Abarth 124 Spider 2016 Owner handbook (in English)

Manufacturer: ABARTH, Model Year: 2016, Model line: 124 Spider, Model: Abarth 124 Spider 2016Pages: 224, PDF Size: 2.89 MB

Page 151 of 224

TIRE SERVICE USAGE

PRECAUTIONS

NoteThe tire sealant cannot be reused.

Purchase new tire sealant at an Abarth

Dealership.

The tire service kit cannot be used in

the following cases. Consult an Abarth

Dealership:

– the period of effective use for the

tire sealant has expired (the period

of effectiveness is indicated on the

bottle label);

– the tear or puncture exceeds about

4 mm;

– the damage has occurred to an

area of the tire other than the tread;

– the vehicle has been driven with

nearly no air remaining in the tire;

– the tire has come off the wheel rim;

– damage to the wheel rim has

occurred;

– the tire has two or more punctures.

SEALING A TIRE WITH

TIRE SERVICE

Proceed as follows:

move the vehicle off the right-of-way

to a safe place on a level and hard

surface where the vehicle does not

obstruct traffic;

shift the shift lever to the 1 or

Reverse (R) position (manual

transmission), and shift the selectorlever to the P position (automatic

transmission);

apply the parking brake with the

brake pedal depressed and turn off the

engine;

if necessary, flash the hazard warning

lights and set up the roadside

emergency triangle;

unload passengers and cargo and

remove the tire service kit;

shake the tire sealant well. If the

bottle is shaken after the injection hose

is screwed on, tire sealant could spray

out from the injection hose. Tire sealant

contacting clothing or other objects

may be impossible to remove. Shake

the bottle before screwing on the

injection hose;

IMPORTANT The sealant hardens easily

and injecting it will be difficult under

cold weather conditions (0°C or below).

Warm the sealant inside the vehicle to

facilitate injection.

remove the cap 1 from the bottle 2

fig. 132. Screw on the injection hose

3 with the bottle's inner cap left on to

break the inner cap;

remove the valve cap 4 fig. 133 from

the flat tire. Press the back of a valve

core tool 6 to the core of the tire valve

5 and bleed all the remaining air;

13208020202-03A-003AB

13308020202-03A-004AB

149

Page 152 of 224

IMPORTANT If there is air remaining in

the tire when the valve core is removed,

the valve core could fly out. Remove

the valve core carefully.

turn the valve core 7 counter

clockwise with the valve core tool 8 and

remove the valve core fig. 134;

IMPORTANT Store the valve core in a

place where it will not get dirty.

insert the injection hose 9

fig. 135 into the valve 10;

hold the bottom of the bottle upright

11 fig. 136, squeeze the bottle with

your hands, and inject the entire

amount of tire sealant into the tire;

pull out the injection hose from the

valve fig. 137;

reinsert the valve core 12 into the

valve 13 and turn it clockwise to install.

IMPORTANT The tire sealant cannot be

reused. Purchase a new tire sealant kit

at an Abarth Dealership.

IMPORTANT Do not throw away the

empty tire sealant bottle after use.

Return the empty tire sealant bottle to

an Abarth Dealership when replacing

the tire. The empty tire sealant bottle

will need to be used to extract and

dispose of the used sealant from the

tire.

13408020202-03A-005AB

13508020202-03A-006AB

13608020202-03A-008AB

13708020202-03A-007AB

150

IN CASE OF EMERGENCY

Page 153 of 224

13808020202-03A-009AB

13908020202-36A-004AB

14008020202-03A-00BAB

151

after that, install the injection hose to

the tab 14 fig. 138 of the bottle to

prevent leakage of any remaining

sealant;

adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver;

pull out the air compressor hose and

the air compressor plug from the air

compressor 15 fig. 139;

install the air compressor hose 16 to

the tire valve 17 fig. 140;

insert the air compressor plug into

the accessory socket 18 fig. 141 inside

the vehicle and switch the ignition to

ACC;

turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure;

IMPORTANT When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch.

NOTE Check the tire inflation pressure

label driver's door frame for the correct

tire inflation pressure.

NOTE Do not operate the air

compressor for a continuous

10 minutes or longer because using it

for long periods could cause a

malfunction.

14108020202-124-001AB

Page 154 of 224

NOTE If the tire inflation pressure does

not increase, repair of the tire is not

possible. If the tire does not reach the

specified tire inflation pressure within

10 minutes, it may have received

extensive damage. In this case, the

repair using the tire service kit was not

successful. Contact an Abarth

Dealership.

