washer fluid ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 72 of 1640

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

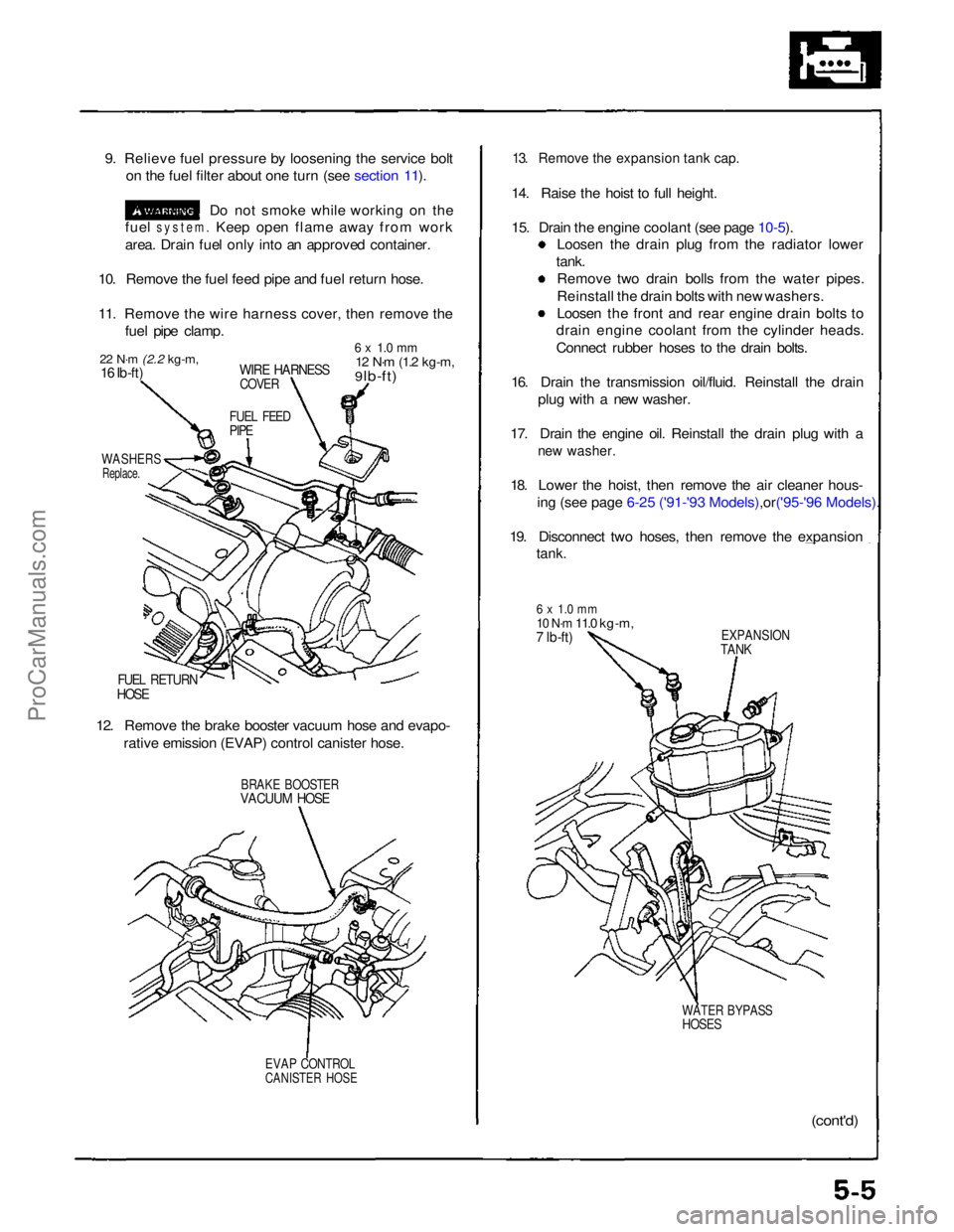

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 378 of 1640

Differential

Reassembl y

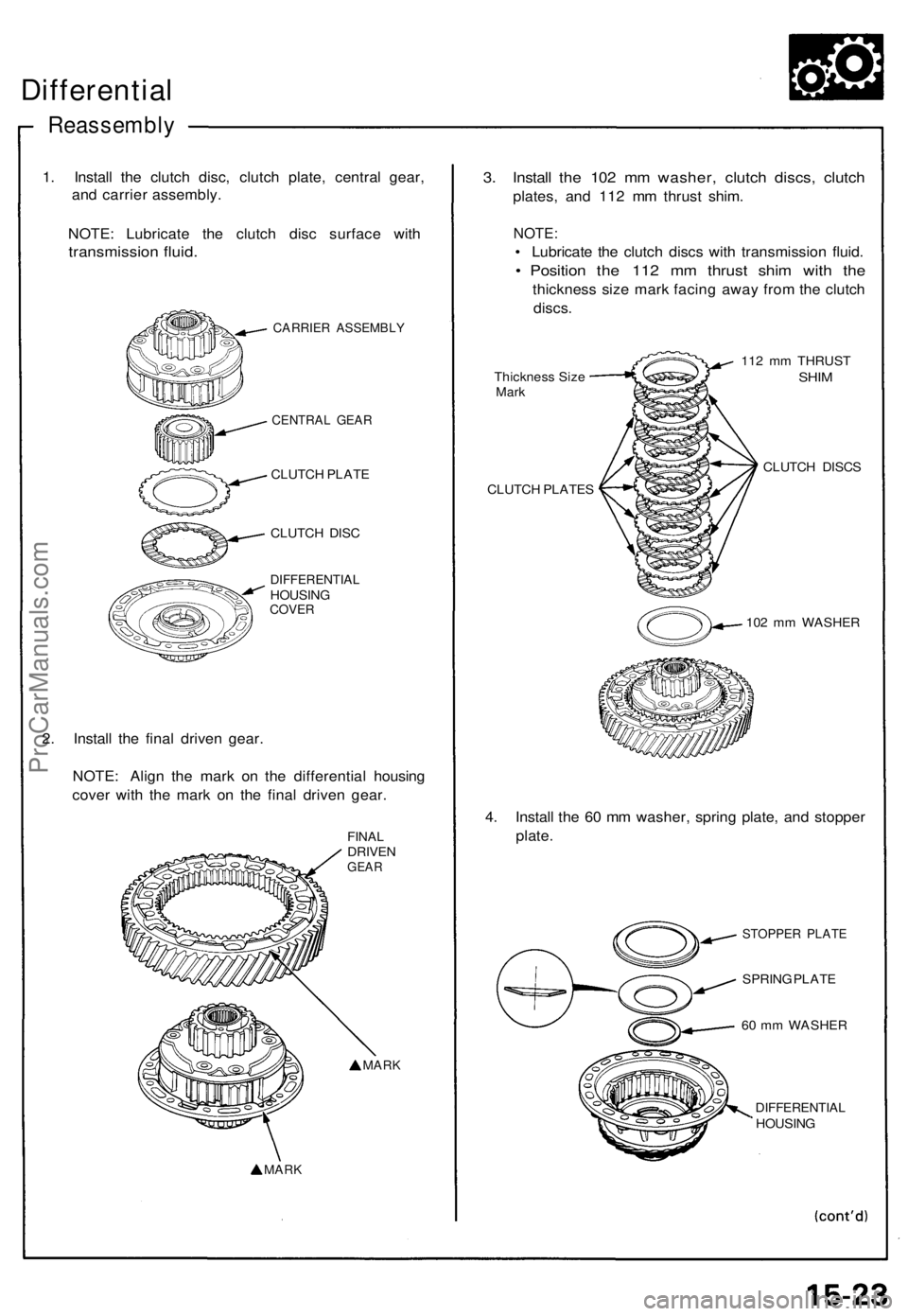

1. Instal l th e clutc h disc , clutc h plate , centra l gear ,

an d carrie r assembly .

NOTE : Lubricat e th e clutc h dis c surfac e wit h

transmissio n fluid .

CARRIE R ASSEMBL Y

CENTRAL GEA R

CLUTC H PLAT E

CLUTC H DIS C

DIFFERENTIA LHOUSINGCOVER

2. Instal l th e fina l drive n gear .

NOTE : Alig n th e mar k o n th e differentia l housin g

cove r wit h th e mar k o n th e fina l drive n gear .

FINALDRIVE NGEAR

