Valve ACURA INTEGRA 1994 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 65 of 1413

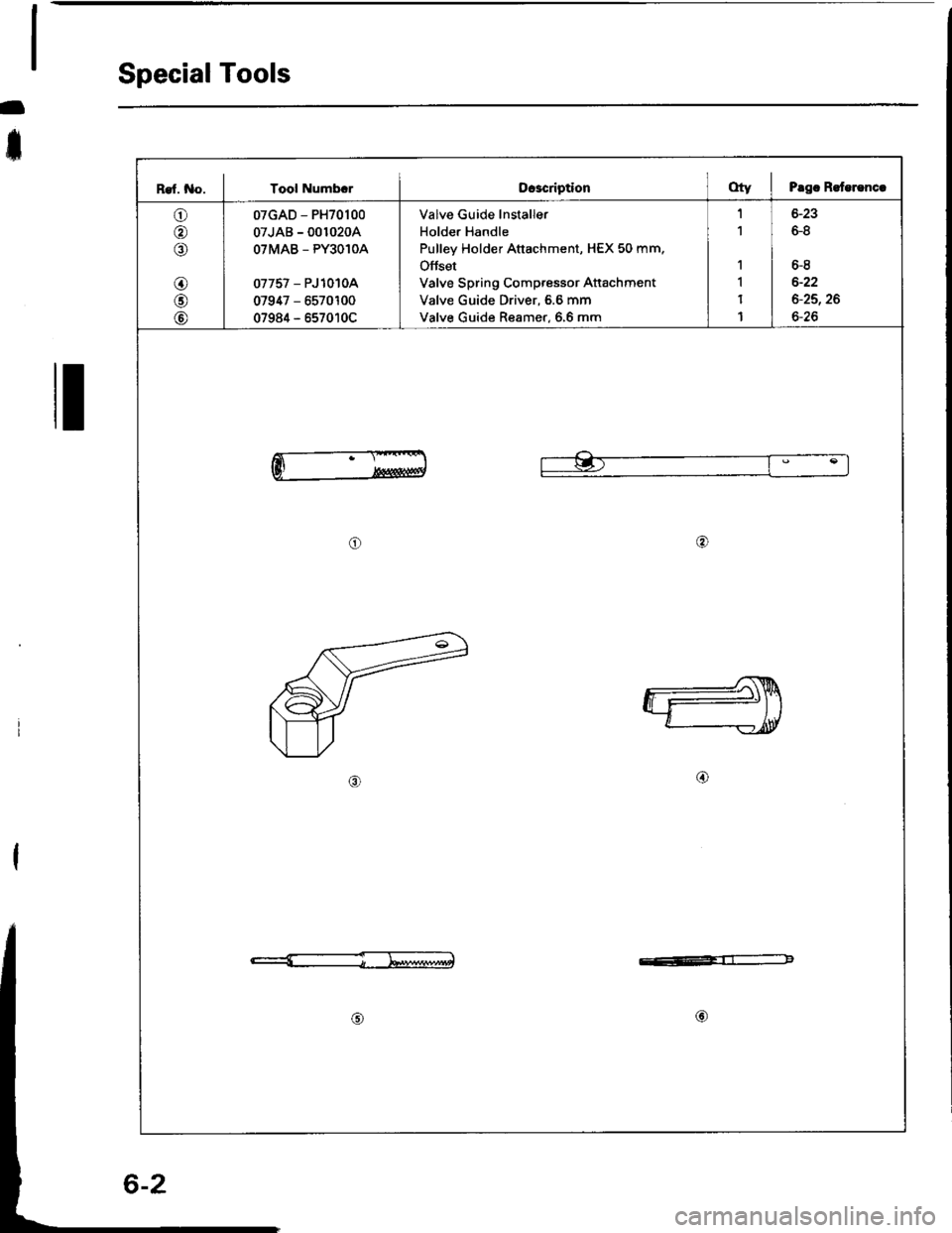

Special Tools

-

t

I

Ref. No. I Tool NumbrrOcacriptionOty I Prgc R.terencc

o

o

o

@

@

07GAD - PH70100

07JAB - 001020A

OTMAB _ PY3O1OA

07757 - PJ 10 toA

07947 - 6570100

07984 - 657010C

Valve Guide lnstaller

Holder Handle

Pulley Holder Attachment, HEX 50 mm,

Offset

Valve Spring Compressor Attachment

Valve Guide Driver, 6.6 mm

Valve Guide Reamer, 6,6 mm

1

1

1

1

1

1

6-8

6-8

6-22

6-25,26

6-26

o@

o

e:=-4-b4altltgtr-l-:ff:-b

@

Page 66 of 1413

6-3

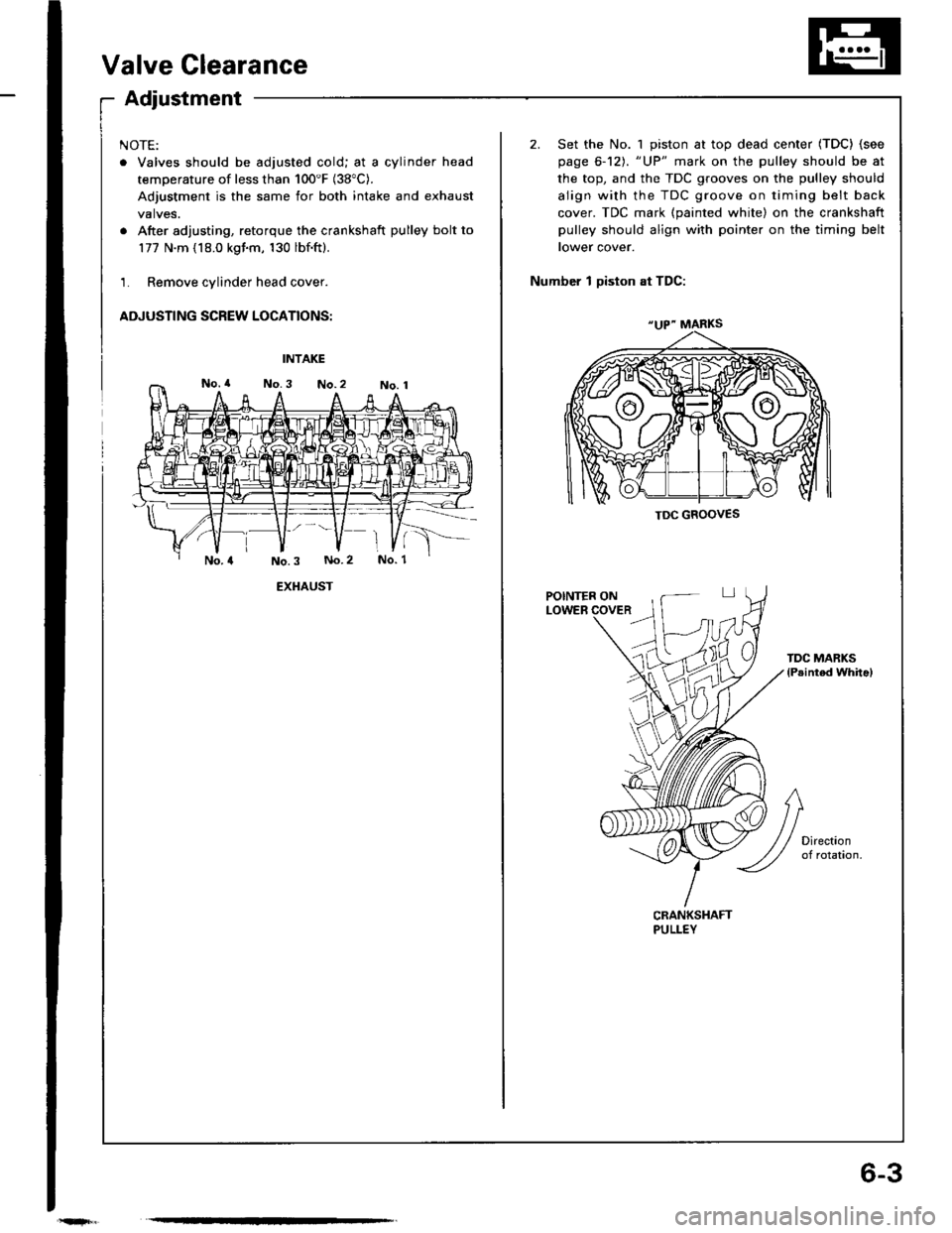

Valve Clearance

Adjustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100'F (38"C).

