sensor ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 53 of 1413

*l

Engine Removal/lnstallation

(cont'dl

27. Remove the radiator assembly {see page 1O-4),

28. Remove the A/C compressor.

a Do not disconnect A/C hoses.

8 x '1.25 mm24 N.m t2.4 kgf.m, 17 lbl.ftl

29. Disconnect the heated oxygen sensor (HO2Sl con-nector, then remove exhaust pipe A.

B'l8Cl engine: Ho2s

I x 1.25 mm24 N.m (2.4 kgf.m,17 rbt.ftt

Replace.

SELF-LOCKING NUT8 x 1.25 mm16 N.m 11.6 kgf.m,12 tbl.ftlReplace.

EXHAUSTPIPE A

SELF10 x 1.25 mm54 N.m (5.5 ksf.m.4O lbf'ltlReplace.

CONNECTOR

5-8

8188l engine:

8 x 1.25 mm24 N.m 12.4 kgf.m,17 tbt.trl

GASKETReplace.

GASKETReplace.

SELF.LOCKING NUTI x 1.25 mm16 N.m (1.6 kgt.m,12 tbf.ft)Replace.10 x 1.25 mm54 N.m (5.5 kgl.m,40 tbt.ttlReplace.

30. Remove the shift rod and extension rod {M/T).

I x 1.25 mm22 N-m 12.2 kgf.m, '16 lbf.ftlSHIFT ROD

Page 79 of 1413

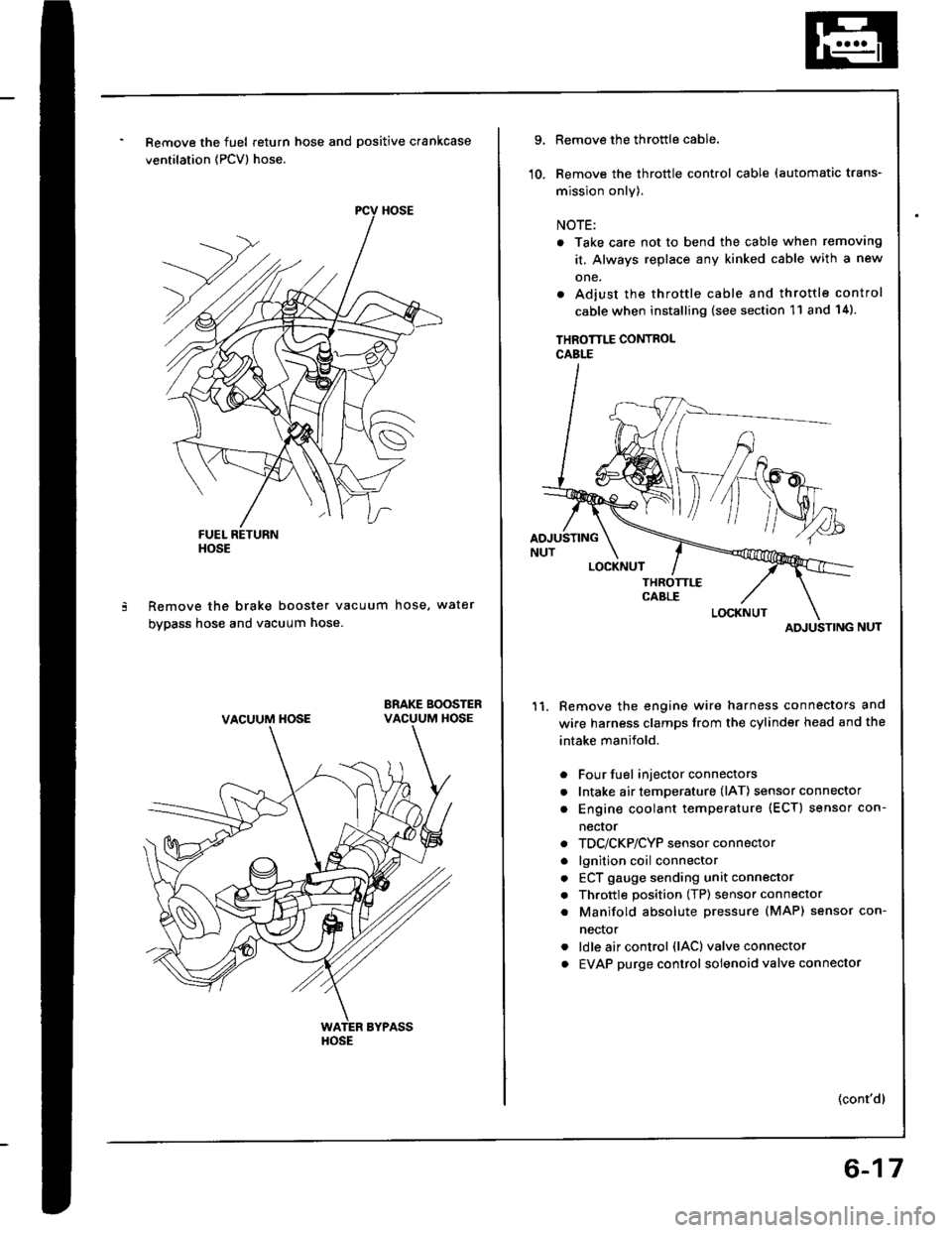

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 118 of 1413

