oil filter ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 12 of 1413

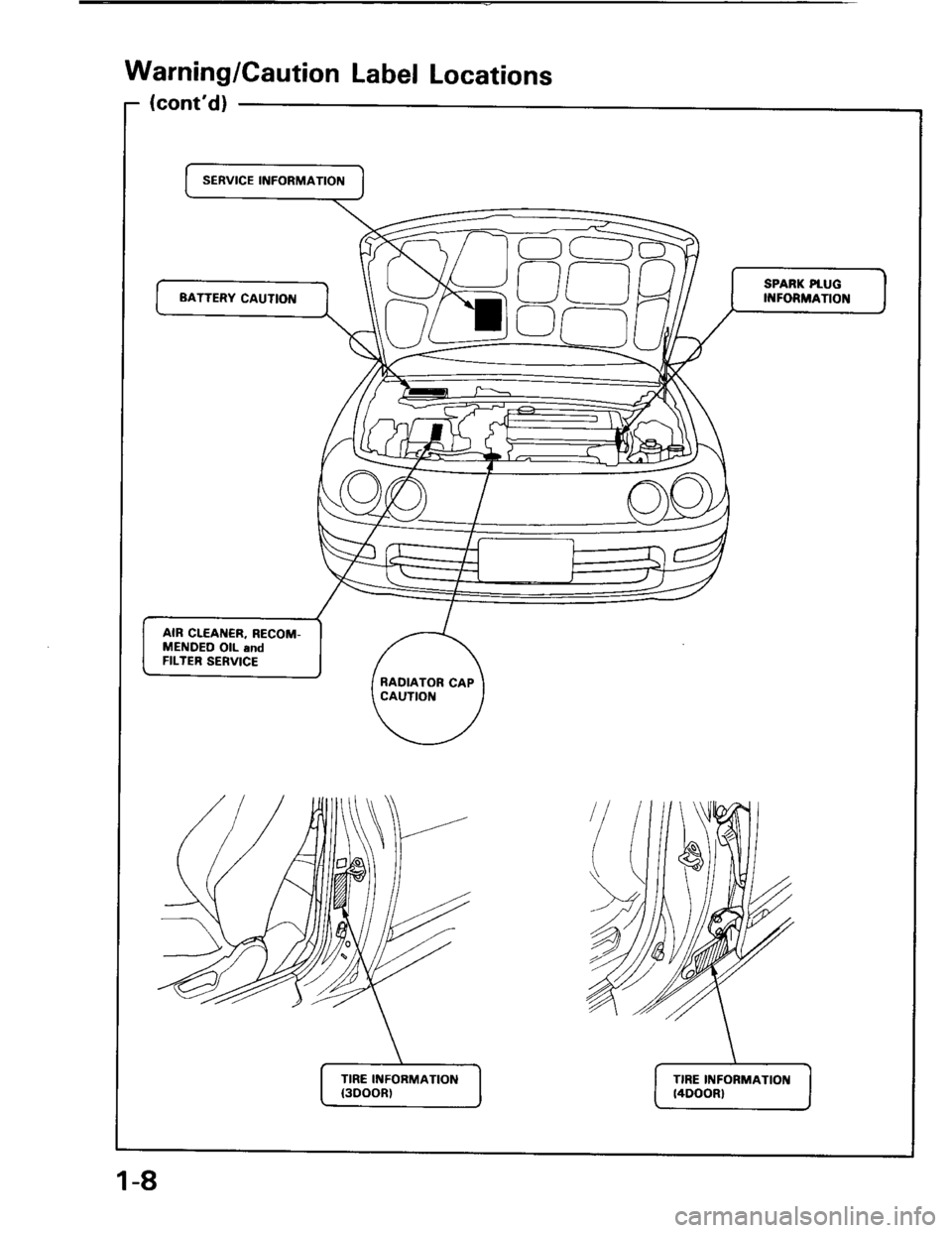

Warning/Caution Label Locations

(cont'd)

SERVICE INFORMATION

C)

SPARK PtUG

II{FORMATIONBATTERY CAUTION

AIR CLEAI{€R, RECOM-

MENDEO OIL and

FILTER SERVICE

RADIATOR CAP

CAUTIOI{

TIRE INFORMATION

{300()R)

TIRE INFORMATIOII

t4DOOR)

