Valve ACURA INTEGRA 1994 Service Manual Online

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 312 of 1413

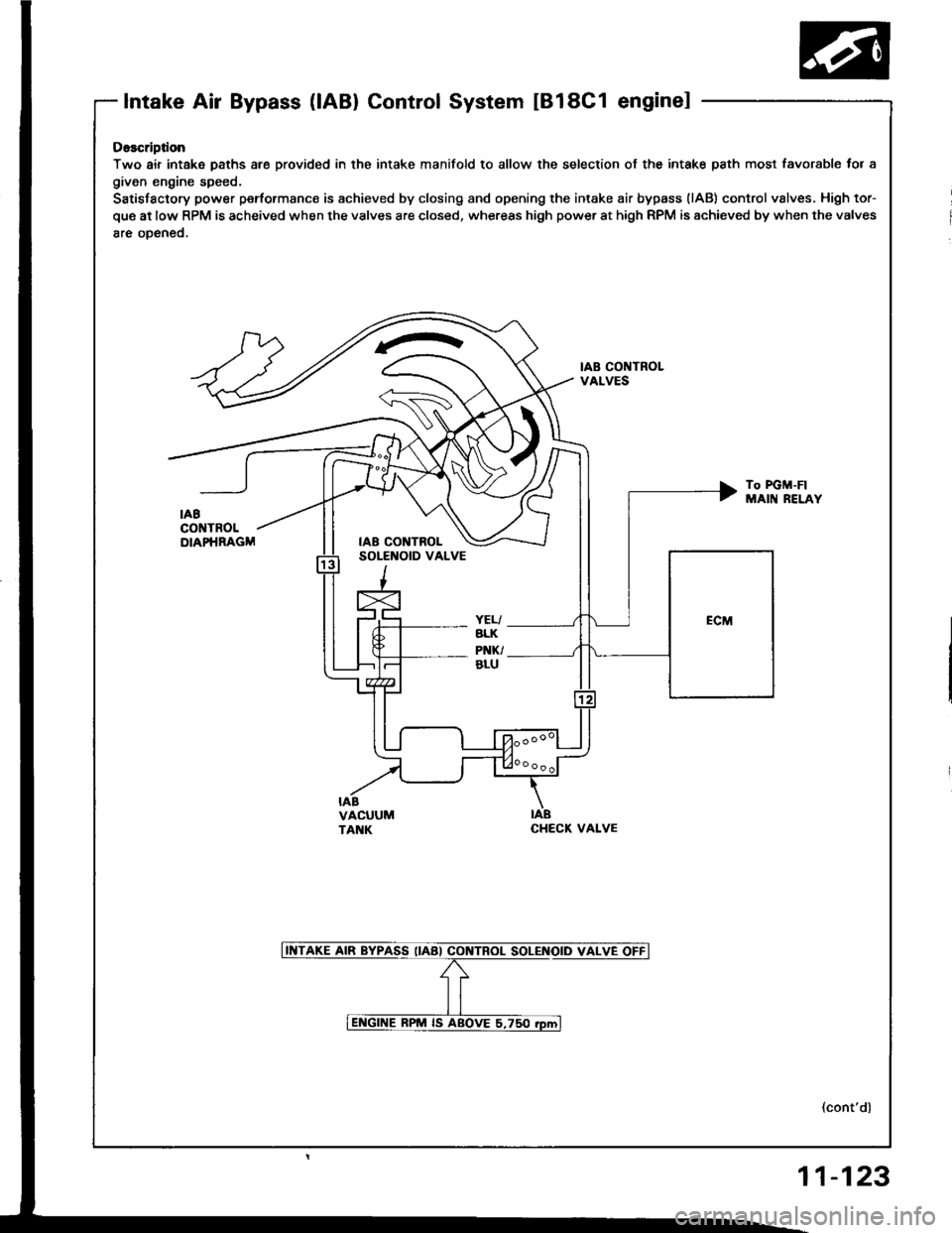

Intake Air Bypass (lABl Control System tBl8C1 enginel

Osscription

Two air intake paths are provided in the intake manifold to allow the selection of the intak€ path most favc

given engine speed.

Satisfactory power peformanc€ is achieved by closing and opening the intake air bypass (lAB) control valve!

que at low RPM is acheived when the valves are closed, whereas high power at high RPM is achieved by when

8re oDeneo.

