ECO mode ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 30 of 1640

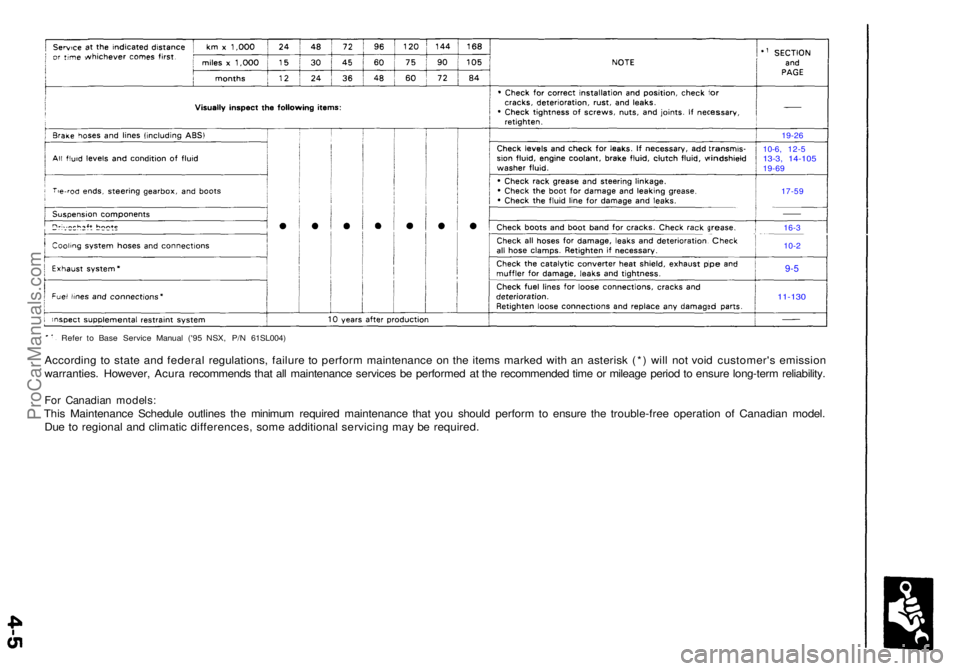

Refer t o Bas e Servic e Manua l ('9 5 NSX , P/ N 61SL004 )

According t o stat e an d federa l regulations , failur e t o perfor m maintenanc e o n th e item s marke d wit h a n asteris k (* ) wil l no t voi d customer' s emissio n

warranties . However , Acur a recommend s tha t al l maintenanc e service s b e performe d a t th e recommende d tim e o r mileag e perio d to ensur e long-ter m reliability .

For Canadia n models :

This Maintenanc e Schedul e outline s th e minimu m require d maintenanc e tha t yo u shoul d perfor m to ensur e th e trouble-fre e operatio n o f Canadia n model .

Du e t o regiona l an d climati c differences , som e additiona l servicin g ma y b e required .

19-26

10-6 , 12- 5

13-3, 14-10 519-69

17-5 9

16-3

10-2

9-5

11-13 0

ProCarManuals.com

Page 66 of 1640

SECTION

and

PAGE

19-26

10-6, 12-5

13-3, 14-105

('91-'93), or('94-'96),19-69('91-'92) or ('93-'96)

17-59

16-3

10-2

9-5

11-130 ('91-'92),('93), or ('94-'96)

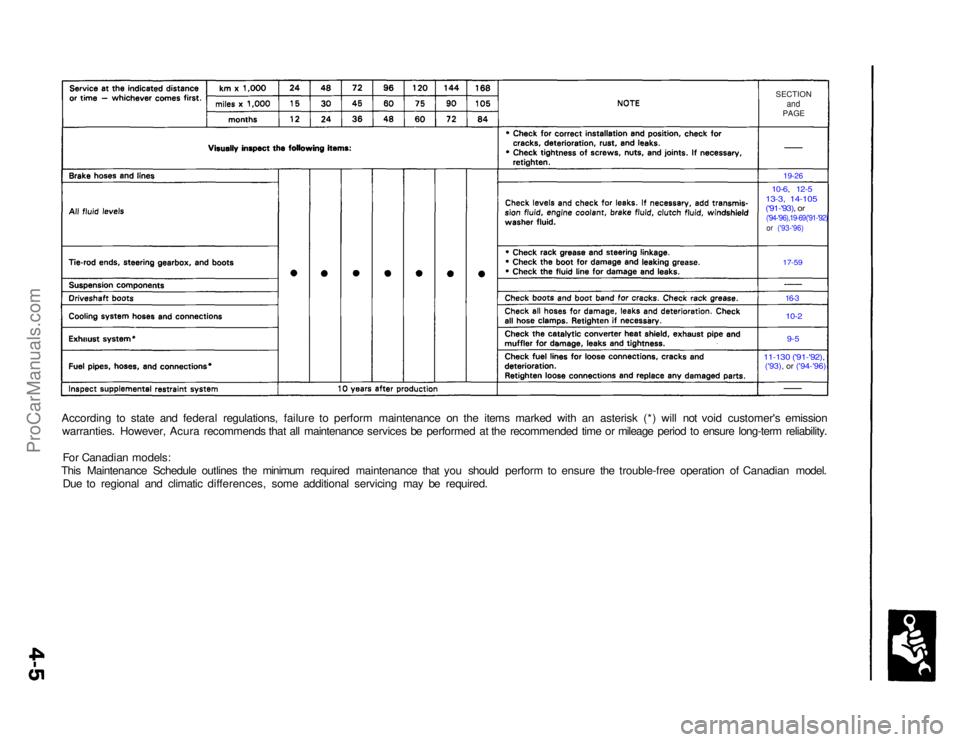

According to state and federal regulations, failure to perform maintenance on the items marked with an asterisk (*) will not void customer's emission

warranties. However, Acura recommends that all maintenance services be performed at the recommended time or mileage period to ensure long-term reliability.

