light Abarth 500 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: ABARTH, Model Year: 2015, Model line: 500, Model: Abarth 500 2015Pages: 215, PDF Size: 19.08 MB

Page 134 of 215

STARTING THE

ENGINE

If thesymbol on the display turns

on constantly, contact an Abarth

Dealership immediately.

JUMP STARTING

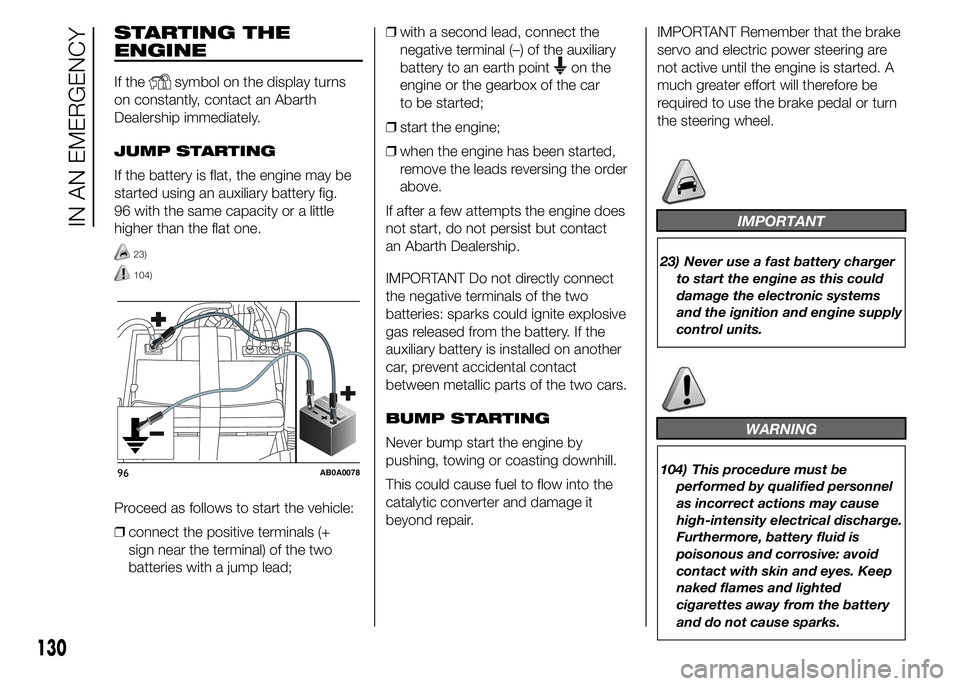

If the battery is flat, the engine may be

started using an auxiliary battery fig.

96 with the same capacity or a little

higher than the flat one.

23)

104)

Proceed as follows to start the vehicle:

❒connect the positive terminals (+

sign near the terminal) of the two

batteries with a jump lead;❒with a second lead, connect the

negative terminal (–) of the auxiliary

battery to an earth point

on the

engine or the gearbox of the car

to be started;

❒start the engine;

❒when the engine has been started,

remove the leads reversing the order

above.

If after a few attempts the engine does

not start, do not persist but contact

an Abarth Dealership.

IMPORTANT Do not directly connect

the negative terminals of the two

batteries: sparks could ignite explosive

gas released from the battery. If the

auxiliary battery is installed on another

car, prevent accidental contact

between metallic parts of the two cars.

BUMP STARTING

Never bump start the engine by

pushing, towing or coasting downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.IMPORTANT Remember that the brake

servo and electric power steering are

not active until the engine is started. A

much greater effort will therefore be

required to use the brake pedal or turn

the steering wheel.

IMPORTANT

23) Never use a fast battery charger

to start the engine as this could

damage the electronic systems

and the ignition and engine supply

control units.

WARNING

104) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.96AB0A0078

130

IN AN EMERGENCY

Page 135 of 215

"Fix&Go Automatic"

kit

The kit (see fig. 97) in the luggage

compartment consists of:

❒a spray bottle A with the sealant,

equipped with filling pipe B,

separated by the compressor C;

❒compressor C with pressure gauge,

fitting valve to couple the bottle A,

cable with supply socket D and pipe

N to restore pressure (this is inside

the body as shown);

❒adhesive label under the spray bottle

A, with the message "max. 80 km/h"

to be placed where the driver can

easily see it (for example on the

dashboard) after repairing the tyre;

❒instruction booklet fig. 98, for using

the Fix&Go quickly and correctly;

❒a pair of protective gloves.

