lock YAMAHA YZF600 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZF600, Model: YAMAHA YZF600 2001Pages: 114, PDF Size: 12.39 MB

Page 77 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

6 Observe these precautions:

l

When checking the fluid level,

make sure that the top of the brake

fluid reservoir is level.

l

Use only the recommended quali-

ty brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

l

Be careful that water does not en-

ter the brake fluid reservoir when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer

check the cause.

EAU03238

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake master cylinder and caliper

as well as the brake hose replaced at

the intervals listed below or whenever

they are damaged or leaking.l

Oil seals: Replace every two

years.

l

Brake hose: Replace every four

years.

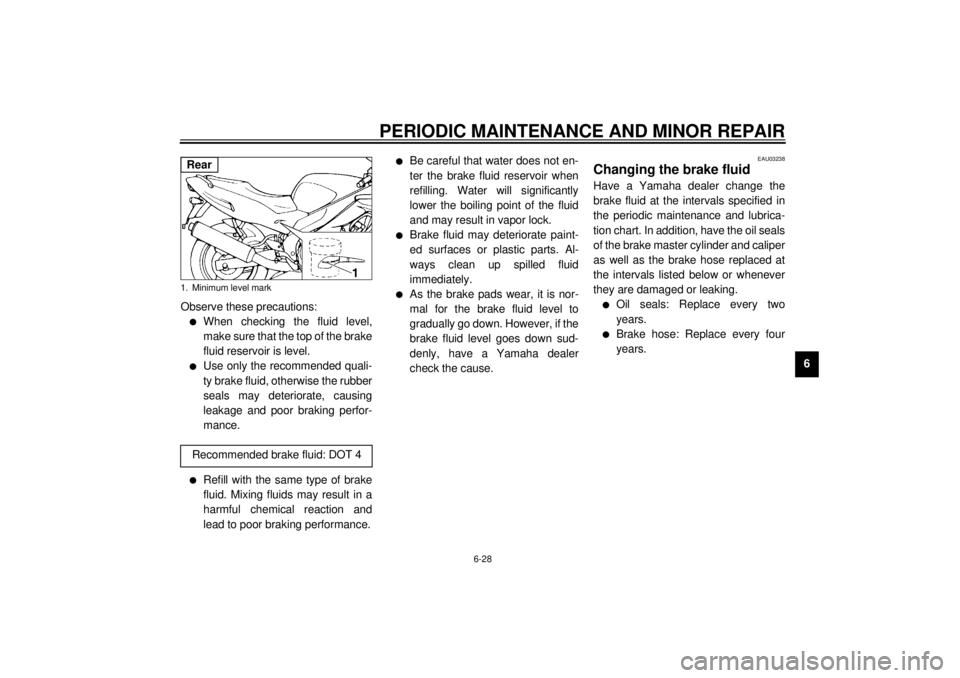

1. Minimum level mark

Recommended brake fluid: DOT 4Rear

E_4tv.book Page 28 Wednesday, October 4, 2000 2:15 PM

Page 78 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-29

6

EAU00744

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

To check the drive chain slack

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:_ When checking and adjusting the drive

chain slack, the motorcycle should be

positioned straight up and there should

be no weight on it. _

2. Shift the transmission into the neu-

tral position.

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain, and

then measure the drive chain

slack as shown.

4. If the drive chain slack is incorrect,

adjust it as follows.

EAU03752

To adjust the drive chain slack

1. Loosen the axle nut, then loosen

the locknut at each end of the

swingarm.

2. To tighten the drive chain, turn the

adjusting nut at each end of the

swingarm in direction

a. To loos-

en the drive chain, turn the adjust-

ing nut at each end of the

swingarm in direction

b, and then

push the rear wheel forward.

