tdc ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 64 of 1680

r.lJ

Valve Clearance

Adjustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100'F (38"C).

Adjustment is the same for both intake and exhaust

valves.

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf'ft).

1. Remove cylinder head cover.

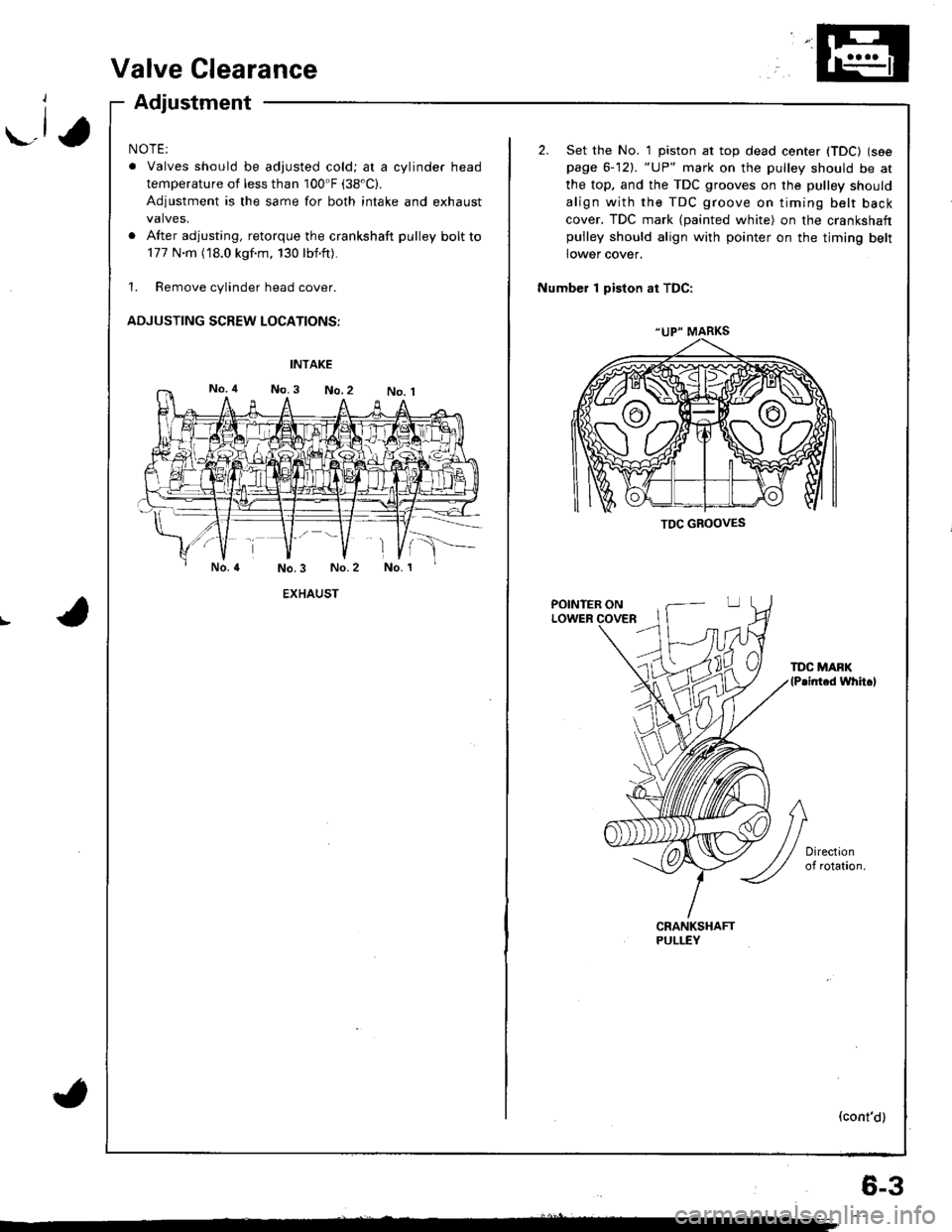

ADJUSTING SCREW LOCATIONS:

EXHAUST

(

"UP" MARKS

TDC GBOOVES

2. Set the No. 1 piston at top dead center (TDC) (see

page 6-12). "UP" mark on the pulley should be at

the top, and the TDC grooves on the pulley should

align with the TDC groove on timing belt back

cover. TDC mark (painted white) on the crankshaftpulley should align with pointer on the timing belt

lower cover.

Number 1 piston at TDC:

POINTER ONLOWER

TDC MAFK(P.inted whh.l

(cont'd)

