ecm ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 205 of 1680

i

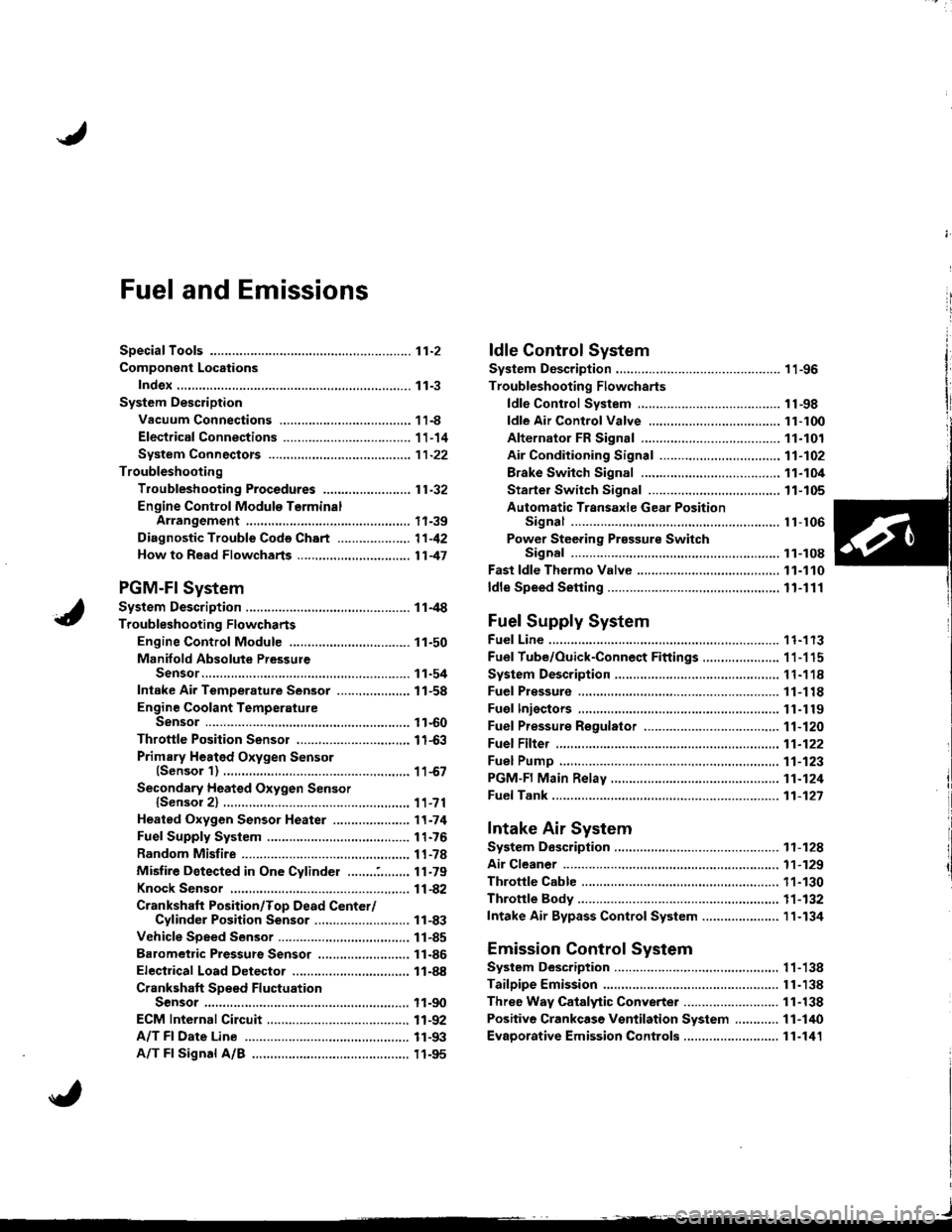

iFuel and Emissions

SDeciaf Toofs ..,...,...............11-2

Component Locations

Index.,..,.,..................................,.,.,.,.,.,..,.,....... 11-3

System Description

Vacuum Connections ..................................,. 11-8

Electrical Connections ................................... 1 1-14

System Connectors ....,.,.,.,............................ 1 1-22

Troubleshooting

Troubfeshooting Procedures ........................ 11.32

Engine Control Module T€rminalArrangement .,.,.,..,.,. 11-39

Diagnostic Trouble Cods Chart .......-.-.......... 11-42

Howto Read Flowcharts ......,..,.,................... 1147

PGM-Fl System

System Description ............ 11-4

Troubleshooting Flowcharts

Engine Control Module ............,...,..,.,........... 11-50

Manifold Absolute PressureSensor...............................,..,.,...,................ 11-54

Intake Air TemDerature Sensor ..........,...,..... 11-58

Engine Coolant TemperatureSensor ....................,.,...,.,........................... 11-60

Throttle Position Sensor .,...........................,. 11-63

Primary Heated Oxygen Sensor(Sensor'l) .......,......,.,. 11-67

Secondary Heated Oxygen Sensorlsensor 2) .................. 11-71

Heated Oxygen Sensor Heater .....................'t1.74

Fuel Supply System ....................................... 1 1-76

Random Mistire ............. 11-78

Misfire Detected in One Cylinder .....,..:,,.,.... 11-79

Knock Sensor .........,.,..,. f -A2

Crankshaft Position/Top Dead Center/Cylinder Position Sensor .,........................ 11-83

Vehicle Speed Sensor .............,.,.,.,....,........... 11-85

Barometric Prsssute Sensor ..,...................... 11-86

Electrical Load Detector ...................,.,.......... 11-88

Crankshaft SDeed FluctuationSensor ...........................................,...,........ 11-90

