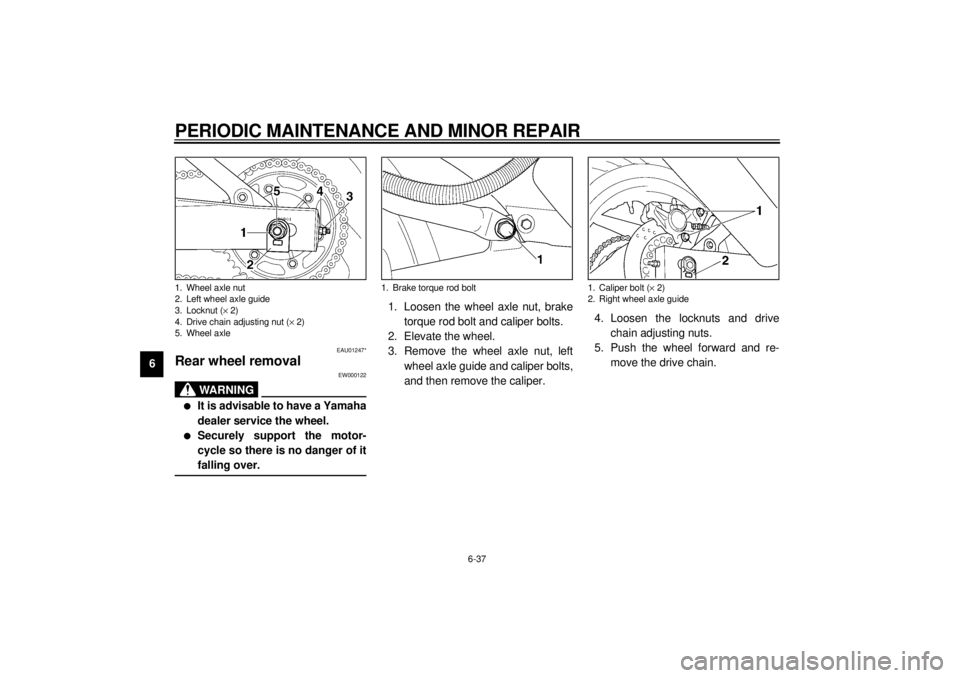

EAU01247*

Rear wheel removal

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so there is no danger of it

falling over.

@

1. Loosen the wheel axle nut, brake

torque rod bolt and caliper bolts.

2. Elevate the wheel.

3. Remove the wheel axle nut, left

wheel axle guide and caliper bolts,

and then remove the caliper.4. Loosen the locknuts and drive

chain adjusting nuts.

5. Push the wheel forward and re-

move the drive chain.

1. Wheel axle nut

2. Left wheel axle guide

3. Locknut (´ 2)

4. Drive chain adjusting nut (´ 2)

5. Wheel axle

1. Brake torque rod bolt

1. Caliper bolt (´ 2)

2. Right wheel axle guide

E_4tv_Periodic.fm Page 37 Wednesday, September 1, 1999 11:12 AM

Page 88 of 109

PERIODIC MAINTENANCE AND MINOR REPAIR

6-38

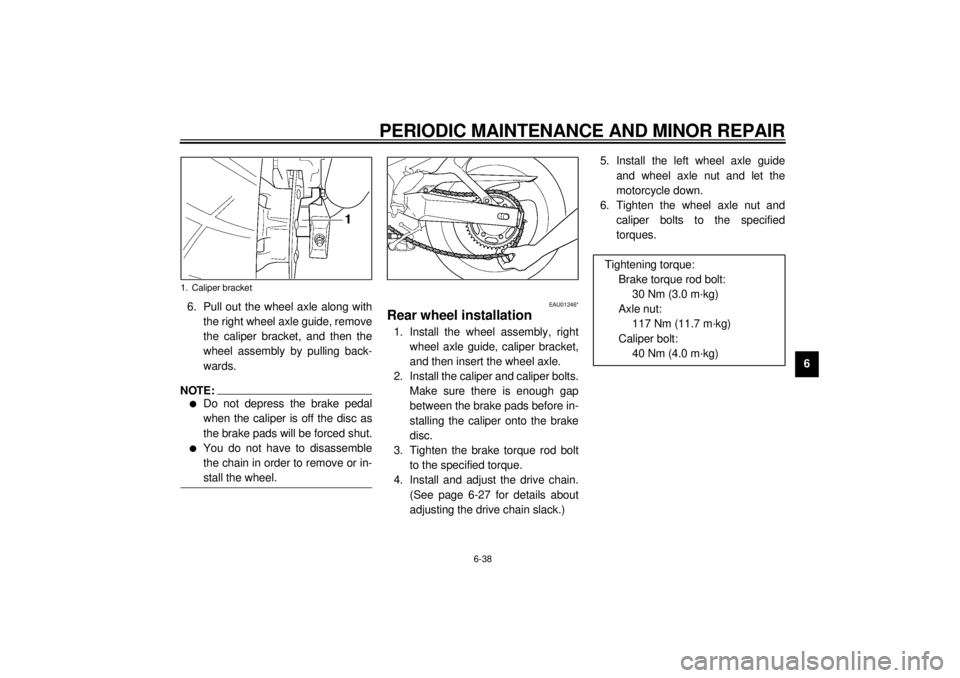

6 6. Pull out the wheel axle along with

the right wheel axle guide, remove

the caliper bracket, and then the

wheel assembly by pulling back-

wards.