Adjustment is the same for both intake and exhaust

valves.

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgim, 130 lbf.ft).

1. Remove cylinder head cover.

ADJUSTING SCREW LOCATIONS:

2. Set the No. 1 piston at top dead center (TDC) (see

page 6-12). "UP" mark on the pulley should be at

the top, and the TDC grooves on the pulley should

align with the TDC groove on timing belt back

cover. TDC mark (painted white) on the crankshaft

pulley should align with pointer on the timing belt

tower cover.

Number 1 Diston at TDC:

INTAKE

EXHAUST

TDC MARKSlPeinted whitel

CRANKSHAFTPULLEY

"UP" MARKS

TDC GROOVES

Page 67 of 1413

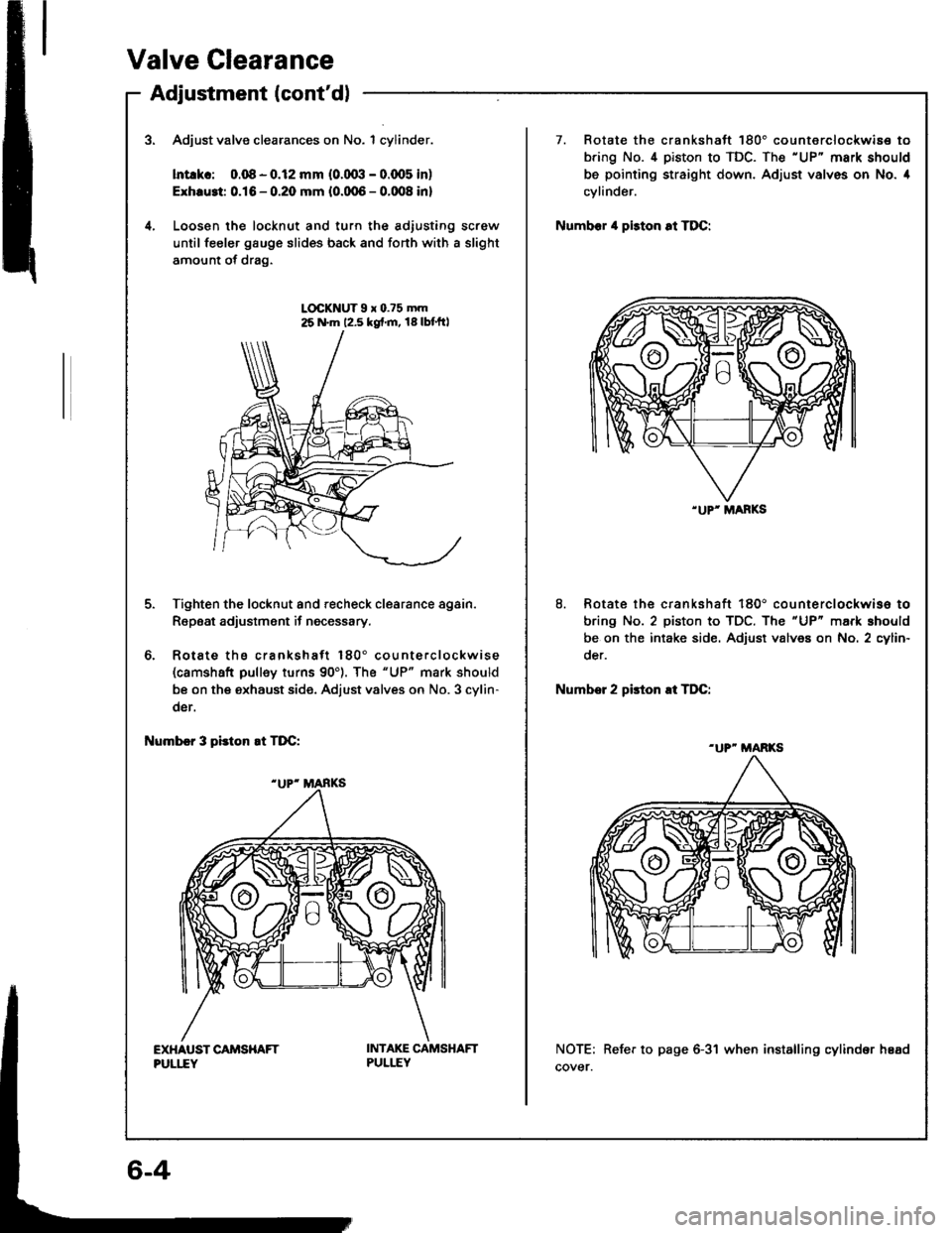

Valve Clearance

Adjustment lcont'dl

a

4.

