belt ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 7 of 1640

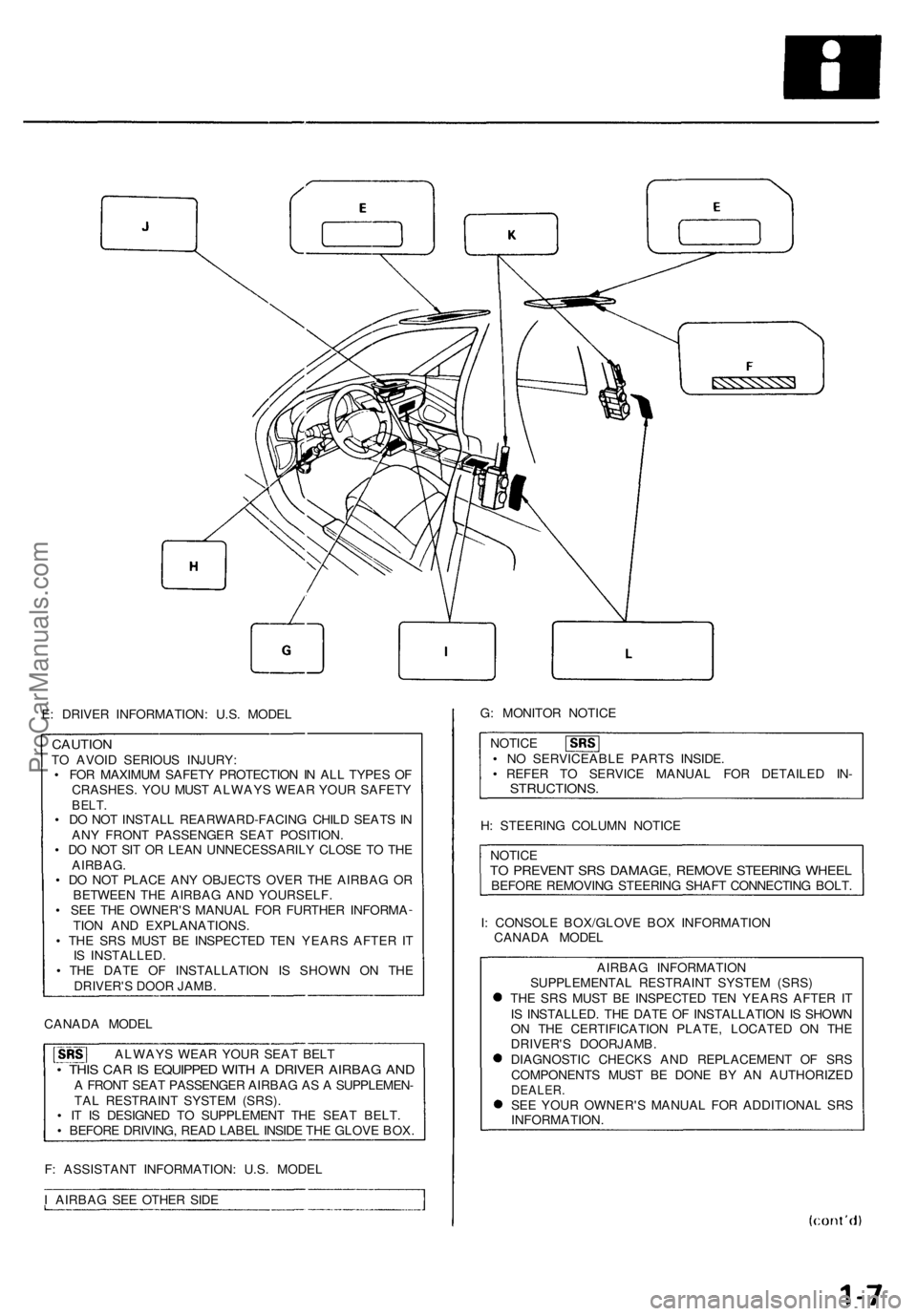

E: DRIVE R INFORMATION : U.S . MODE L

CAUTIO NTO AVOI D SERIOU S INJURY :

• FO R MAXIMU M SAFET Y PROTECTIO N IN AL L TYPE S O F

CRASHES . YO U MUS T ALWAY S WEA R YOU R SAFET Y

BELT.• D O NO T INSTAL L REARWARD-FACIN G CHIL D SEAT S IN

AN Y FRON T PASSENGE R SEA T POSITION .

• D O NO T SI T O R LEA N UNNECESSARIL Y CLOS E T O TH E

AIRBAG .

• D O NO T PLAC E AN Y OBJECT S OVE R TH E AIRBA G O R

BETWEE N TH E AIRBA G AN D YOURSELF .

• SE E TH E OWNER' S MANUA L FO R FURTHE R INFORM A

TIO N AN D EXPLANATIONS .

• TH E SR S MUS T B E INSPECTE D TE N YEAR S AFTE R IT

I S INSTALLED .

• TH E DAT E O F INSTALLATIO N I S SHOW N O N TH E

DRIVER'S DOOR JAMB.

CANAD A MODE L

ALWAY S WEA R YOU R SEA T BEL T

• THI S CA R IS EQUIPPE D WIT H A DRIVE R AIRBA G AN DA FRON T SEA T PASSENGE R AIRBA G A S A SUPPLEMEN -

TA L RESTRAIN T SYSTE M (SRS) .

• I T I S DESIGNE D T O SUPPLEMEN T TH E SEA T BELT .

• BEFOR E DRIVING , REA D LABE L INSID E TH E GLOV E BOX .

F : ASSISTAN T INFORMATION : U.S . MODE L

I AIRBA G SE E OTHE R SID E G

: MONITO R NOTIC E

NOTIC E

• N O SERVICEABL E PART S INSIDE .

• REFE R T O SERVIC E MANUA L FO R DETAILE D IN -

STRUCTIONS .

H: STEERIN G COLUM N NOTIC E

NOTIC E

TO PREVEN T SR S DAMAGE , REMOV E STEERIN G WHEE LBEFOR E REMOVIN G STEERIN G SHAF T CONNECTIN G BOLT .

I : CONSOL E BOX/GLOV E BO X INFORMATIO N

CANAD A MODE L

AIRBA G INFORMATIO N

SUPPLEMENTA L RESTRAIN T SYSTE M (SRS )

TH E SR S MUS T B E INSPECTE D TE N YEAR S AFTE R IT

I S INSTALLED . TH E DAT E O F INSTALLATIO N IS SHOW N

O N TH E CERTIFICATIO N PLATE , LOCATE D O N TH E

DRIVER' S DOORJAMB .