MAR K

MAR K

3. Instal l th e 10 2 m m washer , clutc h discs , clutc h

plates , an d 11 2 m m thrus t shim .

NOTE :

• Lubricat e th e clutc h disc s wit h transmissio n fluid .

• Positio n th e 11 2 m m thrus t shi m wit h th e

thicknes s siz e mar k facin g awa y fro m th e clutc h

discs .

Thicknes s Siz eMar k

CLUTC H PLATE S 11

2 m m THRUS T

SHIM

CLUTC H DISC S

10 2 m m WASHE R

4. Instal l th e 6 0 m m washer , sprin g plate , an d stoppe r

plate .

STOPPE R PLAT E

SPRING PLAT E

6 0 m m WASHE R

DIFFERENTIA LHOUSING

ProCarManuals.com

Page 498 of 1640

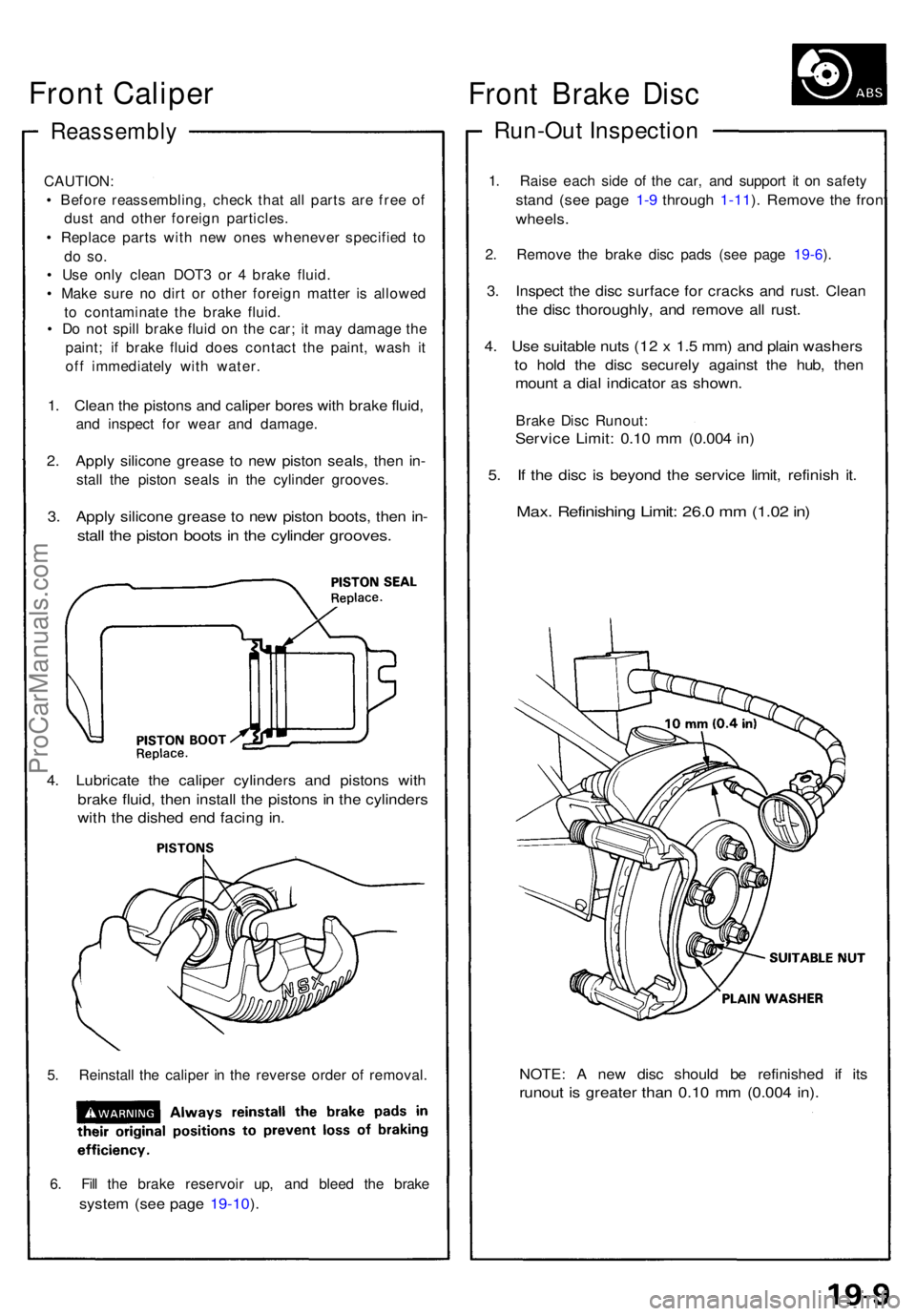

Reassembly

CAUTION:

• Befor e reassembling , chec k tha t al l part s ar e fre e o f

dus t an d othe r foreig n particles .