Adjust valve clearances on No. 1 cylinder.

lntlkc: 0.08 - o.l2 mm (o.(Xxl - 0.qr5 in)

Exhru3t 0.16 - 0.20 mm {0.0,05 - 0.008 in}

Loosen lhe locknut and turn the adjusting screw

until feeler gauge slides back and fonh with a slight

amount of drag.

LOCKNUT9x0.?5mm25 N.m 12,5 kgf.m, 18lbt'ft|

6.

Tighten the locknut and recheck clearance again.

Repeat adjustment if necessary.

Rotate ths crankshaft 180" counte.clockwise(camshaft pulley turns 90'). The "UP" mark should

be on the exhaust side. Adjust valves on No. 3 cylin-

der.

I{umbcr 3 pidon !t TDC:

EXHAUST CAITISHAFTPULI,IY

INTAKE CAMSHAFTPULLEY

.UP' MANKS

7. Rotate the crankshaft 180'counterclockwis€ to

bring No. 4 piston to TDC. The'UP" mark should

be pointing straight down. Adjust valves on No. 4

cylinder.

Numb€r il piston at TDC:

8. Rotate the crankshaft 180' co u nie rclockwise to

bring No. 2 piston to TDC. The "UP" mark should

be on the intake side. Adjust valves on No. 2 cylin-

oer.

Numbor 2 pirton !t TDC:

NOTE: Refer to page 6-31 when installing cylindor hEEd

cover.

"UP'MARKS

-UP" MARKS

Page 68 of 1413

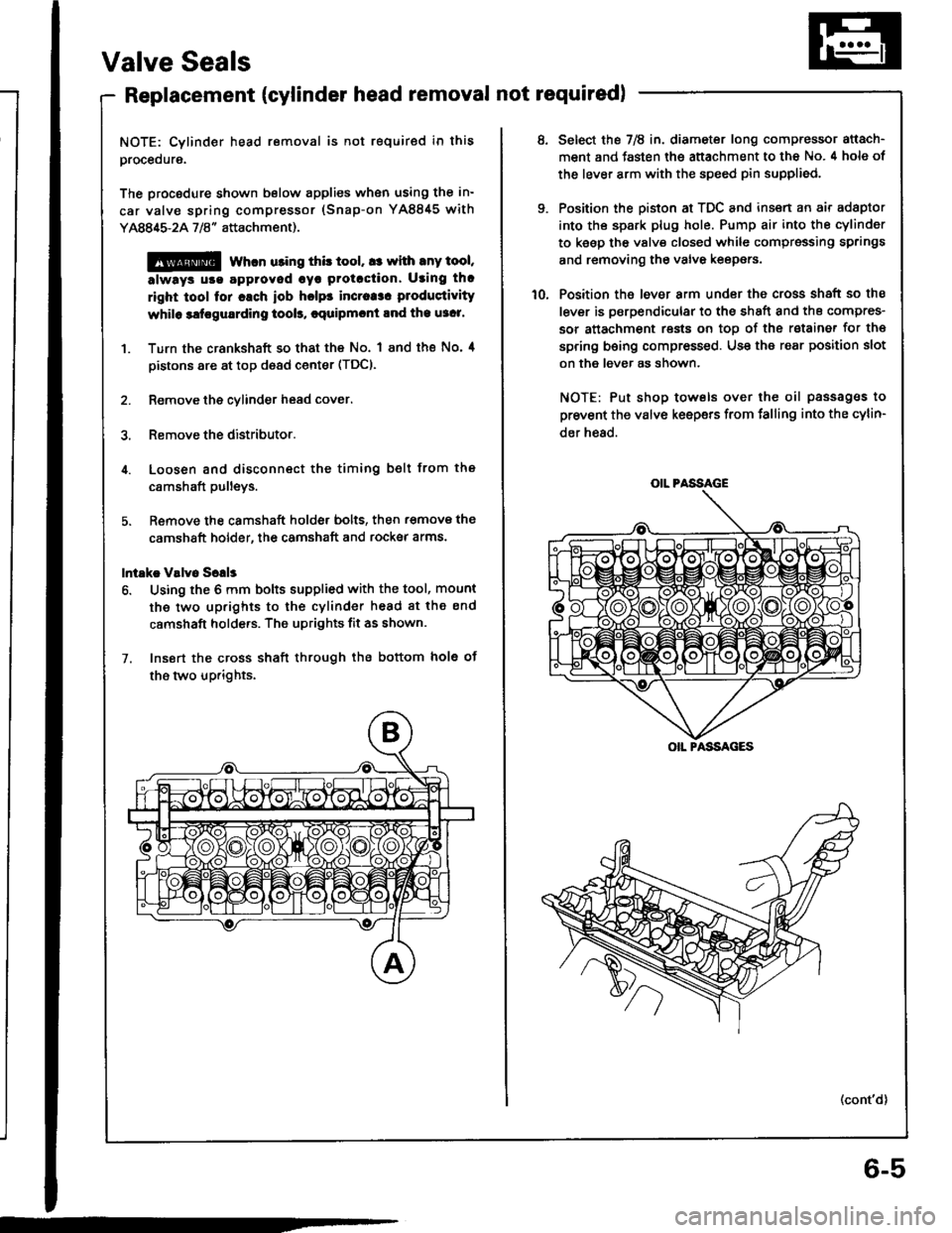

Valve Seals

Replacement (cylinder head removal not requiredl

NOTE: Cylinder head removal is not required in this

procedure.

The procodure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

Y AAA$-2A 718" attachment).

@@ whcn u3ing this tool, a: with any tool,

always u!€ agproved cyr Protcction. Using th.

right tool for cach iob hclps incraa3. produstivity

whilo 3ltrgu8rding tool!, cquipmcnt lnd the u3c1'

1. Turn the crankshaft so that the No. I and the No' 4

pistons are at top d€ad center (TDC).