NOTE:@ l

Do not depress the brake pedal

when the caliper is off the disc as

the brake pads will be forced shut.

l

You do not have to disassemble

the chain in order to remove or in-

stall the wheel.

@

EAU01246*

Rear wheel installation1. Install the wheel assembly, right

wheel axle guide, caliper bracket,

and then insert the wheel axle.

2. Install the caliper and caliper bolts.

Make sure there is enough gap

between the brake pads before in-

stalling the caliper onto the brake

disc.

3. Tighten the brake torque rod bolt

to the specified torque.

4. Install and adjust the drive chain.

(See page 6-27 for details about

adjusting the drive chain slack.)5. Install the left wheel axle guide

and wheel axle nut and let the

motorcycle down.

6. Tighten the wheel axle nut and

caliper bolts to the specified

torques.

1. Caliper bracket

Tightening torque:

Brake torque rod bolt:

30 Nm (3.0 m·kg)

Axle nut:

117 Nm (11.7 m·kg)

Caliper bolt:

40 Nm (4.0 m·kg)

E_4tv_Periodic.fm Page 38 Wednesday, September 1, 1999 11:12 AM

Page 103 of 109

SPECIFICATIONS

8-5

8

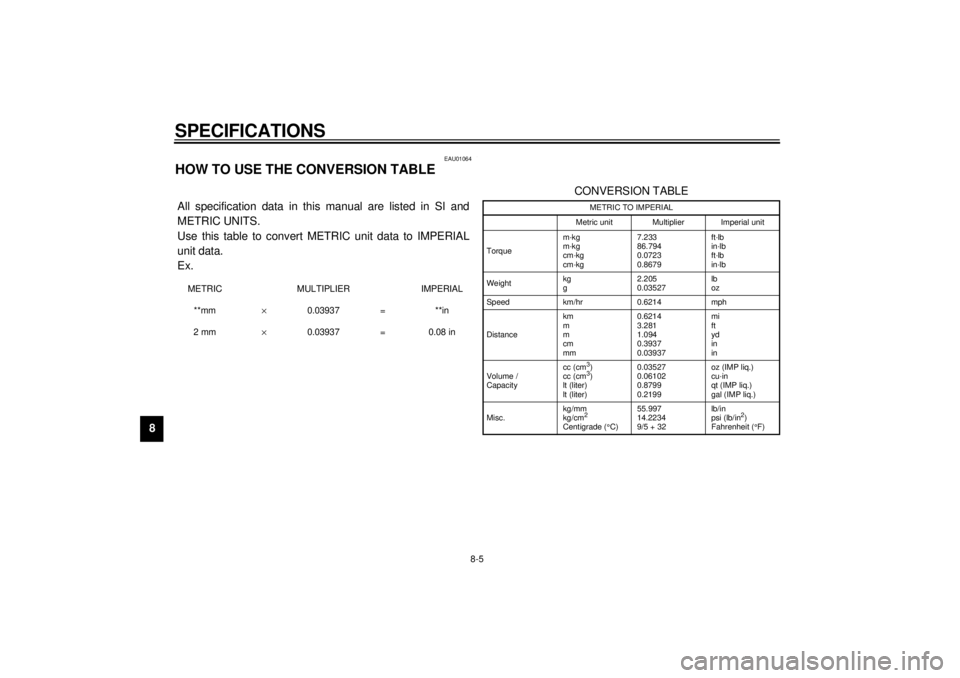

EAU01064

HOW TO USE THE CONVERSION TABLECS-02E All specification data in this manual are listed in SI and

METRIC UNITS.

Use this table to convert METRIC unit data to IMPERIAL

unit data.

Ex.METRIC MULTIPLIER IMPERIAL

**mm´ 0.03937 = **in

2 mm´ 0.03937 = 0.08 in

CONVERSION TABLE

METRIC TO IMPERIAL

Metric unit Multiplier Imperial unit

Torquem·kg

m·kg

cm·kg

cm·kg7.233

86.794

0.0723

0.8679ft·lb

in·lb

ft·lb

in·lb

Weightkg

g2.205

0.03527lb

oz

Speed km/hr 0.6214 mph

Distancekm

m

m

cm

mm0.6214

3.281

1.094

0.3937

0.03937mi

ft

yd

in

in

Volume /

Capacitycc (cm3)

cc (cm3)

lt (liter)

lt (liter)0.03527

0.06102

0.8799

0.2199oz (IMP liq.)

cu·in

qt (IMP liq.)

gal (IMP liq.)

Misc.kg/mm

kg/cm2

Centigrade (

°C)55.997

14.2234

9/5 + 32 lb/in

psi (lb/in

2)

Fahrenheit (

°F)

E_4tv_Spec.fm Page 5 Wednesday, September 1, 1999 11:14 AM