brake fluid ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 40 of 1413

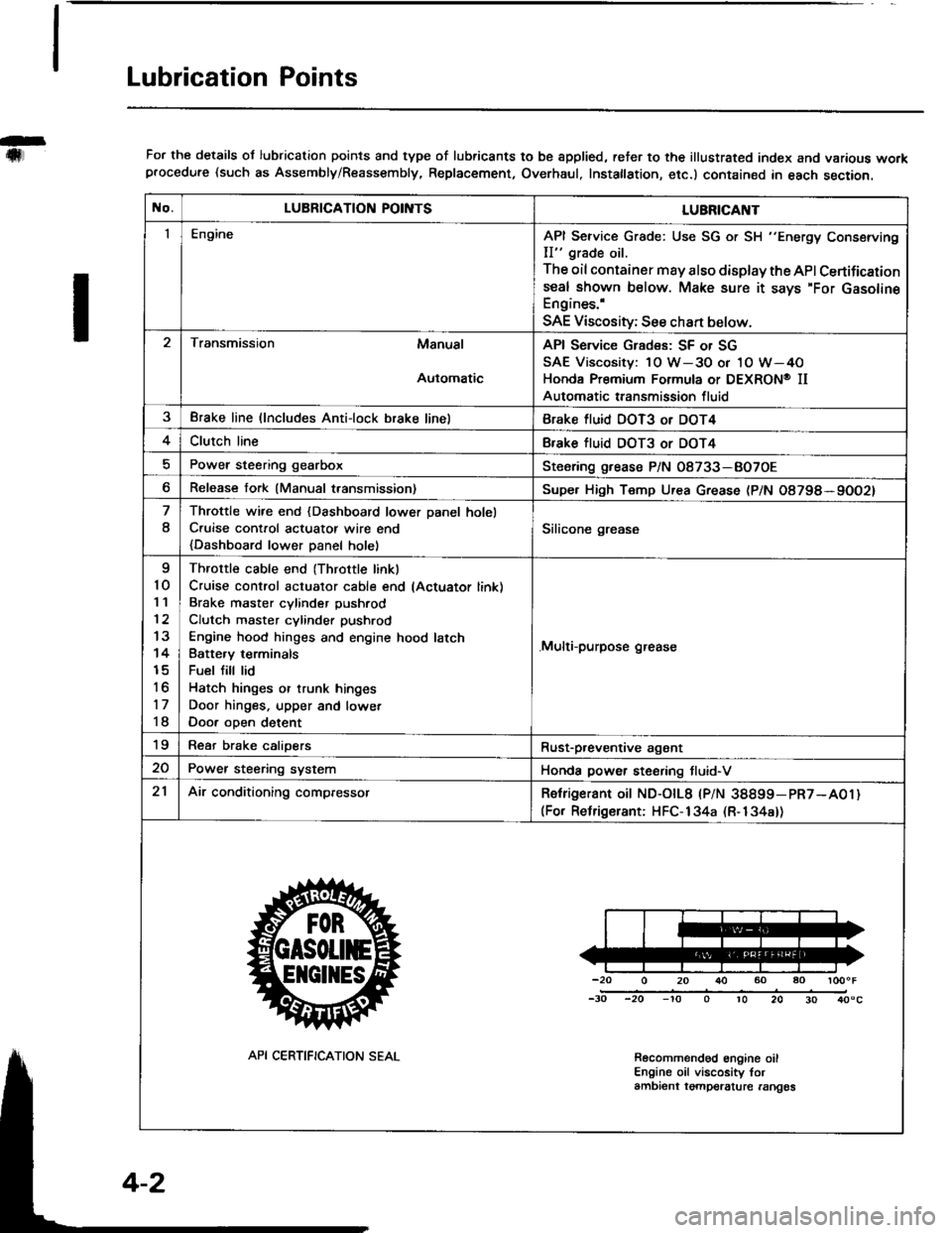

Lubrication Points

For the details ol lubrication points and type of lubricants to be spplied, reter to the illustrated index and various workprocedure (such as Assembly/Reassembly, Replacement, Overhaul, Instatlation, etc.) contained in each section.

No.LUBRICATION POII\ITSLUBRICAI\IT

IEngineAPI Service Grade: Use SG or SH "Energy Conserving

II" grade oil.

The oil container may also display the API Certifications€al shown below. Make sure it says'For GasolineEngines.'

SAE Viscosity; See chan below.

Transmission Manual

Automatic

API Service Grades: SF or SG

SAE Viscosity: 1O W-3O or 1O W-4O

Honda Premium Formula or DEXRON@ II

Automatic transmission fluid

3Brake line (lncludes Anti-lock brake linelBrake fluid DOT3 or DOT4

4Clutch lineBfake tluid DOT3 or DOT4

Power steering gearboxSteoring grease P/N 08733-BO7OE

Release fork (Manual transmission)Supe. High Temp Urea Grease (P/N O8798*9OO2)

8

Throttle wire end {Dashboard lower Danel holel

C.uise cont.ol actuatot wire end

{Dashboard lower Danel holel

Silicone grease

I

10'I '�l

12

13

14

15

to

17

18

Throttle cable end (Throttle linkl

Cruise control actuator cable end lActuator link)

Brake master cvlinder Dushrod

Clutch master cylinder pushrod

Engine hood hinges and engine hood latch

Batte.v terminals

Fuel fill lid

Hatch hinges or trunk hinges

Door hinges. upper and lowet

Door oDen detent

.Multi-purpose grease

19Rear brake calioersRust-p,eventive agant

20Power steering systemHonda power steering tluid-V

21Air conditioning compressorRetrigerant oit ND-otL8 |PlN 38899-pR7-A01)(For Relrigerant: HFC-134a (R-134a))