IAB CONTROLVALVES

To PGM-FIMAIN RELi

IABCHECK VALVE

t favorabl€ for a

vslves. High tor-

when the valves

RELAY

(cont'dl

11-123

Page 313 of 1413

Intake

Intake

Air

Air

System

Bypass (lAB) ControlSystem tBl8C1 enginel (cont'dl

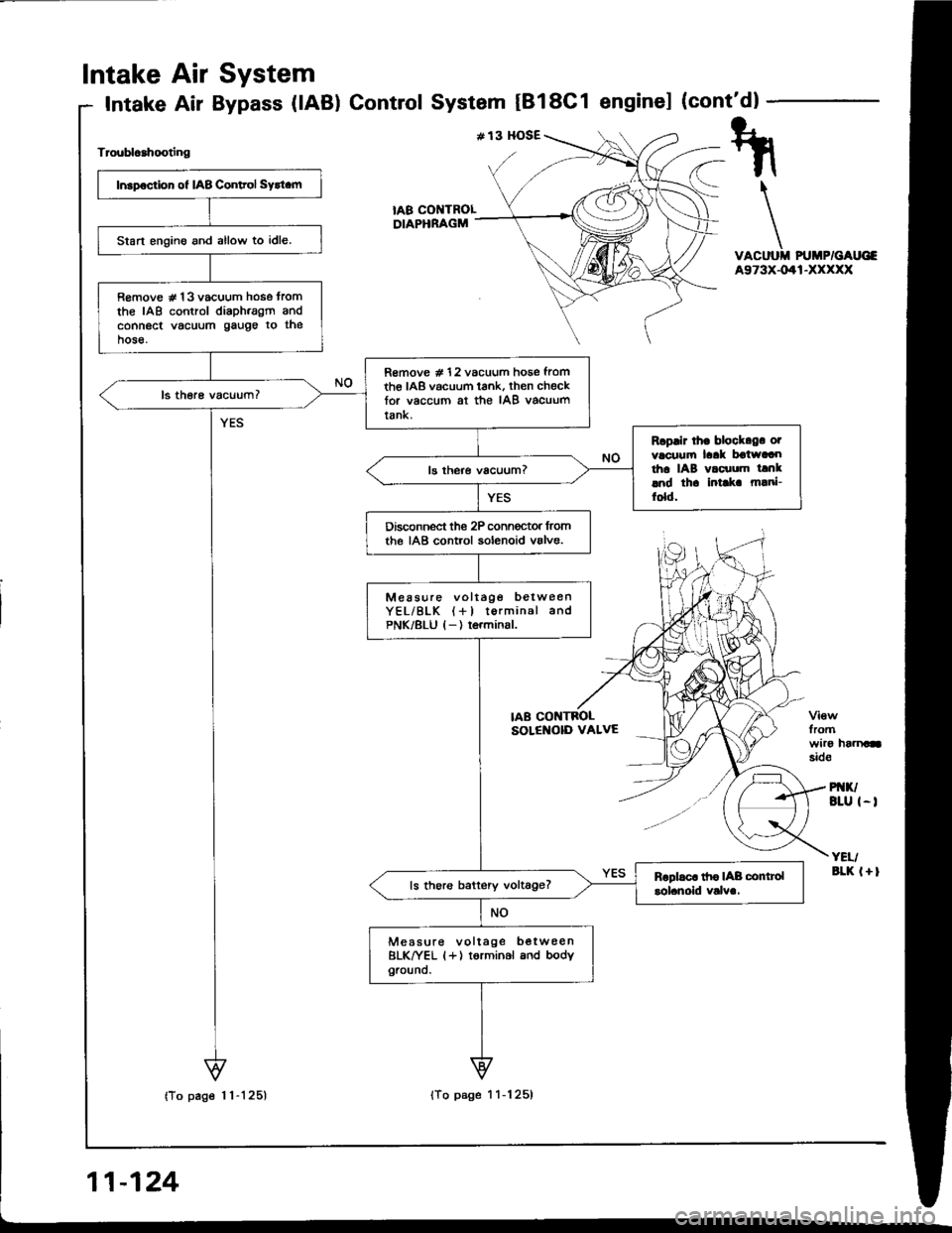

Troublcahooting

VACUUII PUMP/GAUG€A973X-041-XXXXX

fromwiro haanasid€

PI{K/BLU I-I

YEI/aLK l+l

tA8 COI{TROLDIAPHRAGM

Insp€ction of IAB Conltol Sytt.m

Start engino and allow to idle.

R€move # 13 vacuum hose tromthe IAB control diaph.agm andconnect vacuum gauge to thehose.

R€move # 12 vacuum hose fromth€ IAB vacuum tank, then checktor vaccum at the IAB vacuumtank.

Rcplir lh. block.g. otvacuufi laak boiwaaotha IAB vacuum tanklnd th. intlk m!ni-fold.

Disconnect the 2P conn€ctor lromthe IAB control solenoid valve.

Measure voltage betweenYEL/BLK (+l torminal andPNK/8LU l-) terminsl.

ls thoro battery voltage?

Measure voltage b€twee nBLK^|/EL (+) torminal and bodyground.

