ECU ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 124 of 1640

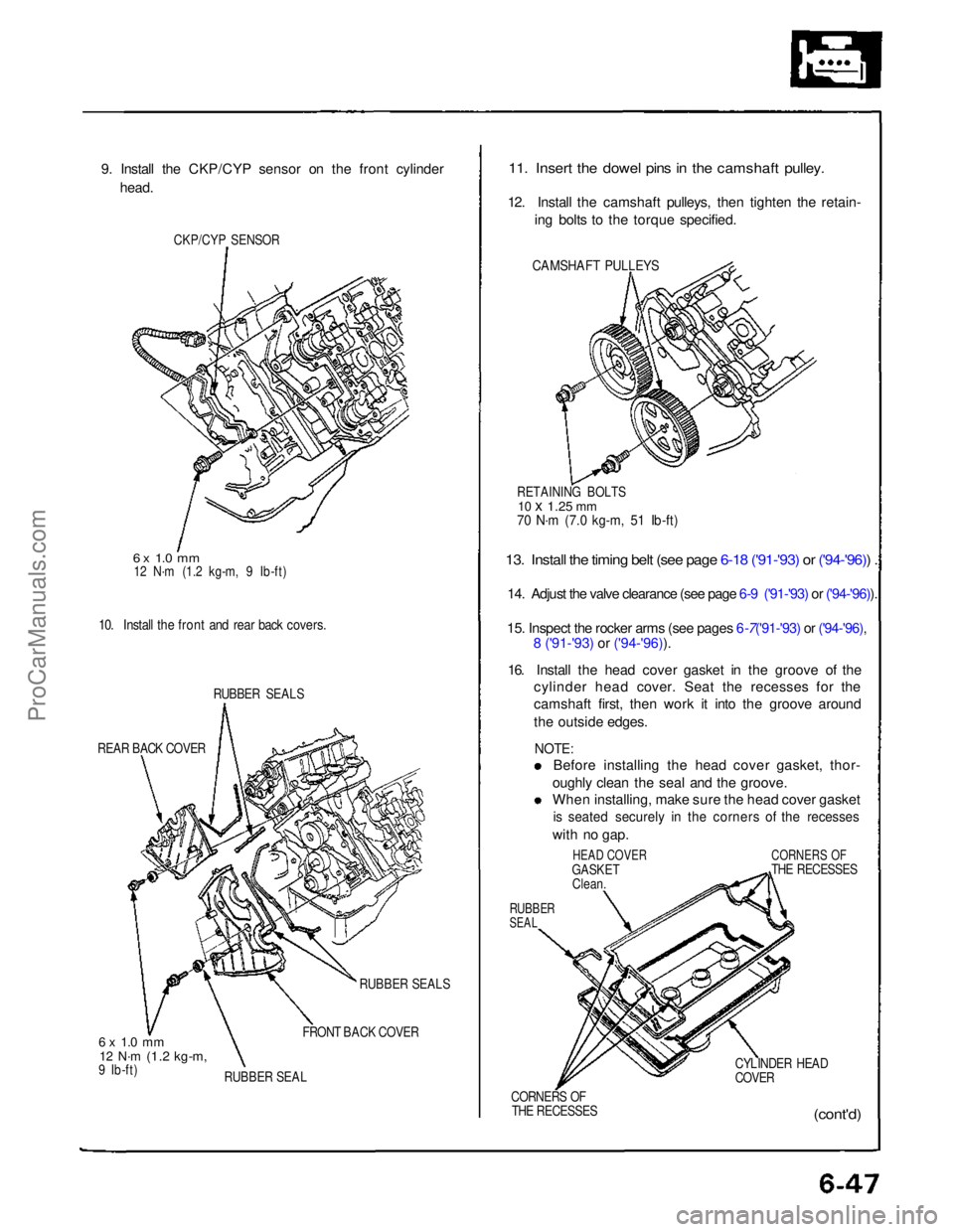

9. Install the CKP/CYP sensor on the front cylinder

head.

CKP/CYP SENSOR

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

10. Install the front and rear back covers.

RUBBER SEALS

REAR BACK COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft) RUBBER SEALS

FRONT BACK COVER

RUBBER SEAL

11. Insert the dowel pins in the camshaft pulley.

12. Install the camshaft pulleys, then tighten the retain- ing bolts to the torque specified.

CAMSHAFT PULLEYS

13. Install the timing belt (see page 6-18 ('91-'93) or ('94-'96)) .

14. Adjust the valve clearance (see page 6-9 ('91-'93) or ('94-'96)).

15. Inspect the rocker arms (see pages

6-7('91-'93) or ('94-'96),8 ('91-'93) or ('94-'96)).

16. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

Before installing the head cover gasket, thor-

oughly clean the seal and the groove. When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

HEAD COVER

GASKET Clean.

RUBBER

SEAL

CORNERS OF

THE RECESSES

CYLINDER HEAD

COVER

CORNERS OF THE RECESSES

(cont'd)