1-8

Page 23 of 1413

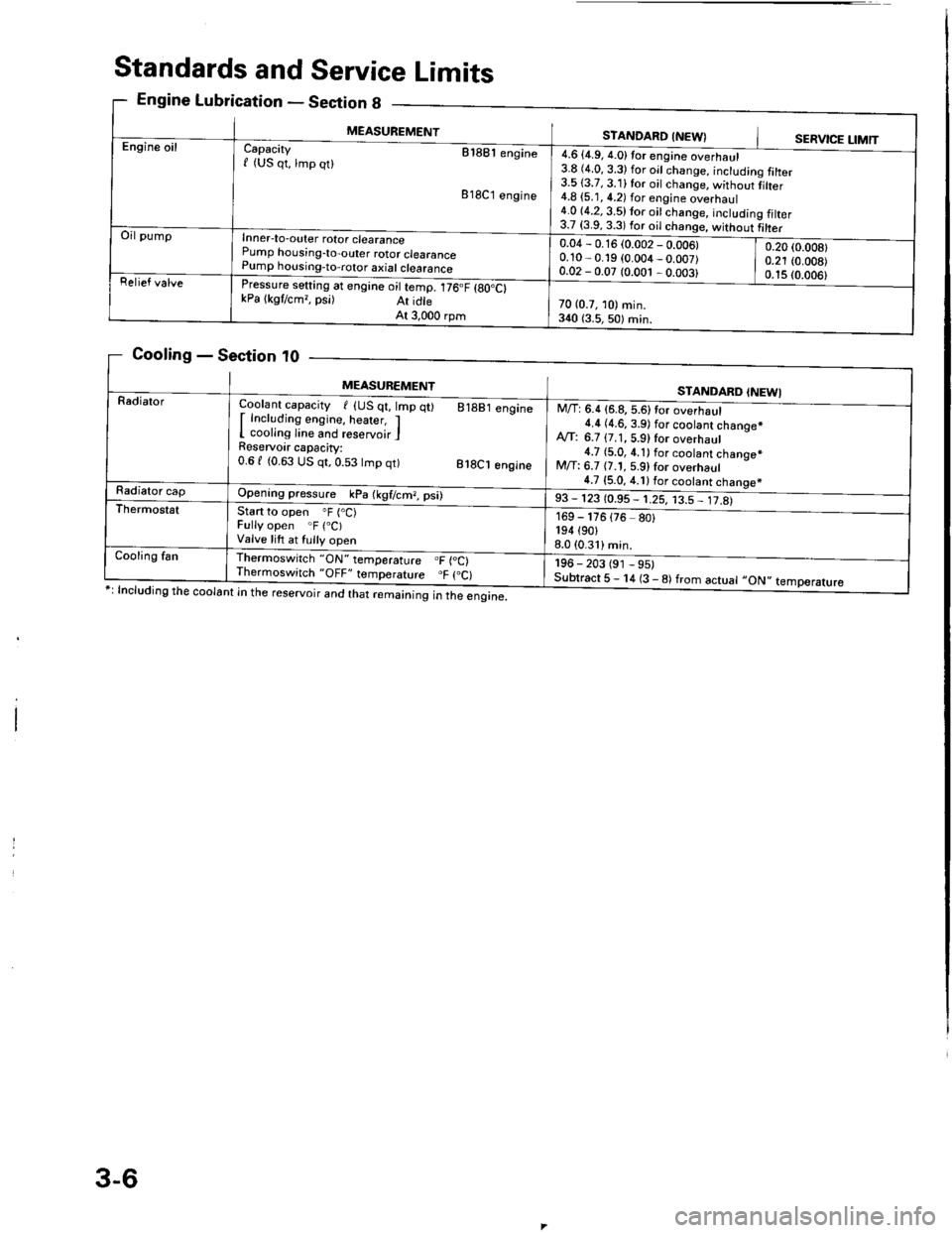

Standards and Service Limits

Engine Lubrication - Section g

Cooling - Section t0

ng the coolant in the reservoir and that remaining in the engine.

eclton u _

MEASUREMENTSTANDARD INEW}SERVICE LIMTT

g talter

tiher

g filter

Engine oilCapacity etaet engine

f (US qt, lmp qt)

818C1 engine

Inner-to-outer rotor clearance

Pump horising-to-outer rotor clearance

Pump housing-to,rotor axial clearance

rressure setting at engine oil temp. 176.F {gO.Ct

kPa lkgtcm,, psi) At idte

At 3,000 rpm

4.6 {4.9, 4.0}tor engine overhaul

3.8 (4.0, 3.3) for oil change, inctudin

3.513.7, 3.11 for oil change, without

4.8 {5.1, 4.2) for engine overhaul

4.0 (4.2, 3.5) lor oit change, includin

3.7 i3.9 3 3l fdr ^il .hi

Oil pump

0.04 - 0.16 (0.002 - 0.006)

0.10 - 0.19 (0.004 _ 0.007)

0.02 - 0.07 (0.001 , 0.003)

0.20 (0.008)

0.21 (0.008)

0.1s (0.006)

Relief valve

70 (0.7, 10) min.

3{0 {3.5,50) min.

MEASUBEMENTSTANDARD INEWI

RadialorCoolant capacity I {US qt, lmp

I Including engine, heater, I

I cooling line and reservoir I

Reservoir capacity:

0.61 (0.63 US qt,0.53 tmp qt)

q0 81881 engine

818C1 engine

Opening pressure kPa (kgf/cm?, psi)

start to open oF (.C)

Fully open .F (.C)

Valve lift at fully open

lhermoswitch "ON" temperature .F {oC)

Thermoswitch "OFF" temporature "F (.C)

M/T: 6.4 (6.8, 5.6)tor overhaul

4.4 (4.6.3.9) f6r s66lsn1gh66q.*

A,rf: 6.7 {7.1, 5.9) for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

M/T: 6.7 {7.1, 5.9} for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

,3 - 113 toss - trs, r3= Jt&

-

196 - 203 (91 - 95)

Subtract 5 - 14 (3 - 8) from actuat -ON',

169 - 176

194 (90,

8.0 (0.31)

