fuel filter ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 72 of 1640

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

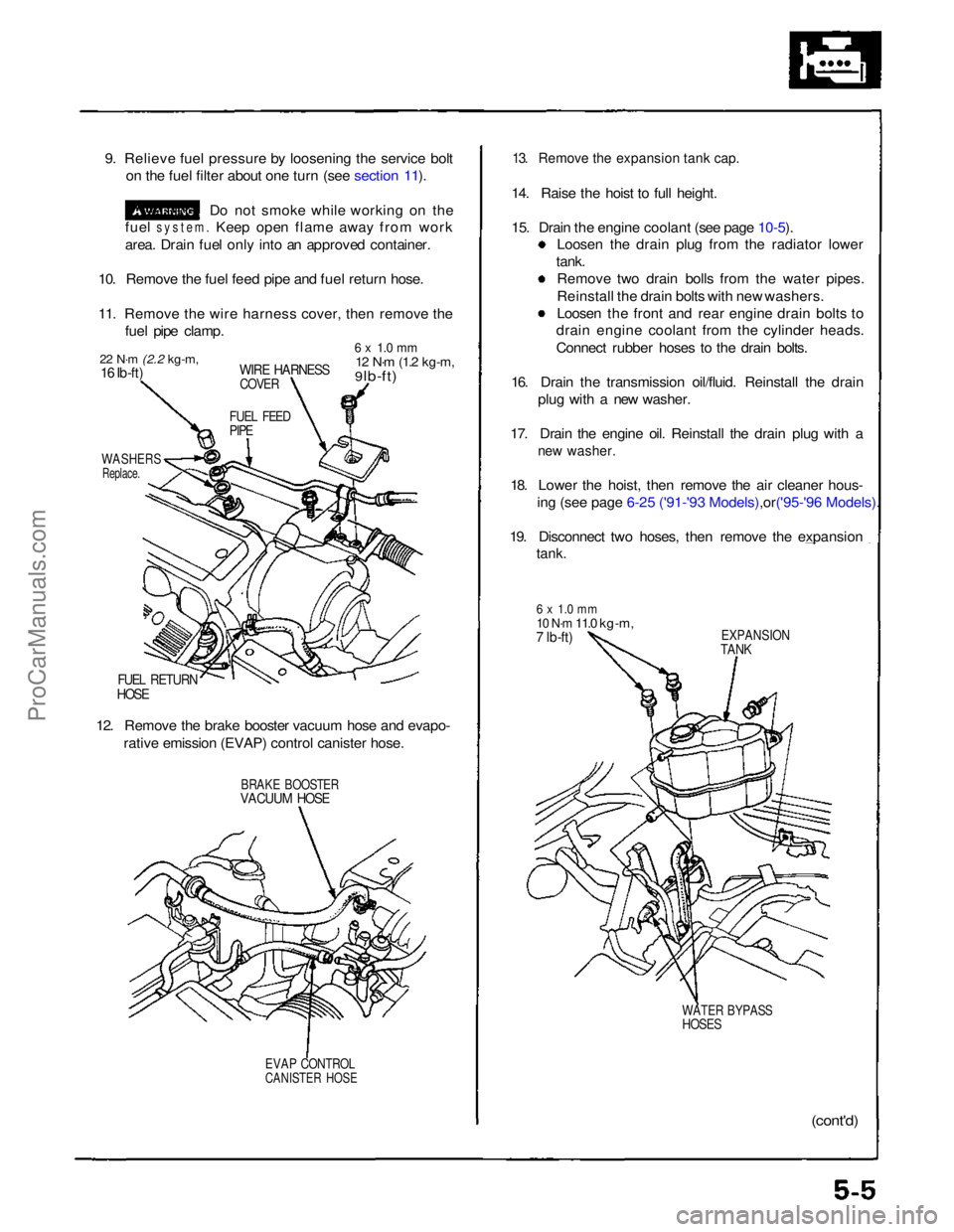

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 100 of 1640

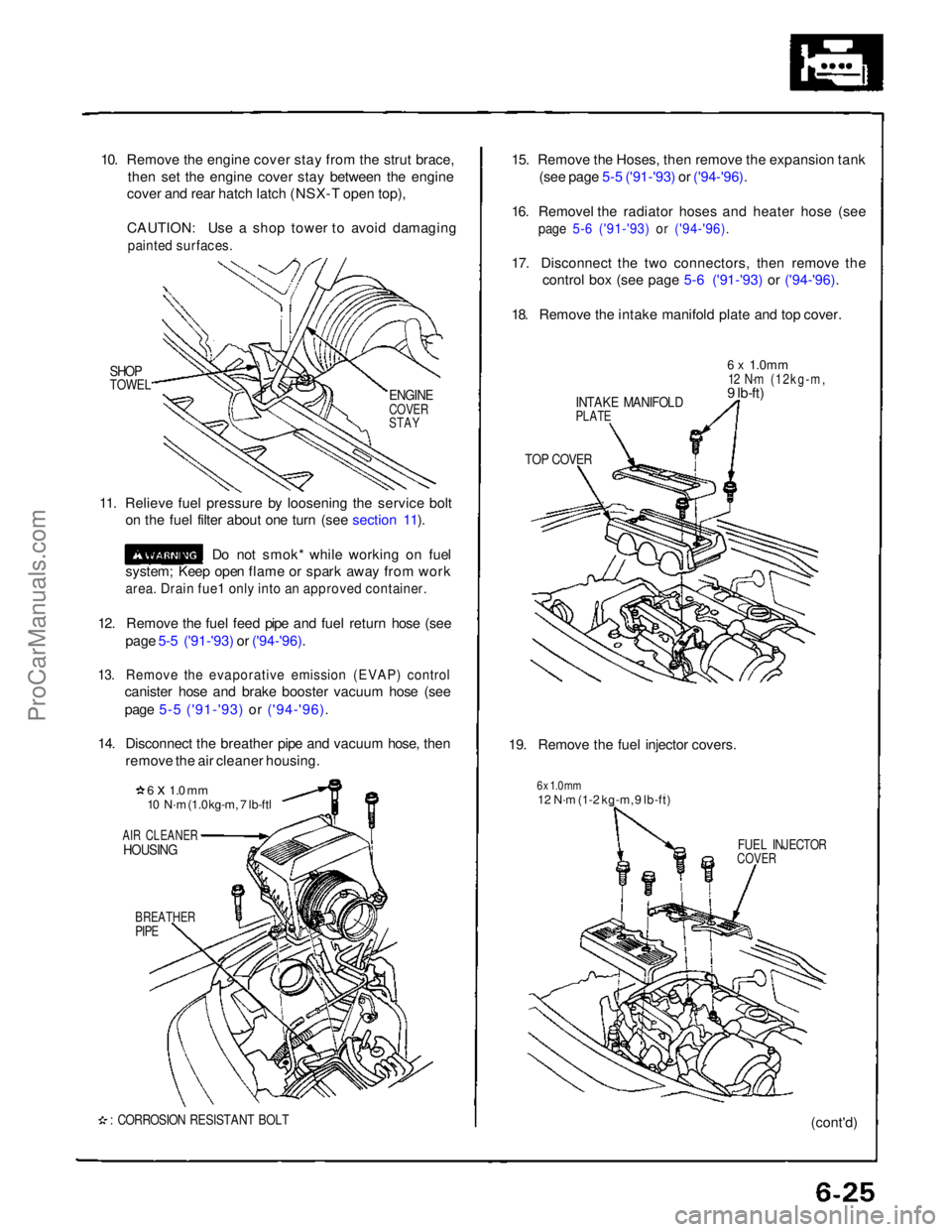

10. Remove the engine cover stay from the strut brace,

then set the engine cover stay between the engine

cover and rear hatch latch (NSX-T open top),

CAUTION: Use a shop tower to avoid damaging

painted surfaces.

SHOP

TOWEL

11. Relieve fuel pressure by loosening the service bolt on the fuel filter about one turn (see section 11).

Do not smok* while working on fuel

system; Keep open flame or spark away from work

area. Drain fue1 only into an approved container.

12. Remove the fuel feed pipe and fuel return hose (see page 5-5 ('91-'93) or ('94-'96).

13. Remove the evaporative emission (EVAP) control

canister hose and brake booster vacuum hose (see

page 5-5 ('91-'93) or ('94-'96).

14. Disconnect the breather pipe and vacuum hose, then remove the air cleaner housing.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 lb-ftl

AIR CLEANER

HOUSING

BREATHER

PIPE

: CORROSION RESISTANT BOLT

15. Remove the Hoses, then remove the expansion tank

(see page 5-5 ('91-'93) or ('94-'96).

16. Removel the radiator hoses and heater hose (see

page 5-6 ('91-'93) or ('94-'96).

17. Disconnect the two connectors, then remove the

control box (see page 5-6 ('91-'93) or ('94-'96).

18. Remove the intake manifold plate and top cover.

INTAKE MANIFOLD

PLATE

6 x

1.0mm

12 N·m (12kg-m,

9 lb-ft)

TOP COVER

19. Remove the fuel injector covers.

6 x 1.0 mm

12 N·m (1-2 kg-m, 9 lb-ft)

FUEL INJECTOR

COVER

(cont'd)

