Damper ACURA INTEGRA 1994 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 492 of 1413

Transmission

Removal {cont'd)

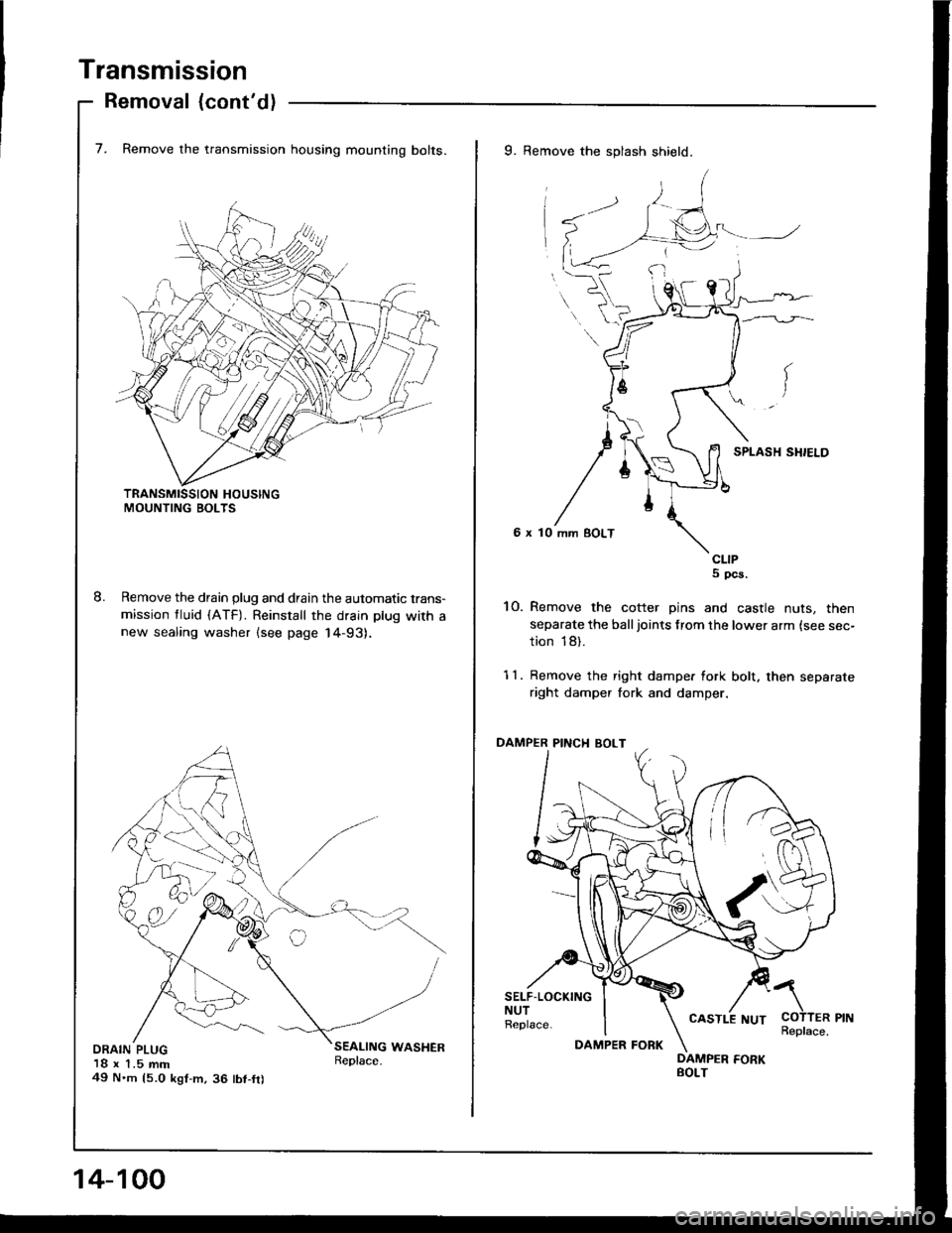

7. Remove the transmission housing mounting bolts.

Remove the drain plug and drain the automatic trans-

mission tluid (ATF). Reinstall the drain plug with anew sealing washer lsee page 14-93).

DRAIN PLUG18 x 1.5 mm49 N'm 15.0 kgt-m,36 tbt-fr)

9. Remove the splash shield.

6 x 10

CLIPS pcs.

10. Remove the cotter pins and castle nuts, then

separate the balljoints from the lower arm {see sec-

tion 18).

11. Remove the right dampe. fork bolt. then separate

right damper fork and damper.

PINCI{ BOLT

SELF.LOCKINGNUTReplace.COTTER PINReplace.

/\

14-100

DAMPER FORK

CASTLE NUT

Page 556 of 1413

Transmission

Installation {cont'd)

14.

15.

Install new set rings on the end of the intermediate

shaft and the driveshaft.

Install the intermediate shaft.

SET RINGBeplace.

16.

10 x 139 N.m14.O kgf.m, 29 lbf.ftl

Install exhaust pipe A. and connect the heated oxv-gen sensor {HO2S) connector.

SELF-LOCKING NUT10 x 1.25 mm54 N.m (5.5 kgl.m,40 rbt.trlReplace.

GASKETReplace.

SELF.LOCKING NUTSI x 1.25 mm22 N.m 12.2 kgl'n,16 lbt.trlRepl6ce.

SHAFT

14-166

DAMPER PINCH BOLT10 x 1.25 mm43 N.m 14.4 kgf.m,32 tbr.ftl

1 7. Install the right and left drivershafts (see section l6l.