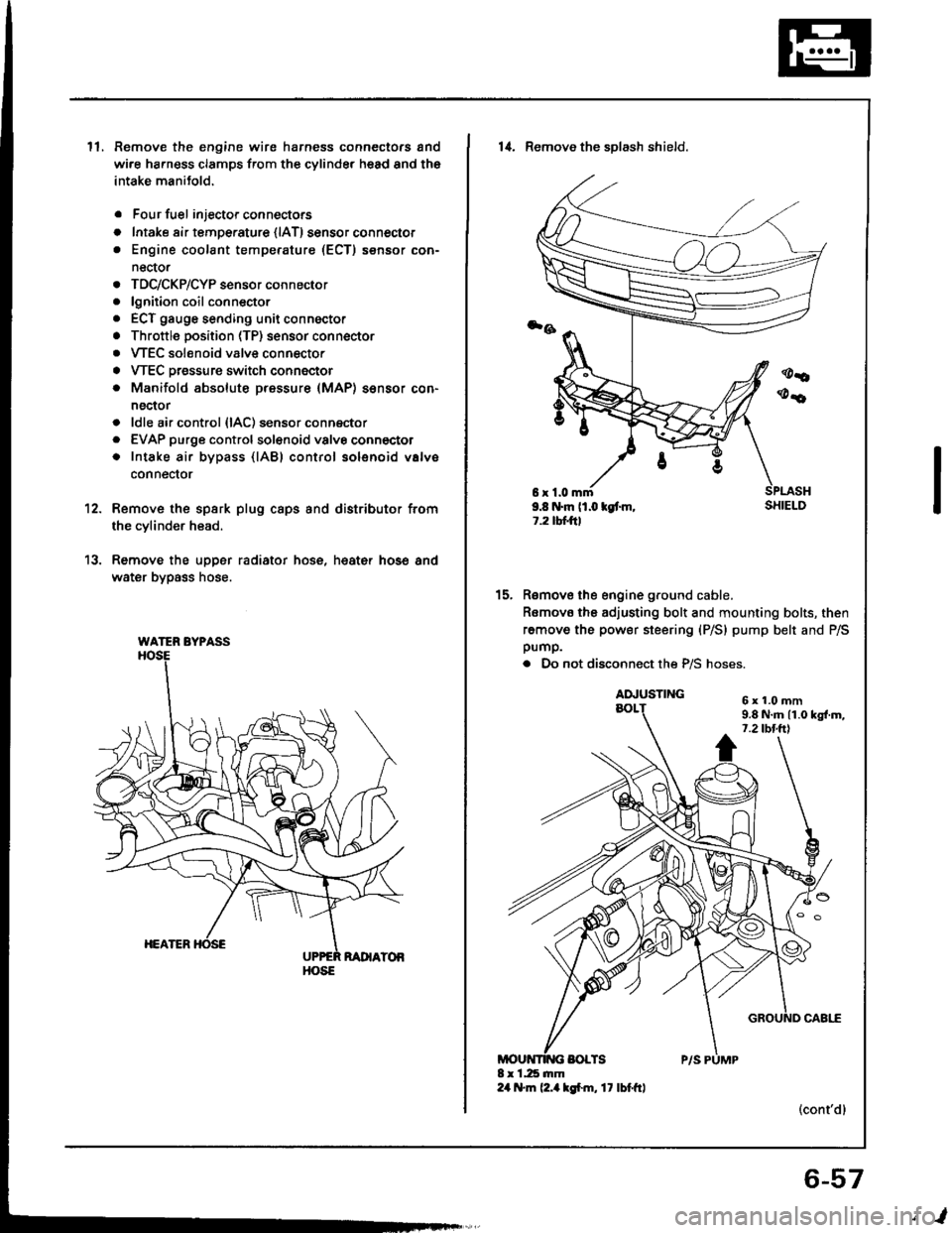

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 180 of 1413

Intake Manifold

Replacement

NOTE: Use new O-rings and gaskets when reassembling.

CAUTION: Check for tolds or scratches on the aurface ot the gasket. Roplace with a now gasket it damagod,

81881 engine:

5r0.8mm6 N'm {0.6 kgl.m.4 rbr.ftlINTAKE AIRTEMPERATUREIIATI SENSOR

'*o*ot'u""'""N

5xO.8mm6 .m (0.6 kg{.m.4 tbf.ftl

O-RINGReplace.

IiITAKE MANIFOLDReplace iI cracked orit mating s!rtaces arodamag€o.

PURGE CONTROLSOLENOID VALVE

8 x 1.25 mm22 N.r 12.2 kgl.m,'16 tbt.ftt

IDLE AIR

GASKETSReplace.

I x 1.25 mm20 N.m (2.0 kgt.m.14 rbf.ftl

O.RINGReplace.{IACI VALVEBe careful notto damage.THROTTLE

8 x 1.25 mm

BODY

O-RINGSBeplace.

24 N.m (2.4 kgf'm,17 rbf.ft)

8 x 1.25 mm23 N.m (2.3 kgl.m,17 lbf.frl

BRACKET"o

aYc

g

/

1.25 mmN.m (2.4 kgl'm,rbf'ft1

8x2417

8 x 1.25 mm24 N.m (2.4 kgl'm.17 tbr.ftlTHERMOVALVE8e careful not todamage.

9-2

Page 181 of 1413

NOTE: Use new O-rings and gaskets when reassembling.

