cla ACURA INTEGRA 1998 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 594 of 1680

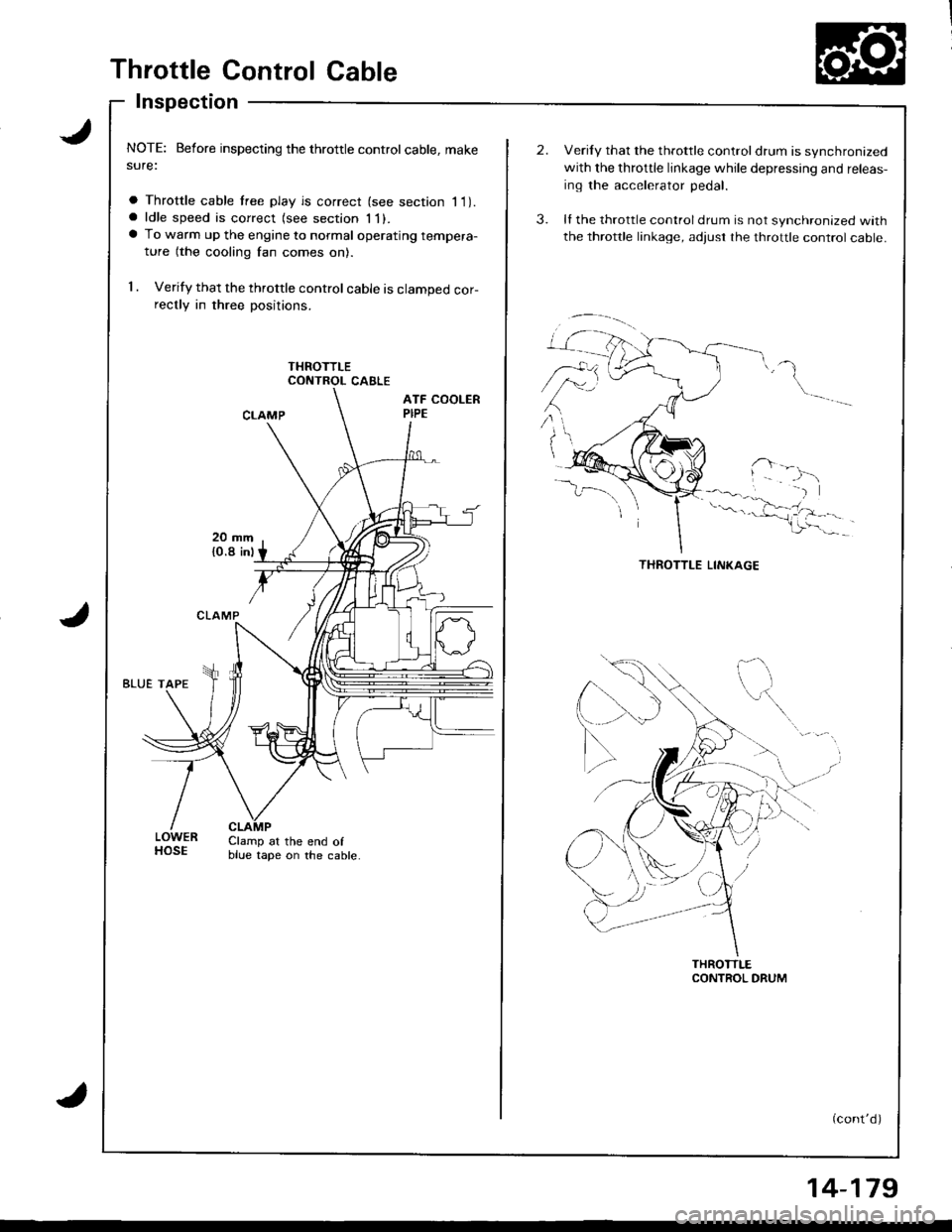

Throttle Control Cable

Inspection

NOTE: Before inspecting the throttle controlcable, makesure:

a Throttle cable tree play is correct (see section I 1).a ldle speed is correct (see section 1l).a To warm up the engine to normal operating tempera-

ture (the cooling fan comes on).

1 . Verify that the throttle control cable is clamped cor-rectly in three positions.

CONTROL CABLE

LOWERHOSEClamp at the end ofblue tape on the cable.

Verily that the throttle controldrum is synchronized

with the throttle linkage while depressing and releas-

ing the accelerator pedal.

ll the throttle control drum is not synchronized with

the throttle linkage, adjust rhe throttle control cable.

(cont'd)