IAB CONTBOLSOLENOID VALVE

Page 314 of 1413

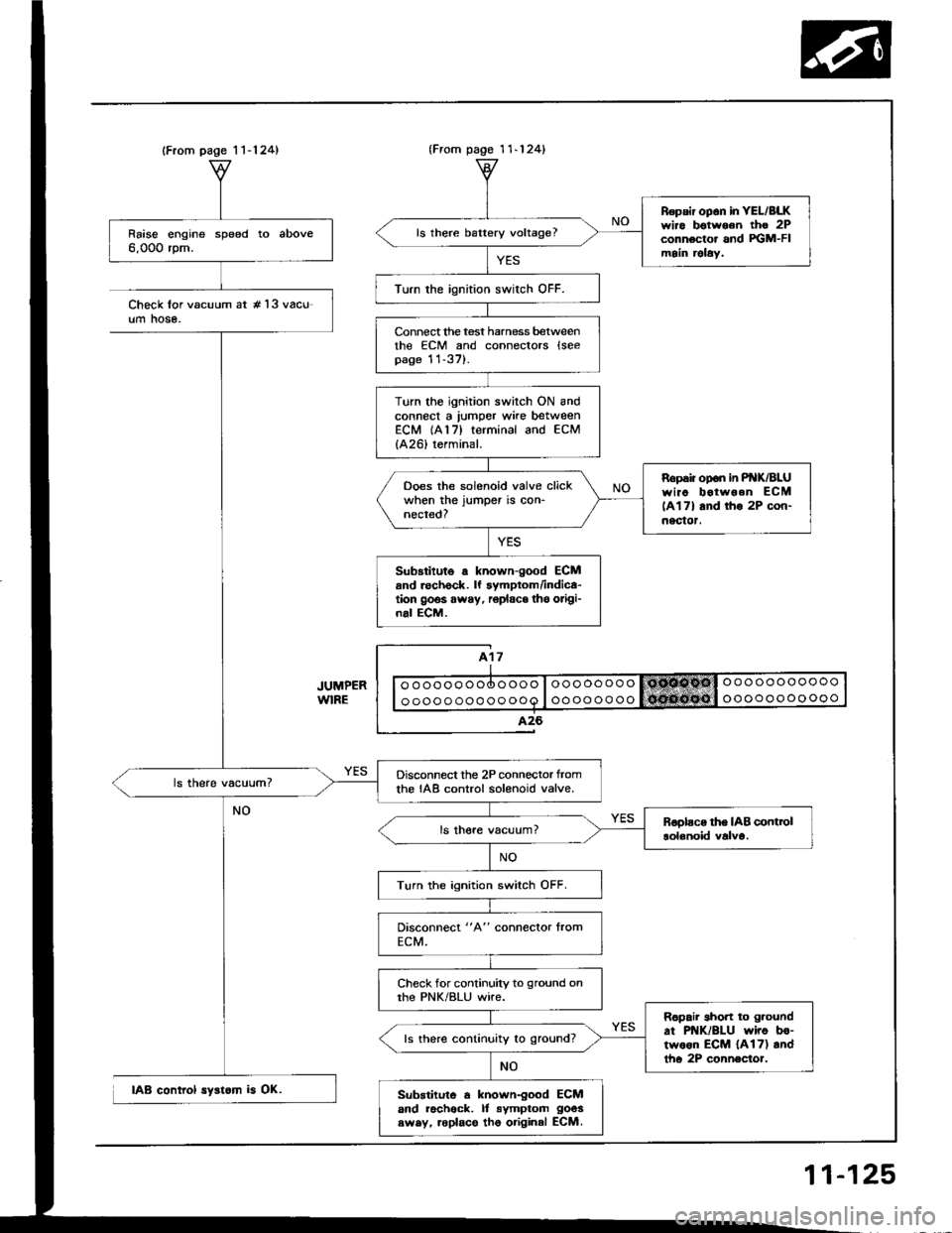

(From page 1 1-124)

Raise engine speed to above6,000 rpm.

Disconnect the 2P connector tromthe IAB control solenoid valve.

Turn the ignition switch OFF.

Check for continuity to ground onthe PNK/BLU wire.

Ropair short to g.ound

at PNK/BLU wiro bo-two6n ECM {A17) andtho 2P connector.

ls there continuity to ground?

Substituto a known-good ECMand racheck. It symptom goos

swsy, roplace tho original ECM.

{From pago 1 1-124}

Repsir op6n in YEL/BLKwiro botwoon tho 2Pconnector and FGM-FImain relaY.

ls there battery voltage?

Turn the ignition swirch OFF.

Connect lhe test harness betweenthe ECM and connectors lseepage 11-37).

Turn the ignition switch ON andconnect a lumper wke betweenECM (A17) terminal and ECM

{A26) terminal.

Ropaiiopon inP K/BLUwiao botwoen ECM

lAl7l and tho 2P con-nectot.

Ooes the solenoid valve clickwhen the jumper is con-nected?

Sub3titute a known-good ECMand rechock. lf symptom/indica-tion goos away, r6place tho origi-nal ECM.

Check lor vacuum at #'l3 vacu-um hose.

IAB control syst6m is OK.