ECM lnternal Circuit,..............................-......, 11-92

A/T Fl Date Line ............ 11-93

A/T Fl Signal A/B .......... 11-95

I,-1

Page 210 of 1680

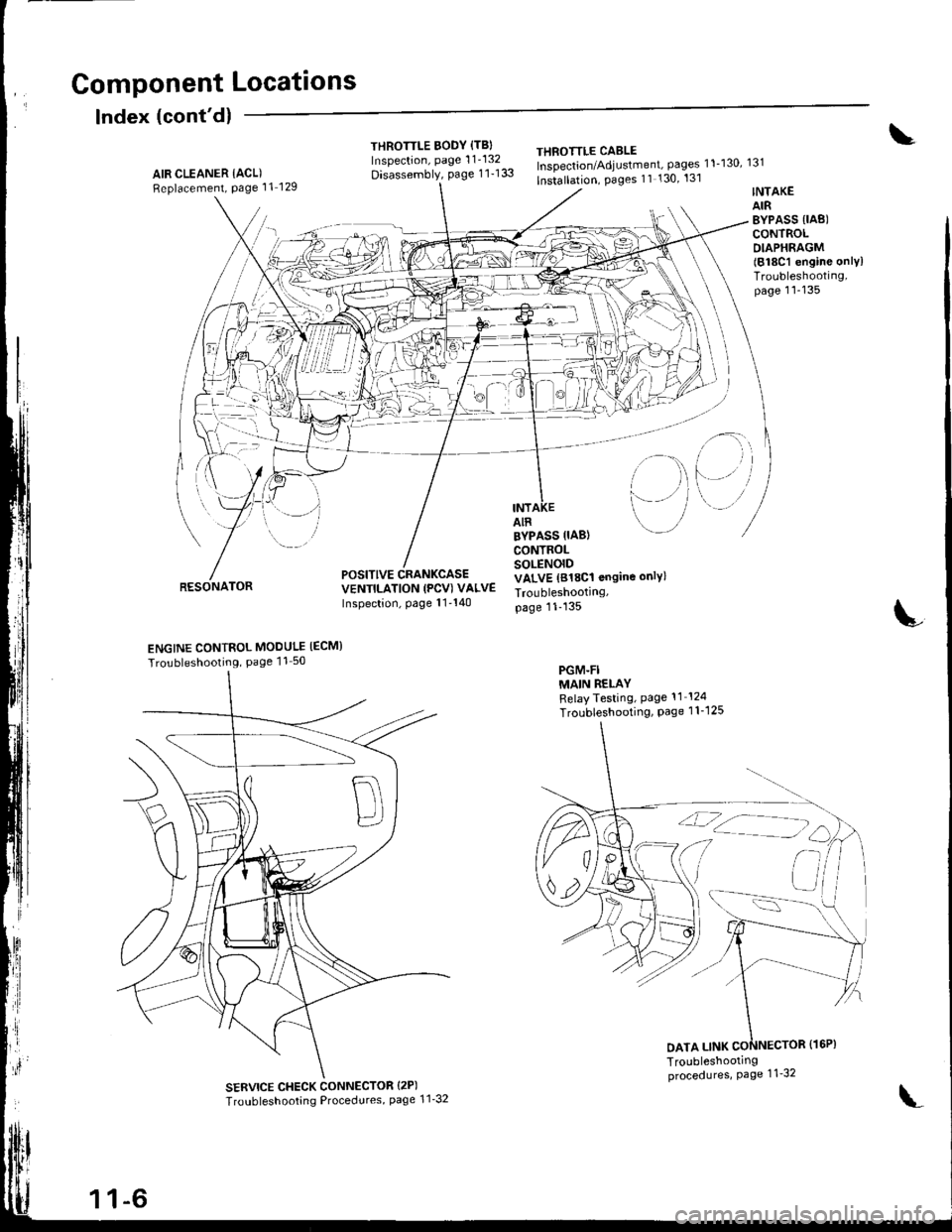

Gomponent Locations

Index (cont'dl

THROTTLE BODY {TBIInspection, page 1 1'132

Disassembly, page 1 1-133

THEOTTLE CABLEInspection/Adjustment, pages 11-130, 131

lnstallation, Pages 11 130' 131AIR CLEANER IACL)Replacement, Page 11 129

RESONATOR

INTAKEAIRBYPASS {IAB)CONTROLDIAPHRAGM(818C1 engine onlylTroubleshooting,page 11-135

i-)

i--- / /

i rl

l'-' i

INTAIR

POSITIVE CRANKCASEVENTILATION (PCV) VALVEInspection, page 11'140

BYPASS IIAB}CONTROLSOLENOIDVALVE (818C1 ongine only)

Troubleshootrng,page 11-135

PGM-FIMAIN RELAYRelayTesting, Page 11 124

Troubleshooting, Page 1 1-1 25

L

ENGINE CONTROL MODULE IECM}

Tro!bleshooting, Page 11 50

SERVICE CHECK CONNECTOR {2P)

Troubleshooting Procedures, page 1 1'32

DATA LINK

1 1-6

\'

Page 234 of 1680

![ACURA INTEGRA 1998 Service Repair Manual System Description

System Connectors [Dash and Floor] (contd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L ACURA INTEGRA 1998 Service Repair Manual System Description

System Connectors [Dash and Floor] (contd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L](/img/32/56983/w960_56983-233.png)