{76 80}

temperature

Radiator cap

Thermostst

Cooling fan

3-6

Page 102 of 1413

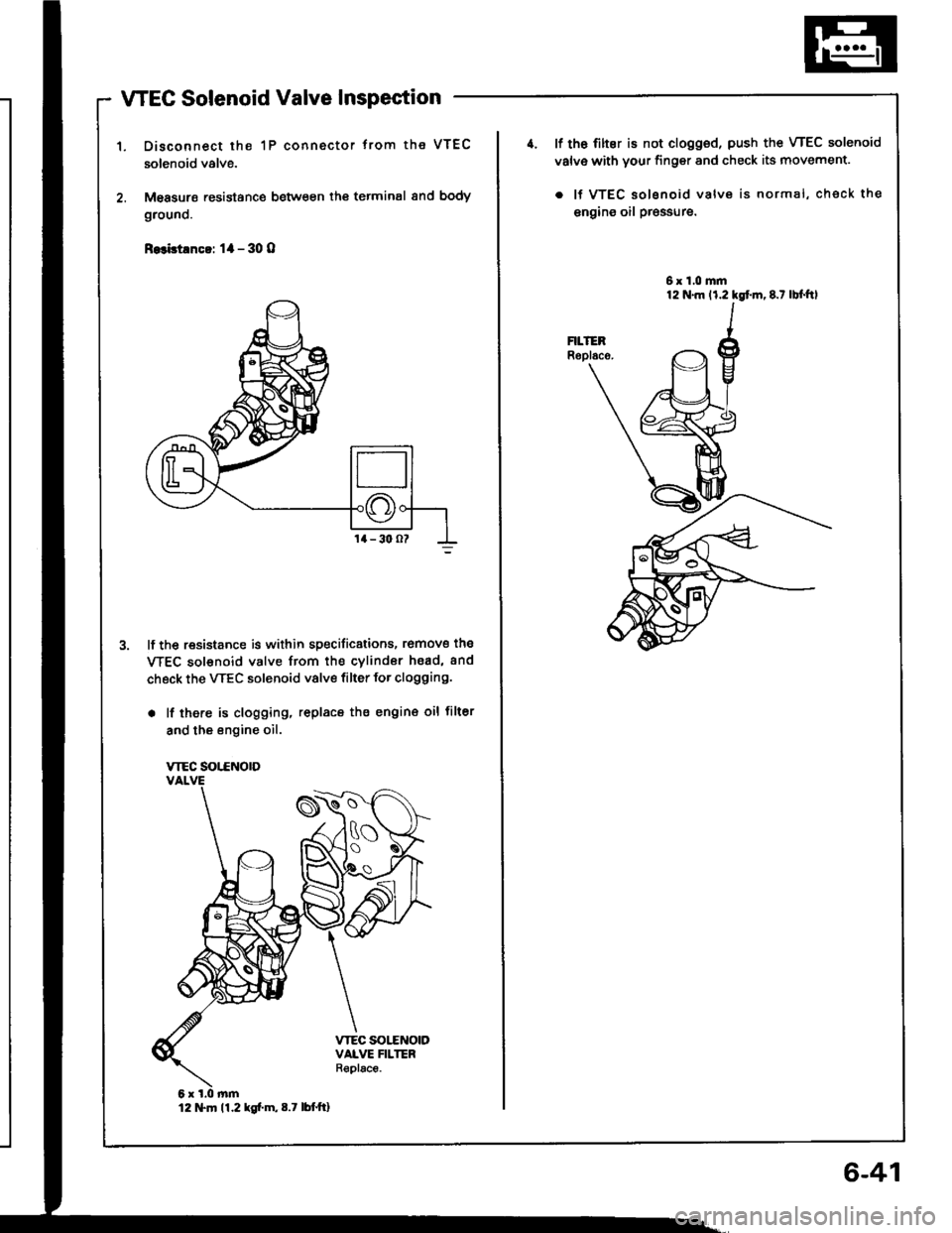

WEC Solenoid Valve Inspection

Disconnect the 1P connector trom the VTEC

solenoid valve.

M€asurs resistance between th€ terminal 8nd body

grouno.

R.3bt!nc!: 1l - 30 O

lf the resistance is within specificstions, romove the

WEC sol€noid valve from the cvlindor hsad, and

check the VTEC solenoid valve filter for clogging.

. lf there is clogging, replacs the engin€ oil filter

and the engine oil.

VTEC SOT.CNOTD

12 tTln 11.2 kg[.m,8.7 lbttt]

6-41

4. lf th6 filter is not clogged, push the VTEC solenoid

valv€ with your finger and check its movement.

. lf VTEC solsnoid valve is normal, check the

engins oil pr€ssure.

