height ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 13 of 1413

![ACURA INTEGRA 1994 Service Repair Manual Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is ACURA INTEGRA 1994 Service Repair Manual Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is](/img/32/56982/w960_56982-12.png)

Lift and Support Points

Lift

Wh€n heavy 16ar compon€nts such aa susponsion, luel tank, spale tile and hatch ale to

il]iii6iliieigltt in the tuggage area bsfore hoisting. When substantial woight is lemoved from ths

b€ removod, plac6

l€ar ol th€ car, ths

cantor of gravity may chango and can cause the cal to tip folward on the hoist'

NOTE: Since each tire/wheel assembly weighs approximately 14 kg (30 lbs), placing the front wheels in trunk can assist

with the weight distribution.

1. Place the lift blocks as shown

2. Raise the hoist a lew inches (centimeters) and rock the car to be sure it is firmly supported.

3. Raise the hoist to full height and inspect lift points for solid support.

FRONT SUPPORT POINTLIFT BLOCKSBEAR SUPPORT POINT

1-9

Page 19 of 1413

Standards and Service Limits

Cylinder Head/Valve Train (B188t enginelSecti6

*: Measured between the camshaft and rocker arm.

NH: NIHON HATSUJO manufactur€d valve spring

CH: CHUO HATSUJO manufacturod valve sDrino

- Declron

MEASUREMENTSTANDARD {NEWI '

SERVICE LIMIT

Compression250 rpm and wide open th.ottl€ Nominal

kPa (kgflcm?, psi) Minimum

Maximum variation

1,370 (14.0, 199)

930 (9.5, 140)

200 t2.0,2a)

Cylinder h.adW6rpage

Heightr31.95- 132.05 (5.195 - 5.199)

0.05 (0.002)

CamshaftEnd play

Camshaft-to-holder oil clearance

Total runout

Cam lobe height tN

EX

0.05 - 0.15 (0.002 - 0.0061

0.030 - 0.069 10.0012 - 0.0027)

0.03 (0.001) max.

33.7 16 11 .327 1l

33.528 (1.3200)

0.5 (0.02)

0.1s {0.006)

0.04 (0.002)

Valve clearance (Cold)* lN

EX

Valve stem O.D. tN

EX

Stem-to-guide clearance lN

EX

0.08 - 0.12 {0.003 - 0.005)

0.'r 6 - 0.20 (0.006 - 0.008)

6.580 - 6.590 (0.2591 - 0.2594)

6.550 - 6.s60 (0.2579 - 0.2583)

0.02 - 0.0s (0.001 - 0.002)

0.05 - 0.08 (0.002 - 0.003)

6.s5 (0.258)

6.52 (0.257)

0.0810.003)

0.11 (0.004)

width tN

EX

Stem instslled height tN

EX

r.25 - 1.55 (0.049 - 0.061)

1.25 - 1.55 {0.049 - 0.061)

40.765 - 41.235 (1.6049 - 1.6234)

12.763 - 43.235 t1,6a37 - 1.7022)

2.0 t0.08)

2.0 (0.08)

41.485 (1.6333)

43.485 (1.7120)

Valve springFree length {Reference} lN

EX NH

CH

42.36 (1.668)

47.09 {1.854}

47.08 (1.854)

41.s6 {1.636)

46.27 tl.A22l

46.21 l1.a22l

Valv6 guideLu. lN

EX

Installed height lN

6.61 - 6.63 (0.260 - 0.261)

6.61 - 6.6s (0.260- 0.261)

13.75 - 14.25 {0.541 - 0.561}

r5.75 - 16.25 10.620 - 0.640)

6.65 (0.262)

6.6510.2621

3-2

Page 21 of 1413

Standards and Service Limits

Cylander Head/Valve Train (B18Cl enginelSection 6

': M€asured betwoon the camshatt and rcc(er srm.

NH: NIHON HATSUJO manufacture v6lve spring

CH: CHUO HATSUJO manufscturo v6lve spring

MEASUBEMENTSTA]TDARD INEWISERV|C€ UM|T

Compr€6sion250 rpm and wide op€n throttle Nomin6l

kPa lkgl/cmr, psi) Minimum

Maximum variation

1,860 (19.0, 270)

930 (9.s, 140)

200 t2.o,2a)

Cylind6r hoadWarpage

H6ight'r41.95 - 1C2.05 (5.s89 - 5.593)

0.05 {0.002)

C.mshsftEnd play

Camshaft-to-holdsr oil clearance

Total runout

Cam lobo height lN Primery

Mid

Socondary

EX Primary

Mid

Secondary

0.05 - 0.1s (0.002 - 0.006)

0.050 - 0.089 (0.0020 - 0.0035)

0.015 (0.0006) max.