RETAINING BOLTS

10 x

1.25

mm

70 N·m (7.0 kg-m, 51 Ib-ft)ProCarManuals.com

Page 142 of 1640

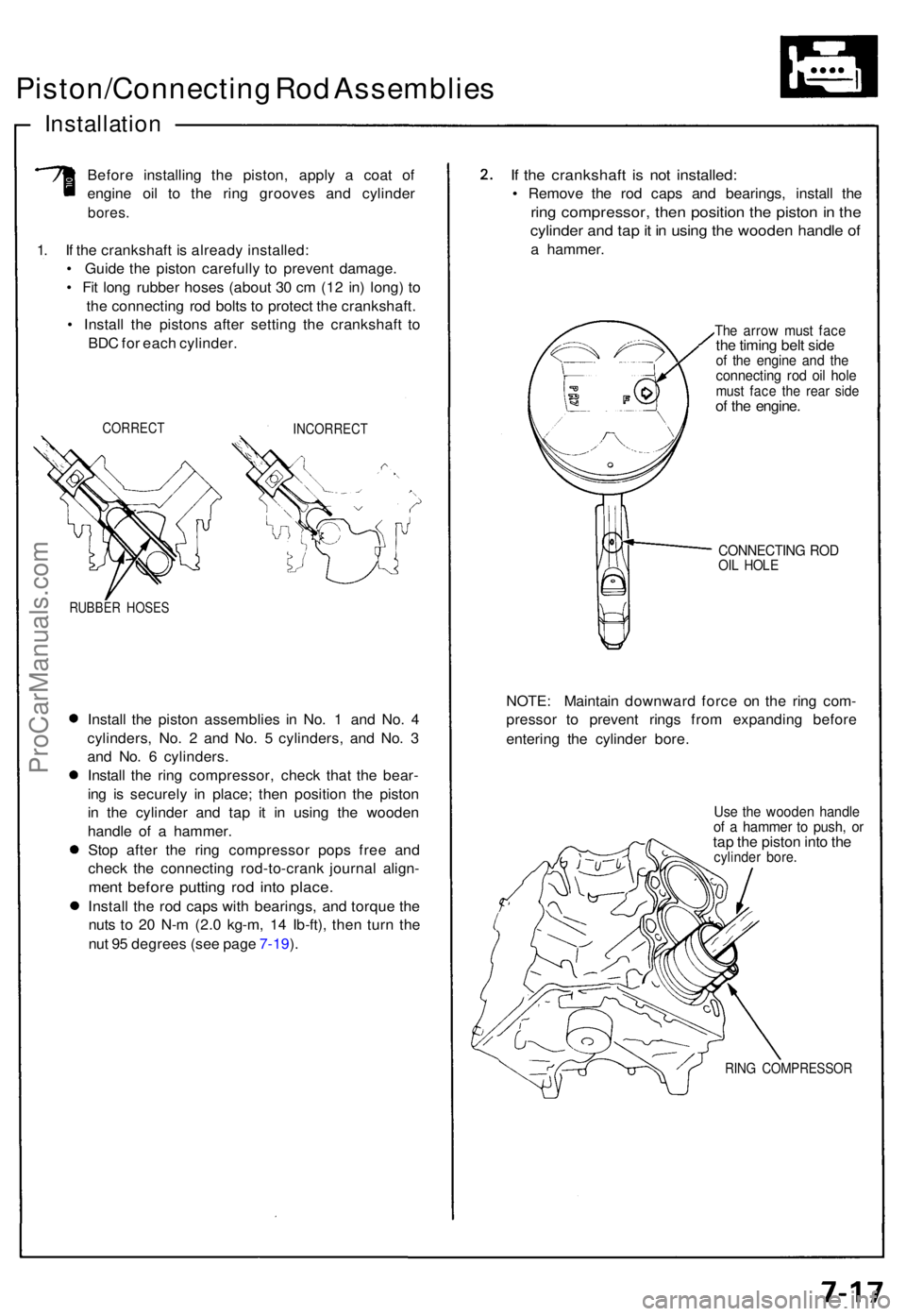

Piston/Connecting Ro d Assemblie s

Installation

Before installin g th e piston , appl y a coa t o f

engin e oi l t o th e rin g groove s an d cylinde r

bores.

1. I f th e crankshaf t i s alread y installed :

• Guid e th e pisto n carefull y t o preven t damage .

• Fi t lon g rubbe r hose s (abou t 3 0 c m (1 2 in ) long ) t o

th e connectin g ro d bolt s t o protec t th e crankshaft .

• Instal l th e piston s afte r settin g th e crankshaf t t o

BD C fo r eac h cylinder .

CORREC TINCORREC T

RUBBER HOSE S

Install th e pisto n assemblie s i n No . 1 an d No . 4

cylinders , No . 2 an d No . 5 cylinders , an d No . 3

an d No . 6 cylinders .

Instal l th e rin g compressor , chec k tha t th e bear -

in g i s securel y i n place ; the n positio n th e pisto n

i n th e cylinde r an d ta p i t i n usin g th e woode n

handl e of a hammer .

Sto p afte r th e rin g compresso r pop s fre e an d

chec k th e connectin g rod-to-cran k journa l align -

ment befor e puttin g ro d int o place .

Install th e ro d cap s wit h bearings , an d torqu e th e

nut s t o 2 0 N- m (2. 0 kg-m , 1 4 Ib-ft) , the n tur n th e

nu t 9 5 degree s (se e pag e 7-19 ).

If th e crankshaf t i s no t installed :

• Remov e th e ro d cap s an d bearings , instal l th e

ring compressor , the n positio n th e pisto n in th e

cylinde r an d ta p it i n usin g th e woode n handl e of

a hammer .

The arro w mus t fac ethe timin g bel t sid eof th e engin e an d th econnectin g ro d oi l hol emus t fac e th e rea r sid eof th e engine .

CONNECTIN G RO DOIL HOL E

NOTE : Maintai n downwar d forc e o n th e rin g com -

presso r t o preven t ring s fro m expandin g befor e

enterin g th e cylinde r bore .

Use th e woode n handl eof a hamme r t o push , o rtap th e pisto n int o th ecylinde r bore .