24)

105) 106) 107)

IMPORTANT

INFORMATION

The sealant of the Fix&Go kit is effective

at external temperatures of between

-20°C and +50°C.

The sealant has an expiry date.

108) 109)

2)

INFLATION PROCEDURE

110)

Proceed as follows:

❒engage the handbrake;

❒place the Fix&Go kit close to the tyre

to be repaired;

❒locate the fig. 100 filling pipe B

already connected to the spray bottle

A;

❒open the side lid E then connect the

spray bottle A to the fitting, following

the direction of the arrow;

❒undo the cap of the tyre valve F and

connect the filling pipe B, tightening

the relevant ring nut on the tyre valve;

❒make sure that the switch G fig. 101

is in position0(off), then start the

engine;

❒place the electric plug H fig. 102 in

the cigar lighter socket of the car

(12 V);

97AB0A0079

98AB0A0080

ON

OFF

99AB0A0081

131

Page 137 of 215

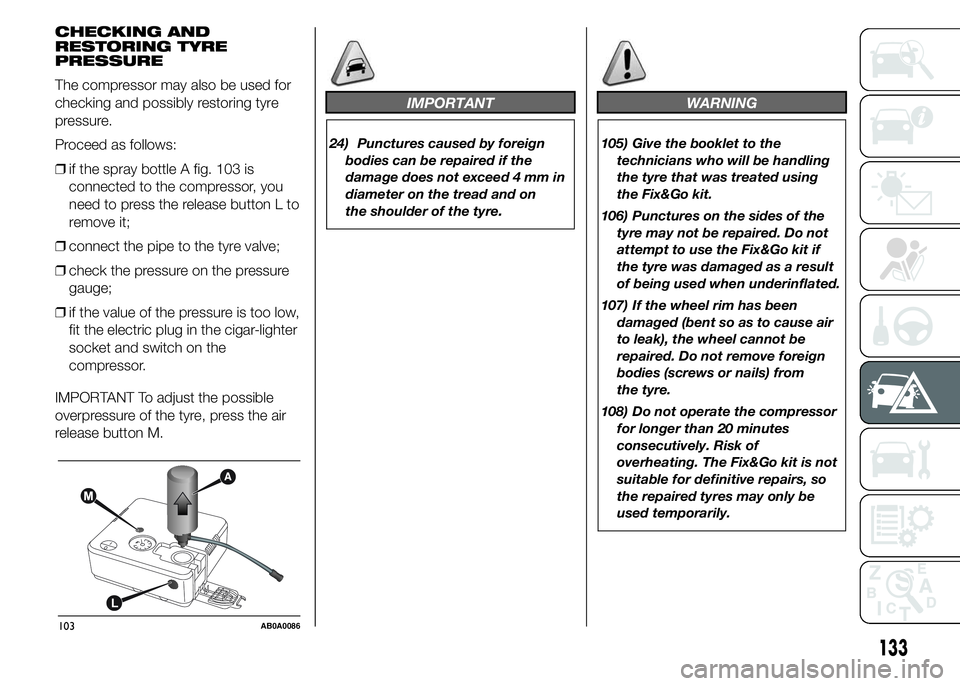

CHECKING AND

RESTORING TYRE

PRESSURE

The compressor may also be used for

checking and possibly restoring tyre

pressure.

Proceed as follows:

❒if the spray bottle A fig. 103 is

connected to the compressor, you

need to press the release button L to

remove it;

❒connect the pipe to the tyre valve;

❒check the pressure on the pressure

gauge;

❒if the value of the pressure is too low,

fit the electric plug in the cigar-lighter

socket and switch on the

compressor.

IMPORTANT To adjust the possible

overpressure of the tyre, press the air

release button M.

IMPORTANT

24) Punctures caused by foreign

bodies can be repaired if the

damage does not exceed 4 mm in

diameter on the tread and on

the shoulder of the tyre

.

WARNING

105) Give the booklet to the

technicians who will be handling

the tyre that was treated using

the Fix&Go kit.

106) Punctures on the sides of the

tyre may not be repaired. Do not

attempt to use the Fix&Go kit if

the tyre was damaged as a result

of being used when underinflated.

107) If the wheel rim has been

damaged (bent so as to cause air

to leak), the wheel cannot be

repaired. Do not remove foreign

bodies (screws or nails) from

the tyre.

108) Do not operate the compressor

for longer than 20 minutes

consecutively. Risk of

overheating. The Fix&Go kit is not

suitable for definitive repairs, so

the repaired tyres may only be

used temporarily.

