value ACURA INTEGRA 1998 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 525 of 1680

L

(t RtcHT sroE covER

@ MAINSHAFT sPEEo sENsoR(O O-RINGS Reptace.

@ couNTERSHAFT spEEo sENsoR

@ HARNESS BRACKET

@ RoLLER

O coLLAR

@ O-RING Replace.

@ FEEo PIPE FLANGE

@ o-RtNG Reptace.

O) SNAP RING

@ 3RD cLUTcH FEED PIPE

@ COUNTERSHAFT LocKNUT (FLANGE NUT) RepIace,

@ couNTERSHAFT CONtcAL spRtNG wAsHER Reptace.

@ PARKING GEAR

G) ONE-WAY cLUTcH

@ COUNTERSHAFT lST GEAR

@ NEEoLE BEARTNG

@ COUNTERSHAFT 1ST GEAR COLLAR

€0 o-RING Reprace.

@ 1sT-HoLD AccUMULAToR ptsTok

@ 1sr-HoLD AccUMULAToR spRtNG

@ o-RING Reptace.

@ rsr-HoLD AccUMULAToR covER

@ SNAP RING

@ PARKING BRAKE PAWL

@ PARKING BRAKE PAWL SPRING

€0 PARKTNG BRAKE PAWL SHAFT

@ PARKTNG BRAKE pawl sroppER

€0 LOCK WASHEF Replace.

@ PARKTNG BRAKE STOP Setecrive oart

@ PARKING BRAKE LEVER

@ PARKING ERAKE LEVER SPRING

@ DowEL PrN

@ o-RlNGs Reptace.

@ RtcHT StOE COVER GASKET Reptace.

@ 1sr cLUTcH FEED ptpE

@ O-R|NGS Reptace.

@ FEEO P|PE GUTOE

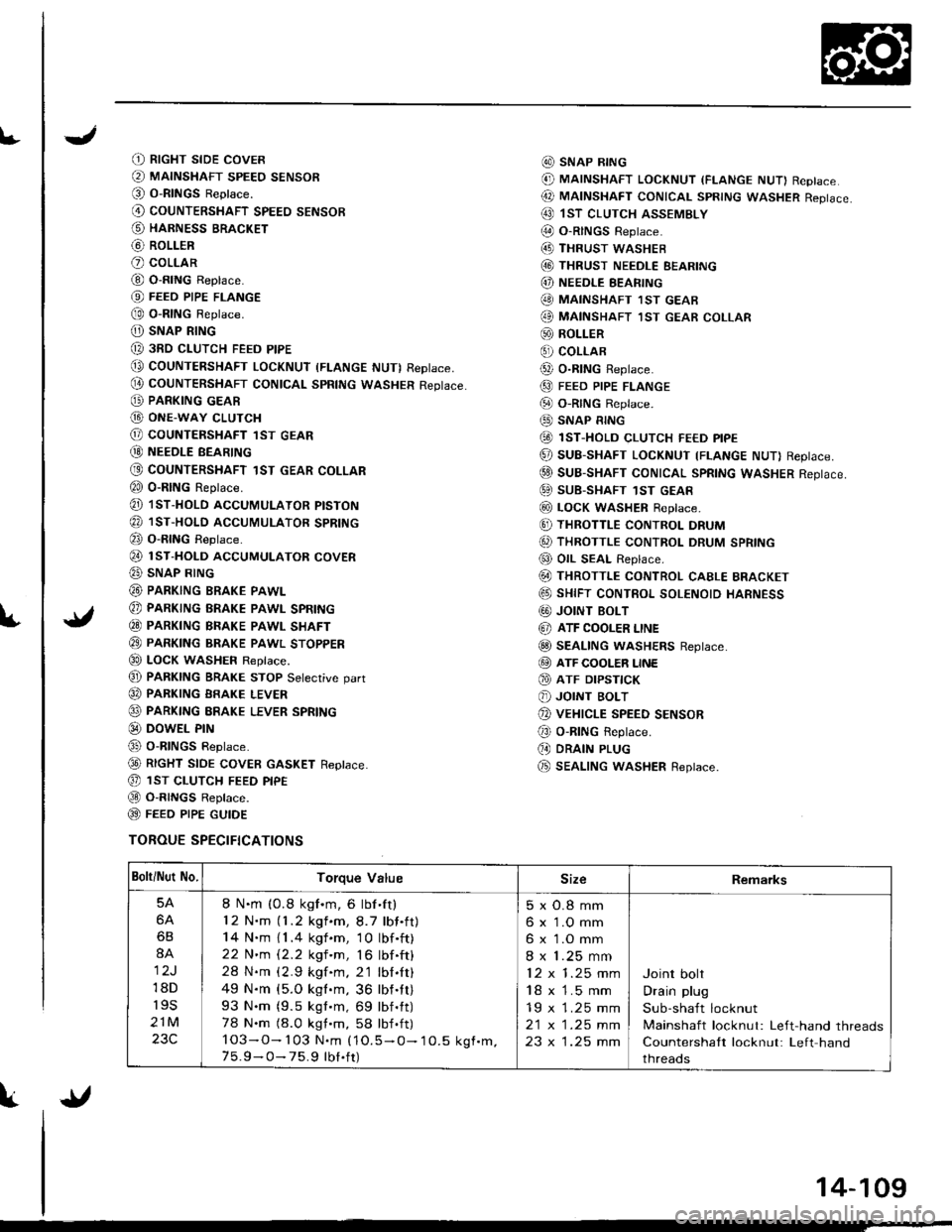

TOROUE SPECIFICATIONS

@ SNAP R|NG

@ MAINSHAFT LocKNUT (FLANGE NUT) Replace

@ MAtNSHAFT coNtcAL spRtNG wAsHER Reptace.

@ 1sT clurcH ASSEMBLY

@ O-RINGS Reptace.(4D THRUST wASHEB

@ THRUST NEEDLE EEARING

@) NEEDLE EEARING

@ MAINSHAFT 1sT GEAB

@ MAINSHAFT ,IsT GEAR coLLAR

@ ROLLER

€) coLLAR

@ o-R|NG Reptace.

@ FEED PIPE FLANGE

@ o-RtNG Reptace.

@ SNAP RING

@ 1sT-HoLD cLUTcH FE€D ptpE

@ SUB-SHAFT LOCKNUT TFLANGE NUT) Reptace.

@ suB-SHAFT CONTCAL SpRtNG WASHER Reptace.

@ SUB-SHAFT 1sT GEAR

@ LocK WASHER Reptace.

@ THRoTTLE coNTRoL DRUM

6, THRoTTLE coNTRoL DRUM SPRING

@ OIL SEAL Replace.

@ THRoTTLE coNTRoL cAELE BRAGKET

@ sHtFT coNTRoL soLENoto HARNESS

G0) JOINT BOLT

@ ATF COOLER LINE

@ SEAL|NG wASHERS Reptace.

@ ATF cooLER LINE

@ ATF DrPsflcK

@ JOINT BoLT

@ vEHrcLE SPEED sENsoR

@ o-RING Reptace.

(, DRAIN PLUG

@ SEAL|NG wasHER Replace.