ENGINE

COVER

STAYProCarManuals.com

Page 251 of 1640

Fuel Suppl y Syste m

Fuel Pressur e

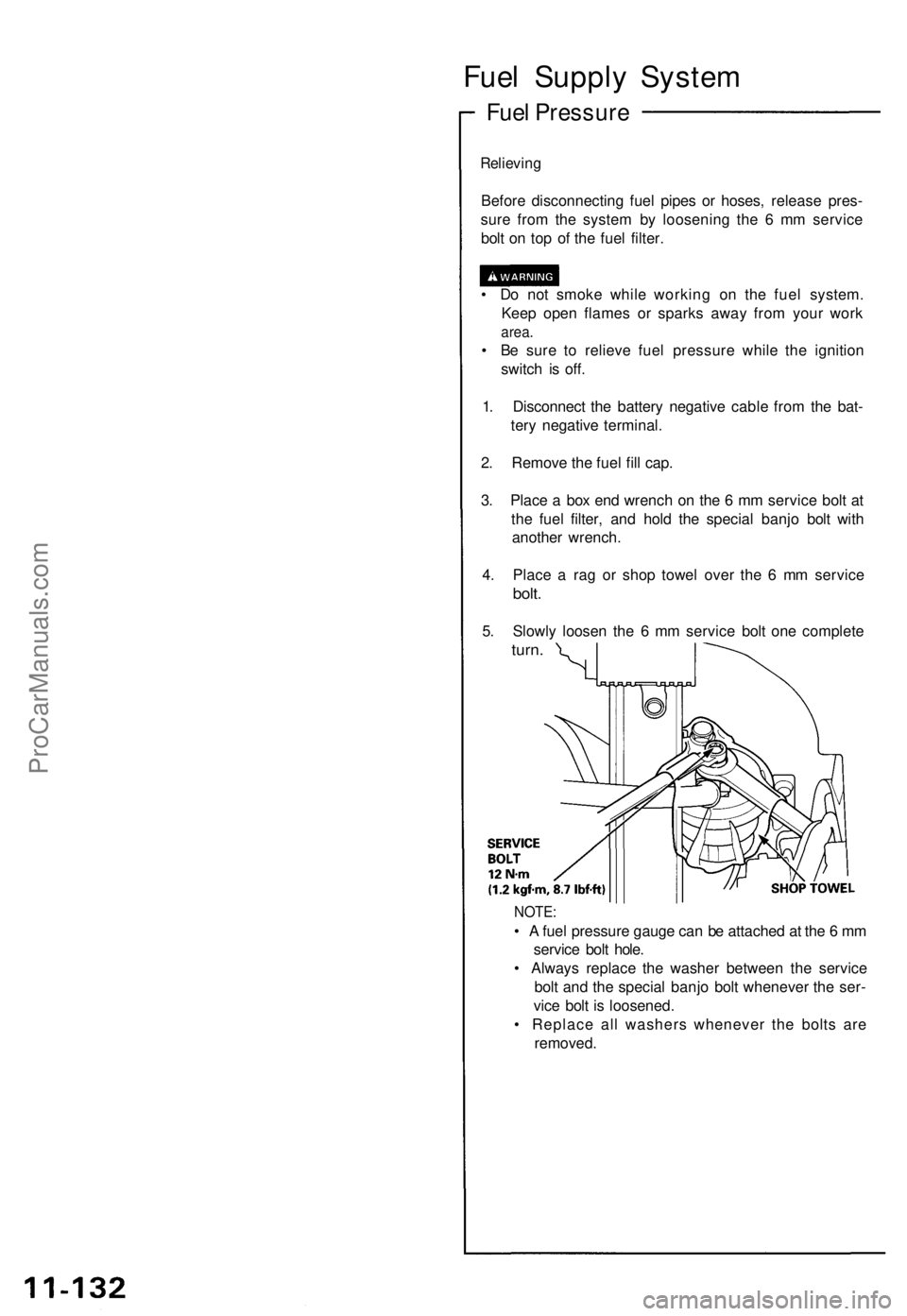

Relieving

Before disconnectin g fue l pipe s o r hoses , releas e pres -

sur e fro m th e syste m b y loosenin g th e 6 m m servic e

bol t o n to p o f th e fue l filter .

• D o no t smok e whil e workin g o n th e fue l system .

Kee p ope n flame s o r spark s awa y fro m you r wor k

area.

• B e sur e t o reliev e fue l pressur e whil e th e ignitio n

switc h i s off .

1 . Disconnec t th e batter y negativ e cabl e fro m th e bat -

ter y negativ e terminal .

2 . Remov e th e fue l fil l cap .

3 . Plac e a bo x en d wrenc h o n th e 6 m m servic e bol t a t

th e fue l filter , an d hol d th e specia l banj o bol t wit h