11-125

Page 315 of 1413

a

Intake Air System

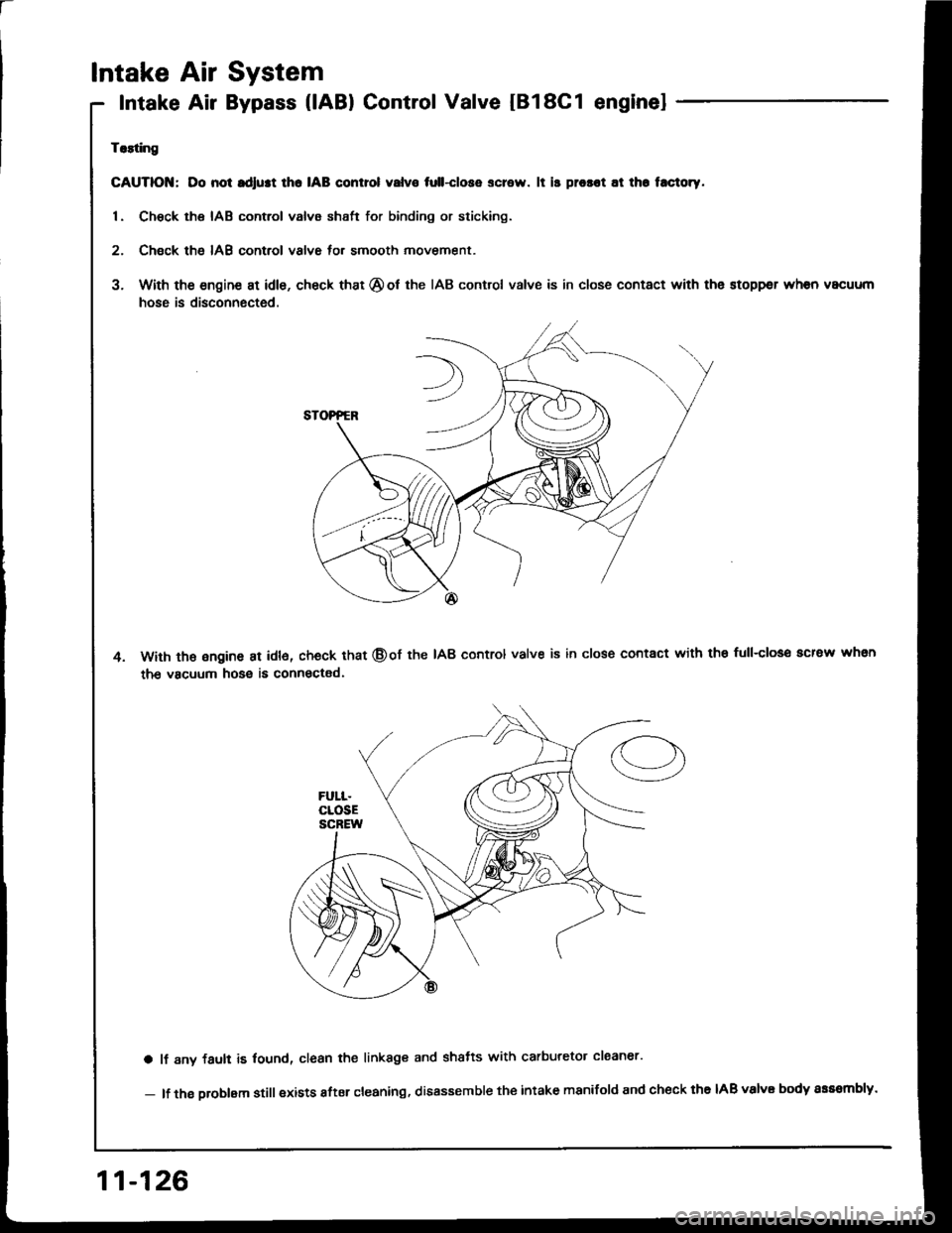

Intake Air Bypass (lABl Control Valve IB18C1 enginel

Trlting

GAUTIOI{; Do not rdlust lho IAB control valvo tull-close screw. lt is prosot at th. t.ctoty.

1. Chsck the IAB control valve shsft for binding or sticking.

2. Check th6 IAB control valve for smooth movement.

3. With the engine at idle, check that @ot the IAB control valve is in close contact with the stoppsr when vacuum

hose is disconnected.

With th€ ongine at idl6, check that @of the IAB control valve is in close contact with the full-closo acrew whsn

the vacuum hose is connectad.

a lf 8ny fault is lound, clean the linkage and shatts with carburetor claaner'

- lf the oroblam still exists after cleaning, disassemble the intake manifold and check the IAB valvE body sss8mbly.

11-126

Page 316 of 1413

![ACURA INTEGRA 1994 Service Manual Online Dls!$.muy:

ITTAKEMANIFOLD23 N.m12.3 kgt.m.17 tbt.ftl

GASXETRgplace.6aa

|AA VALVE AODY

I]{TAKE MANIFOLDCHAMBER24 N.m(2.4 kgf.m,t7 tbf.ftl

11-127 ACURA INTEGRA 1994 Service Manual Online Dls!$.muy:

ITTAKEMANIFOLD23 N.m12.3 kgt.m.17 tbt.ftl

GASXETRgplace.6aa

|AA VALVE AODY

I]{TAKE MANIFOLDCHAMBER24 N.m(2.4 kgf.m,t7 tbf.ftl

11-127](/img/32/56982/w960_56982-315.png)

Dls!$.muy:

ITTAKEMANIFOLD23 N.m12.3 kgt.m.17 tbt.ftl

GASXETRgplace.6aa

|AA VALVE AODY

I]{TAKE MANIFOLDCHAMBER24 N.m(2.4 kgf.m,t7 tbf.ftl

11-127

Page 323 of 1413

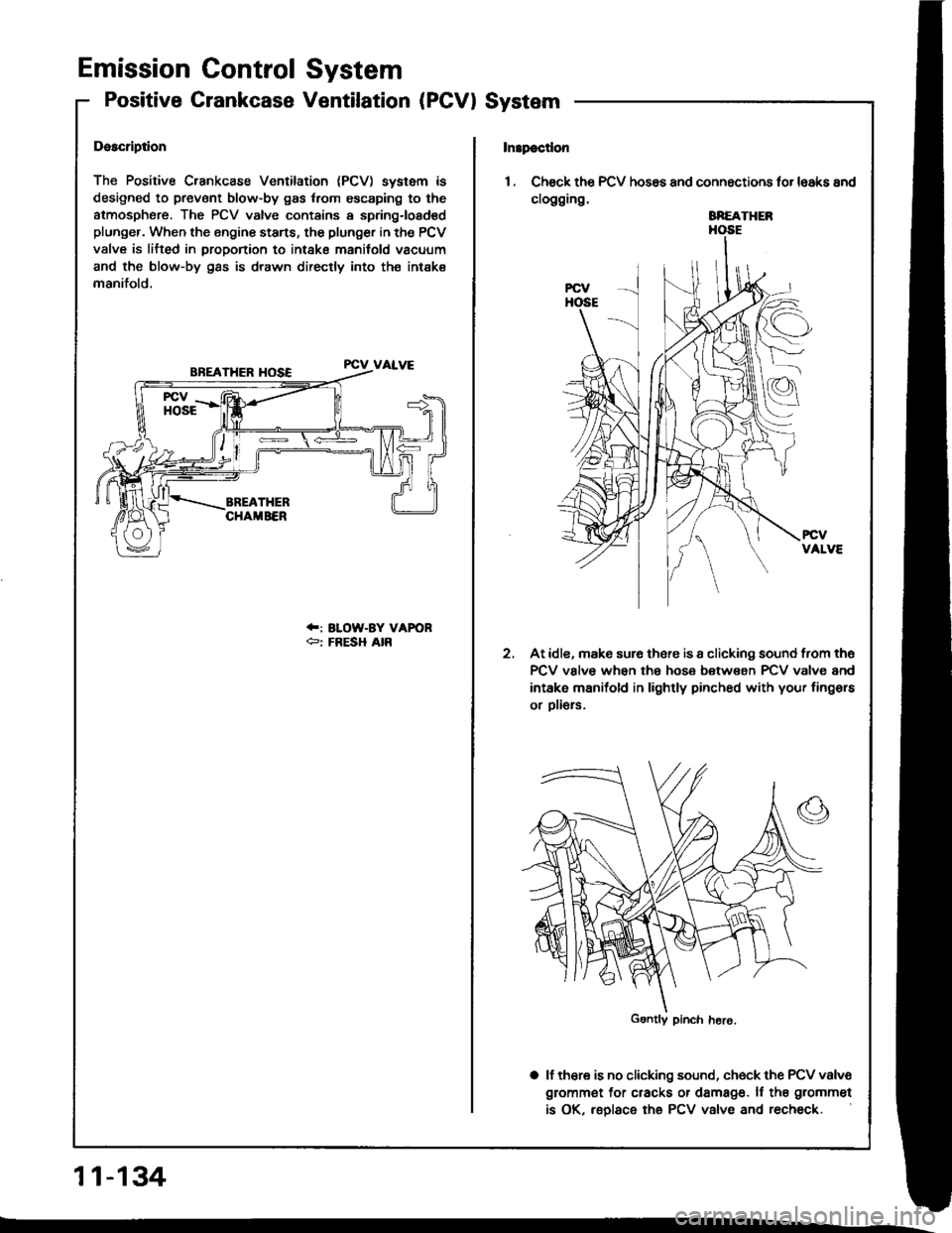

Emission Control System

Positive Crankcase Ventilation (PCVI System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas {rom escaping to the

atmosphsre. The PCV valve contains a spring-loadsd

plunger. When the Bngine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into th€ intak€

manifold.

FCV VALVE

.F: ILOW-BY VAFORer FRESH AIR

11-134

Insp€cdon

1. Check th€ PCV hos6s and connections tor lsaks and

clogging.

At idle, mak6 sur€ th6fe is a clicking sound from th6

PCV valve when the hose between rcV valve and

intake manifold in lightly pinched with your fingors

or oli€rs.

a lf thera is no clicking sound, ch6ck the PCV valve

grommet for cracks or damage. ll the grommet

is OK, reolace the PCV valve and recheck.

2.

SREATHER

Gontly pinch hero.

Page 324 of 1413

A.