Bolti Nut No.Torque ValueSizeRemarks

5A

6A

6B

8A

12J

18D

r9s

21M

23C

8 N.m (0.8 kgf.m, 6 lbf'ft)

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m { 1 .4 kgf .m, 1 0 lbf .ft)

22 N'm 12.2 kgf 'm, 16 lbf .ft)

28 N.m (2.9 kgf.m. 2'1 lbl.It)

49 N.m {5.O kgl.m, 36 lbf.tt)

93 N.m (9.5 kgt.m, 69 lbf.tt)

78 N.m (8.0 kgt.m, 58 lbf .ft)

103-O- 103 N.m (1O.5 - O- 10.5 kgf.m.7 5.9 - O- 75.9 tbt.ft)

5xO.8mm

6 x 1.O mm

6 x 1.O mm

8 x 1.25 mm

12x1.25mm

18 x 1.5 mm

19 x 1.25 mm

2t x |.25 mm

23 x 1.25 mm

Joint bolt

Drain plug

Sub-shaft locknut

Mainshaft locknut: Left-hand threads

Countershaft locknut: Left hand

threads

{l

14-109

Page 527 of 1680

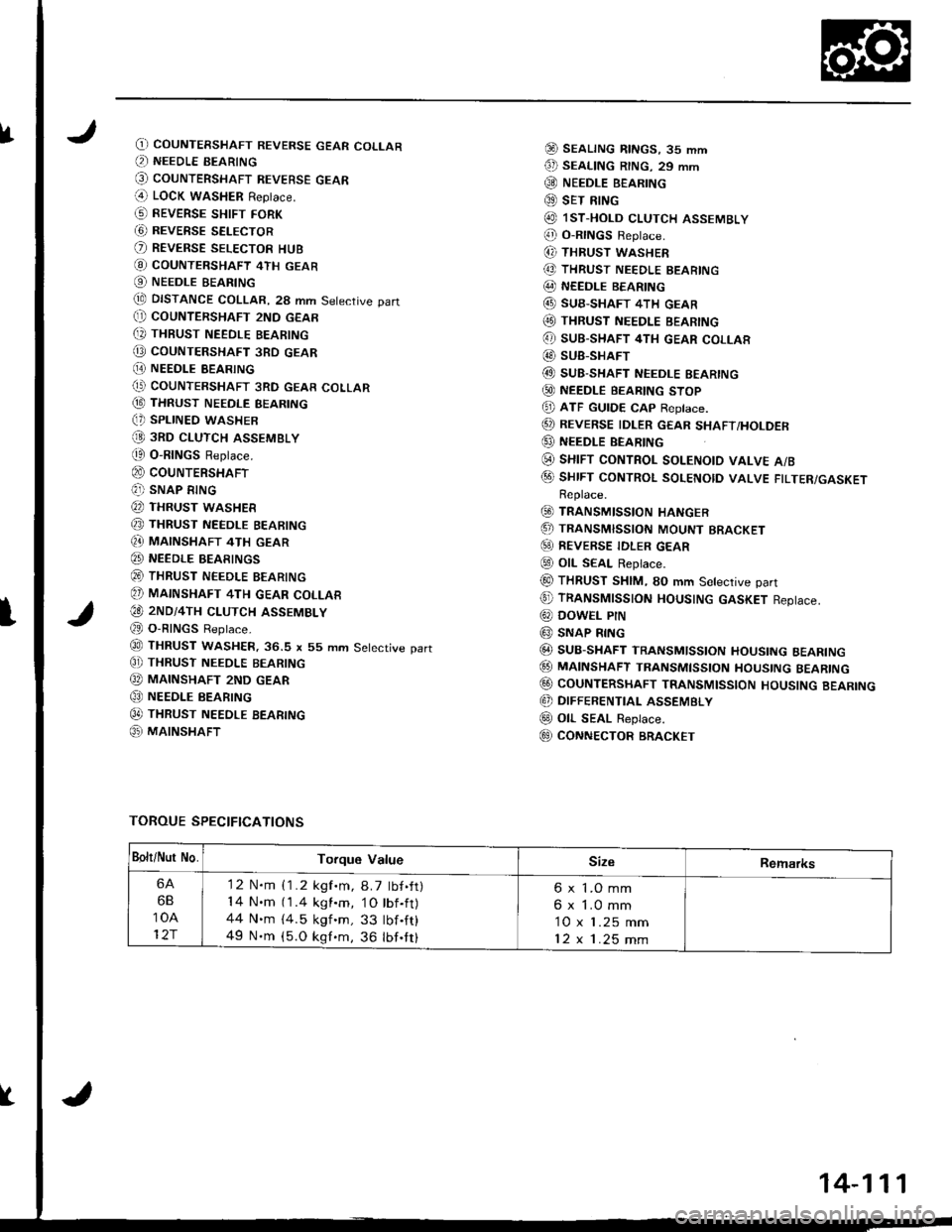

fO) COUNTERSHAFT REVERSE GEAR COLLAR(, NEEDLE BEARING

@ couNTERSHAFT REVEBsE GEAR(4 LOCK waSHER Replace.

G) REVERSE sHtFr FoRK

G) REVERSE SELECTOR

O REVERSE SELEcToR HUB

@ coUNTERSHAFT 4TH GEAR

O NEEDLE BEARING

tE DISTANCE COLLAR, 28 mm Setective part(} COUNTERSHAFT 2ND GEAR

[, THBUST NEEDLE BEARING

@ coUNTERSHAFT 3RD GEAR

[E NEEDI.E BEARING(' COUNTERSHAFT 3RD GEAR COLLAR

@ THRUST NEEDLE BEARING(, SPLINED WASHER

@ 3RD cLUTcH ASSEMBLY

t0 O-RINGS Replace.

@ couNTERSHAFT(?]) SNAP RING

@ THRUST WASHER

@ THRUST NEEDLE BEARING

Q} MAINSHAFT 4TH GEAR

@ NEEDLE BEARINGS

@ THRUST NEEDLE BEARING

@ MAINSHAFT 4TH GEAR coLLAR

€O 2ND/4TH cLUTcH ASSEMBLY

@ O-RINGS Reptace.

@ THRUST WASHER.36.S x 55 mm Setective part

C]) THRUST NEEoLE BEARING

@ MAINSHAFT 2ND GEAR

@ NEEDLE BEARING

0t THRUST NEEDLE BEARTNG

@ MAINSHAFT

@ SEALTNG RtNGs, 35 mm

€D SEAL|NG R|NG. 29 mm

@ NEEDLE B€ARING

@ sET RING

@ lsT.HoLD cLUTCH ASSEMBLY

@ o-RtNGs Reptace.

(, THRUST WASHER

@ THRUST NEEDLE BEARING

@ NEEDLE BEARING

@ SUB-SHAFT 4TH GEAR(O THRUST NEEDLE BEARING

@ sUB-SHAFT 4TH GEAR coLLAR

@ SUB-SHAFT

@ SUB-SHAFT NEEDLE EEARING

@ NEEDLE BEARTNG sToP

@ ATF GUTDE cAp Reptace.

@ REVERSE IDLER GEAR sHAFT/HoLDER

@ NEEDLE BEARING

(i) sHrFT coNTRoL soLENotD vALvE A/B

@ sHrFT coNTRoL soLENotD vALVE FTLTER/GASKETReplace.

@ TRANSMISSIoN HANGER

.5, TRANSMISSIoN MoUNT BRACKET

@) REVERSE TDLER GEAR

@ otL SEAL Replace.

@ THRUST SHIM, SO mm Setective part

@ TRANSMTSSTON HOUSTNG GASKET Reptace.

@ DowEL PtN

@ SNAP RING

@ SUB-SHAFT TRANSMlsstoN HoustNG BEARTNG

@ MA|NSHAFT TRANsMtssroN HoustNG BEARTNG

@ CoUNTERSHAFT TRANSMIssloN HoUsING BEARING

@ DIFFERENTIAL ASSEMBLY

@ oll- SEAL Replace.

