frame ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 236 of 1680

t-

il

Troubleshooting ".

Troubleshooting Proccdures

How To Begin Troubleshooting

When the Malfunction lndicator Lamp {MlL) has been reponed on, or there is a driveability problem, use the appropri-

ate procedure below to diagnose and repair the problem.

A. When the MIL has come on:

'1. Connect the Honda PGM Tester or an OBD ll

scan tool to the 16P Data Link Connector (DLC)

located behind the front console right side.

2. Turn the ignition switch ON (ll).

3. Check the DTC and note it. Also check and note

the freeze frame data. Refer to the Diagnostic

Trouble Code Chart and begin troubleshooting.

NOTE:

. SeetheOBDll scantool or Honda PGM Tester user's manuals for specific operating instructions.

. The scan tool or tester can read the Diagnostic Trouble Codes (OTC). freeze frame data, current data, and other

Engine Control Module (ECM) data.

. Freeze frame data indicates the engine conditions when the first malfunction, misfire or luel trim malfunction

was detected. lt can be useful information when troubleshooting.

B. When the MIL has not come on, but there is a driveability problem, refer to the Symptom Chart on page 11-36.

C. DTCS wjll be indicated by the blinking of the Malfunction lNdicator Lamp {MlL) with the SCS service connector con-

nected.

Connect the SCS service connector to Service Check Connector as shown. (The 2P Service Check Connector is

located under the dash on the passenger's side of the car,) Turn the ignition switch on (lll.

scs sERvlcE coNNEcToEo?PAZ - 0010100

MAI-FUNCTIONINDICATORLAMP{MIL)

DATA LINK CONNECTOR Il6PI

OBO ll SCAN TOOL orHONDA PGM TESTER

Page 662 of 1680

I

Troubleshooting

17-14

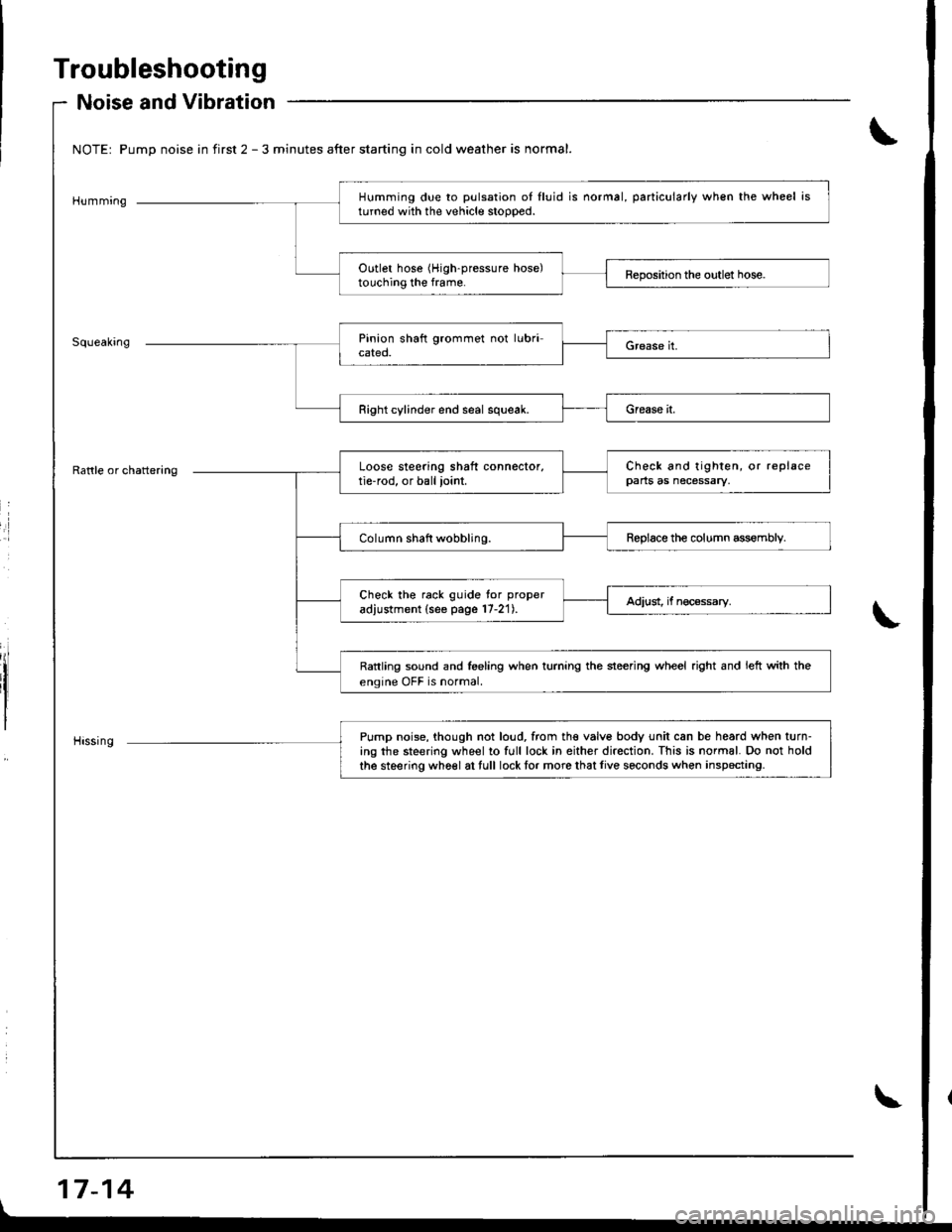

Noise and Vibration

NOTEr Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation oI lluid is normal, particularly when the wheel isturned with the vehicle stoooed.