CAUTION: Chock for folds 01 scratches on th6 surfac6 of tho gaskot. Replace wilh a new gasket if damaged.

818C1 engino:

INTAKE MANIFOLDReplace il cracked oril mating surfaces are

5 x O.8 rnm6 N.m 10.6 kgl.m,4 tbt.ttl

lI

{,/

?,/

EVAP PURGE CONTROLVALVEdamageo.

IAT SENSOR

5xO.8mm6 N.m 10.6 kgf.m,4 tbf.ftl

INTAKE AIRBYPASS VALVE

IAC VALVEBe carelul notlo oamage.

O.RINGSReplace.

GASKETSReplace.

O.BI GReplace.

BODY

INTAKE MANIFOLDCHAMBER

8 x 1.25 mm23 N.rn 12.3 kgt'm,17 tbf.frl

I x 1.25 mm22 N.m 12.2 kgl.ft,t6 tbt.tt)

BRACKET

8 r 1.25 mm24 N.m {2.4 kgf.h,t7 rbr.ftl

8 x t.25 mfi24 N.m (2.4 lgf.m.17 tbt.ft)I r 1.25 lnm24 N.m 12.4 kgt.m,17 tbt.ftl

8 x 1.25 mm20 .m (2.0 kgt.m,14 tbf.ftl

THROTTLEAODY

FAST IDL€ THERMO VALVEBe carelul not to damage.

HEATER BYPASSPIPE

o-Rt GsReplace.

I x 1.25 mm24 N.m (2.4 kgl.m, 17lbf'ft|

9-3

Page 183 of 1413

Exhaust Pipe and Muffler

Replacement

NOTE: Use new gaskets and

Bl88l engine:

selflocking nuts when reassembling.