NOTE: Turn the right and left steering knuckle fullyoutward, and slide the right driveshaft into the

differential until you feel its spring clip engages theside geaf. Slide the left driveshaft into the intermedi-

ate shaft until you teel the spring clip of the inter-mediate shaft engage the driveshaft.

18. Install right damper fork, then install the right andlett balljoints to each lower arm with the castle nuts

and new cotter Dins.

\

COTTERReplace.CASTLE NUT12 x 1.25 mm49-59 N.m{5.O-6.0 ksf.m, 36-43

SELF.LOCKING NUT12 x 1 .25 mm64 N.m (6.5 kgl.h, 47 lbt.ftlReplace.

rbt'ft1

19. Install the splash shield.

6 x 10 mm BOLT

cltPs, 5

Page 598 of 1413

Driveshafts

Disassembly (cont'd)

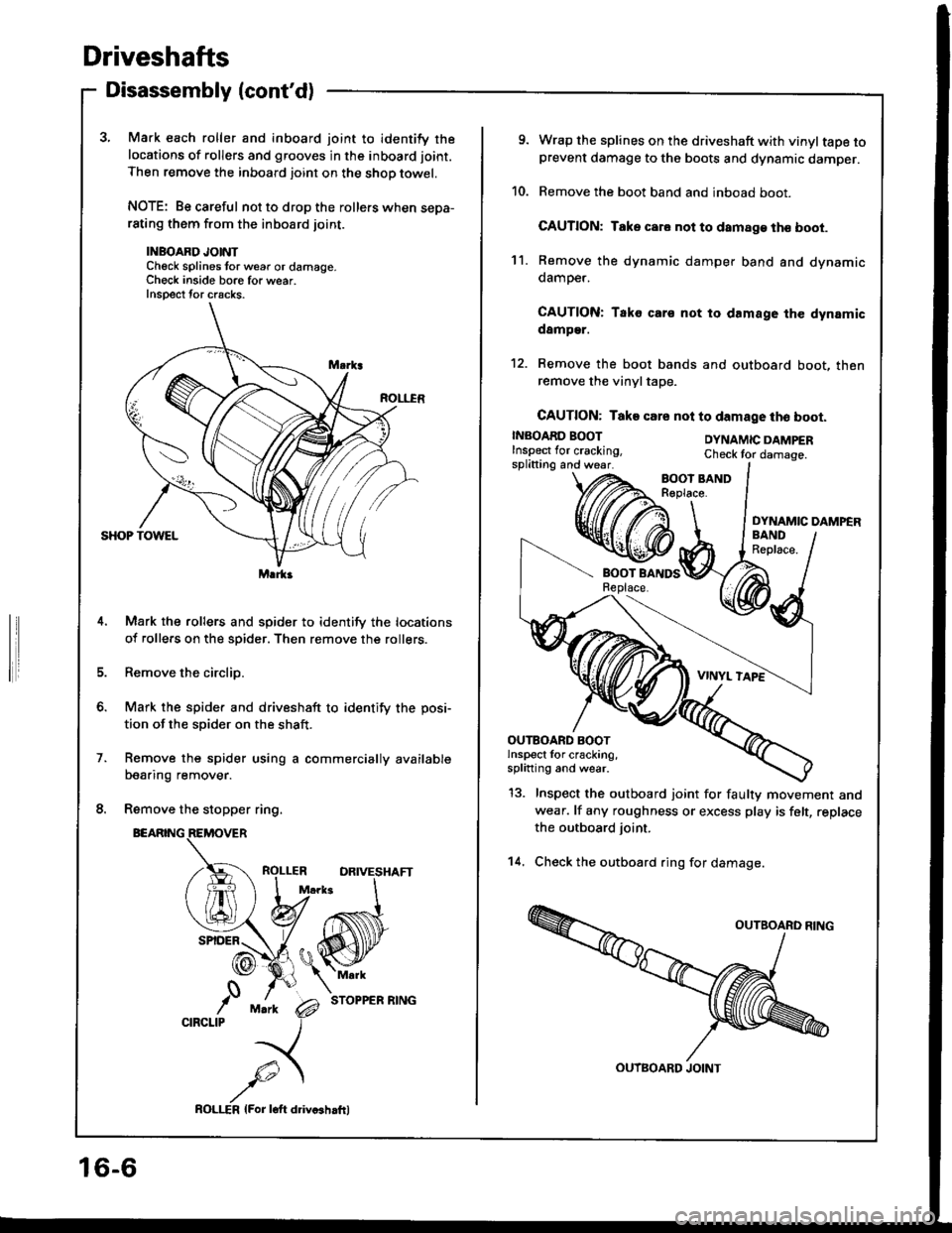

3, Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-rating them from the inboard joint.

INBOARD JOINTCheck splines tor w6ar or damage.Ch€ck inside bore for wear.Inspect tor cracks.

Mark the rollers and spider to identify the locations

of rollers on the spider. Then remove the rollers.

Remove the circlip.

Mark the spider and driveshaft to identify the posi-

tion of the spider on the shaft.

Remove the spider using a commercially available

bearing remover.

Remove the stopper ring.

BEARING

STOPPER RING

Marka

o.

,'0CIRCLIP

16-6

ROLI-€R lFor loft ddvcshrfrl

9. Wrap the splines on the driveshaft with vinyltape toprevent damage to the boots and dynamic damper.

10. Remove the boot band and inboad boot.

CAUTION: Take car. not to damage th€ boot.

11. Remove the dynamic damper band and dynamicdamoer.

CAUTION: Tako cars not to damage the dynamicdamper.

12. Remove the boot bands and outboard boot, thenremove the vinyltape.

CAUTION: Take csre nol to damage tho boot.

INBOARD BOOTInspect lor cracking,splitting and wear.