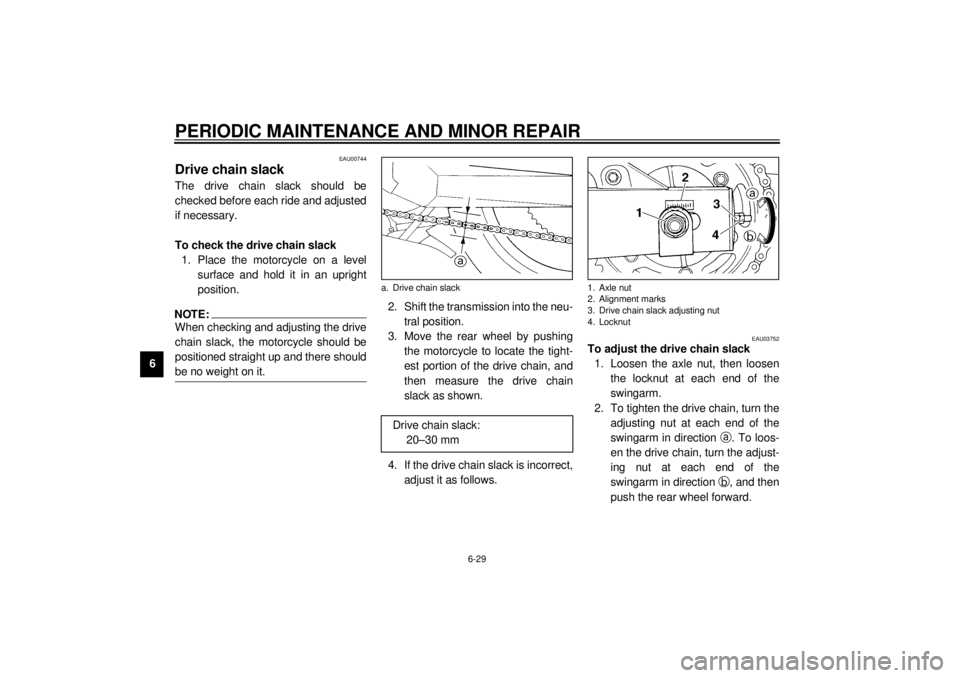

a. Drive chain slack

Drive chain slack:

20–30 mm

1. Axle nut

2. Alignment marks

3. Drive chain slack adjusting nut

4. Locknut

E_4tv.book Page 29 Wednesday, October 4, 2000 2:15 PM

Page 79 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-30

6

NOTE:_ Using the alignment marks on each

side of the swingarm, make sure that

both adjusting nuts are in the same po-

sition for proper wheel alignment. _

EC000096

CAUTION:_ Improper drive chain slack will over-

load the engine as well as other vital

parts of the motorcycle and can lead

to chain slippage or breakage. To

prevent this from occurring, keep

the drive chain slack within the

specified limits. _3. Tighten the locknuts, and then

tighten the axle nut to the specified

torque.

EAU03006

Lubricating the drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

EC000097

CAUTION:_ The drive chain must be lubricated

after washing the motorcycle or

riding in the rain. _1. Clean the drive chain with kero-

sene and a small soft brush.

ECA00053

CAUTION:_ To prevent damaging the O-rings,

do not clean the drive chain with

steam cleaners, high-pressure

washers or inappropriate solvents. _2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

ECA00052

CAUTION:_ Do not use engine oil or any other

lubricants for the drive chain, as

they may contain substances that

could damage the O-rings. _

Tightening torque:

Axle nut:

117 Nm (11.7 m·kg)

E_4tv.book Page 30 Wednesday, October 4, 2000 2:15 PM

Page 87 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-38

6

EW000119

WARNING

_ Headlight bulbs get very hot. There-

fore, keep flammable products away

from a lit headlight bulb, and do not

touch the bulb until it has cooled

down. _3. Place a new bulb into position, and

then secure it with the bulb holder.

EC000104

CAUTION:_ Take care not to damage the follow-

ing parts:l

Headlight bulb

Do not touch the glass part of

the headlight bulb to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosi-

ty of the bulb, and the bulb life

will be adversely affected. Thor-

oughly clean off any dirt and fin-

gerprints on the headlight bulb

using a cloth moistened with al-

cohol or thinner.

l

Headlight lens

• Do not affix any type of tinted

film or stickers to the head-

light lens.

• Do not use a headlight bulb of

a wattage higher than speci-

fied.

_4. Install the bulb cover, and then

connect the coupler.

5. Have a Yamaha dealer adjust the

headlight beam if necessary.