2. Remove the cylinder head cover.

3. Remove the distributor.

4. Loosen and disconnect the timing belt from the

c8mshaft pulleys.

5. Remove the camshaft holde, bolts, then r€move the

camshaft holder, the camshaft and rocksr arms.

lntakc V!lv6 Sclls

6. Using the 6 mm bolts supplied with the tool, mount

the two up.ights to the cylinder head 8t the end

camshaft holde.s. The uprights fit as shown.

7. Insort the cross shaft through the bottom hole ot

the two up.ights.

6-5

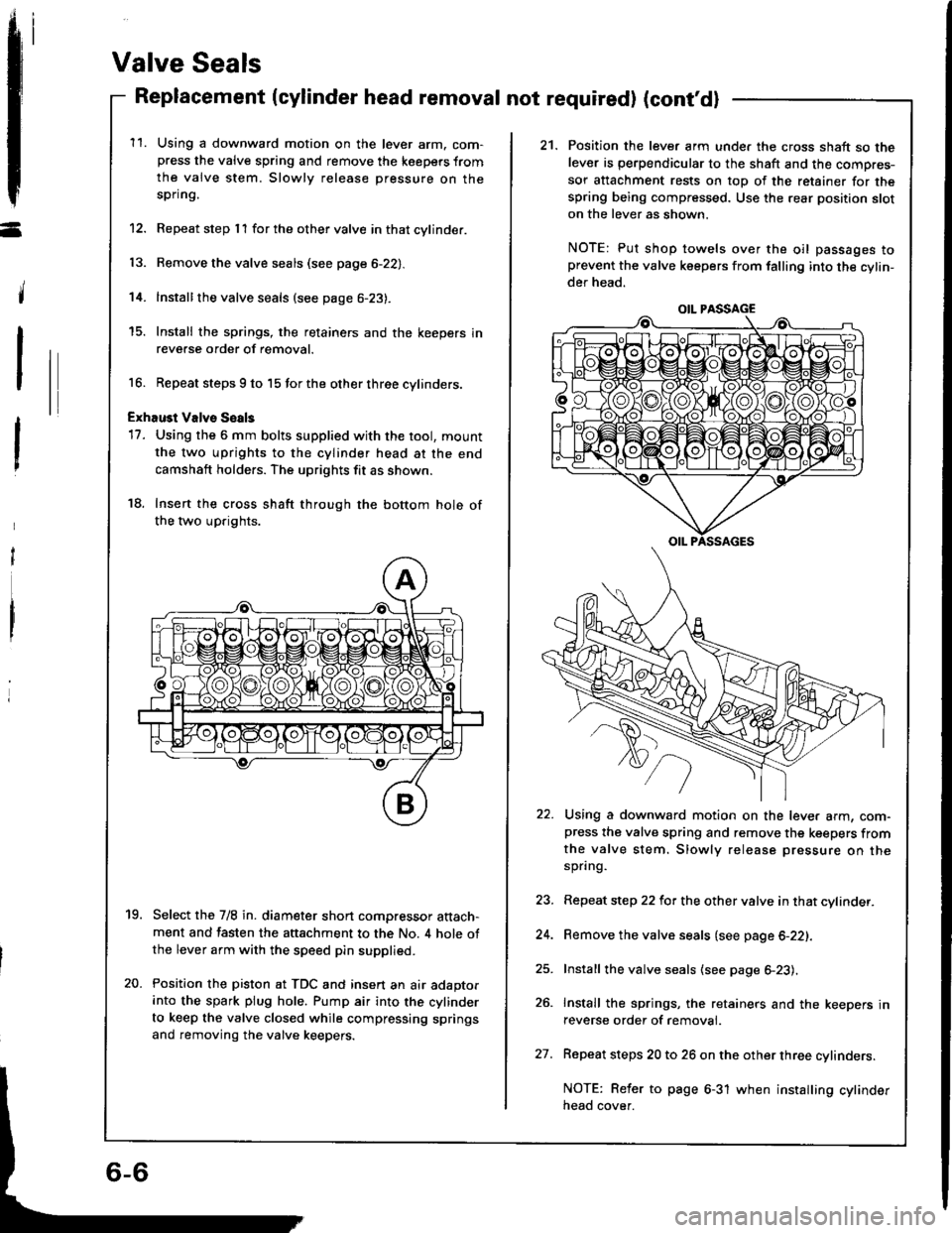

OIL PASSAGE

OIL PASSAGES

Select the 7E in. diameter long compressor attach-

ment and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC and insert an air adaptor

into th€ spark plug hole. Pump air into the cylinder

to keep the valv€ closed while cgmpressing springs

and removing the valve keepers.

Position the lever arm under the cross shaft so the

lever is psrpendicular to the shEft and ths compres-

sor attachment rests on toD of the rstainer for th€

spring being compressed. Use the rear position slot

on the lever as shown.

NOTE: Put shop towels over the oil passag€s to

prevent the valve keepers from falling into the cylin-

der h€ad.

(cont'd)

Page 69 of 1413

-

'14.

Valve Seals

Replacement (cylinder head removal not required) (cont'dl

'11.Using a downward motion on the lever arm. com-press the valve spring and remove the keepers from

the valve stem. Slowly release pressure on the

spring.

Repeat step l1 for the other valve in that cylinder.

Remove the valve seals (see page 6-22).

Installthe valve seals (see page 6-23).

Install the springs, the retainers and the keepers in

reverse order of removal.

16. Repeat steps 9 to l5 for the other three cylinders.

ExhaGt Valvs Soals

17. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

18. Insert the cross shaft through the bottom hole of

the two uprights.

Select the 7/8 in. diameter short compressor attach-ment and fasten the attachment to the No. 4 hole ofthe lever arm with the speed pin supplied.

Position the piston at TDC and insert an air adaptorinto the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing springs

and removing the valve keepers.

19.

20.

21. Position the lever arm unde. the cross shaft so thelever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for thespring being compressed. Use the rear position sloton the lever as shown.

NOTE: Put shop towels over the oil passages toprevent the valve keepers from falling into the cylin-der head.

Using a downward motion on the lever arm, com-press the valve spring and remove the keepers fromthe valve stem. Slowly release pressure on thespring.

Repeat step 22 for the other valve in that cylinder.