-20 0 20 r}() 60 ao loooF

-30 -20 -'to o 10 20 30 40"c

Recolnmendod engine oilEngine oil viscosity torambient tgmpelalure rangos

API CERTIFICATION SEAL

Page 335 of 1413

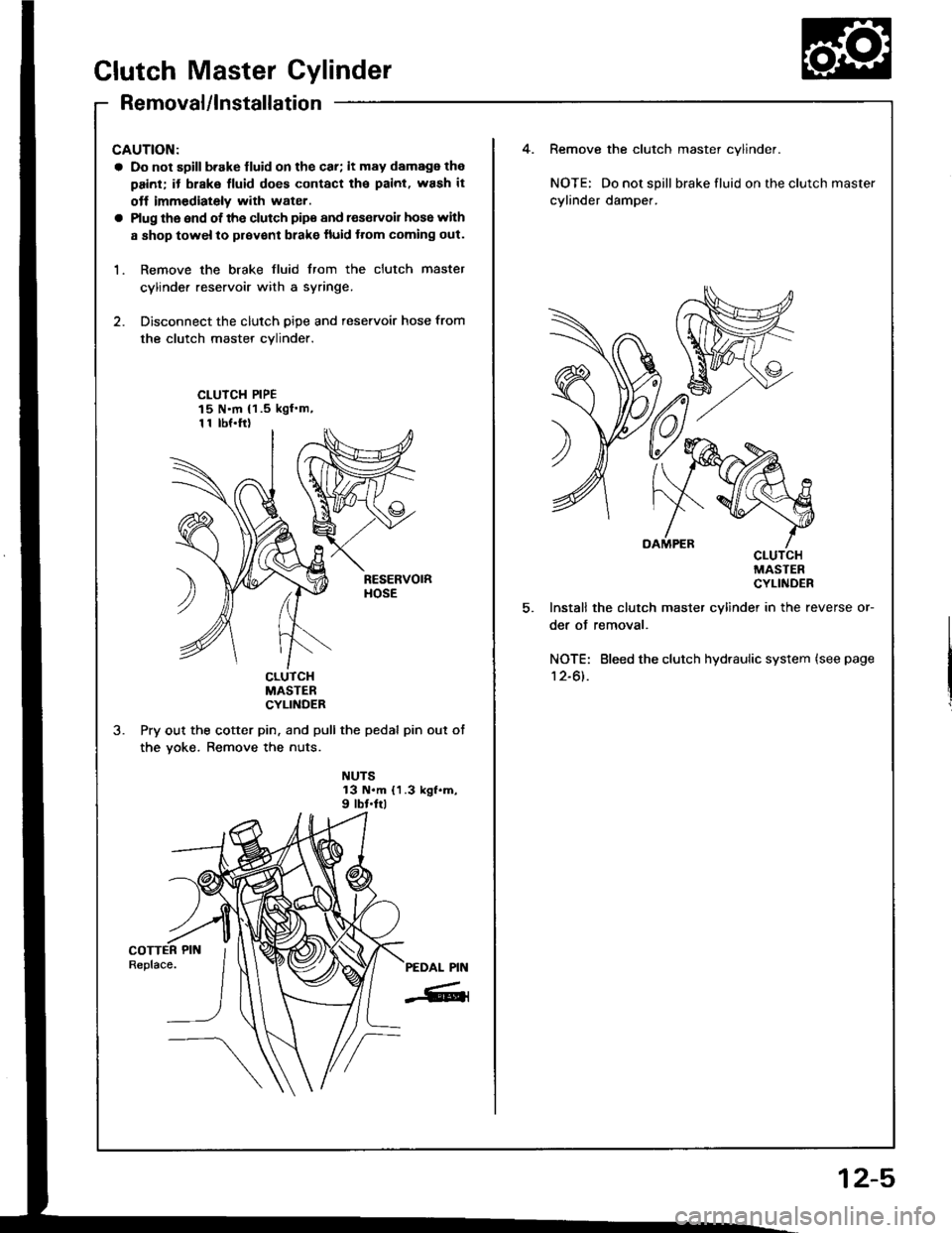

Clutch Master Cylinder

Removal/lnstallation

CAUTION:

a Do not sgill b.ake lluid on the car; it may damags the

painl; it biake fluid does contact tha paint. wash it

otf immediately with water.

a Plug lhe end ot the clutch pips and r€servoil hose with

a shop towel to prsvent blake fluid ttom coming out.

1. Remove the brake fluid from the clutch master

cylinde. reservoir with a syringe.

2. Disconnect the clutch oioe and reservoir hose from

the clutch master cvlinder.

CLUICH PIPE15 N'm {1.5 kgl.m,1 1 tbf.ftl

CLUTCHMASTERCYLINDER

Pry out the cotter pin. and pull the pedal pin out ot

the yoke. Remove the nuts.

NUTS13 N.m {1.3 kgf.m,9 lbt.frl

Remove the clutch master cylinder.

NOTE: Do not spill brake fluid on the

cylinder damper.

OAMPERCLUMAIcYL

Install the clutch master cylinder in

der of removal.

NOTE: Bleed the clutch hydraulic s\

12-61.