6-3

Page 65 of 1680

Valve Clearance

Adjustment (cont'dl

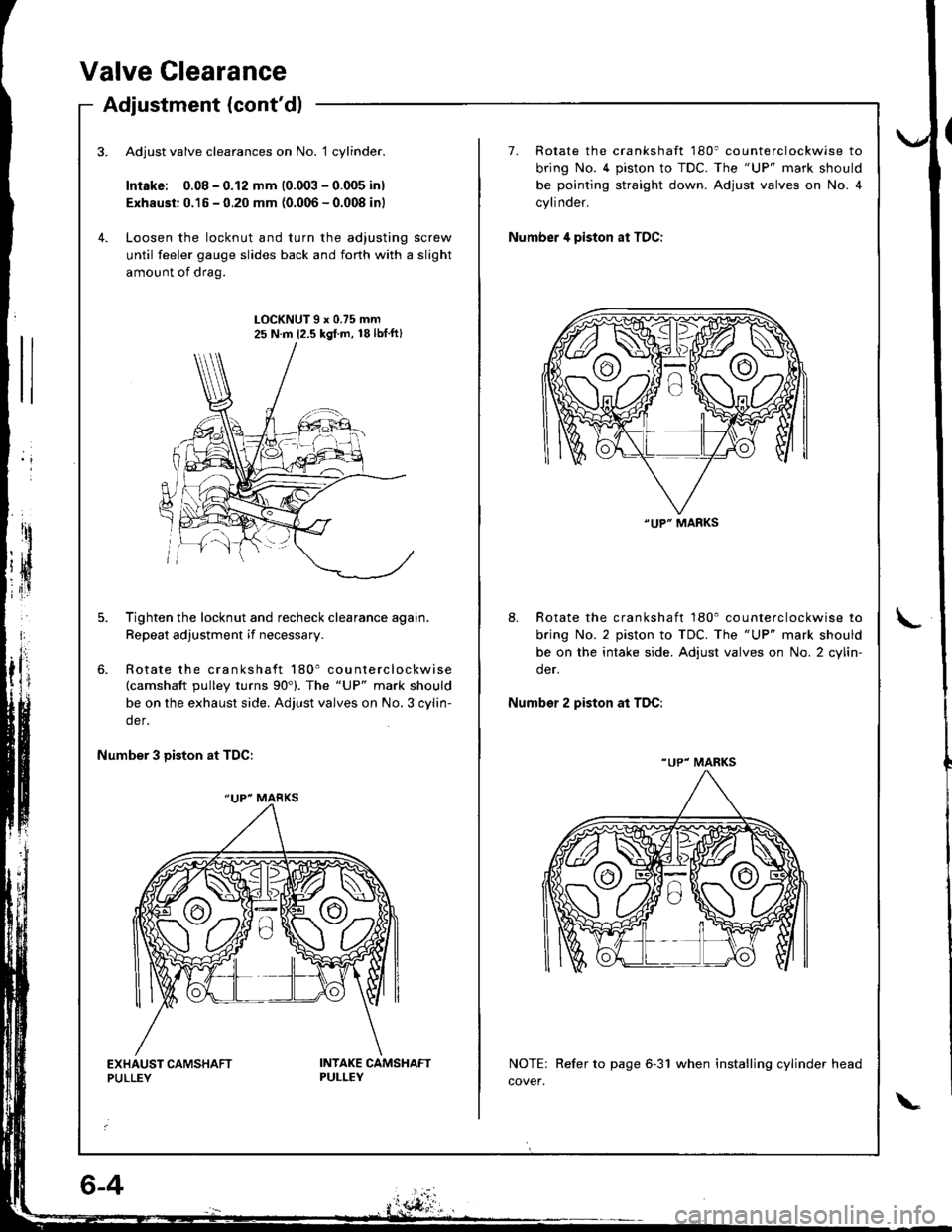

Adjust valve clearances on No. 1 cylinder.

Intske: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.15 - 0.20 mm (0.006 - 0.008 inl

Loosen the locknut and turn the adjusting screw

until feeler gauge slides back and forth with a slight

amount of drag.

7. Rotate the crankshaft 180' counterclockwise to

bring No. 4 piston to TDC. The "UP" mark should

be pointing straight down. Adjust valves on No. 4

cylinder.

Number 4 piston at TDC:

LOCKNUT9x0.75mm25 N.m {2.5 kgl.m, 18lbtft}

Tighten the locknut and recheck clearance again,

Repeat adjustment if necessary.

Rotate the crankshaft 180' counterclockwise(camshaft pulley turns 90'). The "UP" mark should

be on the exhaust side. Adjust valves on No,3 cylin-

der.

8. Rotate the crankshaft 180' counterclockwise to

bring No. 2 piston to TDC. The "UP" mark should

be on the intake side. Adjust valves on No. 2 cylin-

der.

Number 2 piston at TDC:

Number 3 Diston at TDC:

NOTE: Refer to page 6-31 when installing cylinder head

cover.

"UP" MARKS

"UP" MARKS

"UP" MARKS

Page 66 of 1680

Valve Seals

Replacement (cylinder head removal not required)

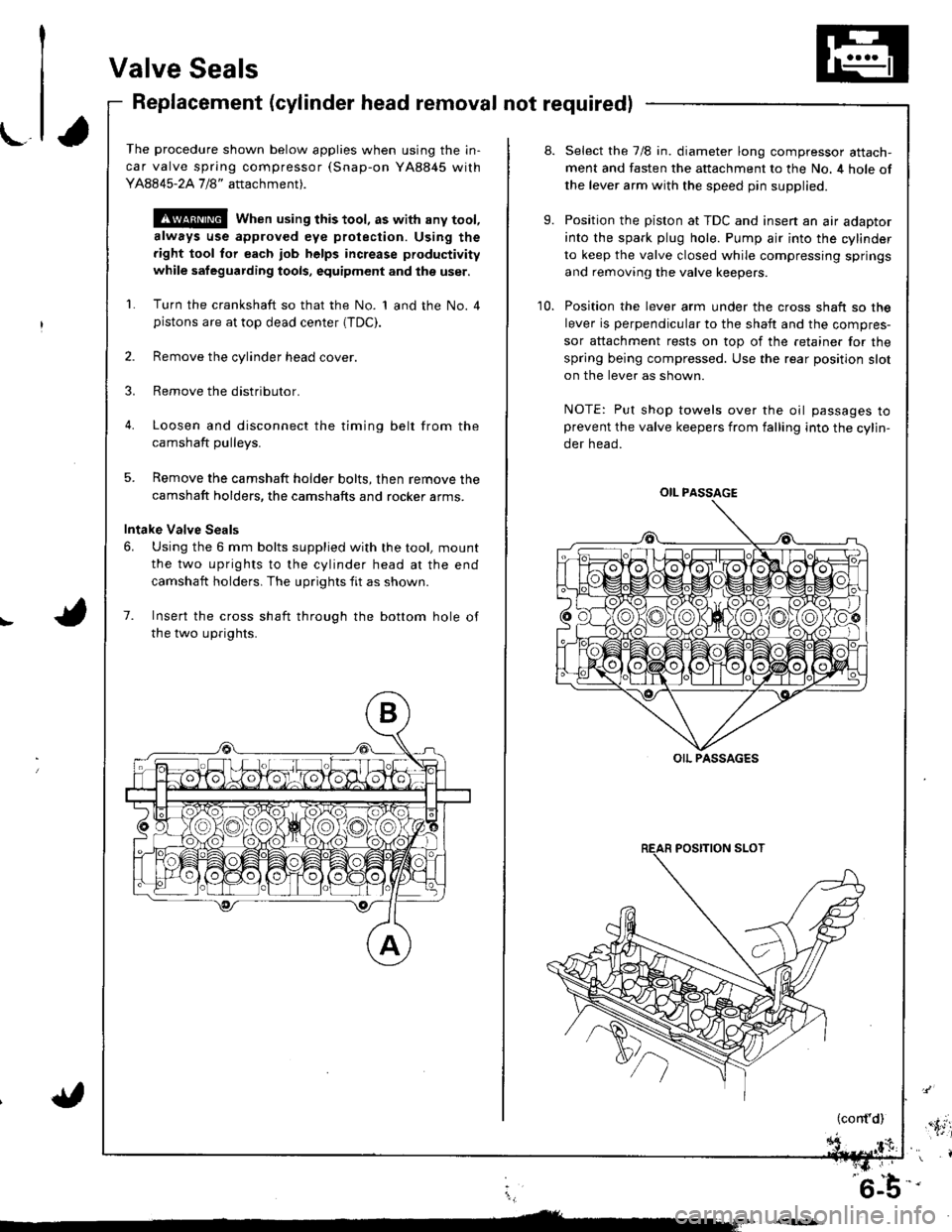

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

Y AAA45-2A 1 /8" attachment).