33.411{1.3154)

36.377 tl.13221

34.547 (1.3601)

33.1110.3036)

35.72011.4063)

34.381 {1.3536)

0.5 (0.02)

0.15 {0.006)

0.03 (0.001)

Valvo clorrance lcoldl* lN

EX

Valve stem O.D. lN

EX

Stom-to-guid6 clerrsnco lN

EX

0.15 - 0.19 {0.006 - 0.007}

0.17 - 0.21 (0.007 - 0.008)

5.475 - 5.48s (0.2156 - 0.21591

5.450 - 5.460 (0.2146 - 0.21s0'

0.025 - 0.055 {0.00'10 - 0.0022}

0.050 - 0.080 (0.0020 - 0.0031)

5.11510.21441

s.420 {0.2134)

0.08 10.003)

0.11{0.(x)4)

Valvo seatWidth tN

EX

Sr6m installed h€ight lN

EX

1.25 - 't.5s (0.049 - 0.06't)'1.25 - 1.s5 {0.049 - 0.061)

37.465 - 37.935 ('1.4750 - 1.4935)

37.16s - 37.635 t1.4632 - 1.4817)

2.0 (0.08)

2.0 (0.08)

38.185 (1.5033)

37.885 (1.491s)

Valv€ BpringFre6length (Roferenca) lN Outer

Inner NH

CH

EX NH

CH

41.05 (r.6161

36.'16 {1.4241

36.19 t1.425)

41.96 (1.652)

41.94 {1.651)

40.26 (1.585)

35.30 (1.390)

35.30 (1.390)

40.95 (1.612)

40.95 (1.612)

Valve guidol.D. tN

EX

Instslled hoight lN

EX

5.51 - 5.53 (0.217 - 0.218)

5.5r - 5.53 {0.2r7 - 0.218)

12.55 - r3.0s (0.494 - 0.514)

12.55 - 13.05 (0.494 - 0.s14t

5.55 (0.219)

5.5s {0.219}

Rock€r ermArm-to-shaft clearance lN

EX

0.025 - 0.0s2 {0.0010 - 0.0020)

0.025 - 0.0s2 (0.0010 - 0.0020)

0.08 (0.003)

0.08 (0.003)

3-4

Page 24 of 1413

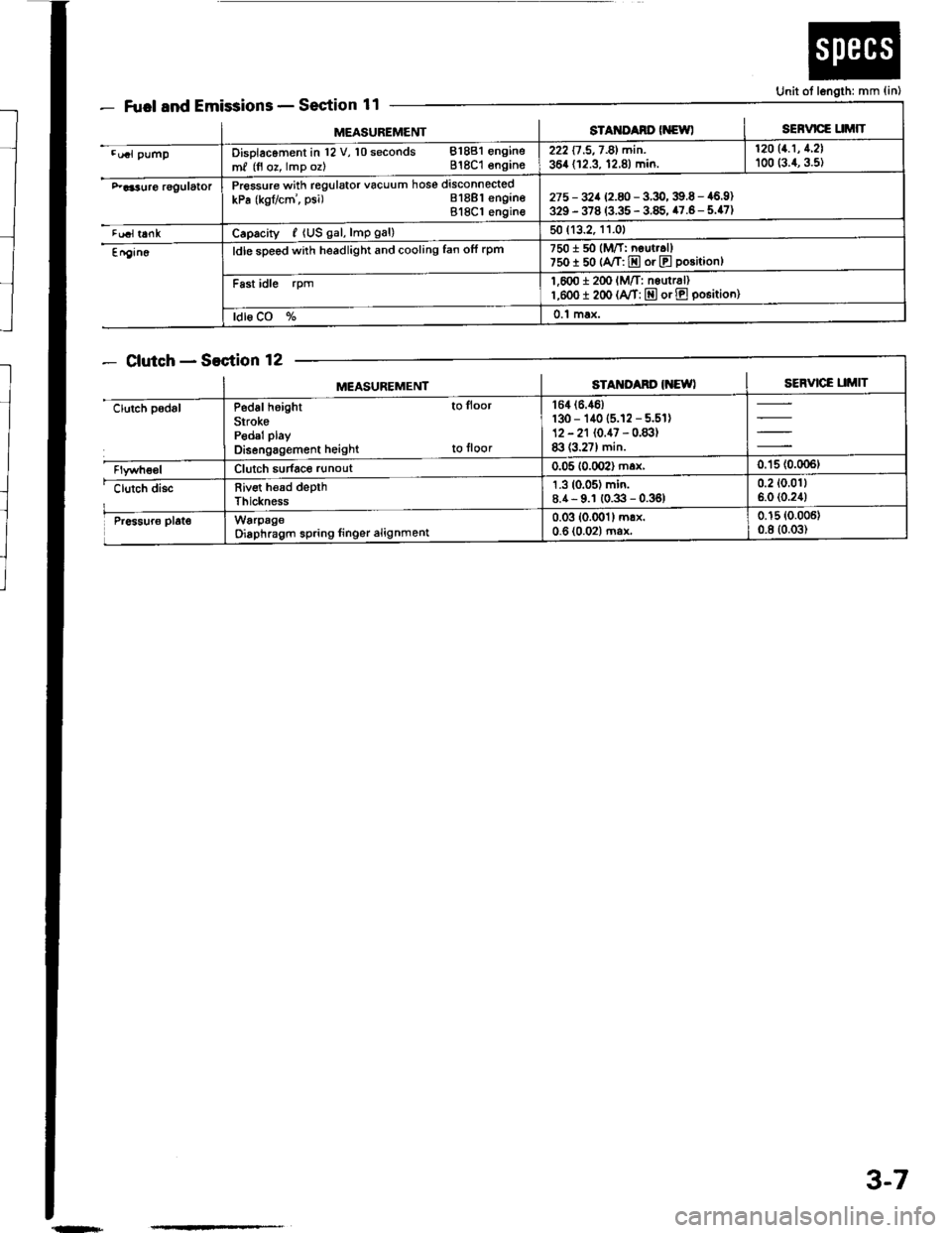

Fuel and EmissionsSection 11

ClutchSection 12

Unit ot length: mm {in)