If the tire has been over-inflated, loosen

the screw cap on the air compressor

and bleed some of the air out;

when the tire inflates to the specified

tire inflation pressure, turn the air

compressor switch off, turn the sleeve

of the air compressor hose to the left,

and pull it out of the tire valve;

install the tire valve cap;

put the tire service kit into the boot;

start driving immediately to spread

the sealant in the tire.

IMPORTANT Carefully drive the vehicle

at a speed of 80 km/h or less. If the

vehicle is driven at a speed of 80 km/h

or more, the vehicle may vibrate.

If the tire is not properly inflated, the

warning light will illuminate.

after driving the vehicle for about

10 minutes or 5 km (3 miles), connect

the air compressor to the tire and check

the tire inflation pressure using the tire

pressure gauge on the air compressor.

If the tire inflation pressure is lower than

the specified tire inflation pressure, turn

the air compressor on and wait until it

reaches the specified tire inflation

pressure;

the emergency flat tire repair is

completed successfully if the tire

inflation pressure does not decrease.

Carefully drive the vehicle to the nearest

Abarth Dealership and have the flat tire

replaced. Replacement with a new tire

is recommended. If the tire is to be

repaired or reused, contact an Abarth

Dealership.

IMPORTANT Before checking the tire

inflation pressure using the tire pressure

gauge, turn the air compressor switch

off.

NOTEIf an emergency flat tire repair has

been performed using the tire service

kit, FCA recommends that the tire be

replaced with a new one as soon as

possible. If the tire is to be repaired or

reused, contact an Abarth Dealership.

The wheel can be reused if the

sealant adhering to it is removed.

However, replace the valve with a new

one.

REPLACING THE BOTTLE

Inspect the tire service kit at regular

intervals.

Check the tire sealant period of

effective use. Check the operation of

the tire compressor.

IMPORTANT The tire sealant has a

period of effective use. Check the

period of effective use indicated on the

152

IN CASE OF EMERGENCY

bottle label and do not use it if it has

expired. Have the tire sealant replaced

at an Abarth Dealership before the

period of effective use has expired.

Page 155 of 224

WARNING

170)Punctures on the sides of the tire may

not be repaired. Do not use the kit if the tire

was damaged as a result of being used

when underinflated.

171)Do not adhere the speed restriction

sticker to the padded area on the steering

wheel. Adhering the speed restriction

sticker to the padded area on the steering

wheel is dangerous because the air bag

may not operate (deploy) normally resulting

in serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

172)If the tire inflation pressure has

decreased below 130 kPa (1.3 kgf/cm

2or

bar, 18.9 psi), stop driving and contact a

Dealership. The repair using the emergency

at tire repair kit was not successful. If you

see a decrease in the tire inflation pressure,

stop driving. Contact a Dealership.

173)You must always indicate that the tyre

was repaired using the kit. Give the booklet

to the technicians who will be handling the

tire that was treated using the kit.

174)Repairs are not possible in the case of

damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

foreign bodies (screws or nails) from the

tire.175)The information required by the

applicable regulation is indicated on the tire

service kit package label. Compliance with

the indications on the label is an essential

condition to ensure the safety and the

effectiveness of the tire service kit. Carefully

read the label before use, avoid improper

use. Tire service kit is subject to expiration

and must be replaced periodically. The kit

should be used by adults and cannot be

used by children.

176)Do not allow children to touch the tire

sealant: ingestion of tire sealant is

dangerous. In the event tire sealant is

accidentally swallowed, drink large

amounts of water immediately and seek

medical assistance. Tire sealant that

comes into contact with the eyes and skin

is dangerous. If tire sealant enters the eyes

or contacts the skin, flush immediately with

large amounts of water and seek medical

assistance.

IMPORTANT

3)Dispose of the bottle and the sealant

liquid properly. Have them disposed of in

compliance with national and local

regulations.

JUMP STARTING

PREPARATIONS FOR

JUMP STARTING

177) 178) 179) 180) 181) 182) 183) 184) 185) 186)

34)

Jump-starting is dangerous if done

incorrectly. So follow the procedure

carefully fig. 142. If you feel unsure

about jump-starting, we strongly

recommend that you have a competent

service technician do the work.

IMPORTANT When using booster

battery is used, comply with the

utilisation and precaution instructions

specified by the producer.

153

Page 156 of 224

IMPORTANT Do not use the booster

battery or any other source of external

supply with a voltage above 12 V: the

battery, the starter, the alternator and

the electrical system of the vehicle

could be damaged. You can damage a

12 V starter, ignition system, and other

electrical parts beyond repair with a

24 V power supply (two 12 V batteries

in series or a 24 V motor generator set).IMPORTANT Do not attempt jump

starting if the battery is wet. The battery

could break and explode!