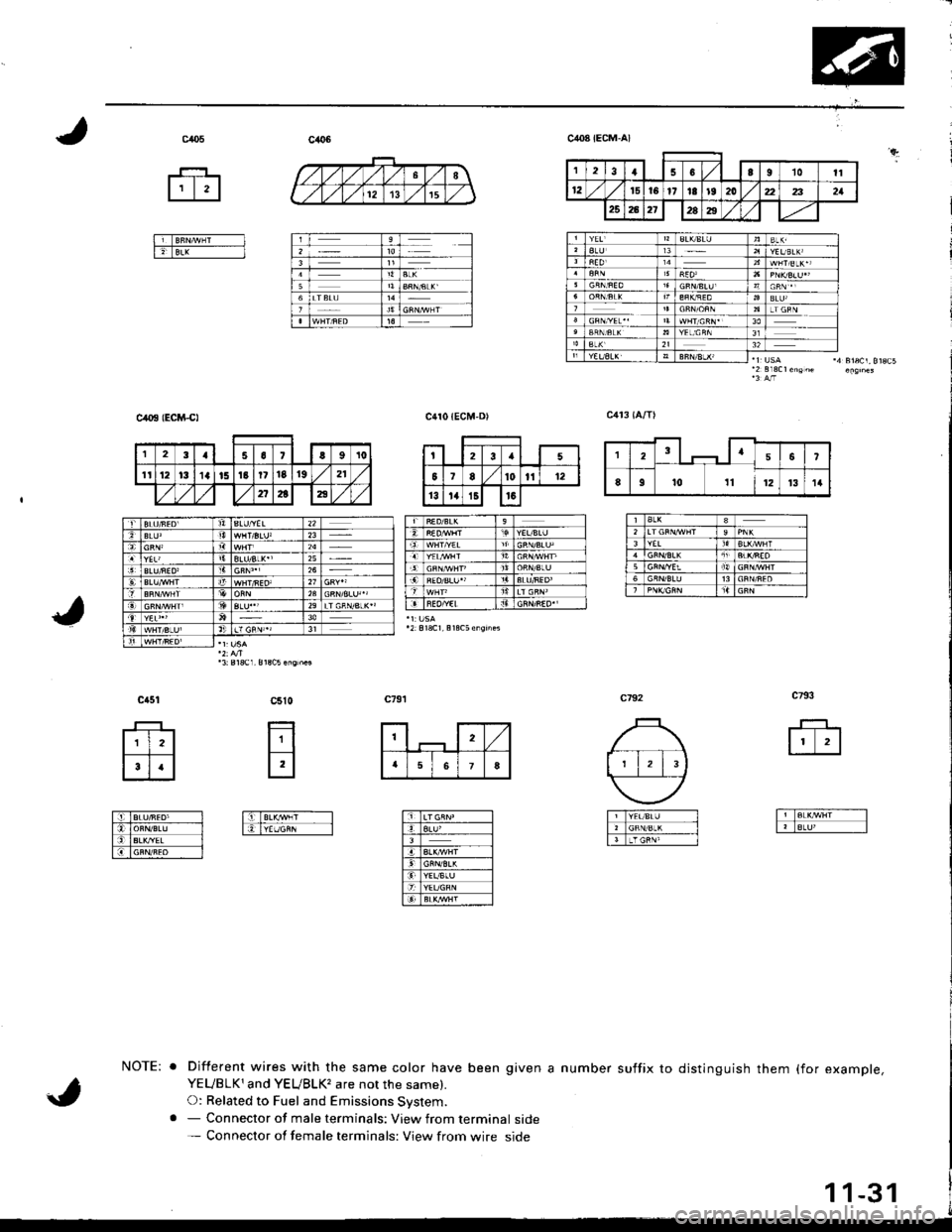

System Description

System Connectors [Dash and Floor] (cont'd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L

Page 235 of 1680

ffi

C/|o8IECM-AI

c4r0 tEcM,D)

Different wires with the same color have been given a number

YEUBLKIand YEUBLK, are not the same).

O: Related to Fuel and Emissions System.- Connector of male terminals: View from terminal side- Connector of female terminals: View from wire side

c4r3 (a/Tlotolt (EcM-ct

cir5l

r;TJJ

\]7

f;TGnBru----ltt|cnN/Brx Il

tIl,acR*---'l

FI

H

ffi

2a58910lt't2t5t6l7!8r920z2z321

25232128a

I23o,aI'r0

1t12t31at5llt71a1s l/21

t367

E9to't1121314

2

567E

NOTE:.suffix to distinguish them (for example,

Page 236 of 1680

t-

il

Troubleshooting ".

Troubleshooting Proccdures

How To Begin Troubleshooting

When the Malfunction lndicator Lamp {MlL) has been reponed on, or there is a driveability problem, use the appropri-

ate procedure below to diagnose and repair the problem.

A. When the MIL has come on:

'1. Connect the Honda PGM Tester or an OBD ll

scan tool to the 16P Data Link Connector (DLC)

located behind the front console right side.

2. Turn the ignition switch ON (ll).

3. Check the DTC and note it. Also check and note

the freeze frame data. Refer to the Diagnostic

Trouble Code Chart and begin troubleshooting.

NOTE:

. SeetheOBDll scantool or Honda PGM Tester user's manuals for specific operating instructions.

. The scan tool or tester can read the Diagnostic Trouble Codes (OTC). freeze frame data, current data, and other

Engine Control Module (ECM) data.

. Freeze frame data indicates the engine conditions when the first malfunction, misfire or luel trim malfunction

was detected. lt can be useful information when troubleshooting.