MEASUREMENTsTAt{ItAno (NewlSERVICE UMIT

.u.l pumpDisolacoment in l2 V, 10 seconds 81881 engine

m, (fl oz, lmp oz) 818C1 engins222 17 .5,7 -81 min. | 12011.1' 1'21

364 (12.3, 12.8) min. I too (:.1, g.st

F aa3uro rggulatorPressure with regulator vacuum hose disconnected

kPa (kgflcm', psi) Bl8Bl engineBl8Cl engin€275 - 32a 12.8 -3.9,39.6 - 46.9)329 - 378 (3.35 - 3.85, 47.6- 5.47)

tualt6nkCaprcity, {US gal, lmp gal)50 (13.2, 11.01

En9in6ldle sDeed with headlight and cooling fan ofi rpm7501 50 (M/T: neut..ll750I 50 {A/T: E or E position}

Fast idle rpm1,600 i 2(x' lM/T: nsurr6l)l,eoo I 200 (A/T: E or E po6itioo)

ldl6 CO %0.1 max.

MEASUREMENTSTAM'Ad' IiEWISERVICE UMIT

clutch padslP6d6l height to lloor

SirokePedal play

Disengagement height to floor

164 (6.46)

130 - 140 (5.12 - 5.51)12 - 21 (0.47 - 0.83)83 (3.27) min.

Clutch sudace runout0.05 10.002) max,0.'15 (0.006t

clutch discRiv€t h€ad depthThickness

1.3 (0.05) min.8.4- 9.1 (0.3 - 0.36)0.2 (0.011

6.0 (0.24)

Pr6sur6 plat€WarpageOiaphragm spring linger alignment0.03 (0.001) mrx.0-6 (0.02) ma*0.15 (0.006)

0.8 (0.03)

{n+

3-7

Page 34 of 1413

![ACURA INTEGRA 1994 Service Repair Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38 ACURA INTEGRA 1994 Service Repair Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38](/img/32/56982/w960_56982-33.png)

Design Specifications

]TEMMETRICENGLISHNOIES

:' vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.380 mm

4.525 mm

'1,710 mm

1,335 mm

1,370 mm

2,570 mm

2,620 mm

't,475/1,470 mm

150 mm

Four (3 DOOR)

172.1in

178.1 in

67.3 in

52.6 in

101.2 in

103.1 in

5|8.1/57.9 in

Five (4 DOOR)

,rerght (usA)cross V€hicle Weight Rating {GVWR)3,680lbs

'le,ght {CANADA)Gross Vehicls Weight Rating {GVWR)1,670 kg

:\GINEType81881 engine

818C1 engine

Cylinder Arrangement

Bore and Stroke

Displacement

Compression Ratio

81881

818C1

81881

B18C I

81881

B 18C1

81881

818C1

engrne

engane

engrne

engine

engine

engine

engine

engine

L!brication Systom

OilPump Displacement

Wster Pump Displacement

FuelRequired

81881

B18C 1

81881

B 18C1

91881

engrne

engrne

engine

engine

engine

818C1 engine

Water-cooled, 4-stroke DOHC

gasoline engine

Watercooled, 4-stroke DOHC

VTEC gasoline engine

Inline 4-cylinder, transverse

81.0 x 89.0 mm

81.0 x 87.2 mm

1,834 cm3 (mf )

1,797 cm3 (m{)

3.19 x 3.50 in

3.19 x 3.43 in

112 cu-in

110 cu-in

9.2:1

10.0 : 1

Eelt driven, OOHC 4 valve per cylinder

Belt driven, DOHC VTEC

4 valve per cylinder

Forced and wet sump, trochoid pump

50, {53 US qt, 44 lmp qt)/minute'l

71 f {75 US qt, 62 lmp qt)/minute"

140 f (148 US qt, 123 lmp qt)/minute*!

140 f (148 US qt. 123 lmp qt)/minute*'

UNLEADED gasoline with 86 Pump

Octane Numb€r or higher

Premium UNLEADED gasoline wilh

91 Pump Octane Number or higher

STARTERTypo

NormalOutput

NominalVoltage

Hour Rating

Direction of Rotation

Weight

Gear reduction

1.4 kW

12V

30 seconds

Clockwise as viewed lrom g6ar end

3.7 k9 | 8.3lbs

CLUTCHClutch Type

Clutch Facing Area

M/TSingle plate dry, diaphragm spring

Torq!e converter

203 cm'� I 31 sq-in

TRANSMISSIONTransmission Type M/T

Primary Reduction

Synchronized 5-speed forward, 1 reverse

Electronically controlled

4-speed automatic. 1 rcverse

Diract 1 : 1

'1: At 6,000 engine

'2: At 7,600 engine

rpm

rpm

(cont'd)