HEAT SHIELDS

6 x 1.0 mm9.8 N.m l1.O kgf.m, 7.2 lbf.ftl

HEAT SHI€LD

SELF-LOCKIIIG NUT

,@\

10 x 1.25 mm33 N.m (3.4 kgt.m,25 tbf.fttReplace.HEATEO OXYGENSENSOR (HO2Sl

44 N.m 14.5 kgt.m,33 rbf.ftlI x 1.25 mm24 N.m 12.4 kgf.m,17 tbl.frl

BRACKET

GASKETSReplace.

SELF-LOCKING NUTS10 x 1,25 mm54 N'm 15.5 kgf'm,40 tbf.ftlReplace.

SELF-LOCKING NUT8 x 1.25 mm16 N.m {1.6 kgf.m,r2 tbt.frlReplace.

I x 1.25 mm22 N.m (2.2 kgl.m, r6lbt.ftlReplace.Tighten the flange nuts in steps,alternating side-to-side.

MUFFLER

EXHAUST

I,

^1

e

e

8 x 1.25 mm22 N.m 12.2 kgt.m, 16 lbf.ftlReplace.Tighten the bolts in steps,alternating side-to-side.

COVER

GASKETReplace.

THREE WAYCATALYTICCONVERTER

COVER

6 x 1.0 mm9.8 N.m l1.O kgf.m, 7.2 lbl.ttl

PIPE TIP

(cont'd)

Page 192 of 1413

![ACURA INTEGRA 1994 Service Repair Manual Water Pump

NOTE:

a Use new O-rings and new special bolts when reassembling.

a Use liquid gasket, Part No. O8718-0OO1.

3;iil3 B18c1 onsino:

ECT GAUGE SEDING U]{ITI N.m (0.9 tgf.n, 7 lbftt)Apply liquid ACURA INTEGRA 1994 Service Repair Manual Water Pump

NOTE:

a Use new O-rings and new special bolts when reassembling.

a Use liquid gasket, Part No. O8718-0OO1.

3;iil3 B18c1 onsino:

ECT GAUGE SEDING U]{ITI N.m (0.9 tgf.n, 7 lbftt)Apply liquid](/img/32/56982/w960_56982-191.png)

Water Pump

NOTE:

a Use new O-rings and new special bolts when reassembling.

a Use liquid gasket, Part No. O8718-0OO1.

3;iil3 B18c1 onsino:

ECT GAUGE SEDING U]{ITI N.m (0.9 tgf.n, 7 lbf'tt)Apply liquid gaskot

to tho threads.

6r1.Omm

ENGI E COOLAI{TTEMPERATURE IECTI SENSORt8 N.m 11.8 kot.m, 13lbt'ttl

1l t{.m ll.1 tgl.m.8.O tbt.ftl

lllustrated Index

WATER PUMPInspectaon,page lO-9

KNOCK SEI{SOR3l N.m {3.2 kgf.m.23 tbf.ftl(8l8Cl .ngin€ onlyl

WATER OUTLETCOVERApply liquid gasket

to mating sudace.

ECT SEI{SOR

6 r 1.0 mm11 N.m l1.l kgl.m,8.O lbl.ftl

BLEED BOLT9.8 N.m (l.O rg[.m. 7.2 lbt'ft|

Bl8Bl cngln :

OUTIET

ECT SIY]TCH22-26 .m 12.2-2.C )l{/l'nt.

16-19 tbr.ftl

o-Rtt{GRoplaco.

o-itltcRoplrco.

8r1.Orxtr12 .|n ll.2 lgt.m,8.7 n{.ftt

6xt.Omm12 N'ft (1.2 kgf..n.8.7 lbt.ft)