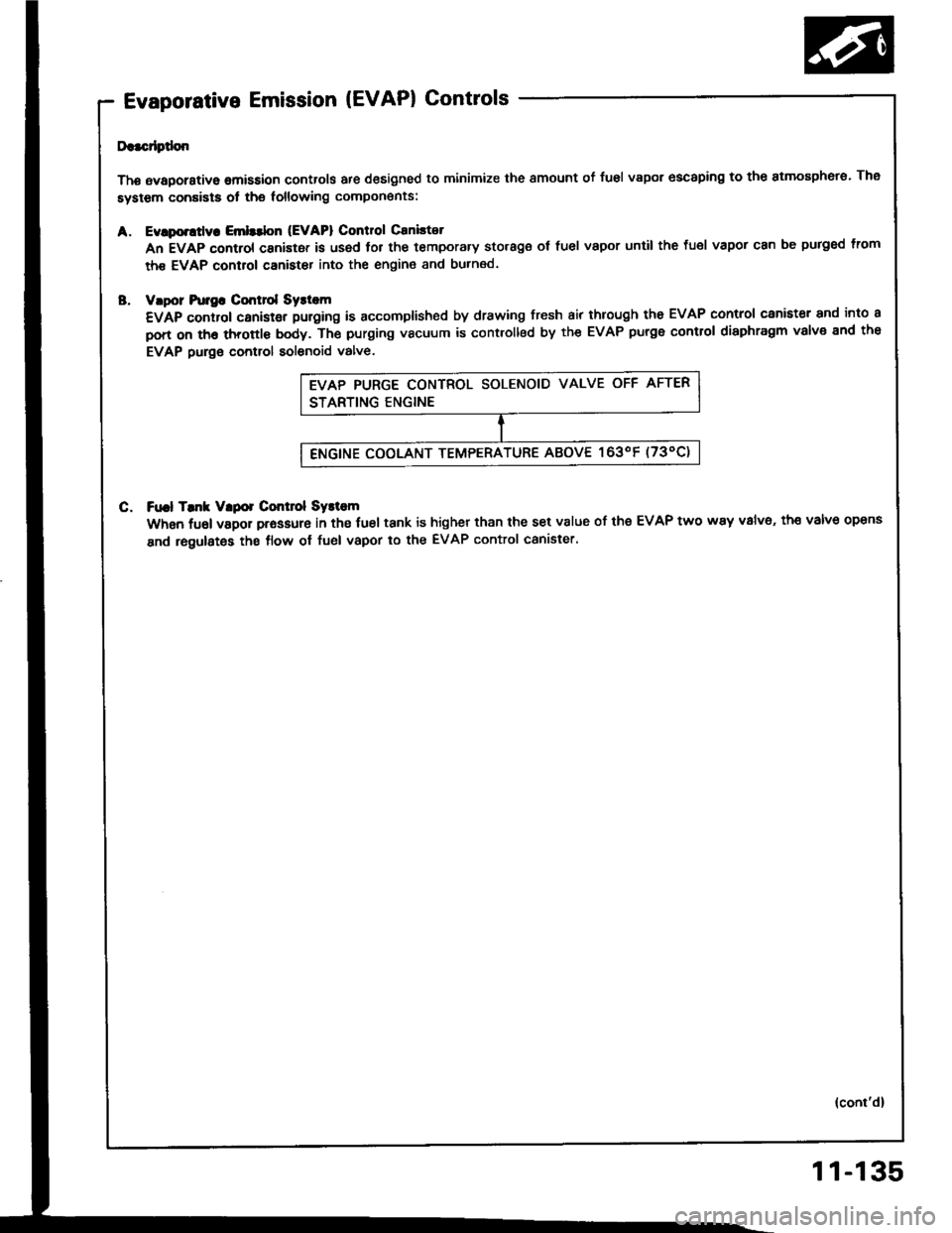

Evaporative Emission (EVAPI Controls

Da.cdptlon

Thg avaporstive omission controls are designed to minimize the smount of fusl vapor escaping to the atmosphero. The

system conaists ot the following compon€nts:

Evlporttly. Emlttbn (EVAPI Control Caniltot

An EVAP control canistor is used lor the temporary storage ot fuel vapor until the fuel vapor can be purged lrom

th€ EVAP control canister into the engin€ and burned.

vlpor hr]gG Cmt]ol Syst m

€VAp control canistgr puroing is accomplished by drawing fresh air through tho EVAP control canister and into a

pon on th6 throttl€ body. Th€ purging vacuum is controllsd by the EVAP purge control diaphragm valve end the

EVAP purge control solenoid valve.

C. Ft|.l Tmk Vlpor Control Systom

When fuel vapor prassure in the fuel tank is higher than the set v8lue of the EVAP two way v8lv6, th€ valve opens

and regulates the flow ol fuel vapor to the EVAP control canister.

(cont'd)

11-135

Page 325 of 1413

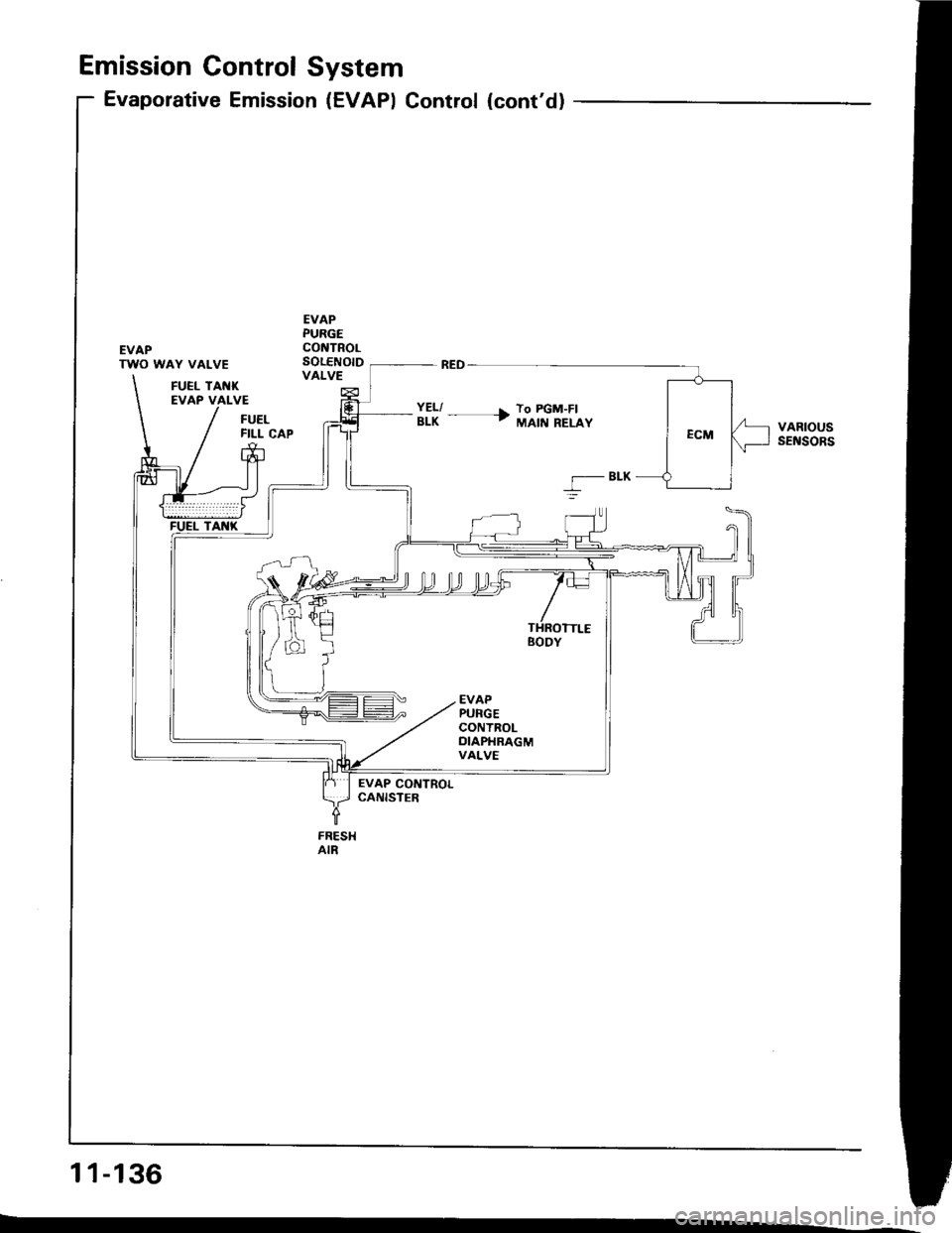

Emission Gontrol System

Evaporative Emission (EVAPI Control (cont'd)