• Replac e part s wit h ne w one s wheneve r specifie d t o

do so .

• Us e onl y clea n DOT 3 o r 4 brak e fluid .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e th e

paint ; i f brak e flui d doe s contac t th e paint , was h i t

of f immediatel y wit h water .

1. Clea n th e piston s an d calipe r bore s wit h brak e fluid ,

and inspec t fo r wea r an d damage .

2. Appl y silicon e greas e t o ne w pisto n seals , the n in -

stal l th e pisto n seal s i n th e cylinde r grooves .

3. Appl y silicon e greas e t o ne w pisto n boots , the n in -

stal l th e pisto n boot s in th e cylinde r grooves .

4. Lubricat e th e calipe r cylinder s an d piston s wit h

brak e fluid , the n instal l th e piston s i n th e cylinder s

with th e dishe d en d facin g in .

5. Reinstal l th e calipe r i n th e revers e orde r o f removal .

6 . Fil l th e brak e reservoi r up , an d blee d th e brak e

system (se e pag e 19-10 ).

NOTE : A ne w dis c shoul d b e refinishe d i f it s

runou t i s greate r tha n 0.1 0 m m (0.00 4 in) .

Fron t Brak e Dis c

Run-Ou t Inspectio n

1. Rais e eac h sid e o f th e car , an d suppor t i t o n safet y

stand (se e pag e 1-9 throug h 1-11 ). Remov e th e fron t

wheels .

2. Remov e th e brak e dis c pad s (se e pag e 19-6 ).

3 . Inspec t th e dis c surfac e fo r crack s an d rust . Clea n

the dis c thoroughly , an d remov e al l rust .

4. Us e suitabl e nut s (1 2 x 1. 5 mm ) an d plai n washer s

to hol d th e dis c securel y agains t th e hub , the n

moun t a dia l indicato r a s shown .

Brake Dis c Runout :

Service Limit : 0.1 0 m m (0.00 4 in )

5. I f th e dis c i s beyon d th e servic e limit , refinis h it .

Max . Refinishin g Limit : 26. 0 m m (1.0 2 in )

Front Caliper

ProCarManuals.com

Page 512 of 1640

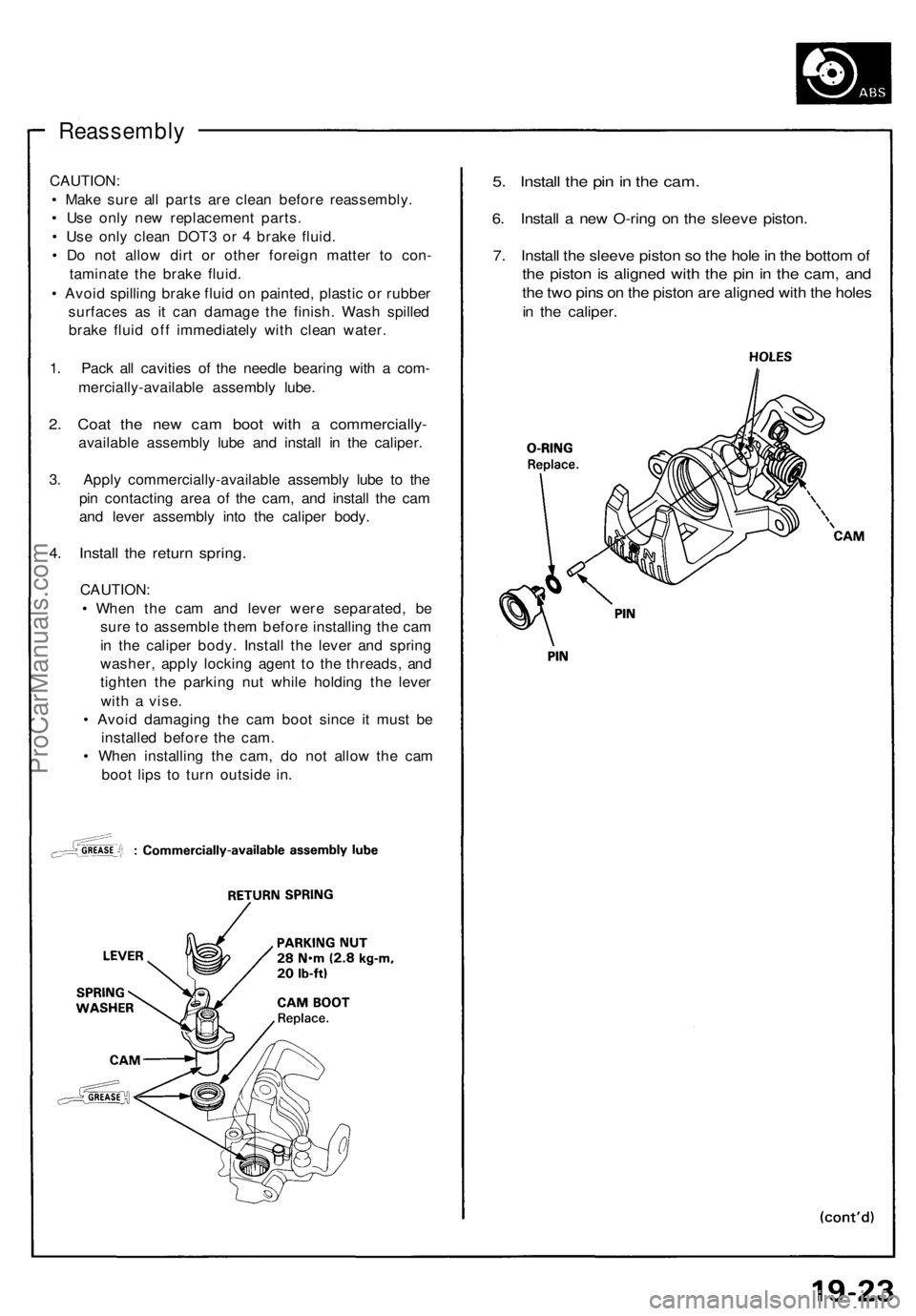

Reassembly

CAUTION:

• Mak e sur e al l part s ar e clea n befor e reassembly .

• Us e onl y ne w replacemen t parts .

• Us e onl y clea n DOT 3 o r 4 brak e fluid .

• D o no t allo w dir t o r othe r foreig n matte r t o con -

taminat e th e brak e fluid .

• Avoi d spillin g brak e flui d o n painted , plasti c o r rubbe r

surface s a s i t ca n damag e th e finish . Was h spille d

brak e flui d of f immediatel y wit h clea n water .