Remove the valve seals (see page 6-22).

Install the valve seals (see page 6-23).

Install the springs, the retainers and the keepers inreverse order of removal.

Repeat steps 20 to 26 on the other three cylinders.

NOTE: Reler to page 6-31 when installing cylinderneao cover.

OIL PASSAGE

27.

Page 77 of 1413

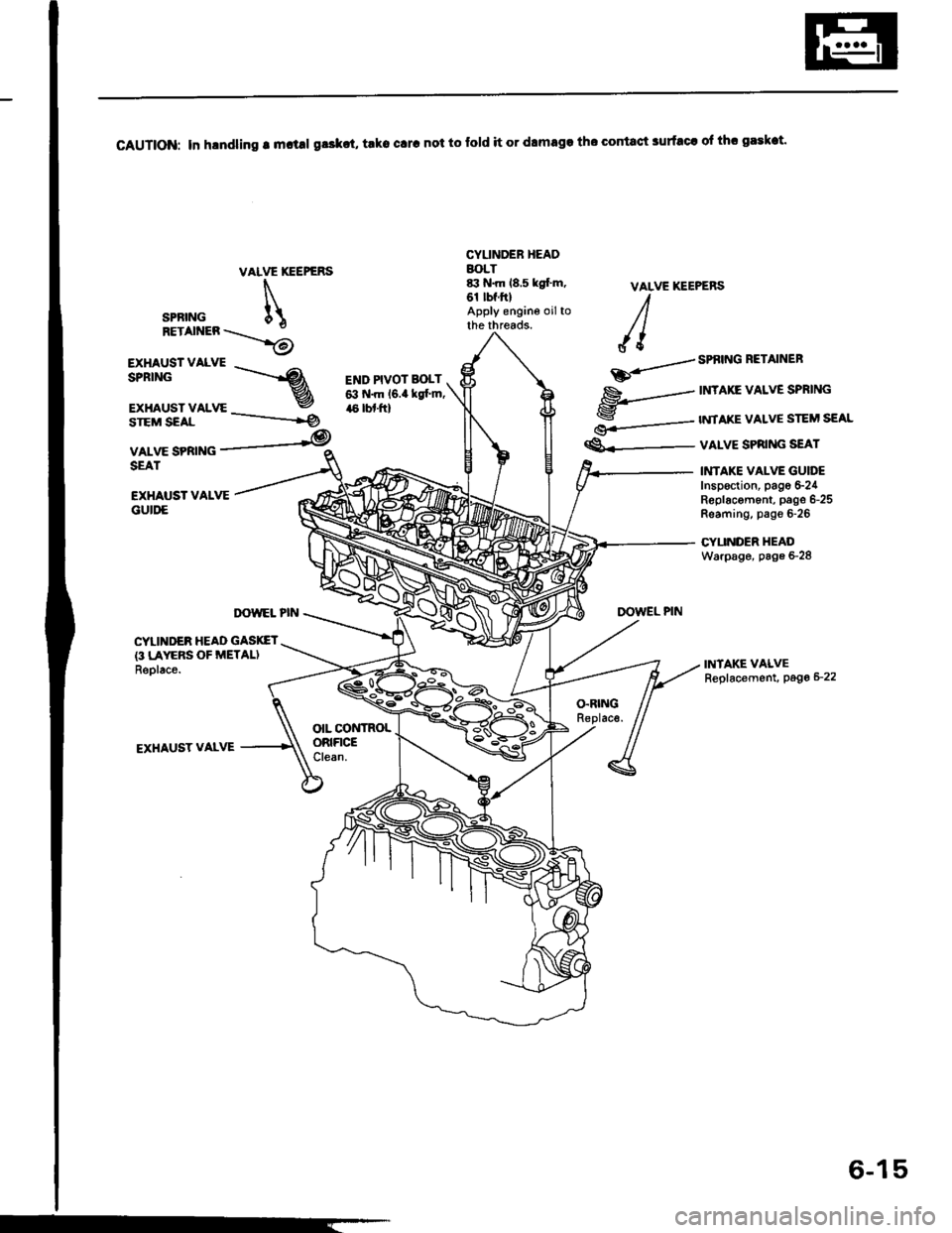

CAUTION: In h.ndling r m.t!l gr3kct, trko clrc not to fold it or dlmaga tho contact surfacr ol thr gaskat.

VAIVE XEEPERS

SPRING

RETAINER \.\...i6

r*#:-3STEM SEAL

VALVE SPRINGSEAT

CYUNDEB HEADBOLT&t N.m 18,5 kgl'm,61 tbf.ftlApply engine oiltothe threads.

END PIVOT BOLT6:t N.m l6.a kst'm,,16 lbl.ftl

VALVE KEEPERSI

JI

--../ SPf,ING RETAINEB

ED..-

$----

nrAxE vaLvE SPRING

S---- twtAKE vALvE STEM SEAL

€.---- valvE SPRING sEAT

EXHAUST VALVEGUII'E

INTAKE VAI-VE GUIT'EInsp€ction, pago S24R6placom6nt, pago 6-25Reaming, pag€ 6-26

CYUNDER HEADWarpage, page 6-28

INTAKE VALVEReplacement, Page 6_22

TX)WEL PINDOWEL PIN

CYLINDER HEAD GASKET{3 LAYERS OF METALIReolac6.

O.RINGReplac€.

EXHAUST VALVE

OIL CONTROLORIFICEClean.

