light ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 5 of 1640

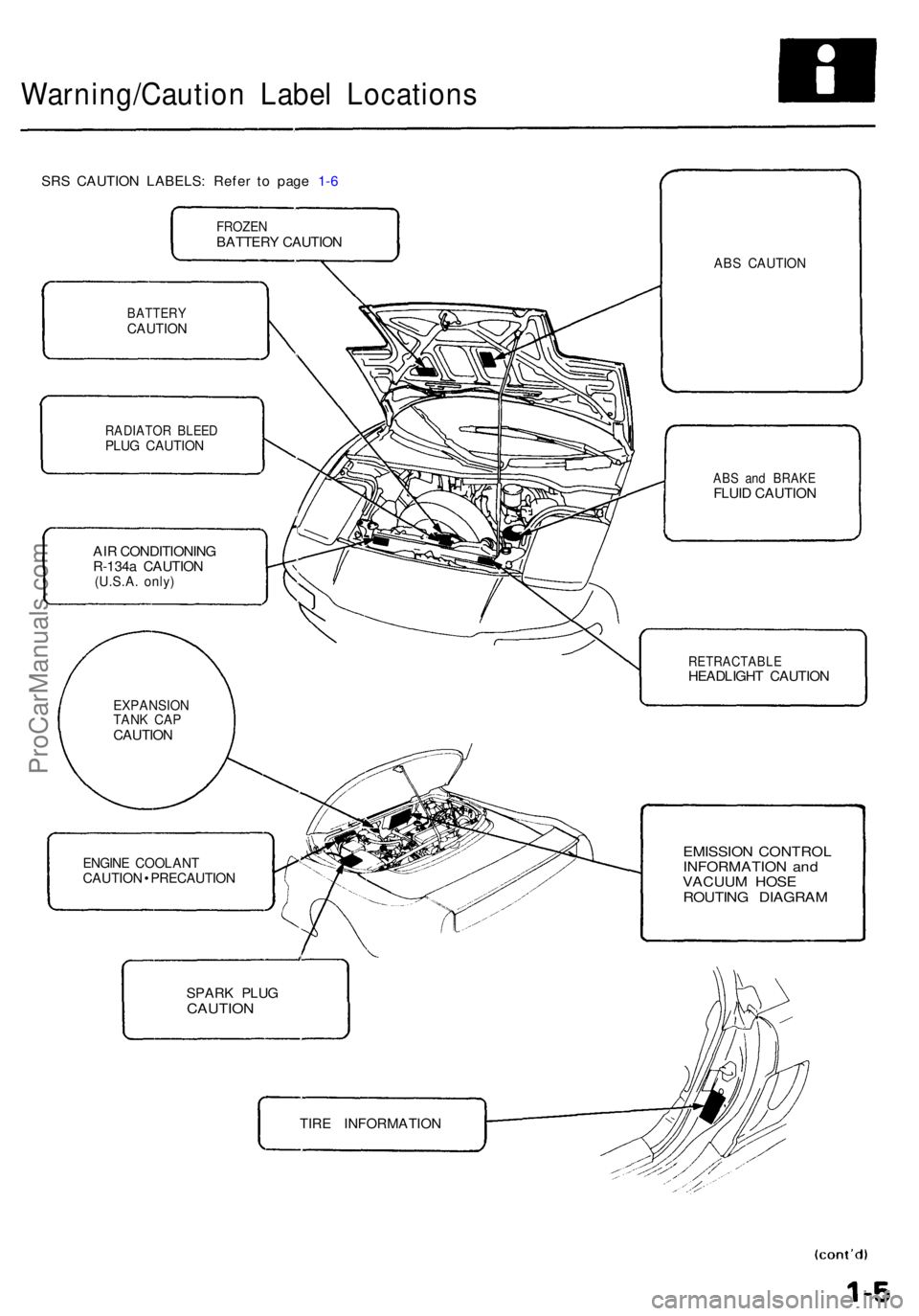

Warning/Caution Labe l Location s

SRS CAUTIO N LABELS : Refe r t o pag e 1- 6

FROZE NBATTER Y CAUTIO N

AI R CONDITIONIN G

R-134 a CAUTIO N

(U.S.A. only )