RING COMPRESSO R

ProCarManuals.com

Page 164 of 1640

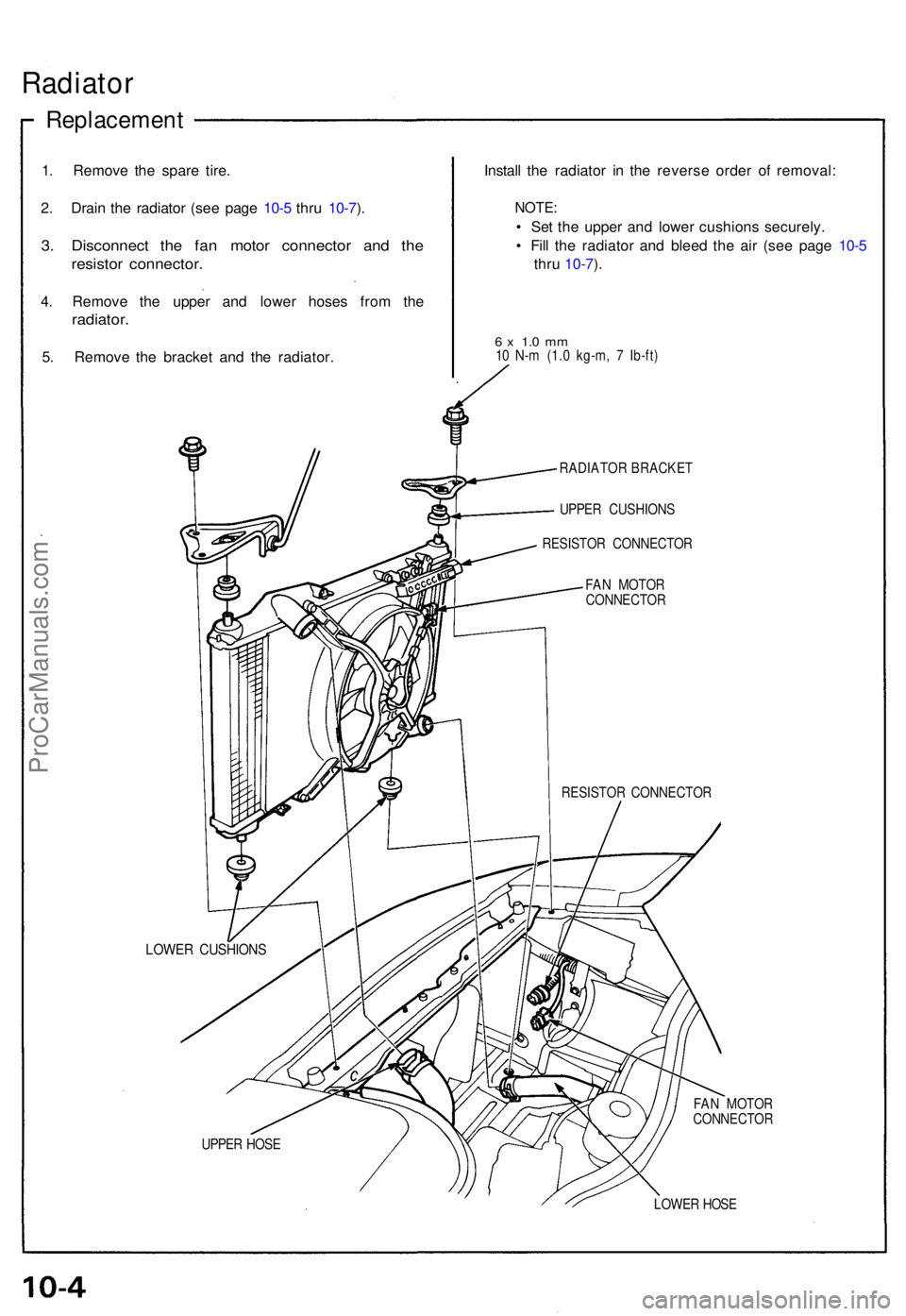

Radiator

Replacemen t

1. Remov e th e spar e tire .

2 . Drai n th e radiato r (se e pag e 10- 5 thr u 10-7 ).

3 . Disconnec t th e fa n moto r connecto r an d th e

resisto r connector .

4. Remov e th e uppe r an d lowe r hose s fro m th e

radiator .

5. Remov e th e bracke t an d th e radiator . Instal

l th e radiato r i n th e revers e orde r o f removal :

NOTE:

• Se t th e uppe r an d lowe r cushion s securely .

• Fil l th e radiato r an d blee d th e ai r (se e pag e 10- 5

thr u 10-7 ).