14-179

Page 596 of 1680

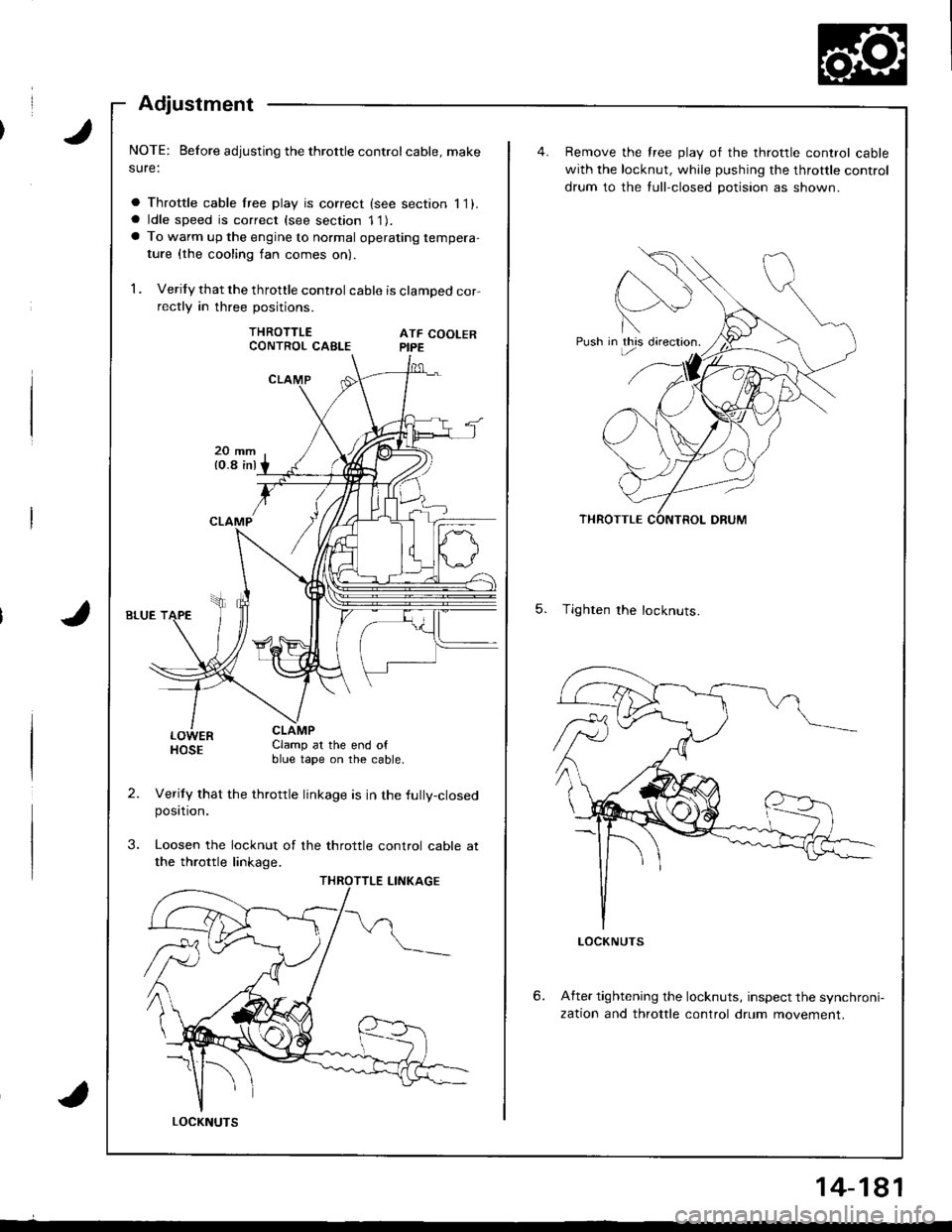

Adjustment

NOTE: Before adjusting the throttle controlcable, make

sure:

a Throttle cable lree play is correct (see section 11).a ldle speed is correct (see section 11).a To warm up the engine to normal operating tempera-

ture {the cooling fan comes on)

1 . Verify that the throttle control cable is clamped correctly in three positions.

THROTTLEATF COOLERPIPE

LOWERHOSEClamp at the end ofblue tape on the cable.

Verily that the throttle linkage is in the fully-closedposttron.

Loosen the locknut of the throttle control cable at

the throttle linkage.

CONTROL CABLE

LOCKNUTS

14-181

Push in this directron.

Remove the free play of the throttle control cable

with the locknut, while pushing the throttle control

drum to the tull-closed potision as shown.

5. Tighten the locknuts.

6.After tightening the locknuts, inspect the synchroni-

zation and throttle control drum movement.