B. When the MIL has not come on, but there is a driveability problem, refer to the Symptom Chart on page 11-36.

C. DTCS wjll be indicated by the blinking of the Malfunction lNdicator Lamp {MlL) with the SCS service connector con-

nected.

Connect the SCS service connector to Service Check Connector as shown. (The 2P Service Check Connector is

located under the dash on the passenger's side of the car,) Turn the ignition switch on (lll.

scs sERvlcE coNNEcToEo?PAZ - 0010100

MAI-FUNCTIONINDICATORLAMP{MIL)

DATA LINK CONNECTOR Il6PI

OBO ll SCAN TOOL orHONDA PGM TESTER

Page 237 of 1680

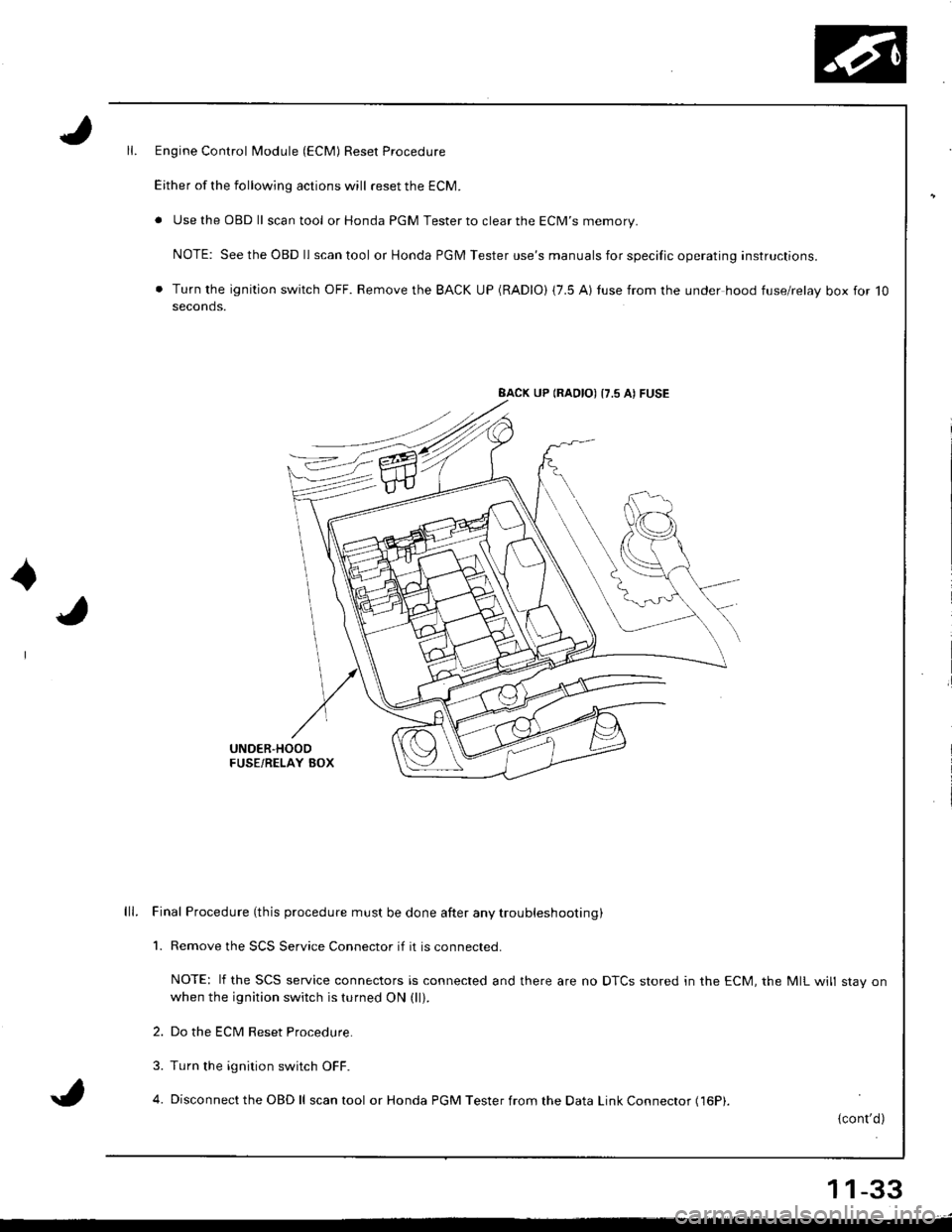

Engine Control Module (ECM) Reset Procedure

Either of the following actions will reset the ECM.

. Use the OBD ll scantool or Honda PGM Tester to clear the ECM'S memory.

NOTE: See the OBD ll scan tool or Honda PGM Tester use's manuals for specific operating instructions.

. Turn the ignition switch OFF. Remove the BACK UP (RADIO) (7.5 AI tuse from the under hood fuse/relay box for 10seconds.

BACK UP (RAOIO) {7.5 AI FUSE

UNDER'HOODFUSE/RELAY BOX

lll. Final Procedure (this procedure must be done after any trou bleshooting )

1. Remove the SCS Service Connector if it is connected.

NOTE: lf the SCS service connectors is connected and there are no DTCS stored in the ECM, the MIL will stav onwhen the ignition switch is turned ON (ll).

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD ll scan tool or Honda PGM Tester from the Data Link Connector (16P|.