103AB0A0086

133

Page 139 of 215

REPLACING A BULB

GENERAL

INSTRUCTIONS

❒Before replacing a bulb check the

contacts for oxidation;

❒burnt bulbs must be replaced by

others of the same type and power;

❒always check the headlight beam

alignment after replacing a bulb;

❒when a light is not working, check

that the corresponding fuse is intact

before replacing a bulb. For the

location of fuses, refer to the

paragraph "Replacing fuses" in this

chapter.

114) 115)

25) 26)

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

135

Page 141 of 215

Bulbs

Use Type Power Ref. Figure

Main beam headlights HI 55 W D

Dipped headlights H7 55 W D

Dipped headlights with gas discharge bulbs

(Xenon) (for versions/markets, where provided)DIS 35 W F

Front side lights/daytime running lights W2I/5W 5/2IW A

Front direction indicators WY2IW 21 W B

Front direction indicators (with xenon gas

discharge bulbs)PY24W 24 W B

Side direction indicators W5W 5 W A

Rear direction indicators PY2IW 2IW B

Rear side lights RI0W I0W B

Brake lights P2IW 2IW B

Reversing light P2IW 2IW B

Rear fog light P2IW 2IW B

Roof light C5W 5 W C

Luggage compartment light W5W 5 W A

Number plate light C5W 5 W C

Fog lights HI 55 W E

Third brake lights W5W 5 W A

137

Page 142 of 215

WARNING

114) Changes or repairs to the electrical system carried out incorrectly and without due consideration for the technical

specifications of the system may lead to malfunctioning and generate a fire hazard.

115) Halogen bulbs contain pressurised gas. If they break, glass fragments could fly everywhere.

IMPORTANT

25) Halogen bulbs must be handled by holding the metallic part only. Touching the transparent part of the bulb with

your fingers may reduce the intensity of the emitted light and even reduce the lifespan of the bulb. In the event of

accidental contact, wipe the bulb with a cloth moistened with alcohol and let the bulb dry.

26) Where possible, it is advisable to have bulbs changed at an Abarth Dealership. The correct operation and alignment

of the external lights are absolutely essential for the safety of the car and of compliance with the law.

138

IN AN EMERGENCY

Page 143 of 215

REPLACING AN

EXTERIOR BULB

For the type of bulb and power rating,

see paragraph "Replacing a bulb".

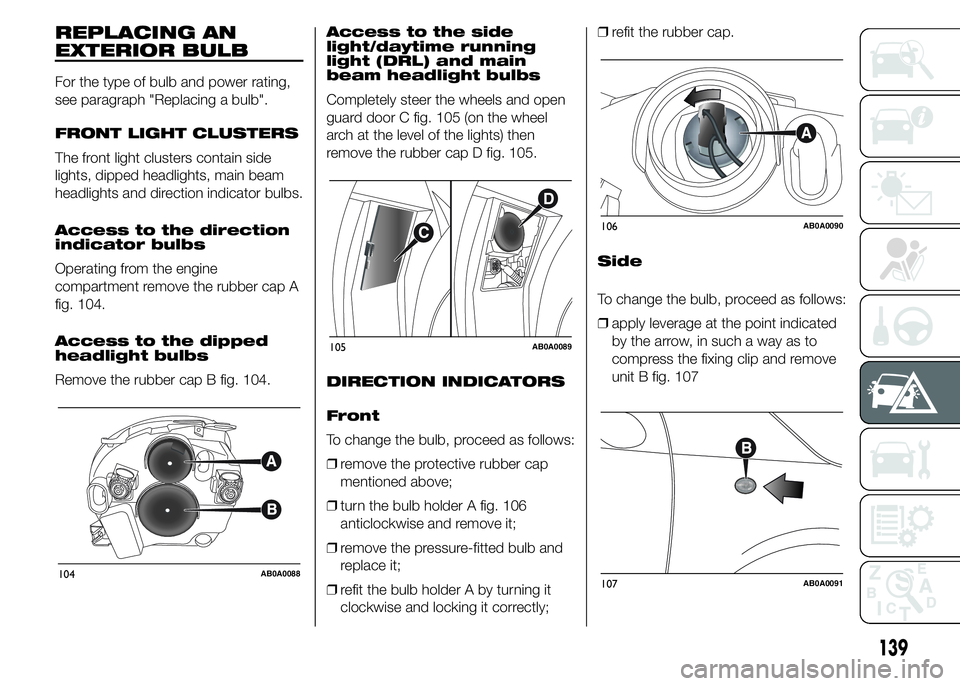

FRONT LIGHT CLUSTERS

The front light clusters contain side

lights, dipped headlights, main beam

headlights and direction indicator bulbs.