E9 CONNECTOR BRACKET

TOROUE SPECIFICATIONS

I

Bolt/Nur No.Torque ValueSizeRemarks

6A

6B

10A

12r

'12 N.m {1.2 kgf.m, 8.7 tbf.ft)14 N.m (1.4 kgl.m, 1O tbf.ft)44 N.m {4.5 kgf 'm, 33 tbf .ft}

49 N.m (5.O kgf.m, 36 lbf.tt)

6 x 1.O mm

6 x 1.0 mm

10 x 1.25 mm

12x1.25mm

14-111

Page 529 of 1680

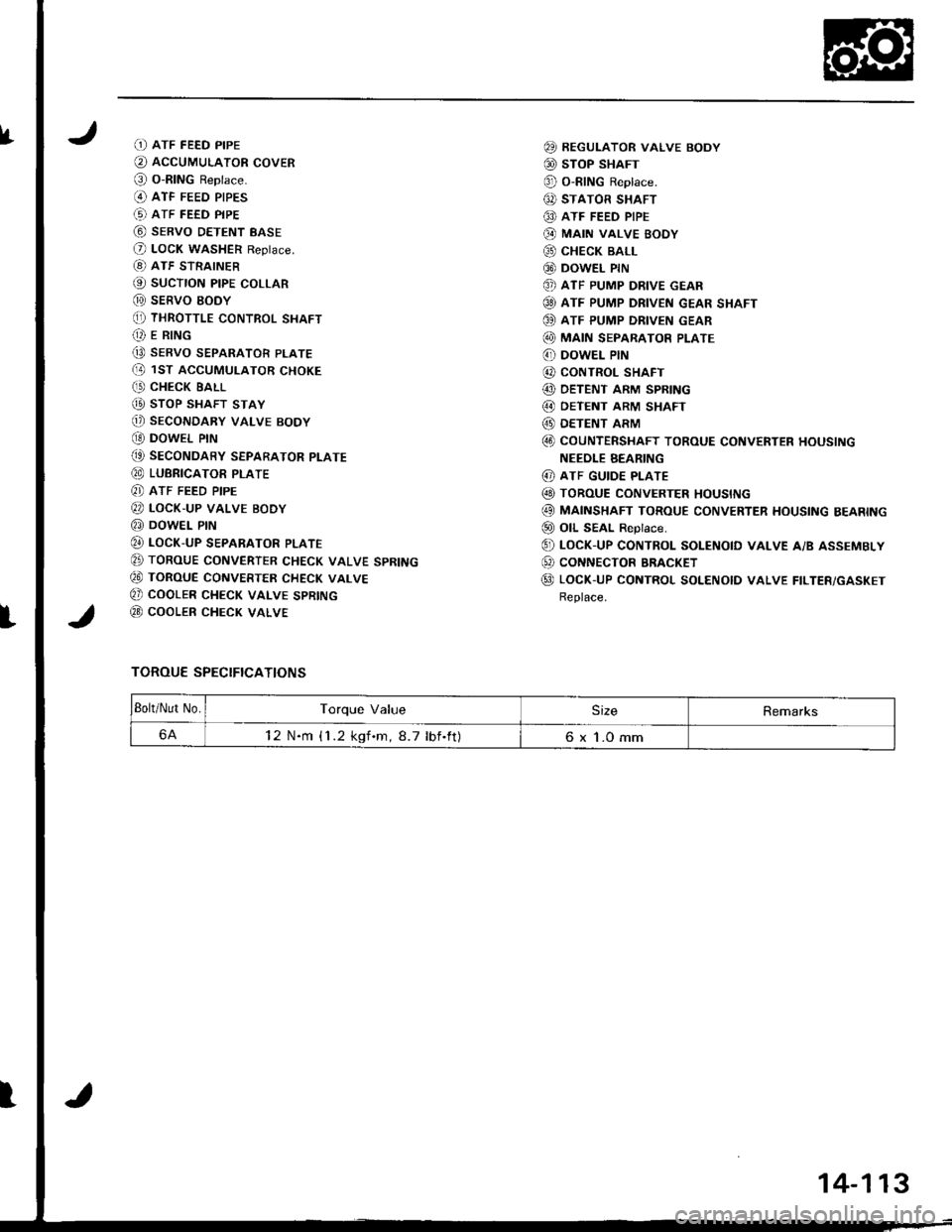

IfD ATF FEED PIPE

O AccUMULAToR covER

@ o-RING Reptace.(O ATF FEED PIPES

(!) ATF FEED PIPE

@ sERvo DETENT BASE

O LocK WASHER Reptace.

[8) ATF STRAINER

@ sucTroN ptpE coLLAR

@ sERVO EODY(, THRoTTLE coNTRoL SHAFT(t E R|NG

Q9 SERVO SEPARATOR PLATE(D 1ST ACCUMULAToR cHoKE

C' CHECK EALL

@ sToP SHAFT STAY

@) SECONDARY VALVE BODY

OO DOWEL PIN

(t SEcoNDARY SEPARAToR PLATE

@ LUBRICAToR PTATE

8] ATF FEED PIPE

@ LocK-uP vALvE BoDy

@ DowEL PrN

@ LocK-uP SEPARAToR PLATE

E TORoUE CoNVERTER cHEcK VALVE SPRING

€0 ToRouE CoNVERTER cHEcK vALvE

Q) COOLER CHECK VALVE SPRING

@ cooLER cHEcK VALVE

TOROUE SPECIFICATIONS

@ REGULAToR vALvE BoDY

@ sToP SHAFT

@ o-RING Reptace.

6, STATOR SHAFT

@ ATF FEED PIPE

@ MA|N VALVE BOOY

@ cHEcK BALL

@ DowEL PrN

@ ATF PUMP DRIVE GEAR

@ ATF PUMP DRIVEN GEAR SHAFT

OO ATF PUMP DRIVEN GEAR

@ MA|N SEPARAToR PLATE

6' DowEL PIN

@ CONTROL SHAFT

@ DETENT ARM SPRING

@ OETENT ARM SHAFT

@ DETENT ARM

@ coUNTERSHAFT ToRoUE coNVERTER HoUSING

NEEOLE BEARING

@ ATF GUIDE PLATE

@ ToRouE coNvERTER HoustNG

@ MAINSHAFT ToRoUE coNvERTER HousING BEARING

@ oll SEAL ReDtace.

@ LocK-up coNTRoL soLENotD vALvE A/B ASSEMBLy

@ coNNEcToR BRACKET

@ LocK-UP coNTRoL SoLENoID vALvE FILTER/GASKET

Replace.

Bolt/Nut No.Torque ValueSizeRemarks

6A12 N.m {1 .2 kgf.m,8.7 lbf.ft)6 x 1.0 mm

I

14-113

Page 613 of 1680

Differential

Ted Roll

(B18C1

er Bearinr

engine)