3-17

Page 52 of 1413

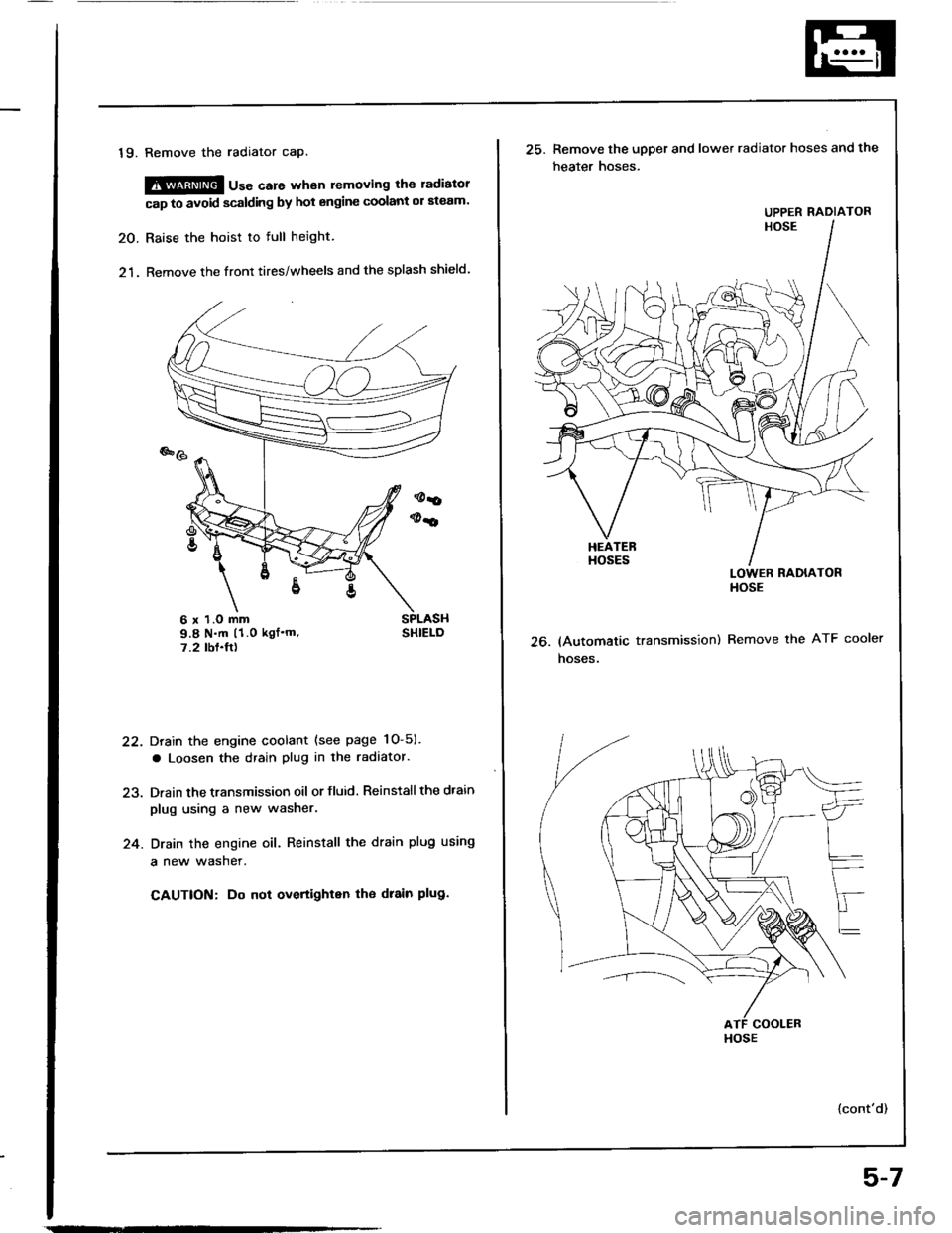

19. Remove the radiator cap.

@@ u"" care whan removing the ladiatol

cap to avoid scalding by hot engine coolant ol ateam.

20. Raise the hoist to full height.

21. Remove the front tires/wheels and the splash shield.

Drain the engine coolant (see page 1O-5).

a Loosen the drain plug in the radaator.

Drain the transmission oil or fluid. Reinstall the dtain

plug using a new washer.

Drain the engine oil. Reinstall the drain plug using

a new wasner.

CAUTION: Do not overtighten tho drain plug.

22.

24.

6 x 1.O mm9.8 N.m (1.0 kgf'm'7.2 tbf.ft)26.

25. Remove the upper and lower radiator hoses and the

heater hoses.

LOWER RADIATORHOSE

(Automatic transmission) Remove the ATF cooler

hoses.

{cont'd)