Access to the direction

indicator bulbs

Operating from the engine

compartment remove the rubber cap A

fig. 104.

Access to the dipped

headlight bulbs

Remove the rubber cap B fig. 104.Access to the side

light/daytime running

light (DRL) and main

beam headlight bulbs

Completely steer the wheels and open

guard door C fig. 105 (on the wheel

arch at the level of the lights) then

remove the rubber cap D fig. 105.

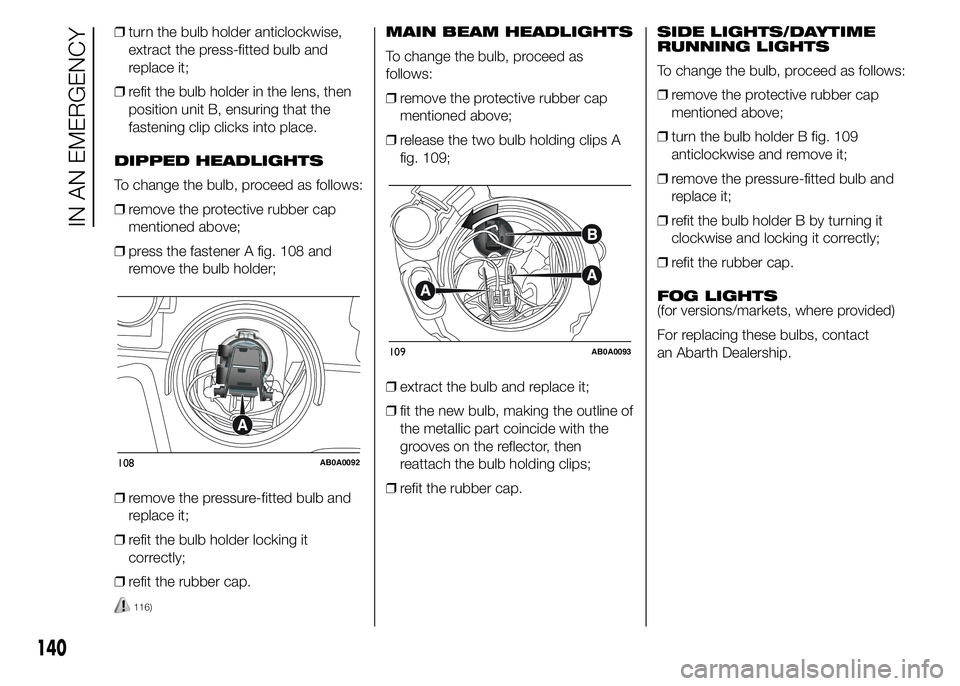

DIRECTION INDICATORS

Front

To change the bulb, proceed as follows:

❒remove the protective rubber cap

mentioned above;

❒turn the bulb holder A fig. 106

anticlockwise and remove it;

❒remove the pressure-fitted bulb and

replace it;

❒refit the bulb holder A by turning it

clockwise and locking it correctly;❒refit the rubber cap.

Side

104AB0A0088

105AB0A0089

106AB0A0090

107AB0A0091

139

To change the bulb, proceed as follows:

❒apply leverage at the point indicated

by the arrow, in such a way as to

compress the fixing clip and remove

unit B fig. 107

Page 144 of 215

❒turn the bulb holder anticlockwise,

extract the press-fitted bulb and

replace it;

❒refit the bulb holder in the lens, then

position unit B, ensuring that the

fastening clip clicks into place.

DIPPED HEADLIGHTS

To change the bulb, proceed as follows:

❒remove the protective rubber cap

mentioned above;

❒press the fastener A fig. 108 and

remove the bulb holder;

❒remove the pressure-fitted bulb and

replace it;

❒refit the bulb holder locking it

correctly;

❒refit the rubber cap.

116)

MAIN BEAM HEADLIGHTS

To change the bulb, proceed as

follows:

❒remove the protective rubber cap

mentioned above;

❒release the two bulb holding clips A

fig. 109;

❒extract the bulb and replace it;

❒fit the new bulb, making the outline of

the metallic part coincide with the

grooves on the reflector, then

reattach the bulb holding clips;

❒refit the rubber cap.SIDE LIGHTS/DAYTIME

RUNNING LIGHTS

To change the bulb, proceed as follows:

❒remove the protective rubber cap

mentioned above;

❒turn the bulb holder B fig. 109

anticlockwise and remove it;

❒remove the pressure-fitted bulb and

replace it;

❒refit the bulb holder B by turning it

clockwise and locking it correctly;

❒refit the rubber cap.