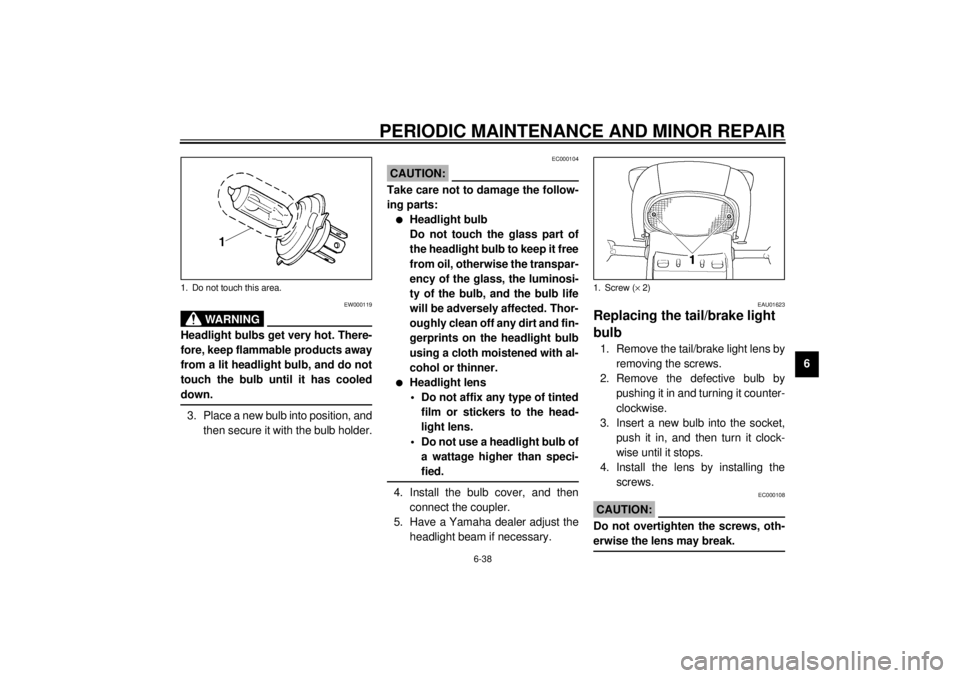

EAU01623

Replacing the tail/brake light

bulb 1. Remove the tail/brake light lens by

removing the screws.

2. Remove the defective bulb by

pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

EC000108

CAUTION:_ Do not overtighten the screws, oth-

erwise the lens may break. _

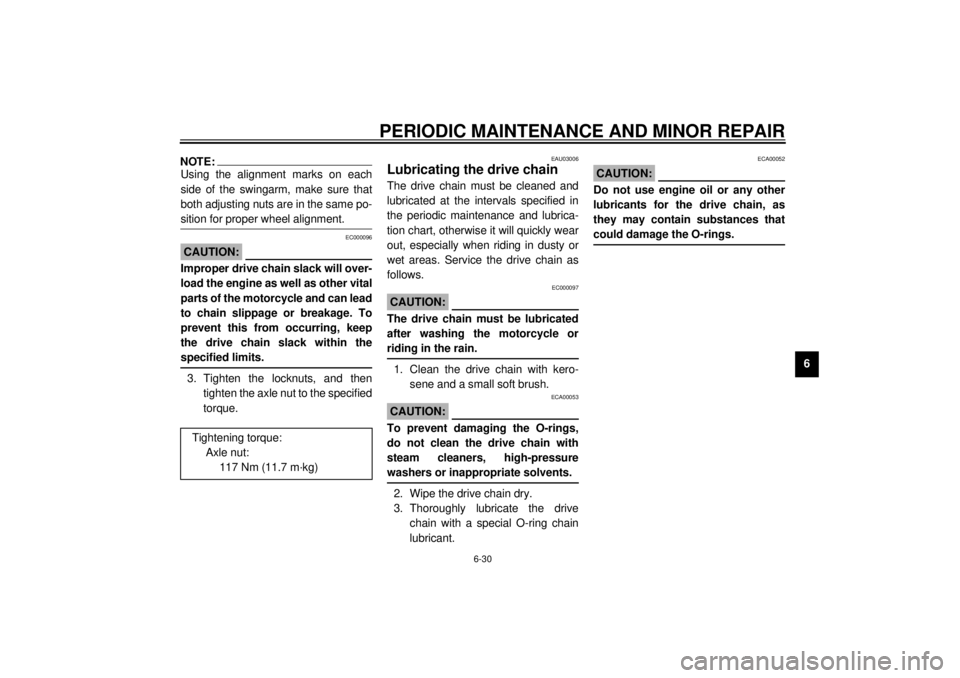

1. Do not touch this area.

1. Screw (´ 2)

E_4tv.book Page 38 Wednesday, October 4, 2000 2:15 PM

Page 88 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-39

6

EAU03497

Replacing a turn signal light

bulb 1. Remove the turn signal light lens

by removing the screw.