clutch master

CLUTCHMASTERCYLINDER

!l rn Ine reverse or-

c system (see page

12-5

Page 336 of 1413

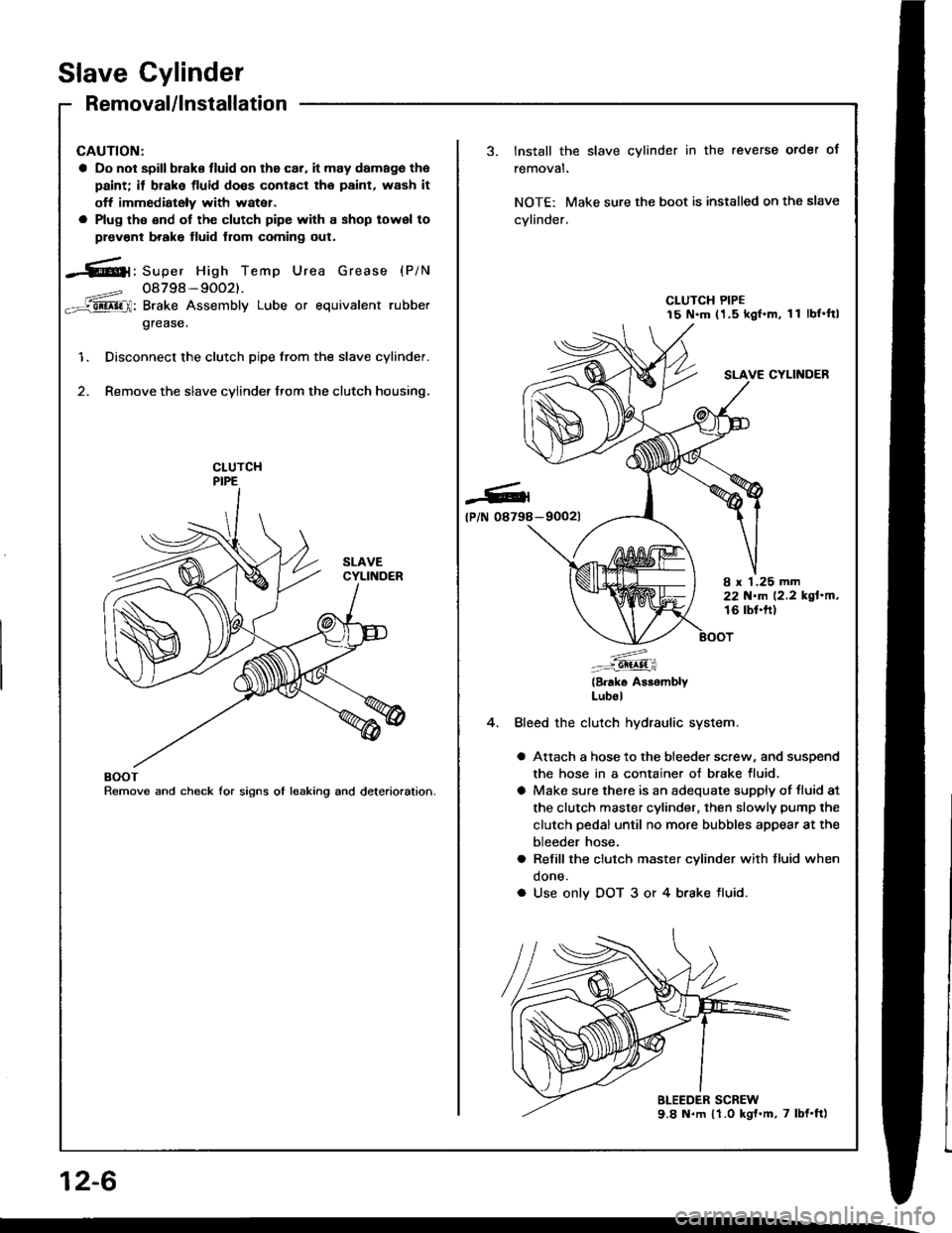

Slave Cylinder

Removal/lnstallation

CAUTION:

a Do not spill brake tluid on the car. it may damago tho

paint; it brake tluid doos conlacl tho paint, wash it

off immediately with watei.

a Plug tho €nd of the clutch pipe with a shop lowsl to

plevcnt b.ake fluid from coming out.

-61, Super High Temp Urea Grease {P/N

08798-9002).

: Brake Assembly Lube or equivalent rubber

grease.

Disconnect the clutch pipe from the slave cylinder.

Remove the slave cylinder from the clutch housing.

'1.

BOOTRemove and check for signs ol leaking and deterioration.

Install the slave cylinder in the reverse order ol

removat.

NOTE: Make sure the boot is installed on the slave

cylinder.

CLUTCH PIPE15 N.m (1.5 kgf.m, 11 lbf'ftl

SLAVE CYLINOER

-90021-Cl

tP/N 08798

8 x 1.25 mm22 N.m 12.2 kgl'm,16 rbt'ft)

4.

:^....:: Gil^lt i

(Brake A$embryLubol

Bleed the clutch hydraulic system.

a Attach a hose 1o the bleeder screw, and suspend

the hose in a container oJ brake fluid.

a Make sure there is an adequate supply of tluid at

the clutch master cylinder. then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

a Refill the clutch master cylinder with fluid when

done.

a Use only DOT 3 or 4 brake tluid.