{cont'd)

11-33

Page 238 of 1680

l7

Troubleshooting

Troubleshooting Procedures (cont'd)

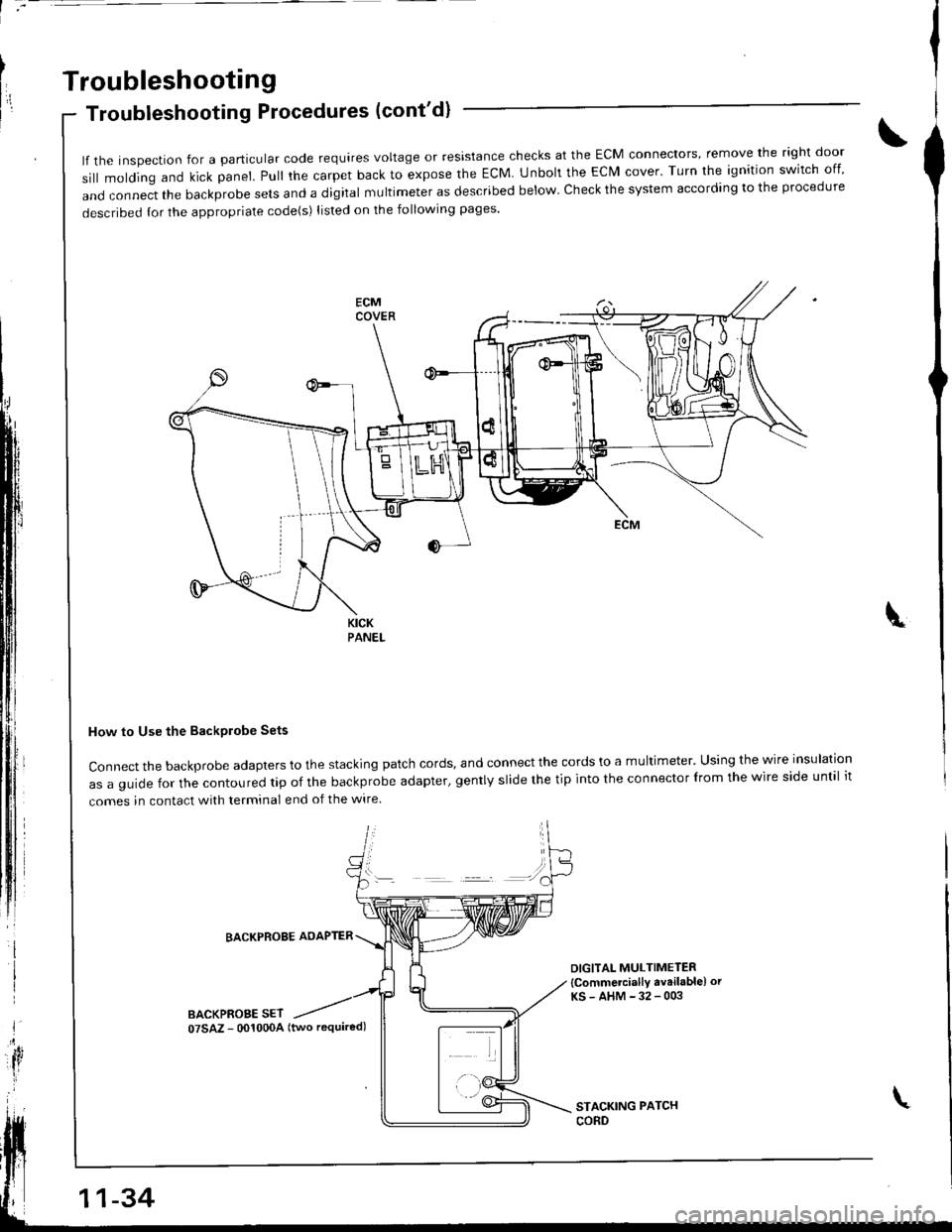

lf the inspection for a particular code requires voltage or resistance checks at the ECM connectors, remove the right door

sill molding and kick panel. pull the carpet back to expose the EcM. Unbolt the EcM cover. Turn the ignition switch off

and connect the backprobe sets and a digital multimeter as described below check the system according to the procedure

described {or the appropriate code(s) listed on the following pages'

How to Use the BackPlobe Sets

Connect the backprobe adapters to the stacking patch cords, and connect the cords to a multimeter' Using the wire insulation

as a guide for the contoured tip of the backprobe adapter, gently slide the tip into the connector lrom the wire side until it

comes in contact with terminal end of the wire

I

BACKPROBE AOAPTER

BACKPROBE SET

DIGITAL MULTIMETER

{Commetcially avrilable) or

KS-AHM-32-003

\

11-34

07SAZ - 001000A (two required)

Page 240 of 1680

Troubleshooting

Troubleshooting Procedures (cont'd)

