Abarth 500 2019 Owner handbook (in English)

Manufacturer: ABARTH, Model Year: 2019, Model line: 500, Model: Abarth 500 2019Pages: 196, PDF Size: 3.53 MB

Page 101 of 196

WARNING

116)Modifications or repairs to the electric system that are not carried out properly or do not take the system technical specifications into

account can cause malfunctions leading to the risk of fire.

117)Halogen bulbs contain pressurised gas, in the case of breakage they may burst causing glass fragments to be projected outwards.

118)Before replacing the bulb, wait for the exhaust ducts to cool down: DANGER OF SCALDING!

119)Only replace the light bulbs when the engine is off and in a position that does not interfere with traffic and lets you safely replace them

(see the description in the “Replacement” paragraph). Also ensure that the engine is cold, to prevent the risk of burns.

WARNING

25)Halogen bulbs must be handled holding the metallic part only. Touching the transparent part of the bulb with your fingers may reduce the

intensity of the emitted light and even reduce the lifespan of the bulb. In the event of accidental contact, wipe the bulb with a cloth moistened

with alcohol and let the bulb dry.

26)Where possible, it is advisable to have bulbs changed at an Abarth Dealership. The correct operation and direction of the external lights

are absolutely essential for the safety of the car and of compliance with the law.

99

Page 102 of 196

REPLACING AN

EXTERIOR BULB

For the type of bulb and power rating,

see paragraph "Replacing a bulb".

FRONT LIGHT CLUSTERS

The front light clusters contain side

lights, dipped headlights, main beam

headlights and direction indicator bulbs.

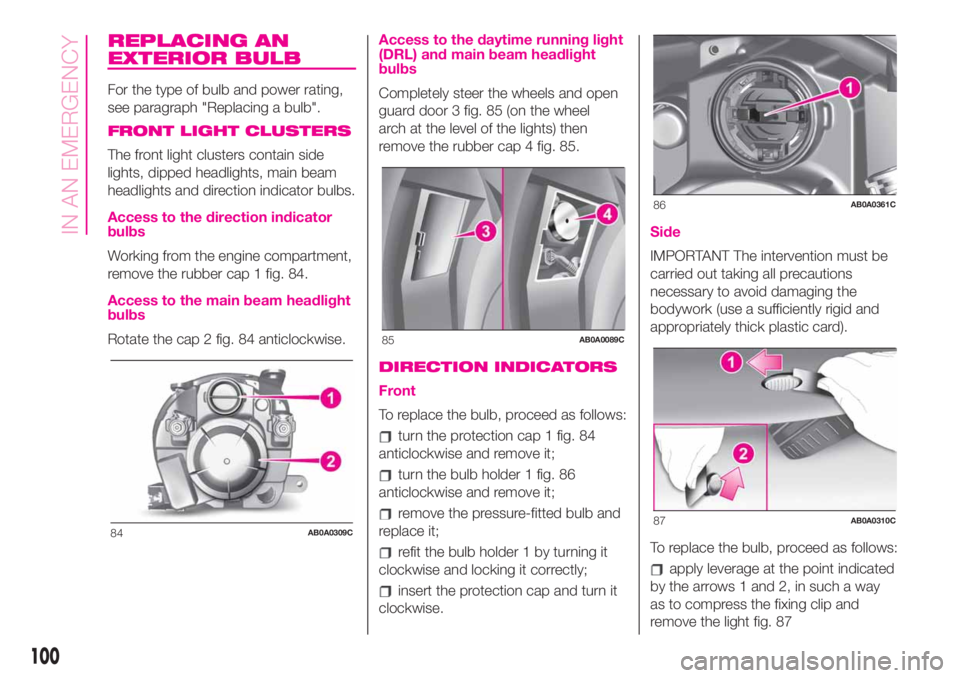

Access to the direction indicator

bulbs

Working from the engine compartment,

remove the rubber cap 1 fig. 84.

Access to the main beam headlight

bulbs

Rotate the cap 2 fig. 84 anticlockwise.