For Canadian models:

This Maintenance Schedule outlines the minimum required maintenance that you should perform to ensure the trouble-free operation of Canadian model. Due to regional and climatic differences, some additional servicing may be required.ProCarManuals.com

Page 80 of 1640

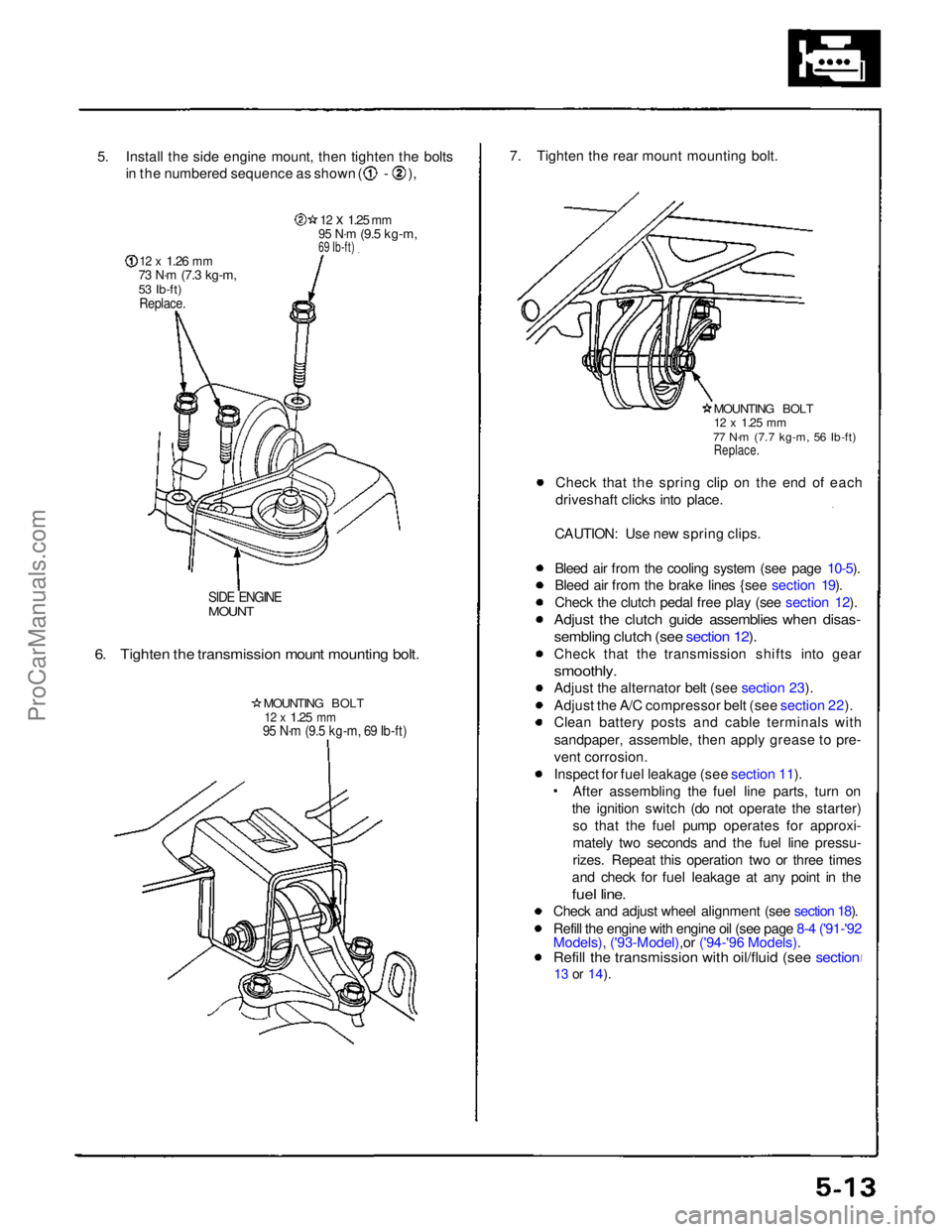

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 228 of 1640

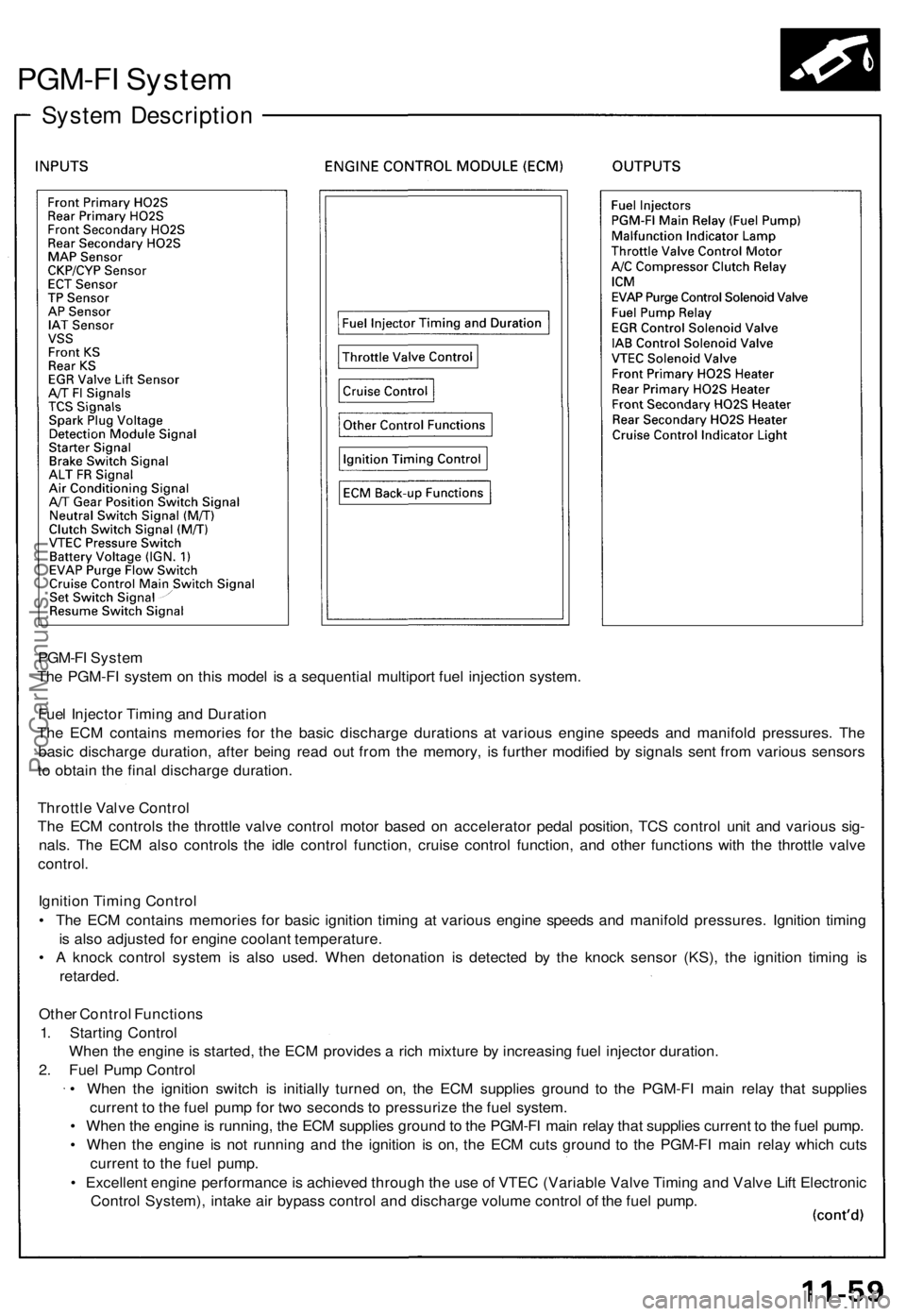

PGM-FI System

System Description

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel Injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Throttle Valve Control

The ECM controls the throttle valve control motor based on accelerator pedal position, TCS control unit and various sig-

nals. The ECM also controls the idle control function, cruise control function, and other functions with the throttle valve

control.

Ignition Timing Control

• The ECM contains memories for basic ignition timing at various engine speeds and manifold pressures. Ignition timing

is also adjusted for engine coolant temperature.

• A knock control system is also used. When detonation is detected by the knock sensor (KS), the ignition timing is

retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

• When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

• When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

• When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

• Excellent engine performance is achieved through the use of VTEC (Variable Valve Timing and Valve Lift Electronic

Control System), intake air bypass control and discharge volume control of the fuel pump.ProCarManuals.com

Page 229 of 1640

PGM-FI Syste m

System Descriptio n