anothe r wrench .

4 . Plac e a ra g o r sho p towe l ove r th e 6 m m servic e

bolt.

5. Slowl y loose n th e 6 m m servic e bol t on e complet e

turn.

NOTE :

• A fue l pressur e gaug e ca n b e attache d a t th e 6 m m

servic e bol t hole .

• Alway s replac e th e washe r betwee n th e servic e

bol t an d th e specia l banj o bol t wheneve r th e ser -

vic e bol t i s loosened .

• Replac e al l washer s wheneve r th e bolt s ar e

removed .

ProCarManuals.com

Page 252 of 1640

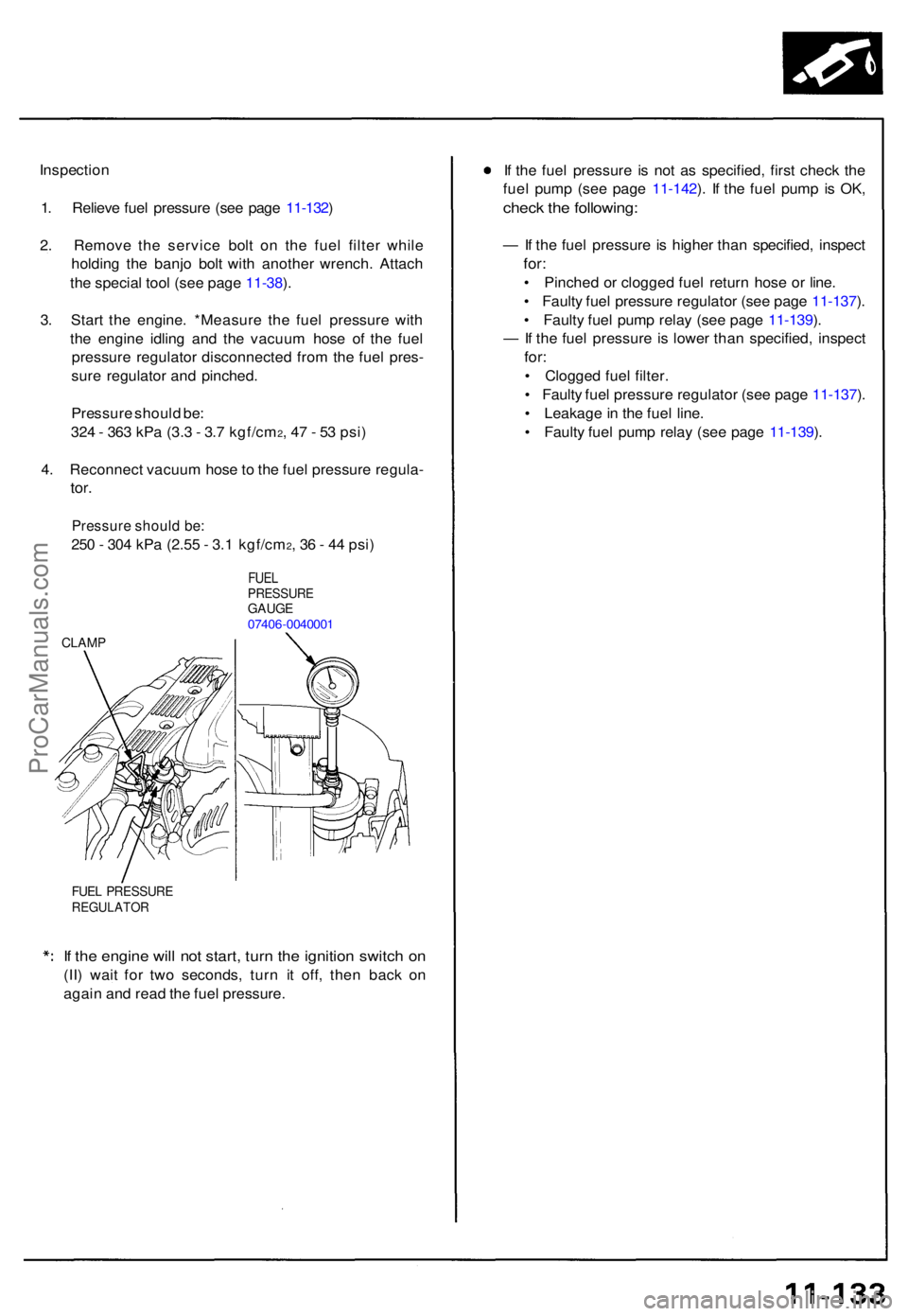

Inspection

1 . Reliev e fue l pressur e (se e pag e 11-132 )

2 . Remov e th e servic e bol t o n th e fue l filte r whil e

holdin g th e banj o bol t wit h anothe r wrench . Attac h

th e specia l too l (se e pag e 11-38 ).