6x1.0mm

Page 167 of 1413

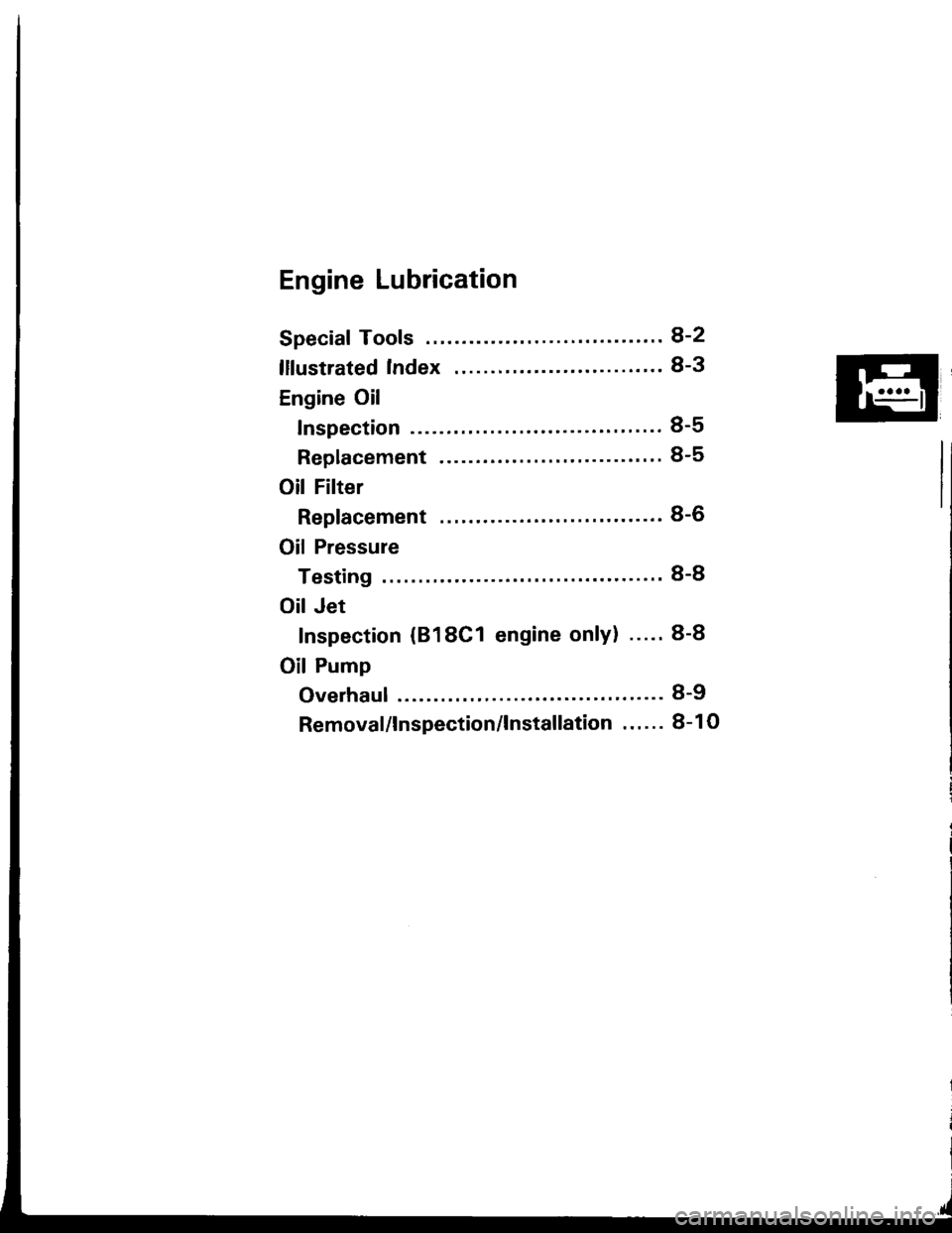

Engine Lubrication

Speciaf Tools ........ ........8-2

lllustrated Index ........ ."' 8-3

Engine Oil

Inspection ..........."'...' 8-5

Replacement ................ " ".......'.'. 8-5

Oil Filter

Replacement ...................... "....... 8-6

Oil Pressure

Testing ....' 8-8

Oil Jet

Inspection {818C1 engine only} ..... 8-8

Oil Pump

Overhaul ... 8-9

Removal/lnspection/lnstallation . . ' . . . 8- 1 O

Page 168 of 1413

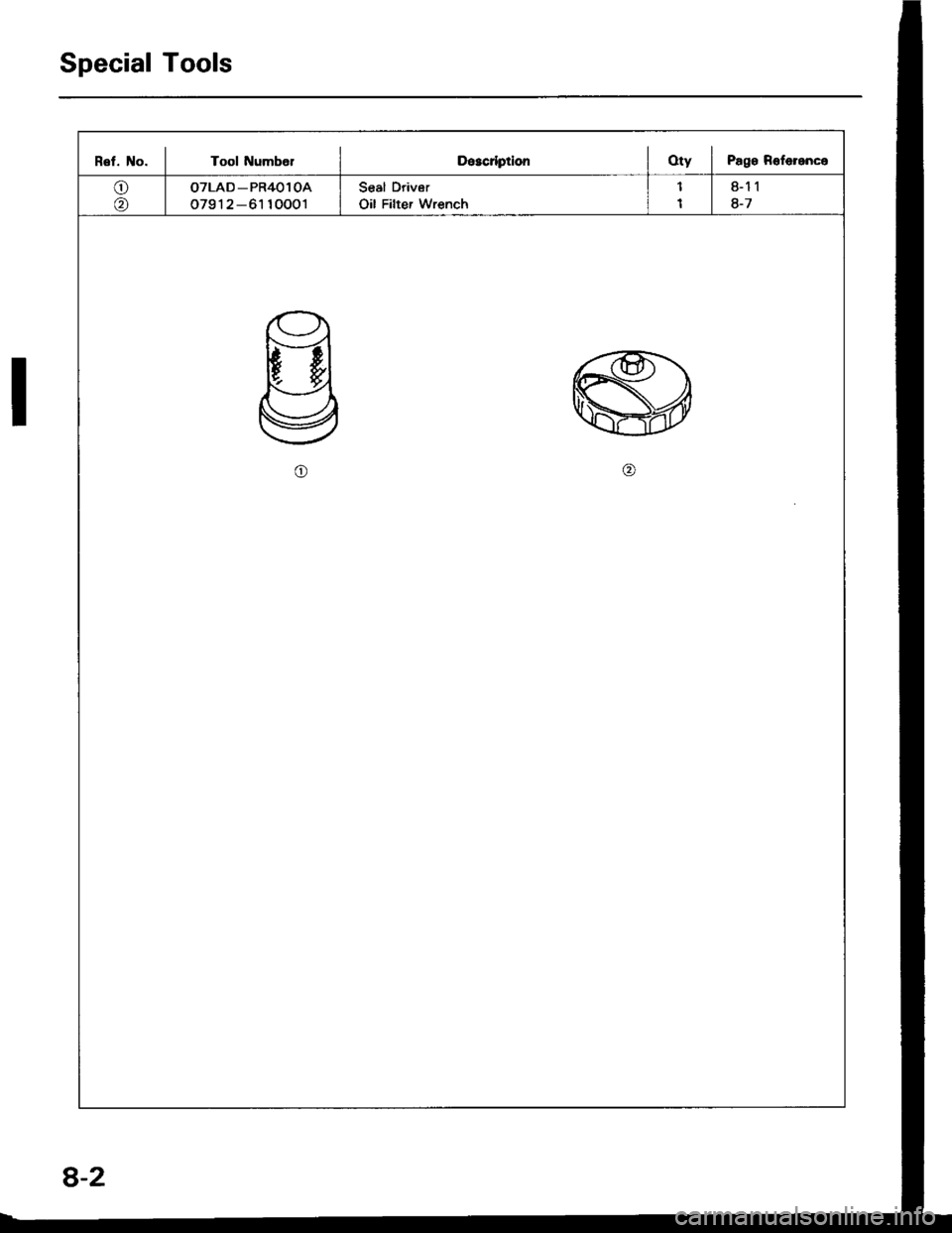

Special Tools

Rel. No. I Tool NumbelDescrlptionOty I Pago Roferenco

o

@

OTLAD _ PR4Ol OA

o791 2 -61 10001

Seal Driver

Oil Filter Wrench

8-11

8-7

o

8-2

Page 170 of 1413

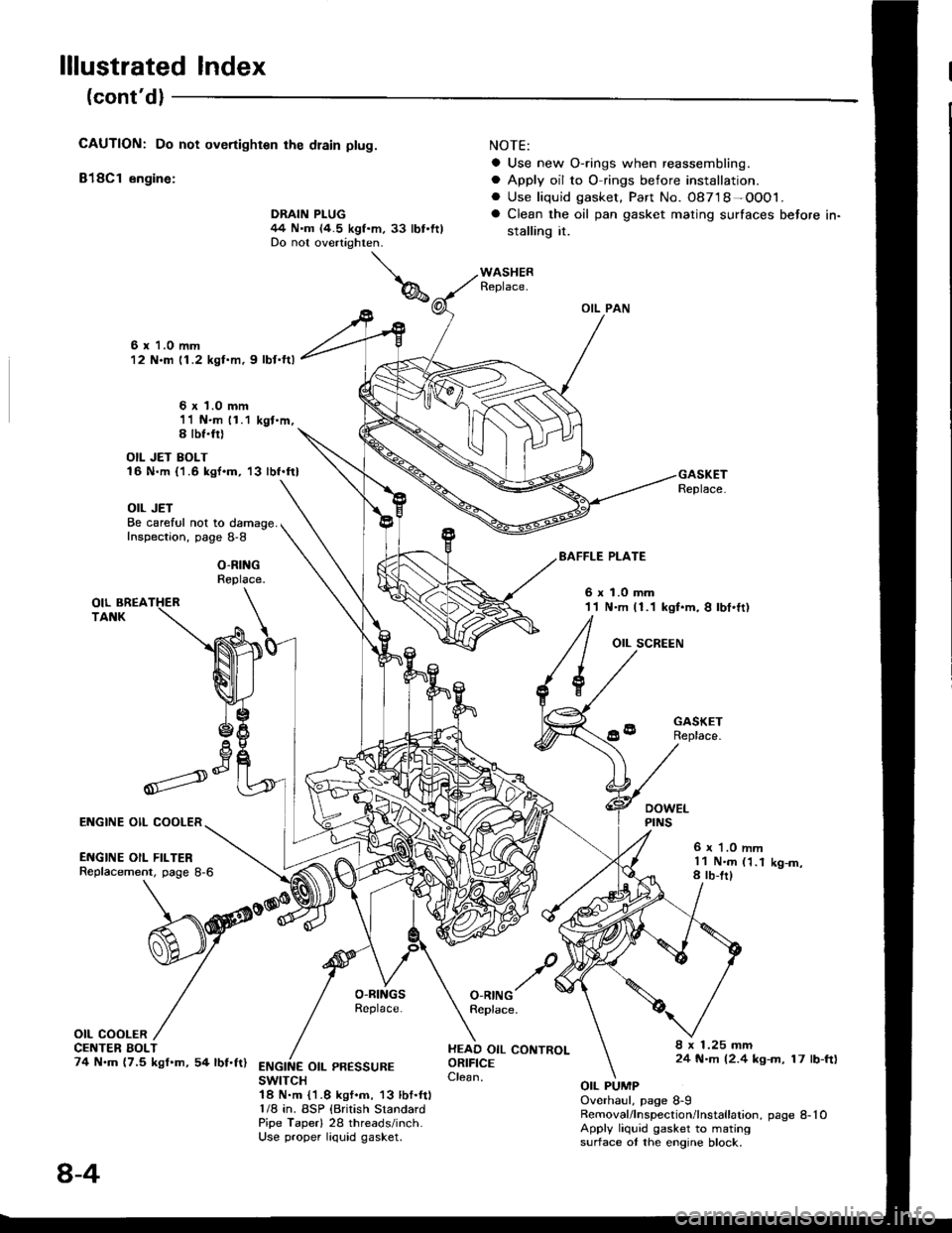

lllustrated Index

(cont'dl

CAUTION: Do not overtighten rhe dlain ptug.

818C1 engine:

NOTE:

a Use new O-rings when reassembling.

a Apply oil to O rings before installation.. Use liquid gasket. Part No. 08718-OOO1.