UPPER RADIATOR

HOSE

5-7

Page 89 of 1413

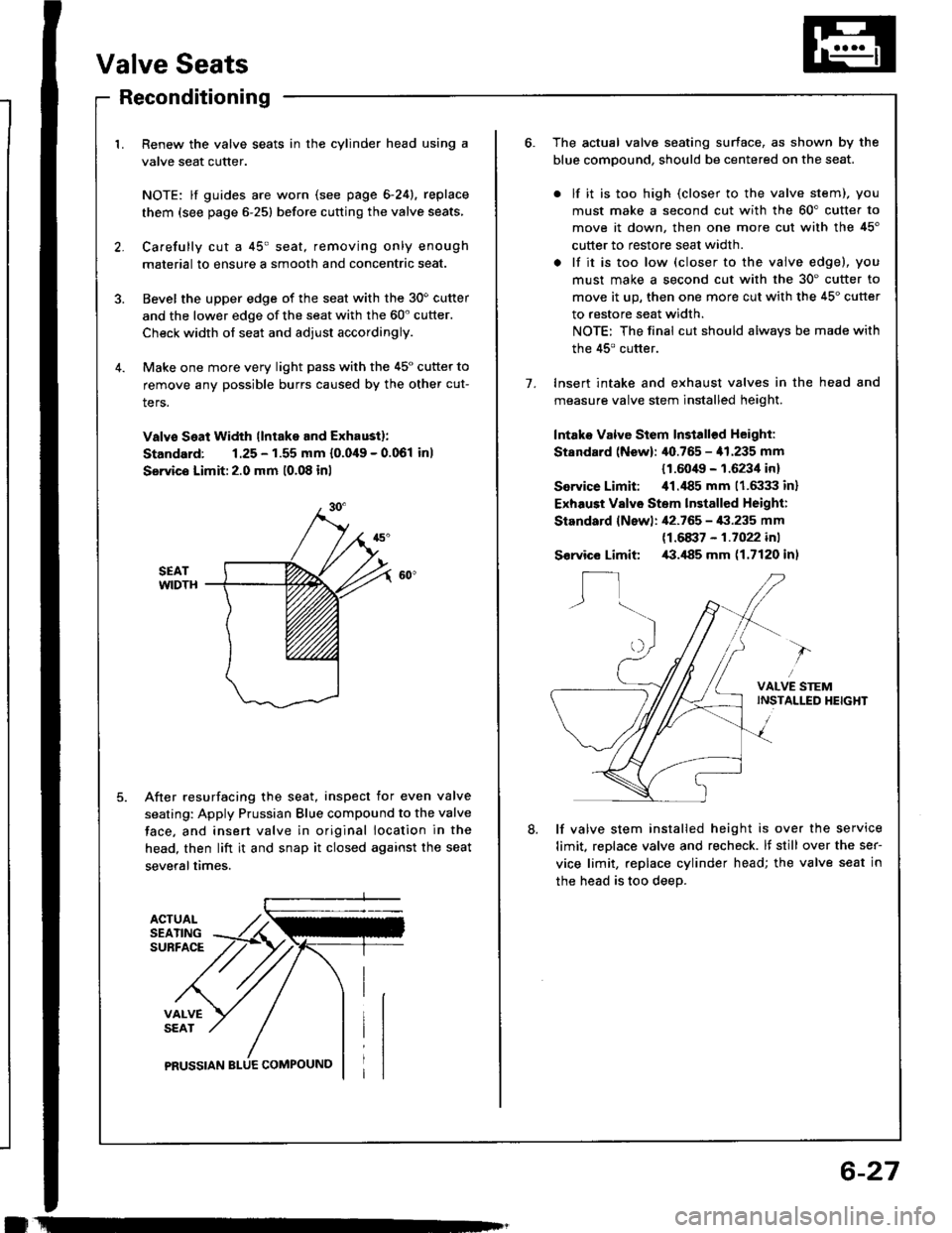

Valve Seats

ACTUALSEATINGSUBFACE

VALVESEAT

PRUSSIAN

Reconditioning

1. Renew the valve seats in the cylinder head using a

valve seat cutter.

NOTE: lf guides are worn (see page 6-24), replace

them (see page 6-251 before cutting the valve seats,

2. Carefully cut a 45' seat, removing only enough

material to ensure a smooth and concentric seat.

3. Bevel the upper edge of the seat with the 30o cutter

and the lower edge of the seat with the 60' cutter.

Check width of seat and adjust accordingly.

4. Make one more very light pass with the 45" cutter to

remove any possible burrs caused by the other cut-

ters.

Valvo Seat Width llntake and Exhaustl:

Standard: 1.25 - 1.55 mm {0.049 - 0.061 inl

Servics Limit:2.0 mm 10.08 inl

SEATWIDTH

After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue compound to the valve

face, and insert valve in original location in the

head, then lift it and snap it closed against the seat

severaltimes.

!

6-27

7.

The actual valve seating surface, as shown by the

blue compound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 60" cutter to

move it down, then one more cut with the 45'

cutter to restore seat width.

. lf it is too low (closer to the valve edgel, you

must make a second cut with the 30' cutter to

move it up, then one more cut with the 45" cutter

to restore seat width.

NOTE: The final cut should always be made with

the 45' cutter.

Insert intake and exhaust valves in the head and

measure valve stem installed height

Intako Valve Stem Install€d Height:

Standard (New): /$.765 - '11.235 mm

{1.604It - 1.6234 in}

Service Limit: ill.il85 mm (1.6:133 inl

Exhaust Valvo Stem lnstalled Height:

Standard {Newl: ,12.765 - i|:|.235 mm

11.6a37 - 1.1022 in1

Service Limit /B.il85 mm (1.7120 inl

lf valve stem installed height is over the service

limit, reDlace valve and recheck. lf still over the ser-

vice limit, replace cylinder head; the valve seat in

the head is too deeo.

8.