DIAGNOSTI C CHECK S AN D REPLACEMEN T O F SR S

COMPONENT S MUS T B E DON E B Y A N AUTHORIZE D

DEALER.SEE YOU R OWNER' S MANUA L FO R ADDITIONA L SR S

INFORMATION .

ProCarManuals.com

Page 8 of 1640

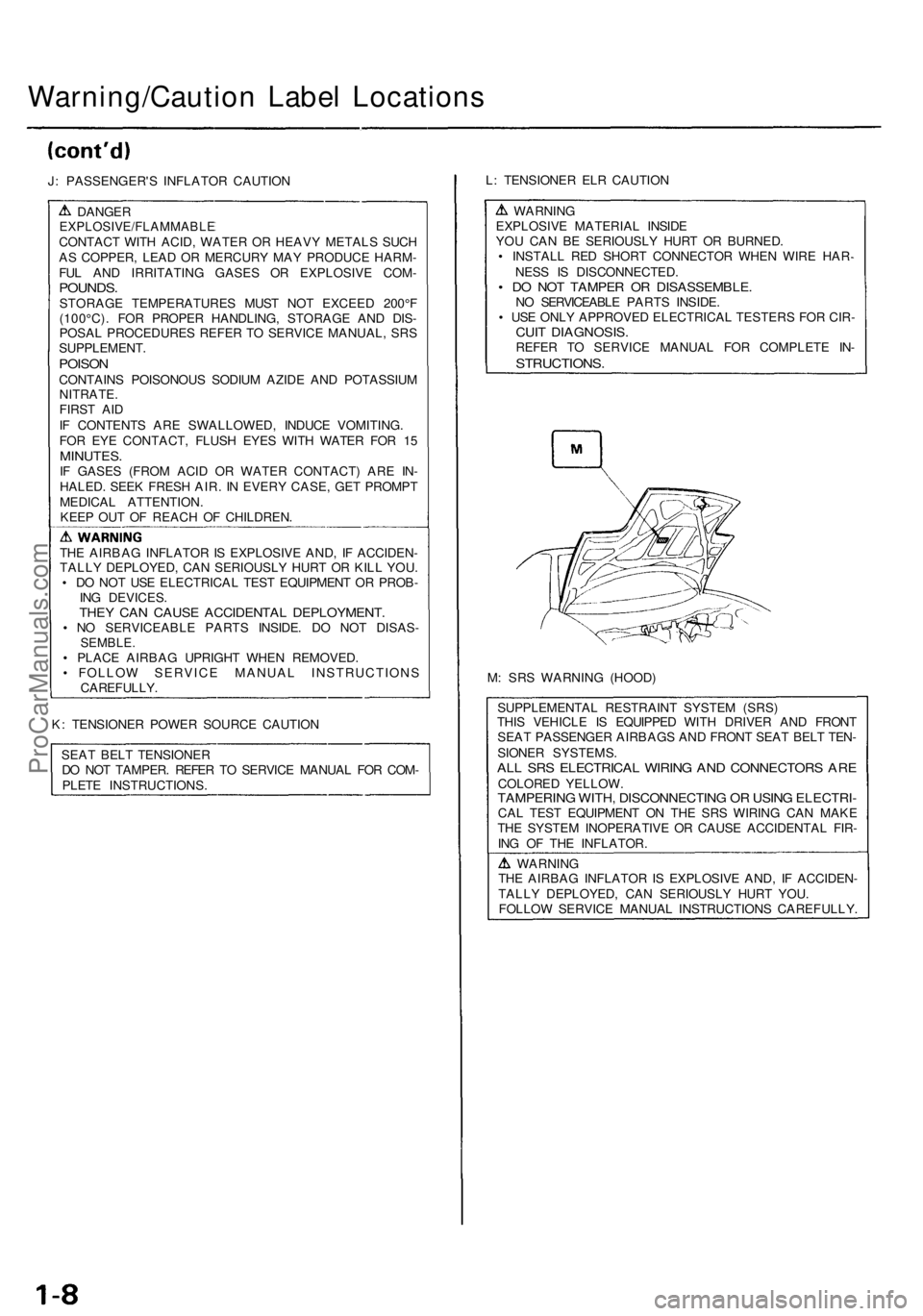

Warning/Caution Label Locations

J: PASSENGER'S INFLATOR CAUTION

DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS SUCH

AS COPPER, LEAD OR MERCURY MAY PRODUCE HARM-

FUL AND IRRITATING GASES OR EXPLOSIVE COM-

POUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 200°F

(100°C). FOR PROPER HANDLING, STORAGE AND DIS-

POSAL PROCEDURES REFER TO SERVICE MANUAL, SRS

SUPPLEMENT.

POISON

CONTAINS POISONOUS SODIUM AZIDE AND POTASSIUM

NITRATE.

FIRST AID

IF CONTENTS ARE SWALLOWED, INDUCE VOMITING.

FOR EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES.

IF GASES (FROM ACID OR WATER CONTACT) ARE IN-

HALED. SEEK FRESH AIR. IN EVERY CASE, GET PROMPT

MEDICAL ATTENTION.

KEEP OUT OF REACH OF CHILDREN.

THE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY DEPLOYED, CAN SERIOUSLY HURT OR KILL YOU.

• DO NOT USE ELECTRICAL TEST EQUIPMENT OR PROB-

ING DEVICES.

THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.

• NO SERVICEABLE PARTS INSIDE. DO NOT DISAS-

SEMBLE.

• PLACE AIRBAG UPRIGHT WHEN REMOVED.

• FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

K: TENSIONER POWER SOURCE CAUTION

SEAT BELT TENSIONER

DO NOT TAMPER. REFER TO SERVICE MANUAL FOR COM-

PLETE INSTRUCTIONS.

L: TENSIONER ELR CAUTION

WARNING

EXPLOSIVE MATERIAL INSIDE

YOU CAN BE SERIOUSLY HURT OR BURNED.

• INSTALL RED SHORT CONNECTOR WHEN WIRE HAR

NESS IS DISCONNECTED.

• DO NOT TAMPER OR DISASSEMBLE.

NO SERVICEABLE PARTS INSIDE.

• USE ONLY APPROVED ELECTRICAL TESTERS FOR CIR-

CUIT DIAGNOSIS.

REFER TO SERVICE MANUAL FOR COMPLETE IN-

STRUCTIONS.

M: SRS WARNING (HOOD)

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

THIS VEHICLE IS EQUIPPED WITH DRIVER AND FRONT

SEAT PASSENGER AIRBAGS AND FRONT SEAT BELT TEN-

SIONER SYSTEMS.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPERING WITH, DISCONNECTING OR USING ELECTRI-

CAL TEST EQUIPMENT ON THE SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTAL FIR-

ING OF THE INFLATOR.

WARNING

THE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY DEPLOYED, CAN SERIOUSLY HURT YOU.

FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.ProCarManuals.com

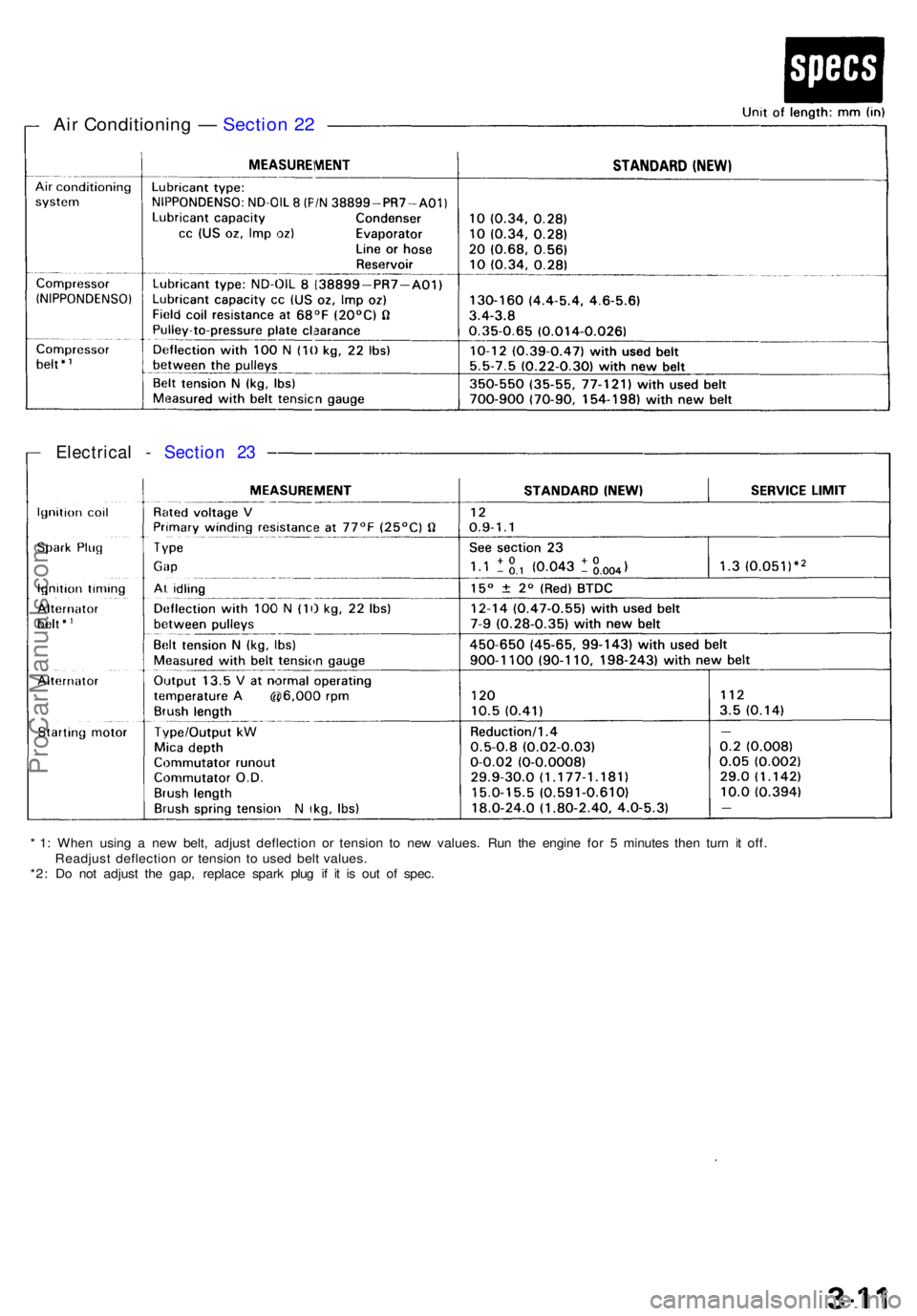

Page 22 of 1640

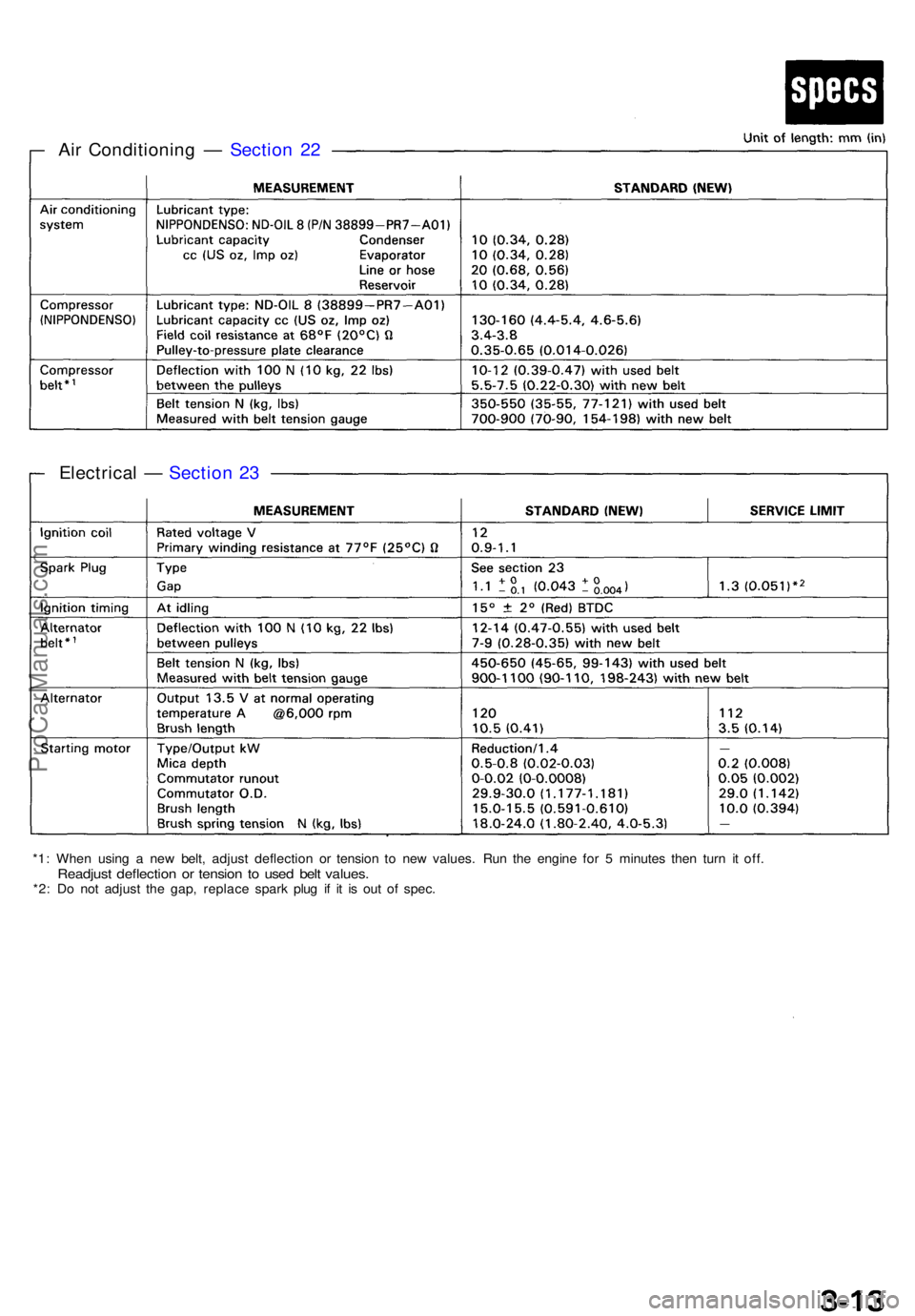

* 1 : Whe n usin g a ne w belt , adjus t deflectio n o r tensio n t o ne w values . Ru n th e engin e fo r 5 minute s the n tur n i t off .

Readjus t deflectio n o r tensio n t o use d bel t values .

*2 : D o no t adjus t th e gap , replac e spar k plu g i f i t i s ou t o f spec .

Electrica l - Sectio n 2 3

Air Conditionin g — Sectio n 2 2

ProCarManuals.com

Page 39 of 1640

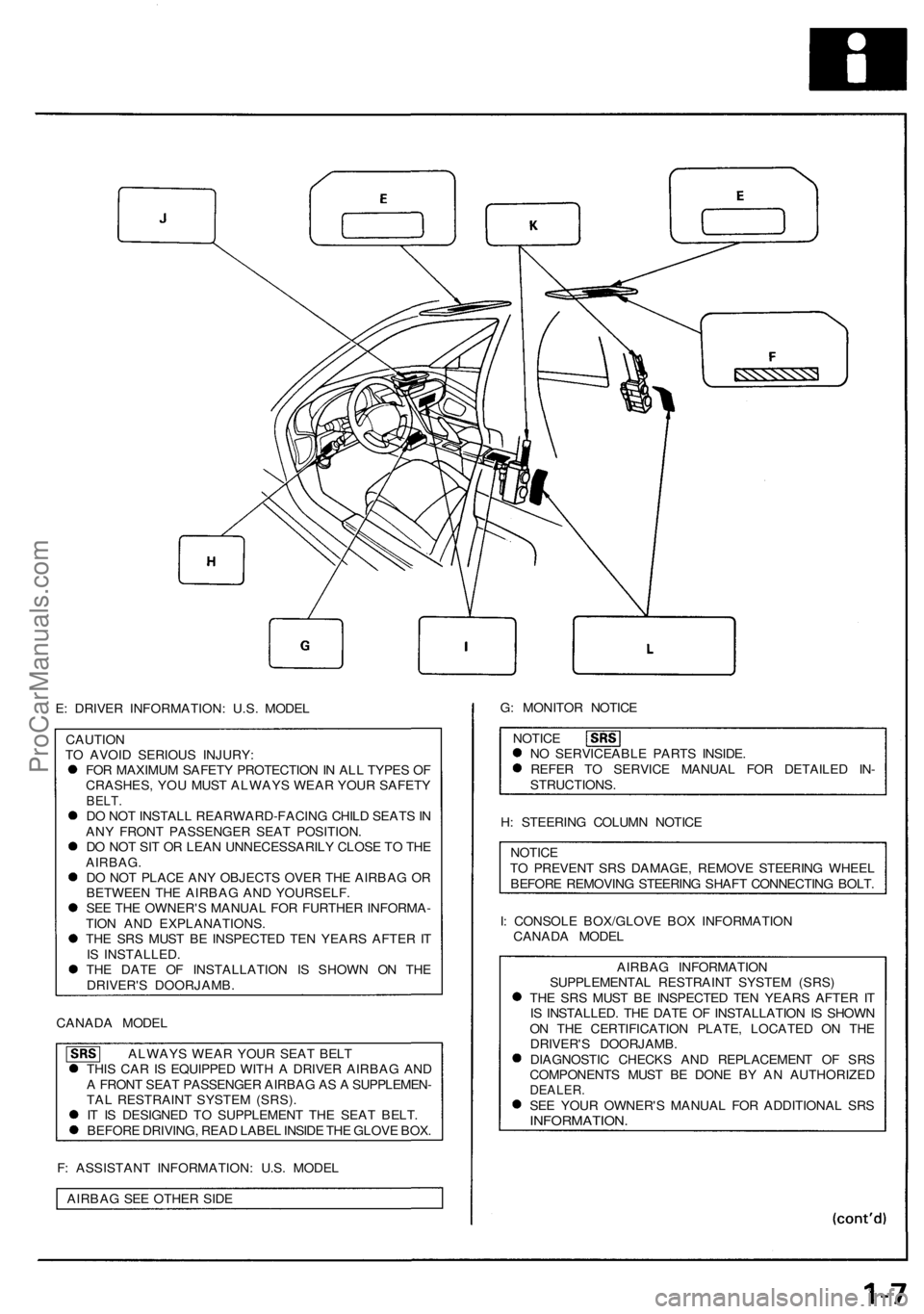

E: DRIVER INFORMATION: U.S. MODEL

CAUTION

TO AVOID SERIOUS INJURY:

FOR MAXIMUM SAFETY PROTECTION IN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

BELT.

DO NOT INSTALL REARWARD-FACING CHILD SEATS IN

ANY FRONT PASSENGER SEAT POSITION.

DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.

DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.

SEE THE OWNER'S MANUAL FOR FURTHER INFORMA-

TION AND EXPLANATIONS.

THE SRS MUST BE INSPECTED TEN YEARS AFTER IT

IS INSTALLED.

THE DATE OF INSTALLATION IS SHOWN ON THE

DRIVER'S DOORJAMB.

CANADA MODEL

ALWAYS WEAR YOUR SEAT BELT

THIS CAR IS EQUIPPED WITH A DRIVER AIRBAG AND

A FRONT SEAT PASSENGER AIRBAG AS A SUPPLEMEN-

TAL RESTRAINT SYSTEM (SRS).

IT IS DESIGNED TO SUPPLEMENT THE SEAT BELT.

BEFORE DRIVING, READ LABEL INSIDE THE GLOVE BOX.