a Clean the oil pan gasket mating surfaces before in-

stalling it.

OIL PAN

Replace.

6 x 1.0 mm12 N.m 11.2 kgl.m, 9 lbf.ftl

6 x 1.0 mm11 N.m 11.1 kgt.m,S lbf.fil

OIL JET BOLT16 N.m {'1.6 kgf.m, '13 lbf.ft}

OIL JETBe careful not to damage.Inspection, page 8-8

O-RINGReplace.

EAFFLE PLATE

6xl.0mm11 N.m (1.1 kgt.m, I lbt.ft)

OIL SCREEN

GASKETReplace.

6 r '1.0 mml1 N.m (1.18 rb-trlK9-m,

O-RINGReplace.

HEAD OIL CONTROLORIFICEClean.

8 x 1.25 mm24 N.m (2.4 kg-m, 17 lb-ft)ENGINE OIL PR€SSUREswtTcH1A N.m {1.8 kgf.m, 13 lbf.ft)1/8 in. BSP {British StandardPipe Taperl 28 threads/inch.Use proper liquid gasket.

OIL PUMPOverhaul, page 8-9Removal/lnspection/lnstallation, page 8-10Apply liquid gasket to matingsurface ot the engine block.

Il

,--)e6V

ENGINE OIL COOLER

ENGINE OIL FILTERReplacement, page 8-6

OIL COOLERCE TER BOLT74 N.m (7,5 kgf.m, 54 lbf.ft)

DRAIN PLUG44 N.m (4.5 kgf.m, 33 lbt.ftlDo not overtighten.