DYNAMIC DAMPERCheck tor damage.

DYNAMIC DAMPER

13. Inspect the outboard joint for faulty movement andwear. lf any roughness or excess play is felt, replace

the outboard joint.

14. Check the outboard ring for damage.

OUTBOARD BOOTlnspect for cracking,splining and wear.

OUTBOARD JOINT

Page 599 of 1413

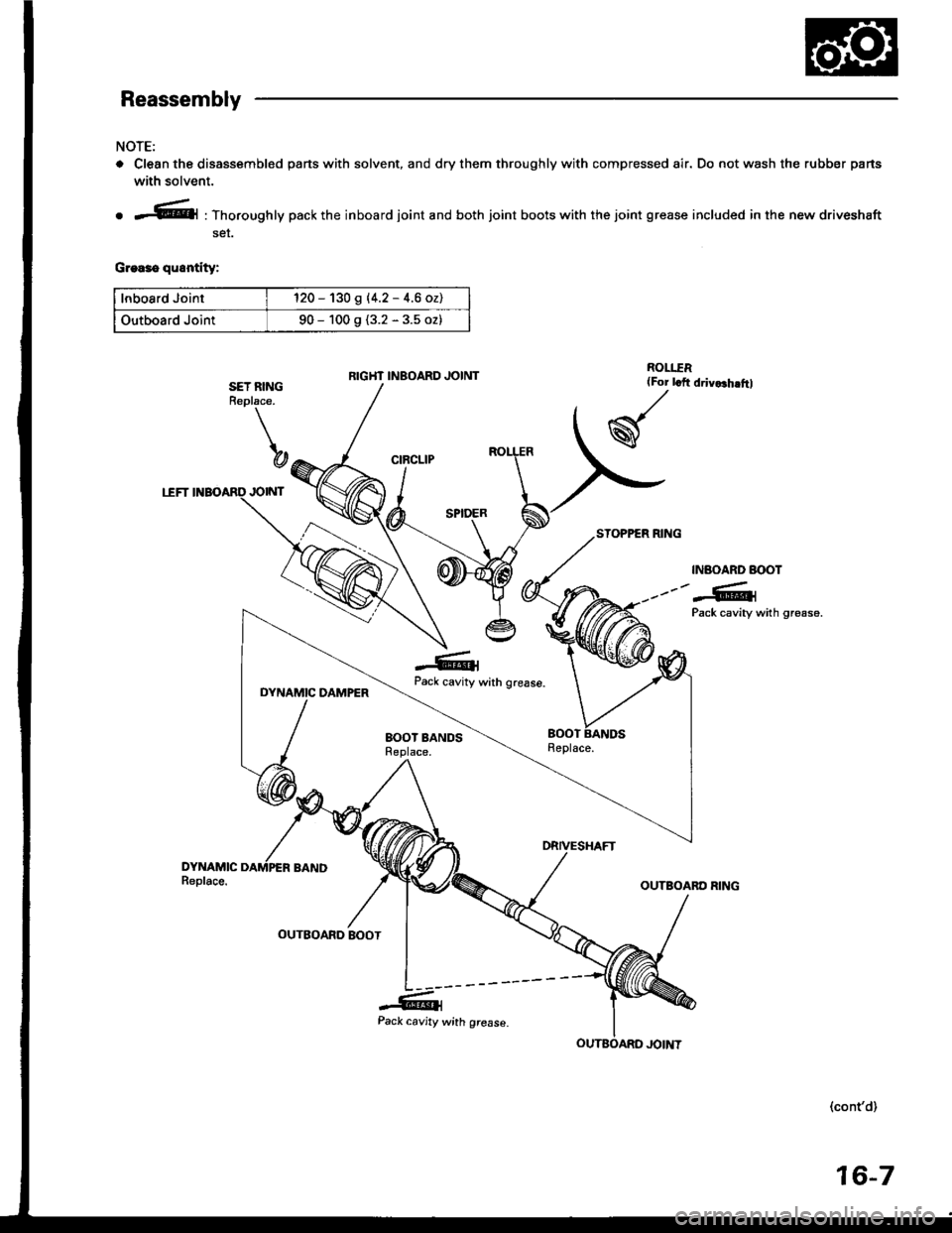

Reassembly

NOTE:

o Clean the disassembled pans with solvent, and dry them throughly with compressed air. Do not wash the rubber parts

with solvent.

ROLI.TR{For lcft

w

o *.'.l|@l : Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

ser.

G.ea3o quontity:

lnboard Joint120 - 130 g |'4.2 - 4.6 ozl

Outboard Joint90 - 100 g {3.2 - 3.5 oz}

INAOARD BOOT

---"-G1Pack cavity with gr€ase.

DYNAMIC DAMPERwrth grease.

SET RINGReplace.

b

,RD JOINT

-GlPack cavity

EOOT BANDSReplace.