F: ASSISTANT INFORMATION: U.S. MODEL

AIRBAG SEE OTHER SIDE

G: MONITOR NOTICE

NOTICE

NO SERVICEABLE PARTS INSIDE.

REFER TO SERVICE MANUAL FOR DETAILED IN-

STRUCTIONS.

H: STEERING COLUMN NOTICE

NOTICE

TO PREVENT SRS DAMAGE, REMOVE STEERING WHEEL

BEFORE REMOVING STEERING SHAFT CONNECTING BOLT.

I: CONSOLE BOX/GLOVE BOX INFORMATION

CANADA MODEL

AIRBAG INFORMATION

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

THE SRS MUST BE INSPECTED TEN YEARS AFTER IT

IS INSTALLED. THE DATE OF INSTALLATION IS SHOWN

ON THE CERTIFICATION PLATE, LOCATED ON THE

DRIVER'S DOORJAMB.

DIAGNOSTIC CHECKS AND REPLACEMENT OF SRS

COMPONENTS MUST BE DONE BY AN AUTHORIZED

DEALER.

SEE YOUR OWNER'S MANUAL FOR ADDITIONAL SRS

INFORMATION.ProCarManuals.com

Page 58 of 1640

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

*1 : Whe n usin g a ne w belt , adjus t deflectio n o r tensio n t o ne w values . Ru n th e engin e fo r 5 minute s the n tur n i t off .Readjus t deflectio n o r tensio n t o use d bel t values .*2: D o no t adjus t th e gap , replac e spar k plu g i f i t i s ou t o f spec .

ProCarManuals.com

Page 74 of 1640

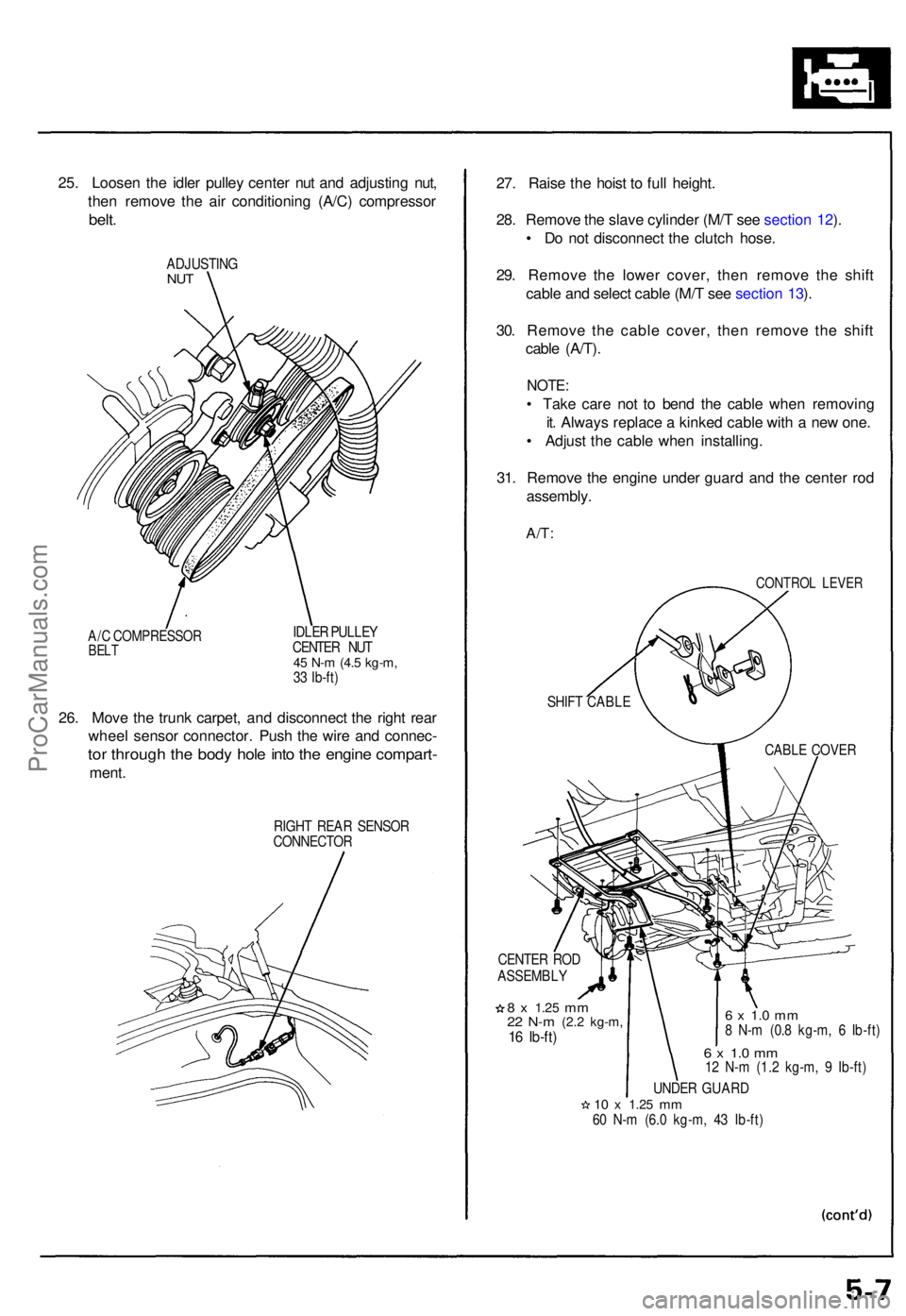

25. Loose n th e idle r pulle y cente r nu t an d adjustin g nut ,

the n remov e th e ai r conditionin g (A/C ) compresso r

belt.

ADJUSTIN GNUT

A/C COMPRESSO RBELT

IDLE R PULLE Y

CENTE R NU T

45 N- m (4. 5 kg-m ,33 Ib-ft )

26. Mov e th e trun k carpet , an d disconnec t th e righ t rea r

whee l senso r connector . Pus h th e wir e an d connec -

tor throug h th e bod y hol e int o th e engin e compart -

ment.

RIGH T REA R SENSO R

CONNECTO R

27. Rais e th e hois t t o ful l height .

28 . Remov e th e slav e cylinde r (M/ T se e sectio n 12 ).

• D o no t disconnec t th e clutc h hose .

29 . Remov e th e lowe r cover , the n remov e th e shif t

cabl e an d selec t cabl e (M/ T se e sectio n 13 ).

30 . Remov e th e cabl e cover , the n remov e th e shif t

cabl e (A/T) .

NOTE :

• Tak e car e no t t o ben d th e cabl e whe n removin g

it . Alway s replac e a kinke d cabl e wit h a ne w one .

• Adjus t th e cabl e whe n installing .

31 . Remov e th e engin e unde r guar d an d th e cente r ro d

assembly .