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

RADIATO R BRACKE T

UPPE R CUSHION S

RESISTO R CONNECTO R

FA N MOTO R

CONNECTO R

RESISTO R CONNECTO R

LOWER CUSHION S

FAN MOTO R

CONNECTO R

UPPE R HOS E

LOWER HOS E

ProCarManuals.com

Page 167 of 1640

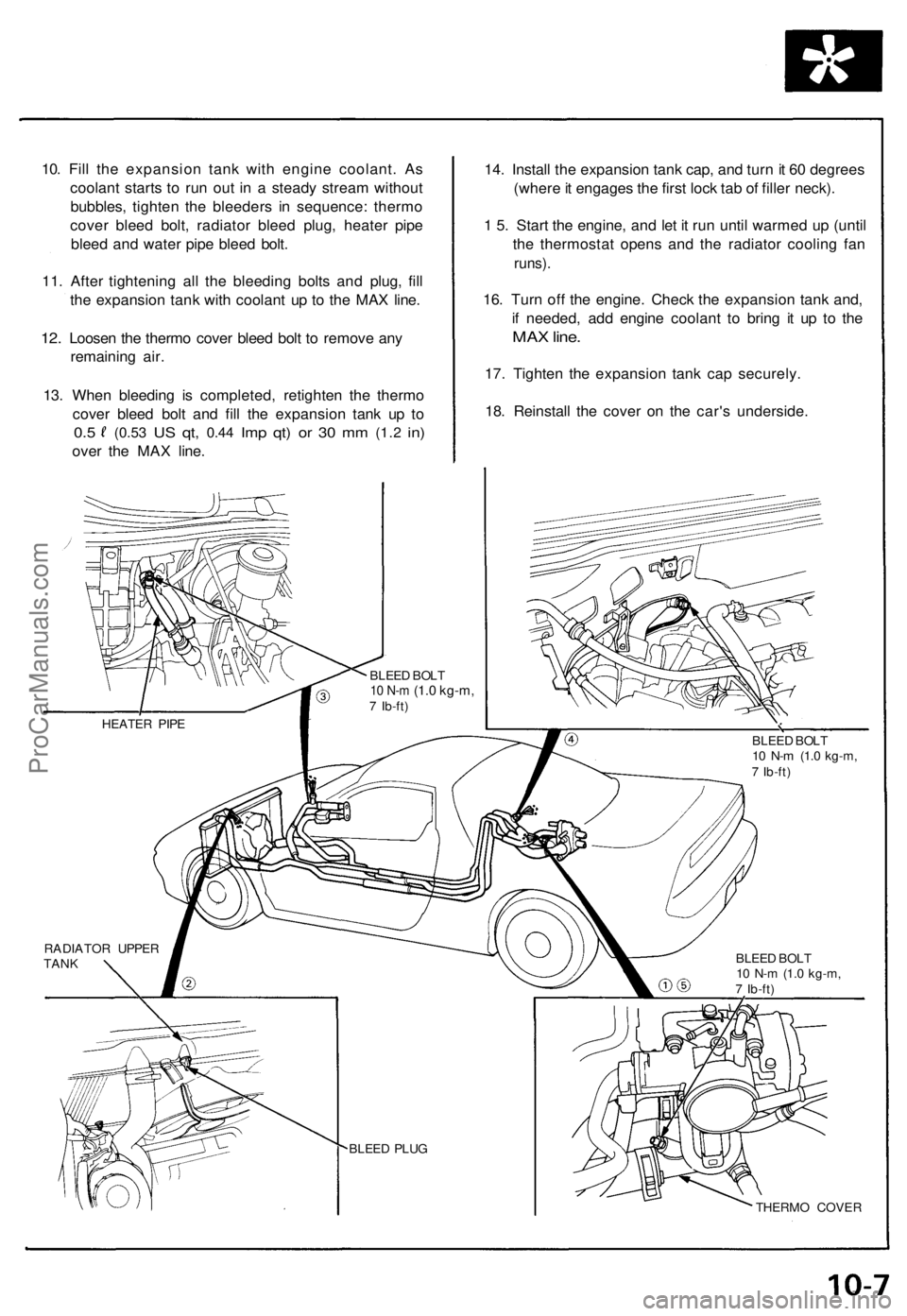

10. Fil l th e expansio n tan k wit h engin e coolant . A s

coolan t start s t o ru n ou t i n a stead y strea m withou t

bubbles , tighte n th e bleeder s i n sequence : therm o

cove r blee d bolt , radiato r blee d plug , heate r pip e

blee d an d wate r pip e blee d bolt .

11 . Afte r tightenin g al l th e bleedin g bolt s an d plug , fil l

th e expansio n tan k wit h coolan t u p t o th e MA X line .

12. Loose n th e therm o cove r blee d bol t t o remov e an y

remainin g air .

13 . Whe n bleedin g i s completed , retighte n th e therm o

cove r blee d bol t an d fill the expansio n tan k u p t o

0. 5 (0.5 3 US qt , 0.4 4 Imp qt ) o r 3 0 m m (1. 2 in)

ove r th e MA X line . 14

. Instal l th e expansio n tan k cap , an d tur n it 6 0 degree s

(wher e it engage s th e firs t loc k ta b o f fille r neck) .

1 5 . Star t th e engine , an d le t i t ru n unti l warme d u p (unti l

th e thermosta t open s an d th e radiato r coolin g fa n

runs) .

16. Tur n of f th e engine . Chec k th e expansio n tan k and ,

i f needed , ad d engin e coolan t t o brin g i t u p t o th e

MA X line .

17. Tighte n th e expansio n tan k ca p securely .

18 . Reinstal l th e cove r o n th e car' s underside .

THERMO COVE R

BLEE

D PLU G

RADIATO

R UPPE R

TAN K HEATE

R PIP E

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 288 of 1640

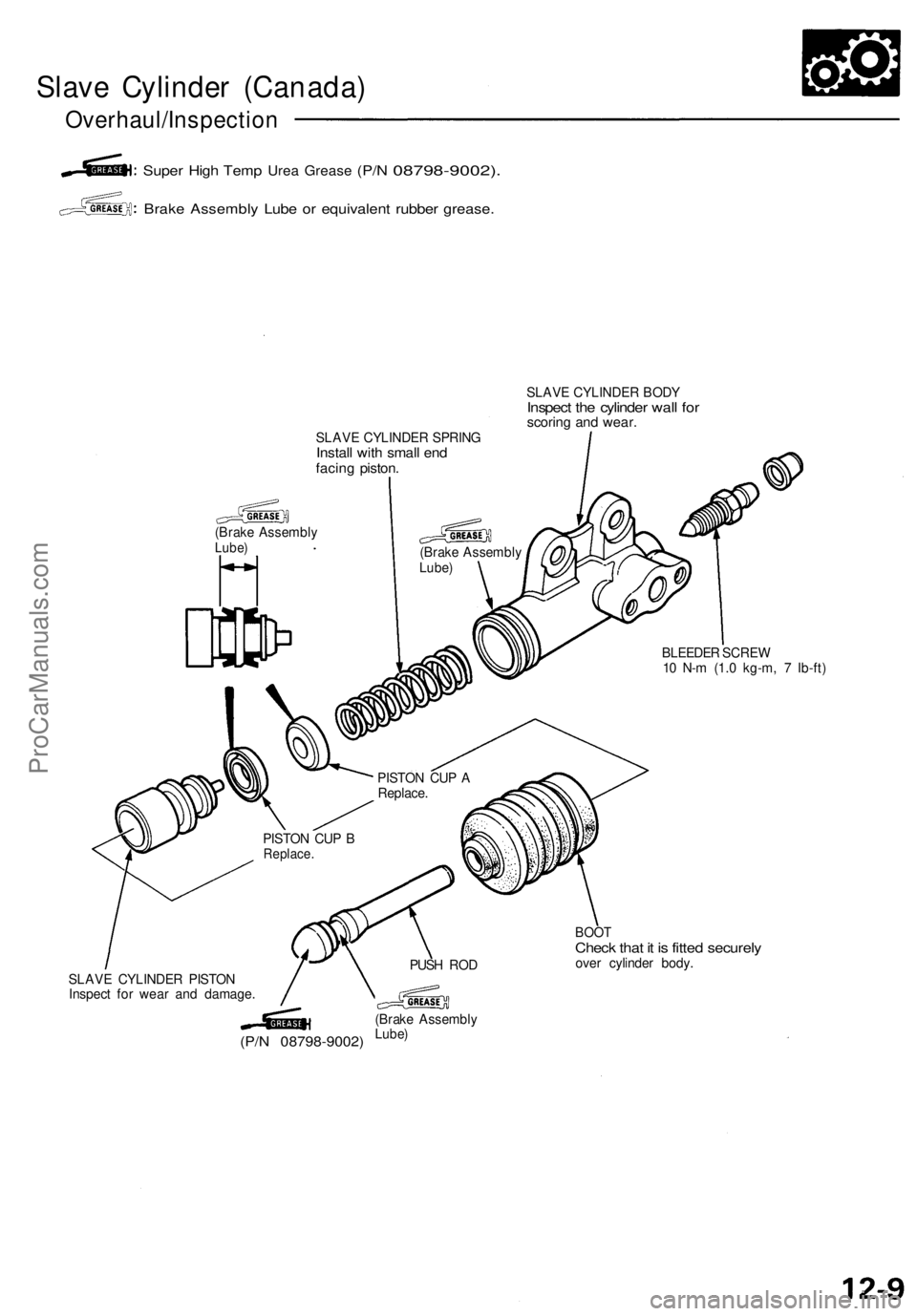

Slave Cylinder (Canada)

Overhaul/Inspection

Super High Temp

Urea

Grease

(P/N

08798-9002).