--------ig

6-15

Page 79 of 1413

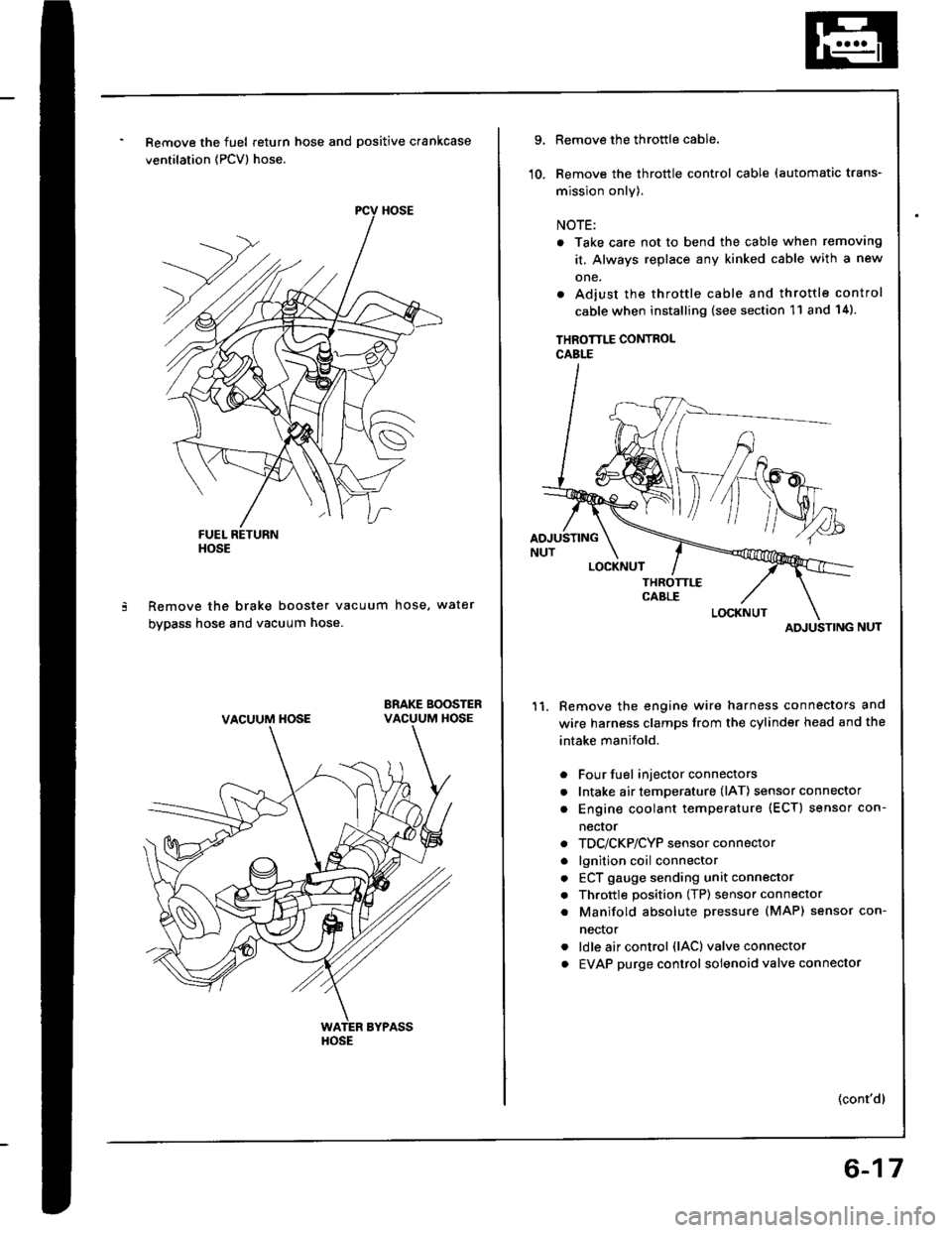

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 84 of 1413

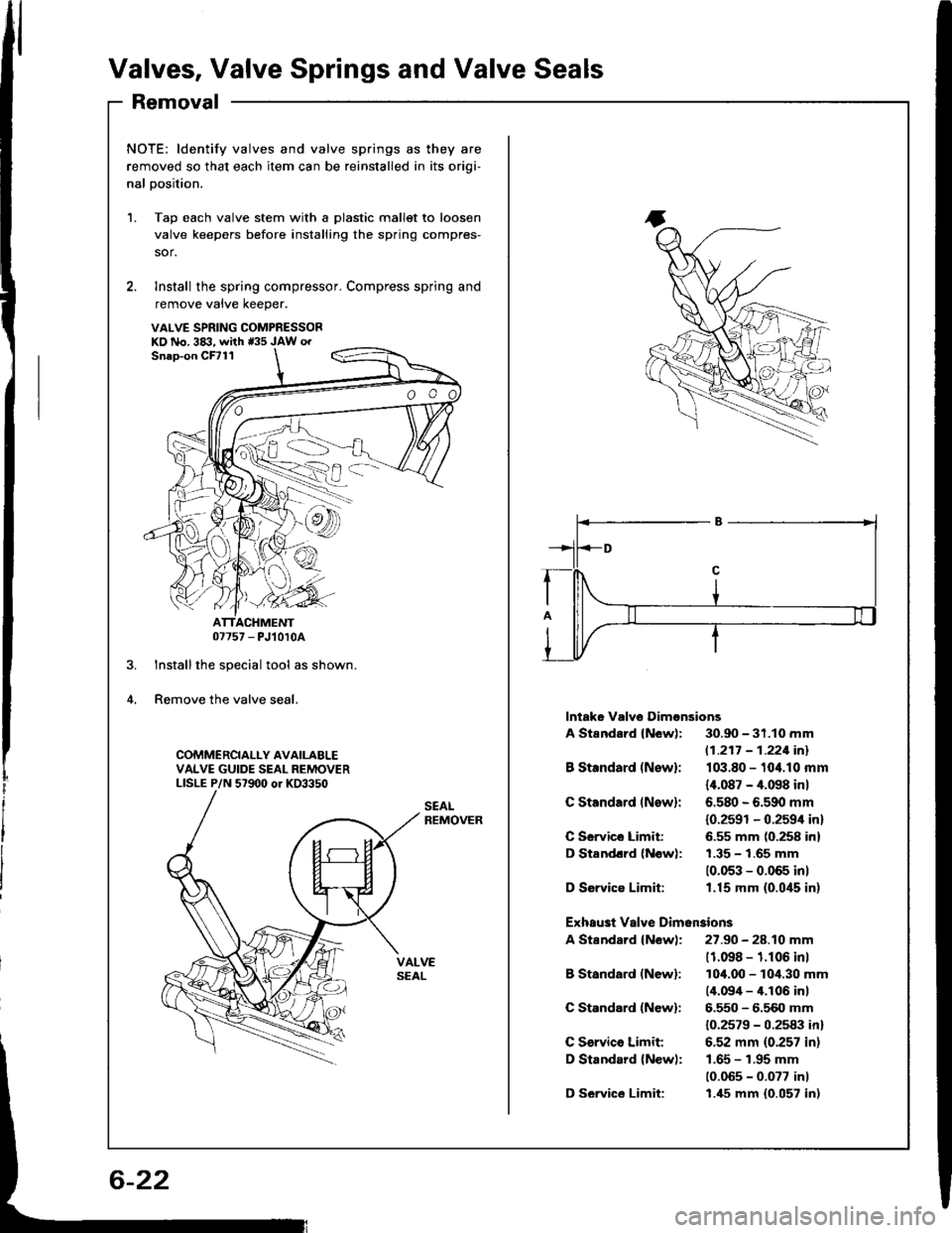

Valves, Valve Springs and Valve Seals

Removal

1.