12-6

Page 393 of 1413

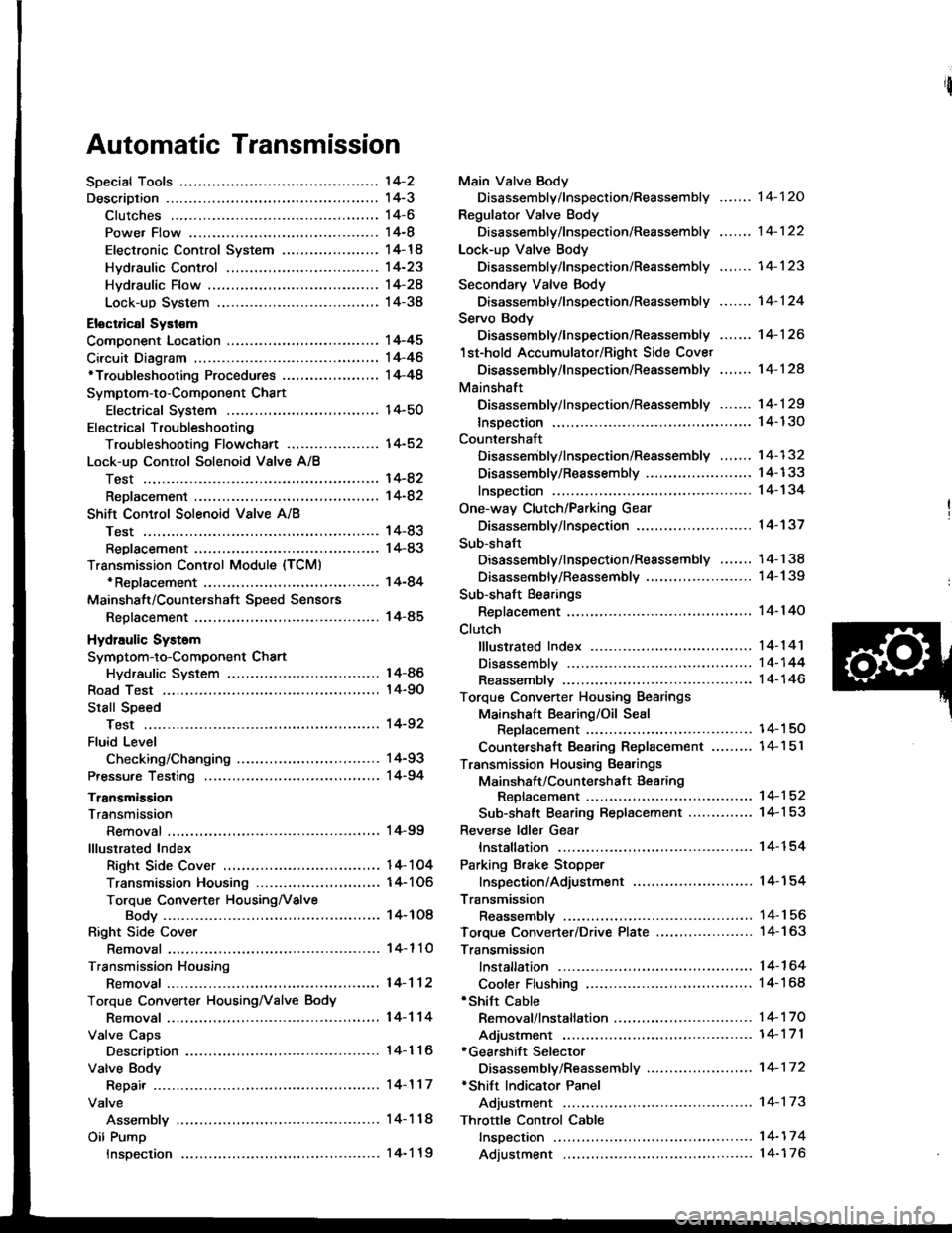

Automatic Transmission

'l4-2

14-3't 4-6

14-8

14-14

14-23

Hvdraulic Flow ...--...... 14-24

Lock-up System ........ 14-38

Eloctrical Systom

Component Location ............,...,................ I 4-45

Circuit Diagram ............. 14-46'Troubleshooting Procedures ........,..........., l4-48

Symptom-to-Component Chart

Electrical System ...... 14-50

Electrical Troubleshooting

Troubleshooting Flowchart .................... 14-52

Lock-uo Control Solenoid Valve A/8

Test .................. --.... \4-82

ReDlacement ,...,...,..,. 14-82

Shift Control Solenoid Vslve A/B

Test .................. ...... 14-83

Reolacement .............. 14-83

Transmission Control Module (TCM)*ReDlacement ........... 14-84

Mainshalt/CountershaJt SDeed Sensors

Reolacement ............. 14-85

Hydraulic Systom

Symptom-to-Component Chart

Hydraulic System

Road Test

Slall Speed

Test ..................

Fluid Level

Checking/Changing

Pressu.e Testing

Transmission

Transmission

Removal ............. ...... 14-99

lllustrated Index

Right Side Cover .................................. 1 4- 1 04

Transmission Housin9 ..................,,....... I 4-1 06

Torque Converter HousingNalve

Body .................. ... 14- 1O8

Right Side Cover

Removal ............. ...... 14-110

Transmission Housing

Removal ............. .-..-. 14-112

Torque Convener HousingNalve Body

Removal ............. ...... 14-114

Valve Caps

Description ................ 14-116

Valve Body

Repair ................ ...-.. 14-117

Valve

Assembly ...........

Oil Pump

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly .......

Secondary Valve Body

Disassembly/lnspection/Reassembly .......

Servo Body

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Covet

Oisassembly/lnspection/Reassembly .,..,..

Mainshaft

Disassembly/lnspection/Reassembly -.. -... 1 4- 1 29

lnsDection ................. 14- 130

Countershaft

Disassembly/lnspection/Reassembly ....... 14-132

Disassembly/Reassembly ....................... 1 4-1 33

lnsDection ................. 14-134

One-way Clutch/Parking Gear

Disassembly/lnspection .................... -.. -. 1 4-137

Sub-shaft

Disassembly/lnspection/Reassembly ....... 14-138

Disassemblv/Reassemblv ....................... 1 4-1 39

Sub-shaft Bearings

Replacement ............. l4-140

Clutch

fllustrated lndex ................. -..-...-.......... 14-1 41

Disassembly ,,,.,,........ 14-144

Reassembly .............. 14-146

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Reolacement ......... 14-1 50

Countershaft Bearing Replacement .......,, 14-1 5l

Transmission Housing Bearings

Mainshsft/Countershaft Bearing

Repfacement ...-..-..14-152

Sub-shaft Bearing Replacement .............. 1 4-1 53

Reve.se ldler Gear

lnstallation ................ 14-154

Parking Brake Stopper

lnspection/Adjustment ..........................'14-'154

Transmission

Reassemblv .............,. .14_156

Toroue Converter/Drive Plate ..,..,............... 1 4- 1 63

Transmission

14-120

14-122

14-123

14-124

14-126

14-124

14-86

14-90

't4-92

14-93

14-94

lnstallation

Cooler Flushing'Shitt Cable

Removal/lnstallation ..............................