Brake Assembly Lube or equivalent rubber grease.

SLAVE CYLINDER SPRING

Install with small end

facing piston.

(Brake Assembly

Lube)

SLAVE CYLINDER BODY

Inspect the cylinder wall for

scoring and wear.

(Brake Assembly

Lube)

BLEEDER SCREW

10 N-m (1.0 kg-m, 7 Ib-ft)

SLAVE CYLINDER PISTON

Inspect for wear and damage.

(P/N 08798-9002)

(Brake Assembly

Lube)

BOOT

Check that it is fitted securely

over cylinder body.

PUSH ROD

PISTON CUP B

Replace.

PISTON CUP A

Replace.ProCarManuals.com

Page 299 of 1640

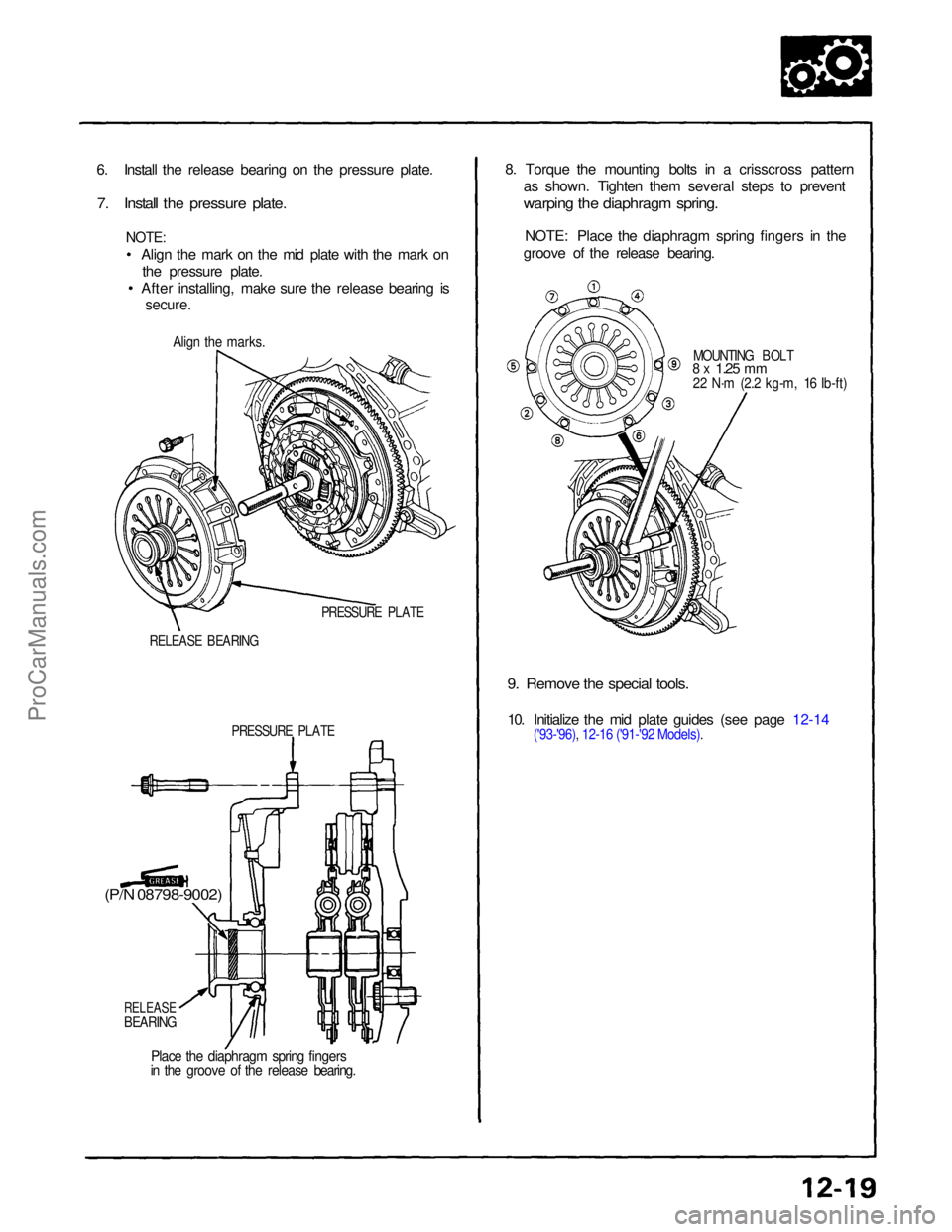

6. Install the release bearing on the pressure plate.

7. Install the pressure plate.

NOTE:

Align the mark on the mid plate with the mark onthe pressure plate.

After installing, make sure the release bearing is

secure.

Align the marks.

PRESSURE PLATE

RELEASE BEARING

PRESSURE PLATE

(P/N 08798-9002)

RELEASE

BEARING

Place the diaphragm spring fingers

in the groove of the release bearing.

9. Remove the special tools.

10. Initialize the mid plate guides (see page 12-14

('93-'96), 12-16 ('91-'92 Models).

MOUNTING BOLT

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

8. Torque the mounting bolts in a crisscross pattern

as shown. Tighten them several steps to prevent

warping the diaphragm spring.