FOG LIGHTS

(for versions/markets, where provided)

For replacing these bulbs, contact

an Abarth Dealership.

108AB0A0092

109AB0A0093

140

IN AN EMERGENCY

Page 145 of 215

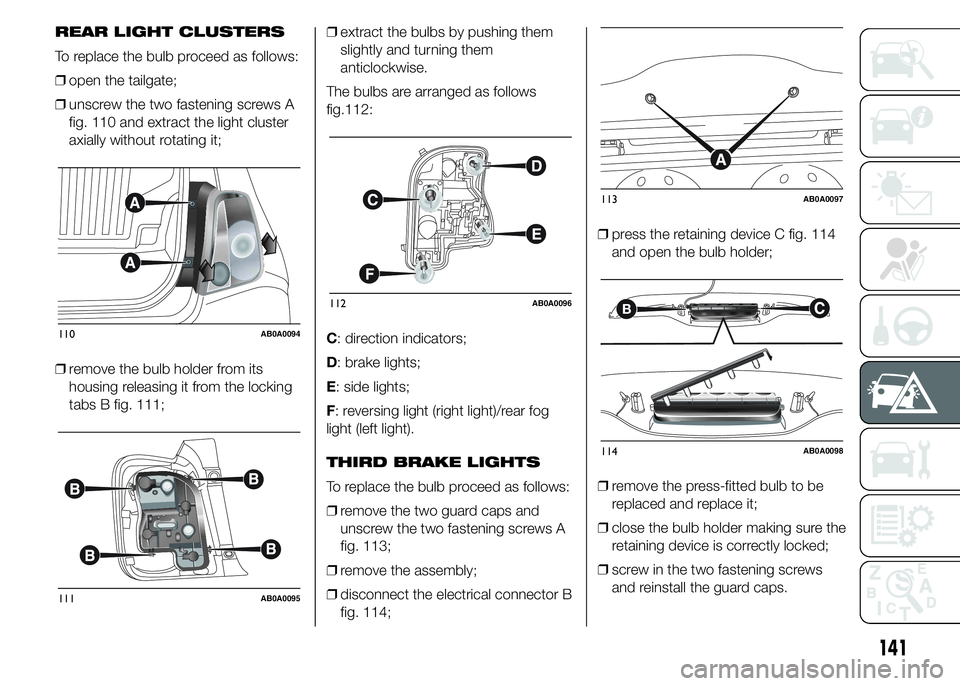

REAR LIGHT CLUSTERS

To replace the bulb proceed as follows:

❒open the tailgate;

❒unscrew the two fastening screws A

fig. 110 and extract the light cluster

axially without rotating it;

❒remove the bulb holder from its

housing releasing it from the locking

tabs B fig. 111;❒extract the bulbs by pushing them

slightly and turning them

anticlockwise.

The bulbs are arranged as follows

fig. 112:

C: direction indicators;

D: brake lights;

E: side lights;

F: reversing light (right light)/rear fog

light (left light).

THIRD BRAKE LIGHTS

To replace the bulb proceed as follows:

❒remove the two guard caps and

unscrew the two fastening screws A

fig. 113;

❒remove the assembly;

❒disconnect the electrical connector B

fig. 114;❒press the retaining device C fig. 114

and open the bulb holder;

❒remove the press-fitted bulb to be

replaced and replace it;

❒close the bulb holder making sure the

retaining device is correctly locked;

❒screw in the two fastening screws

and reinstall the guard caps.

110AB0A0094

111AB0A0095

112AB0A0096

113AB0A0097

B

114AB0A0098

141

Page 146 of 215

NUMBER PLATE LIGHTS

To replace the bulbs proceed as

follows:

❒apply pressure to the point shown by

the arrow fig. 115 and remove the

lens;

❒change the bulb, releasing it from the

side contacts;

❒fit the new bulb and make sure that it

is correctly clamped between the

contacts;

❒then refit the lens.

WARNING

116) Due to the high power supply

voltage, gas discharge bulbs

(Xenon) should only be replaced

by specialised personnel: danger

of death! Contact an Abarth

Dealership.

REPLACING AN

INTERIOR BULB

For the type of bulb and power rating,

see paragraph "Replacing a bulb".

INTERIOR ROOF LIGHT

To replace the bulb, proceed as follows:

❒using the screwdriver provided,

extract the roof light A fig. 116

working in the point shown by the

arrow;

115AB0A0099

116AB0A0100

142

IN AN EMERGENCY