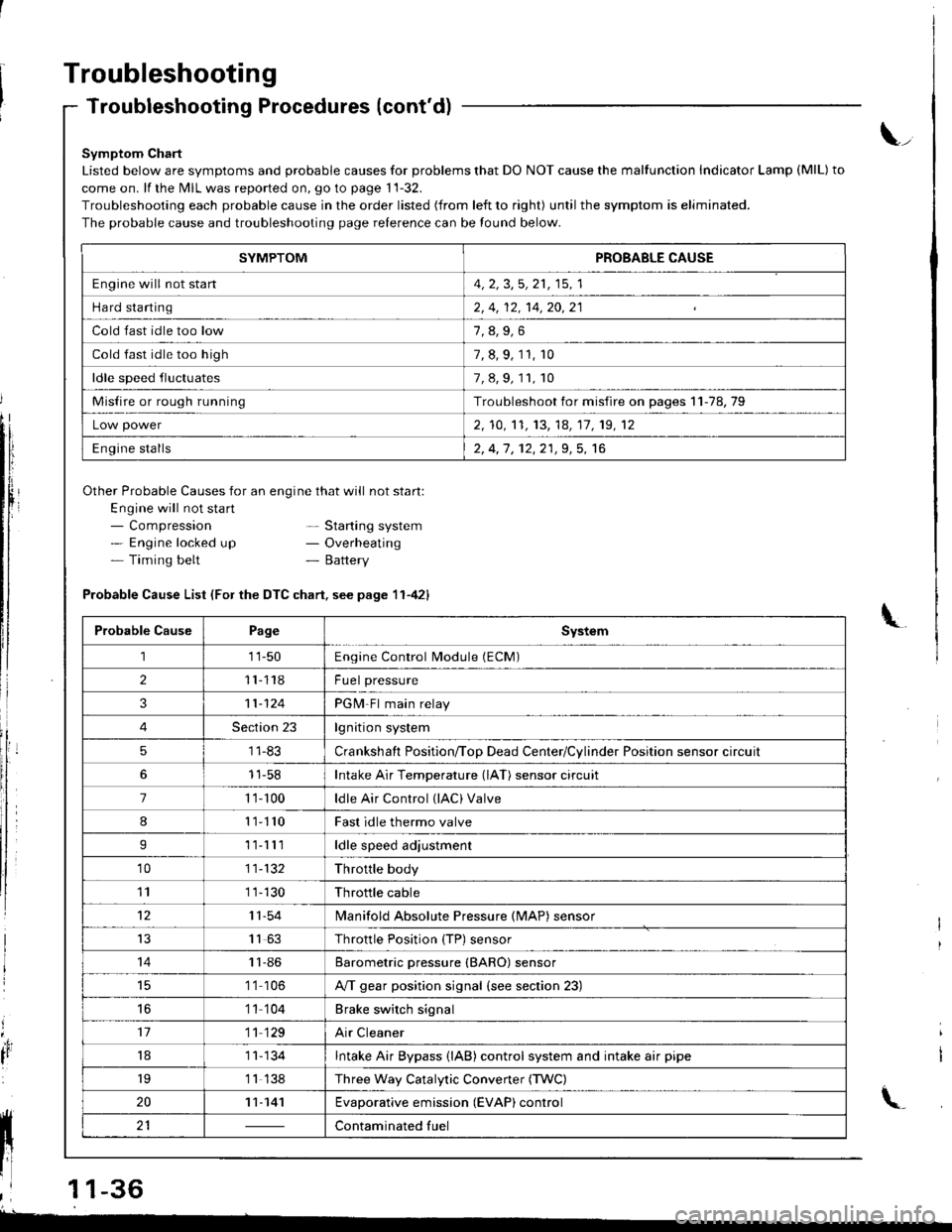

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the malfunction Indicator Lamp (MlL) to

come on. lf the MIL was reported on, go to page 11-32.

Troubleshooting each probable cause in the order listed (from left to right) until the symptom is eliminated.

The probable cause and troubleshooting page relerence can be found below.

Other Probable Causes for an engine that will not start:

Engine will not sta rt- Compression- Engine locked up- Timing belt

\_

- Starting system- Overheating- Battery

'4,

It

Probable Cause List (For the DTC chart. see page 11-421

Probable CausePageSystem

111-50Engine Control Module (ECM)

211118Fuel pressure

311-124PGM-Fl main relay

4Section 23lgnition system

51 1-83Crankshaft Position/ToD Dead Center/Cylinder Position sensor circuit

11-58Intake Air Temperature (lAT) sensor circuit

71 '�t- 100ldle Air Control (lAC) Valve

811110Fast idle thermo valve

I11lllldle speed adjustment

'1011-132Throttle body

111 1-130Throttle cable

1211-54lvlanifold Absolute Pressure {MAP) sensor

IJ1163Throttle Position {TP) sensor

1411-86Barometric pressure (BARO) sensor

1 '1 106A/T gear position signal {see section 23)

16'1 1 104Brake switch signal

1711 129Air Cleaner

181 1- 134Intake Air Bypass {lAB} control system and intake air pipe

19'1 1 138Three Way Catalytic Convener (TWC)

2011-141Evaporative emission (EVAP) control

21Contaminated fuelll ll 21 | - | cont"-in"t"o tu"