NOTE: Place the diaphragm spring fingers in the

groove of the release bearing.ProCarManuals.com

Page 334 of 1640

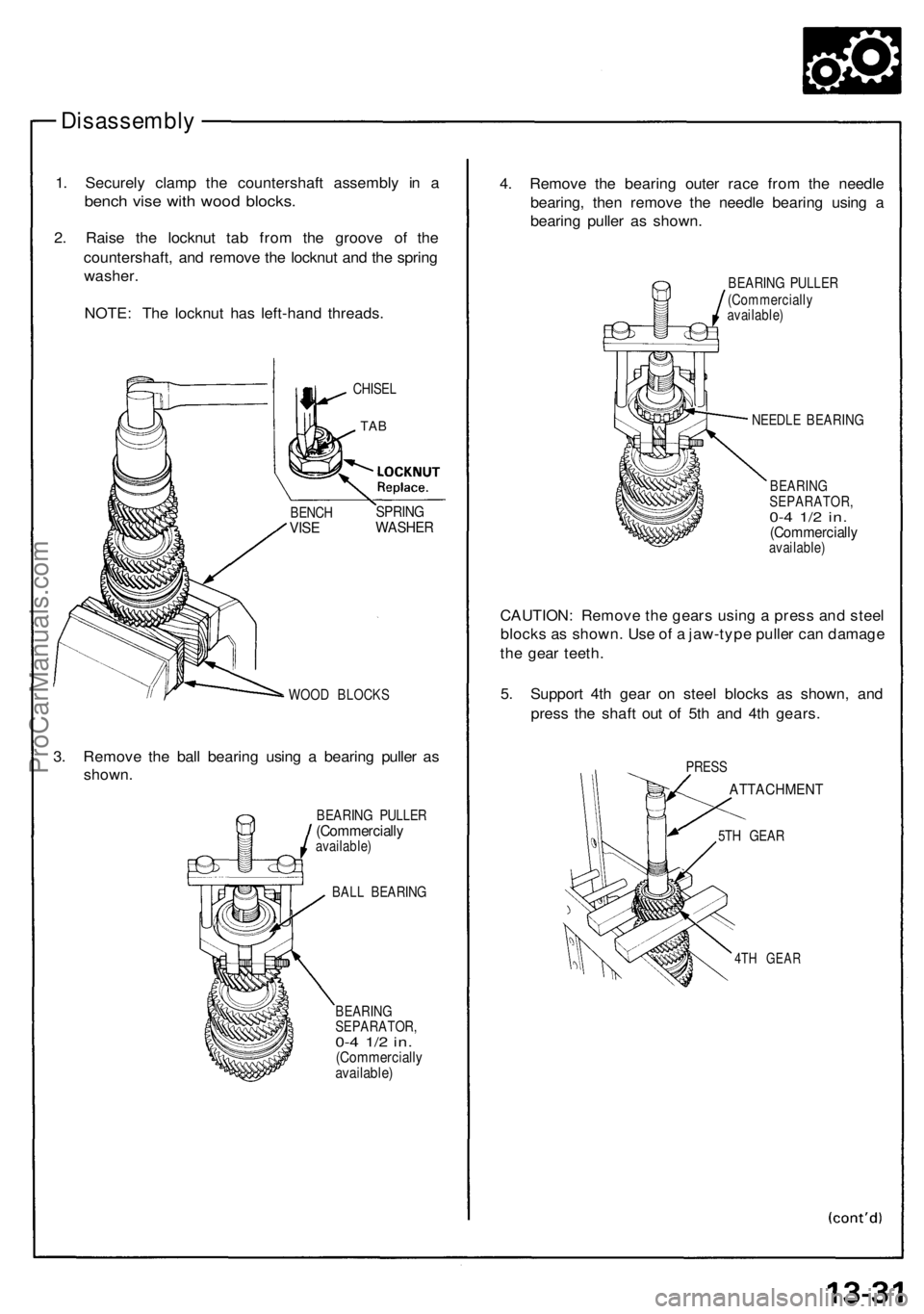

Disassembly

1. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

2. Raise the locknut tab from the groove of the

countershaft, and remove the locknut and the spring

washer.

NOTE: The locknut has left-hand threads.

WOOD BLOCKS

3. Remove the ball bearing using a bearing puller as

shown.

BEARING PULLER

(Commercially

available)

BALL BEARING

BEARING

SEPARATOR,

0-4 1/2 in.

(Commercially

available)

4. Remove the bearing outer race from the needle

bearing, then remove the needle bearing using a

bearing puller as shown.

BEARING PULLER

(Commercially

available)

NEEDLE BEARING

BEARING

SEPARATOR,

0-4 1/2 in.

(Commercially

available)

CAUTION: Remove the gears using a press and steel

blocks as shown. Use of a jaw-type puller can damage

the gear teeth.

5. Support 4th gear on steel blocks as shown, and

press the shaft out of 5th and 4th gears.