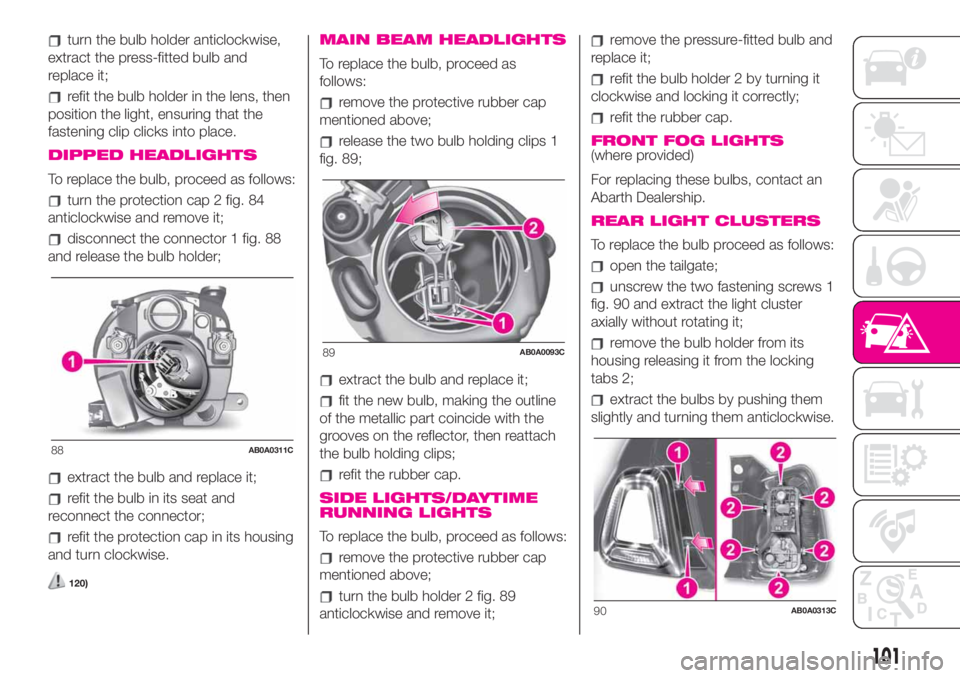

Access to the daytime running light

(DRL) and main beam headlight

bulbs

Completely steer the wheels and open

guard door 3 fig. 85 (on the wheel

arch at the level of the lights) then

remove the rubber cap 4 fig. 85.

DIRECTION INDICATORS

Front

To replace the bulb, proceed as follows:

turn the protection cap 1 fig. 84

anticlockwise and remove it;

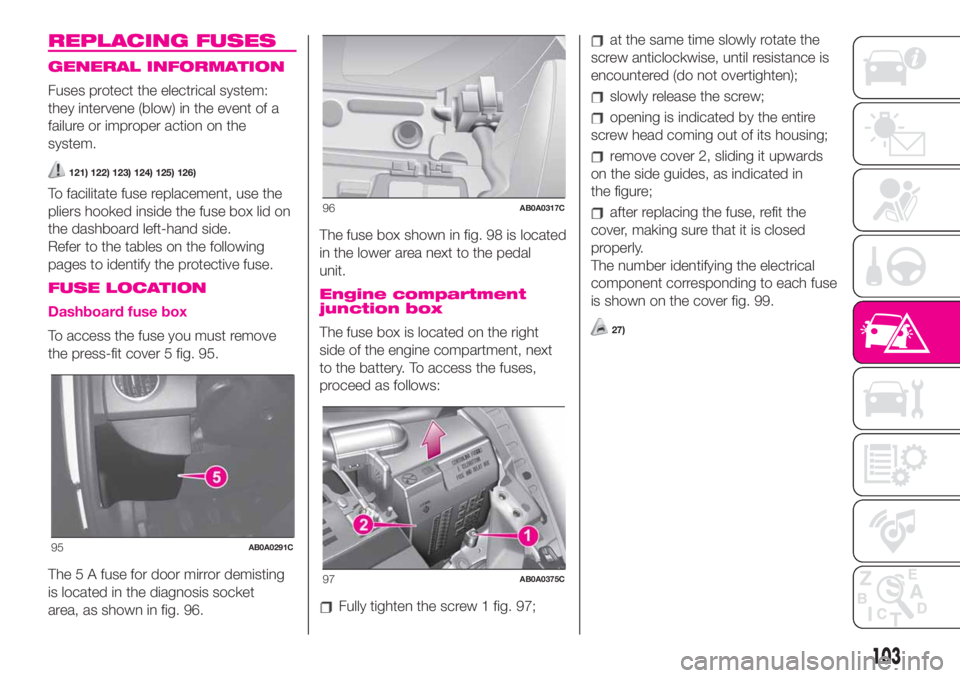

turn the bulb holder 1 fig. 86

anticlockwise and remove it;

remove the pressure-fitted bulb and

replace it;

refit the bulb holder 1 by turning it

clockwise and locking it correctly;

insert the protection cap and turn it

clockwise.