Outlet hose (High-pressure hose)touching the frame.

Right cylinder end seal squeak.

Pump noise, though not loud, from tho valv6 body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not hold

the steering wh6el at tull lock tor more that live seconds wh€n inspecting.

Loose steering shaft connector,tie-rod, or ball ioint.

Check and tighten, or replacepans as necessary,

Column shaft wobbling.Reolace the column assemblv.

Check ihe rack guide tor proper

adjustment (see page 17-21).Adiust, if nec€ssary.

Rattling sound and feeling when turning the steering wheel right and left with the

engine OFF is normal.

Page 664 of 1680

Troubleshooting

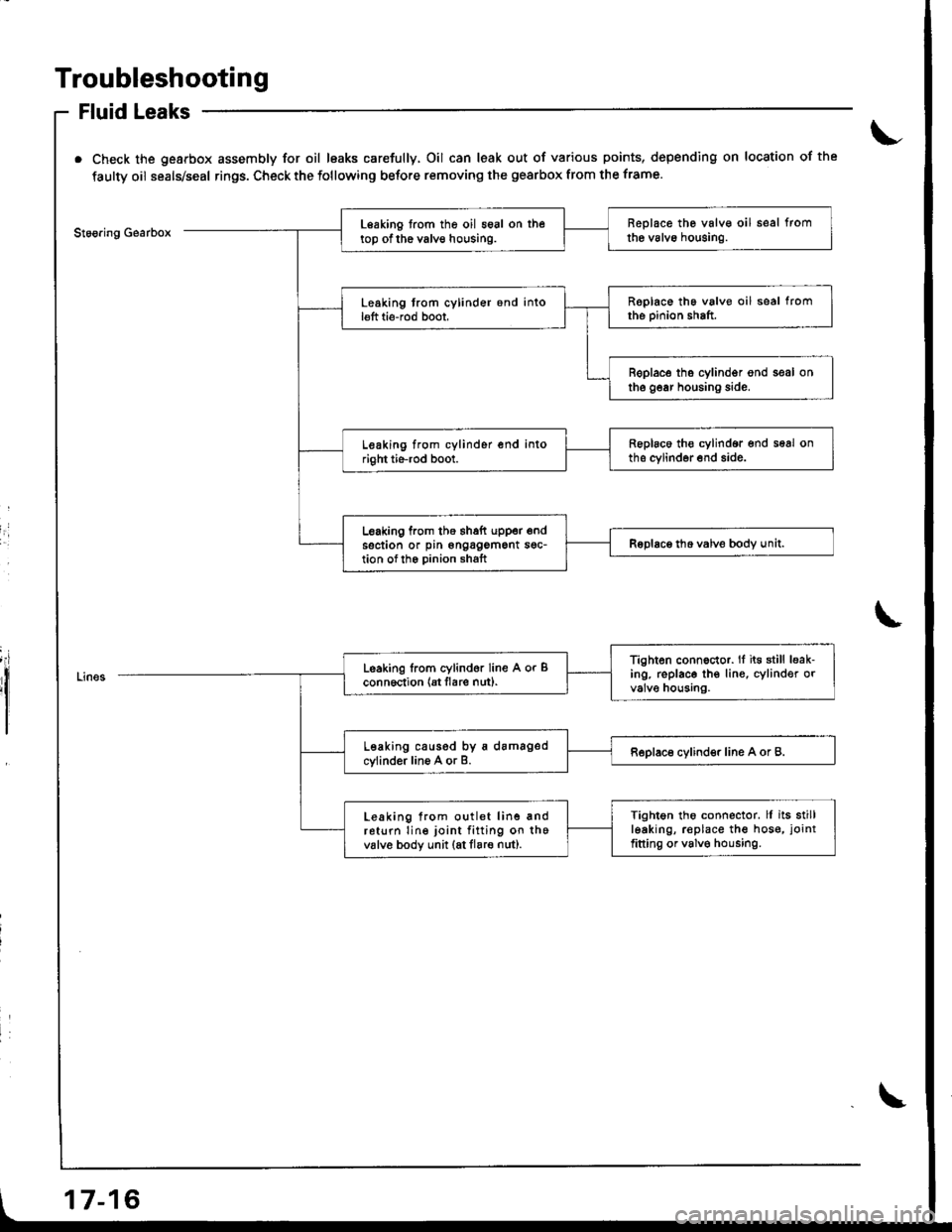

Fluid Leaks

Check the gearbox assembly for oil leaks carefully, Oil can leak out of various points, depending on location of the

faulty oil seals/seal rings. Check the following before removing the gearbox from the frame.

Stoo.ing GearboxReplace the valv€ oil seal fromthe valvo houging.Leaking from the oil seal on thetop of the valve housing.

Roplace the valve oil seal fromthe pinion shaft.Leaking trom cylinder 6nd intol€ft ti6-rod boot,

B€place tho cylindgr ond seal onthe gear housing side.

Replaco th€ cylindor end seal onths cylinder end side.Leaking from cylinder end intoright tie-rod boot.

Leaking from the thaft upper endsection or pin ongagement sgc-tion ofth6 Dinion shaftRoDlace tho valve bodv unit.I

I

Tighten connector. lf it€ still leak-ing. replace th€ lin€, cylinder orvalve housing.

Leaking lrom cylind6r line A or Bconn6ction {Et flare nut).

Leaking caused by a damagedcylinder line A or B.Replace cylinder line A or B.