11 l-

I

,l 11-36

-

SYMPTOMPROBABLE CAUSE

Engine will not stan4, 2, 3,5, 21, 15, 1

Hard starting2, 4, 12, 14,20,21

Cold fast idle too low

Cold fast idle too high7, 8, 9, 11, r0

ldle speed fluctuates7,8,9,11,10

Misfire or rough runningTroubleshoot for misfire on pages 11-78,79

Low power2, 10,'t1, 13, 14, 17, 19, 12

Engine stalls2, 4,1 , 12,21,9, 5, 16

Page 241 of 1680

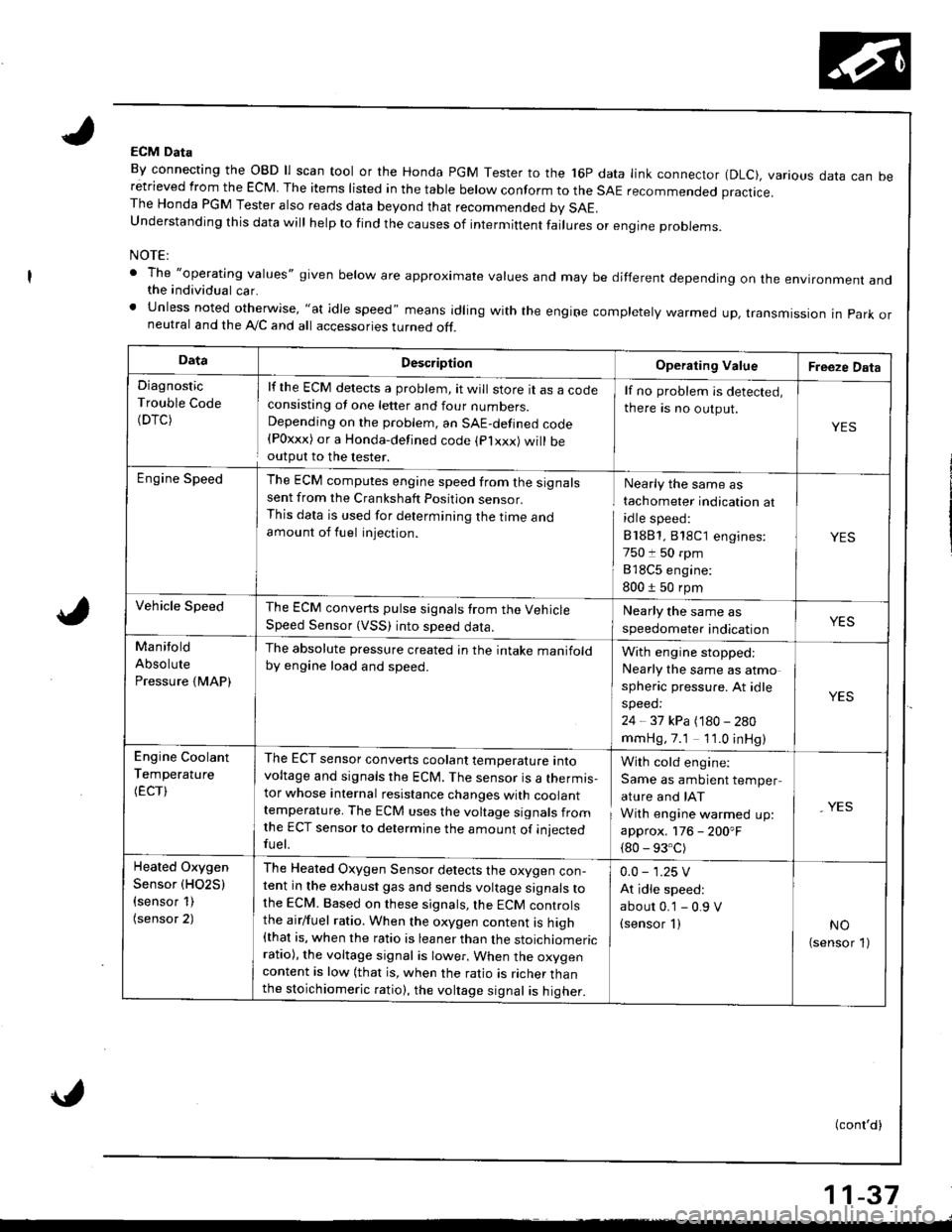

ECM Data

By connecting the OBD ll scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can beretrieved from the EcM The items risted in the tabre berow conform to the sAE recommended practice.The Honda PGM Tester also reads data beyond that recommended bv SAE.understanding this data wirl herp to rind the causes of intermiftent fairures or engine probrems.

NOTE:

' The "operatlng values" given below are approximate values and may be different depending on the environment andthe individual car.' Unless noted otherwise, "at idle speed" means idling with the engiFe completely warmed up, transmissron in park orneutral and the A,/C and all accessories turned off.

DataDescriptionOperating ValueFreeze Data

Diagnostic

Trouble Code(DTC)

lf the ECM detects a problem, it will store tt as a cocteconsisting ot one letter and four numbers.Depending on the problem, an SAE-defined code{Poxxx) or a Honda-defined code (plxxx) will beoutput to the lester.

lf no problem is detected,

there is no output.

YES

Engine SpeedThe ECM computes engine speed from the signalssent from the Crankshaft Position sensor.This data is used for determining the I|me andamount of fuel injection.

Nearly the same as

tachometer indication at

idle speed:

81881,818C1 engines:

750 t 50 rpm

818C5 engine:

800 1 50 rpm

YES

Vehicle SpeedThe ECM converts pulse signals trom the VehicleSpeed Sensor (VSS) into speed data.

Nearly the same as

speedometer indicationYES

Manitold

Absolute

Pressure {MAP)

The absolute pressure created in the intake manifoldby engine load and speed.With engine stopped:

Nearly the same as atmo

spheric pressure. At idle

speed:

24 - 37 kPa (180 - 280

mmHg,7.1 1'1.0 inHg)

YES

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature intovoltage and signals the ECM. The sensor is a thermis-tor whose internal resistance changes with coolanttemperature. The ECM uses the voltage signals fromlhe ECT sensor to determine the amount of iniectedfuel.

With cold engine:

Same as ambient temper

ature and IAT

With engine warmed up:

approx. 176 - 200'F

{80 - 93.C)

, YES

Heated Oxygen

Sensor (HO2S)

{sensor 1)(sensor 2)

The Heated Oxygen Sensor detects the oxygen con-tent in the exhaust gas and sends voltage signals tothe ECM. Based on these signals,lhe ECM controlsthe airlfuel ratio. When the oxygen content is high{that is, when the ratio is leaner than the stoichiomericratio), the voltage signal is lower. When the oxygencontent is low (that is, when the ratio is richer thanthe stoichiomeric ratio), the voltage signal is higher.