Side

IMPORTANT The intervention must be

carried out taking all precautions

necessary to avoid damaging the

bodywork (use a sufficiently rigid and

appropriately thick plastic card).

To replace the bulb, proceed as follows:

apply leverage at the point indicated

by the arrows 1 and 2, in such a way

as to compress the fixing clip and

remove the light fig. 87

84AB0A0309C

85AB0A0089C

86AB0A0361C

87AB0A0310C

100

IN AN EMERGENCY

Page 103 of 196

turn the bulb holder anticlockwise,

extract the press-fitted bulb and

replace it;

refit the bulb holder in the lens, then

position the light, ensuring that the

fastening clip clicks into place.

DIPPED HEADLIGHTS

To replace the bulb, proceed as follows:

turn the protection cap 2 fig. 84

anticlockwise and remove it;

disconnect the connector 1 fig. 88

and release the bulb holder;

extract the bulb and replace it;

refit the bulb in its seat and

reconnect the connector;

refit the protection cap in its housing

and turn clockwise.

120)

MAIN BEAM HEADLIGHTS

To replace the bulb, proceed as

follows:

remove the protective rubber cap

mentioned above;

release the two bulb holding clips 1

fig. 89;

extract the bulb and replace it;

fit the new bulb, making the outline

of the metallic part coincide with the

grooves on the reflector, then reattach

the bulb holding clips;

refit the rubber cap.

SIDE LIGHTS/DAYTIME

RUNNING LIGHTS

To replace the bulb, proceed as follows:

remove the protective rubber cap

mentioned above;

turn the bulb holder 2 fig. 89

anticlockwise and remove it;

remove the pressure-fitted bulb and

replace it;

refit the bulb holder 2 by turning it

clockwise and locking it correctly;

refit the rubber cap.

FRONT FOG LIGHTS(where provided)

For replacing these bulbs, contact an

Abarth Dealership.

REAR LIGHT CLUSTERS

To replace the bulb proceed as follows:

open the tailgate;

unscrew the two fastening screws 1

fig. 90 and extract the light cluster

axially without rotating it;

remove the bulb holder from its

housing releasing it from the locking

tabs 2;

extract the bulbs by pushing them

slightly and turning them anticlockwise.

88AB0A0311C

89AB0A0093C

90AB0A0313C

101

Page 104 of 196

The bulbs are arranged as follows fig.

91:

1: side / brake light;

2: direction indicators.

REVERSING LIGHT/REAR

FOG LIGHT

For bulb replacement, contact an

Abarth Dealership.

THIRD BRAKE LIGHTS

To replace the bulb proceed as follows:

remove the two guard caps and

unscrew the two fastening screws 1 fig.

92;

remove the assembly;

disconnect the electrical connector

2 fig. 93;

press the retaining device 3 fig. 93

and open the bulb holder;

remove the press-fitted bulb to be

replaced and replace it;

close the bulb holder making sure

the retaining device is correctly locked;

screw in the two fastening screws

and reinstall the guard caps.

NUMBER PLATE LIGHTS

To replace the bulbs, proceed as

follows:

apply pressure to the point shown

by the arrow fig. 94 and remove the

lens;

change the bulb, releasing it from

the side contacts;

fit the new bulb and make sure that

it is correctly clamped between the

contacts;

then refit the lens.

WARNING

120)Due to the high power supply

voltage, gas discharge bulbs (Xenon)

should only be replaced by specialised

personnel: danger of death! Contact

an Abarth Dealership.

91AB0A0314C

92AB0A0097C

93AB0A0098C

94AB0A0099C

102

IN AN EMERGENCY

Page 105 of 196

REPLACING FUSES

GENERAL INFORMATION

Fuses protect the electrical system:

they intervene (blow) in the event of a

failure or improper action on the

system.

121) 122) 123) 124) 125) 126)

To facilitate fuse replacement, use the

pliers hooked inside the fuse box lid on

the dashboard left-hand side.

Refer to the tables on the following

pages to identify the protective fuse.

FUSE LOCATION

Dashboard fuse box

To access the fuse you must remove

the press-fit cover 5 fig. 95.