Preload Adjustment (cont'd)aperelng

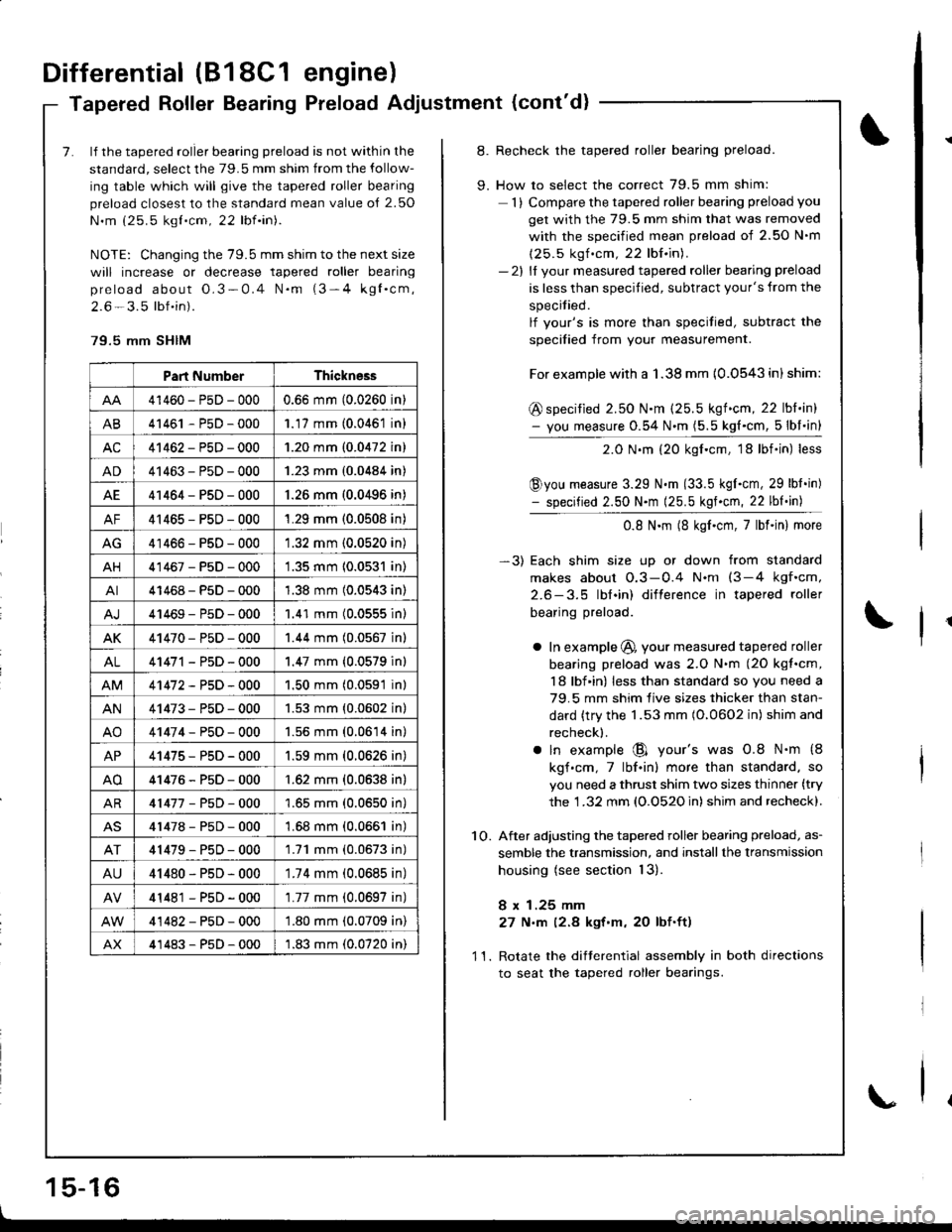

7. lf the tapered roller bearing preload is not within the

standard, select the 79.5 mm shim from the follow-

ing table which will give the tapered roller bearing

preload closest to the standard mean value o{ 2.50

N.m (25.5 kgt.cm, 22 lbf.in).

NOTE: Changing the 79.5 mm shim to the next size

will increase or decrease tapered roller bearing

preload about O.3-0.4 N.m (3-4 kgl.cm,

2.6 - 3.5 lbf.in).

79.5 mm SHIM

Part NumberThickness

41460-PsD-0000.66 mm (0.0260 in)

AB41461 - P5D - 0001.17 mm (0.0461 in)

AC41462-PsD-0001.20 mm (0.0472 in)

AD41463-P5D-0001.23 mm (0.0484 in)

AE41464-PsD-000'1.26 mm (0.0496 in)

AF41465-PsD-0001.29 mm (0.0508 in)

AG41466-PsD-0001.32 mm (0.0520 in)

AH41467-PsD-0001.35 mm 10.0531 in)

AI41468-PsD-0001.38 mm (0.0543 in)

41469-P5D-0001.41 mm (0.0555 inl

AK41470-PsD-0001.44 mm (0.0567 in)

AL41471 - PsD - 000'1.47 mm {0.0579 in}

41472-P5D-0001.50 mm (0.0591 in)

AN41473-PsD-0001.53 mm {0.0602 in}

AO41474-P50-0001.56 mm (0.0614 in)

AP41475-PsD-0001.59 mm (0.0626 in)

AO41476-P5D-000'1.62 mm {0.0638 in}

AR41477-P5D-0001.65 mm (0.0650 in)

41478-P5D-0001.68 mm (0.0661 in)

41479-P50-0001.71 mm (0.0673 in)

AU41480-PsD-0001.74 mm (0.0685 in)

41481 - PsD - 000'1.77 mm (0.0697 in)

41482-PsD-000'1.80 mm (0.0709 in)

AX41483-P5D-0001.83 mm (0.0720 in)

8. Recheck the tapered roller bearing preload.

9. How to select the correct 79.5 mm shim:

1) Compare the tapered roller bearing preload you

get with the 79.5 mm shim that was removed

with the soecified mean Dreload of 2.50 N'm

(25.5 kgf .cm, 22 lbf.in).- 2l ll vour measured tapered roller bearing preload

is less than specified, subtract your's from the

specitied.

lf vour's is more than specitied, subtract the

soecified from vour measurement.

For example with a 1.38 mm {0.0543 in) shim:

@ specified 2.50 N.m (25.5 kgf.cm, 22 lbl.in)- you measure 0.54 N.m (5.5 kg{.cm, 5lbl.in}

2.0 N.m (20 kgf.cm, 18lbf.in) less

@you measure 3.29 N.m (33.5 kgI.cm, 29 lbt.in)- specified 2.50 N.m (25.5 kgf.cm, 22 lbf.in)

0.8 N.m (8 kgf.cm,7lbf.in) more

-3) Each shim size up or down from standard

makes about O.3-0.4 N.nt (3-4 kgf.cm,

2.6-3.5 lbl.in) difterence in tapered roller

bearing preload.

a In example @, your measured tapered roller

bearing preload was 2.O N.m (2O kgt.cm,

18 lbf in) less than standard so you need a

79.5 mm shim live sizes thicker than stan-

dard {try the 1.53 mm (O.0602 in) shim and

recheck).

a ln example @ your's was 0.8 N.m {8

kgf.cm,7lbf.in) more than standard. so

you need a thrust shim two sizes thinner (try

the 1 .32 mm (O.O52O in) shim and recheck).

1O. After adjusting the tapered roller bearing preload, as-

semble the transmission, and installthe lransmission

housing (see section 13).

8 x 1.25 mm

27 N,m (2.8 kgt'm, 20 lbf.ft)

11. Rotate the difterential assembly in both directions

to seat the tapered roller bearings.