3 . Star t th e engine . *Measur e th e fue l pressur e wit h

th e engin e idlin g an d th e vacuu m hos e o f th e fue l

pressur e regulato r disconnecte d fro m th e fue l pres -

sur e regulato r an d pinched .

Pressur e shoul d be :

32 4 - 36 3 kP a (3. 3 - 3. 7 kgf/cm

2, 4 7 - 5 3 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

250 - 30 4 kP a (2.5 5 - 3. 1 kgf/cm2, 3 6 - 4 4 psi )

FUE LPRESSUR EGAUGE07406-004000 1

CLAMP

FUEL PRESSUR EREGULATO R

If th e engin e wil l no t start , tur n th e ignitio n switc h o n

(II ) wai t fo r tw o seconds , tur n i t off , the n bac k o n

agai n an d rea d th e fue l pressure . I

f th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p i s OK ,

chec k th e following :

— If th e fue l pressur e is highe r tha n specified , inspec t

for:

• Pinche d o r clogge d fue l retur n hos e o r line .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Fault y fue l pum p rela y (se e pag e 11-139 ).

— If th e fue l pressur e is lowe r tha n specified , inspec t

for:

• Clogge d fue l filter .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Leakage in th e fue l line .

• Fault y fue l pum p rela y (se e pag e 11-139 ).

ProCarManuals.com

Page 258 of 1640

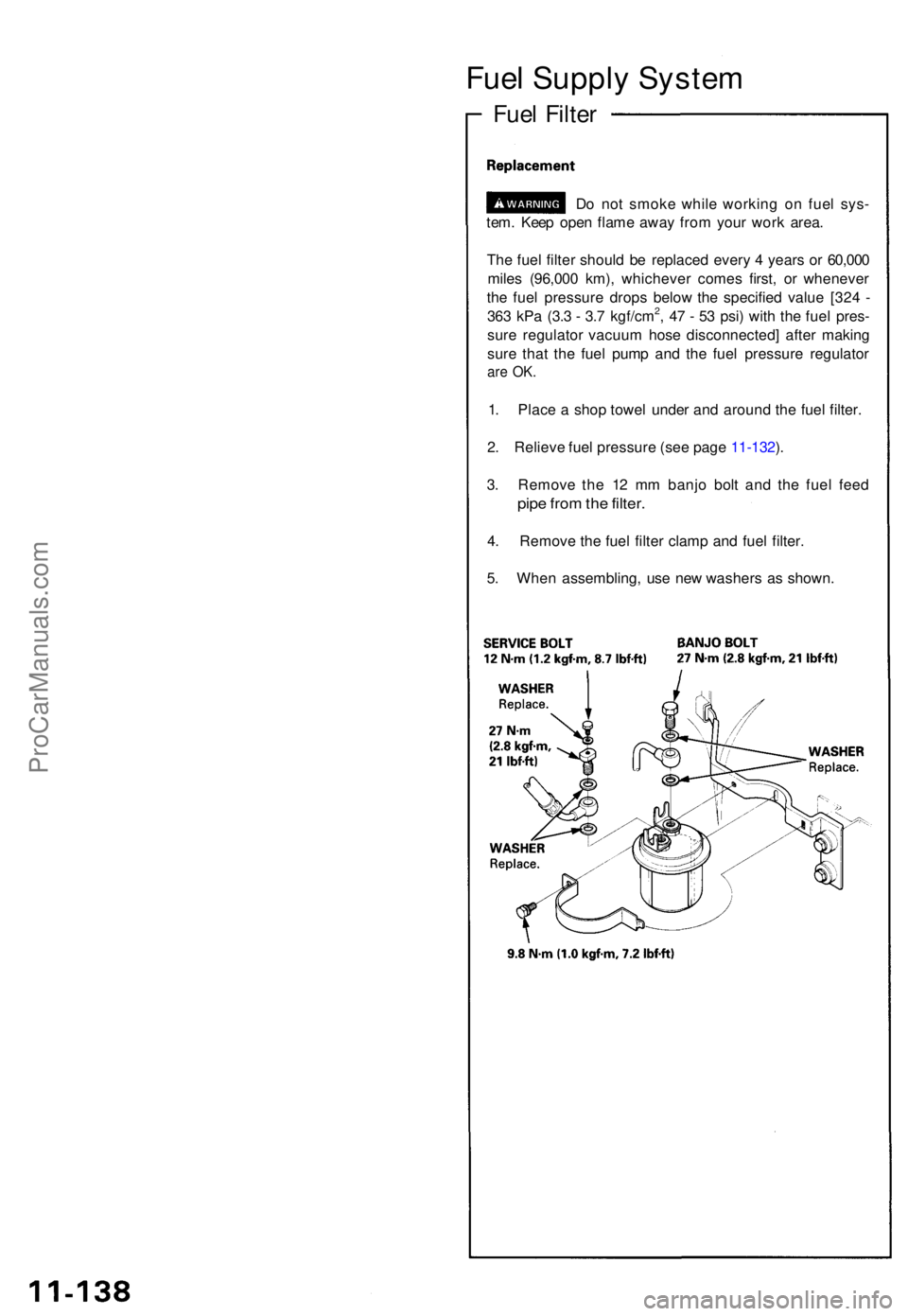

Fuel Suppl y Syste m

Fuel Filte r

Do no t smok e whil e workin g o n fue l sys -

tem . Kee p ope n flam e awa y fro m you r wor k area .

Th e fue l filte r shoul d b e replace d ever y 4 year s o r 60,00 0

mile s (96,00 0 km) , whicheve r come s first , o r wheneve r

th e fue l pressur e drop s belo w th e specifie d valu e [32 4 -

36 3 kP a (3. 3 - 3. 7 kgf/cm

2, 4 7 - 5 3 psi ) wit h th e fue l pres -

sur e regulato r vacuu m hos e disconnected ] afte r makin g

sur e tha t th e fue l pum p an d th e fue l pressur e regulato r

are OK .