The 5 A fuse for door mirror demisting

is located in the diagnosis socket

area, as shown in fig. 96.The fuse box shown in fig. 98 is located

in the lower area next to the pedal

unit.

Engine compartment

junction box

The fuse box is located on the right

side of the engine compartment, next

to the battery. To access the fuses,

proceed as follows:

Fully tighten the screw 1 fig. 97;

at the same time slowly rotate the

screw anticlockwise, until resistance is

encountered (do not overtighten);

slowly release the screw;

opening is indicated by the entire

screw head coming out of its housing;

remove cover 2, sliding it upwards

on the side guides, as indicated in

the figure;

after replacing the fuse, refit the

cover, making sure that it is closed

properly.

The number identifying the electrical

component corresponding to each fuse

is shown on the cover fig. 99.

27)

95AB0A0291C

96AB0A0317C

97AB0A0375C

103

Page 106 of 196

DASHBOARD FUSE BOX

DEVICE PROTECTED FUSE AMPERE

Headlight alignment corrector F13

5(*)

Diagnosis socket, Uconnect, climate control, EOBD F36 15

Brake light switch, instrument panel node F37 5

Central door locking F38 15

Windscreen/rear window washer pump F43 15

Driver's side electric windows F47 20

(*) (where provided)

98AB0A0106C

104

IN AN EMERGENCY

Page 107 of 196

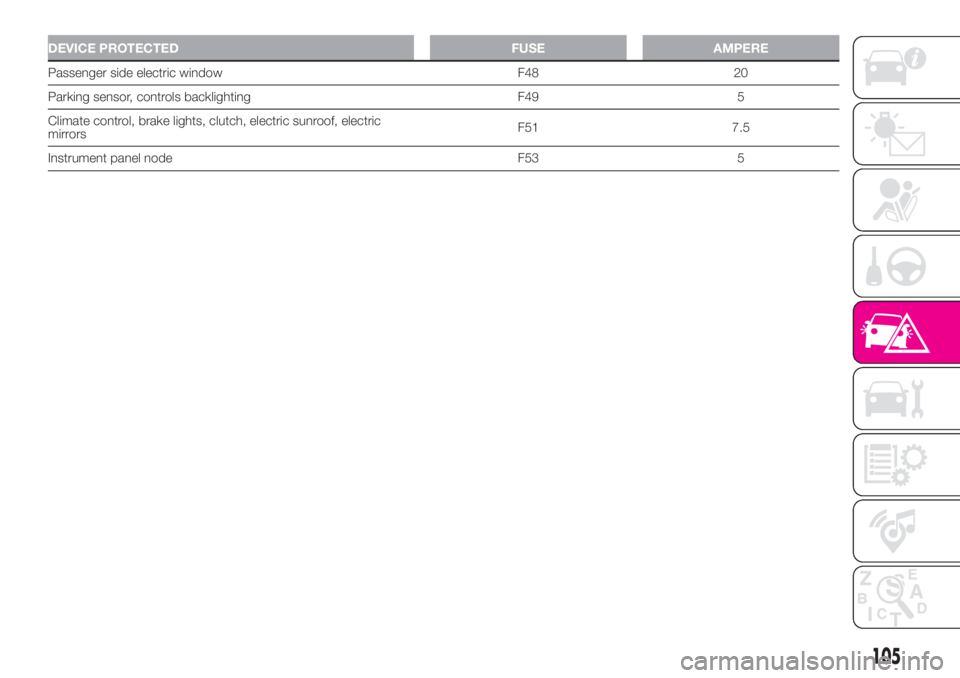

DEVICE PROTECTED FUSE AMPERE

Passenger side electric window F48 20

Parking sensor, controls backlighting F49 5

Climate control, brake lights, clutch, electric sunroof, electric

mirrorsF51 7.5

Instrument panel node F53 5

105

Page 108 of 196

ENGINE COMPARTMENT JUNCTION BOX

DEVICE PROTECTEDFUSE AMPERE

HI-FIF02 20

Climate control electric fanF08 30

Headlight washersF09 30

HornsF10 10

Main-beam headlightsF14

10/15

(*)

Electric roof motorF15 20

(*) Only for versions equipped with Xenon gas discharge lamps

99AB0A0319C

106

IN AN EMERGENCY

Page 109 of 196

DEVICE PROTECTEDFUSE AMPERE

Robotised sequential gearbox control unit power supply (+ ignition) F16 7.5

Heated rear windowF20 30

Fog lightsF30 15

Robotised sequential gearbox control unit F84 10

Front power socket (with or without cigar lighter) F85 20

WARNING

121)If the fuse blows again, contact an Abarth Dealership.