Page 635 of 1680

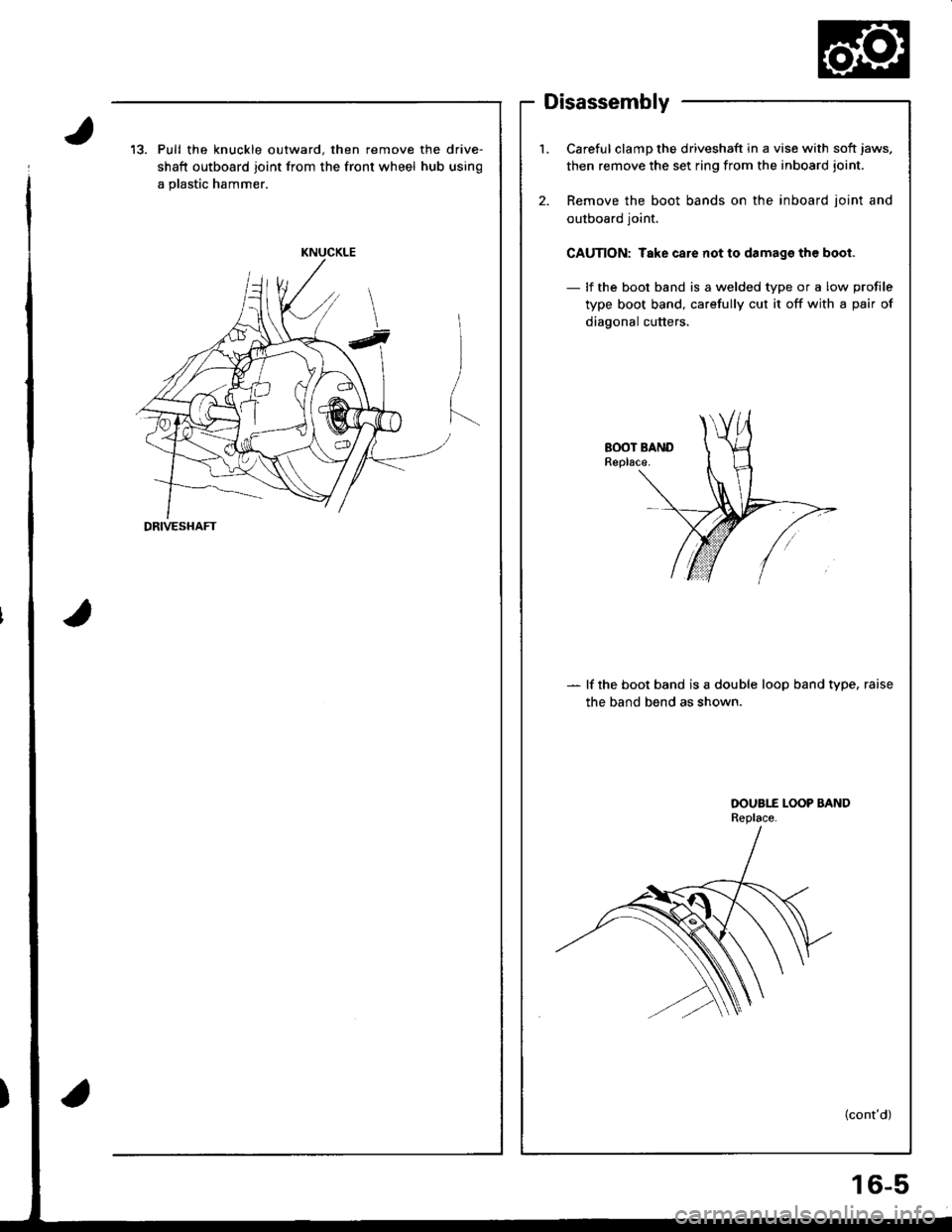

Disassembly

13. Pull the knuckle outward. then remove the drive-

shaft outboard joint from the front wheel hub using

a plastic hammer.

KNUCKLE

DRIVESHAFT

l.Careful clamp the driveshaft in a vise with soft jaws,

then remove the set ring from the inboard joint.

Remove the boot bands on the inboard ioint and

outboard joint.

CAUTION: Take care not to damags th€ boot.

- lf the boot band is a welded type or a low profile

type boot band, carefully cut it off with a pair of

diagonal cutters.

2.

- lf the boot band is a double loop band type, raise

the band bend as shown.

OOUBI-E LOOP BANDReplace.

(cont'd)