2.

NOTE: ldentify valves and valve springs as they are

removed so that each item can be reinstalled in its oriqi-

nal Dosition.

Tap each valve stem with a plastic mallet to loosen

valve keepers before installing the spring compres-

sor.

lnstall the spring compressor. Compress spring and

remove vatve Keeper.

07757 - PJ10r0A

Installthe special tool as shown.

Remove the valve seal.

COMMERCIALLY AVAILABLEVALVE GUIDE SEAL REMOVERLISLE P/N 5t9d) or KO3350

SEALREMOVER

VALVE SPRING COMPRESSORxo No.3tB. whh r35 JAW o.

lntaks Valvo Dimonsions

A Standard (New): 30.90 - 31.10 mm

|.1.217 - 1.221inl

I Standard (Nowl: 103.80 - 10'1.10 mm

{4.087 - 4.098 inl

C Standard lNow): 6.580 - 6.590 mm

{0.2591 - 0.259/r in}

C Servico Limit 6.55 mm (0.258 inl

D Standlrd (N€w): 1.35 - 1.65 mm

10.053 - 0.065 inl

D Ssrvice Limit: 1.15 mm (0.045 in)

Exhau3t Valve Dim6nsions

A Standard {New): 27.90 - 28.10 mm

11.098 - 1.106 inl

B Standard (Newl: 104.00 - 104.30 mm(4.094 - 4.106 inl

C St.ndard (New): 6.550 - 6.500 mm

10.2579 - 0.2583 inl

C Servico Limit 6.52 mm (0.257 in)

D Standard {New): 1.65 - 1.95 mm

10.065 - 0.077 inl

D Service Limit: 1.,[5 mm (0.057 in)

Page 85 of 1413

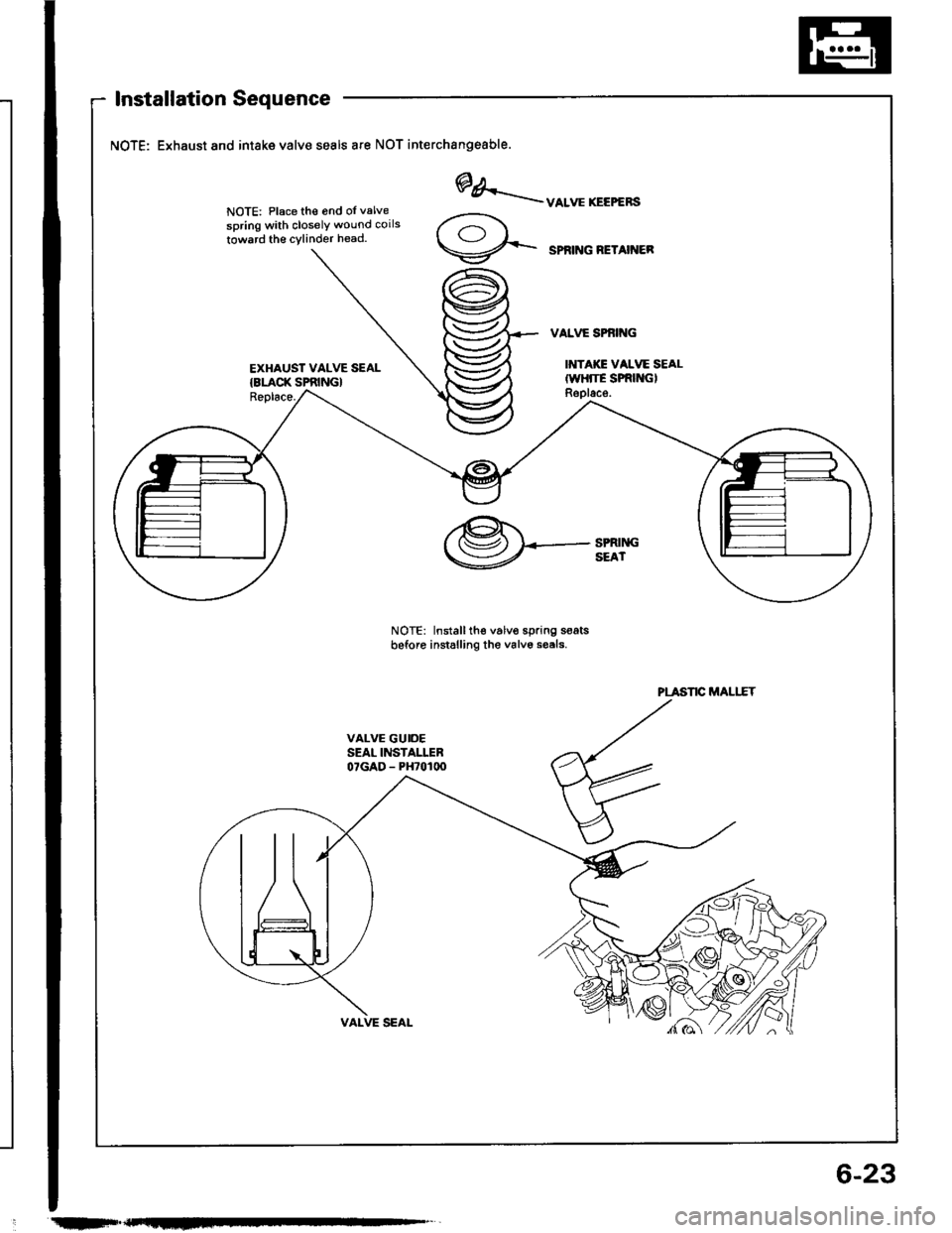

Installation Sequence

NOTE: Exhaust and intake valve seals ate NOT interchangeable.

NOTE: Place th€ 6nd oI valve

spring with closelY wound coils

towrrd th€ cylinder head.