JUMP-STARTING

PROCEDURE

IMPORTANT If the procedure below is

carried out incorrectly can cause severe

injuries to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Proceed as follows to carry out a jump

starting:

remove the battery cover fig. 143;

make sure the booster battery is

12 V and that its negative terminal is

grounded;

if the booster battery is in another

vehicle, do not allow both vehicles to

touch. Turn off the engine of the vehicle

with the booster battery and all

unnecessary electrical loads in both

vehicles;

connect the jumper leads in the

exact sequence as in “Preparations for

jump starting” paragraph:

– connect one end of a lead to the

positive terminal on the discharged

battery;

– attach the other end to the positive

terminal on the booster battery;

– connect one end of the other lead

to the negative terminal of the

booster battery;

– connect the other end to the

ground point indicated in the

illustration away from the

discharged battery.

start the engine of the booster

vehicle and run it a few minutes. Then

start the engine of the other vehicle;

when finished, carefully disconnect

the leads in the reverse order as

previously described;

14208030100-121-001-1AB

14308030100-122-001AB

154

IN CASE OF EMERGENCY

Page 157 of 224

if the battery cover has been

removed, install it in the reverse order of

removal.

IMPORTANT Verify that the covers are

securely installed.

IMPORTANT For versions with

automatic transmission, perform the

toothed wheel learning procedure

described in the “Battery maintenance”

section (see the “Maintenance and

care” chapter).

WARNING

177)Before opening the bonnet, make

sure that the engine is off and that the

ignition switch is in OFF position. During

refuelling, make sure that the engine is off

(and that the ignition switch is in OFF

position).

178)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Pay attention to scarves,

ties and other loose clothing which might

be pulled by moving parts.

179)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

180)Batteries contain acid which may

burn skin and eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Thus keep away flames or

devices which may cause sparks.181)Do not allow the positive (+) terminal

to contact any other metal object that

could cause sparks. Flames and sparks

near open battery cells are dangerous.

Hydrogen gas, produced during normal

battery operation, could ignite and cause

the battery to explode. An exploding

battery can cause serious burns and

injuries. When working near a battery, do

not allow metal tools to contact the positive

(+) or negative (–) terminal of the battery.

182)Keep all flames, including cigarettes,

and sparks away from open battery cells.

Flames and sparks near open battery cells

are dangerous. Hydrogen gas, produced

during normal battery operation, could

ignite and cause the battery to explode. An

exploding battery can cause serious burns

and injuries.

183)Do not jump-start a frozen battery or

one with a low fluid level. Jump-starting a

frozen battery or one with a low fluid level is

dangerous. It may rupture or explode,

causing serious injury.

184)Route the jumper leads away from

parts that will be moving. Connecting a

jumper lead near or to moving parts

(cooling fans, belts) is dangerous. The lead

could get caught when the engine starts

and cause serious injury.

185)Never tow a vehicle to start it. Towing

a vehicle to start it is dangerous. The

vehicle being towed could surge forward

when its engine starts, causing the two

vehicles to collide. The occupants could be

injured.186)Connect the negative lead to a good

ground point (see figure) away from the

battery. Connecting the end of the second

jumper lead to the negative (–) terminal of

the discharged battery is dangerous. A

spark could cause the gas around the

battery to explode and injure someone.

IMPORTANT

34)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

155

Page 158 of 224

TOWING THE

VEHICLE

ATTACHING THE TOW

HOOKS

35) 36) 37)