8-4

Page 171 of 1413

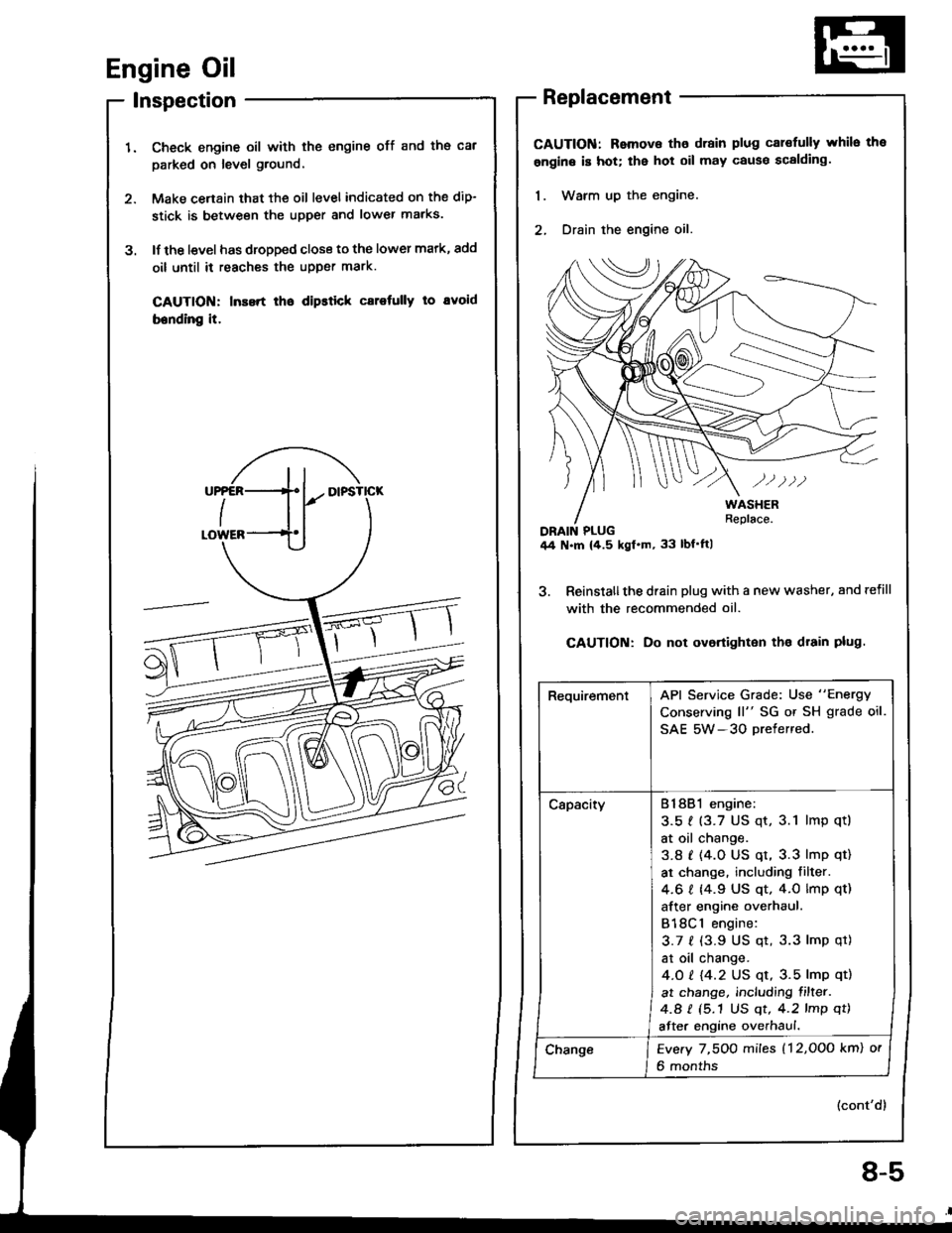

Engine Oil

lnspection

Check engine oil with the engine off and ths cal

parked on level ground,

Make cenain that the oil level indicated on the dip-

stick is between the upper and lower marks.

lf the l€vel has dropped close to the lower mark, add

oil until it reaches the upper mark.

CAUTION: Inssrt lho dipstick carotully to avoid

bending it.

3.

Replacement

CAUTION: Remova tho drain plug cal€fully whilo the

ongine is hot; the hot oil may cause scalding.

1. Warm up the engine.

2, Drain the engine oil.

3. Reinslallthe drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not ovortighton tho drain plug.

(cont'd)

RequirementAPI Service Grade: Use "Energy

Conserving ll" SG or SH grade oil.

SAE 5W-3O Drefered.

CapacityB18B1 engine:

3.51 (3.7 US qt, 3.1 lmp qtl

at oil change.

3.8 t (4.0 US qt, 3.3 lmp qt)

at change. including filter.

4.6 I 14.9 US qt. 4.0 lmp qt)

after engine overhaul.

B18Cl engine:

3.7 f (3.9 US qt, 3.3 lmp qt)

at oil change.

4.O t 14.2 US qt, 3.5 lmp qt)

at change, including filter.

4.a I (5.1 US qt, 4.2 lmp qt)

after engine overhaul.