16-5

Page 636 of 1680

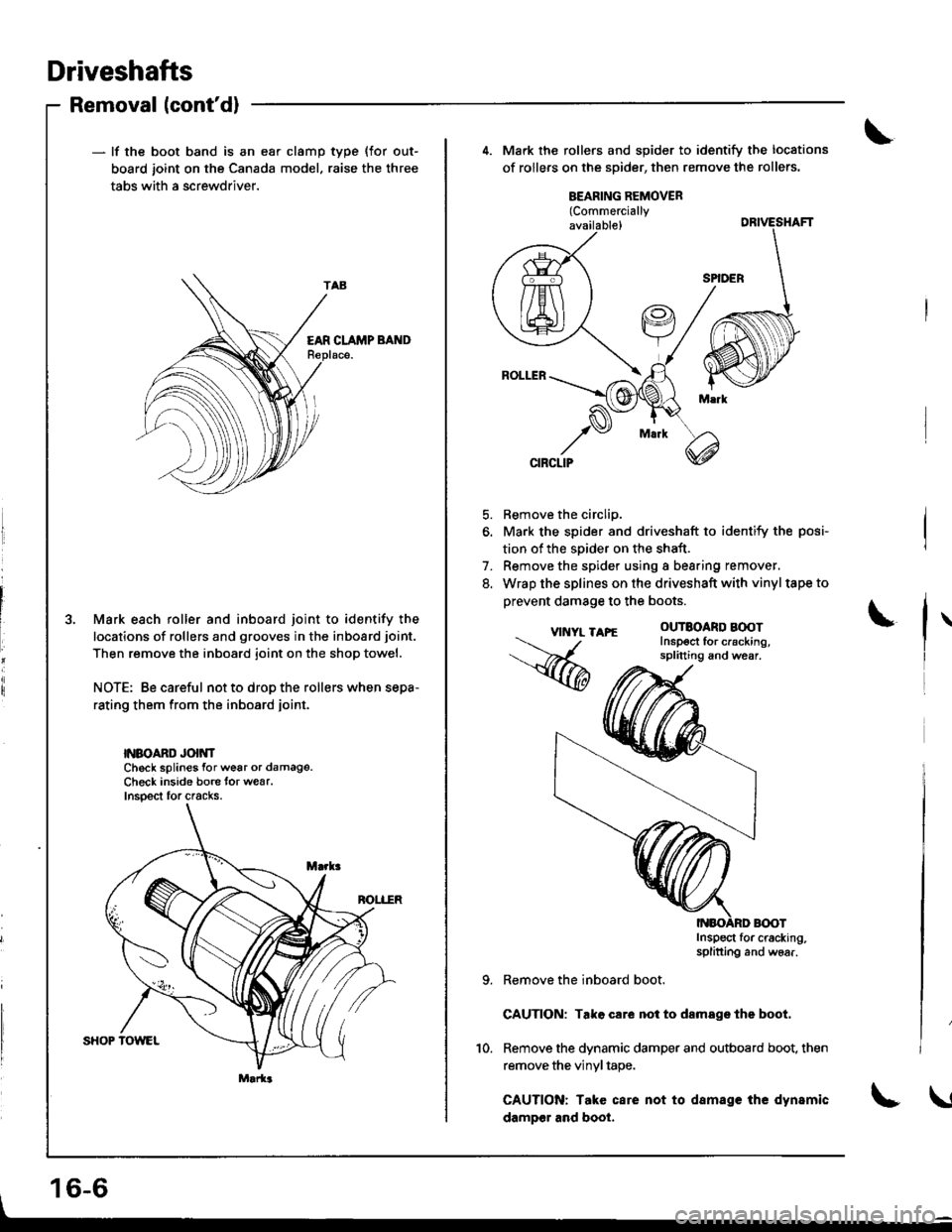

Driveshafts

Removal lcont'd)

- lf the boot band is an ear clamp

board joint on the Canada mode

tabs with a screwdriver.

type {for out-

raise the three

EAR CLAMP BAND

3. Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-

rating them from the inboard joint.

NBOAND Jo|NNCheck splines for wear or damage.Check inside bore lor wear.lnsoect for cracks.

Marla

4. Mark the rollers and spider to identify the locations

of rollers on the spider, then remove the rollers.

VI'{YL T

,%

BEARING REMOVER(Commercially

available)

5. Remove the circlip.

6. Mark the spider and driveshaft to identify the posi-

tion of the soider on the shaft.

7. Remove the spider using a bearing remover,

8. Wrap the splines on the driveshaft with vinyltape to

prevent damage to the boots.

APE ouTBoaRD BOOTInsp€ct ror crackrng,splitting and wear.

Inspect for cracking,splitting and woar.

Remove the inboard boot.

GAUTION: Tako care noi to damsge the boot.

Remove the dynamic damper and outboard boot. then

remove the vinyl tape.

CAUTION: Take care not to damage the dynamic

dampor and boot.

10.

16-6

\

Page 638 of 1680

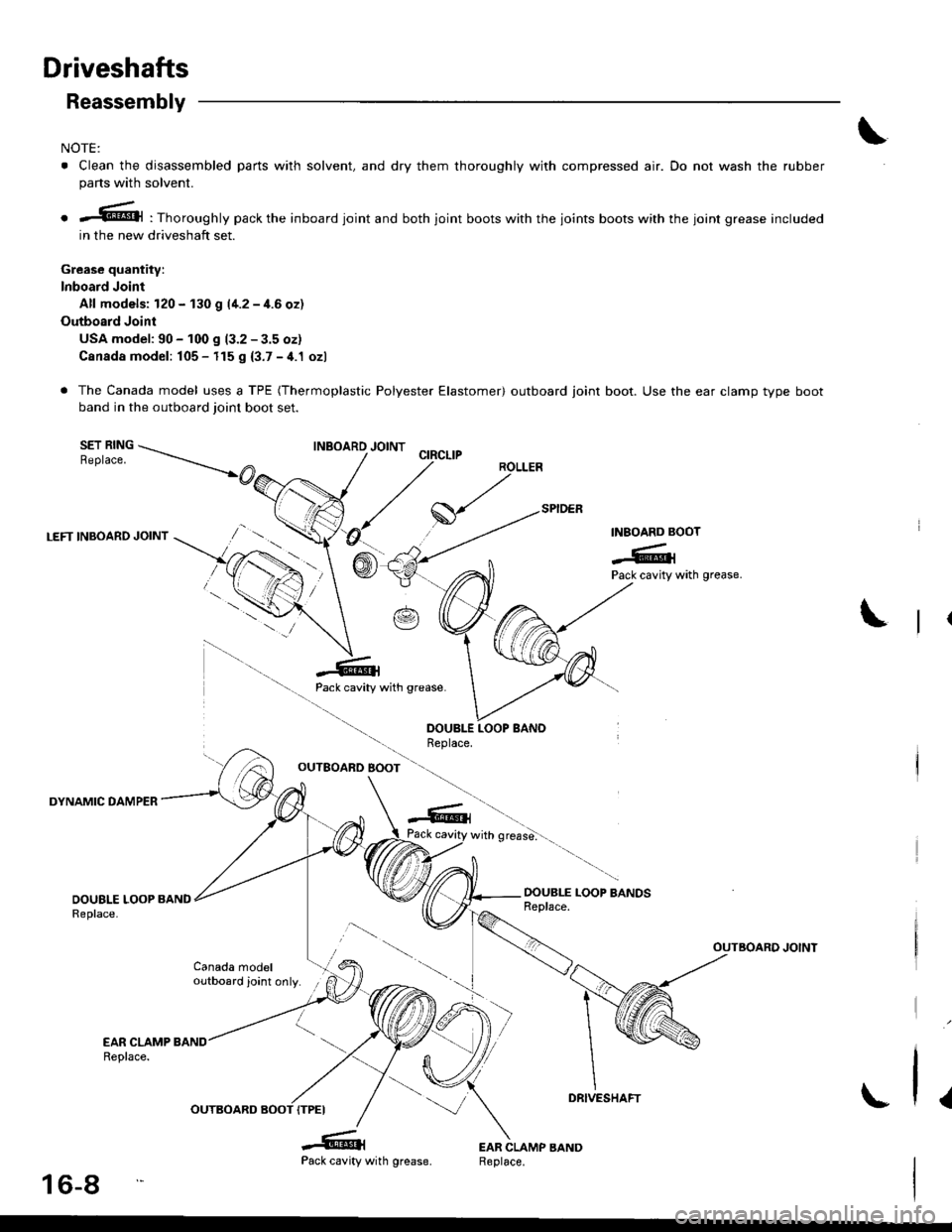

Driveshafts

LEFT INBOARD JOINT

DYNAMIC DAMPER

Reassembly

NOTE:

. Clean the disassembled parts with solvent, and dry them thoroughly with compressed air. Do not wash the rubber

parts with solvent.

o -@l : Thoroughly pack the inboard joint and both joint boots with the joints boots with the joint grease included

in the new driveshaft set.