10-8

Page 194 of 1413

Fuel and Emissions

Spocial Tools ................ 1 1-2

Compon€nt Location

lndex ................. ...... 11-3

System Description

Vacuum Connectiona .......,.................... 1 1 -8

Efectrical Connections ....,.,.,......,...,,.....,'11-12

Syst€m Connectors ...,...,.................-.--. 11-2O

T.oubloshooting

Troubleshooting Guido .......................... 1 1-32

Self -diagnostic Procedures .,..,............... 1 1 -34

How to Road Flowcharts ...................,... 11-39

PGM-Fl System

Systom Description .............................. 1 l-4O

Troubleshooting Flowcharts

Engine Control Moduls ............... ........... 1 1 -42

Heated Oxygon Sensor ......,.................. 1 1-46

Heated Oxyg€n Sonsol Heatel .....,......... 1 1 -47

Fuel Supply System ..............-............... 1 1-50

Manitold Absolute Pressure

Ssnsor ............................................ 1 1-52

Top D6ad Cente./Crankshatr

Position/Cylindor Position sonsor ........ 1 1 -56

Engine Coolant Tempsrature Sonsor ....... 11-58

Throttlo Position Sonsor ........,..,,........... 1 1-60

Intake Air Temperaturs Sensor ............... 11-62

Baromet c Prsssuro Sensor ......,...,...,..,. 11-64

lgnition Output Signal ........................... 1 1 -66

Vehicle Spe€d Sensor ........................... 1 1 -68

Electdcal Load Dotector ....,...,..........,.... 1 1 -7O

Knock Sensor [818C1 engine] ............... 11-74

A/T Fl Signal A/B ................................. 1 1-76

ldle Contlol System

System Troubleshooting Guide .................. 1 1 -78

Systom Description ........ 11-79

Troubloshooting Flowchans

ldl€ Ail Control Valve ........................... 1 1 -82

Ail Conditioning Signal ......................... 1 1 -84

Altemator FR Signal ............................. 1 1 -86

Automatic Transaxle (A/T) Gear

Position Signal ......... 11-88

Brake Switch Signal ............................. 1 1 -9O

Startel Switch Signal ............................ 11-92

Power Steering Pressure Switch Signal ... 11-93

Fast ldle Thermo Valve ...................,......... 1 1 -94

ldls Speed S€tting .................................... 1 1 -95

Fuel Supply System

Systam Tloubloshooting Guid. .................. 1 1 -97

Fuol Linos ...................... 1'l -98

System Description ........ 11-100

Fuol Prassure ................. 11-100

Fu6l Ini6ctors ................. 11-102

Fuel Pressure Ragulato. .,. 11-106

Fuel Filter ...................... 11-108

Fual Pump ..................... 11-109

PGM-Fl Main F6lay ................................... 1 1"1 1 1

Fuel Tank ...................... t 1-114

Intake Air System

System Troubloshooting Guido .................. 1 1 -1 1 5

Systom Dascription ........ 11-116

Air Clean€r .................... 11-117

Throttls Cable ................'11-118

Throttl8 Body ................ 11-120

lntake Air Bypass Cont.ol Systsm

[B18Cl enginal .,......... 11-123

Intake Manilold [B1881 onginol ................. 11-128

Emission Control System

Systsm Troubleshooting Guido .................. 1 1 -1 29

Systam Doscription ........ 11-130

Tailpips Emission ........... 11-130

Thrae Way Catalytic Convortor ...,...,........., 11-131

Positiva CrankcaEo V6ntilation Systcm .,....., 11-134

Evaporativo Emission Contro|,..,..,.,.,,.,,..,.., 1 1-135

Page 196 of 1413

Component Locations

lndex

81881 sngin6:

IOLE AIR CONTROL OACI VALVEpage '11-82T

MANIFOLD ABSOLUTEPRESSURE {MAP} SENSOREVAP

THROTTLE POSITIOIII {TP) SENSORTroubleshooting, page 1 1-60

Troubleshooting,

(ECTI SENSOR HEATEO

PURGE CONTROLSOLENOID VALVETroubleshooting,11-137

THROTTLE CABLEInspection/Adiustment, page 1 1-1 18

Installation, page 11- 1 18

SENSOR lHO2S}

TOP DEAD CENTER/CRATIIKSHAFTPOSITIOf{/CYLINDER POSITION(TDC/CKP/CYP} SENSORTroubleshooting, page 1 1-56

INTAKE AIR TEMP€RATURE IIAT) SEI{SORTroubl€shooting, page 1 1 -62

POWER STEERING PRESSURE (PSP)

swtTcHTroubleshooting. page 11-93

sq

IDLE THERMO VALVEInspection, page 11-94

ELECTRICALLOADOETECTORIELD}Troubleshooting.page,l l-70

IGNITIONMODULE {ICMI

Troubleshooting, page 1 1-66

ENGINE COOLANT TEMPERATroubleshooting, page I 1-58Troubleshooting. pages 11-46, 47

11-3

Page 197 of 1413

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4