EVAPTWO WAY VALVE

EVAPPURGECONTROLSOLENOIDVALVEFUEL TANKEVAP VALVE

FUELFILL CAPVARIOUSsEt{soRs

BLK

5

EVAP CONTROLCANISTEB

FRESHAIR

11-136

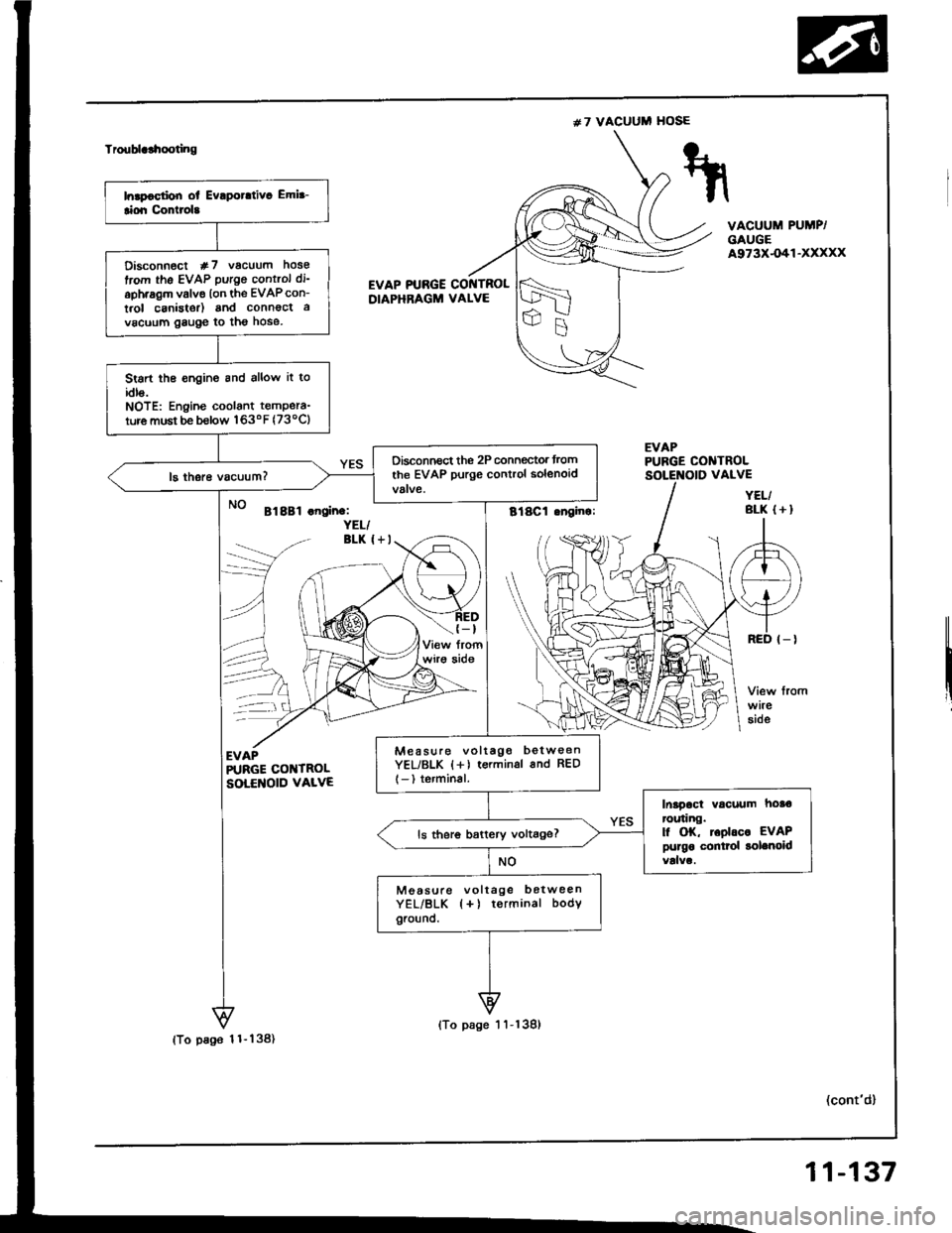

Page 326 of 1413

#7 VACUUM HOSE

Troublclhooting

VACUUM PUMP/GAUGEA973X-O41-XXXXX

EVAP PTJBGE COI{TROLDIAPHRAGM VALVE

EVAPPUBGE CONTROL

Bl8Bl .noin.:YEL/BLK I+I

(-t

wirg aide

--\

EVAPR'RGE COI{TROLSOLENOID VALVE

(cont'd)

VALVE

YEL/BLK (+I

Disconn€ct #7 vacuum hose

trom the EVAP putgo control di'

aph.agm valve lon the EVAPcon-

t.ol canistor) and connoct a

vacuum gauge to tho hose.

Stsrt the €ngine and allow it toidls.NOTE: Engine coolant tempera-

ture must be b€low 163oF (73ocl

Oisconnect the 2P connegtor trom

the EVAP purge control solenoid

Mea suro voltago betw€enYEL/BLK {+) terminsl 6nd RED

l-) terminal.