(cont'd)

RIGHT INBOARD JOINT

16-7

Page 600 of 1413

Driveshafts

Reassembly (cont'dl

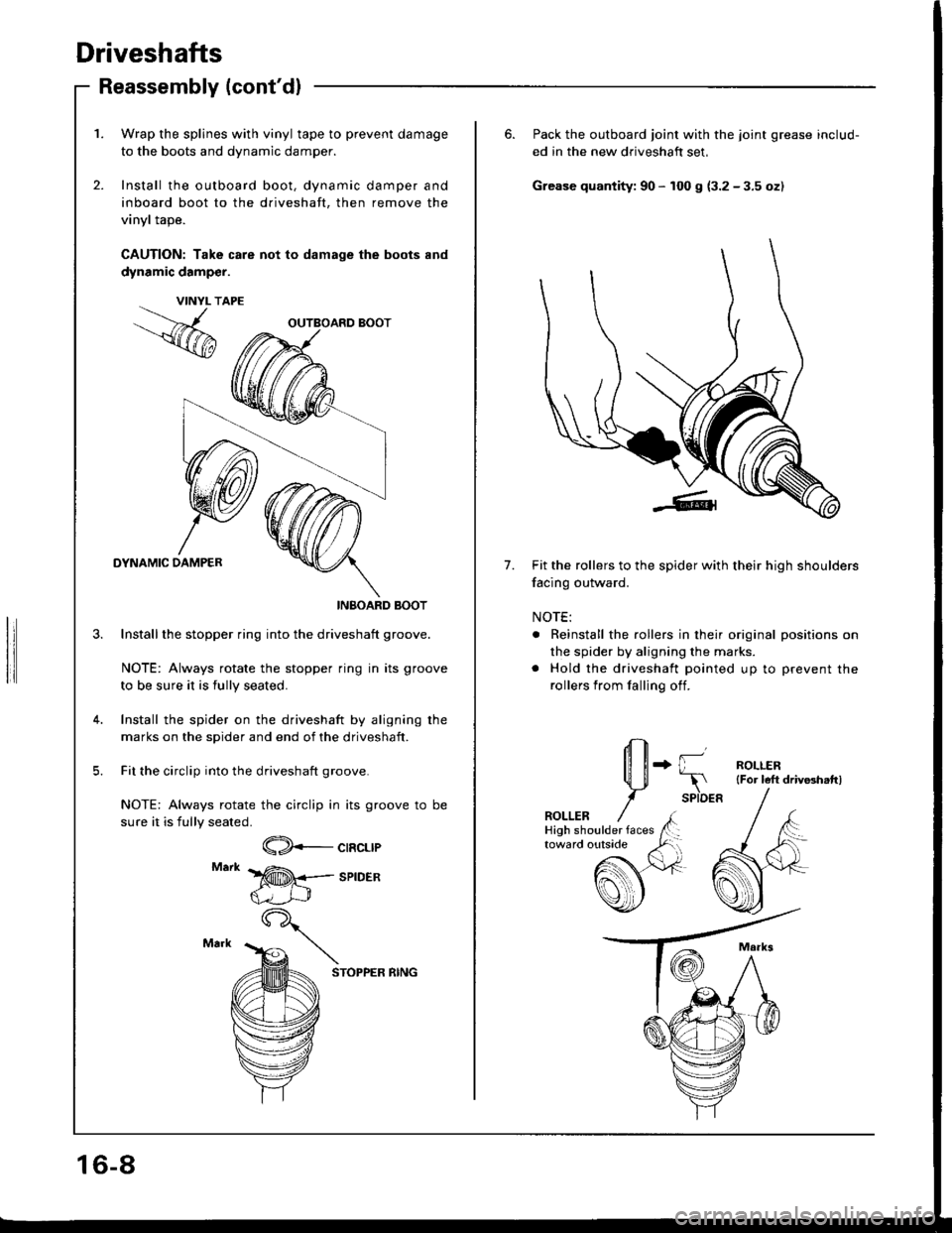

1. Wrap the splines with vinyl tape to prevent damage

to the boots and dynamic damper.

2. Install the outboard boot, dynamic damper and

inboard boot to the driveshaft, then remove the

vinyl tape.

CAUTION: Take care not to damage the boots and

dynamic damp€r.

DYNAMIC DAMPER

INBOARD BOOT

Installthe stopper ring into the driveshaft groove.

NOTE: Always rotate the stopper ring in its groove

to be sure it is fully seated.

Install the spider on the driveshaft by aligning rhe

marks on the spider and end of the driveshaft.

Fit the circlip into the driveshaft groove.

NOTE: Always rotate the circlip in its groove to be

sure it is fully seated.

VINYL T

,.%

CIRCLIP

SPIDER

STOPPER RING

OUTBOARD BOOT

16-8

6. Pack the outboard joint with the joint grease includ-

ed in the new driveshaft set,

Grease quantity: 90 - 100 g (3.2 - 3.5 oz)

7.Fit the rollers to the spider with their high shoulders

facing outward.

NOTE:

. Reinstall the rollers in their original positions on

the spider by aligning the marks.