Grease quantity:

lnboard Joint

Alf models: 120 - 130 g l1-2 - 1.6 ozl

Outboard Joint

USA model: 90 - 100 S 13.2 - 3.5 oz)

Canada model: 105 - 115 g {3.7 - 4.1 ozl

. The Canada model uses a TPE (Thermoplastic Polyester Elastomer) outboard joint boot. Use the ear clamp type boot

band in the outboard joint boot set.

SET RINGReplace.

INBOARD BOOT

-#,1Pack cavity with grease.

Pack cavity with grease.

OUTEOARD BOOT

with grease''

OOUBLE LOOP BANDSReplace.

OUTBOARD JOINT

Canada modeloutboard joint only.

l.

-6{Pack cavity

INBOARD JOINT

DRIVESHAFT

16-8

OUTBOARD

wrln grease,

Page 643 of 1680

![ACURA INTEGRA 1998 Service Owners Manual E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion ACURA INTEGRA 1998 Service Owners Manual E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion](/img/32/56983/w960_56983-642.png)

E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion of the band with a com-

mercially available boot band pincers.

BOOT AAND PINCERS(Commercially available)Oetiker 1098 or equivalent

POSTION

Measure the clearance between the closed ear

portion of the band.

Siandard:0-3 mm (0 - 0.12 in)

lf the band's, clearance is not within the standard,

close the ear portion of the band further.

NOTE:

. Make sure the band does not move.

. Remove any grease remaining in the surround-

ing surfaces.

16-13

Page 663 of 1680

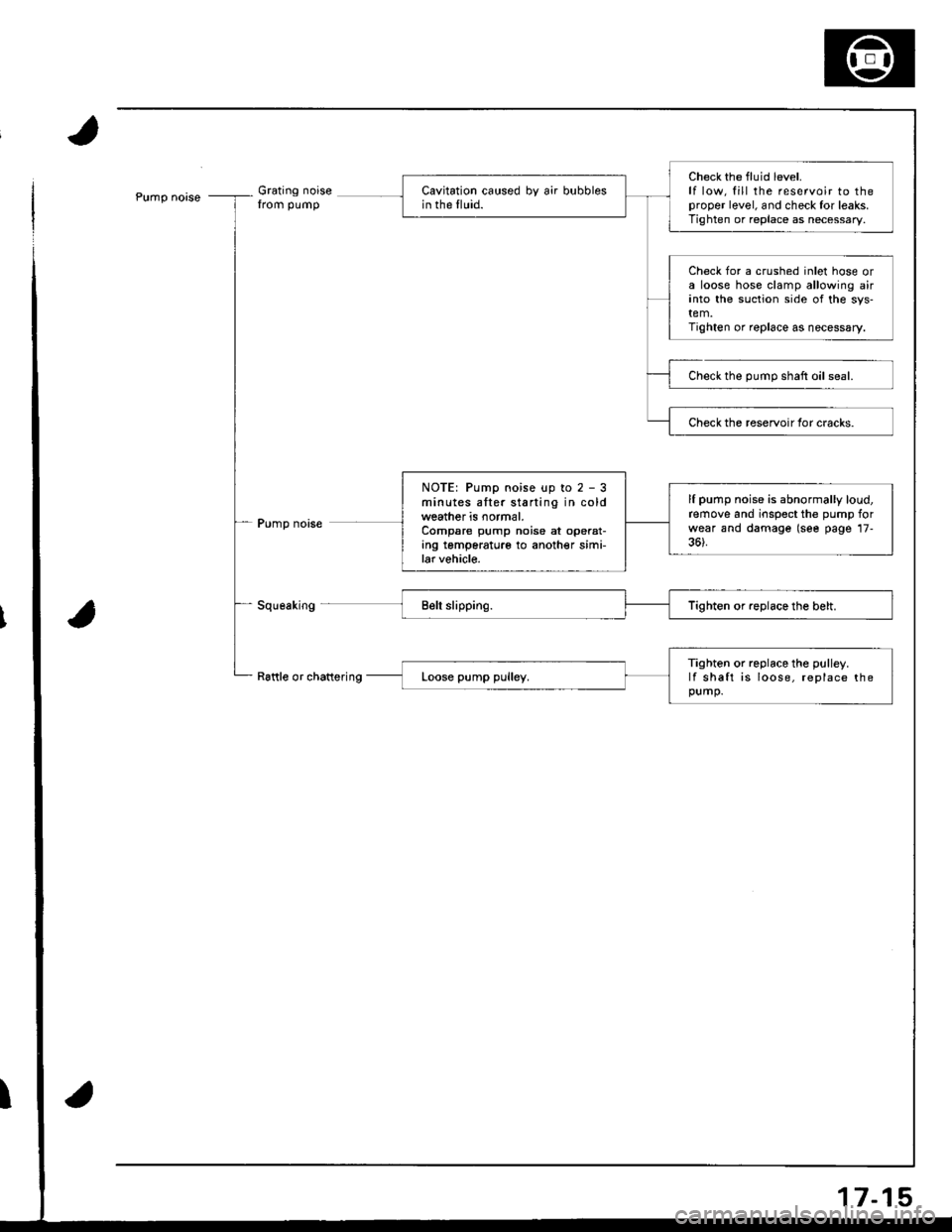

Pump noiseGrating noisefrom pump

Pump noise

I

aou""*,nn

Rattle or chattering

Check the flu id level.lf low, fill the reservoir to theproper level, and check for leaks.Tighten or replace as necessary.