Adiustment ...-..-......-. 14-'171*Gearshift Selector

Disassembly/Reassembly .....................,. 1 4-17 2*Shift Indicator Panel

Adjustment -..........-...14-173

Throttle Control Cable

fnspection .......,..,...... 14-17 4

Adjustment .............. 14-176

14-164

14-168

14-'t 7 0

Inspection

Page 484 of 1413

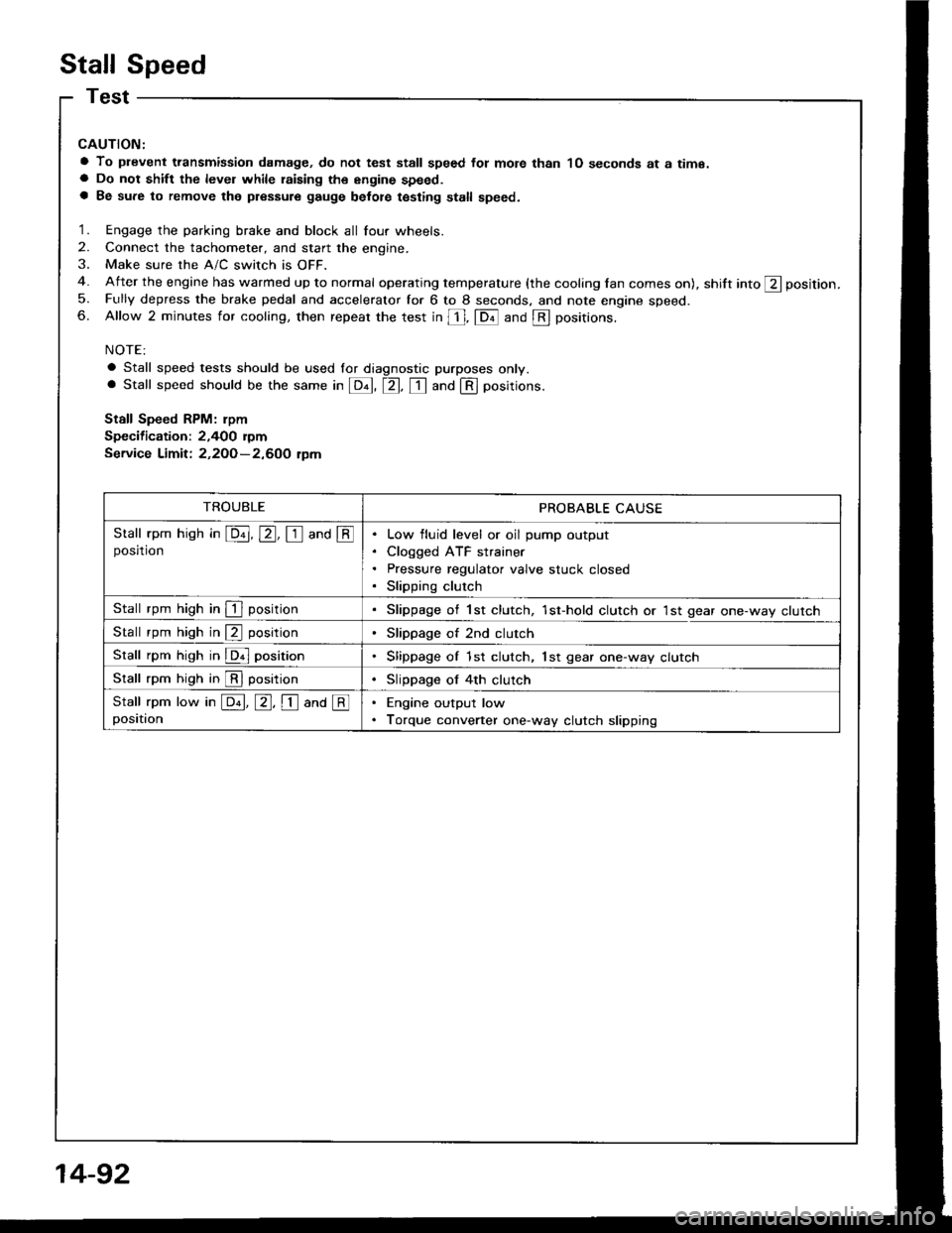

Stall Speed

CAUTION:

a To plevent transmission damage, do not test stall speed fot mote than 1O seconds at a time.a Do not shift the level while raising th€ engine speed.a Be sure to remove the pressure gauge belot€ testing stall speed.

1. Engage the parking brake and block all four wheels.

2. Connect the tachometer, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the cooling lan comes on), shift into ft position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds. and note engine speed.6. Allow 2 minutes for cooling, then repeat the test in [, fDil and @ positions.

NOTE:

a Stall speed tests should be used lor diagnostic purposes only.. Stall speed should be the same in E, tr. tr and @ positions.

Stall Speed RPM: rpm

Specification: 2,400 rymService Limit: 2,2OO-2,600 tpm

TROUBLEPROBABLE CAUSE

Stall rpm hish in E, E, I and @posrtronLow fluid level or oil pump output

Cloqged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in I positionSlippage of 1st clutch, 1st-hold clutch or 1st gear one-way clutch