Page 90 of 1413

t

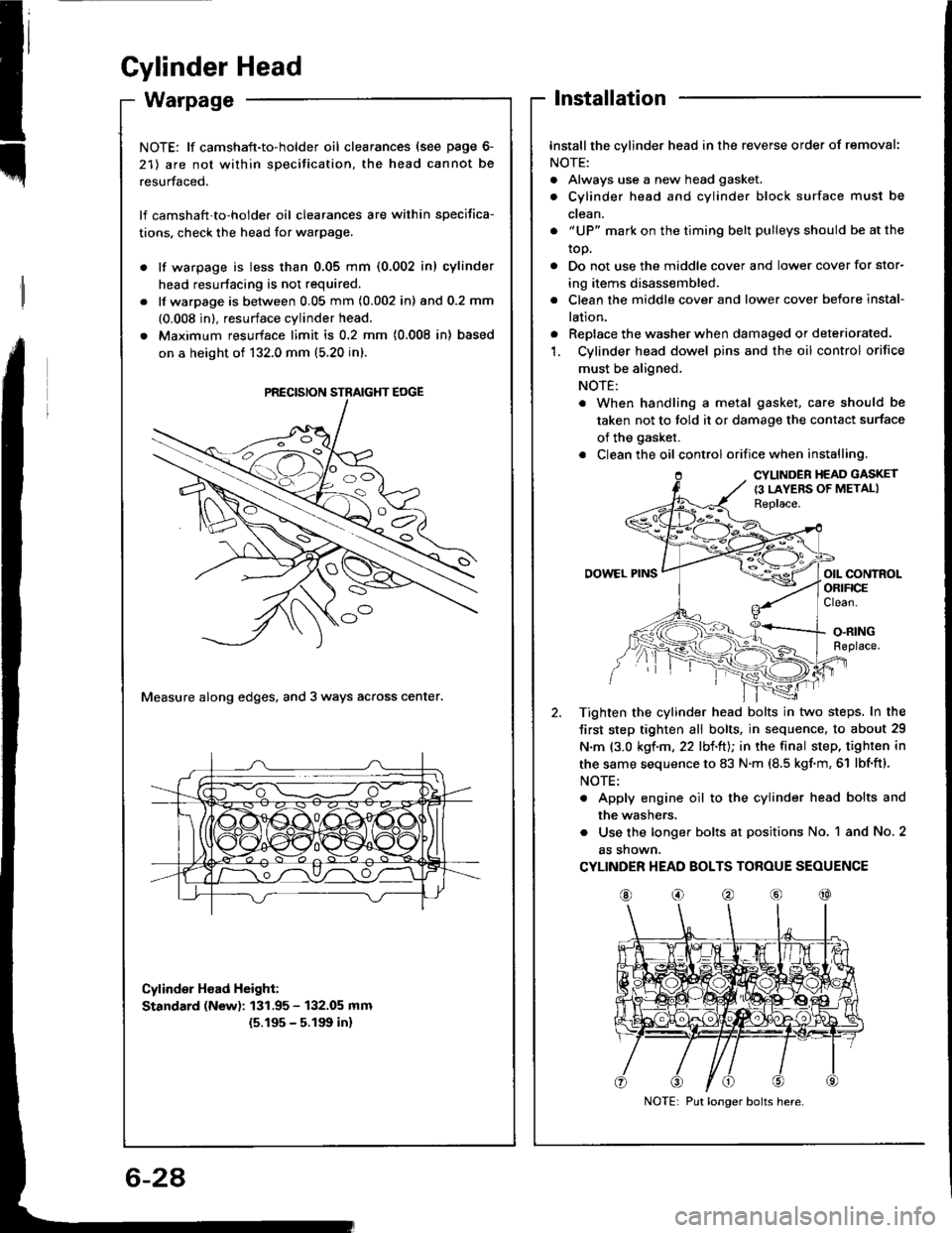

Gylinder Head

Installation

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cylinder block surface must be

ctean.

. "UP" mark on the timing belt pulleys should be at the

top.

. Do not use the middle cover and lower cover for stor-

ing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

. Replace the washer when damaged or deteriorated.'1. Cylinder head dowel pins and the oil control orifice

must be aligned,

NOTE:

. When handling a metal gasket, care should be

taken not to told it or damage the contact surface

of the gasket.

. Clean the oil control orifice when installing.

CYLINDER HEAD GASKET

{3 LAYERS OF METALIReplace.

OOWEL PINSorl coNtnolORIFICEClean.

O.RINGReplace.

Tighten the cylinder head bolts in two steps. In the

Jirst step tighten all bolts, in sequence, to about 29

N.m {3.0 kgf.m, 22 lbl.ltJ; in the final step, tighten in

the same sequence to 83 N.m (8.5 kgf.m, 61 lbf'ft).

NOTE:

. Apply engine oil to the cylinder head bolts and

the washers.

. Use the longer bolts at positions No. 1 and No. 2

as shown.

CYLINDER HEAD BOLTS TOROUE SEOUENCE

@o@@@

NOTE: lf camshaft-to-holder oil clearances (see page 6-

21) are not within specitication, the head cannot be

resurfaced.

lf camshaft'to-holder oil clearances are within specifica-

tions, check the head for warpage.

lf warpage is less than 0.05 mm (0.002 in) cylinder

head resurtacing is not required.

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in), resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Measure along edges, and 3 ways across center.

Cylinder Hoad Height:

Standard (New): 131.95 - 132.05 mm

{5.195 - 5.191t in}

PRECISION STRAIGHT EOGE

Put longer bolts here.