3. Fue l Cut-of f Contro l

• Durin g deceleratio n wit h th e throttl e valv e closed , curren t t o th e fue l injector s i s cu t of f t o improv e fue l econom y a t

speed s ove r 1,50 0 rpm .

• Fue l cut-of f actio n als o take s plac e whe n engin e spee d exceeds , 8,30 0 rpm , regardles s o f th e positio n o f th e throttl e

valve , t o protec t th e engin e fro m over-revving .

4 . A/ C Compresso r Clutc h Rela y

Whe n th e EC M receive s a deman d fo r coolin g fro m th e ai r conditionin g system , i t delay s th e compresso r fro m bein g

energized , an d enriche s th e mixtur e to assur e smoot h translatio n to th e A/ C mode .

5 . Evaporativ e Emissio n (EVAP ) Purg e Contro l Solenoi d Valv e

Whe n th e engin e coolan t temperatur e is belo w 153° F (67°C) , th e EC M control s th e EVA P purg e contro l solenoi d valv e

whic h cut s vacuu m to th e EVA P purg e contro l caniste r diaphragm .

6 . Intak e Ai r Bypas s (IAB ) Contro l Solenoi d Valv e

Whe n th e engin e spee d is belo w 4,80 0 rpm , th e IA B contro l solenoi d valv e is activate d b y a signa l fro m th e ECM . Intak e

ai r the n flow s throug h th e smalle r chamber , an d hig h torqu e is delivered . T o increas e ai r flo w a t engin e speed s highe r

tha n 4,80 0 rpm , th e solenoi d valv e is deactivate d b y th e ECM , an d th e intak e ai r flow s throug h th e large r chamber .

7 . Exhaus t Ga s Recirculatio n (EGR ) Contro l Solenoi d Valv e

Whe n th e EG R is require d fo r contro l o f oxide s o f nitroge n (NOx ) emissions , th e EC M supplie s groun d t o th e EG R

contro l solenoi d valv e whic h supplie s regulate d vacuu m to th e EG R valve .