1 . Pac k al l cavitie s o f th e needl e bearin g wit h a com -

mercially-availabl e assembl y lube .

2. Coa t th e ne w ca m boo t wit h a commercially -

available assembl y lub e an d instal l i n th e caliper .

3 . Appl y commercially-availabl e assembl y lub e t o th e

pi n contactin g are a o f th e cam , an d instal l th e ca m

an d leve r assembl y int o th e calipe r body .

4. Instal l th e retur n spring .

CAUTION :

• Whe n th e ca m an d leve r wer e separated , b e

sur e t o assembl e the m befor e installin g th e ca m

i n th e calipe r body . Instal l th e leve r an d sprin g

washer , appl y lockin g agen t t o th e threads , an d

tighte n th e parkin g nu t whil e holdin g th e leve r

wit h a vise .

• Avoi d damagin g th e ca m boo t sinc e i t mus t b e

installe d befor e th e cam .

• Whe n installin g th e cam , d o no t allo w th e ca m

boo t lip s t o tur n outsid e in .

5. Instal l th e pi n in th e cam .

6. Instal l a ne w O-rin g o n th e sleev e piston .

7. Instal l th e sleev e pisto n s o th e hol e in th e botto m of

the pisto n is aligne d wit h th e pi n in th e cam , an d

the tw o pin s o n th e pisto n ar e aligne d wit h th e hole s

in th e caliper .

ProCarManuals.com

Page 538 of 1640

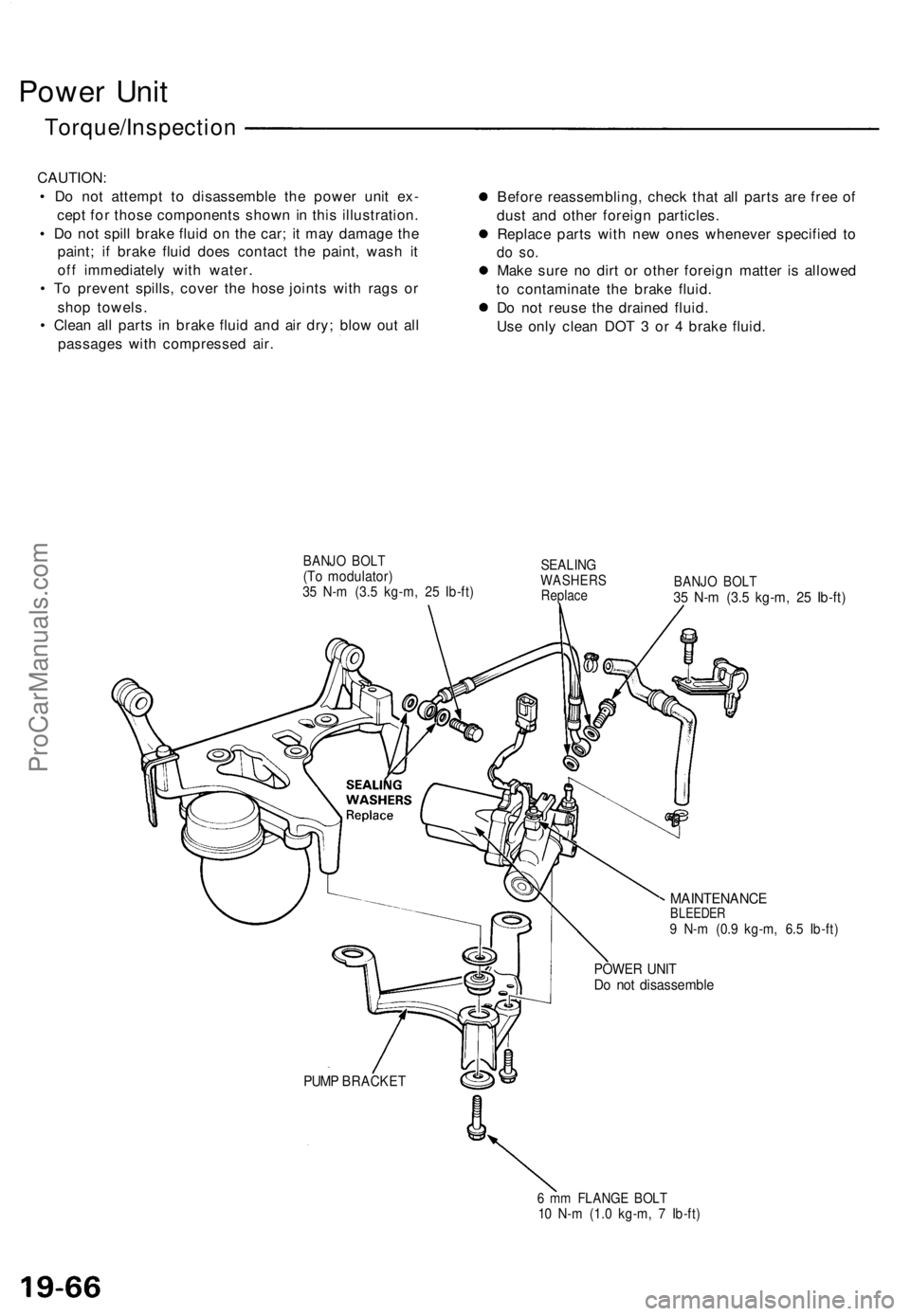

Power Uni t

Torque/Inspectio n

CAUTION:

• D o no t attemp t t o disassembl e th e powe r uni t ex -

cep t fo r thos e component s show n in thi s illustration .

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e th e

paint ; i f brak e flui d doe s contac t th e paint , was h i t

of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s o r

sho p towels .

• Clea n al l part s i n brak e flui d an d ai r dry ; blo w ou t al l

passage s wit h compresse d air . Befor

e reassembling , chec k tha t al l part s ar e fre e o f

dus t an d othe r foreig n particles .

Replac e part s wit h ne w one s wheneve r specifie d t o

do so .

Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

D o no t reus e th e draine d fluid .

Us e onl y clea n DO T 3 o r 4 brak e fluid .