ChangeEvery 7,5OO miles (12,OOo km) or

6 months

8-5

Page 172 of 1413

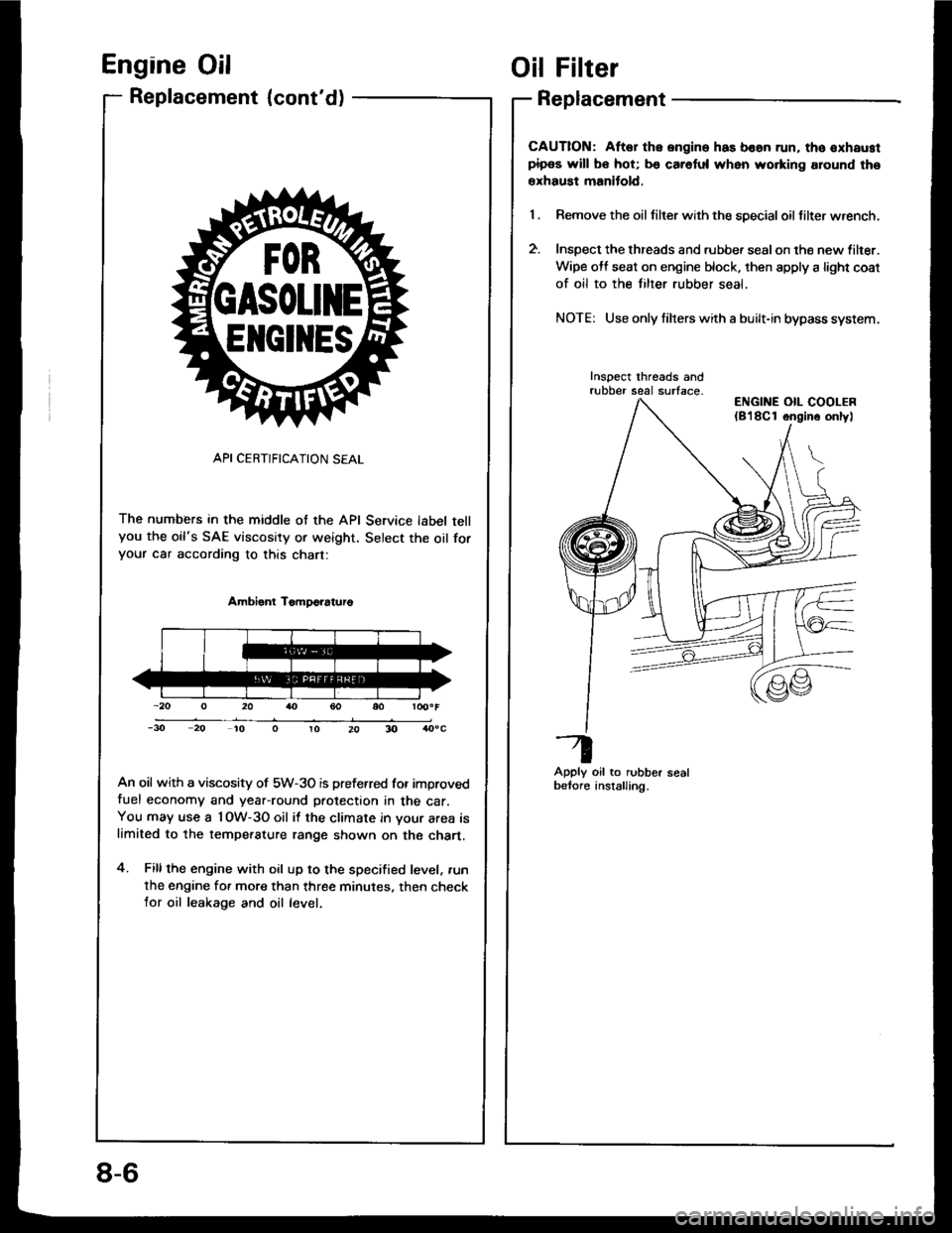

Englne Oil

Replacement {cont'd)

API CERTIFICATION SEAL

The numbers in the middle of the API Service label tellyou the oil's SAE viscosity or weight. Select the oil foryour car according to this chart:

Ambient TomDo?aturo

An oil with a viscosity of 5W-3O is preferred for improvedfuel economy and year-round protection in the car.You may use a l OW-3O oil it the climate in your area islimited to the tempe.ature range shown on the chart.

4. Fillthe engine with oil up to the specified level, .un

the engine for more than three minutes. then checklor oil leakage and oil level.

ElrclltEs

Oil Filter

Replacement

CAUTION: Aftar the ongine has boan run. tho oxhaustpipos will bo hot; b€ caretul when wo.king around tho

erhaust manitold,

Remove the oil tilter with the special oil filter wrench.

Inspect the threads and rubbe. sealon the new lilter.

Wipe off seat on engine block. then apply a light coat

of oil to the tilter rubber seal,

NOTE: Use only filrers with a built-in bypass system.

Inspect threads andrubber seal surface-

Apply oil to rubber sealbetore anstalling.

ENGINE OIL COOLER(8'l8Cl ongino onlyl

8-6

Page 173 of 1413

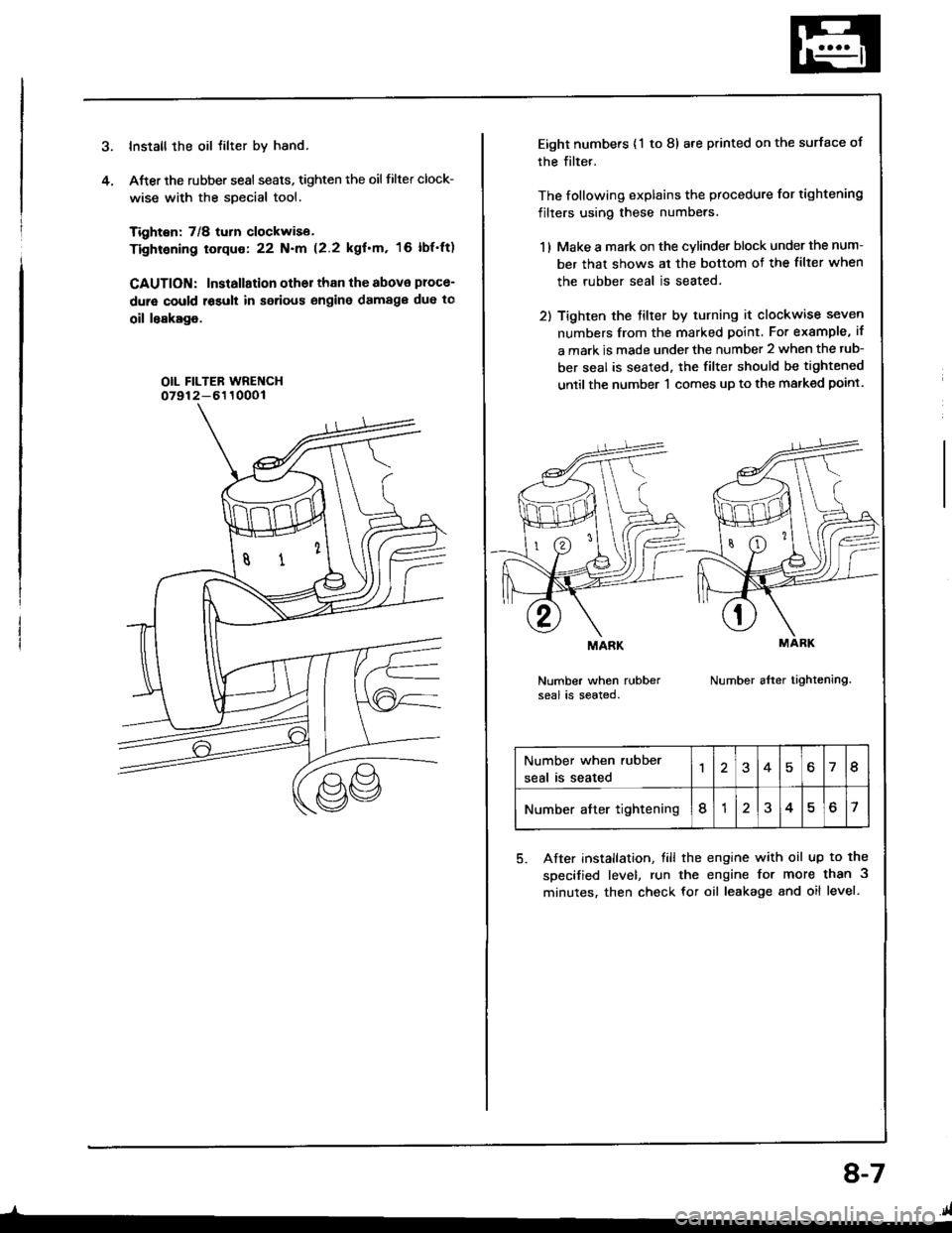

Install the oil tilter by hand.

After the rubber sesl seats, tighten the oil filter clock-

wise with the special tool.

Tighten: 7/8 turn clockwise.