EC M Fail-safe/Back-u p Function s

1 . Fail-Saf e Functio n

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M ignore s tha t signa l an d assume s a pre-programme d

valv e fo r tha t senso r tha t allow s th e engin e t o continu e t o run .

2 . Back-u p Functio n

Whe n a n abnormalit y occur s i n th e EC M itself , th e fue l injector s ar e controlle d b y a back-u p circui t independen t o f th e

syste m in orde r t o permi t minima l driving .

3 . Self-diagnosi s Functio n [Malfunctio n Indicato r Lam p (MIL) ]

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M light s th e MI L an d store s th e diagnosti c troubl e cod e

i n erasabl e memory . Whe n th e ignitio n i s initiall y turne d on , th e EC M supplie s groun d fo r th e MI L fo r tw o second s t o

chec k th e MI L bul b condition .

ProCarManuals.com

Page 521 of 1640

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

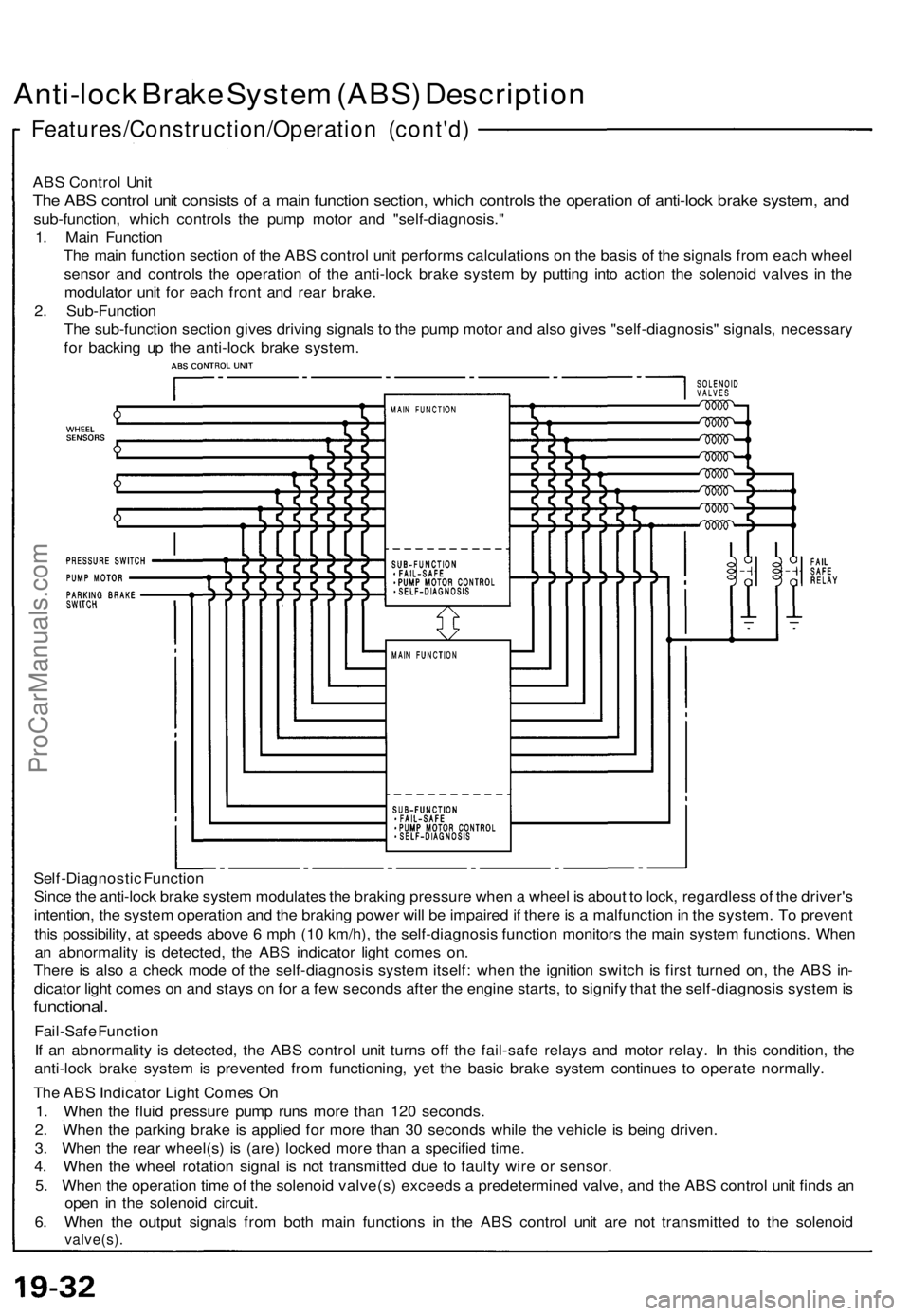

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and

sub-function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the

modulator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary

for backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS in-

dicator light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is

functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the

anti-lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid

valve(s).ProCarManuals.com

Page 527 of 1640

ALB Checke r

Function Tes t

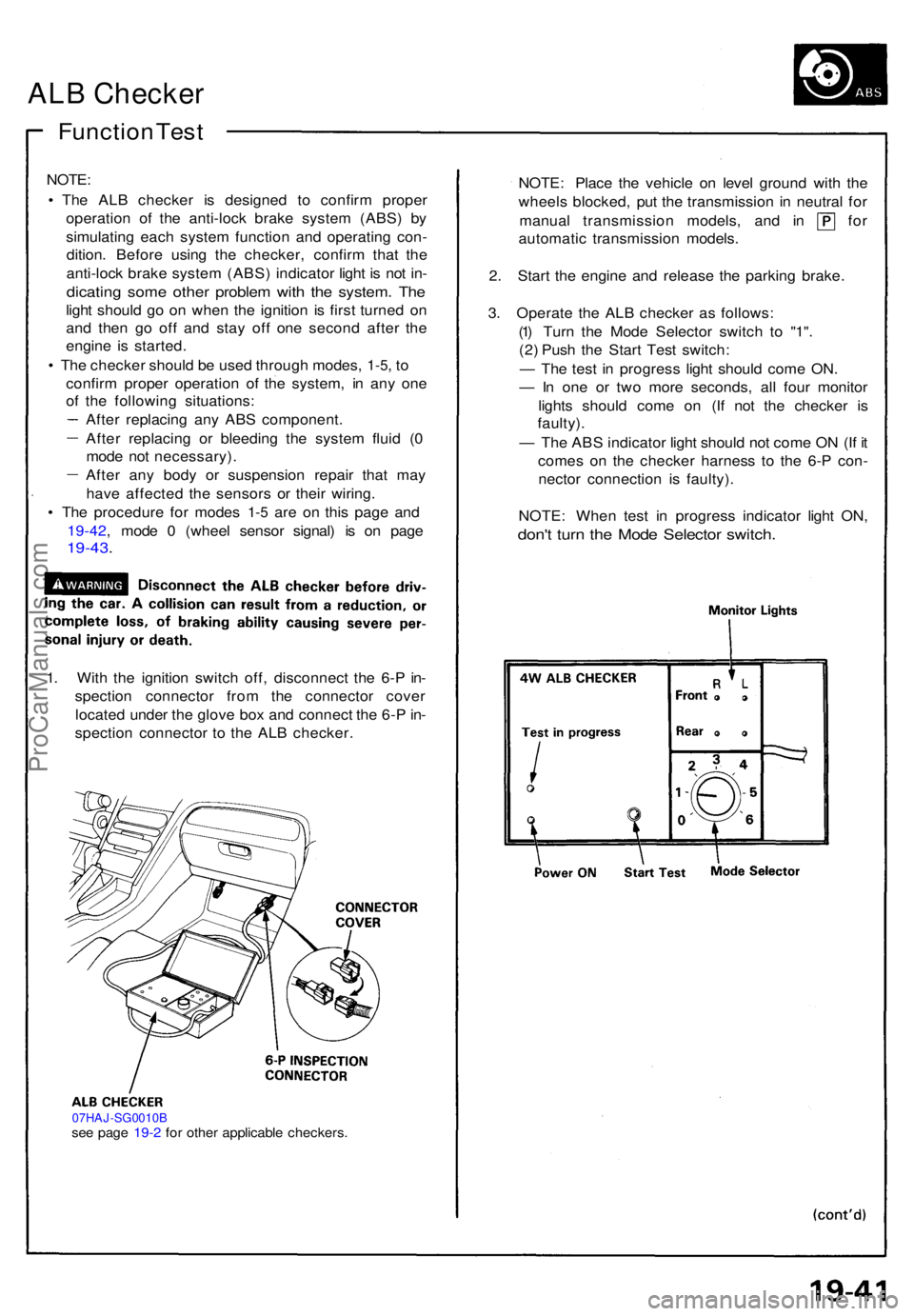

NOTE :

• Th e AL B checke r i s designe d t o confir m prope r

operatio n of the anti-loc k brak e syste m (ABS ) b y

simulatin g eac h syste m functio n an d operatin g con -