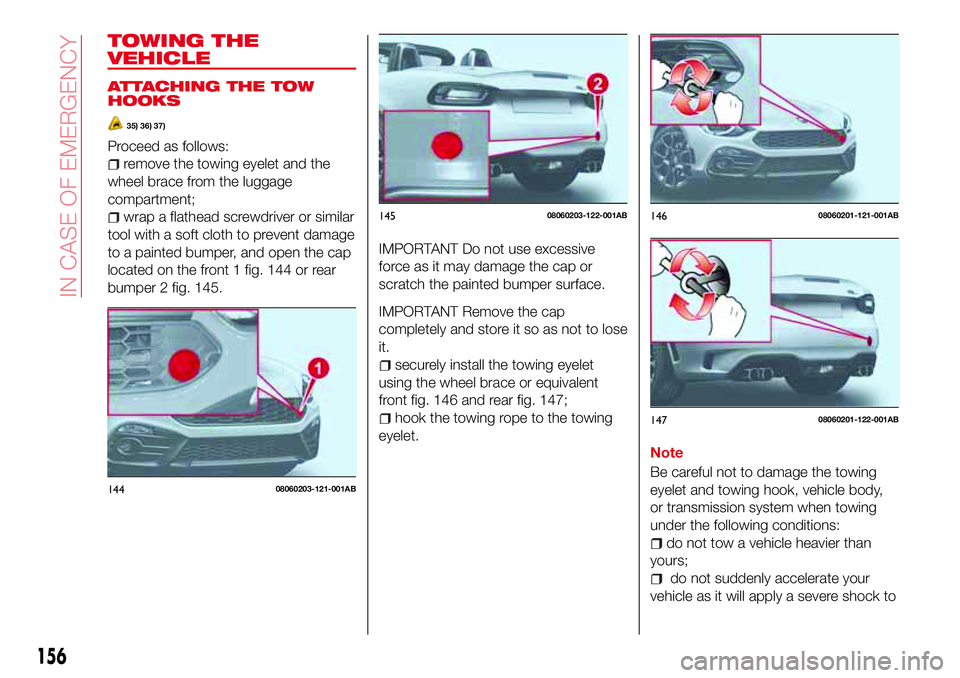

Proceed as follows:

remove the towing eyelet and the

wheel brace from the luggage

compartment;

wrap a flathead screwdriver or similar

tool with a soft cloth to prevent damage

to a painted bumper, and open the cap

located on the front 1 fig. 144 or rear

bumper 2 fig. 145.

IMPORTANT Do not use excessive

force as it may damage the cap or

scratch the painted bumper surface.

IMPORTANT Remove the cap

completely and store it so as not to lose

it.

securely install the towing eyelet

using the wheel brace or equivalent

front fig. 146 and rear fig. 147;

hook the towing rope to the towing

eyelet.

Note

Be careful not to damage the towing

eyelet and towing hook, vehicle body,

or transmission system when towing

under the following conditions:

do not tow a vehicle heavier than

yours;

do not suddenly accelerate your

vehicle as it will apply a severe shock to

14408060203-121-001AB

14508060203-122-001AB14608060201-121-001AB

14708060201-122-001AB

156

IN CASE OF EMERGENCY

Page 159 of 224

the towing eyelet and towing hook or

rope;

do not attach any rope other than to

the towing eyelet and towing hook.

IMPORTANT The towing eyelet should

be used in an emergency (to get the

vehicle out of a ditch or a snow bank,

for example).

IMPORTANT When using the towing

eyelets, always pull the lead or chain in

a straight direction with respect to the

eyelet. Never apply a sideways force.

IMPORTANT When towing with chain

or lead, wrap the chain or lead with a

soft cloth near the bumper to prevent

damage to the bumper.

IMPORTANT

35)Before starting towing operations, put

the ignition switch to OFF position.

36)Before tightening the tow hook, clean

the threaded housing thoroughly. Make

sure that the tow hook is fully fastened in

the housing before towing the vehicle.37)The front and rear tow hooks should be

used only for emergencies on the road. You

are allowed to tow the vehicle for short

distances using an appropriate device in

accordance with the highway code (a rigid

bar), to move the vehicle on the road in

readiness for towing or transport via a

breakdown vehicle. Tow hooks MUST NOT

be used to tow vehicles off the road or

where there are obstacles and/or for

towing operations using ropes or other

non-rigid devices. Respecting the above

conditions, towing must take place with

two vehicles (one towing, the other towed)

aligned as much as possible along the

same center line.

EMERGENCY

TOWING

TOWING DESCRIPTION

Proper lifting and towing are necessary

to prevent damage to the vehicle.

Government and local laws must be

followed.

A towed vehicle usually should have its

drive wheels (rear wheels) off the

ground. If excessive damage or other

conditions prevent this, use wheel

dollies.

When towing with the rear wheels on

the ground, release the parking brake.

IMPORTANT Do not tow the vehicle

pointed backward with driving wheels

on the ground. This may cause internal

damage to the transmission.

IMPORTANT Do not tow with sling-type

equipment. This could damage your

vehicle. Use wheel-lift or flatbed

equipment.

If towing service is not available in an

emergency, the vehicle may be towed

with all four wheels on the ground using

the towing hook at the front of the

vehicle. Only tow the vehicle on paved

surfaces for short distances at low

speeds.

157

Page 160 of 224

the vehicle with all wheels on the

ground:

shift to neutral (manual transmission),

or the N position (automatic

transmission);

switch the ignition to ACC;

release the parking brake.

NOTE Remember that power assist for

the brakes and steering will not be

available when the engine is not

running.

158

IN CASE OF EMERGENCY

Follow these instructions when towing