!@@ When using this tool, as with any tool,

always use approved eye protection. Using the

fight tool tor each job helps increase productivity

while safeguarding tools, equipment and ihe user.

Turn the crankshaft so that the No. 1 and the No. 4pistons are at top dead center (TDC).

Remove the cylinder head cover.

Remove the distributor.

Loosen and disconnect the timinq belt from the

camshaft oullevs.

5. Remove the camshaft holder bolts, then remove the

camshaft holders, the camshafts and rocker arms.

Intake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the bottom hole of

the two uprights.

8.

9.

10.

Select the 7/8 in. diameter long compressor attach-

ment and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing springs

and removing the valve keepers.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

NOTE: Put shop towels over the oil passages toprevent the valve keepers from falling into the cylin-

der head.

OIL PASSAGE

OIL PASSAGES

(cont'd),'.itil

i,

'6-b-'

Page 70 of 1680

\-a

I

I

{

. 6-9

Timing Belt

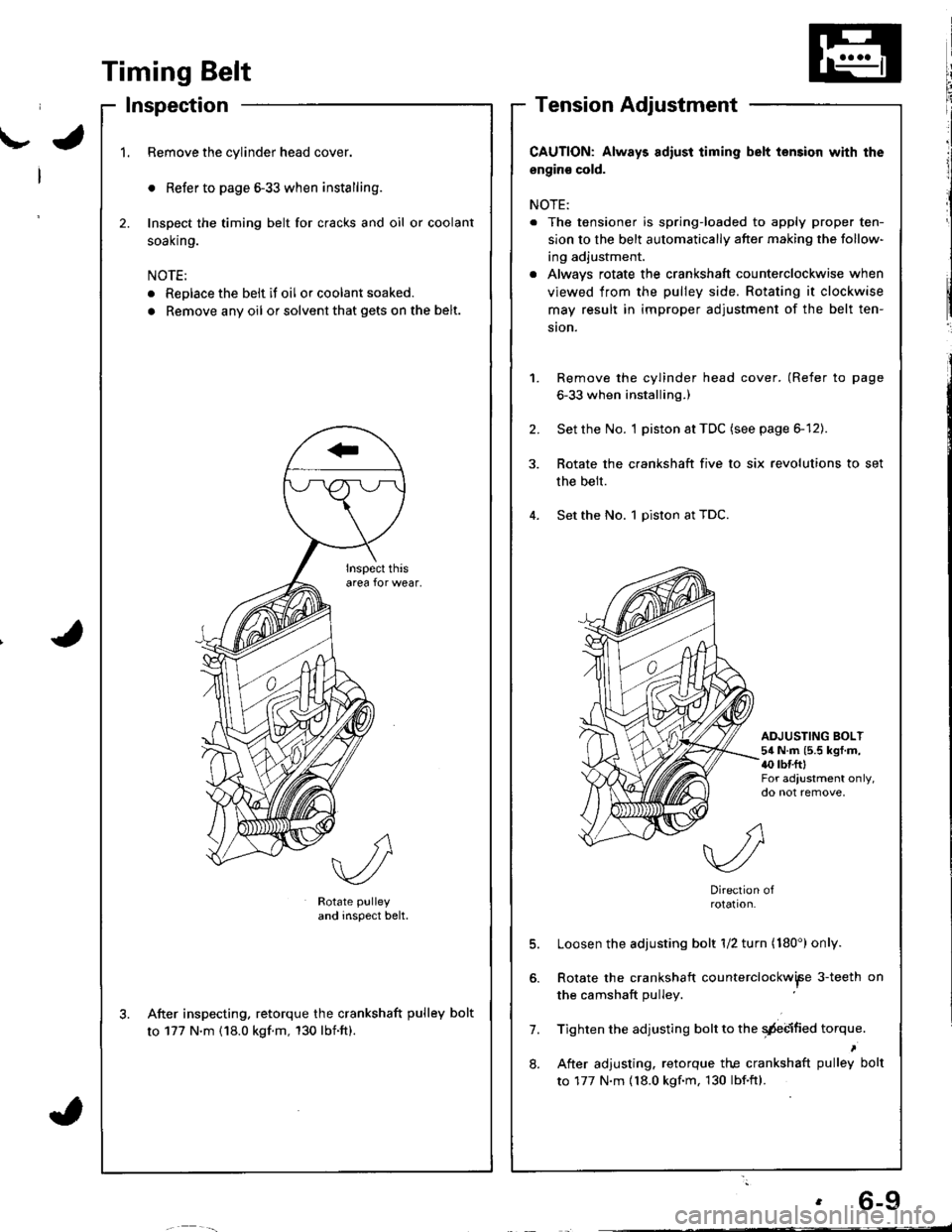

Inspection

1.Remove the cylinder head cover.

o Refer to page 6-33 when installing.

Inspect the timing belt for cracks and oil or coolant

soal(n9.

NOTE:

. Replace the belt if oil or coolant soaked.

. Remove any oil or solvent that gets on the belt.

2.

Rotate pulley

and inspect belt.

After inspecting. retorque the crankshaft pulley bolt

to 177 N'm (18.0 kgf.m, 130 lbnft).

CAUTION: Always adiust iiming belt lension with the

engin€ cold.

NOTE:

. The tensioner is spring-loaded to apply proper ten-

sion to the belt automatically after making the follow-

ing adjustment.

. Alwavs rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockwise

may result in improper adjustment of the belt ten-

ston.

Remove the cylinder head cover. (Refer to page

6-33 when installing.)