Inapact vacuum hoa€ror.ring.l| OK, toolrc. EVAPpurgo conttol solenoidls ther6 battery voltage?

Moasule voltage botweenYEL/BLK {+) terminal bodYground.

(To pa96 1 1- 138)

(To page 1 'l -139)

11-137

Page 329 of 1413

Emission Control System

Evaporative Emission Controls

(cont'dl

Evaporativ€ Emission {EVAPI Two Way Valvo Tasting

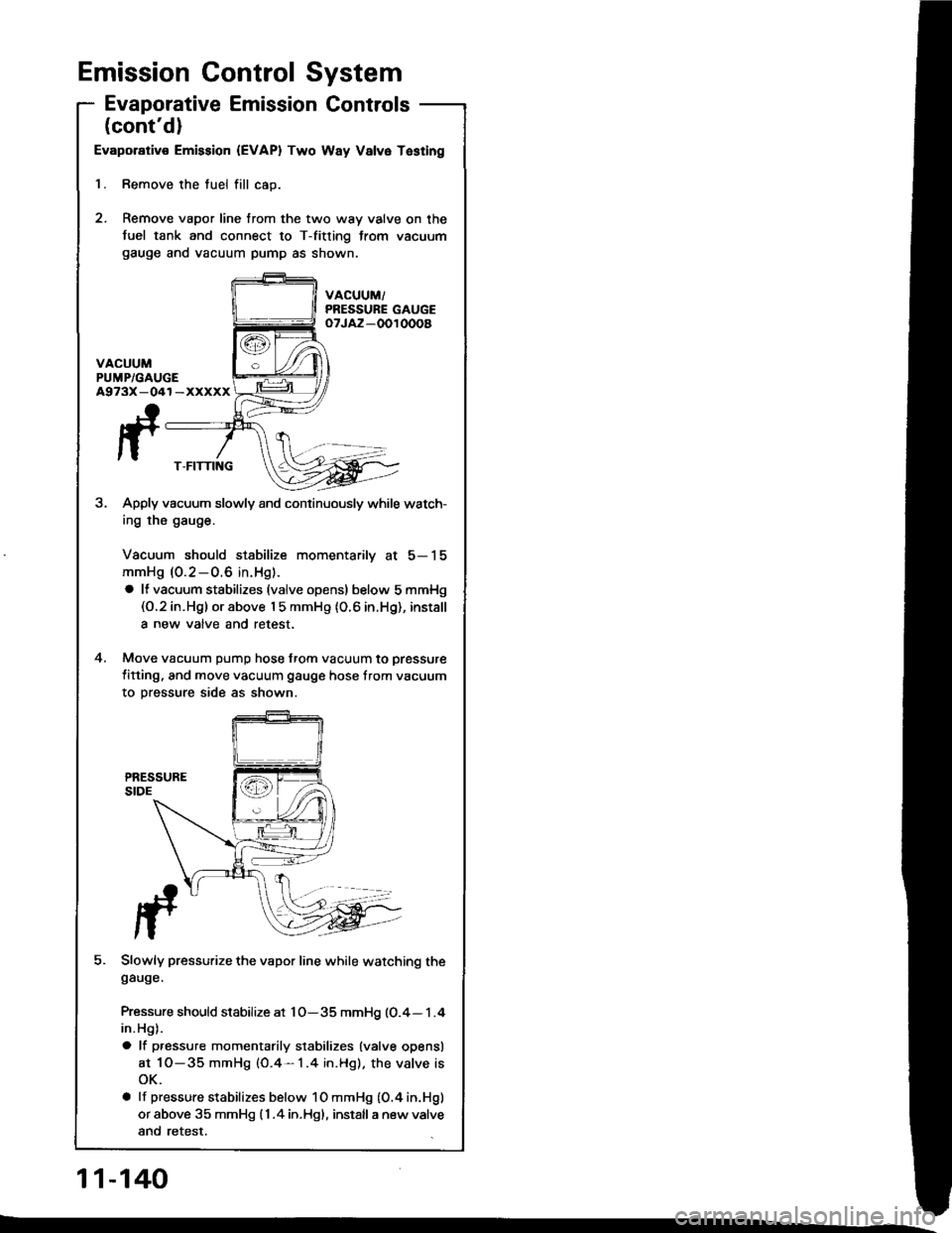

l. Remove the tuel fill cao.

2. Remove vapor line trom the two way valve on the

fuel tank and connect to T-fitting trom vacuum

gauge ano vacuum pump as snown.

VACUUM/PRESSURE GAUGEoTJAZ-OOI OOOa

A973X-041-XXXXX

fT-FITTING

Apply vacuum slowly and continuously while watch-

ing the gauge.

Vacuum should stabilize momentarilv at 5-15

mmHg (0.2-0.6 in. Hg).

a It vacuum stabilizes (valve opensl below5mmHg(O.2 in.Hg) or above I 5 mmHg (O.6 in.Hg), install

a new valve and retest.

Move vacuum pump hose from vacuum to pressure

titting, and move vacuum gauge hose trom vacuum

to oressure side as shown.

Pressure should stabilize at 1O-35 mmHg (0.4- 1 .4

in. Hg).

a lf p.essure momentarily stabilizes {valve opensl

at 1O-35 mmHg (O.4- 1.4 in.Hg), the valve is

oK.

a lf pressure stabilizes below 10 mmHg {O.4 in.Hg)

or above 35 mmHg (1 .4 in.Hgl, install a new valve

and retest.

4.

J-.

fF . -,-/ asr^:

,T 4?e

Slowly pressurize the vapor line while watching thegauge.

11-140