Stall rpm high in @ positionSlippage of 2nd clutch

Stall rpm high in @ positionSlippage of 1st clutch, lst gear one-way clutch

Stall rpm high in @ positionSlippage of 4th clutch

Stall rpm low in E, E, I ana @positionEngine output low

Torque converter one-way clutch slipping

14-92

Page 486 of 1413

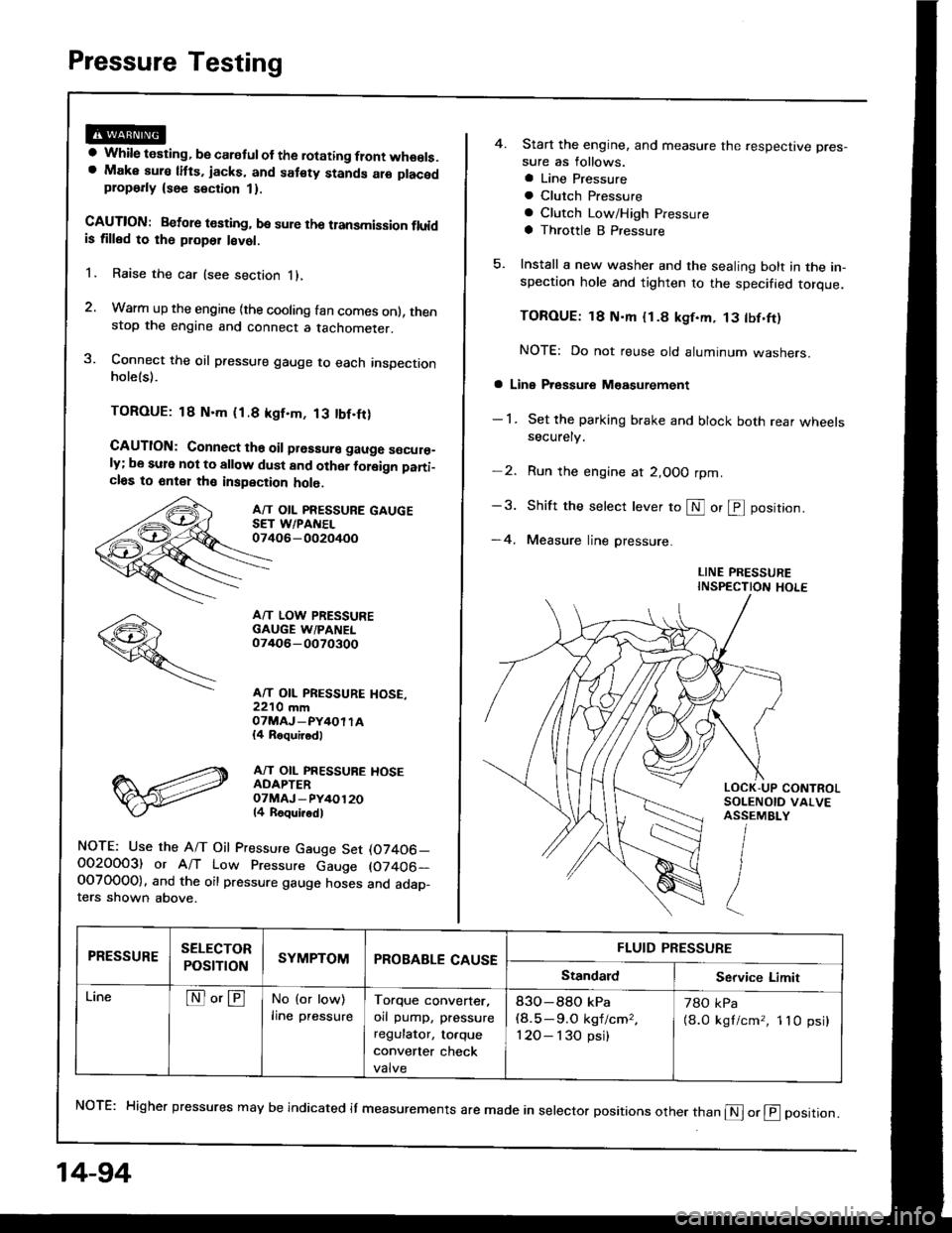

Pressure Testing

a While testing, be caretul of the rotating flont wheels.a Make aura litts, jacks, and sat€ty stands alo placedplop6rly {see section 1}.

CAUTION: Betore t€sting, be sure the transmission fluidis tilled to rh6 ploper l€vet.

1. Raise the car (see section i),

2. Warm up the engine {the cooling fan comes onl, thenstop the engine and connect a tachometer.

3. Connect the oil pressure gauge to each inspectionholels).

TOROUE: 18 N.m (1.8 kgf.m, 13 tbf.fr)

CAUTION: Connect ths oil prsssure gauge s€cur€_ly; be sule not to allow dust and other foleign pani_cl6s to 6nt€1 th€ inspection holo.

A/T OIL PRESSURE GAUGESET WPANEL07406-002oi+oo

A/T LOW PRESSUREGAUGE W/PANEL07/rO6-0O70300

A/T OIL PRESSURE HOSE,22'10 mmOTMAJ_PY4OI TA{4 Roquirod)

A/T OIL PRESSUBE HOSEADAPTEROTMAJ - PY/+O12014 Roqui.odl

NOTE: Use the A/T Oil Pressure Gauge Set (07406_O02OOO3) or A/T Low Pressure Gauge (07406-OOTO0OO). and the oil pressure gauge hoses and adap_ters shown above.

14-94

4. Start the engine, and measure the respective pres-

sure as follows.

a Line Pressure

a Clutch Pfessure

a Clutch Low/High Pressure

a Throttle B Pressure

5. Install a new washer and the sealing bolt in the in-spection hole and tighten to the specified torque.

TOROUE: 18 N'm {1.8 kgf.m, 13 tbf.ft)

NOTE: Do not reuse old aluminum washers.

a Line Pressure M€asurement

- 1 . Set the parking brake and block both rear wheelssecurely.

-2. Run the engine at 2,OOO rpm

-3. Shift the selecr lever to S or @ position.

-4. Measure line pressure.

LINE PRESSUREINSPECTION HOLE

NoTE: Higher pressures may be indicated it measurements are made in selector positions other than @ or @ position.

PRESSURESELECTOR

POStTTONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineNo'ENo (or low)

lrne pressureTorque converter,

orl pump, pressure

regulator, to.que

convener check

valve

83O-88O kPa(8.5-9.O kgf/cm,,

120- I 30 psi)