Set the No. I piston at TDC (see page 6-12).

Rotate the crankshaft five to six revolutions to set

the belt.

Set the No. 1 piston at TDC.

1.

2.

ADJUSTING BOLT54 N.m (5.5 kgf.m,{0 rbr.fttFor adjustment only,do not remove,

7.

8.

Direction ofrotation.

Loosen the adjusting bolt 1/2 turn (180') only.

Rotate the crankshaft counterclockwiFe 3-teeth on

the camshaft pulley

Tighten the adjusting bolt to the qdebified torque.

After adjusting. retorque the crankshaft pulley bolt

to 177 N.m {18.0 kgf.m, 130 lbf.ftl.

Page 79 of 1680

Gylinder Head

Removal (cont'dl

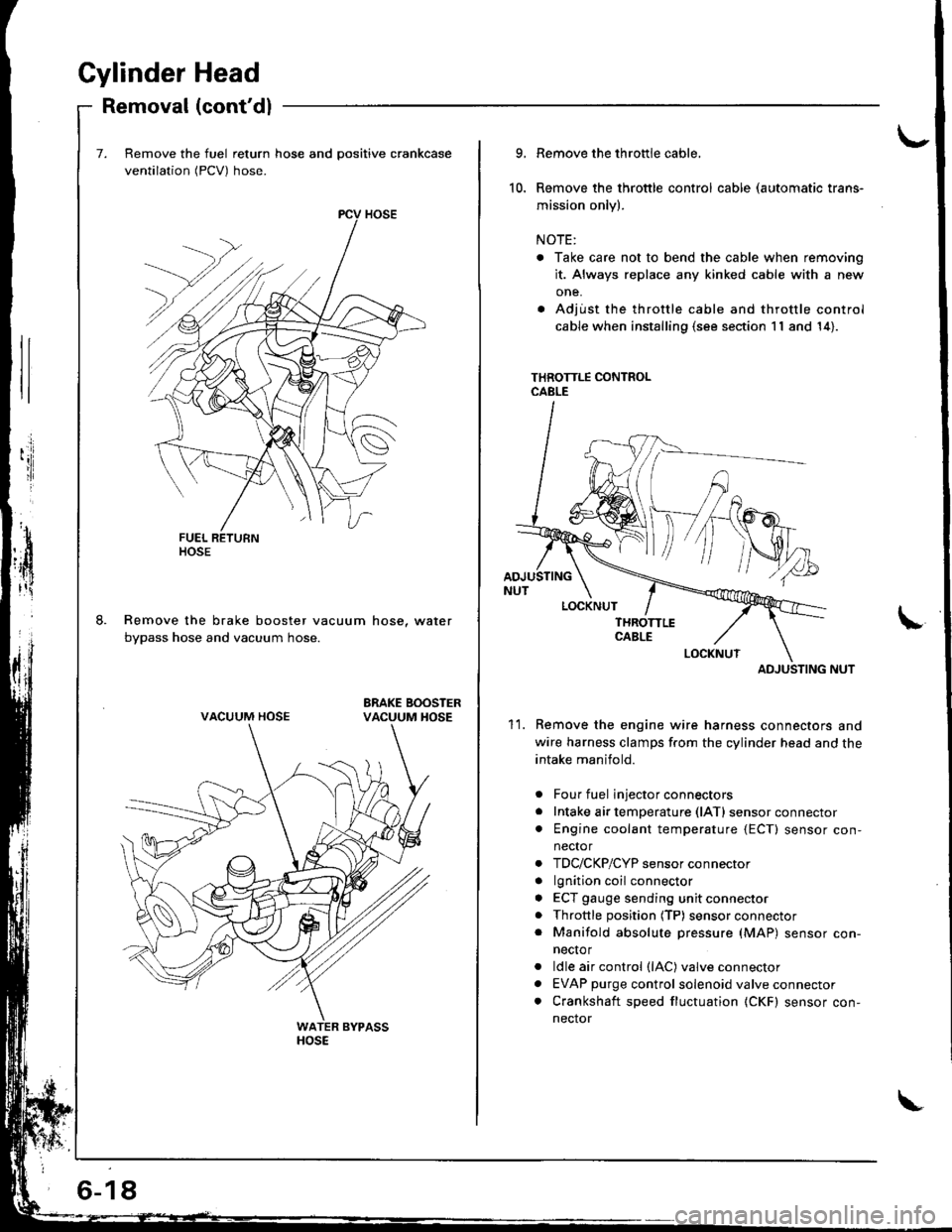

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ltosE

VACUUM HOSE

6-18

10.

9.

11.

Remove the throttle cable,

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (s€e section 11 and 14).

THROTTLE CONTROLCABLE

ADJUSTING NUT

Remove the engine wire harness connectors and

wire harness clamps f.om the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lATl sensor connector

Engine coolant temperature {ECT) sensor con,

nector

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute pressure (MAP) sensor con-