dition . Befor e usin g th e checker , confir m tha t th e

anti-loc k brak e syste m (ABS ) indicato r ligh t i s no t in -

dicatin g som e othe r proble m wit h th e system . Th e

light shoul d g o o n whe n th e ignitio n i s firs t turne d o n

an d the n g o of f an d sta y of f on e secon d afte r th e

engin e i s started .

• Th e checke r shoul d b e use d throug h modes ,

1-5, t o

confir m prope r operatio n of the system , i n an y on e

of th e followin g situations :

Afte r replacin g an y AB S component .

Afte r replacin g o r bleedin g th e syste m flui d ( 0

mod e no t necessary) .

Afte r an y bod y o r suspensio n repai r tha t ma y

hav e affecte d th e sensor s o r thei r wiring .

• Th e procedur e fo r mode s

1-5 ar e o n thi s pag e an d

19-42 , mod e 0 (whee l senso r signal ) i s o n pag e

19-43 .

1. Wit h th e ignitio n switc h off , disconnec t th e 6- P in -

spectio n connecto r fro m th e connecto r cove r

locate d unde r th e glov e bo x an d connec t th e 6- P in -

spectio n connecto r t o th e AL B checker .

07HAJ-SG0010Bsee pag e 19- 2 fo r othe r applicabl e checkers .

NOTE: Plac e th e vehicl e o n leve l ground with th e

wheel s blocked , pu t th e transmissio n i n neutra l fo r

manua l transmissio n models , an d i n fo r

automati c transmissio n models .

2 . Star t th e engin e an d releas e th e parkin g brake .

3 . Operat e th e AL B checke r a s follows :

(1 ) Tur n th e Mod e Selecto r switc h t o "1" .

(2 ) Pus h th e Star t Tes t switch :

— Th e tes t i n progres s ligh t shoul d com e ON .

— In on e o r tw o mor e seconds , al l fou r monito r

light s shoul d com e o n (I f no t th e checke r i s

faulty) .