Tightgn tho connector. ll its stillleaking, r€place the hos€, joint

fitting or valv€ housing.

Leaking from outlet line andreturn line joint fitting on thevalv6 body unit (at flare nut).

17-16

Page 670 of 1680

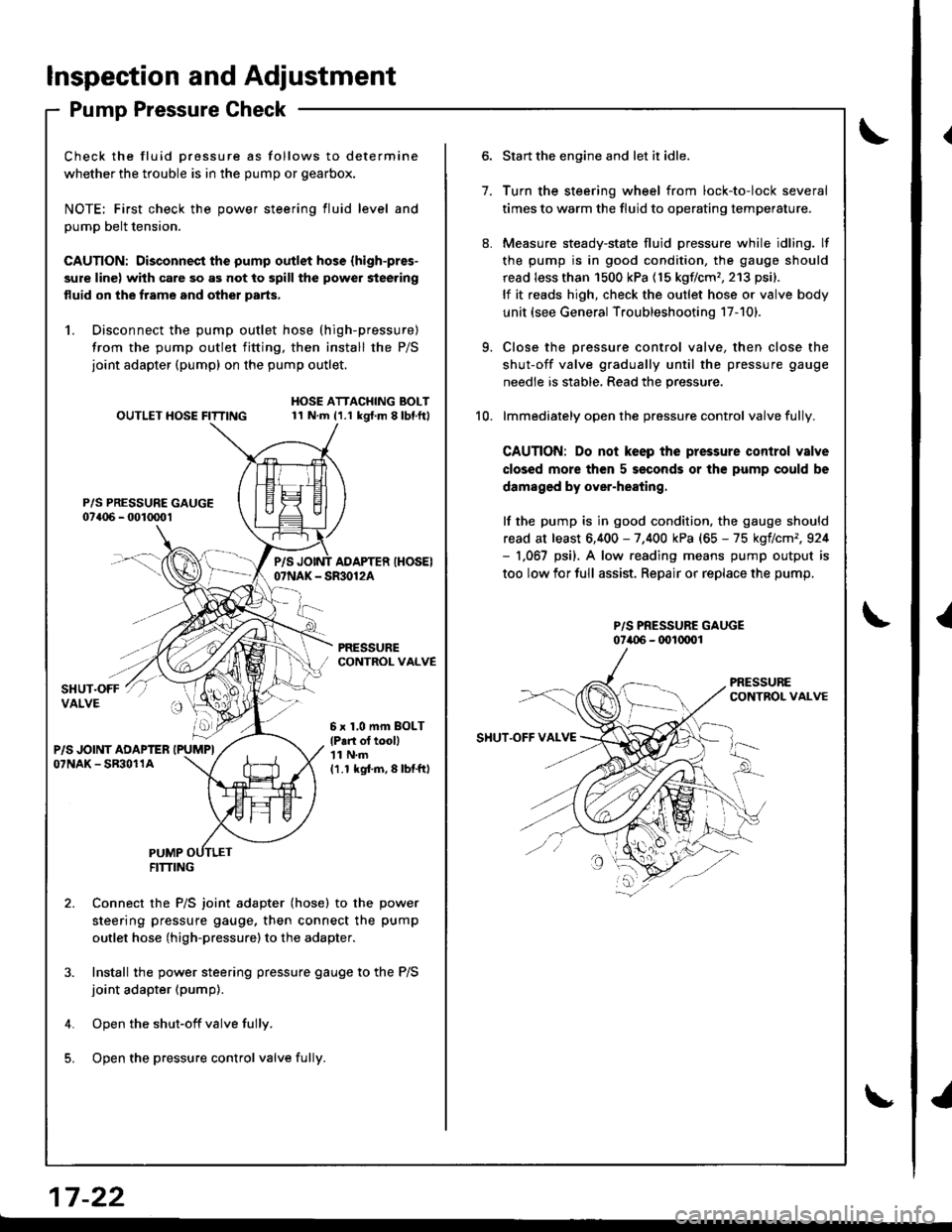

Inspection and Adjustment

Pump Pressure Check

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I

Page 734 of 1680

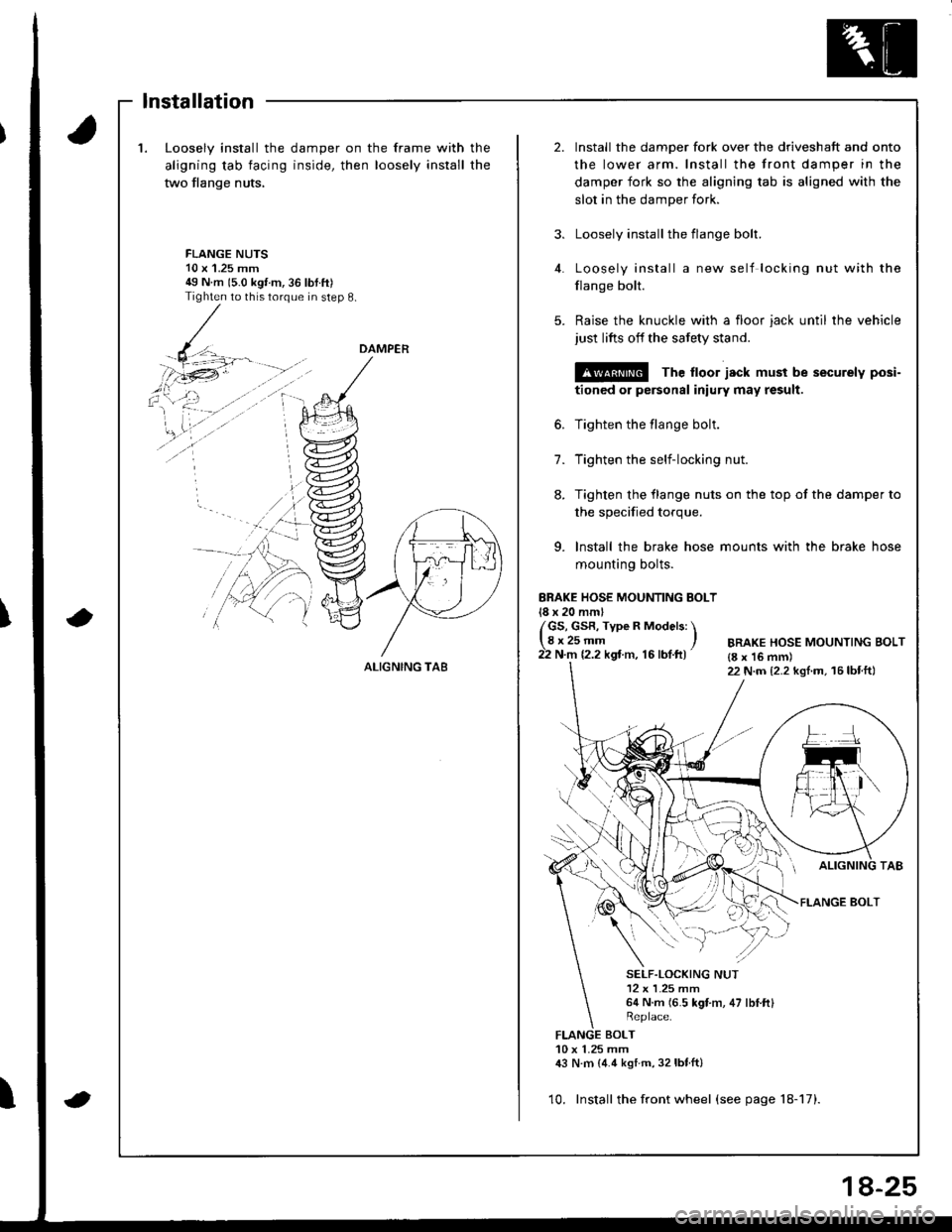

1.Loosely install the

aligning tab facing

two flange nuts,

damper on the frame with

inside, then loosely install

the

the

2.Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper in the

damper fork so the aligning tab is aligned with the

slot in the damper fork.

Loosely install the flange bolt.

Loosely install a new self locking nut with the

flange bolt.

Raise the knuckle with a floor jack until the vehicle

just lifts off the safety stand.

@ The ltoor jack must be securely posi-

tioned or personal iniury may result.

Tighten the flange bolt.

Tighten the self-locking nut.

Tighten the flange nuts on the top of the damper to

3.

FLANGE NUTS10 x'1.25 mm49 N m 15.0 kgt m,36 lbtft)Tighten to this torque in step 8.

4.

5.

6.

7.

8.

the specified torque.

9. lnstall the brake hose mounts with the brake hose

mounting bolts.

ERAKE HOSE MOUNTING BOLT18 x 20 mml

/GS, GsR, Type R Models: \lgr25-- ,22 N.m 12.2 kgt m, 16 lbf.ft)BRAKE HOSE MOUNTING BOLT{8 x 16 mm)22 N.m {2.2 kgl.m, 16lbtft}

FLANGE BOLT

SELF.LOCKING NUT12 x L25 mm64 N.m (6.5 kgt m, 47 lbI.ftl

BOLT10 x 1.25 mm,|:} N.m {4.4 kstm, 32lbtft}

10. Install the front wheel (see page 18-17).

DAMPER

ALIGNING TA8

lnstallation

8-25

Page 815 of 1680

!