necto r

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

Crankshaft speed fluctuation (CKF) sensor con-

nector

a

a

a

a

a

a

a

a

ADJUSTING

Page 92 of 1680

\-

L

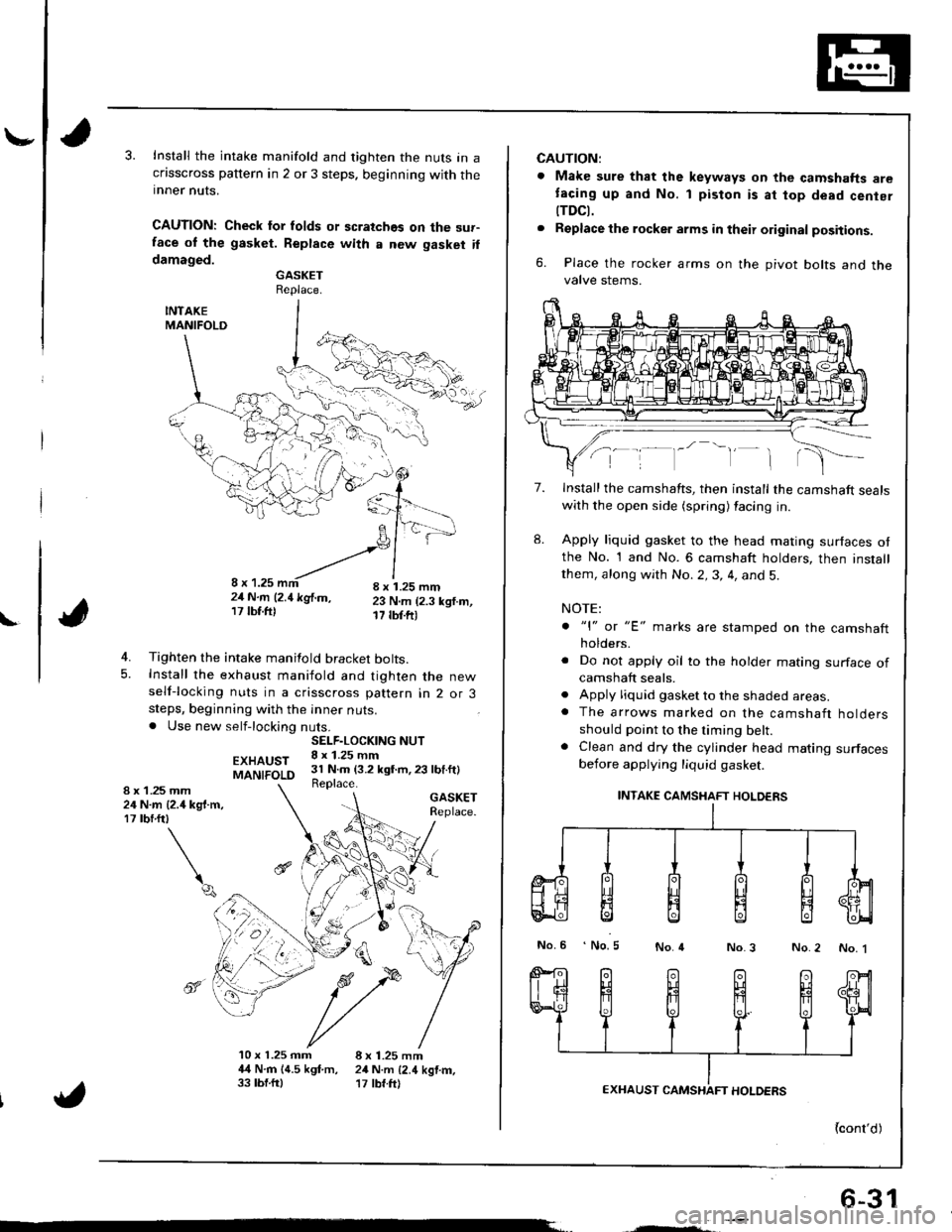

Install the intake manifold and tighten the nuts in acflsscross pattern in 2 or 3 steps. beginning with theinner nuts.

CAUTION: Check lor folds or scratches on the sur-face ol the gasket. Replace with a new gasket ildamaged.GASKETReplace.

INTAKEMANIFOLD

4. Tighten the intake manifold bracket bolts.5. Install the exhaust maniiold and tighten the newself-locking nuts in a crisscross pattern in 2 or 3steps, beginning with the inner nuts.. Use new self-locking nuts.

EXHAUSTMANIFOLD

GASKETReplace.

4

10 x 1.25 mm 8 x 1.25 mm4,{ N.rn 14.5 kgf.m, 24 N.m {2.4 kgtm,33 tbf.ftl '17 tbf.ft)

SELF.LOCKING NUT8 x 1.25 mm31 N.m (3.2 kgt m,23 lbf.ft)Replace.1 .25 mmN.m {2.4 kg{.m,rbrftt

\q

8x2417

",', r, ^-'-"-!,1,,,';-21N.m l2.1kglm, 23 N.m (2.3 ksf.m,17lbf.ftl 17 tbf.ftr

6-31

CAUTION:

. Make sure that the keyways on the camshafts aretacing up and No. 1 piston is at top dead cenier

tTDCt.. Replacethe rocker arms in their original positions.

6. Place the rocker arms on the pivot bolts and thevalve stems.

7.

8.

Install the camshafts, then install the camshaft sealswith the open side (spring) facing in.

Apply liquid gasket to the head mating surfaces otthe No. 1 and No. 6 camshaft holders, then installthem, along with No.2,3, 4, and 5.

NOTE:

. "l" or "E' marks are stamped on the camshaftholders.

. Do not apply oil to the holder mating surface ofcamshaft seals.. Apply liquid gasket to the shaded areas.. The arrows marked on the camshaft holdersshould point to the timing belt.. Clean and dry the cylinder head mating surfacesbefore applying liquid gasket.

INTAKE CAMSHAFT HOLDERS

No.6 No.5No.4No.3 No.2 No. 1

{cont'd)