— Th e AB S indicato r ligh t shoul d no t com e O N (I f i t

come s o n th e checke r harnes s t o th e 6- P con -

necto r connectio n i s faulty) .

NOTE : Whe n tes t i n progres s indicato r ligh t ON ,

don't tur n th e Mod e Selecto r switch .

ProCarManuals.com

Page 528 of 1640

ALB Checker

Function Test (cont'd)

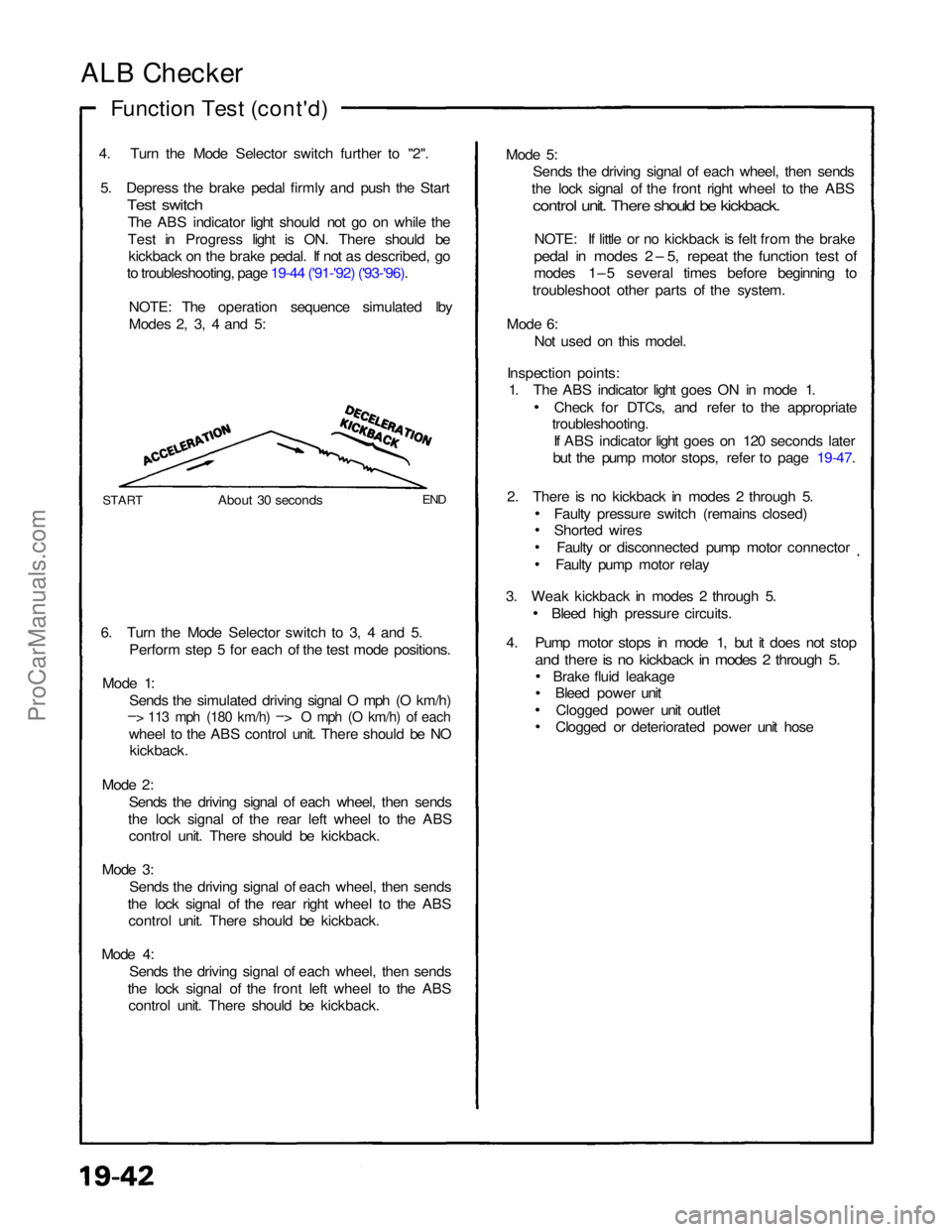

4. Turn the Mode Selector switch further to "2". 5. Depress the brake pedal firmly and push the Start

Test switch

The ABS indicator light should not go on while the

Test in Progress light is ON. There should bekickback on the brake pedal. If not as described, go

to troubleshooting, page 19-44 ('91-'92) ('93-'96).

NOTE: The operation sequence simulated lby

Modes 2, 3, 4 and 5:

START

About 30 seconds

END

6. Turn the Mode Selector switch to 3, 4 and 5. Perform step 5 for each of the test mode positions.

Mode 1: Sends the simulated driving signal O mph (O km/h)

– > 113 mph (180 km/h) –

>

O mph (O km/h) of each

wheel to the ABS control unit. There should be NO

kickback.

Mode 2: Sends the driving signal of each wheel, then sends

the lock signal of the rear left wheel to the ABS control unit. There should be kickback.

Mode 3: Sends the driving signal of each wheel, then sends

the lock signal of the rear right wheel to the ABS control unit. There should be kickback.

Mode 4: Sends the driving signal of each wheel, then sends

the lock signal of the front left wheel to the ABS control unit. There should be kickback. Mode 5:

Sends the driving signal of each wheel, then sends

the lock signal of the front right wheel to the ABS

control unit. There should be kickback.