122)Never replace a fuse with metal wires or anything else.

123)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE.

124)If a general protection fuse (MEGA-FUSE, MIDI-FUSE, MAXI-FUSE) blows, contact an Abarth Dealership.

125)Before replacing a fuse, make sure that the ignition key has been removed and that all the other services are switched off and/or

disengaged.

126)If a general protection fuse for the safety systems (airbag system, braking system), power unit systems (engine system, gearbox system)

or driving system blows, contact an Abarth Dealership.

WARNING

27)If you need to wash the engine compartment, take care not to directly hit the engine compartment fuse box with the water jet.

107

Page 110 of 196

“Fix&Go” KIT

127) 128)

28)

DESCRIPTION

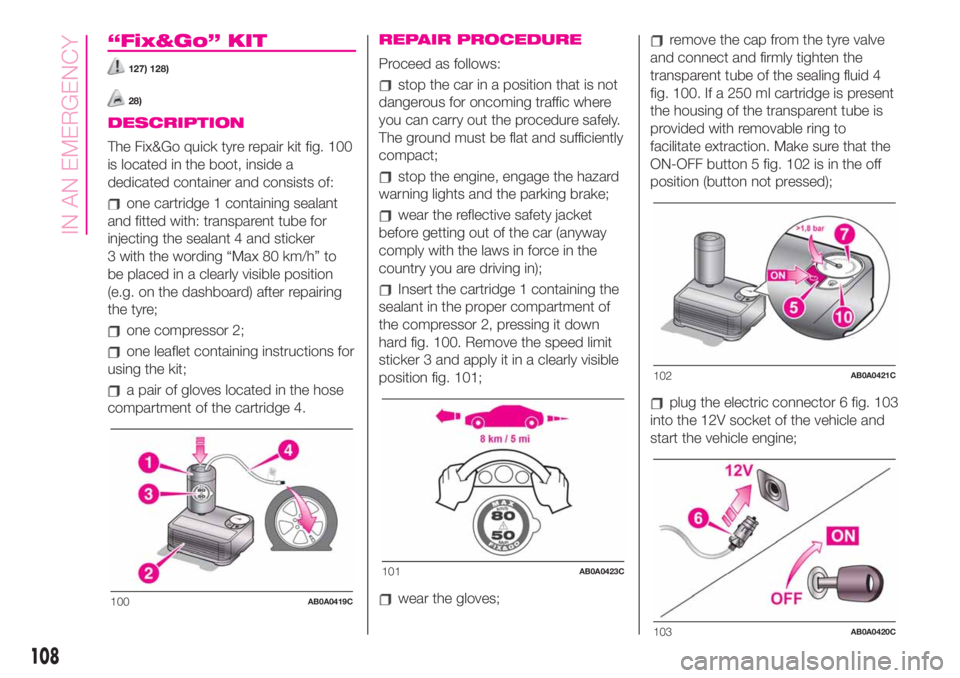

The Fix&Go quick tyre repair kit fig. 100

is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker

3 with the wording “Max 80 km/h” to

be placed in a clearly visible position

(e.g. on the dashboard) after repairing

the tyre;

one compressor 2;

one leaflet containing instructions for

using the kit;

a pair of gloves located in the hose

compartment of the cartridge 4.

REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

Insert the cartridge 1 containing the

sealant in the proper compartment of

the compressor 2, pressing it down

hard fig. 100. Remove the speed limit

sticker 3 and apply it in a clearly visible

position fig. 101;

wear the gloves;

remove the cap from the tyre valve

and connect and firmly tighten the

transparent tube of the sealing fluid 4

fig. 100. If a 250 ml cartridge is present

the housing of the transparent tube is

provided with removable ring to

facilitate extraction. Make sure that the

ON-OFF button 5 fig. 102 is in the off

position (button not pressed);

plug the electric connector 6 fig. 103

into the 12V socket of the vehicle and

start the vehicle engine;

100AB0A0419C

101AB0A0423C

102AB0A0421C

103AB0A0420C

108

IN AN EMERGENCY