1. Plac e a sho p towe l unde r an d aroun d th e fue l filter .

2 . Reliev e fue l pressur e (se e pag e 11-132 ).

3 . Remov e th e 1 2 m m banj o bol t an d th e fue l fee d

pipe fro m th e filter .

4. Remov e th e fue l filte r clam p an d fue l filter .

5 . Whe n assembling , us e ne w washer s a s shown .

ProCarManuals.com

Page 966 of 1640

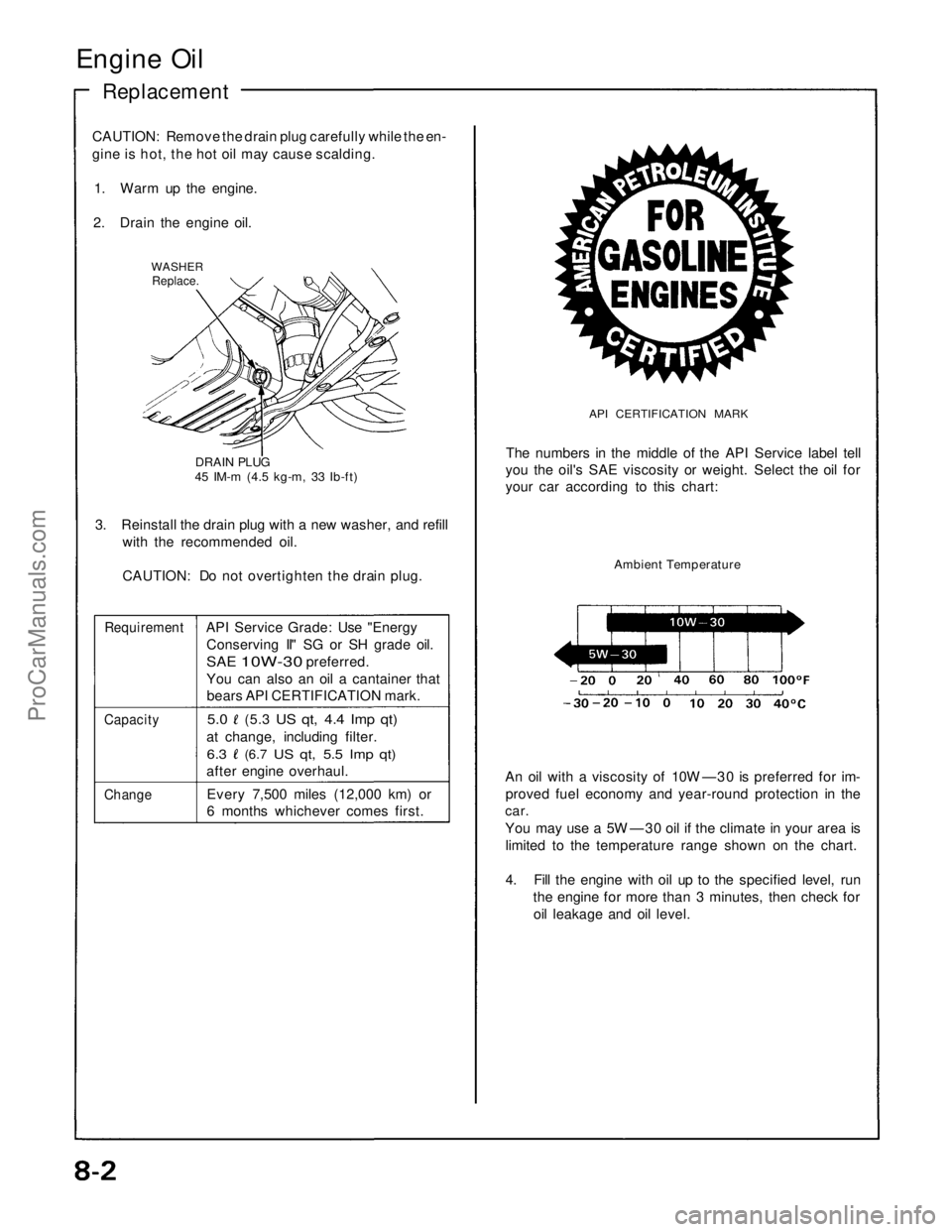

Engine Oil

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 988 of 1640

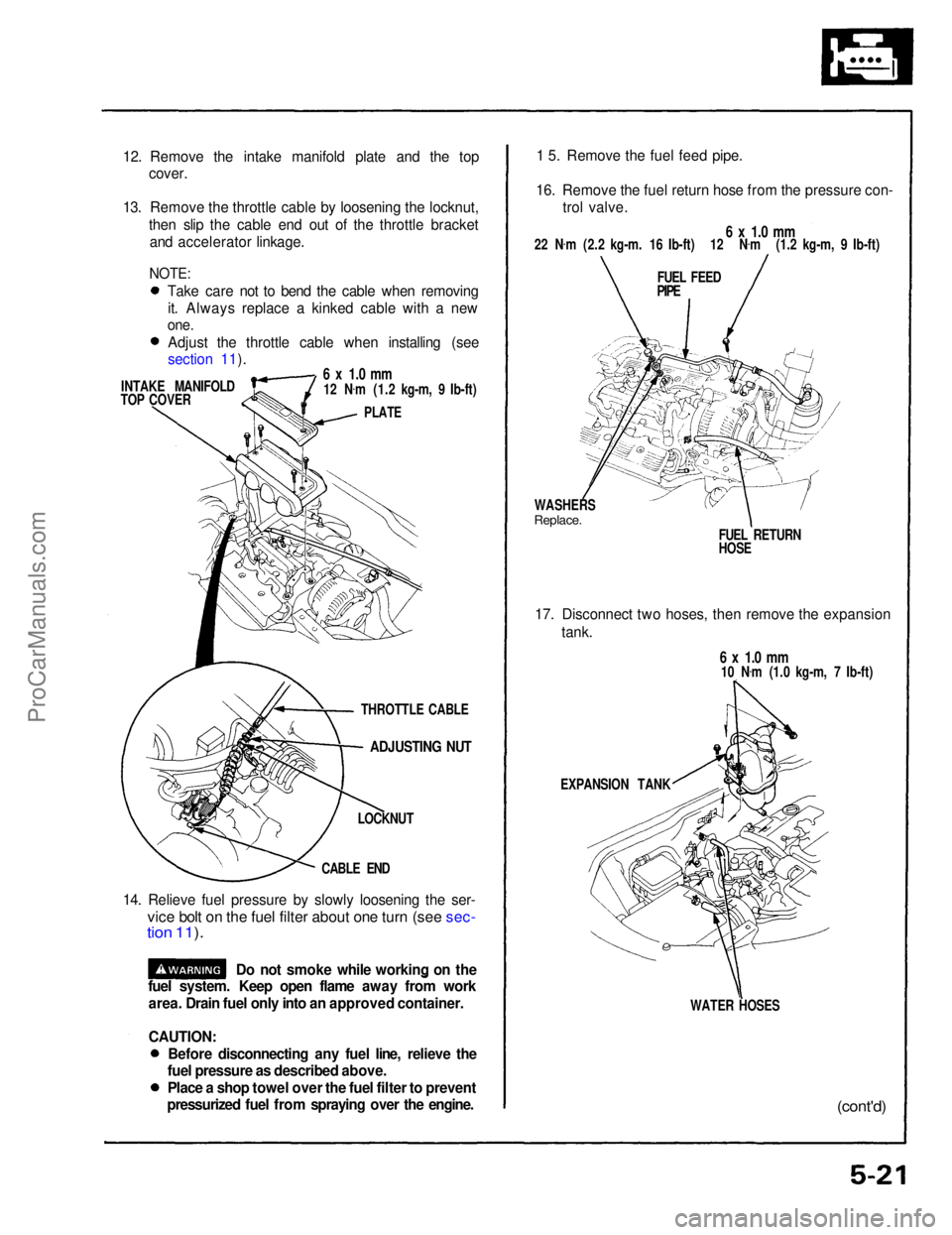

12. Remove the intake manifold plate and the top

cover.

13. Remove the throttle cable by loosening the locknut, then slip the cable end out of the throttle bracketand accelerator linkage.

INTAKE MANIFOLD

TOP COVER

6 x 1.0 mm

12 N .

m (1.2 kg-m, 9 Ib-ft)

PLATE

ADJUSTING NUT

LOCKNUT

CABLE END

14. Relieve fuel pressure by slowly loosening the ser-

vice bolt on the fuel filter about one turn (see sec-

tion 11 ).

1 5. Remove the fuel feed pipe.

16. Remove the fuel return hose from the pressure con- trol valve.

6 x 1.0 mm

22 N .

m (2.2 kg-m. 16 Ib-ft) 12 N .

m (1.2 kg-m, 9 Ib-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

17. Disconnect two hoses, then remove the expansion tank.

6 x 1.0 mm

10 N .

m (1.0 kg-m, 7 Ib-ft)

EXPANSION TANK

WATER HOSES

(cont'd)

Do not smoke while working on the

fuel system. Keep open flame away from work

area. Drain fuel only into an approved container.

CAUTION:

THROTTLE CABLE

NOTE:

Take care not to bend the cable when removingit. Always replace a kinked cable with a new

one.

Adjust the throttle cable when installing (see

section 11).

Before disconnecting any fuel line, relieve the

fuel pressure as described above.