Body

Bumpers

Front Bumper Replacement ....................-..... 20-111

Rear Bumpar Replacemeni

Hatchback ................. 20-1/B

Sedan .................... ....20-111'Carpet

. Repfacemenl .,.,.,.,,..-....-.20-126

Consoles, Front and Rear

* Replacement ..................20-130

Dashboard

Component Removal/lnstallation ................ 20-133

Replacement Precautions ...........,................. 20-138

R€placement ....,.,...........20-139

Doors

Door Index Hatchback ................................... 20-2

Front Door Index Sedan .................,.,..,.,....,.. 20-18

Rear Door Index Sedan ........,.,........,.............. 20-30

Emblems

Installation .....................20-167

FenderwellTrim

+ Replacement., ................20.162

Fram€ Repair Chart .-..........20-170

Hatch

Replacoment .......,..........20-118

Adiustment .................... 20-150

Hatch Latch and Lock Cylinder

Replacement ..,.,..... ........ 20-158

Hstch Spoiler

Replacement ......... .......-.20.161

Hatch Weatherstrip/Trunk Lid Wsatherstrip

Replacement ..................20.163

Headliner

ReDlacement

Hatchbsck ,.,....,......,.. 20-98

Sedan .........................................................20-100

Hood

Replacsment ......... ......... 20.146

Adiustment ....................20-117

lnterior Trim

Reolacement

Hatchback ................. 20-91

Sedan .........................................................20-9,1

Mirrors

Power Mirror Reolacement ..........,................ 20-49

Mirrol Holder Removal ............................,..... 20.50

Mirror Holder Installation .............................. 20-50

Mirror Visor and Mirrot Covet

Replacement

Haichback ............20-51

Sedan .................................................... 20-51

Rearview Mirror Reolacement ..........-....-.-.... 20.52

Roof Molding Rep|acament ................................ 20.164

Door and Sid€ Moldings

Replacement .,..........,..... 20-165

Moonroot

lnd6x

Hatchback -................20-77

Sodan .........................................................20-8il

Opener and Latch

Replacement .......... ......,. 20-156

Opensr Cables

Replacamsnt .,.,...,.. ......., 20-154

Retainers and W€atherstrip

Replacement .................. 20-160

Seats

Front Seat Romoval ....................................... 20-103

Front Seat Replacement ...........................,.,.. 20-104

Front Soat Disassembly and Reassembly ...20-106

Torsion Bar ReDlacomant .....,...,......,.......,..,., 2O-1O7

Seat Eelt Switch Ha.ness Location ..,...,.,.,..,2O-1O7

Front Seat Cover Replacemont ..,....,..,..,.....,. 20-108

Rear Soat Roplscemont

Hatchback ................. 20.110

Sedan.........................................................20-112

R€al Seat Cover Replacomont ...................... 20-114

Seat Belts

Front Seat Beh Replacement

Hatchback..................20.117

Sedan20-r18

Rear S6at Bolt R€plac€ment

Hatchback .-......-.-......20-121

Sedan.......................-.-....-.-..........-.............20-122

fnspection ......-.-.,....-.-....20-121

Chifd Seat Anchor Plate ................................ 20-125

Side Sill Panol

Beplacom€nt .................. 20-166

Sub-frame ........................... 20.169

Trunk Lid

Replacement ......... ..,..,.,.20-151

Adiustmeni .................... 20-153

Trunk Lid Latch and Lock Cvlindot

Replac€ment ......... ......... 20-159

Trunk Trim

Replacement .,.,,.,........... 20-97

Windshield, Rear Window, Ouarter Glass

lndex

Hatchback ...........,,.20-53

!