BANJ O BOL T(To modulator )35 N- m (3. 5 kg-m , 2 5 Ib-ft )

SEALIN GWASHER SReplaceBANJO BOL T35 N- m (3. 5 kg-m , 2 5 Ib-ft )

MAINTENANC EBLEEDER9 N- m (0. 9 kg-m , 6. 5 Ib-ft )

POWE R UNI TDo no t disassembl e

PUMP BRACKE T

6 m m FLANG E BOL T10 N- m (1. 0 kg-m , 7 Ib-ft )

ProCarManuals.com

Page 539 of 1640

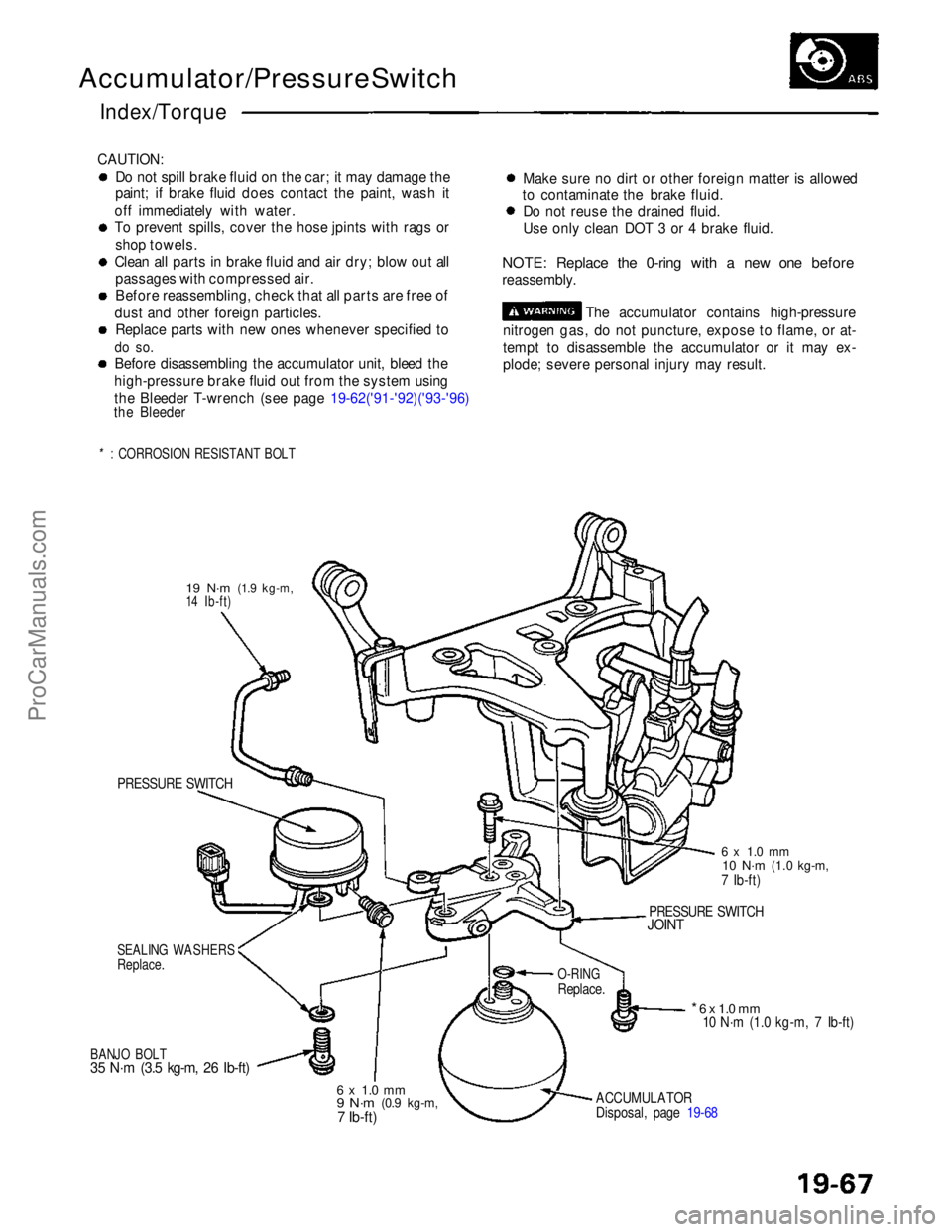

Accumulator/Pressure Switch

Index/Torque

CAUTION: Do not spill brake fluid on the car; it may damage the

paint; if brake fluid does contact the paint, wash it

off immediately with water.

To prevent spills, cover the hose jpints with rags or shop towels.

Clean all parts in brake fluid and air dry; blow out all passages with compressed air.

Before reassembling, check that all parts are free of

dust and other foreign particles. Replace parts with new ones whenever specified to

do so.

Before disassembling the accumulator unit, bleed the

high-pressure brake fluid out from the system using

the Bleeder T-wrench (see page 19-62('91-'92)('93-'96)

the Bleeder

*: CORROSION RESISTANT BOLT

Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid. Do not reuse the drained fluid.

Use only clean DOT 3 or 4 brake fluid.

NOTE: Replace the 0-ring with a new one before

reassembly. The accumulator contains high-pressure

nitrogen gas, do not puncture, expose to flame, or at-

tempt to disassemble the accumulator or it may ex-

plode; severe personal injury may result.

19 N·m

(1.9 kg-m,

14 Ib-ft)

PRESSURE SWITCH

SEALING WASHERS

Replace.

BANJO BOLT

35 N·m (3.5 kg-m, 26 Ib-ft)

6 x 1.0 mm

9 N·m

(0.9 kg-m,7 Ib-ft)

ACCUMULATOR

Disposal, page 19-68

* 6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft)

O-RING

Replace.