1 5-16

\

Page 622 of 1680

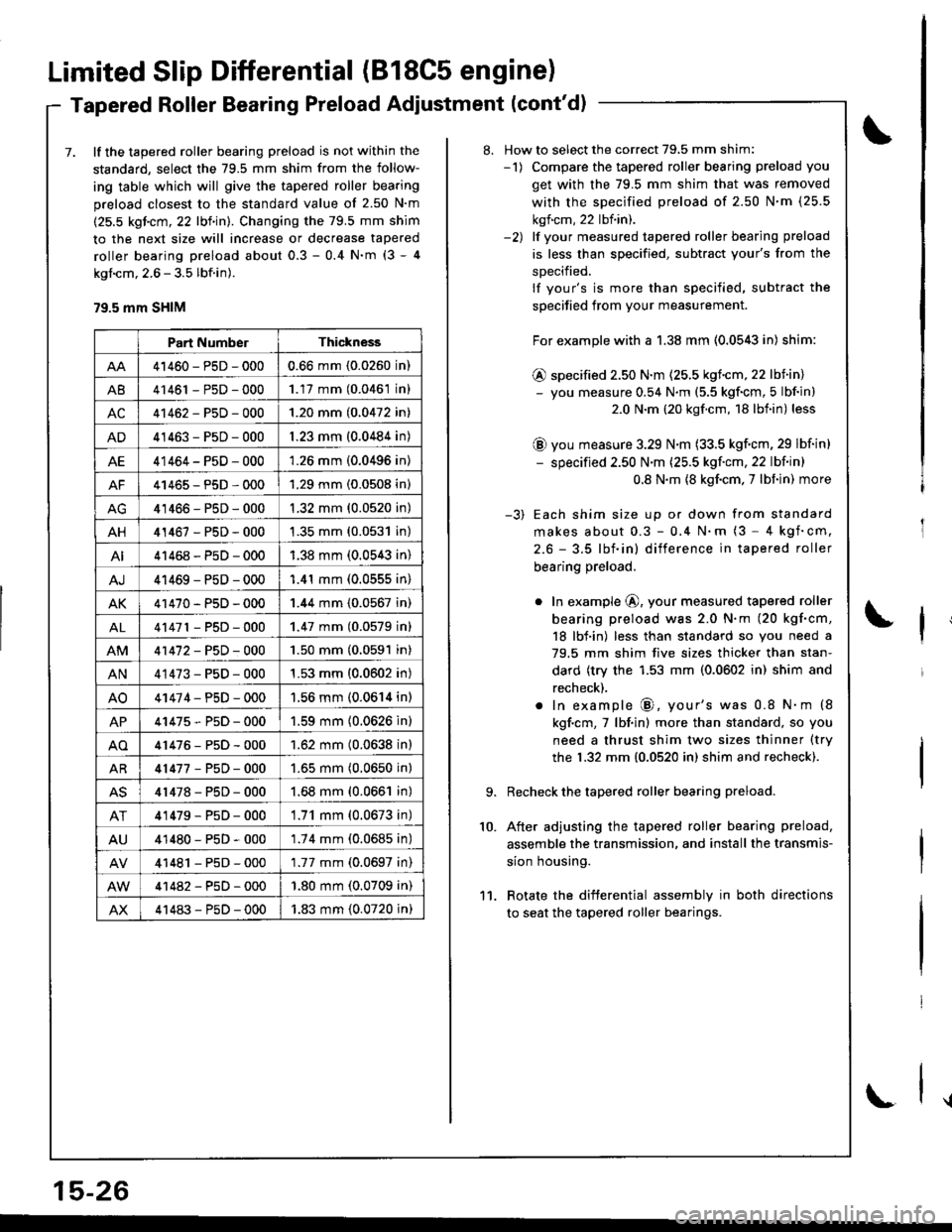

Limited Slip Differential (B18C5 engine)

Tapered Roller Bearing Preload Adiustment (cont'd)

7. lf the tapered roller bearing preload is not within the

standard, select the 79.5 mm shim from the follow-

ing table which will give the tapered roller bearing

preload closest to the standard value of 2.50 N'm

(25.5 kgicm, 22 lbf in). Changing the 79.5 mm shim

to the next size will increase or decrease tapered

roller bearing preload about 0.3 - 0.4 N'm (3 - 4

kgl.cm, 2.6 - 3.5 lbf.in).

79.5 mm SHIM

Part NumberThickness

41460-PsD-0000.66 mm (0.0260 in)

A841461 - P5D - 0001.17 mm (0.0461 in)

AC41462-P5D-0001.20 mm (0.0472 in)

AD41463-P5D-0001.23 mm (0.0484 in)

AE41464-P5D-0001.26 mm (0.0496 in)

AF41465-P5D-0001.29 mm (0.0508 in)

41466-PsD-0001.32 mm (0.0520 in)

AH41467-PsD-0001.35 mm (0.0531 in)

AI41468-P5D-0001.38 mm (0.0543 in)

AJ41469-PsD-0001.41 mm (0.0555 in)

AK41470-PsD-0001.44 mm (0.0567 in)

AL41471 - PsD - 0001.47 mm (0.0579 inl

41472-P5D-0001.50 mm (0.0591 in)

AN41473-P5D-0001.53 mm (0.0602 in)

AO41474-PsD-0001.56 mm (0.0614 in)

AP41475-P5D-0001.59 mm (0.0626 in)

AO41476-P5D-0001.62 mm (0.0638 in)

AR41477-P5D-0001.65 mm (0.0650 in)

AS41478-PsD-0001.68 mm (0.0661 in)

AT41479-P5D-0001.71 mm (0.0673 in)

AU41480-PsD-0001.74 mm (0.0685 in)

41481 - PsD - 0001.77 mm (0.0697 in)

41482-P5D-000'1.80 mm (0.0709 in)

AX41483-P5D-0001.83 mm (0.0720 in)

15-26

\

8. How to select the correct 79,5 mm shim:-1) Compare the tapered roller bearing preload you

get with the 79.5 mm shim that was removed

with the sDecified preload of 2.50 N'm (25.5

kgf.cm, 22 lbf.in).-2) lf vour measured tapered roller bearing preload

is less than specified, subtract your's from the

sDecified.

lf your's is more than specified, subtract the

specified from your measurement.

For example with a 1.38 mm (0.0543 in) shim:

@ specified 2.50 N.m (25.5 kgf.cm,22 lbiin)- you measure 0.54 N.m (5.5 kgf'cm, 5 lbf in)

2.0 N.m (20 kgf.cm, 18 lbf.in) less

@ you measure 3.29 N.m (33.5 kgf.cm, 29 lbf in)

- specified 2.50 N'm (25.5 kgf'cm, 22 lbf in)

0.8 N.m {8 kgf.cm. 7 lbf in) more

-3) Each shim size up or down from standard

makes about 0.3 - 0,4 N.m (3 - 4 kgf'cm,

2.6 - 3.5 lbf.in) difference in tapered roller

bearing preload.

o In example @, your measured tapered roller

bearing preload was 2.0 N.m (20 kgf.cm,

18 lbf.in) less than standard so you need a

79.5 mm shim five sizes thicker than stan-

dard (try the 1.53 mm (0.0602 in) shim and

recheck).

. In example @, your's was 0.8 N.m (8

kgf.cm,7 lbf.in) more than standard, so you

need a thrust shim two sizes thinner (try

the 1.32 mm {0.0520 in) shim and recheck).

Recheck the tapered roller bearing preload.

After adjusting the tapered roller bearing preload,

assemble the transmission, and install the transmis-

sion housing.

Rotate the difterential assembly in both directions

to seat the tapered roller bearings.

10.

11.