S6dan ......................................................... 20.54

Page 891 of 1680

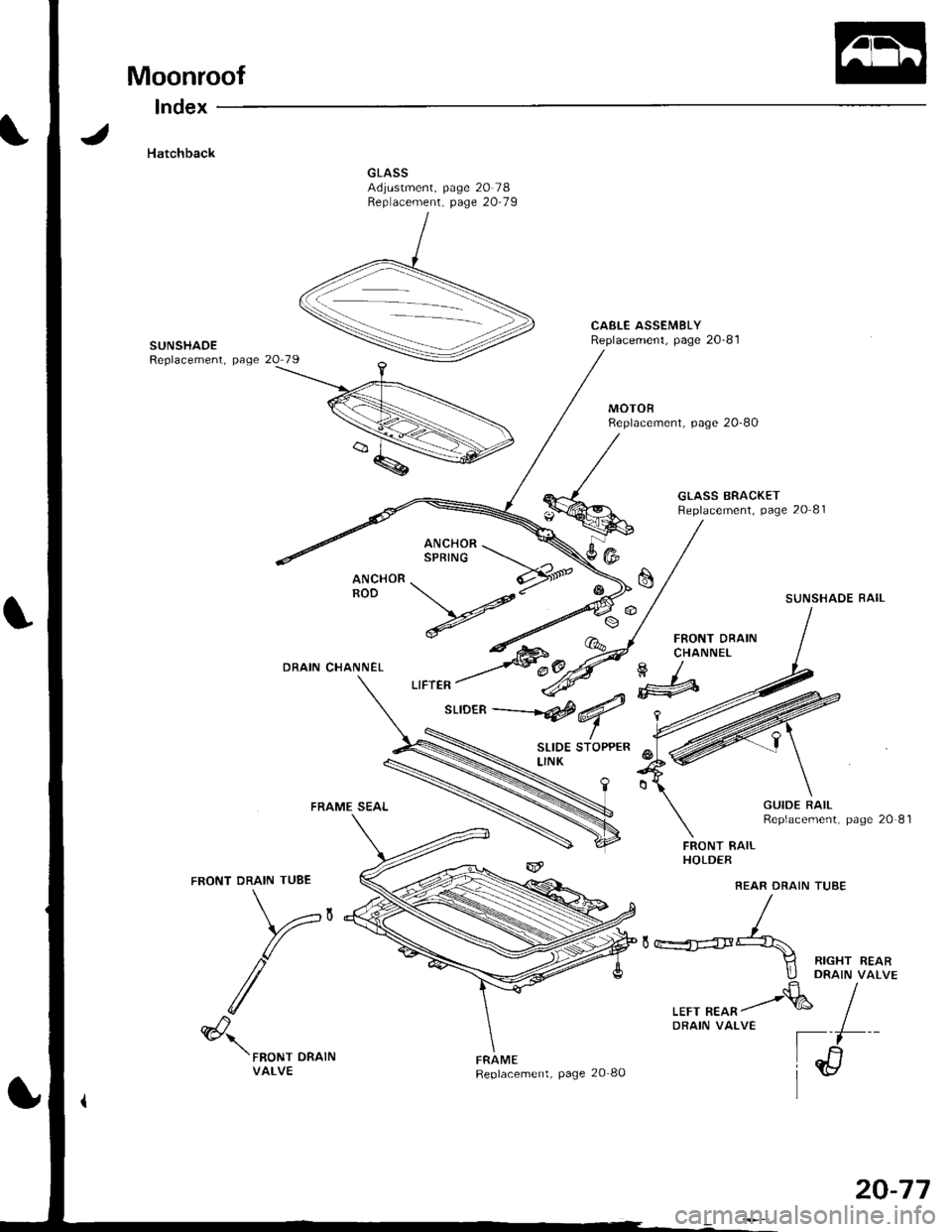

Moonroof

lndex

Hatchback

CAELE ASSEMBLYReplacement, page 20-81SUNSHAOEReplacement, page

MOTOBReplacement, page 20-80

GLASS BRACKETReplacement, page 20 81

SUNSHADE RAIL

FRONT DRAINCHANNELDRAIN CHANNEL

FRAME SEAL

FRONT DRAIN TUBE

V,

/

SLIDE STOPPERLINK

FRAMEReplacement, page 20 80

FRONT RAILHOLDER

REAR DRAIN TUSE

GUIDE RAILReplacement, page 20 81

(@

II RIGHT REARllj DRA|N vaLVE.fr/

,rr, ^*^/& IDRAIN VALVE I

[il

ir/l

@'\'FRoNT DRATNVALVE

20-77

Page 892 of 1680

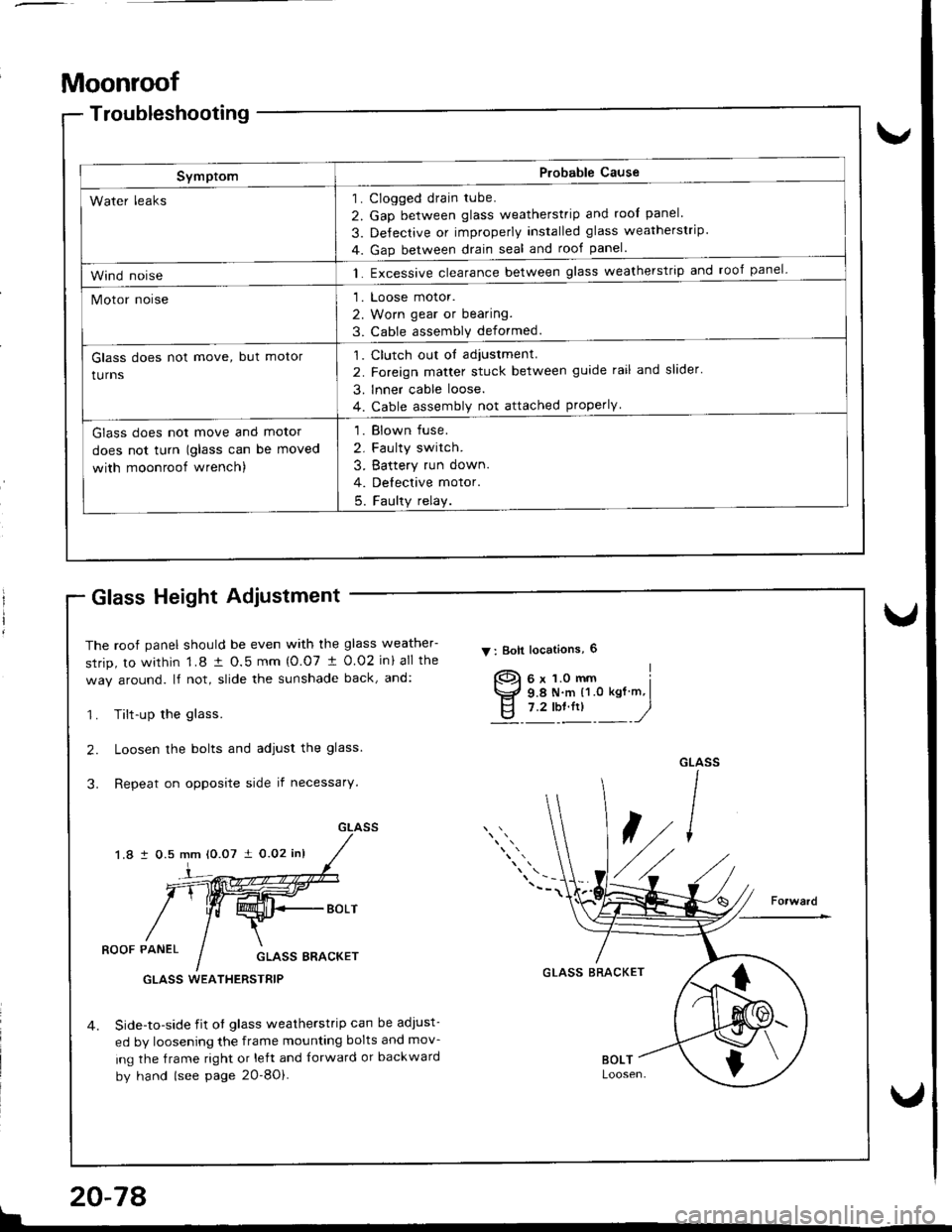

Moonroof

Troubleshooting

SymptomP.obable Cause

Clogged drain tube.

Gap between glass weatherstrip and roof panel

De{ectrve or improperly Installed glass weatherstrip

Gap between drain seal and rool panel.

Excessive clearance between glass weatherstrip and roof panel-

Loose motor.

Worn gear or bearing.

Cable assemblv deformed.

1

2

3

4

1

2

3

1.

Water leaks

Wind noise

Motor noise

Glass does not move, but motor

turns

Clutch out ol adiustment.

Foreign matter stuck between guide rail and slider'

lnner cable loose.