NOTE: If little or no kickback is felt from the brake

pedal in modes 2 – 5, repeat the function test of

modes 1–5 several times before beginning to

troubleshoot other parts of the system.

Mode 6: Not used on this model.

Inspection points: 1. The ABS indicator light goes ON in mode 1.

Check for DTCs, and refer to the appropriate

troubleshooting.

If ABS indicator light goes on 120 seconds later

but the pump motor stops, refer to page 19-47.

2. There is no kickback in modes 2 through 5. Faulty pressure switch (remains closed)

Shorted wiresFaulty or disconnected pump motor connector

Faulty pump motor relay

3. Weak kickback in modes 2 through 5. Bleed high pressure circuits.

4. Pump motor stops in mode 1, but it does not stop

and there is no kickback in modes 2 through 5.

Brake fluid leakageBleed power unit

Clogged power unit outlet

Clogged or deteriorated power unit hoseProCarManuals.com

Page 686 of 1640

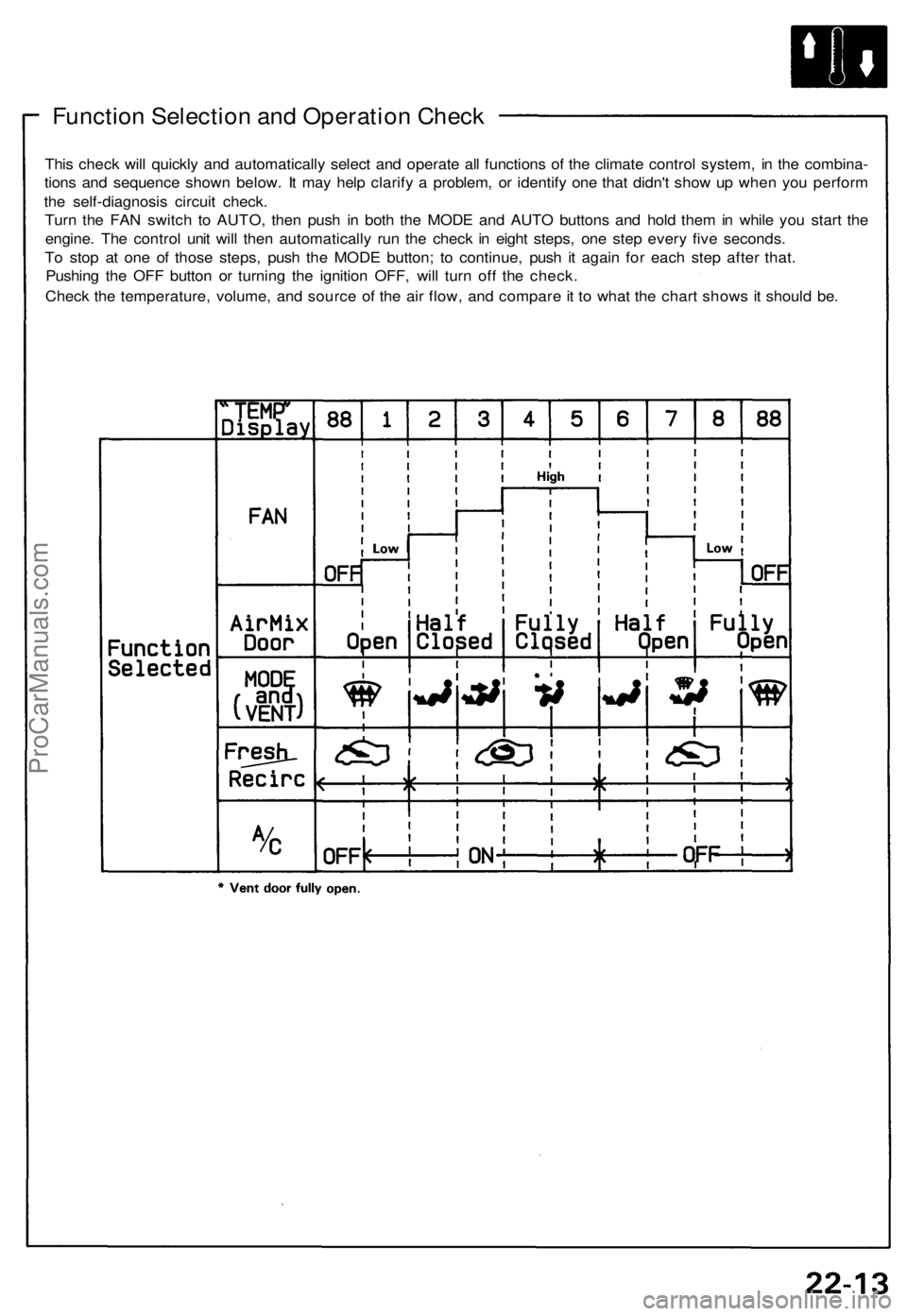

Function Selection and Operation Check

This check will quickly and automatically select and operate all functions of the climate control system, in the combina-

tions and sequence shown below. It may help clarify a problem, or identify one that didn't show up when you perform

the self-diagnosis circuit check.

Turn the FAN switch to AUTO, then push in both the MODE and AUTO buttons and hold them in while you start the

engine. The control unit will then automatically run the check in eight steps, one step every five seconds.

To stop at one of those steps, push the MODE button; to continue, push it again for each step after that.

Pushing the OFF button or turning the ignition OFF, will turn off the check.