5TH GEAR

4TH GEAR

PRESS

ATTACHMENT

BENCH

VISE

SPRING

WASHER

TAB

CHISELProCarManuals.com

Page 338 of 1640

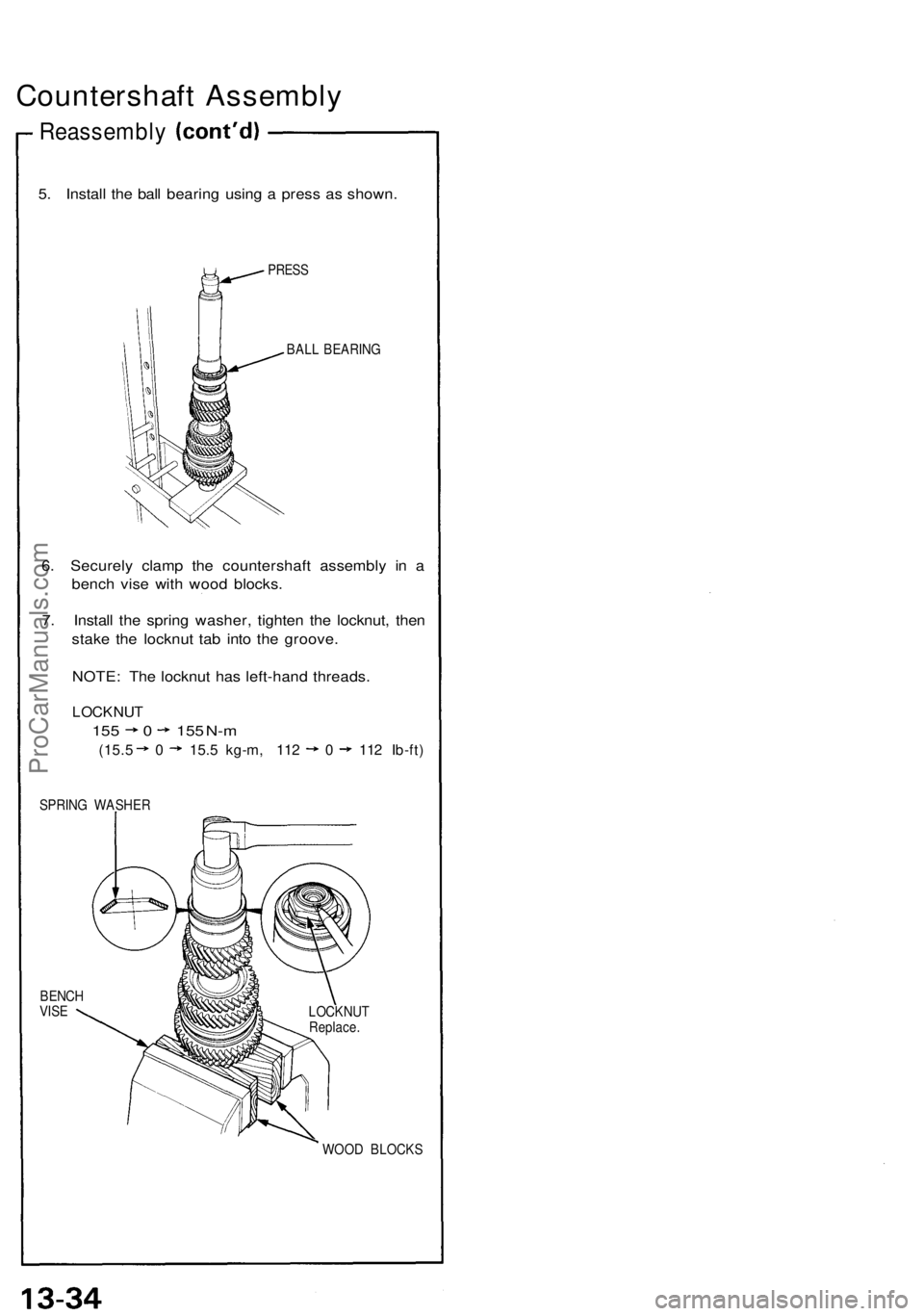

Countershaft Assembly

Reassembly

5. Install the ball bearing using a press as shown.

PRESS

BALL BEARING

6. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

7. Install the spring washer, tighten the locknut, then

stake the locknut tab into the groove.

NOTE: The locknut has left-hand threads.

LOCKNUT

155 0 155 N-m

(15.5 0 15.5 kg-m, 112 0 112 Ib-ft)

SPRING WASHER

BENCH

VISE

WOOD BLOCKS

LOCKNUT

Replace.ProCarManuals.com

Page 350 of 1640

Transmission

Reassembly

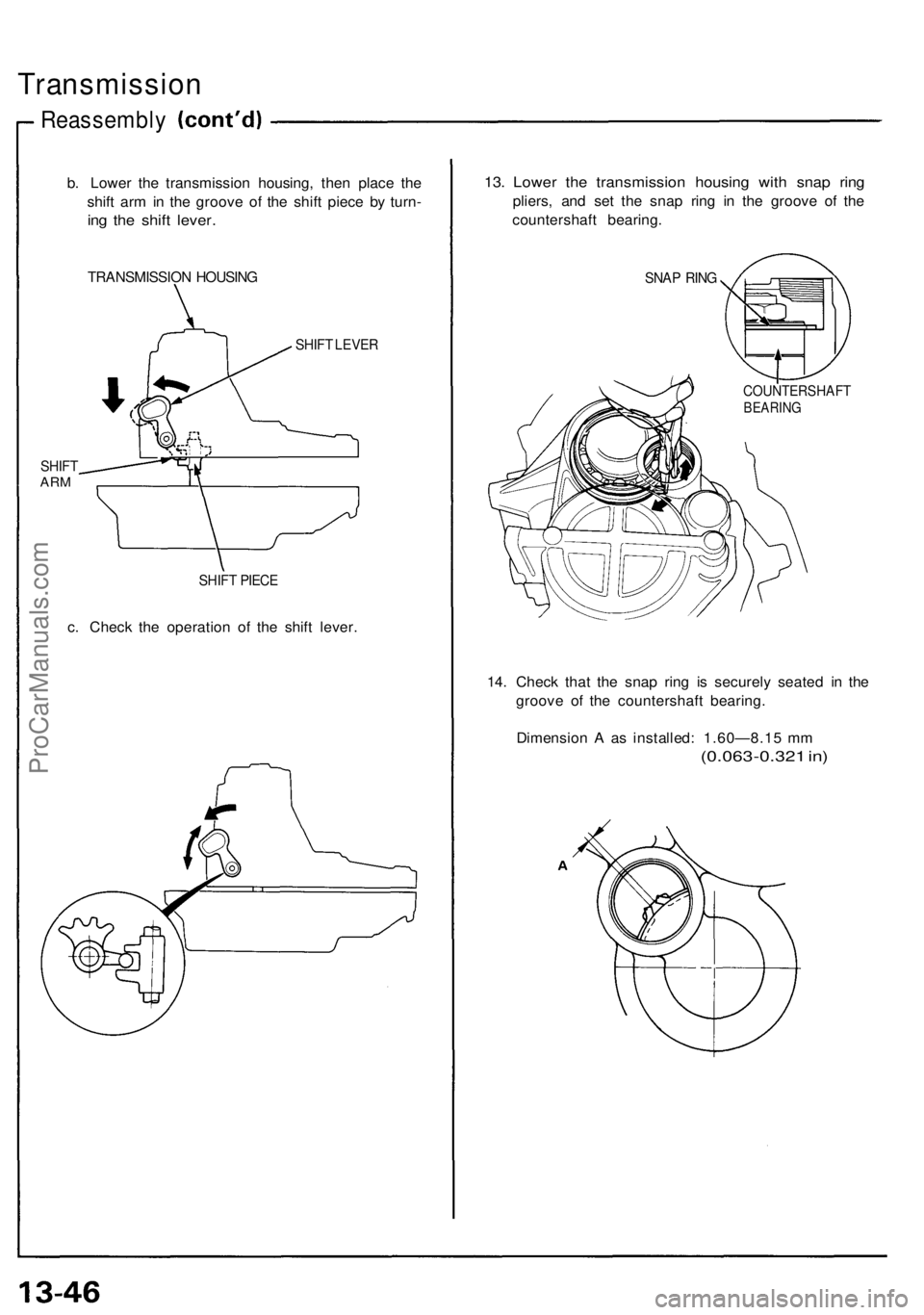

b. Lower the transmission housing, then place the

shift arm in the groove of the shift piece by turn-

ing the shift lever.