Cable assembly not attached properly

,l

2

3

4

Glass does not move and motor

does not turn (glass can be moved

with moonroof wrench)

1. Blown fuse.

2. Faulty switch.

3. Battery run down.

4. Delective motor.

5. Faulty relay.

Glass Height Adiustment

The roof panel should be even with the glass weather-

srrip, to within 1.8 t O.5 mm {O.07 t 0.02 in} all the

way around. lf not, slide the sunshade back, and:

1. Tilt-up the glass.

2. Loosen the bolts and adjust the glass.

3. Repeat on opposite side if necessary.

1.8 i 0.5 mm 10.07 i 0.02 inl

V : Boll locations, 6

]-

ROOF PANELGLASS BRACKET

Side-to-side iit of glass weatherstrip can be adJust-

ed by loosening the frame mounting bolts and mov-

ing the frame right or left and {orward or backward

by hand (see page 2O-8Oi.

GLASS BRACKETGLASS WEATHERSTRIP

{

$

I

!

20-78

Page 894 of 1680

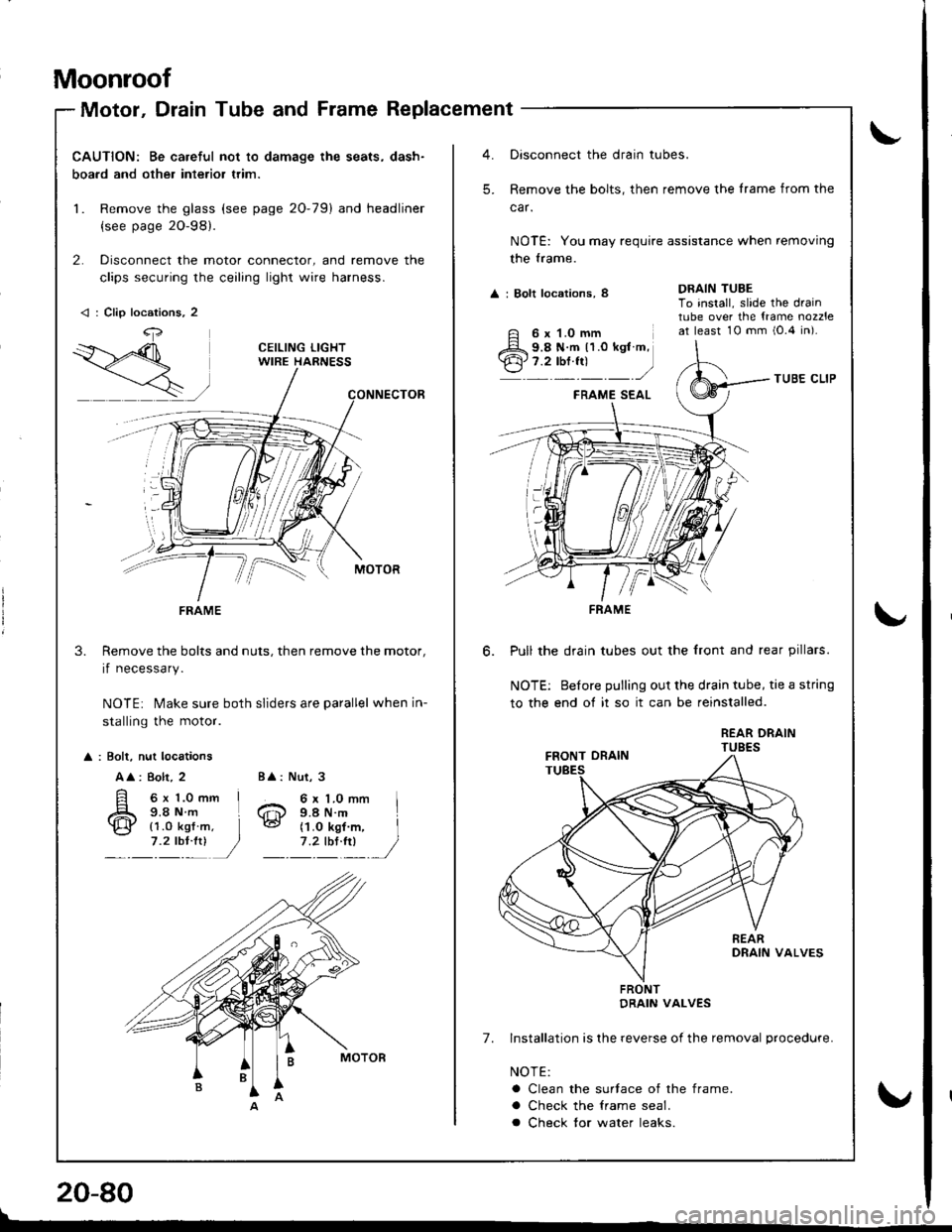

Moonroof

Motor, Drain Tube and Frame Replacement

CAUTION: Be careful not to damage the seats, dash-

boa.d and other interior trim.

1. Remove the glass (see page 20-79) and headliner

{see page 2O-98}.

2. Disconnect the motor connector, and remove the

clips securing the ceiling light wire harness.

Remove the bolts and nuts, then remove the motor,

if necessary.

NOTE: Make sure both sliders are parallel when in-

stalling the motor.

3.

: Bolt, nut locations

A

: 8olt, 2

6x 1.0mm I9.8Nm L

Nut, 3

6 x 1.0 mm I9.4 N.m

BA:

6@{1.0 kgf7 .2 tbl:!)(1.O kgf m, I

1'�lIltl /

< : Clip locations, 2

4,

FRAME

Oisconnect the drain tubes.

Remove the bolts, then remove the lrame from the

car.

NOTE: You may require assistance when removing

the trame.

A : Bolt locations, 8

TUBE CLIP

FRAME SEAL

Pull the drain tubes out the front and rear pillars.

NOTE: Before pulling out the drain tube, tie a string

to the end of it so it can be reinstalled.