PRESSURE SWITCH

JOINT

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)ProCarManuals.com

Page 926 of 1640

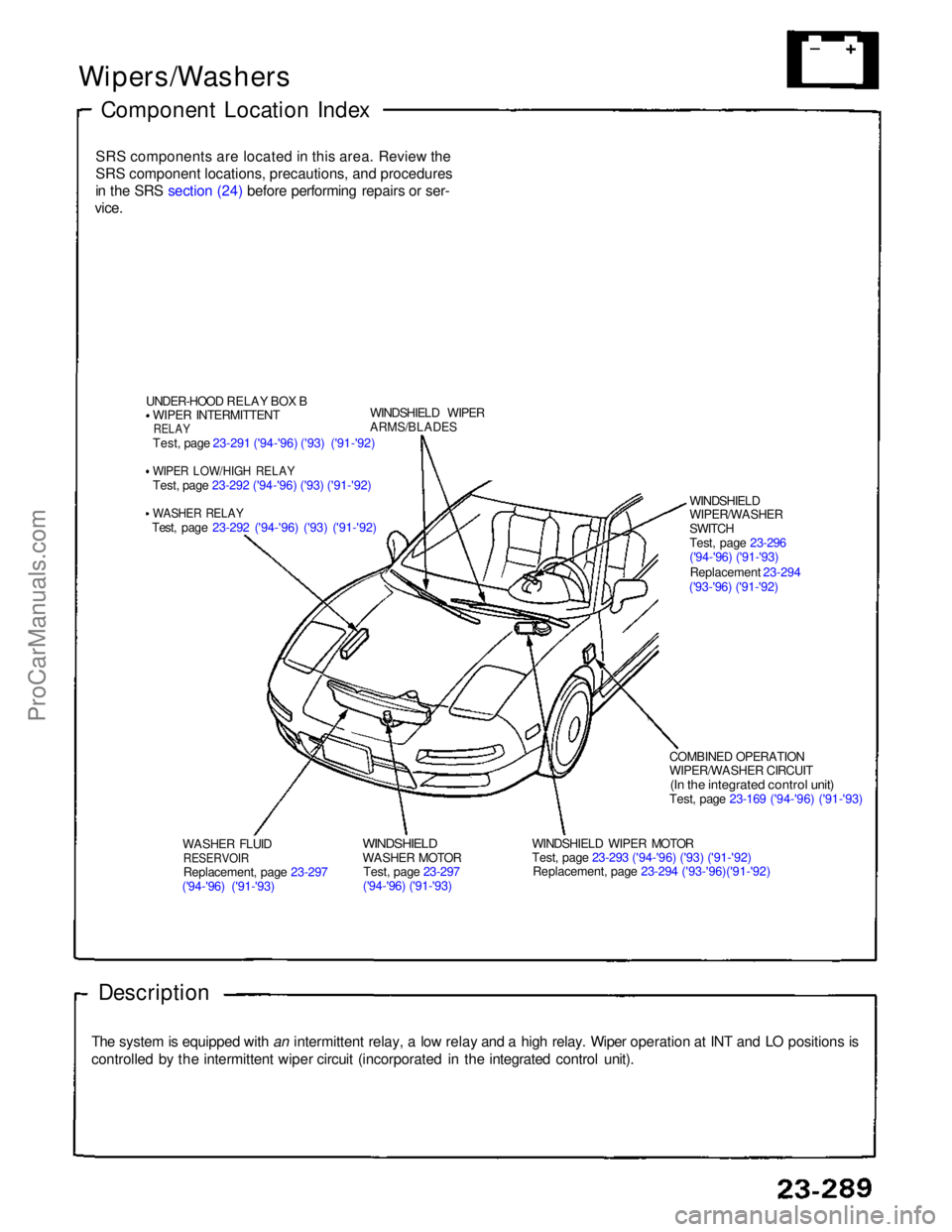

Wipers/Washers

Component Location Index

SRS components are located in this area. Review theSRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

UNDER-HOOD RELAY BOX BWIPER INTERMITTENT

RELAY

Test, page 23-291 ('94-'96) ('93) ('91-'92)

WIPER LOW/HIGH RELAY

Test, page 23-292 ('94-'96) ('93) ('91-'92)

WASHER RELAY

Test, page 23-292 ('94-'96) ('93) ('91-'92) WINDSHIELD WIPER

ARMS/BLADES

WASHER FLUID

RESERVOIR

Replacement, page 23-297

('94-'96) ('91-'93)

WINDSHIELD

WASHER MOTOR

Test, page 23-297

('94-'96) ('91-'93) WINDSHIELD WIPER MOTOR

Test, page 23-293 ('94-'96) ('93) ('91-'92)

Replacement, page 23-294 ('93-'96)('91-'92) COMBINED OPERATION

WIPER/WASHER CIRCUIT

(In the integrated control unit)

Test, page 23-169 ('94-'96) ('91-'93)

Description

The system is equipped with an intermittent relay, a low relay and a high relay. Wiper operation at INT and LO positions is

controlled by the intermittent wiper circuit (incorporated in the integrated control unit). WINDSHIELD

WIPER/WASHER

SWITCH

Test, page 23-296

('94-'96) ('91-'93)