Page 93 of 1680

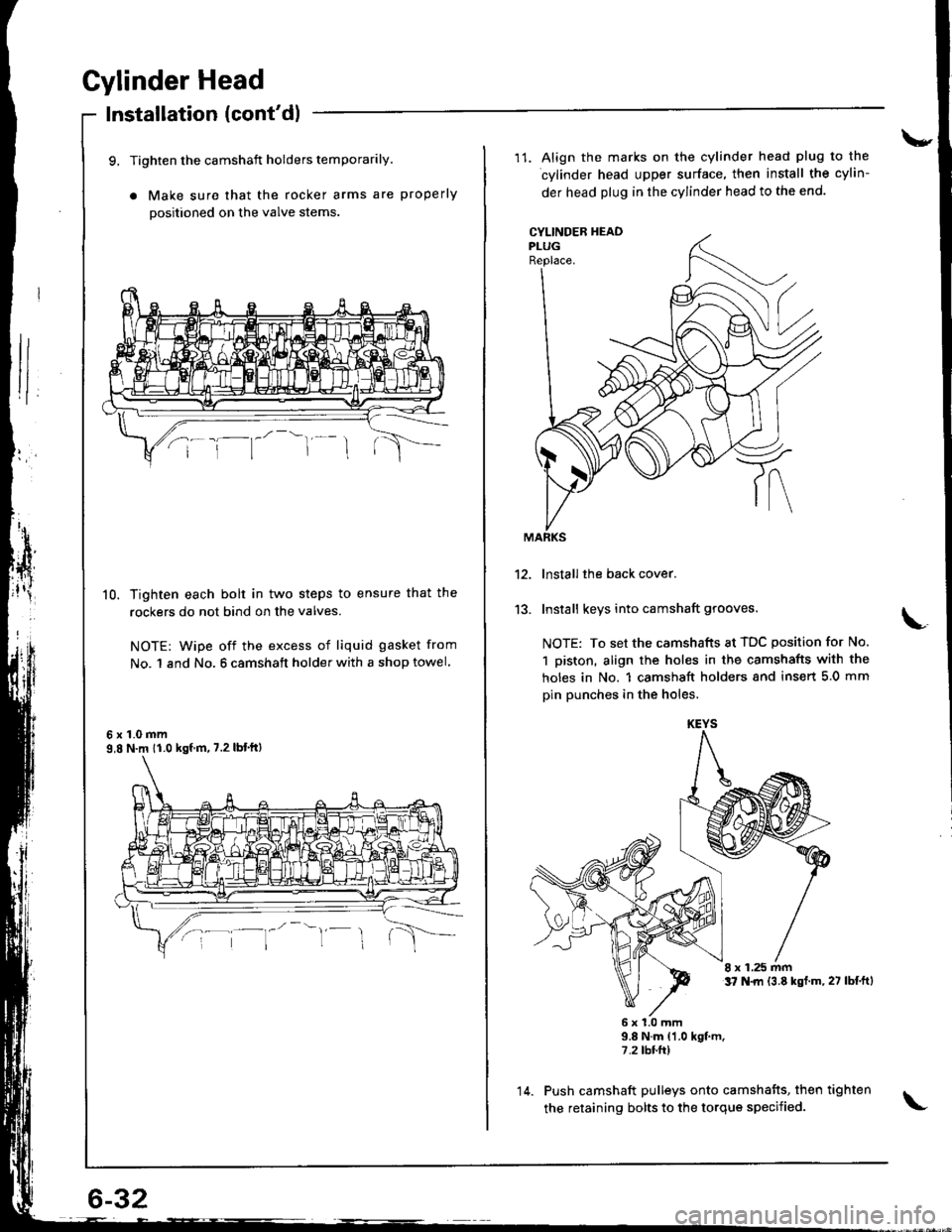

Cylinder Head

Installation (cont'dl

9, Tighten the camshaft holders temporarily.

a Make sure that the rocker arms are properly

positioned on the valve stems

10. Tighten each bolt in two steps to ensure that the

rockers do not bind on the valves.

NOTE: wipe off the excess of liquid gasket from

No. 1 and No. 6 camshaft holder with a shop towel

6x1.0mm9,8 N.m 11.0 kgf m, 7.2 lbt'ftl

\-

11. Align the marks on the cylinder head plug to the

cylinder head upper surface, then install the cylin-

der head plug in the cylinder head to the end.

CYLINDEB HEADPLUGReplace.

13.

lnstall the back cover.

Install keys into camshaft grooves.

NOTE: To set the camshafts at TDC position for No.

1 piston, align the holes in the camshafts with the

holes in No. 1 camshsft holders snd insert 5.0 mm

pin punches in the holes.

8 x 1.25 mmt7 N.|rl {3.8 kst.m,27 lbf.ftl

6x1.0mm9.8 N.m {1.0 kgt m.7.2 tbr.ft)

Push camshaft pulleys onto camshafts, then tighten

the retaining bolts to the torque specified.

KEYS

14.

Page 207 of 1680

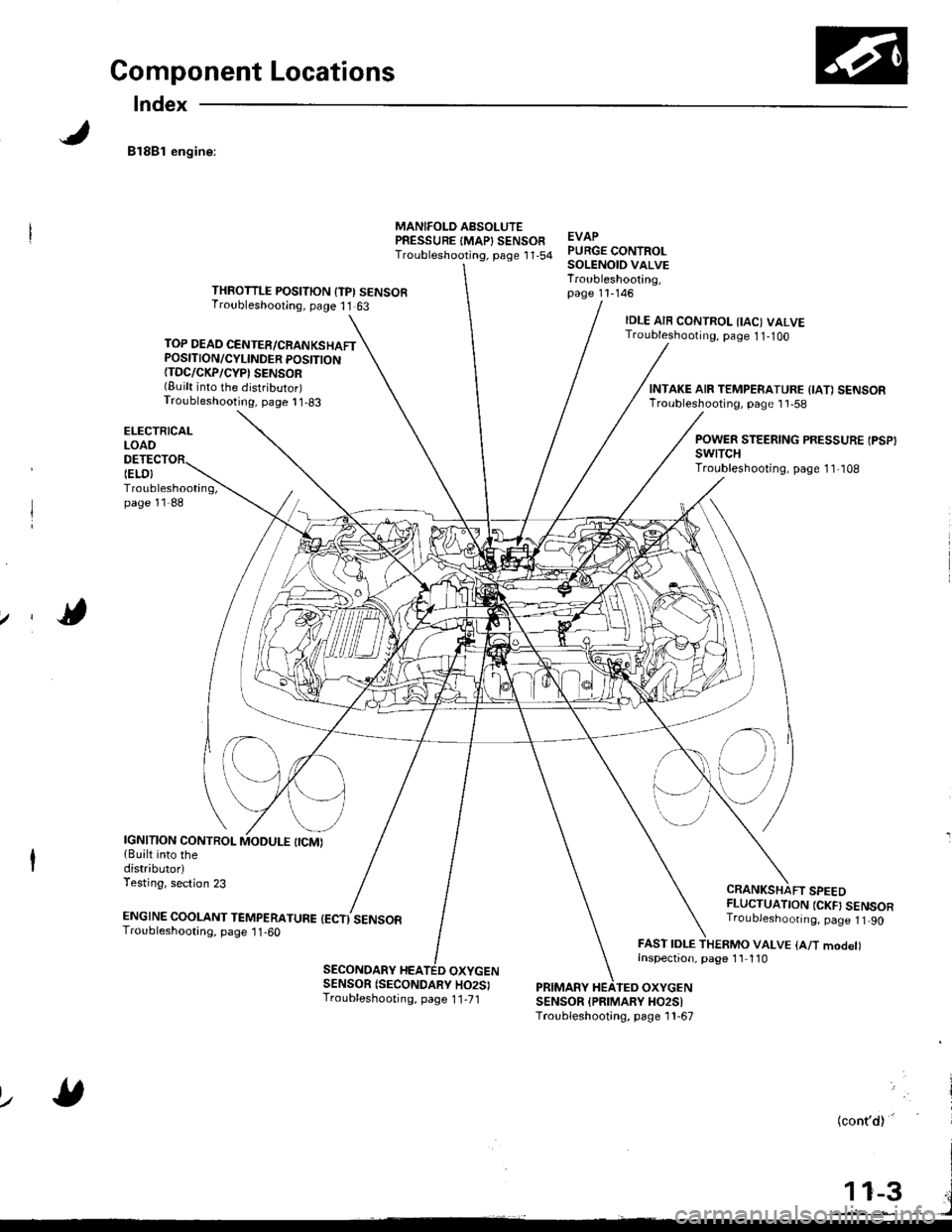

Component Locations

Index

81881 engine:

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION{TDC/CKP/CYP' SENSOR(Built into the distributor)Troubleshooting, page I 1-83

ELECTRICALLOAO

Troubleshooting,page 11-88

MANIFOLD AsSOLUTEPRESSURE IMAP} SENSOFTroubleshooting, psge 1 '1,54EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page 11-146THROTTLE POSITION {TPI SENSORTroubleshooting, page 11 63

IELO}

IDLE AIR CONTROL IIAC) VALVETroubleshooting, page 1 1-1OO

CRANKSHAFT SPEEDFLUCTUATION {CKF} SENSORTroubJeshoonng. page 1t 90

FAST IDLE THERMO VALVE {A/T modet)Inspection, page 1'l 110

INTAKE AIR TEMPERATURE {IA1 SENSORTroubleshooting, page 1 'l -58

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 1 1,108

IGNITION CONTROL{Built into thedistributorlTesting, section 23

ENGTNE cooLANT TEnapenerune {ectisensoaTroubleshooting, page 1 1 -60

SECONDARY HEATED OXYGENSENSOR (SECONDARY HO2SITroubleshooting, page 1 1-71PRIMARY HEATEO OXYGENSENSOR {PFIMARY HO2SITroubleshooting, page 1 1-67

lz

(cont'd)'

Page 208 of 1680

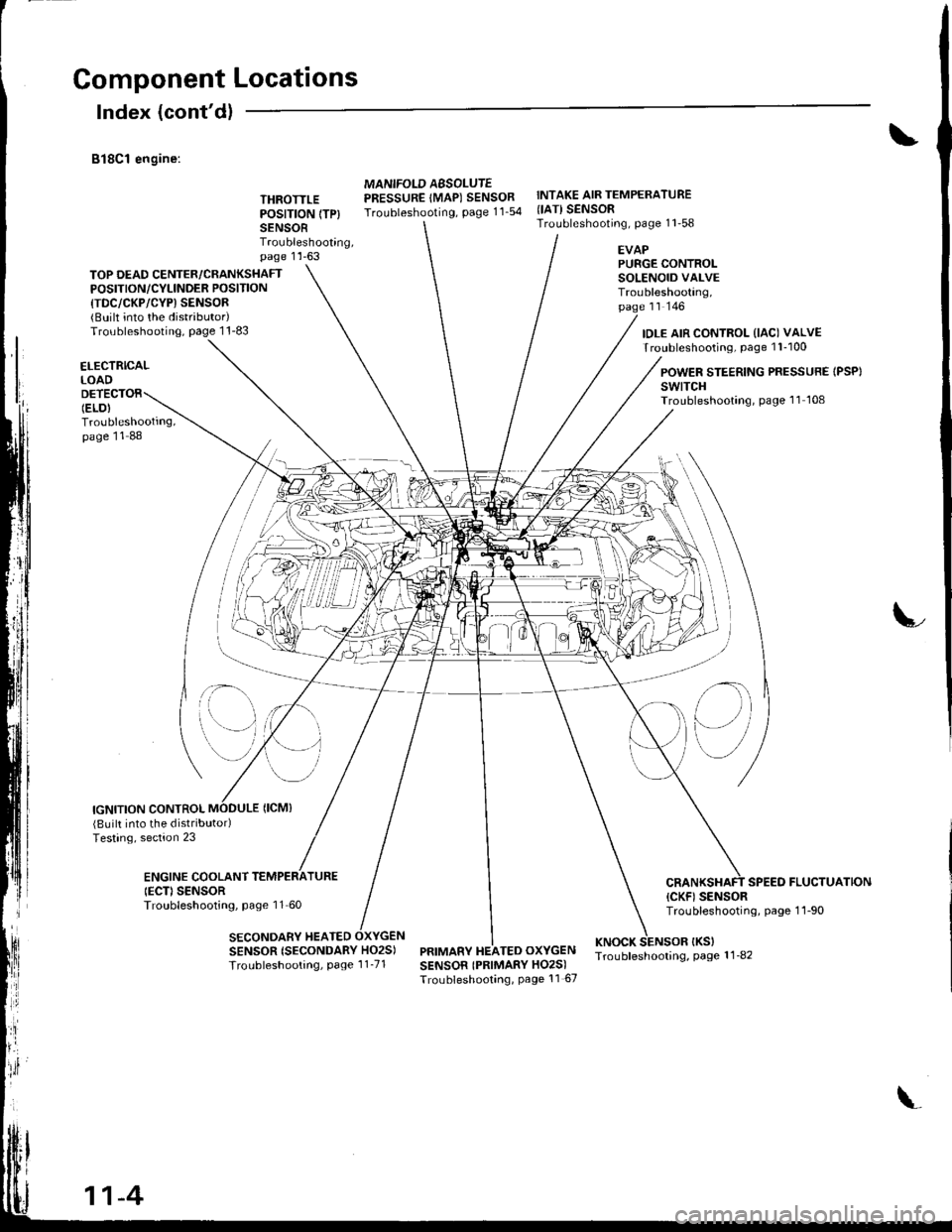

Component Locations

Index (cont'dl

B18C1 engine:

THROTTLEPOSITION (TP}

SENSORTroubleshooting,page 1 'l -63

MANIFOLD AESOLUTEPRESSURE IMAP) SENSORTroubleshooting, page 11_54

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting, page 11'58

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINOER POSITION

{TDC/CKP/CYP) SENSOR{BUilt into the distributor)Troubleshooting, page 1 1-83

EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page rr rqo

IDLE AIR CONTROL (IAC) VALVETroubleshooting, page 1 l-100

ELECTRICALLOAD

Troubleshooting,page 11 88

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 'l1 108

IGNITION CONTROL

;- \

SENSOR {SECONDARY HO2S)