Page 133 of 1413

Valve Guides

Replacement (cont'dl

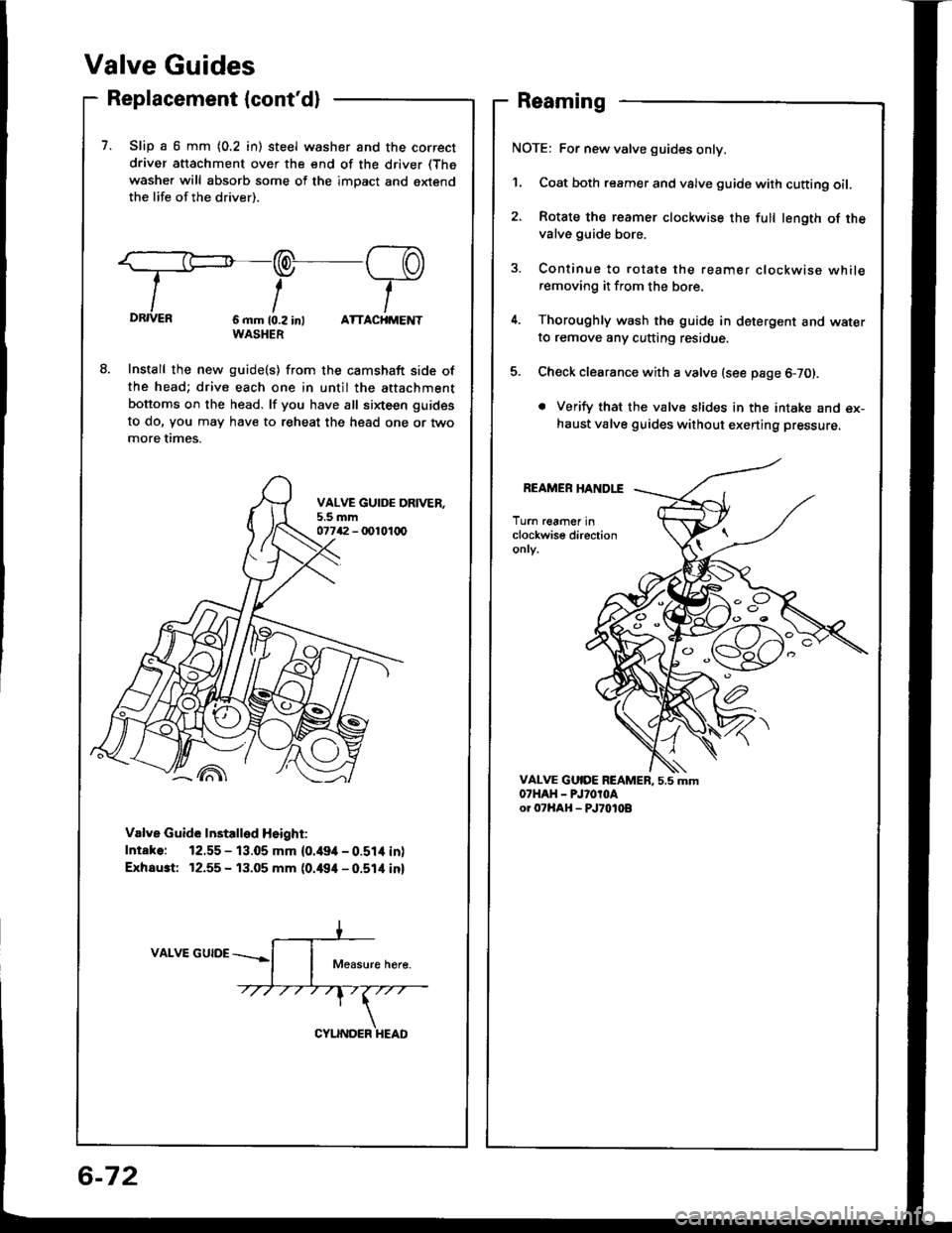

7. Slip a 6 mm {0.2 in) steel washer and the correct

driver attachment over the end of the driver (The

washer will absorb some of the imDact and extendthe life of the driver).

:=:-/--PDRIVER6 mm 10.2 int ATTACHMENTWASHER

Install the new guide(s) from the camshaft side ofthe head; drive each one in until the attachment

bottoms on the head. lf you have all sixteen guides

to do, Vou may have to reheat the head one or twomore times.

Valve Guide Installed Height:

Intake: 12.55 - 13.05 mm {0.49it - 0.51it inl

Exhaust 12.55 - 13.05 mm {0.494 - 0.514 inl

VALVE GUIDE

Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2, Rotate the reamer clockwise the full length of thevalve guide bore.

3. Continue to rotate the reamer clockwise whileremoving it from the bore.

4. Thoroughly wash the guide in detergent and waterto remove any cutting residue.

5. Check clearance with a valve (see page 6-70).

. Verify that the valve slides in the intake and ex-haust valve guides without exerting pressure.

REAMER HANDLE

Turn reamer inclockwise directiononry.