2. Remove the defective bulb by

pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screw.

ECA00065

CAUTION:_ Do not overtighten the screw, other-

wise the lens may break. _

EAU01579

Supporting the motorcycle Since this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motor-

cycle is in a stable and level position

before starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcycle

by using a motorcycle stand or, if

an additional motorcycle stand is

not available, by placing a jack un-

der the frame in front of the rear

wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

1. ScrewE_4tv.book Page 39 Wednesday, October 4, 2000 2:15 PM

Page 90 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-41

6

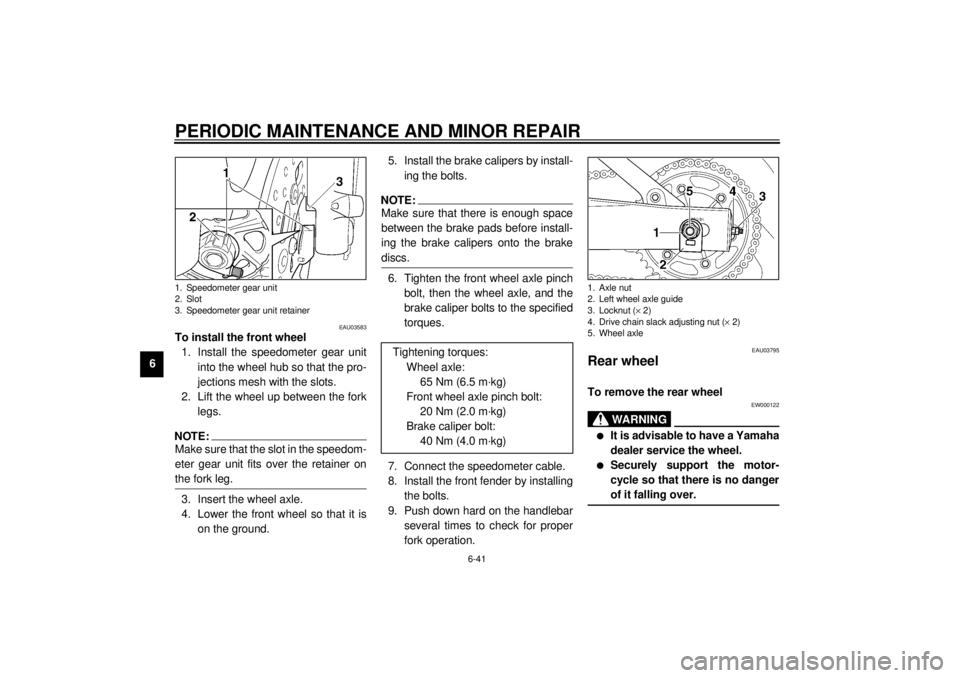

EAU03583

To install the front wheel

1. Install the speedometer gear unit

into the wheel hub so that the pro-

jections mesh with the slots.

2. Lift the wheel up between the fork

legs.NOTE:_ Make sure that the slot in the speedom-

eter gear unit fits over the retainer on

the fork leg. _3. Insert the wheel axle.

4. Lower the front wheel so that it is

on the ground.5. Install the brake calipers by install-

ing the bolts.

NOTE:_ Make sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs. _6. Tighten the front wheel axle pinch

bolt, then the wheel axle, and the

brake caliper bolts to the specified

torques.

7. Connect the speedometer cable.

8. Install the front fender by installing

the bolts.

9. Push down hard on the handlebar

several times to check for proper

fork operation.

EAU03795

Rear wheel To remove the rear wheel

EW000122

WARNING

_ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

_

1. Speedometer gear unit

2. Slot

3. Speedometer gear unit retainer

Tightening torques:

Wheel axle:

65 Nm (6.5 m·kg)

Front wheel axle pinch bolt:

20 Nm (2.0 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

1. Axle nut

2. Left wheel axle guide

3. Locknut (´ 2)

4. Drive chain slack adjusting nut (´ 2)

5. Wheel axle

E_4tv.book Page 41 Wednesday, October 4, 2000 2:15 PM

Page 91 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-42

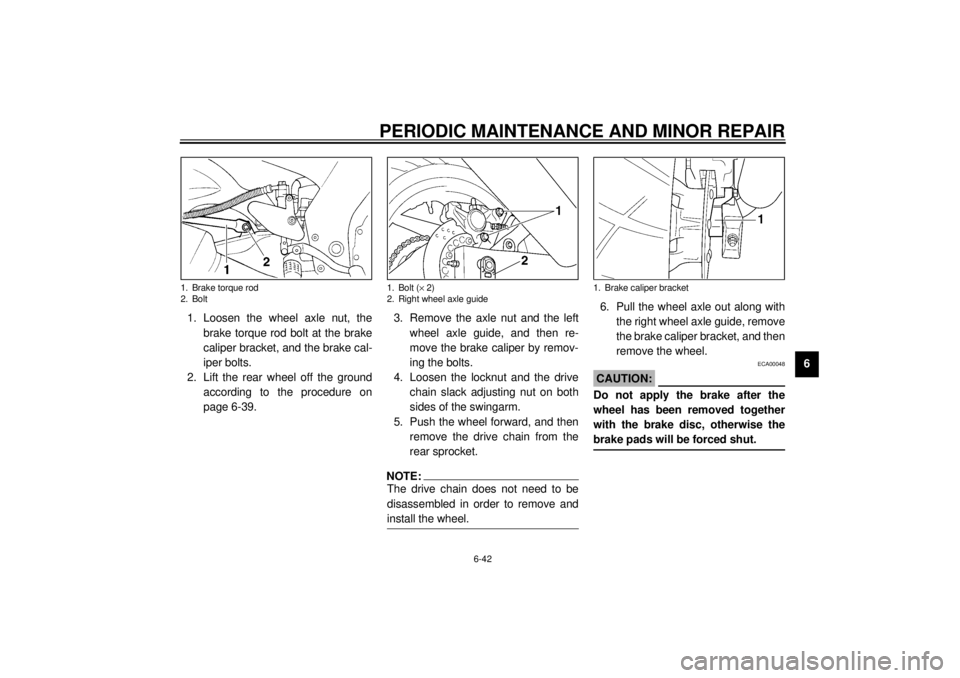

6 1. Loosen the wheel axle nut, the

brake torque rod bolt at the brake

caliper bracket, and the brake cal-

iper bolts.

2. Lift the rear wheel off the ground

according to the procedure on

page 6-39.3. Remove the axle nut and the left

wheel axle guide, and then re-

move the brake caliper by remov-

ing the bolts.

4. Loosen the locknut and the drive

chain slack adjusting nut on both

sides of the swingarm.

5. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

NOTE:_ The drive chain does not need to be

disassembled in order to remove and

install the wheel. _

6. Pull the wheel axle out along with

the right wheel axle guide, remove

the brake caliper bracket, and then

remove the wheel.