REAR DRAINTUBES

7. Installation is lhe reverse of the removal procedure.

NOTE:

a Clean the surtace of the frame.

a Check the lrame seal.

a Check tor water leaks.

DRAIN TUBETo install, slide the draintube over the {rame nozzleat least 10 mm i0.4 in).

-'

6 x 1.0 mm9.8 N.m 11.0 kgt m,7.2 tbf.fr)

FRAME

FRONTDRAIN VALVES

!

\"

20-80

\

v

Page 895 of 1680

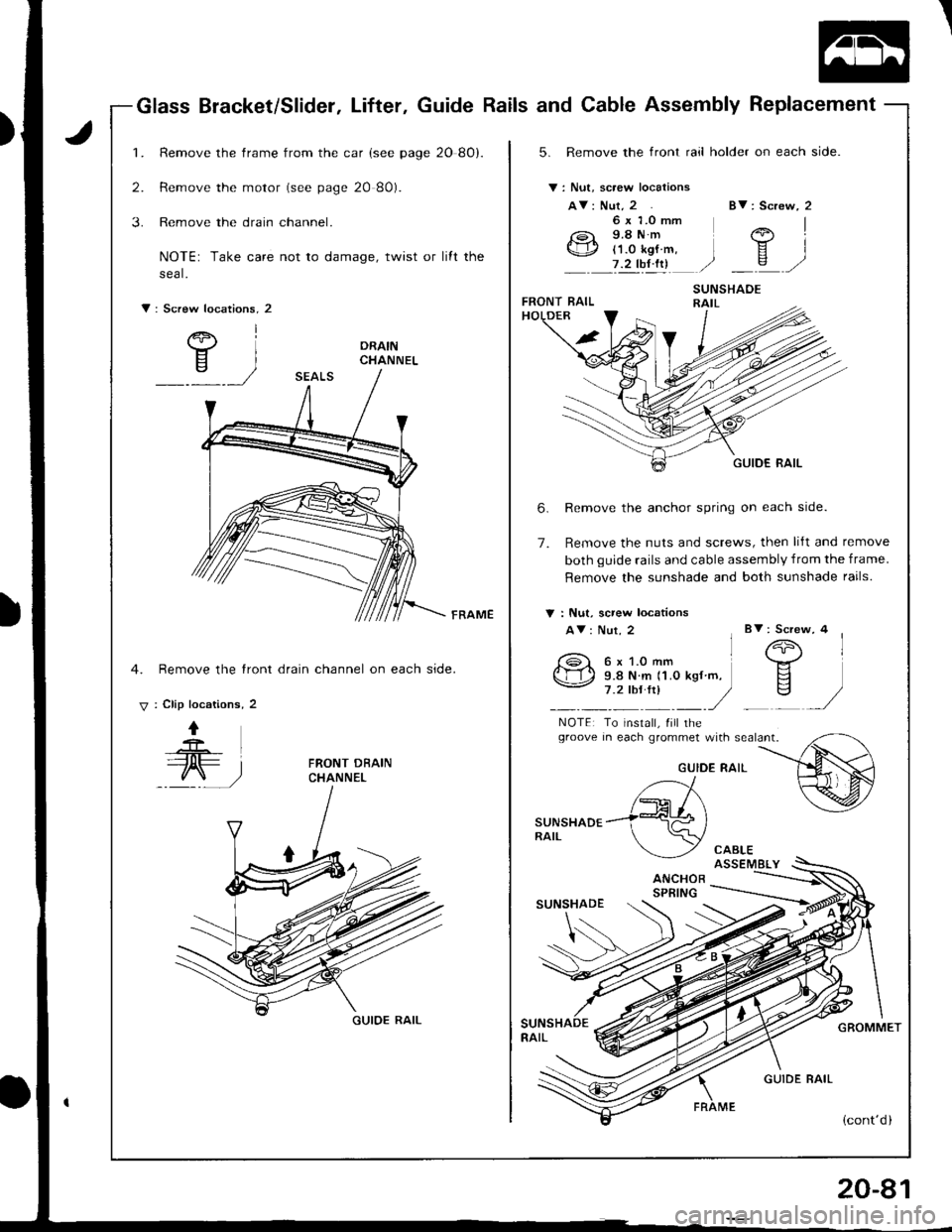

Glass Bracket/SlidetLifterGuide Rails and Cable Assembly Replacement

1.

2.

3.

Remove the frame from the car (see page 20 8O).

Remove the motor (see page 20 80).

Remove the drain channel.

NOTE: Take care not to damage, twist or lift the

sea L

5. Remove the front rail holder on each side.

V: Nut, scaew locations

AV: Nut, 2Bv: Screw, 2

1er I

YIc,/

6 x 1.0 mm9.8Nm('1.0 kgf m, I7 2 !!!!!l ./

V : Screw locations. 2

/e, I

Y)

6.

7.

Remove the anchor spring on each side.

Remove the nuts and screws, then lift and remove

both guide rails and cable assembly from the frame.

Remove the sunshade and both sunshade rails.

FRAMEV : Nut, screw locations

AV: Nut, 2Bv: Screw, 4

4. Remove the tront drain channel on each side.

V : Clip locations, 2

I

@

NOTE: To install, Iill rhegroove in each grommet with sealant.

FRONT DBAINCHANNELGUIDE RAIL

,._--'//r\/-rr / \

sur'rsHaor ---i:579 )RA|L \/\---_ _/,/ CABLE

ANCHORSPFING

GUIOE RAIL

GUIDE RAIL

GROMMET