EXHAUST VALVE SEAL{8LACK SPRING}Replace.

NOTE: Installth€ v6lvo spring s€atsbeforo instslling the valv6 sesls.

@/.-uo.**.r..",

SPRNG NETAINER

@*_-.tt*

PLASTIC MALIIT

.tIF"F-

6-23

Page 86 of 1413

Valves, Valve Springs and

Valve Seals

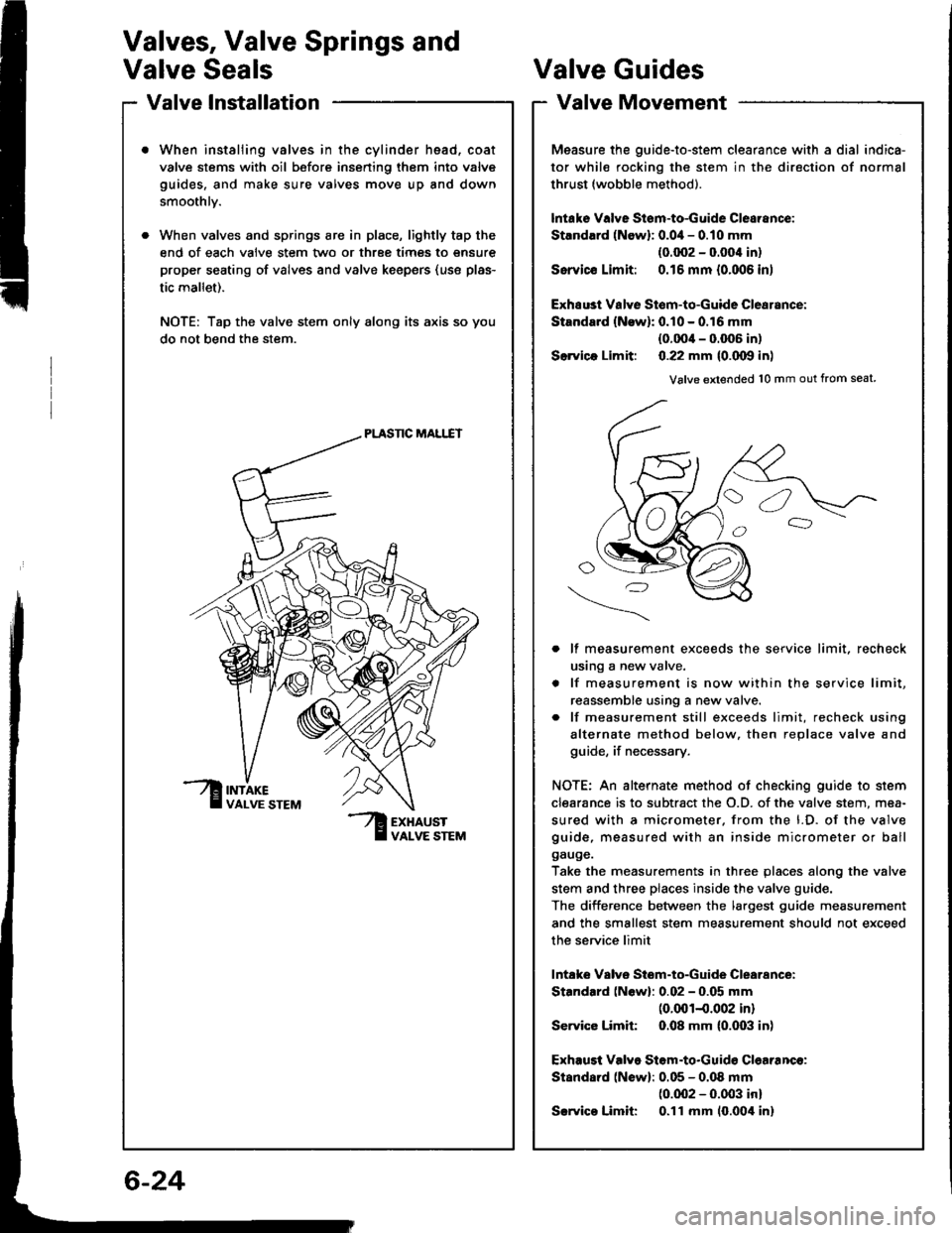

Valve lnstallation

When instaliing valves in the cylinder head, coat

valve stems with oil before insening them into valve

guides, and make sure valves move up and down

smoothlv.

When valves and springs are in place, lightly tap the

end of each valve stem two or three times to snsure

proper seating of valves and valve keepsrs (use plas-

tic mallet).

NOTE: Tap the valve stem only along its axis so you

do not bend the stem.

PLASNC MALI.IT

?ur

Valve Guides

Valve Movement

Measure the guide-to-stem clearance with a dial indica-

tor while rocking the stem in the direction of normal

thrust (wobble method).

lntake Valve Stsm-to-Guide Clearance:

Strndlrd (Newl: 0.0i1- 0.10 mm

(0.002 - 0.004 in)

Ssrvicc Limit: 0.16 mm {0.006 in)

Exhsust Valye Stom-to-Guide Clearance:

Standard {N€w): 0.10 - 0.16 mm

{0.0O'l - 0.006 in)

Slrvica Limit: 0.22 mm {0.000 in)

Valve extended 10 mm out from seat

lf measurement exceeds the service limit, recheck

using a new valve.

lf measurement is now within the service limit,

reassemble using a n€w valve.

lf measurement still exceeds limit, recheck using

alternate method below. then replace valve and

guide, if necessary.

NOTE: An alternate method of checking guide to stem

clearance is to subtract the O.D. of the valve stem, mea-

sured with a micrometer. from the l.D. of the valve

guide, measured with an inside micrometer or ball

gauge.

Take the measurements in three places along the valve

stem and three places inside the valve guide.

The diiference between the largest guide measurement

and the smallest stem measurement should not exceed

the service limit

lntake Valve Stom-to-Guide Clearance:

Standard (Newl: 0.02 - 0.05 mm(0.001-0.002 in)

Service Limit 0.08 mm (0.003 in)

Exhaust Valve Stom.to.Guid€ Clearanco:

Standard (Newl: 0.05 - 0.08 mm(0.002 - 0.003 inl

Srrvico Limit 0.ll mm 10.00't inl

6-24