78O kPa

{8.0 kgl/cm,, 1lO psi}

Page 487 of 1413

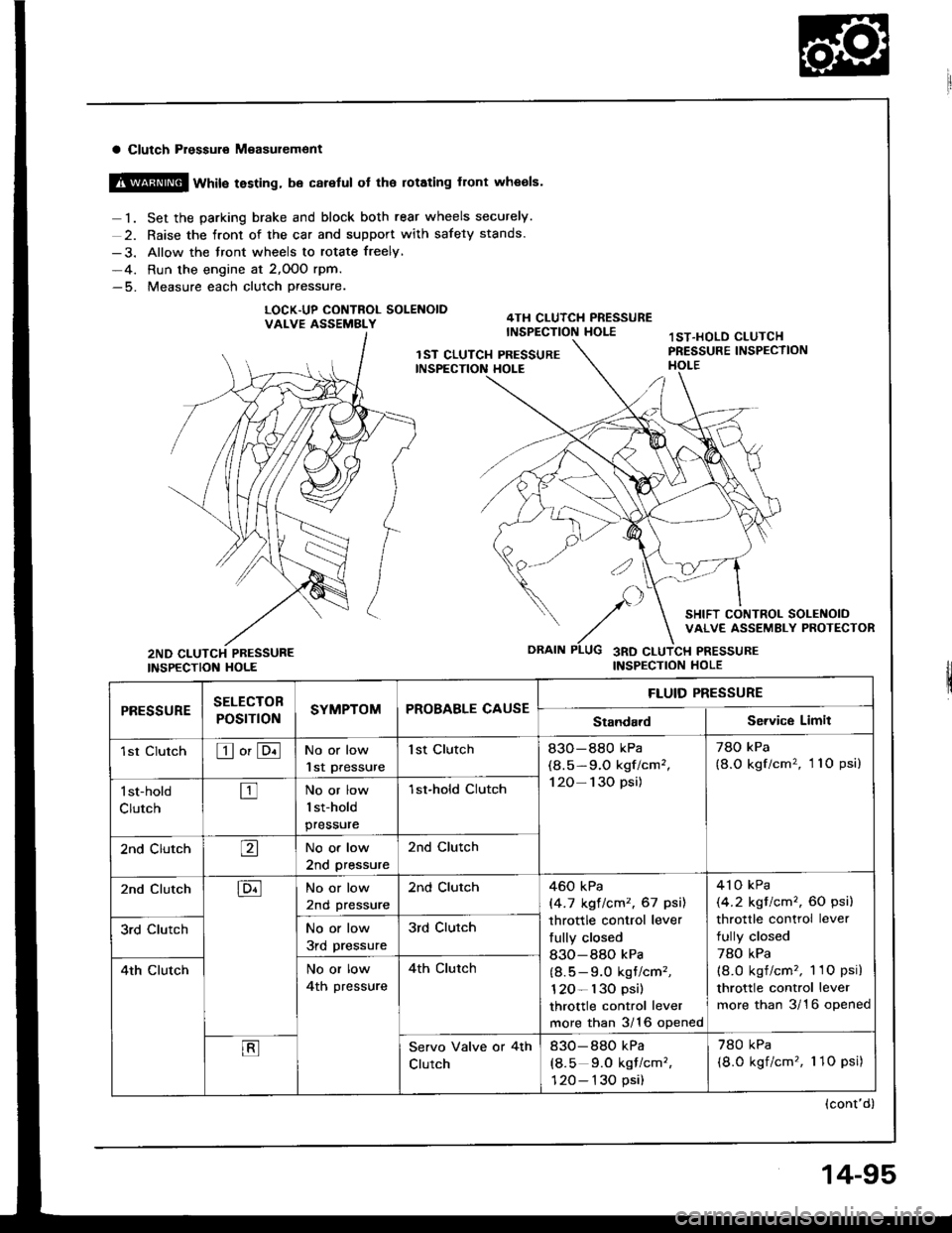

a Clutch Pressuro M€asur€ment

@ wtit" testing, be careful ot the rotating front wheols.

1. Set the parking brake and block both rear wheels securely.

2. Raise the front of the car and support with safety stands.

-3. Allow the front wheels to rotate freely,

-4. Run the engine at 2,OOO rpm.-5. Measure each clutch Pressure.

LOCK.UP CONTNOL SOLENOIDVALVE ASSEMBLY

INSPECTION HOLE

SELECTOB

POST ONSYMPTOMPROBABLE CAUSE

FLUID PRESSURE

rl|E!!UltEStandardService Limit

1st ClutchEo'ENo or low

lst Pressure

1st Clutch83O-880 kPa

(8.5-9.O kgf/cm',

120- 130 psi)

78O kPa

{8.O kgf/cm'�, 11O psi)

l st-hold

ClutchtrNo or low

1st-hold

pressure

1st-hold CIutch

2nd ClutchaNo or low

2nd pressure

2nd Clutch

2nd ClutchENo or low

2nd pressure

2nd Clutch460 kPa

|'4.7 kgt lcm2, 67 psil

throttle control lever

fully closed

830-880 kPa

(8.5 - 9.0 kgt/cm'�,

120- l30 psi)

throttle control lever

more than 3/16 opened

4'l o kPa

(4.2 kgt/cm'�, 60 psi)

throttle control lever

fully closed

78O kPa(8.O kgf/cm'�, 1 1O psi)

throttle control lever

more than 3/16 opened

3rd ClutchNo or low

3rd pressure

3rd Clutch

4th ClutchNo or low

4th pressure

4th clutch

EServo Valve or 4th

Clutch

830-880 kPa

(8.5 9.0 kqf/cm'�,

120- 130 psi)

780 kPa

(8.0 kgf/cm'�, 1 1O psi)

(cont'd)

14-95

Page 557 of 1413

20. Connect the vehicle speed sensor (VSS), mainshatt

speed sensor and counterchalt speed sensor con

nectors.

VEHICLE SPEED SEiISORCONNECTOR

21. Connect the lock-uD control solenoid valve connec-

tor and shift control solenoid valve connector. then

clamp the lock-up control solenoid harness with the

harness stay.

22. Connect the transmission ground cable.

LOCK-UP CONTROLSOLENOID VALVE HARNESS STAY

23. Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side of the ring terminal

is facing out (see section 23).

CABLEHOLDER

6x 1.0 mm'12 N.m (1.2 kgf'm,8.7 lbt.tl)

24.

N.mlO.9 ksr.m, 7 tbr-rtt

STARTER CAELE

Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGASSEMBLYINTAKE AIRDUCT

25.

26.

24.

29.

30.

Retill the transmission with ATF(see page '14-93).

Connect the battery positive ( + ) and negative ( - )

cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shitr cable adjustment as described on page

14-171 .

Check that front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-

ing tan comes on) with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-9o and 91.