Cavitation caused by air bubblesin the fluid.

Check for a crushed inlet hose ora loose hose clamp allowing airinto the suction side of the sys-tem.Tighten or replace as oecessary.

Check the oumo shaft oil seal.

Check the reservoir for cracks.

NOTE: Pump noise up to 2 - 3minutes alter starting in coldweather is normal.Compare pump noise at operat-ing tomperature to another simi-lar vehicle.

lf pump noise is abnormally loud,remove and inspect the pump forwear and damage (see page 17-36).

Tighten or replace the pulley.lf shaft is loose, replace thepump.

17-15

Page 680 of 1680

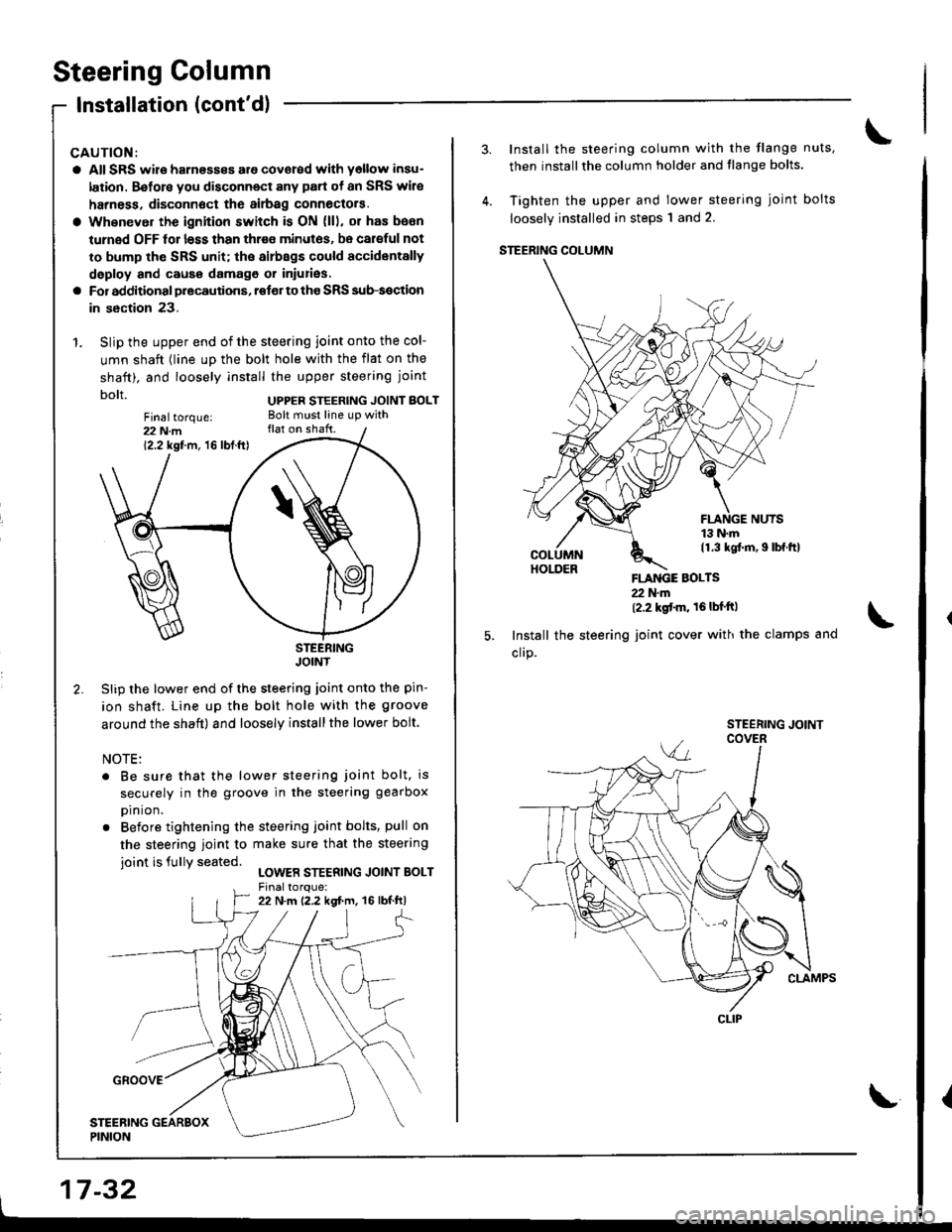

Steering Column

Installation (cont'dl

CAUTION:

a All SRS wire harness€s are covored with yollow insu-

lation. B€fors you disconnect any part of an SRS wire

harness. disconnoct the airbag connoctois.

a Whenever the ignition switch is ON (lll, or has beon

turned OFF for less than throo minutos, be caleful not

to bump the SRS unit; ths airbags could accidsntslly

deploy and caus€ damago or iniuries.

a For additionalpracautions, reter to the SRS sub-section

in section 23,

1. Slip the upper end of the steering joint onto the col-

umn shaft (line up the bolt hole with the flat on the

shaft). and loosely install the upper steering joint

bolt UPPER STEERTNG JorNT BoLT

STEERINGJOINT

Slip the lower end of the steering joint onto the pin-

ion shaft. Line up the bolt hole with the groove

around the shaft) and loosely installthe lower bolt.