Page 656 of 1680

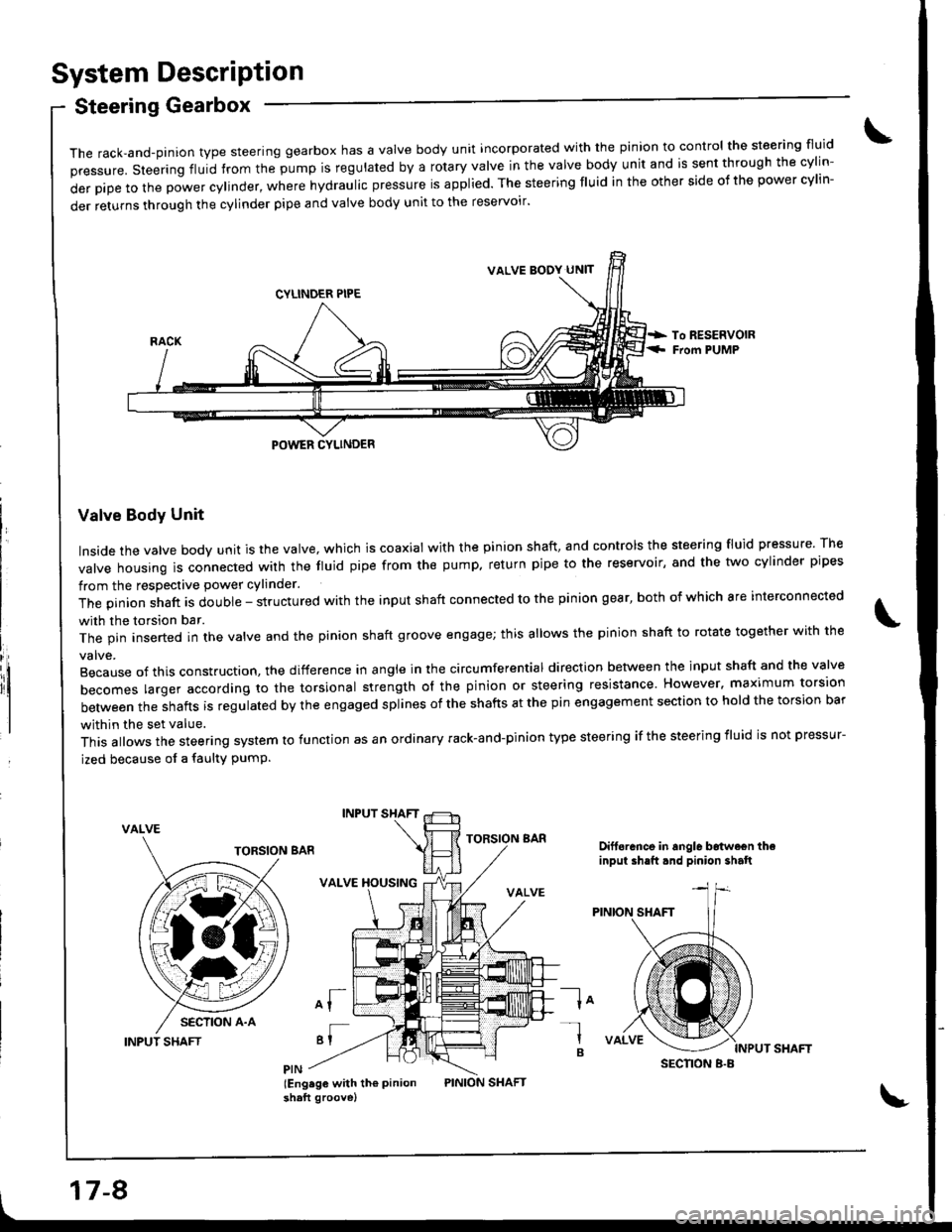

System DescriPtion

Steering Gearbox

it

The rack,and-pinion type steering gearbox has a Valve body unit incorporated with the pinion to control the steering fluid

pressure. steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin-

derpipetothepowercy|inder,wherehydrauIicpressureisapp|ied.Thesteeringf|Uidintheothersideofthepowercy|in-

der returns through the cylinder pipe and valve body unit to the reservoir'

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure The

valve housing ls connected wirh the fluid pipe from the pump. return pipe to the reservoir, and the two cylinder pipes

from the respective power cylinder.

The pinion shaft is double - structured with the input shaft connected to the pinion gear, both of which are interconnected

with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with the

Because of this construction. the difference in angle in the circumferential direction between the input shaft and the valve

becomes larger according ro the torsional strength ol the pinion or steering resistance. However. maximum torsion

between the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion bar

within the set value.

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering iluid is not pressur-

ized because of a faulty PumP.

VALVE

INPUT SHAFT

INPUT SHAFT

VALVE XOUSING

of

'I

lEng.ge with th€ Pinionshaft groove)

TORSION BARDift6rance in angle b6twe€n theinput ih.ft.nd pinion shalt

la-l

B

VALVE BODY UN]T

SECNON B.B

17-8

Page 668 of 1680

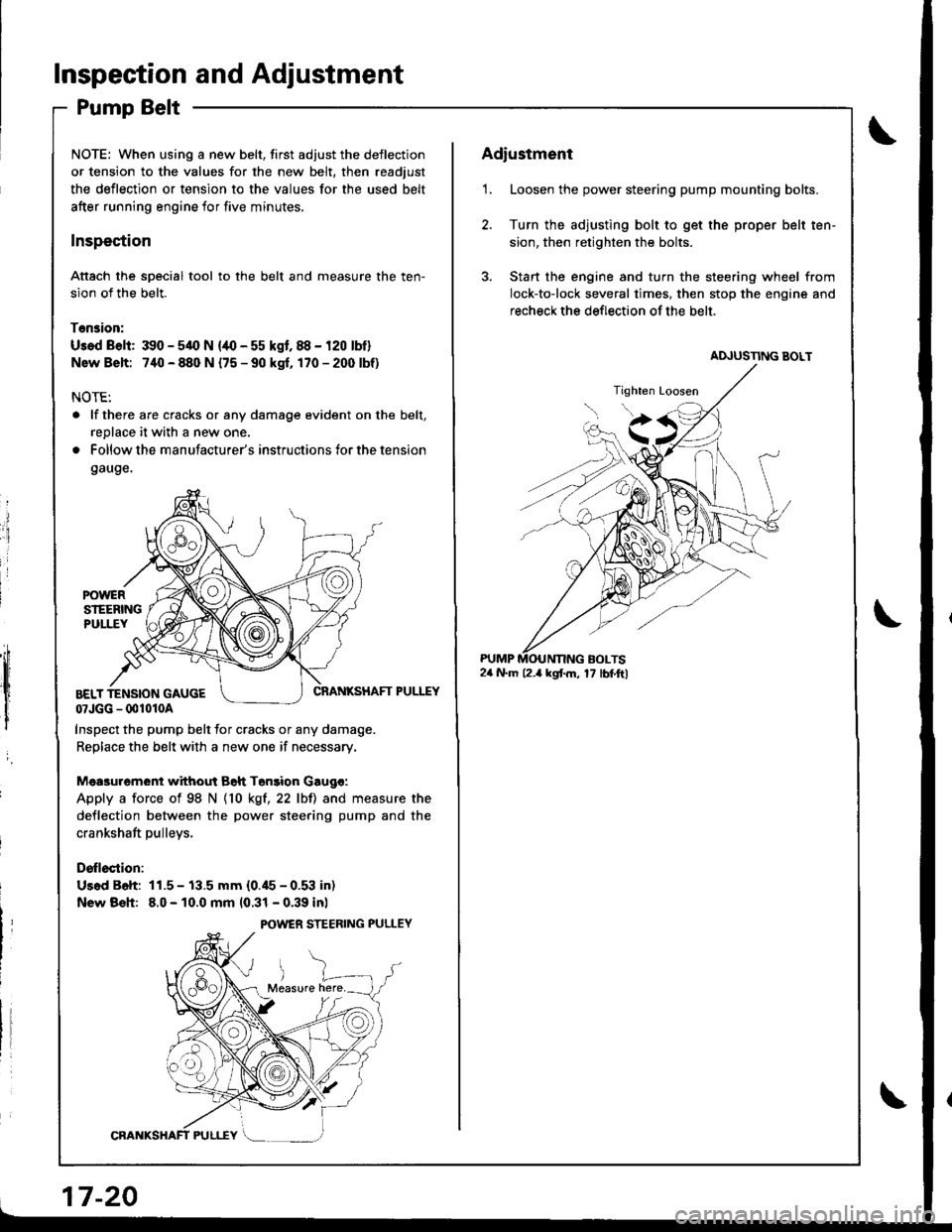

Inspection and Adjustment

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used belt

after running engine for five minutes,

Inspection

Attach the soecial tool to the belt and measure the ten-

sion of the belt.

Tension:

Usad Belt: 390 - 54O N {/10 - 55 kgf. 88 - 120 lbf}

Nsw Belt: 740 - 880 N {75 - 90 kgf. 170-2(X)lbf)

NOTE:

. lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions for the tension

gauge.

ii

:i

i

I

,;h

,lt l

I

i

CRANKSHAFT PULEYBELT TENSION GAUGE07JGG - 001010A

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if necessary.

Mea3urement without Bah Tonsion Gaugo:

Apply a force of 98 N {10 kgt,22 lbll and measure the

deflection between the power steering pump and the

crankshaft pulleys,

Drllection:

Us.d B6h: 11.5 - 13.5 mm (0.45 - 0.53 in)

New Bsh: 8.0 - 10.0 mm 10.31 - 0.39 inl

POWER STEERING PULLEY

17-20

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Turn the adjusting bolt to get the proper belt ten-

sion, then retighten the bolts.

3. Stan the engine and turn the steering wheel from

lock-to-lock several times. then stop the engine and

recheck the deflection of the belt.

