value ACURA INTEGRA 1998 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 1340 of 1680

)

Troubleshooting

Self-diagnostic Procedures

The self-diagnostic function of the SRS system allows it to locate the causes of system problems and to store this informa-

tion in memorv. For easier troubleshooting, this data can be retrieved via 8 dats link circuit.

o When you turn the ignition switch ON (ll), the SRS indicator will come on. lf it goes off after six seconds, the system is

normat.

. lf there is 8n abnormality, the system locstes and defines the problem, stores this information in memory, and turns

th€ SRS indicator light on. The data will remain In the memory even when the ignition switch is turned off or if the bat-

terv is disconnected.

. When you connect the SCS service connector to the service check connector (2P), and turn the ignition switch ON {ll),

the sRs indicator light will indicate the diagnostic trouble code (DTCI by th€ number of blinks.

. After reading and recording the DTC, proceed with the troubleshooting for this code

Pr6crution!

. Use only a digital multimeter to check the system, lf it's not a Honda multimeter, make sure its output is 10 mA (0.01 A)

or less when switched to the smallest value in the ohmmeter range. A tester with a higher output could damsge the

airbag circuit or cause sccidental airbag deployment and possible injury.

. Whenever the ignition switch is ON (ll), or has been turned OFF for less than three

SRS unit; the airbags could accidentally deploy and cause damage or injuries'

. Before you remove the SRS main harness, disconnect the driver's airbag connector

conneclor.

and the front passenger's airbag

. Make sure the battery is sufficiently charged (s6e psge 23-67). lf the battsry is dead or low, msasuring values won't be

correct,

a Do not touch a tester probe to the terminals in the SRS unit or harness connectors, and do not connect the terminals

with a jumper wire. Use only the backprobe set and the SCS service connector.

For backprobing spring-loaded lock type connectors, refer to psge 23-283.

Reading the DTC

When the SRS indicator light is on, read the DTC using one ot th"sc rn"ihod<

A. Connect the Honda PGM Toster io the 16P D

MEASUREMENTSTANDARD (NEWI

Steering wheelRotational play at steering wheel circumferenceStarting load at steering wheel circumferenceN (kgf, lbf) Engine running

0 - 10 (0 - 0.39)

34 (3.5,7 .71

GearboxAngle of rack-guide-screw loosened from lockedoosition20'MAX

PumpPump pressure with shut-off valve closedkPa (kgf/cm,, psi)6,400 - 7,400 (65 - 75, 924 - 1,067],

Power steeringfluidRecommended fluidFluid capacity GSR, Type Rf (US qt, lmp qtl cS, RS, LSReservoir

Honda Power Steering Fluid-V or S1.06 (1.12,0.93)

1.0 (1.06,0.88)

0.4 (0.42, 0.35)

Power steeringbelt*Deflection with 98 N (10 kgf,22 lbflbetween pulleys1 1.5 - 13.5 (0.45 - 0.531 with used belt8.0 - 10.0 (0.31 - 0.39) with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 - 880 (75 - 90, 170 - 2001with new belt

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readiust deflection or tension to used belt values.

Suspension - Section 18

BrakeSection 19

Unit of length: mm (in)

$t

MEASUREMENTSTANDARD (NEWI

WheelalignmentCamber Front Type RAll except Type RRearCaster FrontTotal toe FrontRearFront wheel turning angle Inward wheelOutward wheel

-0'30'r 1"-0' 10'r 1.-0" 45'�1?:i3i1. 10'�1 1.0!210!1116!,lN 2 lf (t7t6 1 1716136. 00'1 2"30'30'

Wheel bearingEnd play FrontRear0 - 0.05 (0 - 0.002)0 - 0.05 (0 - 0.002)

WheelRim runout (Aluminum wheel) AxialRadialRim runout (Steel wheel) AxialRadial

STANDARD (NEW}SERVICE LIMIT

0 - 0.7 (0 - 0.03)0 - 0.7 (0 - 0.03)0 - 1.0 (0 - 0.04)0 - 1.0 (0 - 0.04)

2.0 (0.08)

1.5 (0.06)2.0 (0.08)1.5 (0.06)

MEASUREMENTSTANDARD (NEW}

Parking brakeleverPlay in stroke at 196 N (20 kgf,44 lbf)lever forceLocks when oulled 6 -10

notches

Foot brakepedalPedal height (With floor mat removed)