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

+ {l--r

SPIDER

ROLLER{For left driv8hattl

ROLLER

Page 602 of 1413

Driveshafts

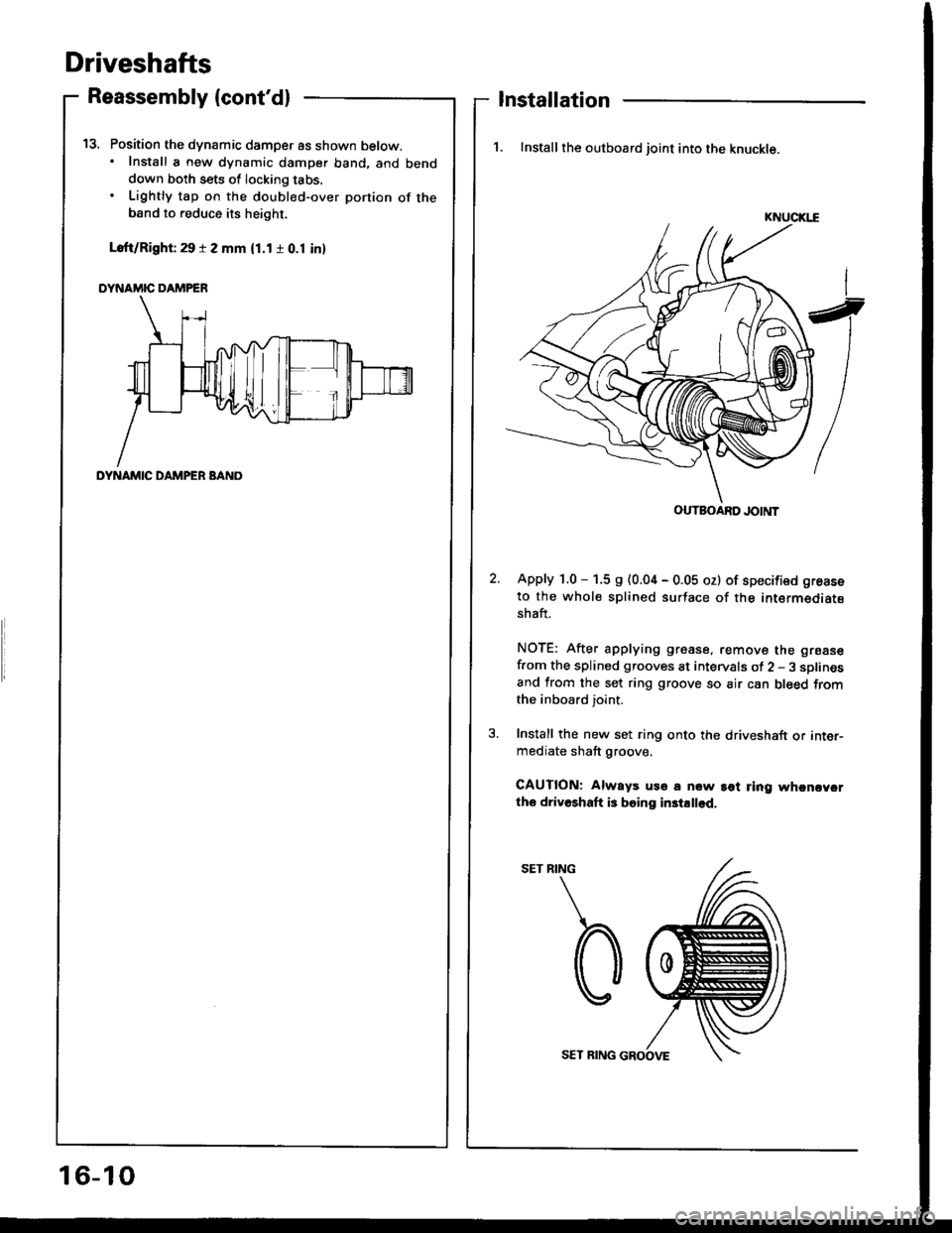

Position the dynamic damper as shown below.. Install a new dynamic damper band. and benddown both sets of locking tabs.

Lightly tap on the doubl€d-over ponion of theband to reduce its height,

Loft/Right 29 r 2 mm (1.1 r 0.1 inl

DYNAMIC DAMPER

t5.

Reassembly (cont'dl

DYNAMIC DAMPER BANO

Installation

1. Install the outboard joint into the knuckle.

KNUCIGE

Apply 1.0 - 1.5 s (0.04 - 0.05 oz) of specified groase

to the whole splined surtace of the intermediatsshaft.

NOTE: After applying grease, remove the grsase

f.om the splined grooves at intervals of 2 - 3 sDlinesand from the set ring groove so air can bleed fromthe inboard joint.

Install the new set ring onto the driveshaft or inter-mediate shaft groove.

CAUTION: Always uso a now sot ring whcncycrtho driveshaft is boing in3tallod.

RING

b

OUTBOARD JOINT

16-10

SET RING GROOVE

Page 603 of 1413

5.