A/T:

CONTRO L LEVE R

CENTE R RO D

ASSEMBL Y

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

6 x 1. 0 m m8 N- m (0. 8 kg-m , 6 Ib-ft )

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

UNDE R GUAR D

10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

SHIF

T CABL E

CABLE COVE R

ProCarManuals.com

Page 80 of 1640

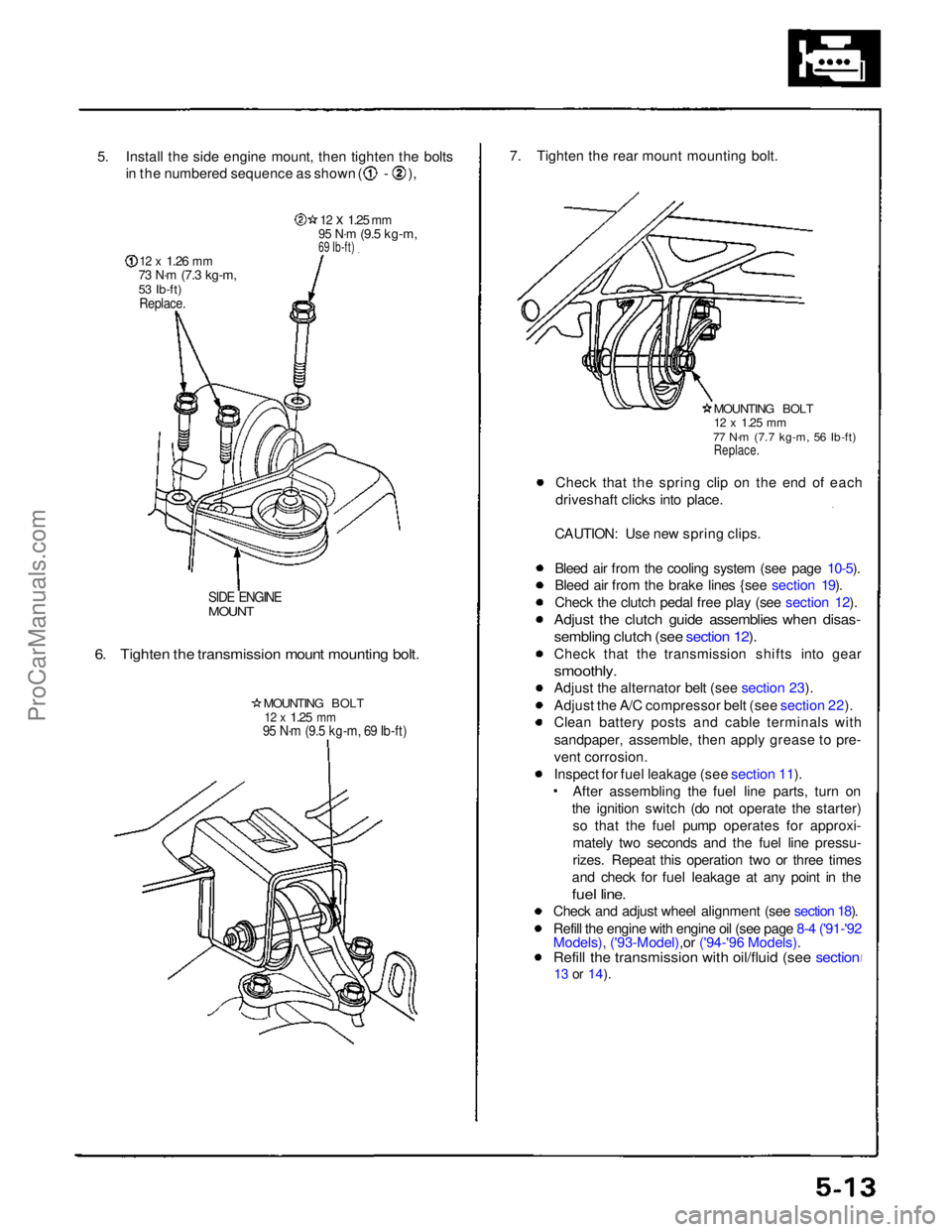

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 83 of 1640

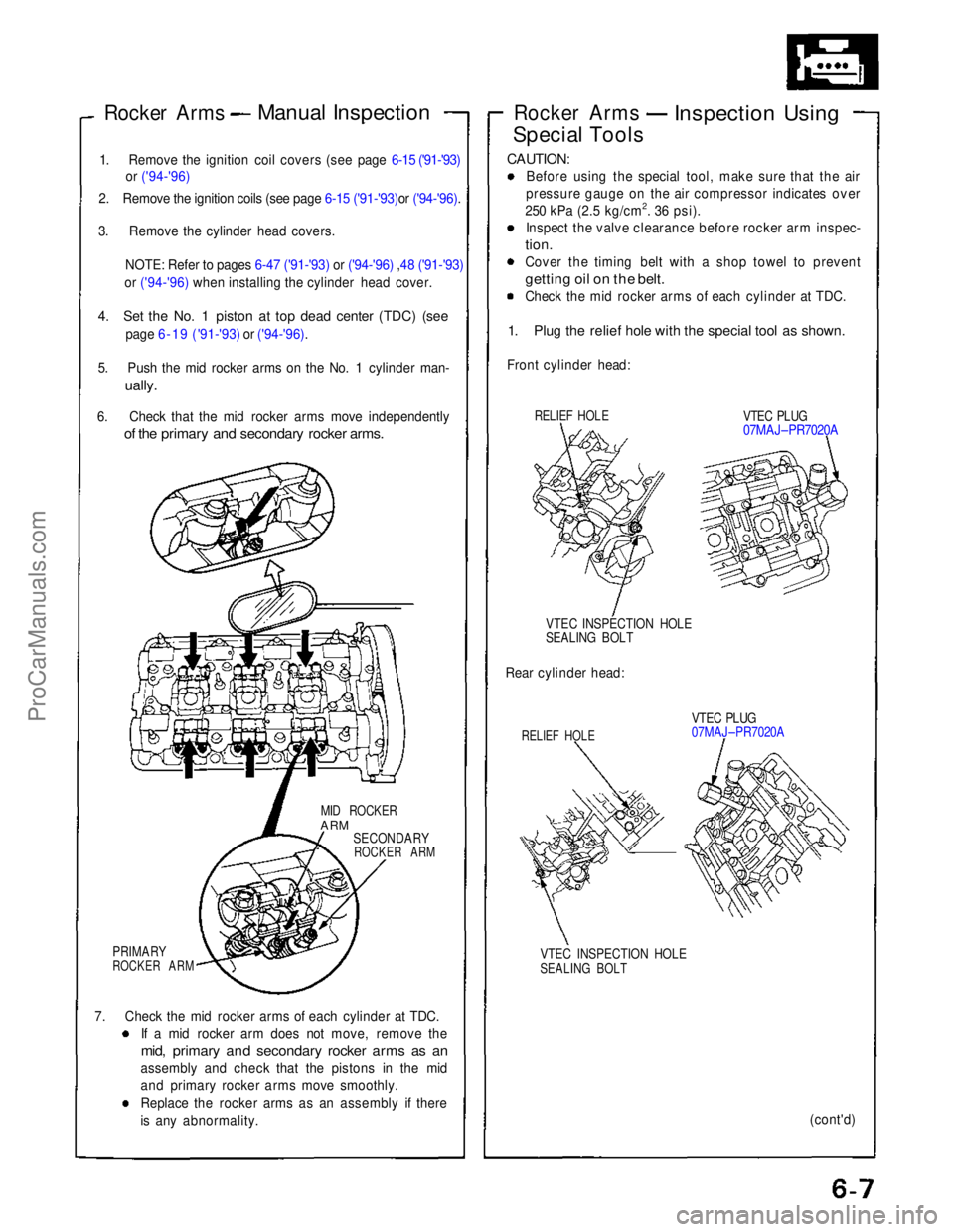

Rocker Arms

Manual Inspection

1. Remove the ignition coil covers (see page 6-15 ('91-'93) or ('94-'96)

2. Remove the ignition coils (see page 6-15 ('91-'93)or ('94-'96).

3. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93)

or ('94-'96) ,48 ('91-'93)

or ('94-'96) when installing the cylinder head cover.

4. Set the No. 1 piston at top dead center (TDC) (see

page 6-19 ('91-'93)

or ('94-'96).

5. Push the mid rocker arms on the No. 1 cylinder man-

ually.

6. Check that the mid rocker arms move independently

of the primary and secondary rocker arms.

MID ROCKER

ARM

SECONDARY

ROCKER ARM

PRIMARY

ROCKER ARM