Replacement 23-294

('93-'96) ('91-'92)ProCarManuals.com

Page 932 of 1640

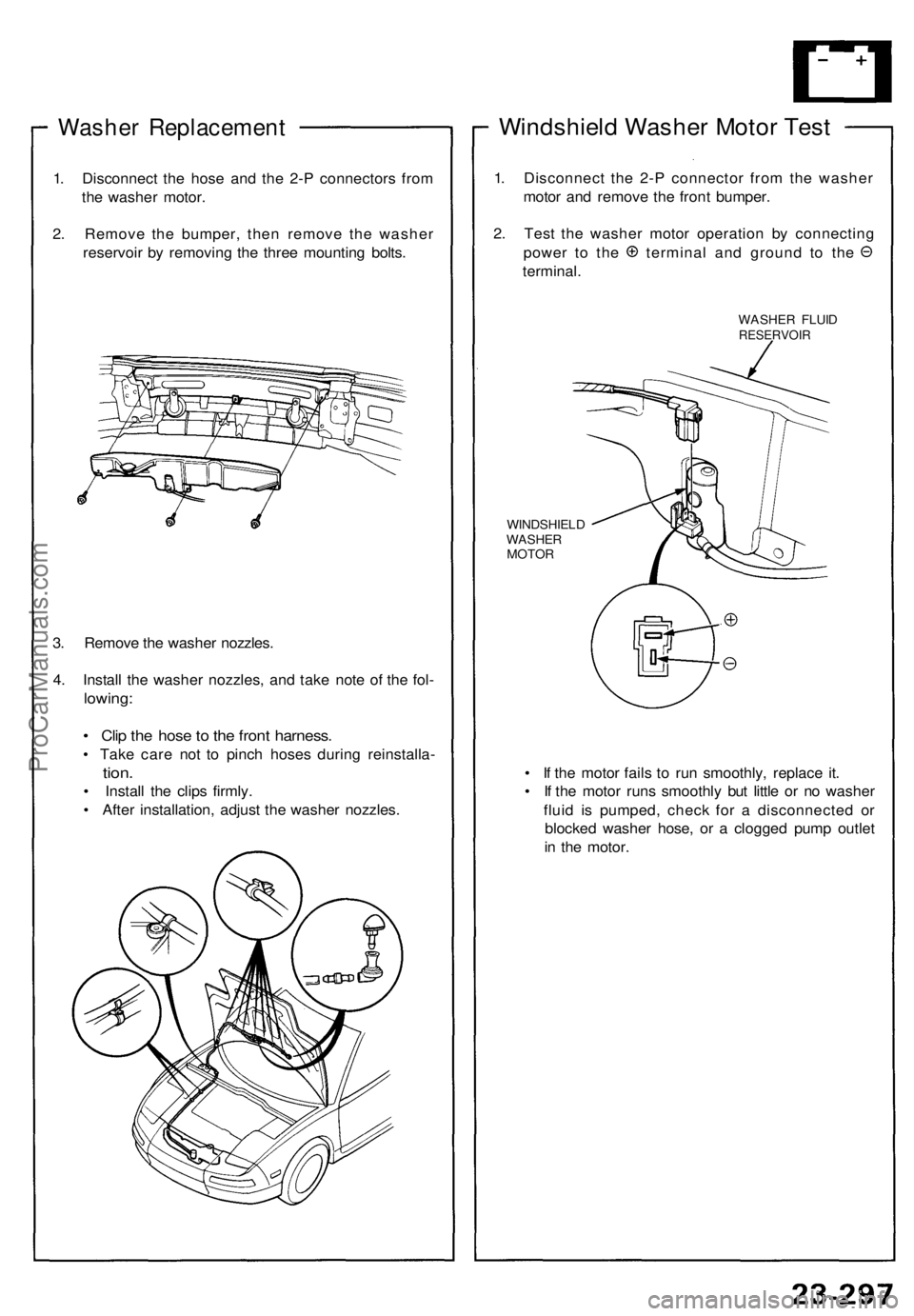

Washer Replacement

1. Disconnect the hose and the 2-P connectors from

the washer motor.

2. Remove the bumper, then remove the washer

reservoir by removing the three mounting bolts.

3. Remove the washer nozzles.

4. Install the washer nozzles, and take note of the fol-

lowing:

• Clip the hose to the front harness.

• Take care not to pinch hoses during reinstalla-

tion.

• Install the clips firmly.

• After installation, adjust the washer nozzles.

Windshield Washer Motor Test

1. Disconnect the 2-P connector from the washer

motor and remove the front bumper.

2. Test the washer motor operation by connecting

power to the terminal and ground to the

terminal.

WASHER FLUID

RESERVOIR

WINDSHIELD

WASHER

MOTOR

• If the motor fails to run smoothly, replace it.

• If the motor runs smoothly but little or no washer

fluid is pumped, check for a disconnected or

blocked washer hose, or a clogged pump outlet

in the motor.ProCarManuals.com

Page 986 of 1640

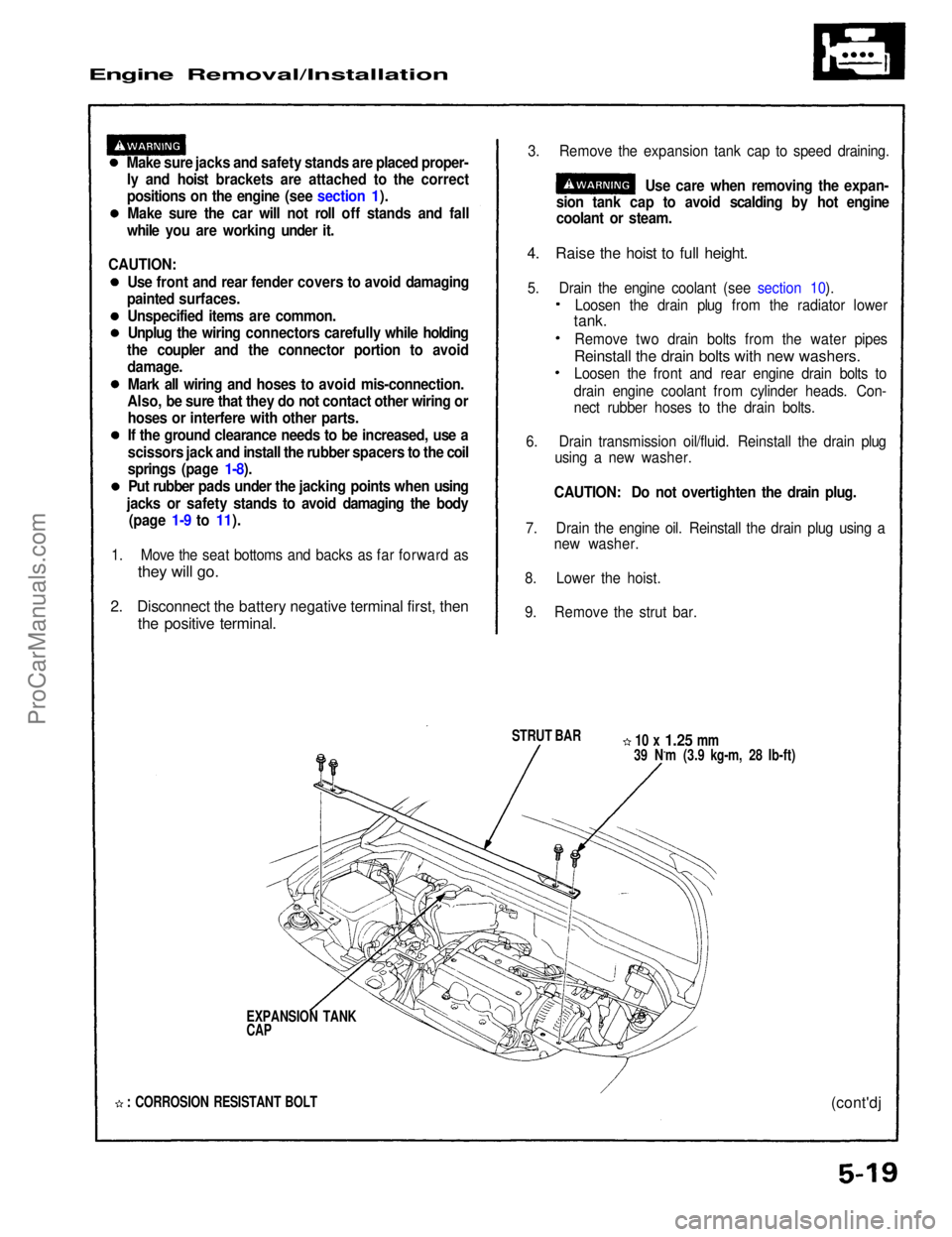

Engine Removal/Installation

Make sure jacks and safety stands are placed proper-ly and hoist brackets are attached to the correct

positions on the engine (see section 1).

Make sure the car will not roll off stands and fall

while you are working under it. 3. Remove the expansion tank cap to speed draining.

Use care when removing the expan-

sion tank cap to avoid scalding by hot engine

coolant or steam.