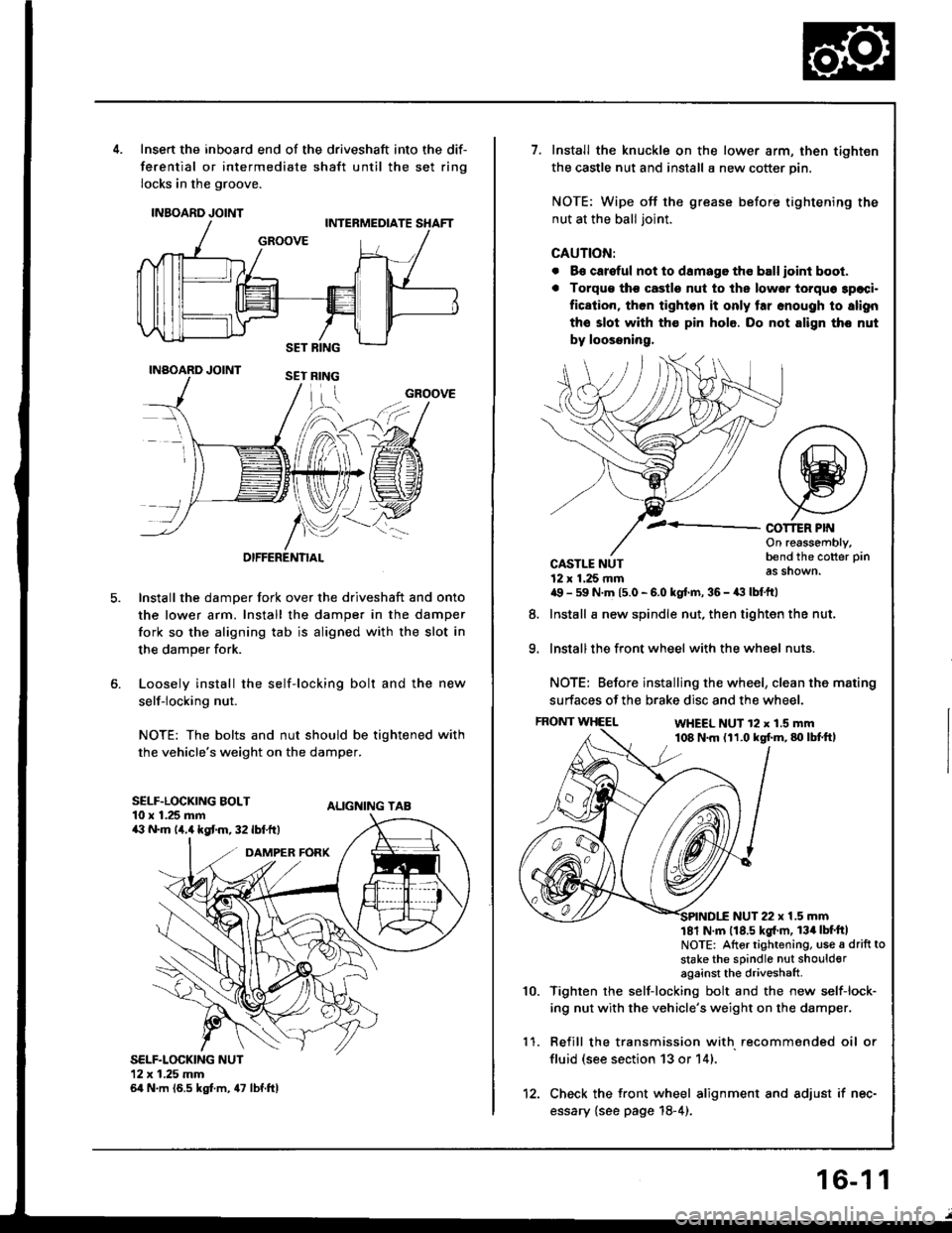

Insert the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set ring

locks in the groove.

INBOARD JOINT

INAOARD JOINT

OIFFERENTIAL

Install the damper fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damper fork.

Loosely install the self-locking bolt and the new

self-locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

ALIGNING TAB

SELF.LOCKING NUT12x 1.25 mm64 N.m (6.5 kgt m, 47 lbf.ftl

GROOVE

SELF.LOCKING BOLT10 x 1.25 mma:' N.m lir,4 kgt m, 32 lbf.ftt

1.Install the knuckle on the lower arm, then tighten

the castle nut and install a new cotter pin.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. B€ careful not to damago tho ball ioint boot.

. Torqu€ tho castle nut to ths lower torquo 3paci.

fication, then tighlon it only tar snough to slign

the slot with th€ pin hole. Do not align tho nut

by loossning,

COT1ER PIf{On reassembly,bend the cotter pin

as shown.

9.

CASTLE NUT12 x 1.25 rnma9 - 59 N.m 15.0 - 6.0 kgt.m, 36 - a:t lbtftl

Install a new spindle nut, then tighten the nut,

Install the front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbtft,

8.

1 '�I.

10.

NUT 22 x 1.5 mm181 N m 118.5 kgl'm, 134lbt'ftlNOTE: Altor tightening, use a drift to

stake the sPindle nut shoulderagainst the driveshaft

Tighten rhe self-locking bolt and the new self-lock-

ing nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

Check the front wheel alignment and adjust if nec-

essary {see page 18-4).

12.