Troubleshooting, Page 1 1_71

(Built into the distributodTesting, section 23

ENGINE COOLANTIECD SENSORTroubleshooting, page 11 60

SECONDARY HEATED

SPEED FLUCTUATION(CKF) SENSORTroubleshooting, page 1 1-90

PRIMARY HEATED OXYGENKNOCK SENSOR IKSITroubleshooling, page 1 1_82SENSOR IPRIMARY HO2S)Troubleshooting, Page 11 67

il\

e)

11-4

Page 242 of 1680

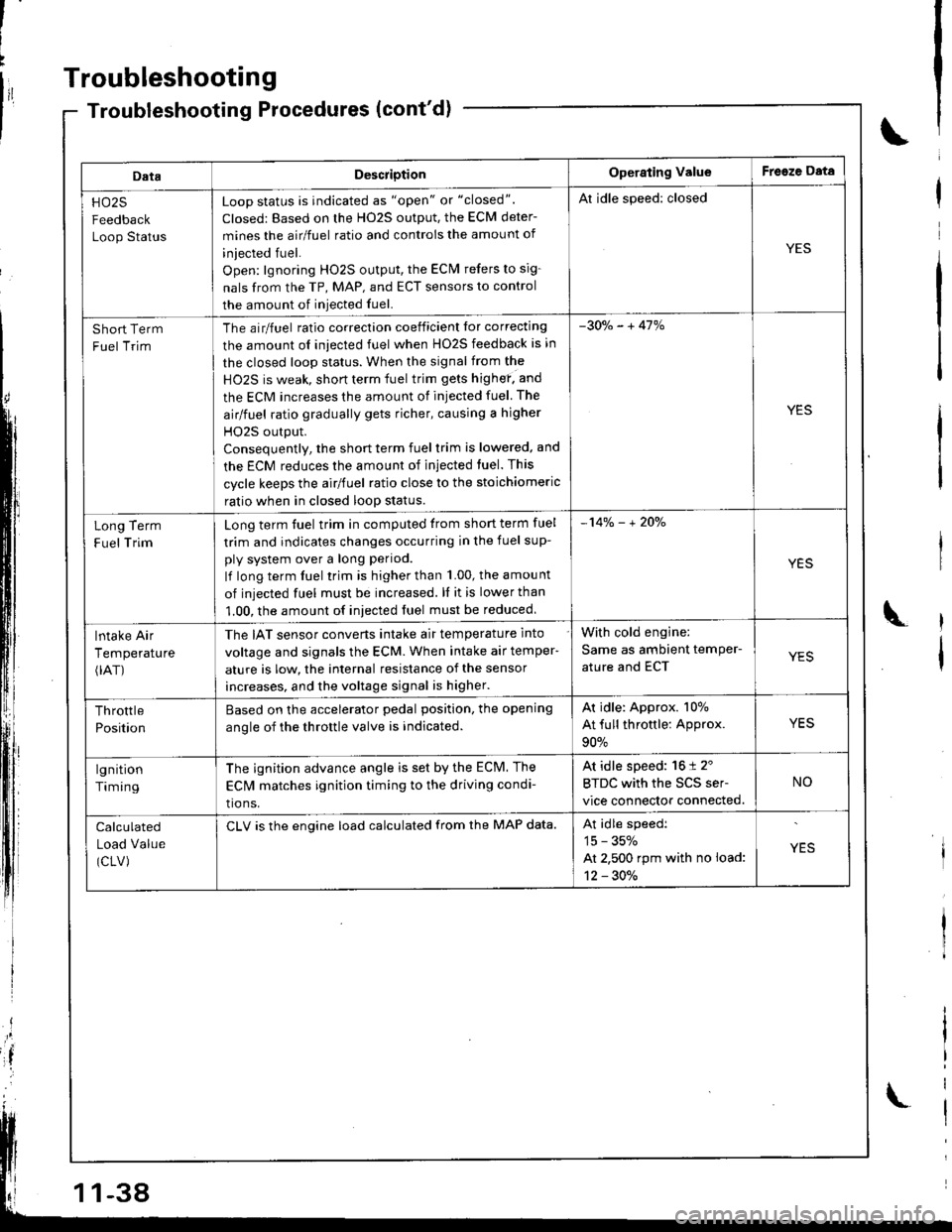

Troubleshooting

DataDescriotionOperating ValueFreeze Data

HO25

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the H02S output, the ECM deter-

mines the airlfuel ratio and controis the amount of

iniected fuel.

Open: lgnoring HO2S output, the ECM refers to sig-

nals from the TP, MAP, and ECT sensors to control

the amount of iniected fuel.

Al idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correclion coeificient lor correcting

the amount ol iniected fuel when HO2S feedback is in

the closed loop status. When the signal from the

HO2S is weak, short term fuel trim gets highef. and

the ECM increases the amount of injected fuel The

airlfuel ratio gradually gets richer, causing a higher

HO2S output.

Consequentlv, the short term fuel trim is lowered, and

the ECM reduces the amount of injected tuel. This

cycle keeps the airlfuel ratio close to the stoichiomeric

ratio when in closed loop status.

-30o/" - + 41%

YES

Term

Trim

Long

F uel

Long term fuel trim in computed trom short term fuel

trim and indicates changes occurring in the fuel sup-

ply system over a long period.

lf long term fuel trim is higher than 1.00, the amou nt

of injected fuel must be increased. ll it is lower than

1.00, the amount of iniected fuel must be reduced

-14% - + 2Oo/"

YES

lntake Air

Temperature(rAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air temper-

ature is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temPer-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position. the opening

anole of the throttle valve is indicated.

Ar idle: Approx. 107o

At full throttle: Approx.

90%

YES

lgnition

Timing

The ignition advance angle is set by the ECM. The

EClvl matches ignition timing to the driving condi-

tio ns.

At idle speed: 16 t 2'

BTDC with the SCS ser-

vice connector connected.

NO

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAP data.At idle speedi

15 - 35%

At 2,500 rpm with no load:

12 - 30./.

YES

-38