Place a shop towel over the fuel filter to prevent

pressurized fuel from spraying over the engine.ProCarManuals.com

Page 1050 of 1640

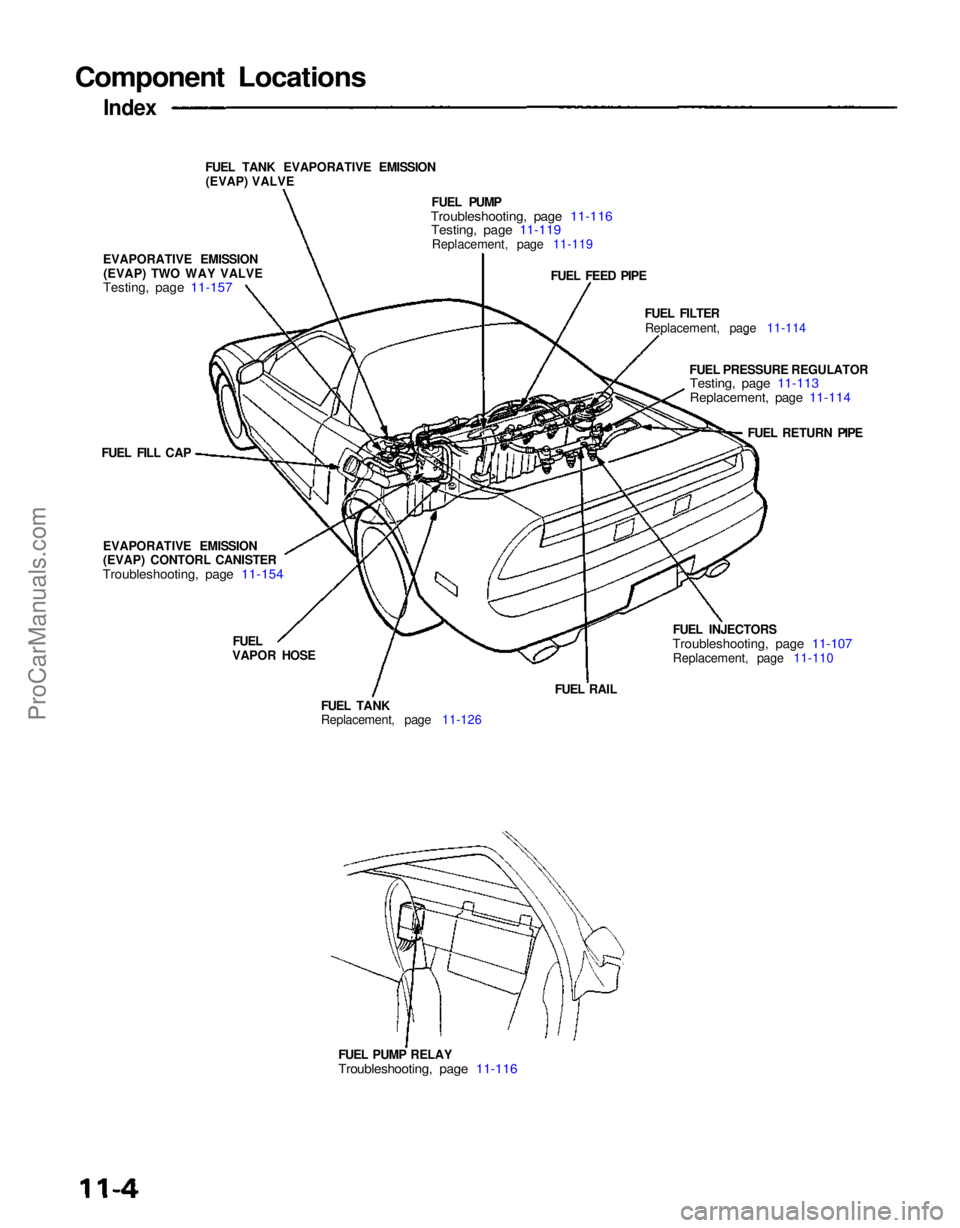

Component Locations

Index

FUEL TANK EVAPORATIVE EMISSION(EVAP) VALVE

EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

Testing, page 11-157

FUEL PUMP

Troubleshooting, page 11-116

Testing, page 11-119

Replacement, page 11-119

FUEL FEED PIPE

FUEL FILTERReplacement, page 11-114

FUEL PRESSURE REGULATOR

Testing, page 11-113

Replacement, page 11-114

FUEL RETURN PIPE

FUEL INJECTORS

Troubleshooting, page 11-107

Replacement, page 11-110

FUEL PUMP RELAY

Troubleshooting, page 11-116

FUEL RAIL

FUEL TANK

Replacement, page 11-126

FUEL

VAPOR HOSE

EVAPORATIVE EMISSION

(EVAP) CONTORL CANISTER

Troubleshooting, page 11-154

FUEL FILL CAPProCarManuals.com

Page 1054 of 1640

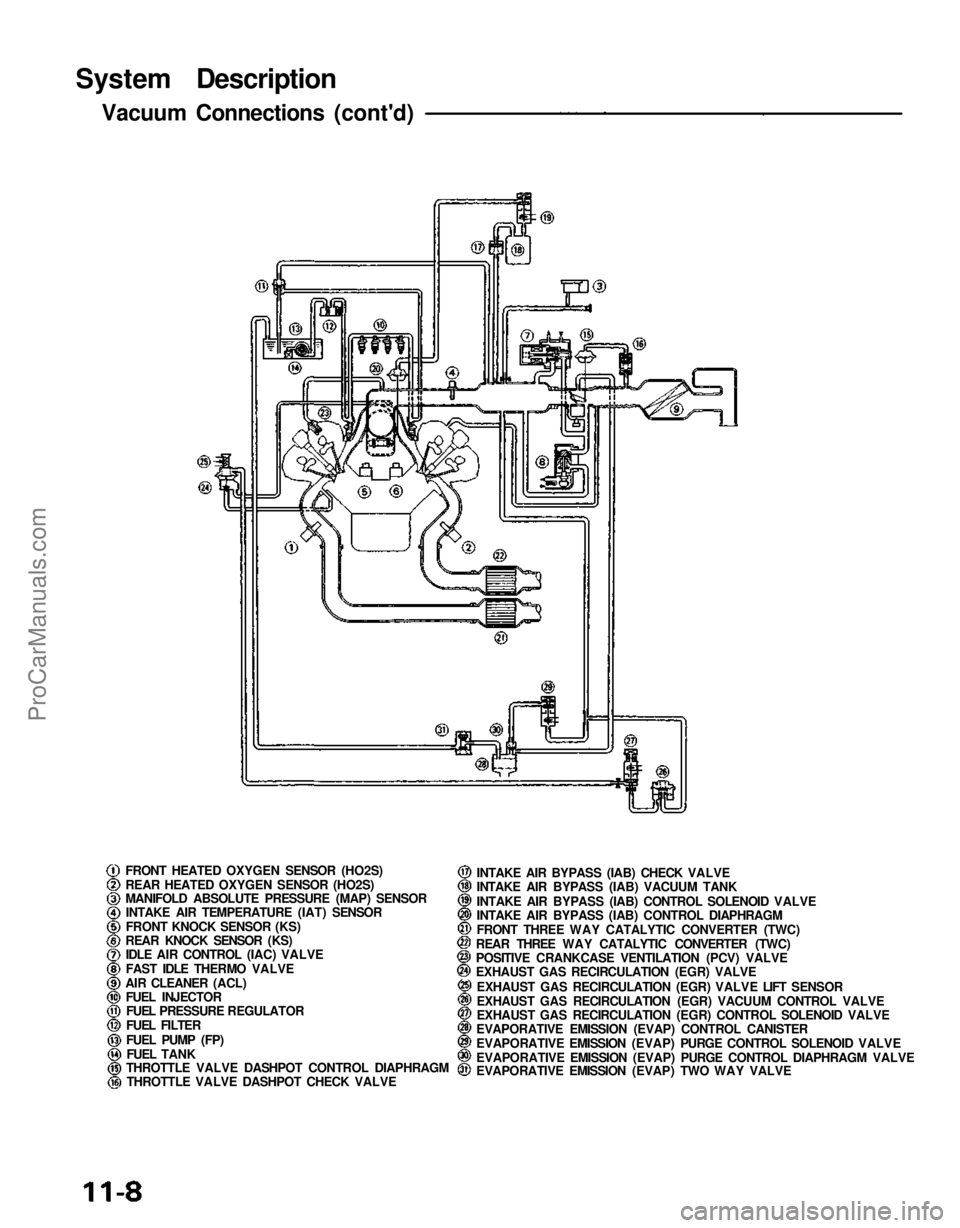

System Description

Vacuum Connections (cont'd)

FRONT HEATED OXYGEN SENSOR (HO2S)

REAR HEATED OXYGEN SENSOR (HO2S)

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSORINTAKE AIR TEMPERATURE (IAT) SENSOR

FRONT KNOCK SENSOR (KS)