Tightening torque: 22 N.m (2.2 kgf'm, 16 lbf'ft)

CAUTION: Installation other than the abova ploce-

dure could r6suh in serious engine damag€ due to

oil leakage.

OIL FILTEB WRENCH07912-6110001

4.

_l-

8-7

Eight numbers {'l to 8) are printed on the surface of

rhe filter.

The following explains the procedure for tightening

filters using these numbers.

1 ) Make a mark on the cvlinder block under the num-

ber that shows al the bottom of the filter when

the rubber seal is seated.

2) Tighten the tilter by turning it clockwise seven

numbers from the marked point. For example, if

a mark is made under the number 2 when the tub-

ber seal is seated. the filter should be tightened

until the number 'l comes up to the marked point.

Number when rubberseal is seated.Number after tightening.

MARK

Number when rubber

seal is seated46I

Number after tightening8?o7

5. After installation, till the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage and oil level.

.41

Page 291 of 1413

Fuel Supply System

Fuel Injectors

- --l- - \-l-l

116l- -ltc l-/---r- / ---i- \

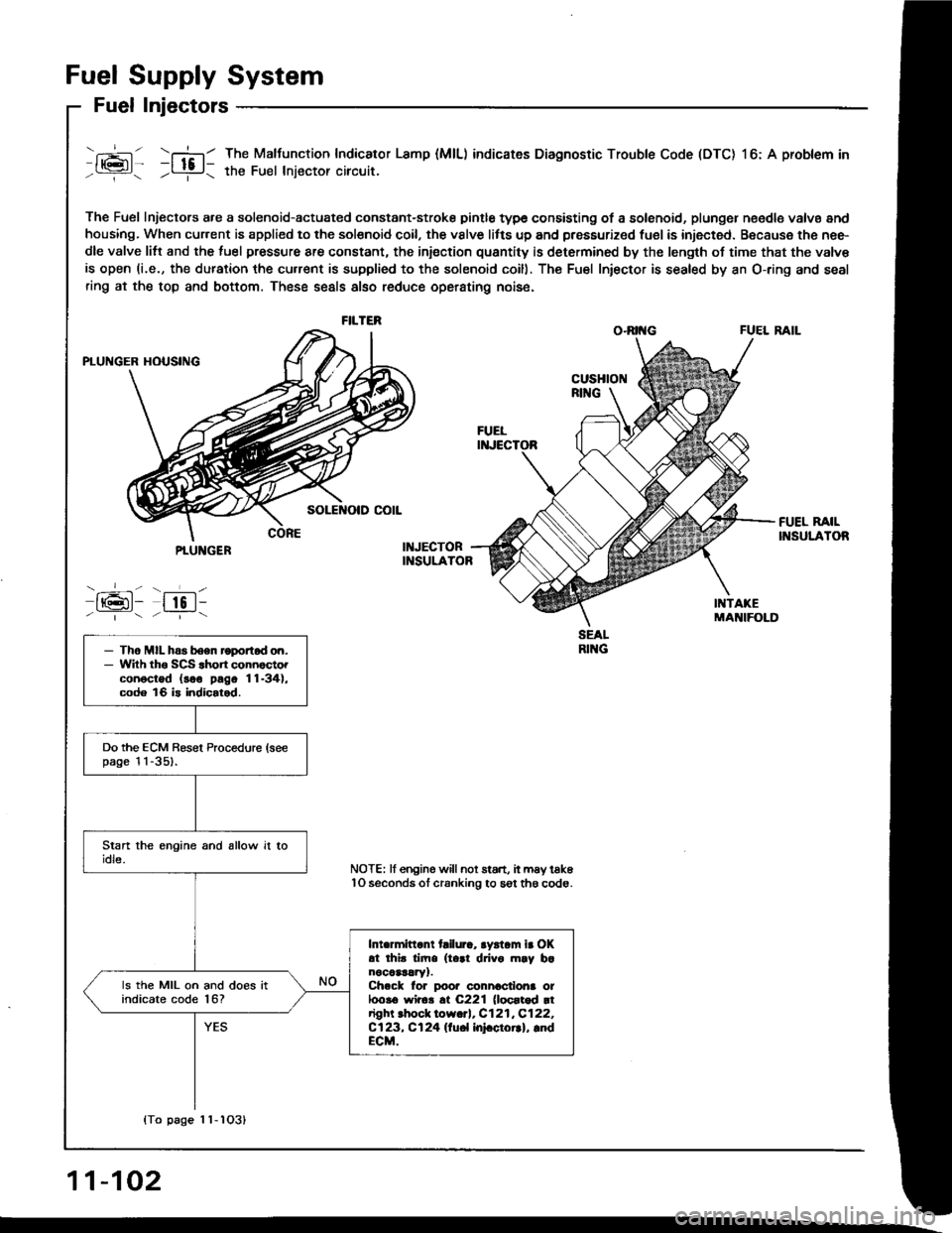

The Fuel Injectors a.e a solenoid-actuated constant-stroke pintle type consisting of a solenoid, plungel n€edle valvs and

housing. When cur.ent is applied to the solsnoid coil, the vslve litts up and pressurized fuel is injected. Because the nee-

dle valve litt and the luel pressure are constant, the iniection quantity is determined by the length of time that the valv€

is open (i.e., the duration the cu.rent is supplied to the solenoid coill. The Fu€l Iniector is sealed by an O-ring and seal

ring at the top and bottom. These seals also reduce operating nois6.

O.RII{G FUEL RAIL

The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) l6: A problem in

the Fuel lniector circuit.

FILTER

PTUNGER

-_-- - ___L-

IrGl- lto l--|.---:_-

- Tho MIL has boen roportod on.- Wilh tho SCS .hon connocto.conoctod (soo pago 11-34),code 16 is indicalod.

Do the ECM Besel Procedure (seepage l l -351.

Intermittant tailura, aystam ir OKat thir tim. (t..1 drivo m.y b.nocaar!ry1.Ch.ck lor poor connactiona ot100!6 wir6!.t C221 (loortod rtright .hock low.rl, C121,C122,Cl23, Cl24 llu6l InFctorrl, lndECM.

ls the MIL on and does itindicate code l6?

NOTE: lf engine willnot start, it may tak6lO seconds ol cranking to sgt th6 code.

{To page 1 1-1O31

11-102