4. Raise the hoist to full height.

5. Drain the engine coolant (see section 10).

STRUT BAR

10 x

1.25

mm

39 N.m (3.9 kg-m, 28 Ib-ft)

EXPANSION TANK

CAP

: CORROSION RESISTANT BOLT

(cont'dj

1. Move the seat bottoms and backs as far forward as

they will go.

2. Disconnect the battery negative terminal first, then

the positive terminal.

Loosen the drain plug from the radiator lower

tank.

Remove two drain bolts from the water pipes

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from cylinder heads. Con-

nect rubber hoses to the drain bolts.

6. Drain transmission oil/fluid. Reinstall the drain plug using a new washer.

CAUTION: Do not overtighten the drain plug.

7. Drain the engine oil. Reinstall the drain plug using a new washer.

8. Lower the hoist.

9. Remove the strut bar.

CAUTION:

Use front and rear fender covers to avoid damaging

painted surfaces.

Unspecified items are common.Unplug the wiring connectors carefully while holding

the coupler and the connector portion to avoid damage.

Mark all wiring and hoses to avoid mis-connection.

Also, be sure that they do not contact other wiring or hoses or interfere with other parts.

If the ground clearance needs to be increased, use a

scissors jack and install the rubber spacers to the coil

springs (page 1-8).

Put rubber pads under the jacking points when using

jacks or safety stands to avoid damaging the body (page 1-9 to 11).ProCarManuals.com

Page 1224 of 1640

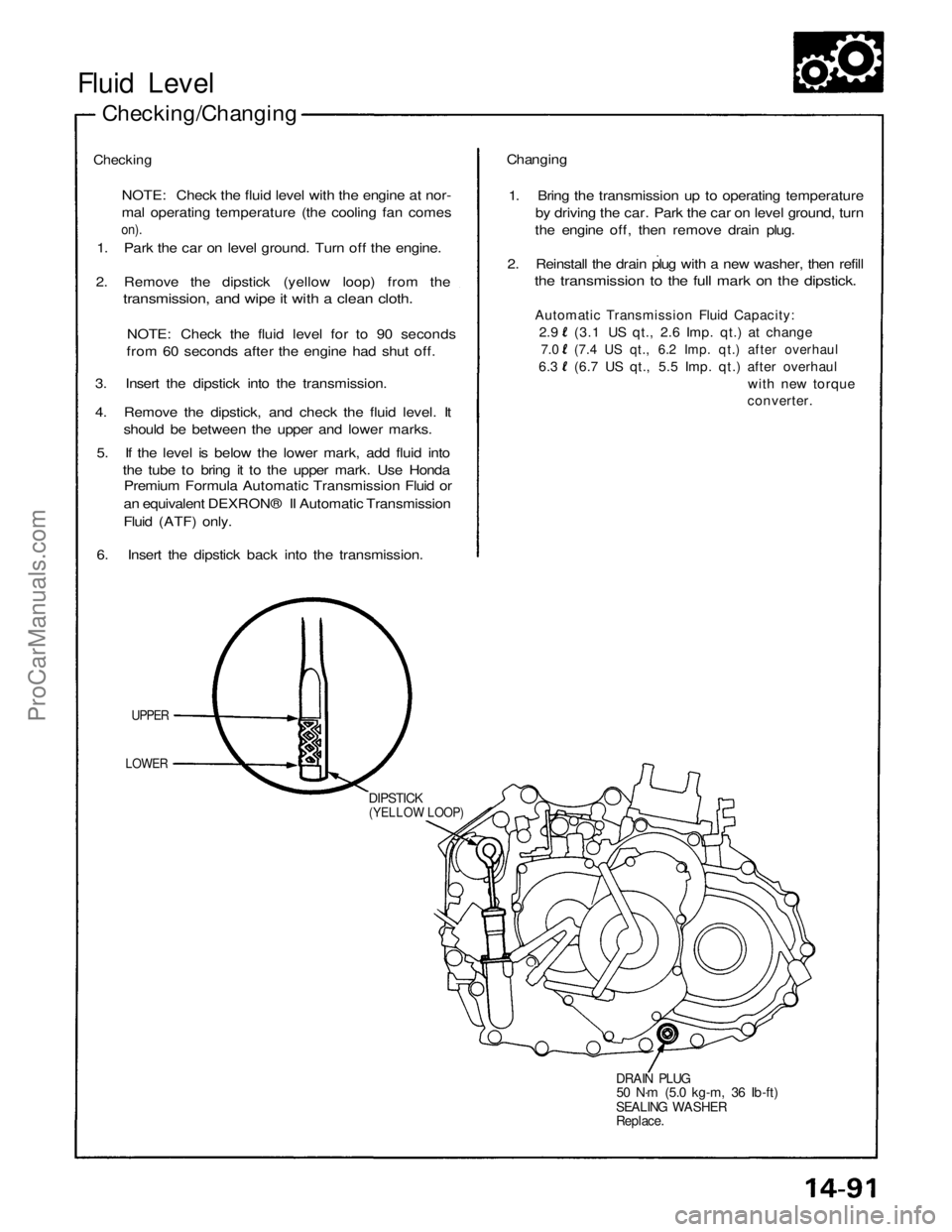

Fluid Level

Checking/Changing

Checking

NOTE: Check the fluid level with the engine at nor-

mal operating temperature (the cooling fan comes

on).

1. Park the car on level ground. Turn off the engine.

2. Remove the dipstick (yellow loop) from the

transmission, and wipe it with a clean cloth.

NOTE: Check the fluid level for to 90 seconds

from 60 seconds after the engine had shut off.

3. Insert the dipstick into the transmission.

4. Remove the dipstick, and check the fluid level. It

should be between the upper and lower marks.

5. If the level is below the lower mark, add fluid into

the tube to bring it to the upper mark. Use Honda

Premium Formula Automatic Transmission Fluid or

an equivalent DEXRON® II Automatic Transmission

Fluid (ATF) only.

6. Insert the dipstick back into the transmission.

UPPER

LOWER

DIPSTICK

(YELLOW LOOP)

DRAIN PLUG

50 N·m (5.0 kg-m, 36 Ib-ft)

SEALING WASHER

Replace.

Changing

1. Bring the transmission up to operating temperature

by driving the car. Park the car on level ground, turn

the engine off, then remove drain plug.

2. Reinstall the drain plug with a new washer, then refill

the transmission to the full mark on the dipstick.

Automatic Transmission Fluid Capacity:

2.9 (3.1 US qt., 2.6 Imp. qt.) at change

7.0 (7.4 US qt., 6.2 Imp. qt.) after overhaul

6.3 (6.7 US qt., 5.5 Imp. qt.) after overhaul

with new torque

converter.ProCarManuals.com