24 N.m l2.a kgf.m, 17 lbf.ftl

Page 858 of 1680

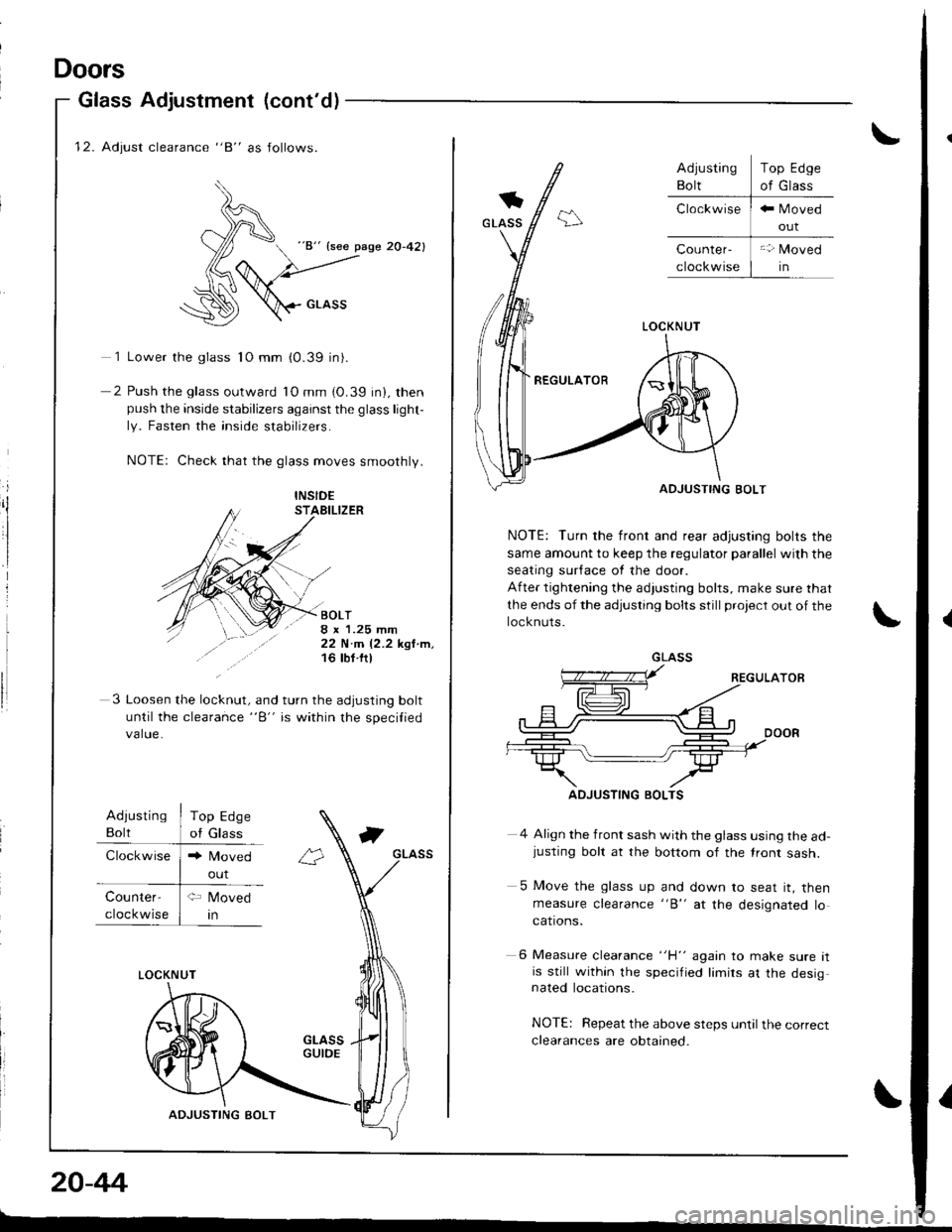

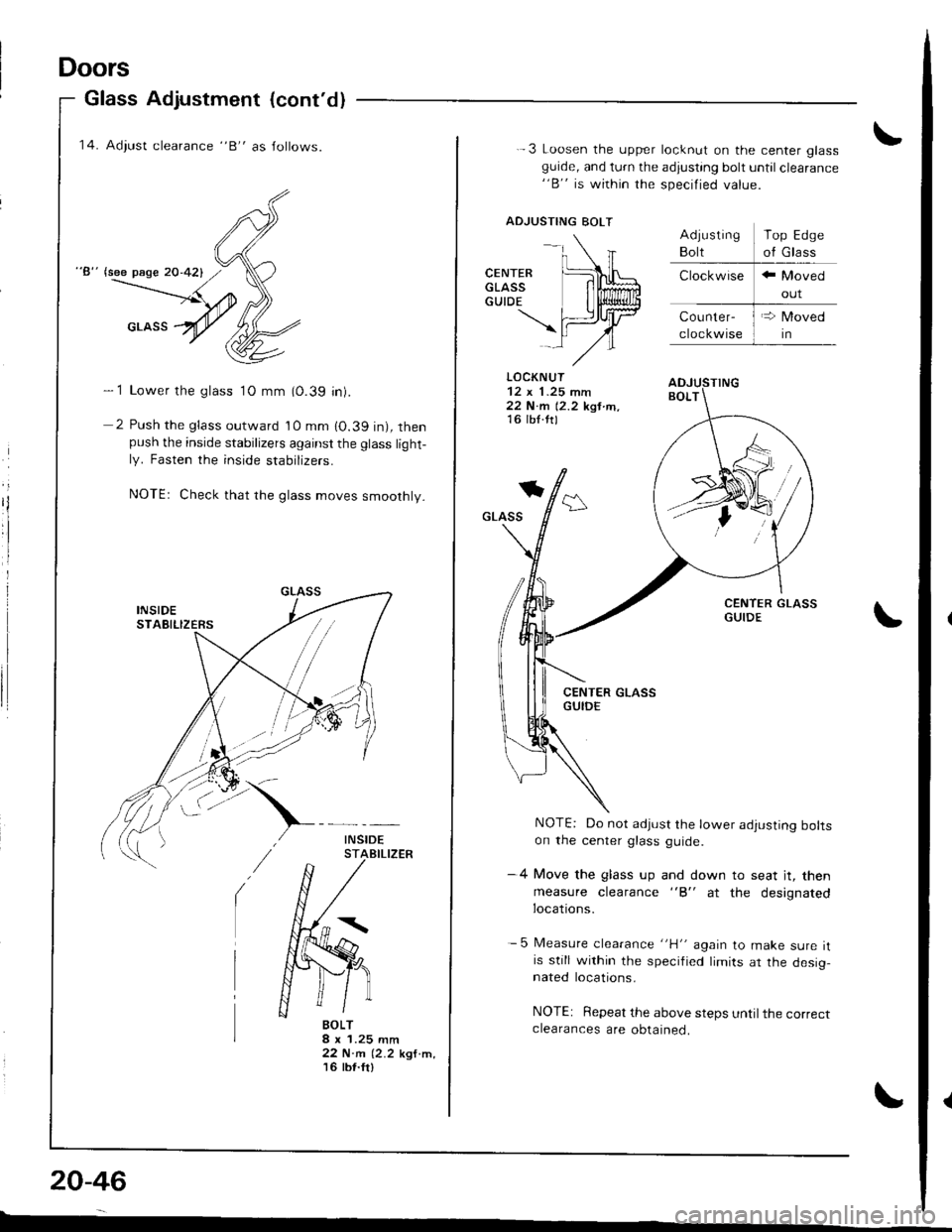

12. Adjust clearance "8" as follows.

)^

d "8" {see pase 20-42}

(6

:\D \crnss

1 Lower the glass 1O mm (0.39 in).

2 Push the glass outward lO mm (0.39 in), thenpush the inside stabilizers against the glass light-

ly. Fasten the inside stabilizers.

NOTE: Check that the glass moves smoothly.

i

ilINSID€STAEILIZER

BOLT8 x 1.25 mm22 N.m 12.2 kgl.m,16 tbt ftl

3 Loosen the lo"knrt, "nd turn the adjusting bolt

until the clearance "B" is within the specilied

value.