Check the temperature, volume, and source of the air flow, and compare it to what the chart shows it should be.ProCarManuals.com

Page 1084 of 1640

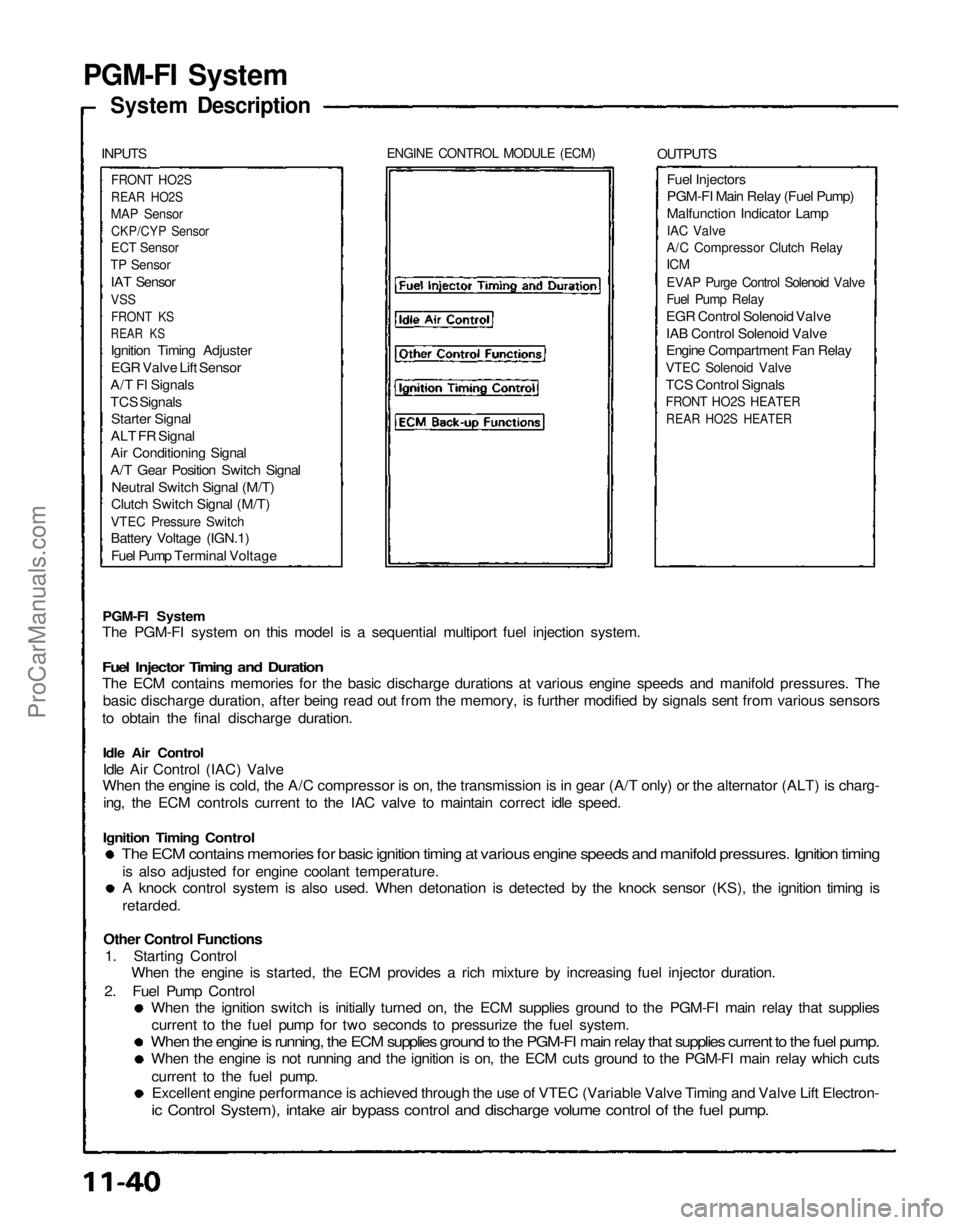

PGM-FI System

System Description

INPUTS

ENGINE CONTROL MODULE (ECM)

OUTPUTS

FRONT HO2S

REAR HO2S

MAP Sensor

CKP/CYP Sensor

ECT Sensor

TP Sensor

IAT Sensor

VSS

FRONT KS

REAR KS

Ignition Timing Adjuster

EGR Valve Lift Sensor

A/T Fl Signals

TCS Signals

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Switch Signal

Neutral Switch Signal (M/T)

Clutch Switch Signal (M/T)

VTEC Pressure Switch

Battery Voltage (IGN.1)

Fuel Pump Terminal Voltage

Fuel Injectors

PGM-FI Main Relay (Fuel Pump)

Malfunction Indicator Lamp

IAC Valve

A/C Compressor Clutch Relay

ICM

EVAP Purge Control Solenoid Valve

Fuel Pump Relay

EGR Control Solenoid Valve

IAB Control Solenoid Valve

Engine Compartment Fan Relay

VTEC Solenoid Valve

TCS Control Signals

FRONT HO2S HEATER

REAR HO2S HEATER

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel Injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Idle Air Control

Idle Air Control (IAC) Valve

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) or the alternator (ALT) is charg-

ing, the ECM controls current to the IAC valve to maintain correct idle speed.

Ignition Timing Control

The ECM contains memories for basic ignition timing at various engine speeds and manifold pressures. Ignition timing

is also adjusted for engine coolant temperature.

A knock control system is also used. When detonation is detected by the knock sensor (KS), the ignition timing is

retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

Excellent engine performance is achieved through the use of VTEC (Variable Valve Timing and Valve Lift Electron-

ic Control System), intake air bypass control and discharge volume control of the fuel pump.ProCarManuals.com