16-1 1

Page 1004 of 1413

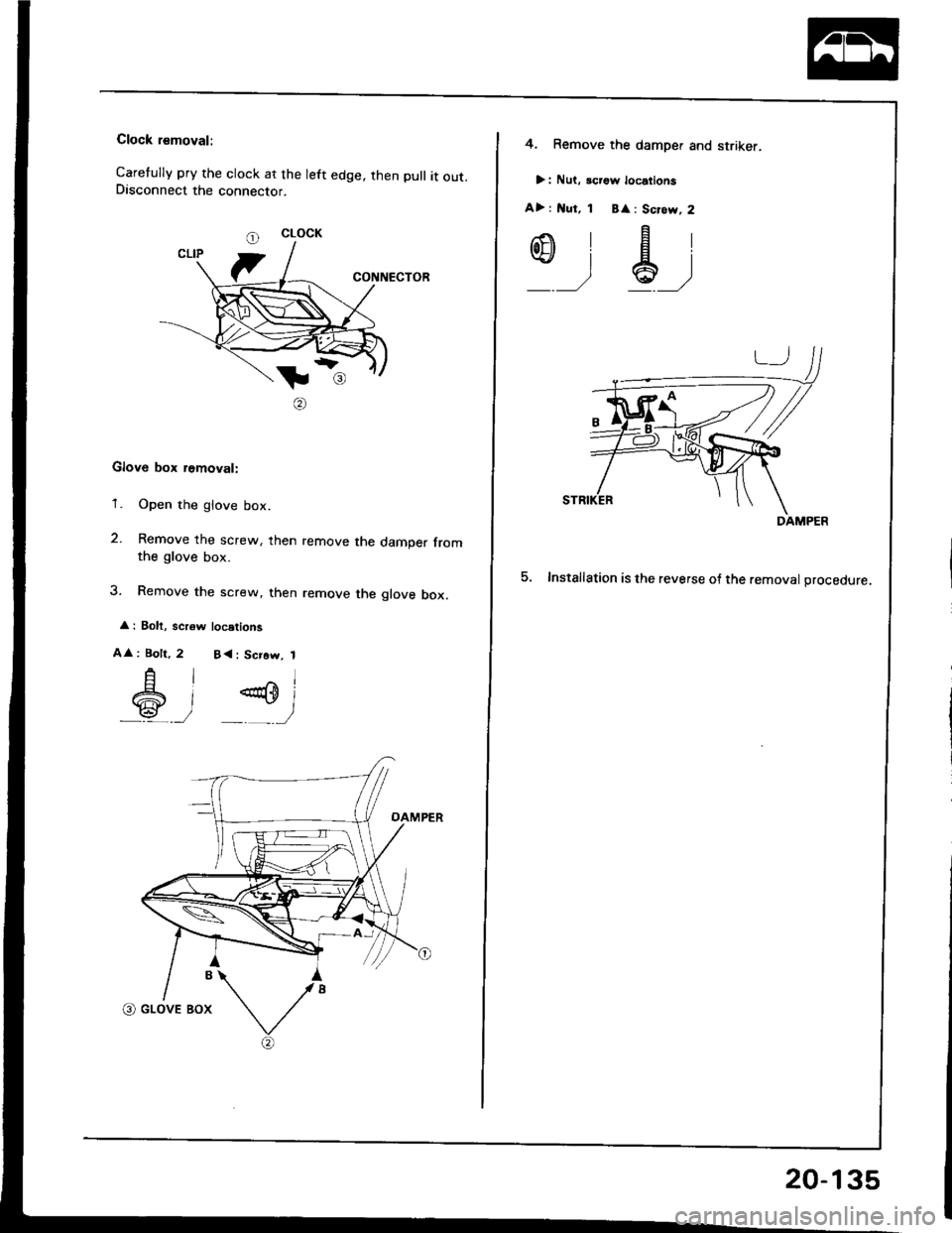

Clock rsmoval:

Caretully pry the clock at the left edge. then pull it out.Disconnect the connector.

CONNECTOR

tl

@

Glove box removal:

'1. Open the glove box.

2. Remove the screw, then remove the damper fromthe glove box.

3. Remove the screw, then remove the glove box.

: Bolt, scr6w locstions

A

: Bolt,

A

6

l^l

)P)

2 B<: Scrow, 1

CLOCK

4. Remove the damper and striker.

>: Nut, icrgw locations

A> : l{ut, 1 B

: Scrow, 2

,-.\'Flot]}lEl\+!lal

_ __,/ *' ,/

5. Installation is the reverse o{ the removal orocedure.

DAMPER

20-135

Page 1061 of 1413

Heater Unit

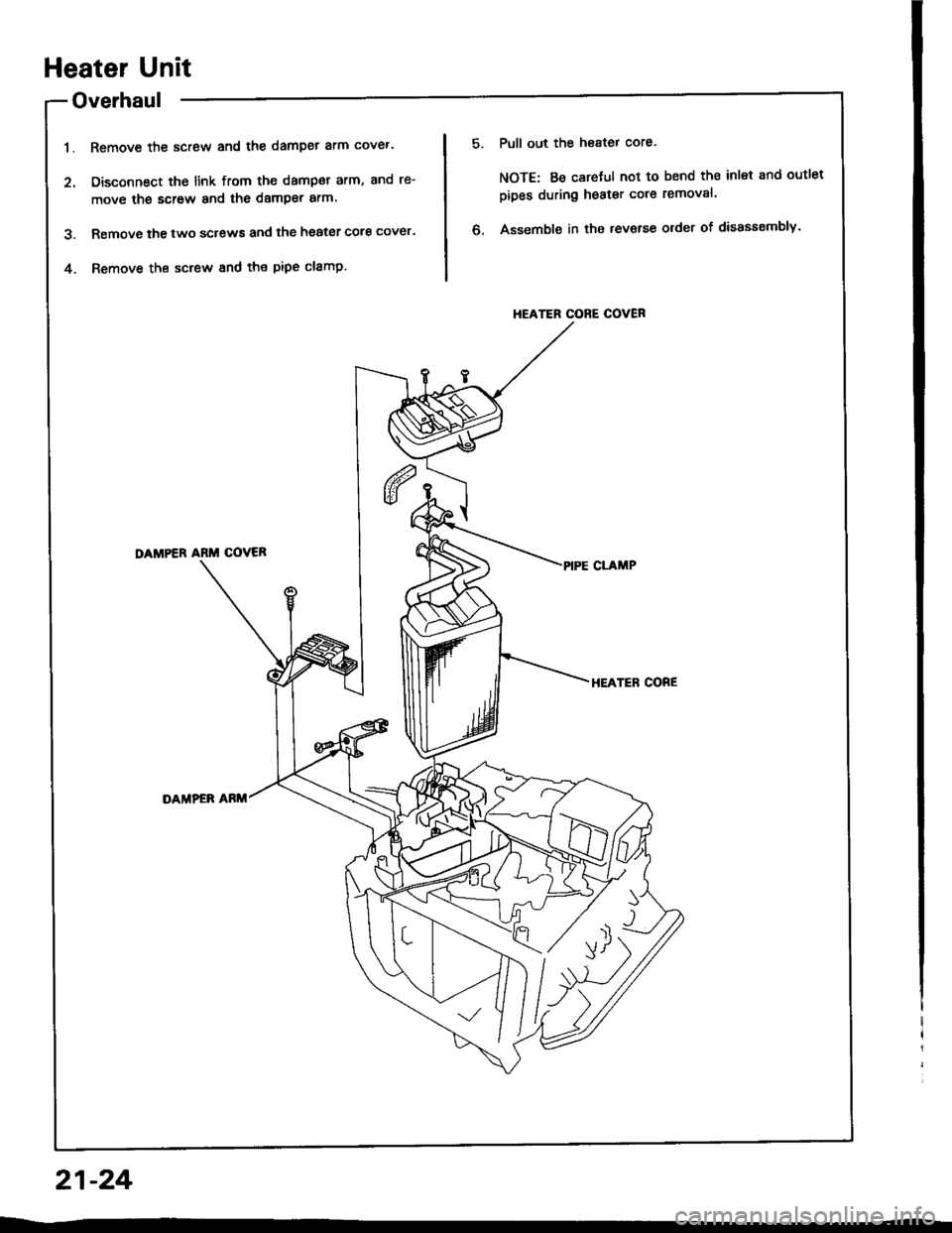

Overhaul

Remove the screw and the damper arm cover.