0.0 - 1.25 V

At idle speed:

abour 0.'1 - 0.9 V(sensor I )NO(sensor 1)

(conl'd)

11-37

Page 242 of 1680

Troubleshooting

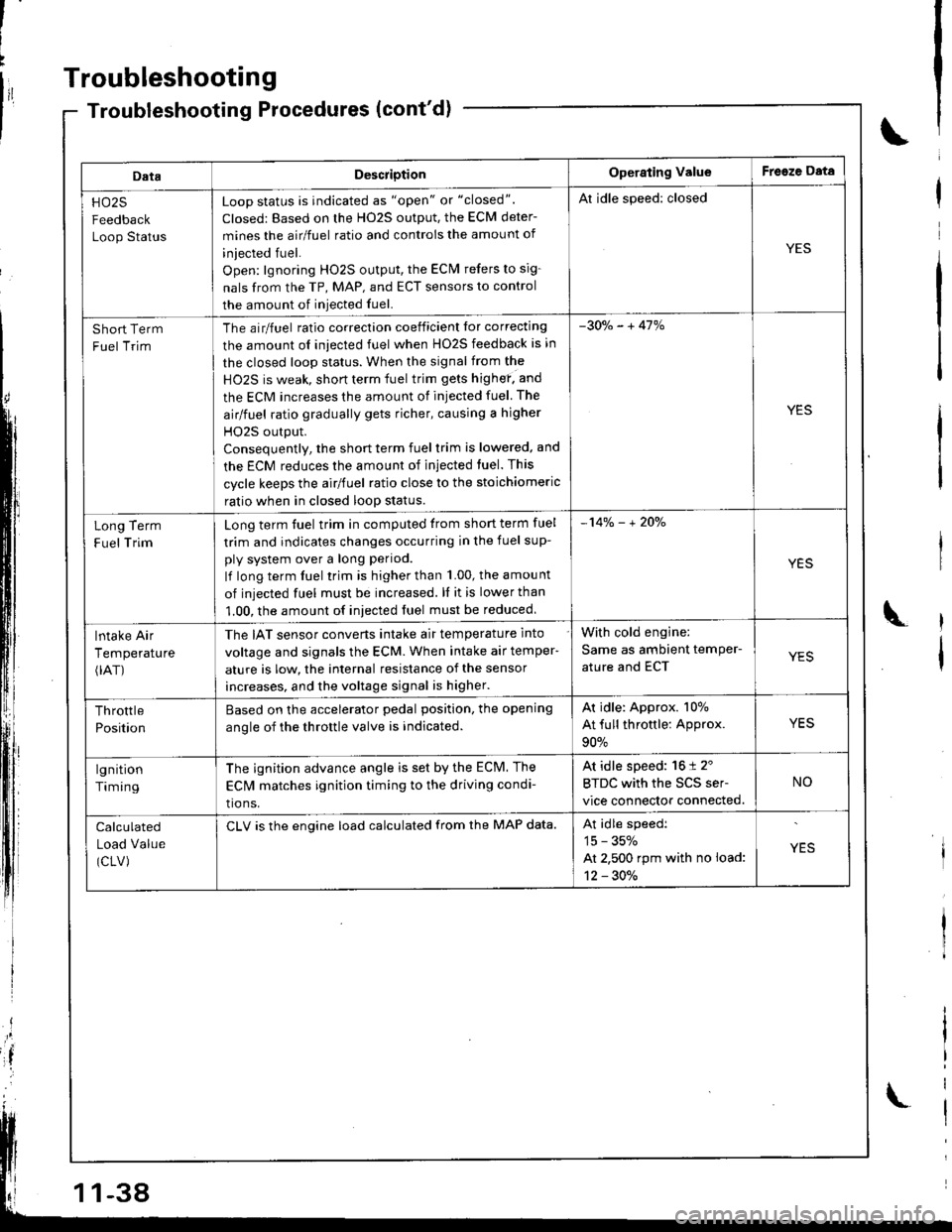

DataDescriotionOperating ValueFreeze Data

HO25

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the H02S output, the ECM deter-

mines the airlfuel ratio and controis the amount of

iniected fuel.

Open: lgnoring HO2S output, the ECM refers to sig-

nals from the TP, MAP, and ECT sensors to control

the amount of iniected fuel.

Al idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correclion coeificient lor correcting

the amount ol iniected fuel when HO2S feedback is in

the closed loop status. When the signal from the

HO2S is weak, short term fuel trim gets highef. and

the ECM increases the amount of injected fuel The

airlfuel ratio gradually gets richer, causing a higher

HO2S output.

Consequentlv, the short term fuel trim is lowered, and

the ECM reduces the amount of injected tuel. This

cycle keeps the airlfuel ratio close to the stoichiomeric

ratio when in closed loop status.

-30o/" - + 41%

YES

Term

Trim

Long

F uel

Long term fuel trim in computed trom short term fuel

trim and indicates changes occurring in the fuel sup-

ply system over a long period.

lf long term fuel trim is higher than 1.00, the amou nt

of injected fuel must be increased. ll it is lower than

1.00, the amount of iniected fuel must be reduced

-14% - + 2Oo/"

YES

lntake Air

Temperature(rAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air temper-

ature is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temPer-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position. the opening

anole of the throttle valve is indicated.

Ar idle: Approx. 107o

At full throttle: Approx.

90%

YES

lgnition

Timing

The ignition advance angle is set by the ECM. The

EClvl matches ignition timing to the driving condi-

tio ns.

At idle speed: 16 t 2'

BTDC with the SCS ser-

vice connector connected.

NO

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAP data.At idle speedi

15 - 35%

At 2,500 rpm with no load:

12 - 30./.

YES

-38