Adiusting

Bolt

Clockwise

Top Edge

of Glass

Counter-

cloc kwise

LOCKNUT

ADJUSTING BOLT

20-44

Doors

Glass Adjustment (cont'd)

out

\

LOCKNUT

REGULATOR

ADJUSTING BOLT

NOTE: Turn the front and rear adjusting bolts the

same amount to keep the regulator parallel with the

seating sur{ace ot the door.

After tightening the adjusting bolts, make sure that

the ends of the adjusting bolts still project out of the

locknuts.

4 Align the front sash with the glass using the ad-justing bolt at the bottom of the lront sash.

5 Move the glass up and down to seat it, thenmeasure clearance "B" at the designated locations.

6 Measure clearance "H" again to make sure itis still within the specified limirs at the desig,nated locations.

NOTE: Repeat the above steps until the correct

clearances are obtained.

Top Edge

of Glass

GLASS

ADJUSTING BOLTS

I

Page 860 of 1680

Doors

Glass Adjustment (cont'dl

'14. Adiust clearance "B" as Jollows.

"8" lsee page 20-421

- 1 Lower the glass 1O mm (0.39 in).

2 Push the glass outward 10 mm 10.39 in), thenpush the inside stabilizers against the glass light-ly. Fasten the inside stabrIzers.

NOTEr Check that rhe glass moves smoothly.

BOLT8 x 1.25 mm22 N.m (2.2 kgf.m,'t6 tbt.fr)

20-46

-

-.\

CENTER [L\LGLAss lilffiGUTDE I li$lliun

\fiJrtrlAl-,/"

.-3 Loosen the upper locknut on the center glassguide, and turn the adjusting bolt until clearance"B" is within the specified value.

ADJUSTING BOLT

LOCKNUT

22 N.m 12.2 kgt tn,16 lb{.ttl

*

GLASS

NOTE: Do not adjust the lower adjusting boltson the center glass guide.

-4 Move the glass up and down to seat jt, then

measure clearance "B" at the designatedlocations.

- 5 Measure clearance "H" again to make sure itis still within the specified limits ar the desig,nated locations.

NOTE: Repeat the above steps until the correctclearances are obtained.

Top Edge

of Glass

Page 1334 of 1680

)

Precautions/Procedures

General Precautions

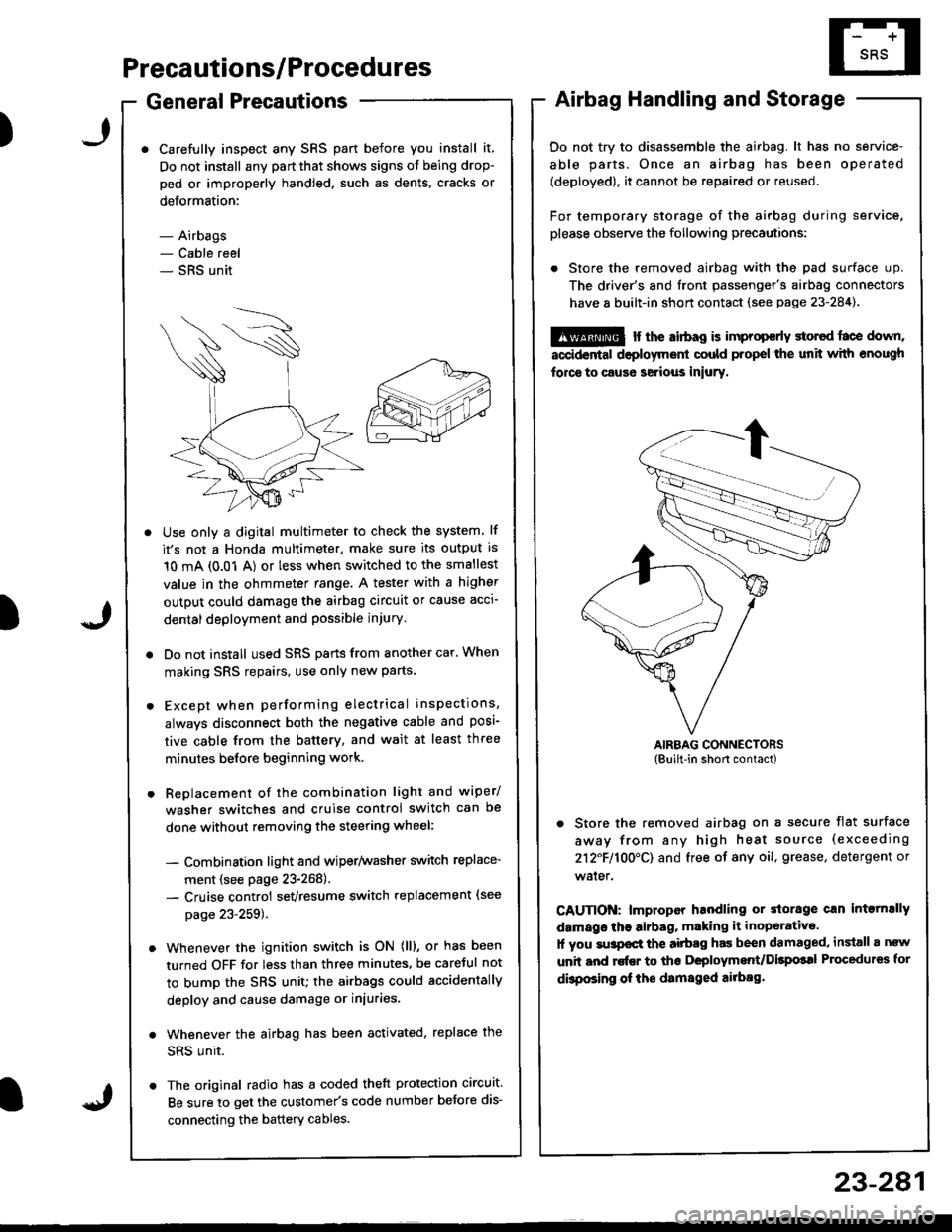

Carefully inspect any SRS part before you install it,

Do not install any part that shows signs of being drop-

ped or improperly handled. such as dents, cracks or

deformstion:

- Airbags- Cable reel- SRS unit

' Use only a digital multimeter to check the system lf

it's not a Honda multimeter. make sure its output is

10 mA (0.01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

r Do not install used SRS parts from anothercar.When

making SRS repairs, use only new parts.

r Except when performing electrical inspections,

always disconnect both the negative cable and posl-

tive cable from the batterY, and wait at least three

minutes before beginning work.

r Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiperlwasher switch replace-

ment (see page 23-268).- Cruise controi sevresume switch replacement (see

page 23-259t�.

. Whenever the ignition switch is ON (ll), or has been

turned OFF for less than three minutes, be caretul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or iniuries.

. Whenever the airbag has been activated, replace the

SRS unit.

. The original radio has a coded theft protection circuit.

Be sure to get the customer's code number beJore dis-

connecting the battery cables.

23-281

Airbag Handling and Storage

Do not try to disassemble the airbag. lt has no service-

able parts. Once an airbag has been operated

(deployed), it cannot be repaired or reused.

For temporary storage of the airbag during service,

please observe the following precautions:

. Store the removed airbag with the pad surface up.

The driver's and tront passenger's airbag connectors

have 8 built-in short contact (see page 23-284).

@ r the airbag is improp€rly storcd face down,

accidental deployment could propel the unit with enough

force to caus6 serious iniury.

AIRBAG CONNECTORS(Built-in short contact)

. Store the removed airbag on a secure flat surface

away from any high heat source (exceeding

212F110O'CI and free of any oil, grease, detergent or

water.

CAUTION: lmproper handling or storage can intornally

damags the airbag, making it inoperative.

1l you su3pocl the aitbag has been damaged, install a ncw

unit and rofEr to ths Deployment/Dilpolal Procedures for

dbposing of ihe damsged ailbag.

)