NOTE:

. Be sure that the lower steering joint bolt, is

securely in the groove in the steering g€arbox

prn ron.

. Before tightening the steering joint bolts, pull on

the steering ioint to make sure that the steering

ioint is fullY seated.LOWER STEERING JOINT BOLT

Fin6ltorque:22 N.m12.2 kgf.m, 16 lbf.ft)

17-32

Install the steering column with the flange nuts,

then installthe column holder and flange bolts.

Tighten the upper and lower steering joint bolts

loosely installed in steps'l and 2.

STEERING COLUMN

FLANGE BOLTS22 N'm(2.2 kgt'm' 16lbf'ftl

Install the steering joint cover with the clamps and

cllP.

CLIP

\{

Page 681 of 1680

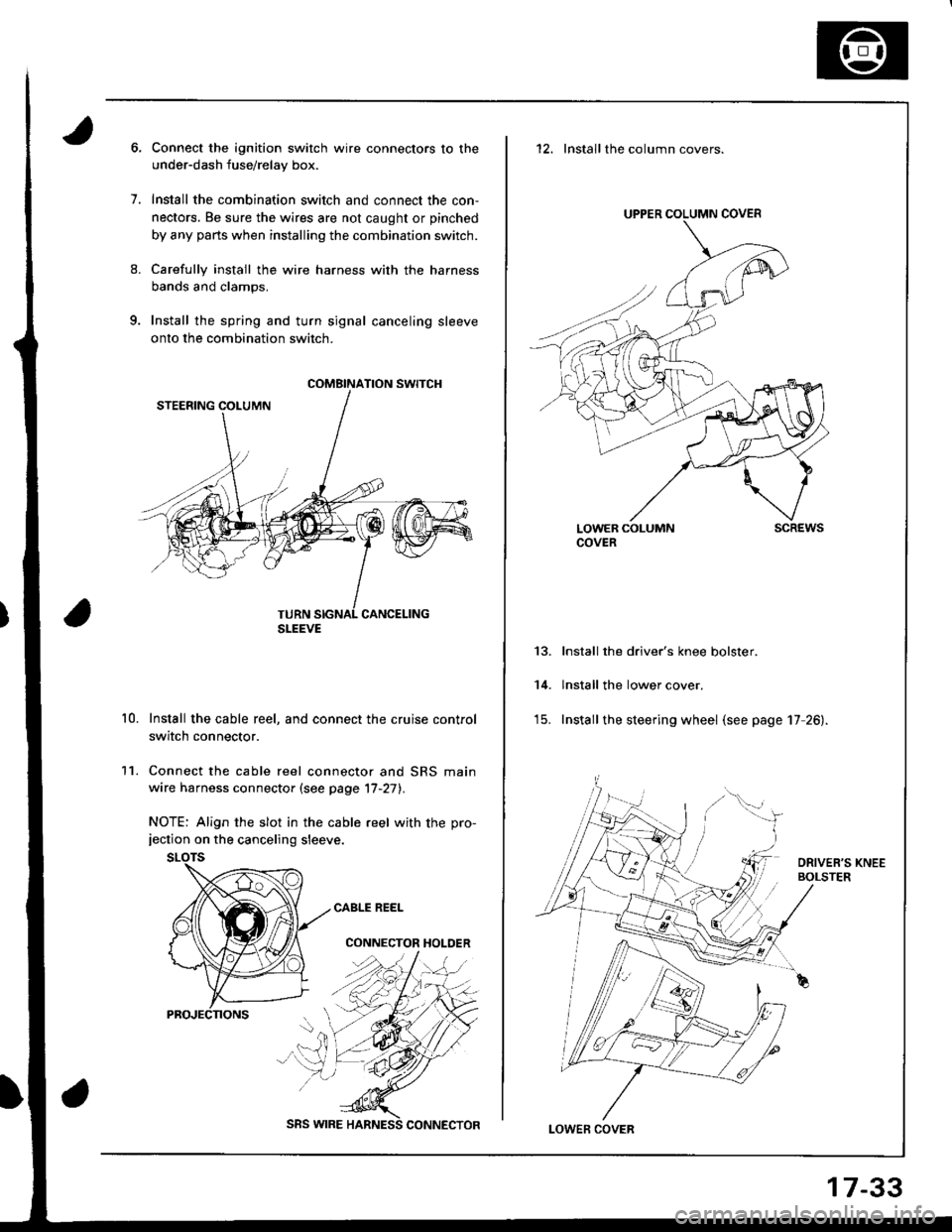

9.

1.

8.

11.

10.

Connect the ignition switch wire connectors to the

under-dash fuse/relay box.

Install the combination switch and connect the con,

nectors. Be sure the wires are not caught or pinched

by any parts when installing the combination switch.

Carefully install the wire harness with the harness

bands and clamps.

Install the spring and turn signal canceling sleeve

onto the combination switch.

Install the cable reel, and connect the cruise control

switch connector.

Connect the cable reel connector and SRS main

wire harness connector (see page '17-27).

NOTE: Align the slot in the cable reel with the pro-jection on the canceling sleeve.