ECA00048

CAUTION:_ Do not apply the brake after the

wheel has been removed together

with the brake disc, otherwise the

brake pads will be forced shut. _

1. Brake torque rod

2. Bolt

1. Bolt (´ 2)

2. Right wheel axle guide

1. Brake caliper bracket

E_4tv.book Page 42 Wednesday, October 4, 2000 2:15 PM

Page 94 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-45

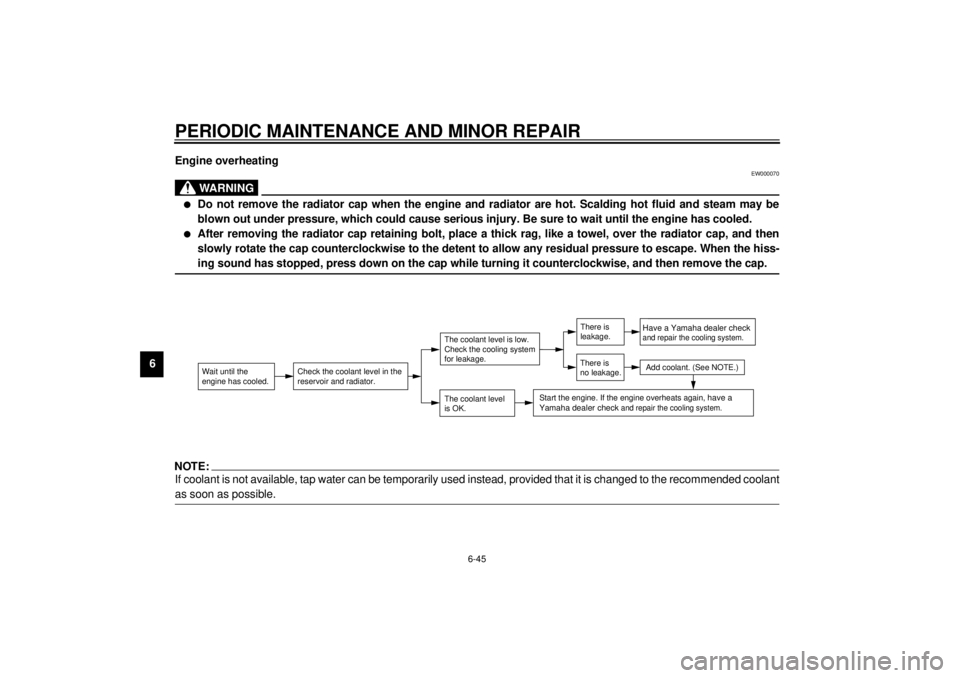

6Engine overheating

EW000070

WARNING

_ l

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

l

After removing the radiator cap retaining bolt, place a thick rag, like a towel, over the radiator cap, and then

slowly rotate the cap counterclockwise to the detent to allow any residual pressure to escape. When the hiss-

ing sound has stopped, press down on the cap while turning it counterclockwise, and then remove the cap.

_NOTE:_ If coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended coolant

as soon as possible. _

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See NOTE.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

E_4tv.book Page 45 Wednesday, October 4, 2000 2:15 PM

Page 110 of 114

INDEXAAir filter element, cleaning ...................... 6-17

Air intake duct ........................................ 6-19

Air vent hose, checking .......................... 6-18

Anti-theft alarm ........................................3-5BBattery ................................................... 6-35

Brake and clutch levers, checking and

lubricating ............................................ 6-32

Brake and shift pedals, checking and

lubricating ............................................ 6-32

Brake fluid, changing ............................. 6-28

Brake fluid level, checking...................... 6-27

Brake lever...............................................3-7

Brake light switch (rear), adjusting ......... 6-26

Brake pads, checking............................. 6-27

Brake pedal..............................................3-8

Brake pedal position, adjusting .............. 6-25CCables, checking and lubricating............ 6-31

Carburetors, adjusting............................ 6-19

Care.........................................................7-1

Clutch lever ..............................................3-7

Clutch lever free play, adjusting ............. 6-25

Conversion table ......................................8-5

Coolant .................................................. 6-13

Changing .......................................... 6-14

Checking .......................................... 6-13

Coolant temperature gauge .....................3-5

Cowlings, removing and installing ............6-5

DDimmer switch ......................................... 3-5

Drive chain, lubricating .......................... 6-30

Drive chain slack ................................... 6-29

Checking .......................................... 6-29

Adjusting .......................................... 6-29EEngine break-in ....................................... 5-5

Engine oil and oil filter cartridge ............. 6-10

Engine stop switch................................... 3-6FFront and rear suspension settings ........ 3-17

Front fork, adjusting ............................... 3-12

Front fork, checking ............................... 6-33

Fuel ......................................................... 3-9

Fuel consumption, tips for reducing ......... 5-4

Fuel level warning light ............................ 3-3

Fuel tank breather hose

(Germany only) ..................................... 3-9

Fuel tank cap ........................................... 3-8

Fuses, replacing .................................... 6-36HHandlebar switches ................................. 3-5

Headlight bulb, replacing ....................... 6-37

Helmet holder ........................................ 3-11

High beam indicator light ......................... 3-3

Horn switch ............................................. 3-6

IIdentification numbers ..............................9-1

Idling speed, adjusting ...........................6-19

Ignition circuit cut-off system ..................3-19

Indicator and warning lights......................3-2KKey identification number .........................9-1LLight switch ..............................................3-6

Luggage strap holders ...........................3-18MMain switch/steering lock .........................3-1

Model label ..............................................9-2NNeutral indicator light ...............................3-2OOil level warning light ...............................3-2PParking.....................................................5-6

Part locations ...........................................2-1

Pass switch ..............................................3-5

Periodic maintenance and lubrication

chart ......................................................6-2

Pre-operation check list ............................4-1

E_4tv.book Page 1 Wednesday, October 4, 2000 2:15 PM