Free play

M/TAtT160 (6 5/161165 rc 1nl1-5(1/16-3/16)

Master cylinderPiston-to-oushrod clearance0 - 0.4 (0 - 0.021

Disc brakeDisc thickness Front Type RAll except Type RRearDisc runout FrontRearDisc parallelism Front and rearPad thickness Front Type R

All except Type RRear Type RAll except Type R

STANDARD (NEWISERV]CE LIMIT

22.9 - 23.1 (0.90 - 0.91120.9 - 21.1 (0.82 - 0.83)

1= t (0.35-0.361

10.5 - 11.5 (0.41 - 0.45)9.5 - 10.5 (0.37 * 0.41)8.5 - 9.5 (0.33 - 0.37)7.0 - 8.0 (0.28 - 0.31)

21.0 (0.83)19.0 (0.75)

8.0 (0.31)

0.10 (0.004)

0.10 (0.004)

0.015 (0.0006)1.6 (0.06)

1.6 (0.06)1.6 (0.06)

1.6 (0.06)

Page 1655 of 1680

ng

MEASUREMENTSTANDARD {NEW}

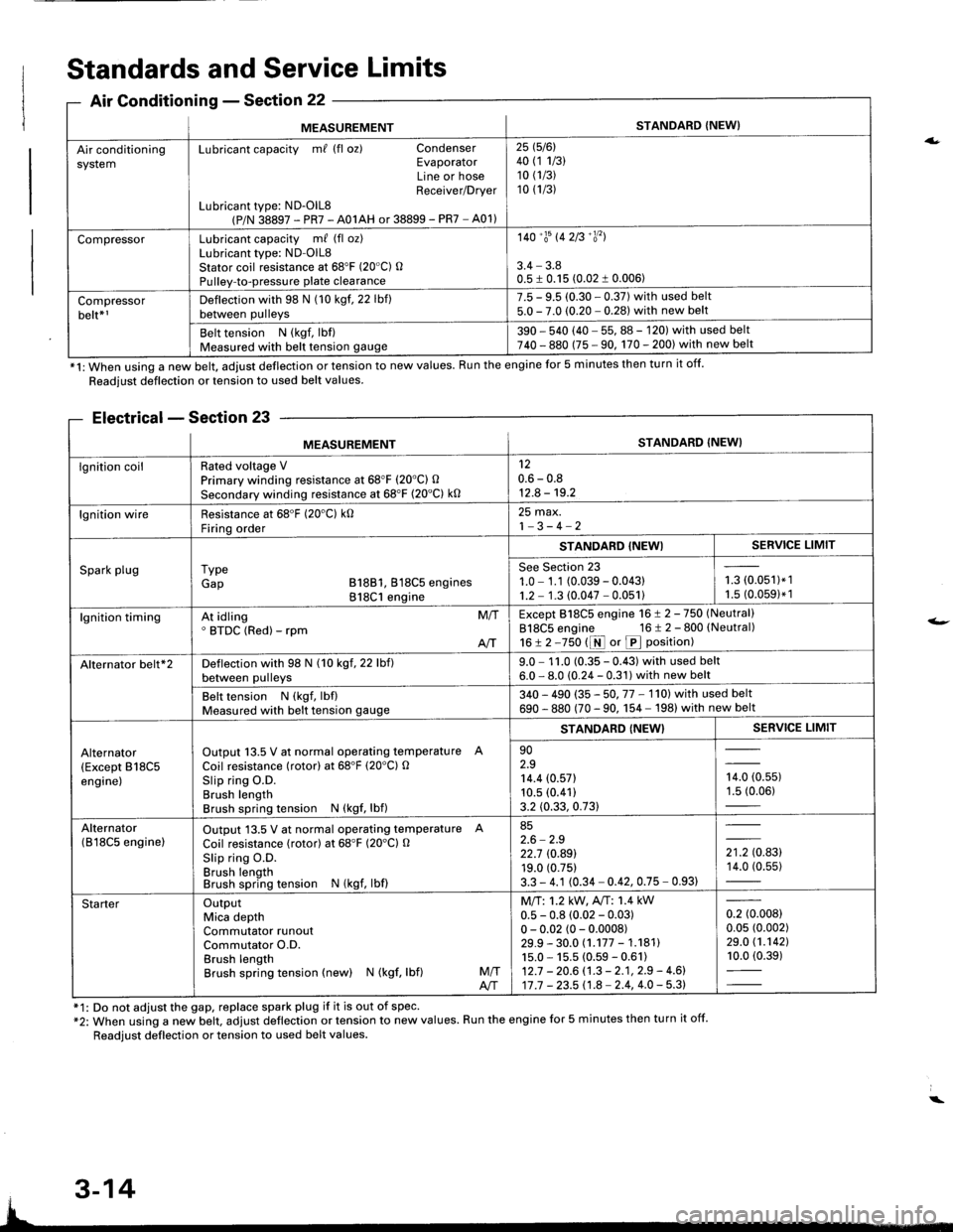

Air conditioningsystemLubricant capacity m/ (fl oz) CondenserEvaporatorLine or hoseReceiver/Drver

Lubricant type: ND-OlL8(P/N 38897 - PR7 - A01AH or 38899 - PR7 - A01)

25 1516l40 (1 1/3)10 (1/3)

10 (1/3)

CompressorLubricant capacity m/ (fl oz)Lubricant type: ND-OlL8Stator coil resistance at 68'F (20"C) OPulley-to-pressure plate clearance

140'�trs 142B'�y'�l

3.4 - 3.80.5 I 0.15 (0.02 1 0.006)

Compressorbelt*rDeflection with 98 N (10 kgf. 22 lbf)between pulleys

7.5 - 9.5 (0.30 - 0.37) with used belt5.0 - 7.0 (0.20 - 0.281 with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 - 880 (75 - 90, 170 - 200) with new belt

*1: When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Standards and Service Limits

Air Conditionins - Section 22

Readjust deflection or tension to used belt values.

Electrical - Section 23

f1: Do not adjust the gap, replace spark plug if it is out of spec'*2: When using a new belt. adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Readjust deflection or tension to used belt values.

a.

t-