REAR KNOCK SENSOR (KS) IDLE AIR CONTROL (IAC) VALVE

FAST IDLE THERMO VALVE

AIR CLEANER (ACL) FUEL INJECTORFUEL PRESSURE REGULATOR

FUEL FILTER

FUEL PUMP (FP)

FUEL TANK

THROTTLE VALVE DASHPOT CONTROL DIAPHRAGM

THROTTLE VALVE DASHPOT CHECK VALVE INTAKE AIR BYPASS (IAB) CHECK VALVE

INTAKE AIR BYPASS (IAB) VACUUM TANK

INTAKE AIR BYPASS (IAB) CONTROL SOLENOID VALVE

INTAKE AIR BYPASS (IAB) CONTROL DIAPHRAGM

FRONT THREE WAY CATALYTIC CONVERTER (TWC)

REAR THREE WAY CATALYTIC CONVERTER (TWC)

POSITIVE CRANKCASE VENTILATION (PCV) VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE LIFT SENSOR

EXHAUST GAS RECIRCULATION (EGR) VACUUM CONTROL VALVE

EXHAUST GAS RECIRCULATION (EGR) CONTROL SOLENOID VALVE

EVAPORATIVE EMISSION (EVAP) CONTROL CANISTER

EVAPORATIVE EMISSION (EVAP) PURGE CONTROL SOLENOID VALVE

EVAPORATIVE EMISSION (EVAP) PURGE CONTROL DIAPHRAGM VALVE

EVAPORATIVE EMISSION (EVAP) TWO WAY VALVEProCarManuals.com

Page 1108 of 1640

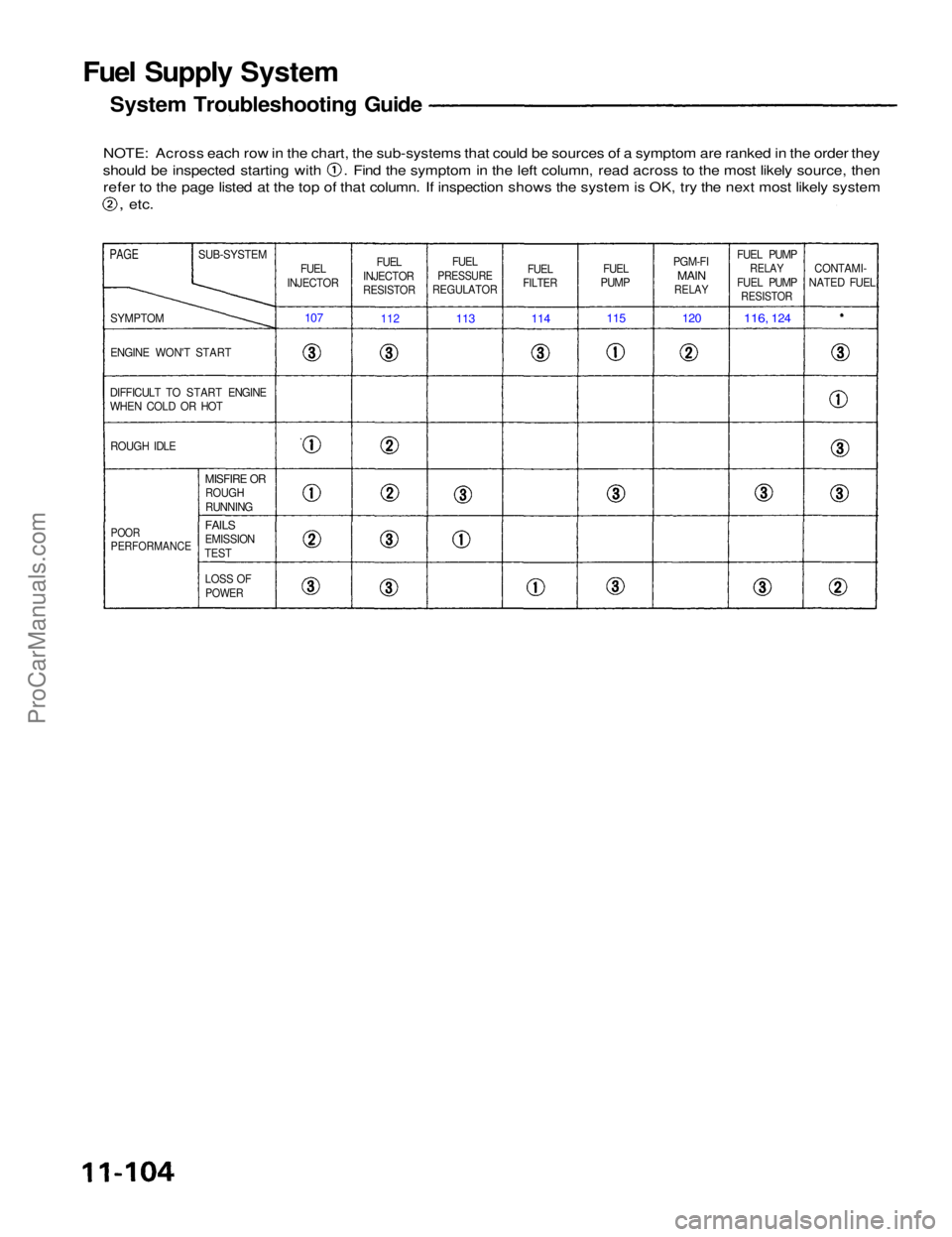

Fuel Supply System

System Troubleshooting Guide

NOTE: Across each row in the chart, the sub-systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then

refer to the page listed at the top of that column. If inspection shows the system is OK, try the next most likely system

,

etc.

PAGE

SUB-SYSTEM

FUEL

INJECTOR FUEL

INJECTOR

RESISTOR

FUEL

PRESSURE

REGULATOR

FUEL

FILTER

FUEL

PUMP PGM-FI

MAIN

RELAY

FUEL PUMP

RELAY

FUEL PUMP

RESISTOR

CONTAMI-

NATED FUEL

SYMPTOM

ENGINE WON'T START

DIFFICULT TO START ENGINE

WHEN COLD OR HOT ROUGH IDLE

107

112

113

114

115

120

116,

124

POOR

PERFORMANCE

MISFIRE OR

ROUGH

RUNNING

FAILS

EMISSION

TEST

LOSS OF

POWERProCarManuals.com