14-167

Page 603 of 1413

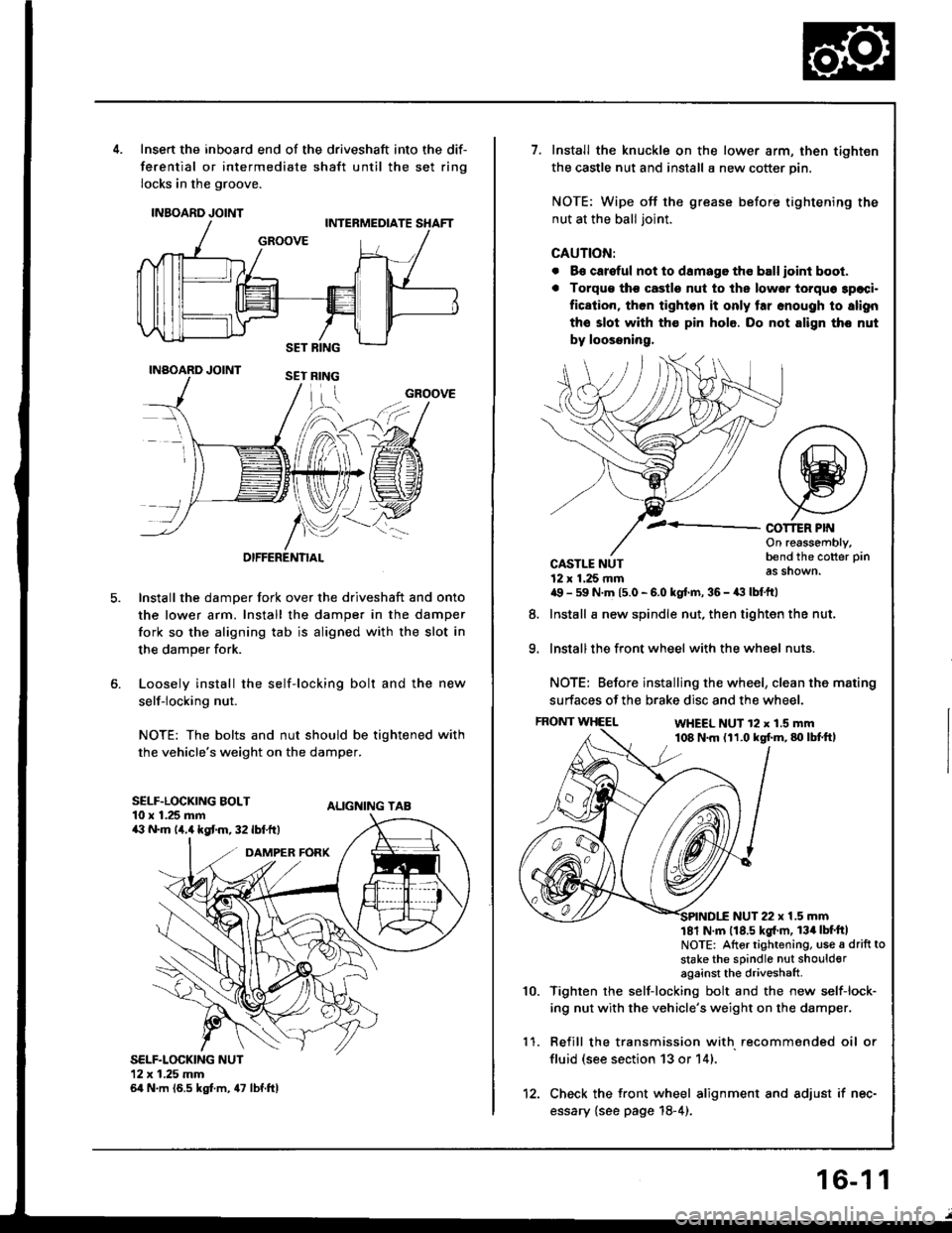

5.

Insert the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set ring

locks in the groove.

INBOARD JOINT

INAOARD JOINT

OIFFERENTIAL

Install the damper fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damper fork.

Loosely install the self-locking bolt and the new

self-locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

ALIGNING TAB

SELF.LOCKING NUT12x 1.25 mm64 N.m (6.5 kgt m, 47 lbf.ftl

GROOVE

SELF.LOCKING BOLT10 x 1.25 mma:' N.m lir,4 kgt m, 32 lbf.ftt

1.Install the knuckle on the lower arm, then tighten

the castle nut and install a new cotter pin.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. B€ careful not to damago tho ball ioint boot.

. Torqu€ tho castle nut to ths lower torquo 3paci.

fication, then tighlon it only tar snough to slign

the slot with th€ pin hole. Do not align tho nut

by loossning,

COT1ER PIf{On reassembly,bend the cotter pin

as shown.

9.

CASTLE NUT12 x 1.25 rnma9 - 59 N.m 15.0 - 6.0 kgt.m, 36 - a:t lbtftl

Install a new spindle nut, then tighten the nut,

Install the front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbtft,

8.

1 '�I.

10.

NUT 22 x 1.5 mm181 N m 118.5 kgl'm, 134lbt'ftlNOTE: Altor tightening, use a drift to

stake the sPindle nut shoulderagainst the driveshaft

Tighten rhe self-locking bolt and the new self-lock-

ing nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

Check the front wheel alignment and adjust if nec-

essary {see page 18-4).

12.

16-1 1

Page 1126 of 1413

Connector ldentification and Wire Harness Routing

ABS Modulatol Unit Wile Harness

Engine Compartmont Wile Hatnaaa

Connoctor or

Torminal

Numbor ot

CaviiieELocationConnocta tooies

Ltol

c162

c163

c164

c165

c166

c't 67

c168

't4

2

2

Right side of engine comPartment

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unat

Main wire harness (c21 1)

ABS Dressure switch

ABS right Jront solenoid (OUT)

ABS right front solenoid (lN)

ABS rear solenoid (OUT)

ABS rear solenoid llN)

ABS le{t front solenoid {OUT)

ABS left tront solenoid (lNl

Connector or

Tolminal

Numbd of

CaviliesLocationConnocta tot{oioE

c301

c302

c303

c304

c305

c306

c307

c308

c309

c310

c31 1

c312

c313

c314

c315

c316

c317

c318

c319

c320

20

20

1

2

14

2

1

1

2

4

2

2

1

2

2

5

Behind left kick Panel

Behind left kick panel

Behind lett kick Panel

Left side of engine compartment

Left side of engine comPartment

Left side of engine comPartment

Left side o{ engine comPartment

Left side of engine comPartment

Left side of engine compartment

Lelt side oJ engine comPartment

Middle of engine comPartment

Left side of engine comPartment

Left side oJ engine comPafiment

Behind leJt headlight

Behind left headlight

Behind left headlight

Behind left corner ot front

bumper

Behind lett corner ot front

DUmper

Behind left corner of ftont

DUmper

Behind left cornet of front

DUmper

Main wire harness (C4231

Main wire harness (C424)

Front fog light sYstem

Engine wire harness (C126)

Engine wire harness (C 127)

Test tachometer connector

Daytime running lights resistor

Windshi€ld wiper motot

Brake fluid level sensor ( + |

Brake fluid level sensor (- )

Power steering pressure (PSPI

Lett front wheel sensor

Cruise control actuator

Left headlight (Low beam)

LeJ-t headlight (High beam)

Front fog light system

Windshield washer motor

switch

Rear window washer motor

Left front side matker light

Left front tu.n signal/parking lights

USA

ABS

Option

Canada

Option

G301Lett side of engine comPartmentBody ground, via engine comPart-

ment wire harness

23-20