C'

o

a

-'{)

6-72

Page 134 of 1413

Valve Seats

Reconditioning

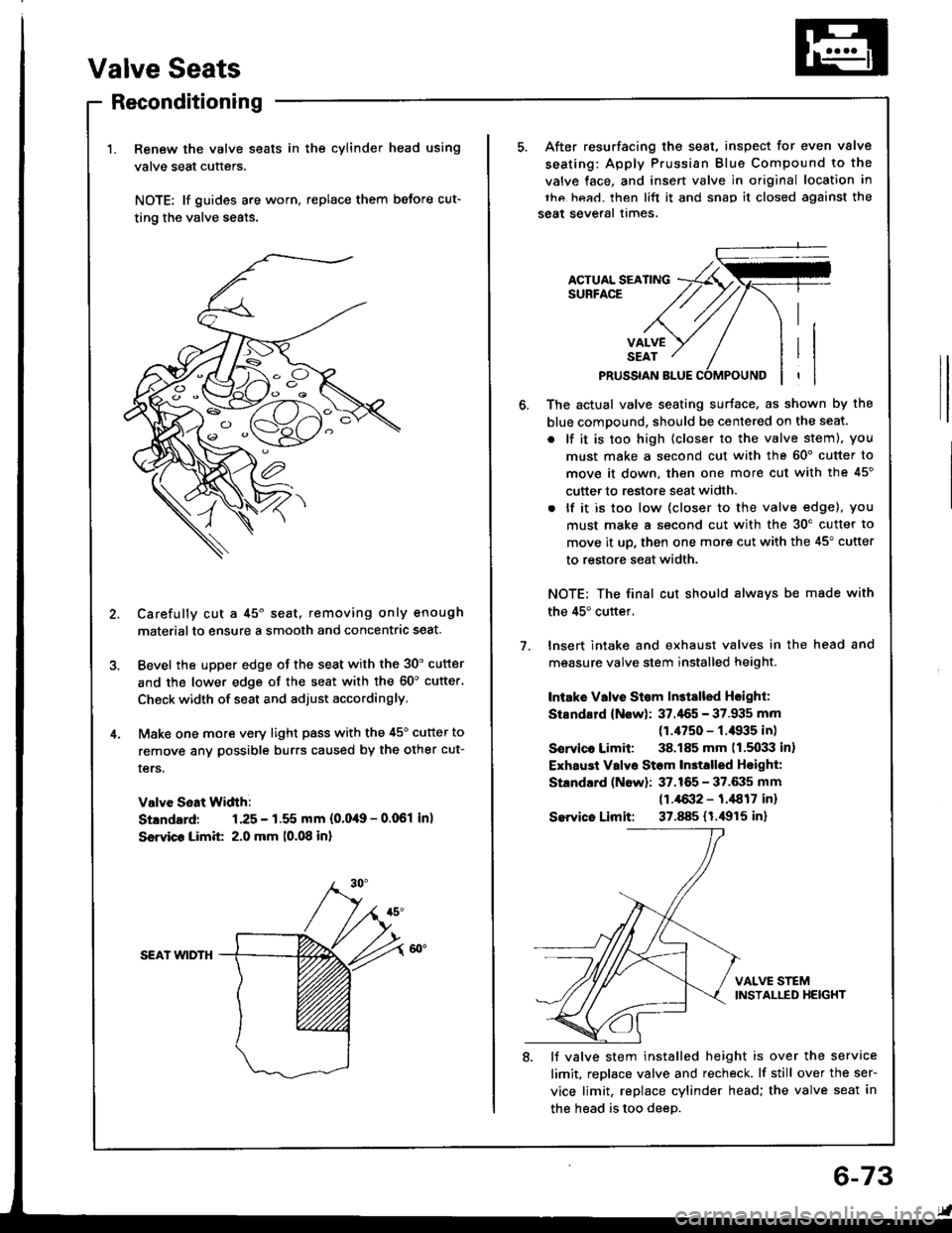

Renew the valve seats in the cylinder head using

valve seat cutters.

NOTE: lf guides are worn, replace them before cut-

ting the valve seats.

Carefully cut a 45o seat, removing only enough

materialto ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30' cutter

and the lower edge of the seat with the 60'cutter'

Check width of seat and adjust accordingly.

Make one more very light pass with the 45o cutter to

remove anv possible burrs caused by the other cut-

ters.

Valve Seat Width:

Stlndard: 1.25 - 1.55 mm {0.0,19 - 0.061 in)

Ssrvico Limit 2.0 mm 10.08 in)

SEAI wlDTH

After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue Compound to the

valve face, and insen valve in original location in

thc hea.l. then lift it and snap it closed against the

seat several times.

ACTUAL SEATINGSURFACE

VALVESEAT

PRUSSIAN BLUE

1.

The actual valve seating surface, as shown by the

blue compound, should be centered on the seat.

. lf it is too high (closer to the valve steml, you

must make a second cut with the 60' cutter to

move it down, then one more cut with the 45'

cutter to restore seat width.

. lf it is too low (closer to the valve edge), you

must make a second cut with the 30'cutter to

move it up, then one more cut with the 45" cutter

to restore seat width.

NOTE; The final cut should alwavs be made with

the 45'cuttef.

lnsert intake and exhaust valves in the head and

measure valve stem installed height.

Intake Vllve St€m ln3tslled Hsighl:

Stsndard (Now): 37.'155 - 37.935 mm

(1.4750 - f .il935 in)

Sorvico Limit: 38.185 mm 11.5033 in)

Exhaust Valvo Stom In3talled Hoight:

Standard (Now): 37.165 - 37.6:15 mm

11.4{X}2 - 1.,1817 inr

Sewico Limit: 37.885 (1.i1915 in)

VALVE STEMINSTALLED HEIGHT

8. lJ valve stem installed height is over the service

limit, replace valve and recheck. lf still over the ser-

vice limit. replace cylinder head; the valve seat in

the head is too deeD.

6-73