CABLE REEL

CONNECTOR HOLDER

COMBINATION SWITCH

SLEEVE

SRS WIRE

17-33

12. Installthe column covers.

UPPER COLUMN COVER

LOWER COLUMNCOVERscREws

13.

14.

Install the driver's knee bolster.

lnstall the lower cover.

Install the steering wheel (see page 17 26).

LOWEF COVER

Page 682 of 1680

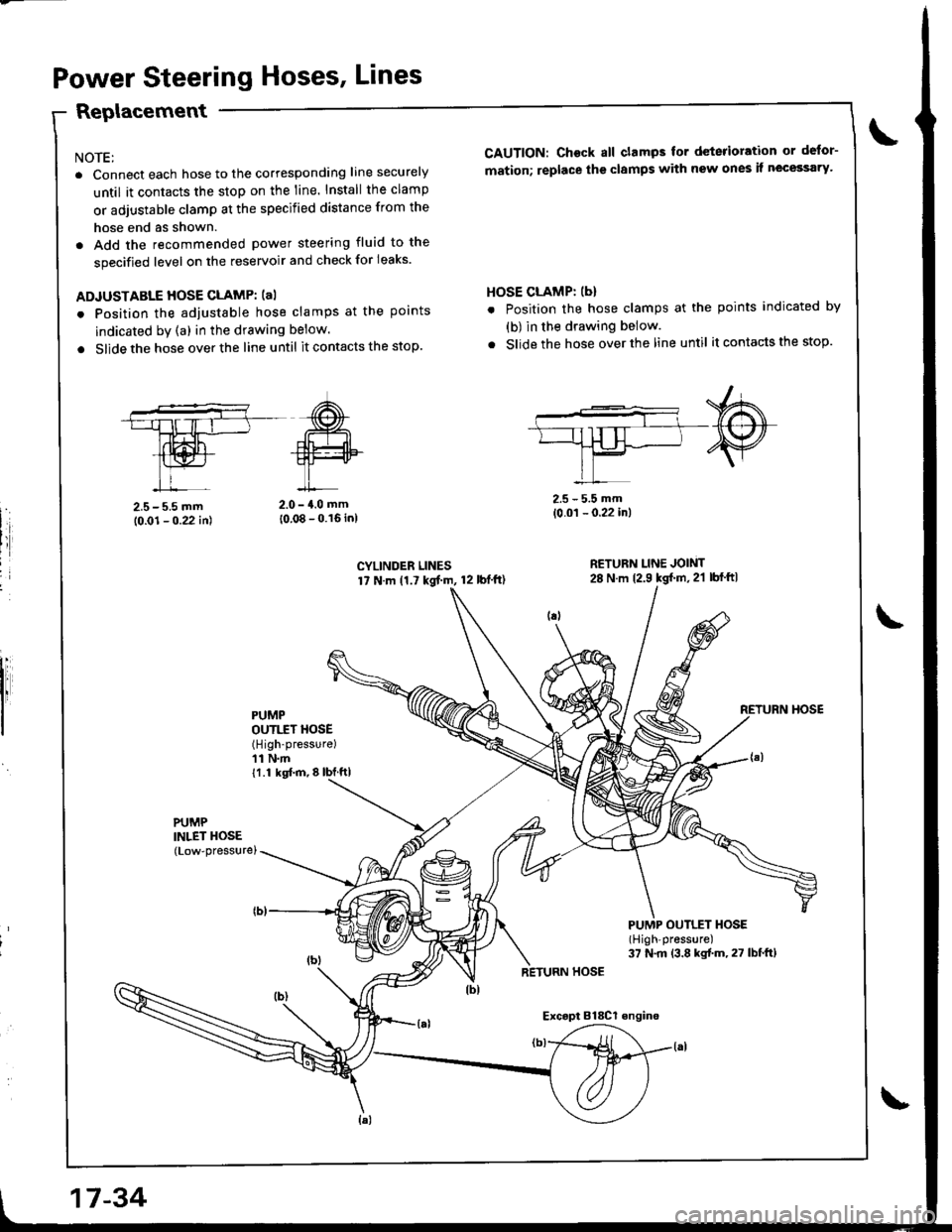

Power Steering Hoses, Lines

Replacement

NOTE:

. Connect each hose to the corresponding line securely

until it contacts the stop on the line. Install the clamp

or adjustable clamp at the specified distance from the

hose end as shown.

. Add the recommended power steering fluid to the

specified level on the reservoir and check for leaks.

ADJUSTABLE HOSE CLAMP: (al

. Position the adjustable hose clamps at the points

indicated by (a) in the drawing below.

. Slide the hose over the line until it contacts the stop.

CAUTION: Ch€ck all clamps for deterioration or defor-

mation; replace the clamps with new ones it necessary'

HOSE CLAMP: (b)

. Position the hose clamps at the points indicated by

(b) in the drawing below.

. Slide the hose over the line until itcontactsthe stop.

2.5 - 5.5 mm(0.01 - 0.22 in)

RETURN LINE JOINT28 N m 12.9 kg{'m,2'l lbf'ft|

PUMP OUTLET HOSE(High'pressure)

37 N.m (3.8 kgtm,27 lbf.ft)

2.5-5.5 mm

10.01 - 0.22 in)2.0 - {.0 mm

10.08 - 0.16 inl

CYLINDER LINES17 N.m (1.7 kgt m, 12 lbf'ft)

PUMPOUTI.IT HOSE(High-pressure)

11 N.m11.1 kgl.m,8lbJftl

PUMPINLET HOSE(Low-pressurel

RETURN HOSE

Exc.pt Bl8Cl engino

17-34