MEASUREMENTSTANDARD (NEW}

lgnition coilRated voltage VPrimary winding resistance at 68"F (20'C) O

Secondary winding resistance at 68'F (20"C) k0

120.6 - 0.812.8 - 19.2

lgnition wireResistance at 68'F (20'C) k0Firinq order

25 max.1-3-4-2

Spark plugI ypeGap B18B1, 818C5 engines818C1 engine

STANDABD {NEWISERVICE LIMIT

See Section 231.0 - 1.1 (0.039 - 0.04311.2 - 1.3 (0.047 - 0.051)i-= roru',t.',1.5 (0.0591* 1

lgnition timingAt idling' BTDC (Red) - rpmM/T

AIT

Except 818C5 engine 16 ! 2 -750 (Neutral)

818C5 engine 16 t 2 - 800 (Neutral)

16!2-750 t1r{ or p position)

Alternator belt*2Deflection with 98 N (10 kgf, 22 lbf)between pulleys9.0 - 1 1.0 (0.35 - 0.43) with used belt6.0 - 8.0 (0.24 - 0.31) with new belt

Belt tension N (kgf, lbflMeasured with belt tension gauge340 - 490 (35 - 50. 77 - 1'l0l with used belt

690 - 880 (70 - 90. 1 54 - 198) with new belt

Alternator(Except B18C5engine)

Output 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68'F (20'C) OSlip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

STANDARD {NEW}SERVICE LIMIT

902.914.4 (0.571

10.5 (0.41)

3.2 (0.33, 0.73)

,0, to.uur1.5 (0.06)

Alternator(B l8C5 enginelOutput 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68"F (20'Cl O

Slip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

852.6 - 2.922.7 rc.89119.0 (0.75)

3.3 - 4.1 (0.34 - 0.42, 0.75 - 0.93)

',to.tg14.0 (0.55)

StarterOutputMica depthCommutator runoutCommutator O.D.Brush lengthBrush spring tension (new) N (kgf, lbf)M/TA/T

Mll:1.2 kW, A"rT: 1.4 kW0.5 - 0.8 (0.02 - 0.03)0 - 0.02 (0 - 0.0008)29.9 - 30.0 (.177 - 1.18111s.0 - 15.5 (0.59 - 0.61)12.7 - 20.6 (.3 - 2.1, 2.9 - 4.6)17 .7 - 23.5 11.8 - 2.4, 4.0 - 5.3)

0.2 (0.008)

0.05 (0.002)

29.0 (1.1421

10.0 (0.39)

3-14