7. Check the mid rocker arms of each cylinder at TDC. If a mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

Replace the rocker arms as an assembly if there

is any abnormality. Rocker Arms

Inspection Using

Special Tools

CAUTION:

Before using the special tool, make sure that the air

pressure gauge on the air compressor indicates over

250 kPa (2.5 kg/cm2. 36 psi). Inspect the valve clearance before rocker arm inspec-

tion.

Cover the timing belt with a shop towel to prevent

getting oil on the belt.

Check the mid rocker arms of each cylinder at TDC.

1. Plug the relief hole with the special tool as shown.

Front cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

Rear cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

(cont'd)ProCarManuals.com

Page 84 of 1640

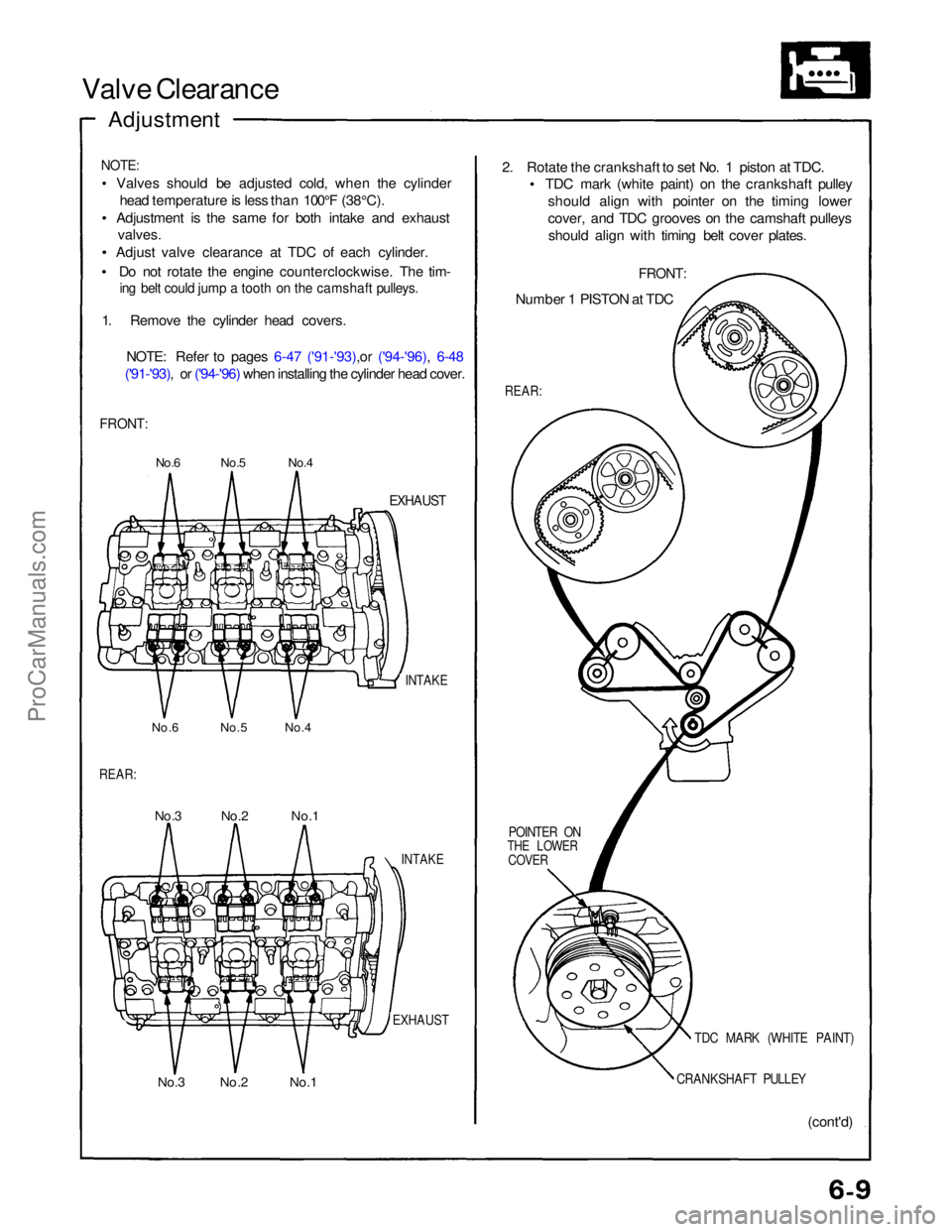

Valve Clearance

Adjustment

NOTE:

Valves should be adjusted cold, when the cylinderhead temperature is less than 100°F (38°C).

Adjustment is the same for both intake and exhaust valves.

Adjust valve clearance at TDC of each cylinder.

Do not rotate the engine counterclockwise. The tim-

ing belt could jump a tooth on the camshaft pulleys.

1. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93),or ('94-'96), 6-48

('91-'93), or ('94-'96) when installing the cylinder head cover.

FRONT:

No.6 No.5 No.4

EXHAUST

INTAKE

No.6 No.5 No.4

REAR:

No.3 No.2 No.1

INTAKE

EXHAUST

No.3 No.2 No.1 (cont'd)

CRANKSHAFT PULLEY

TDC MARK (WHITE PAINT)

POINTER ON

THE LOWER

COVER

REAR:

Number 1 PISTON at TDC

FRONT:

2. Rotate the crankshaft to set No. 1 piston at TDC.

TDC mark (white paint) on the crankshaft pulley

should align with pointer on the timing lower

cover, and TDC grooves on the camshaft pulleysshould align with timing belt cover plates.ProCarManuals.com

Page 88 of 1640

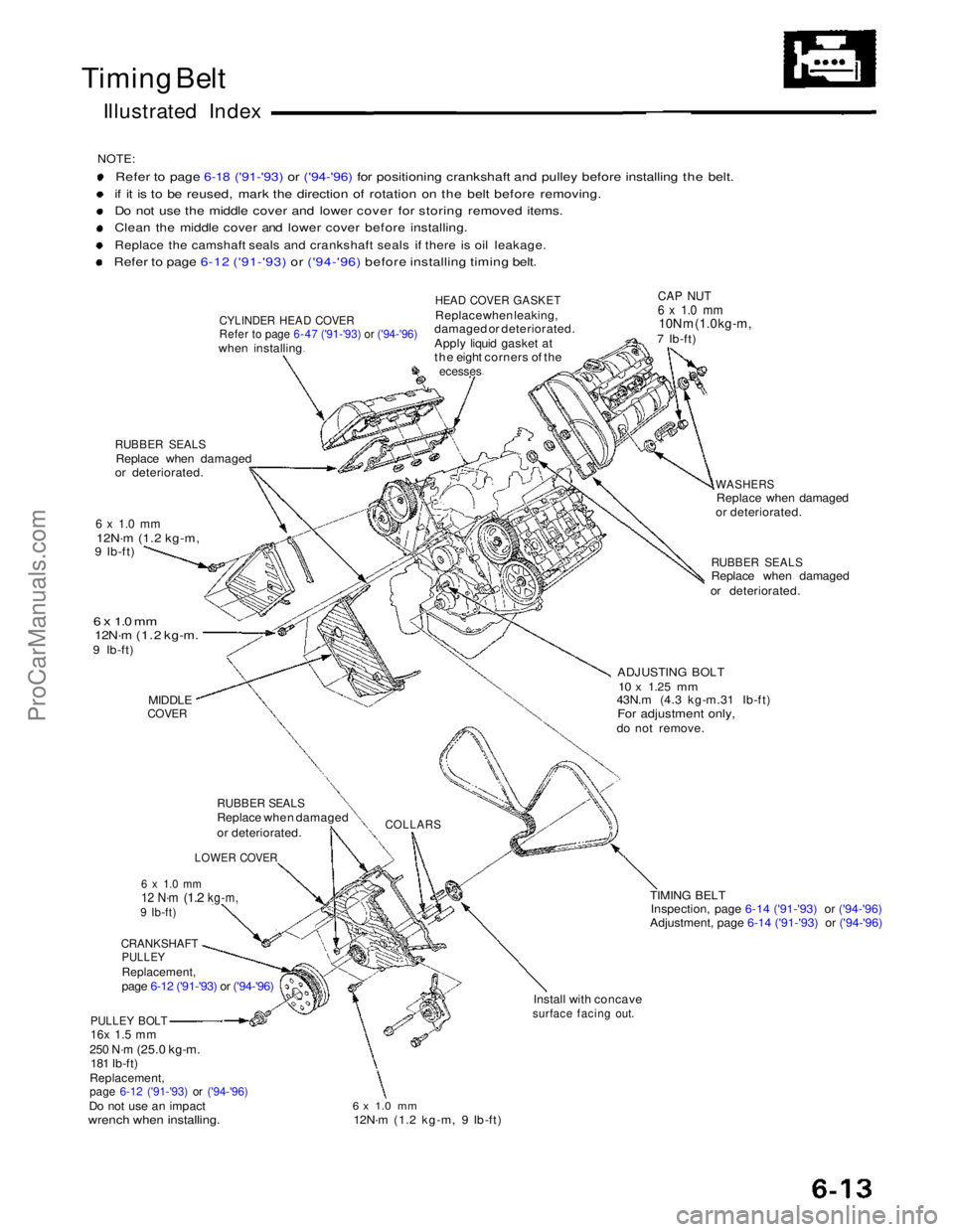

Timing Belt

Illustrated Index

NOTE:

Refer to page 6-18 ('91-'93) or ('94-'96) for positioning crankshaft and pulley before installing the belt.

if it is to be reused, mark the direction of rotation on the belt before removing.

Do not use the middle cover and lower cover for storing removed items.

Clean the middle cover and lower cover before installing.

Replace the camshaft seals and crankshaft seals if there is oil leakage.

Refer to page 6-12 ('91-'93) or ('94-'96) before installing timing belt.

CYLINDER HEAD COVER

Refer to page 6-47 ('91-'93) or ('94-'96)

when installing

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N·m (1.2 kg-m,

9 Ib-ft)

6 x 1.0 mm

12N·m (1.2 kg-m.

9 Ib-ft)

MIDDLE

COVER

RUBBER SEALS

Replace when damaged

or deteriorated.

LOWER COVER

6 x 1.0 mm

12 N·m

(1.2

kg-m,

9 Ib-ft)

CRANKSHAFT

PULLEY

Replacement,

page 6-12 ('91-'93) or ('94-'96)

PULLEY BOLT

16x 1.5 mm

250 N·m

(25.0 kg-m. 181 Ib-ft)

Replacement,

page 6-12 ('91-'93)

or ('94-'96)

Do not use an impact

wrench when installing.

HEAD COVER GASKET

Replace when leaking,

damaged or deteriorated.

Apply liquid gasket at

the eight corners of the

ecesses

CAP NUT

6 x 1.0 mm

10N m (1.0 kg-m,

7 Ib-ft)

WASHERS

Replace when damaged

or deteriorated.

RUBBER SEALS

Replace when damaged

or deteriorated.

ADJUSTING BOLT

10 x

1.25

mm

43N.m (4.3 kg-m.31 Ib-ft)

For adjustment only,

do not remove.

COLLARS

TIMING BELTInspection, page 6-14 ('91-'93) or ('94-'96)

Adjustment, page 6-14 ('91-'93) or ('94-'96)

Install with concave

surface facing out.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)ProCarManuals.com