Disconnect the link from the dampar arm, and re-

move the screw and the damper arm.

Removs the two screws and the heater core cover.

Remove the screw and the pipe clamp.

Pull out the heater core.

NOTE: Be careful not to bend the inlet and outlet

pipes during heater core removal.

Assemble in the rev€rse older of disassembly.

1.

?

4.

HEATER CORE COVER

DAMPER ARM COVER

HEATER CORE

DAMPEF ARM

21-24

Page 1378 of 1413

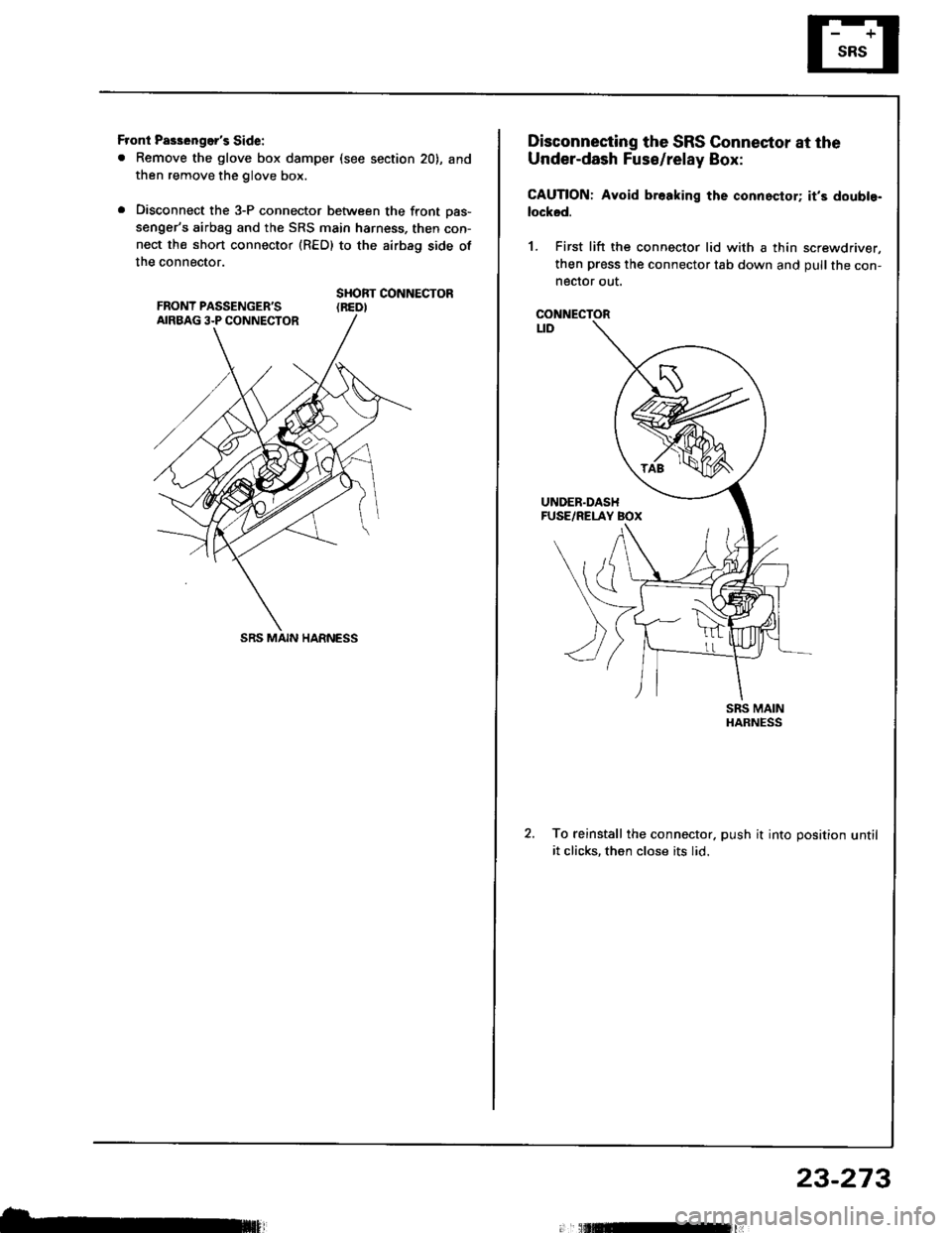

Front Pas3enger's Side:

. Remove the glove box damper (see section 20), and

then remove the glove box.

. Disconnect the 3-P connector between the front oas-

senger's airbag and the SRS main harness, then con-

nect the short connector (RED) to the airbag side of

the connector.

SHORT CONNECTOR(REDI

SRS MAIN HARNESS

b,

Disconnecting the SRS Connector at the

Under-dash Fuse/relay Box:

CAUTION: Avoid br.aking the connoctor; it's doubte-

locksd.

1. First lift the connector lid with a thin screwdriver,

then press the connector tab down and pull the con-neclor out.

CONNECTORt_tD

To reinstall the connector. push it into position untilit clicks, then close its lid.

23-273