TRANSMISSION HOUSING

SHIFT LEVER

SHIFT

ARM

SHIFT PIECE

c. Check the operation of the shift lever.

13. Lower the transmission housing with snap ring

pliers, and set the snap ring in the groove of the

countershaft bearing.

SNAP RING

14. Check that the snap ring is securely seated in the

groove of the countershaft bearing.

Dimension A as installed: 1.60—8.15 mm

(0.063-0.321 in)

COUNTERSHAFT

BEARINGProCarManuals.com

Page 387 of 1640

Driveshafts

Removal

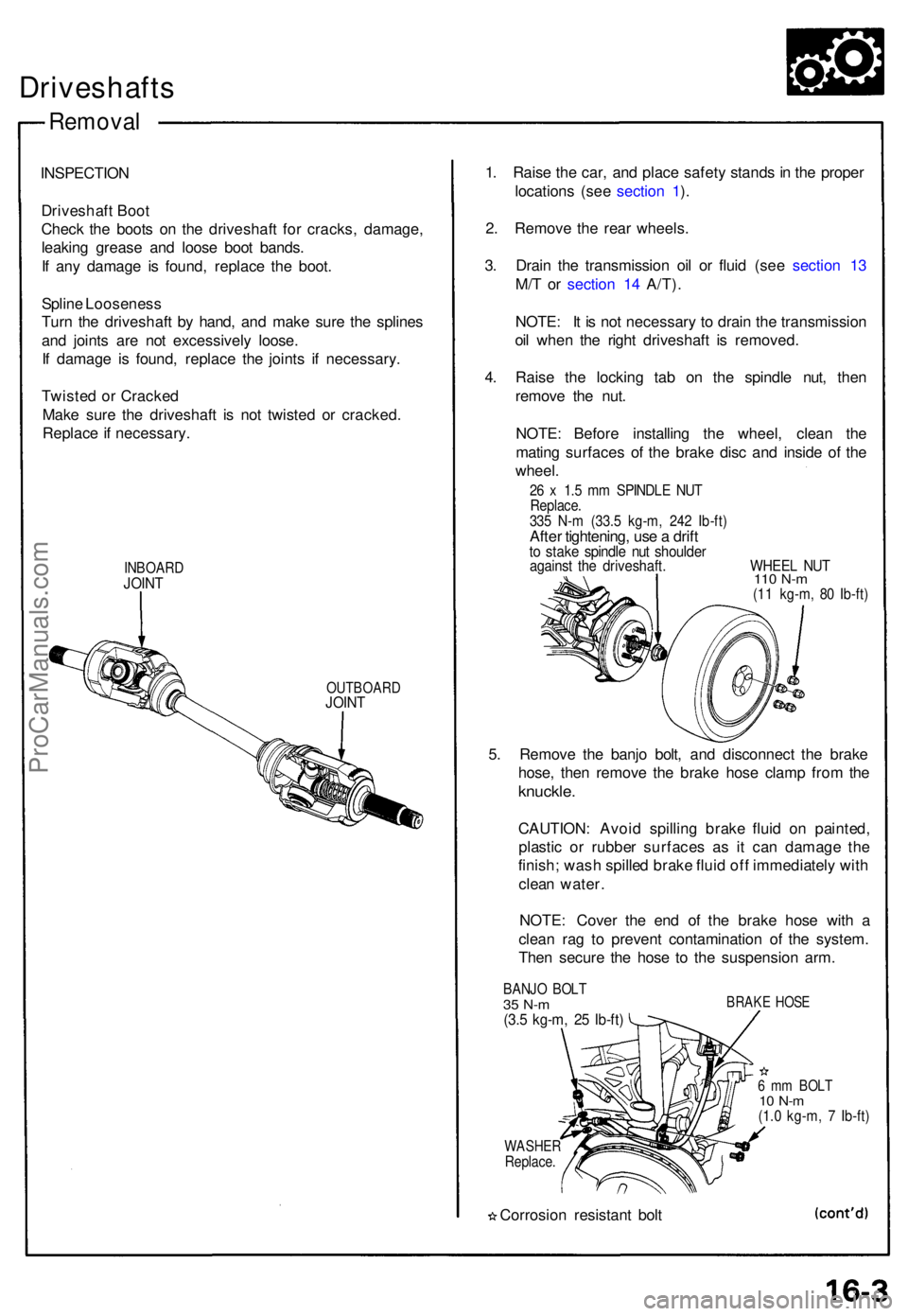

INSPECTIO N

Driveshaf t Boo t

Chec k th e boot s o n th e driveshaf t fo r cracks , damage ,

leakin g greas e an d loos e boo t bands .

I f an y damag e i s found , replac e th e boot .

Splin e Loosenes s

Tur n th e driveshaf t b y hand , an d mak e sur e th e spline s

an d joint s ar e no t excessivel y loose .

I f damag e i s found , replac e th e joint s i f necessary .

Twiste d o r Cracke d

Mak e sur e th e driveshaf t i s no t twiste d o r cracked .

Replac e if necessary .

INBOARDJOINT

OUTBOAR DJOINT

1. Rais e th e car , an d plac e safet y stand s in th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e rea r wheels .

3 . Drai n th e transmissio n oi l o r flui d (se e sectio n 1 3

M/ T o r sectio n 1 4 A/T) .

NOTE : I t i s no t necessar y t o drai n th e transmissio n

oi l whe n th e righ t driveshaf t i s removed .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

NOTE : Befor e installin g th e wheel , clea n th e

matin g surface s of the brak e dis c an d insid e of the

wheel .

26 x 1. 5 m m SPINDL E NU TReplace .335 N- m (33. 5 kg-m , 24 2 Ib-ft )After tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft . WHEE L NU T110 N- m(11 kg-m , 8 0 Ib-ft )

5. Remov e th e banj o bolt , an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e

finish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

NOTE : Cove r th e en d o f th e brak e hos e wit h a

clea n ra g t o preven t contaminatio n of the system.

The n secur e th e hos e t o th e suspensio n arm .

BANJ O BOL T35 N- m(3.5 kg-m , 2 5 Ib-ft )

BRAK E HOS E

WASHE RReplace.

Corrosio n resistan t bol t

6 m m BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

ProCarManuals.com