ENGIN E COOLAN TCAUTION • PRECAUTIO N

ABS CAUTIO N

ABS an d BRAK EFLUID CAUTIO N

RETRACTABL EHEADLIGHT CAUTIO N

EMISSION CONTRO L

INFORMATIO N an d

VACUU M HOS E

ROUTIN G DIAGRA M

BATTERYCAUTION

RADIATO R BLEE DPLUG CAUTIO N

EXPANSIO NTANK CA PCAUTIO N

SPAR K PLU G

CAUTIO N

TIRE INFORMATIO N

ProCarManuals.com

Page 85 of 1640

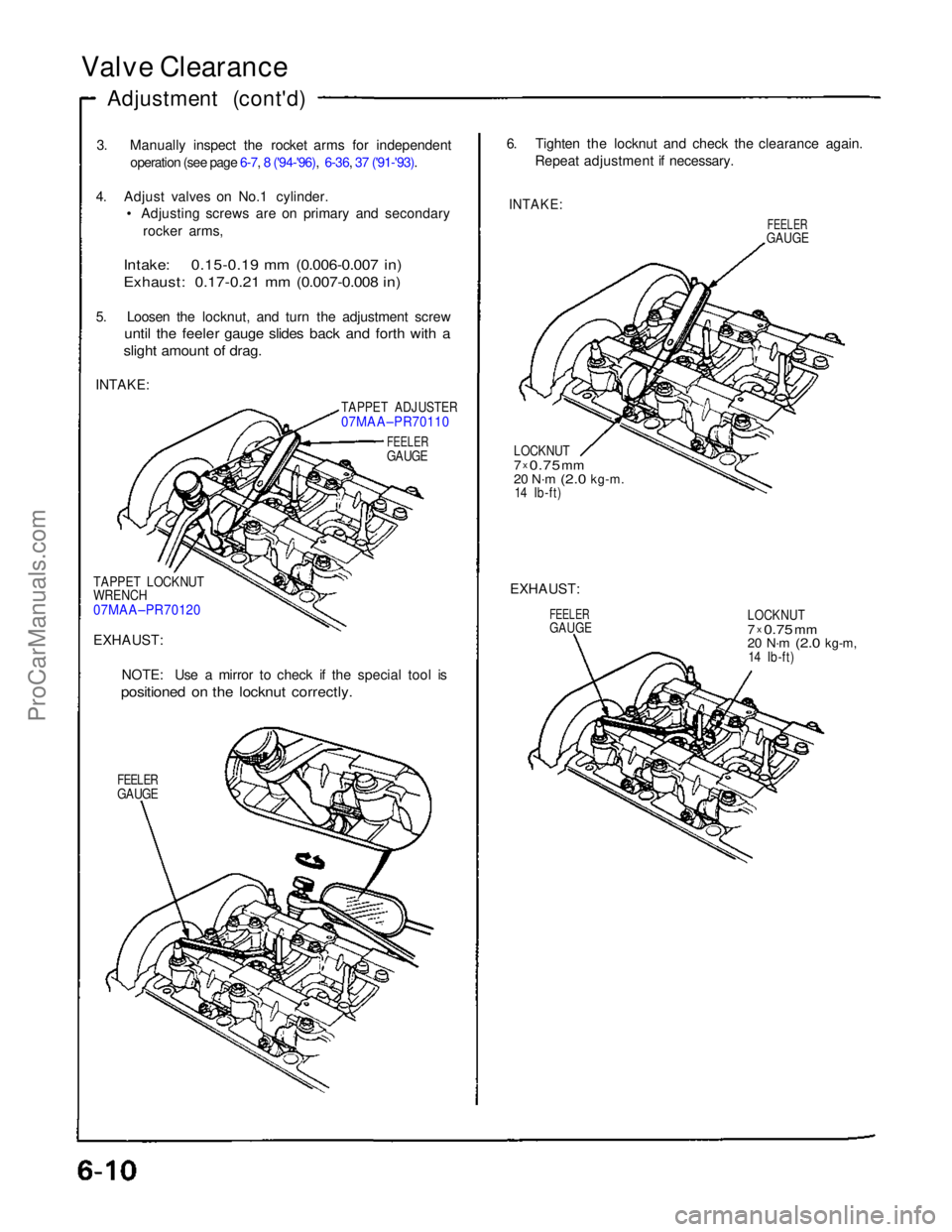

Valve Clearance

Adjustment (cont'd)

3. Manually inspect the rocket arms for independentoperation (see page 6-7, 8 ('94-'96), 6-36, 37 ('91-'93).

4. Adjust valves on No.1 cylinder.

• Adjusting screws are on primary and secondary

rocker arms,

Intake: 0.15-0.19 mm (0.006-0.007 in)

Exhaust: 0.17-0.21 mm (0.007-0.008 in)

5. Loosen the locknut, and turn the adjustment screw

until the feeler gauge slides back and forth with a

slight amount of drag.

INTAKE:

TAPPET ADJUSTER

07MAA–PR70110

FEELER

GAUGE

TAPPET LOCKNUT

WRENCH

07MAA–PR70120

EXHAUST: NOTE: Use a mirror to check if the special tool is

positioned on the locknut correctly.

FEELER

GAUGE

6. Tighten the locknut and check the clearance again.

Repeat adjustment if necessary.

INTAKE:

FEELER

GAUGE

LOCKNUT

7 x

0.75

mm

20 N·m

(2.0

kg-m.

14 Ib-ft)

EXHAUST:

FEELER

GAUGE

LOCKNUT

7

x

0.75

mm

20 N·m

(2.0

kg-m,

14 Ib-ft)ProCarManuals.com

Page 89 of 1640

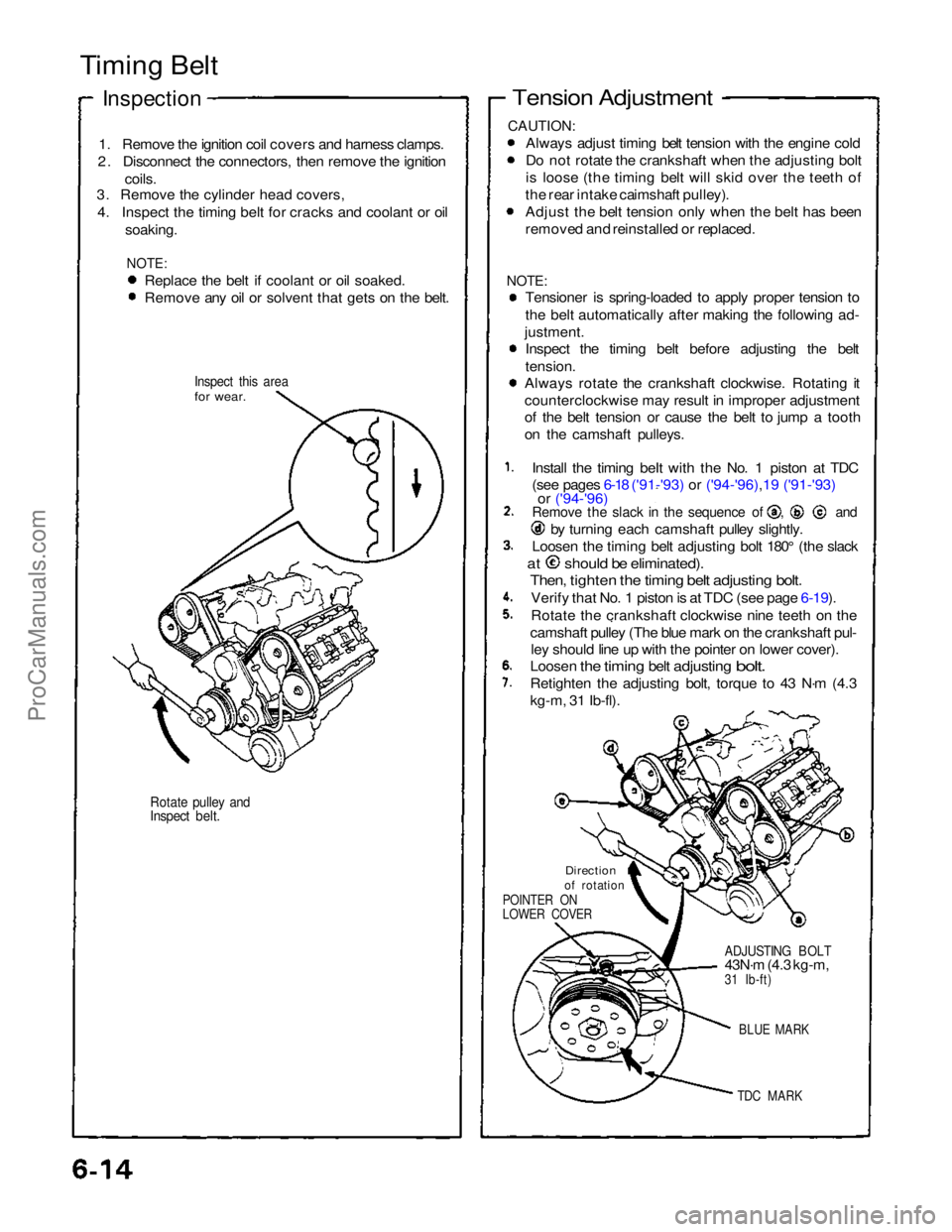

Timing Belt

Inspection

1. Remove the ignition coil covers and harness clamps.

2. Disconnect the connectors, then remove the ignition

coils.

3. Remove the cylinder head covers,

4. Inspect the timing belt for cracks and coolant or oil soaking.

NOTE:

Replace the belt if coolant or oil soaked.

Remove any oil or solvent that gets on the belt.

Inspect this area

for wear.

Rotate pulley and

Inspect belt.

Tension Adjustment

CAUTION:

Always adjust timing belt tension with the engine cold

Do not rotate the crankshaft when the adjusting bolt

is loose (the timing belt will skid over the teeth of

the rear intake caimshaft pulley).

Adjust the belt tension only when the belt has been

removed and reinstalled or replaced.

NOTE:

Tensioner is spring-loaded to apply proper tension to

the belt automatically after making the following ad-

justment. Inspect the timing belt before adjusting the belt

tension.

Always rotate the crankshaft clockwise. Rotating it

counterclockwise may result in improper adjustment

of the belt tension or cause the belt to jump a tooth

on the camshaft pulleys.

Install the timing beIt with the No. 1 piston at TDC

(see pages 6-18 ('91-'93) or ('94-'96),19 ('91-'93)

or ('94-'96) Remove the slack in the sequence of , and

by turning each camshaft pulley slightly.

Loosen the timing belt adjusting bolt 180° (the slack

at should be eliminated).

Then, tighten the timing belt adjusting bolt.

Verify that No. 1 piston is at TDC (see page 6-19).

Rotate the crankshaft clockwise nine teeth on the

camshaft pulley (The blue mark on the crankshaft pul- ley should line up with the pointer on lower cover).

Loosen

the

timing

belt

adjusting

bolt.

Retighten the adjusting bolt, torque to 43 N·m (4.3

kg-m, 31 Ib-fl).

Direction

of rotation

POINTER ON

LOWER COVER

ADJUSTING BOLT

43N·m (4.3 kg-m,

31 Ib-ft)

BLUE MARK

TDC MARK

ProCarManuals.com

Page 107 of 1640

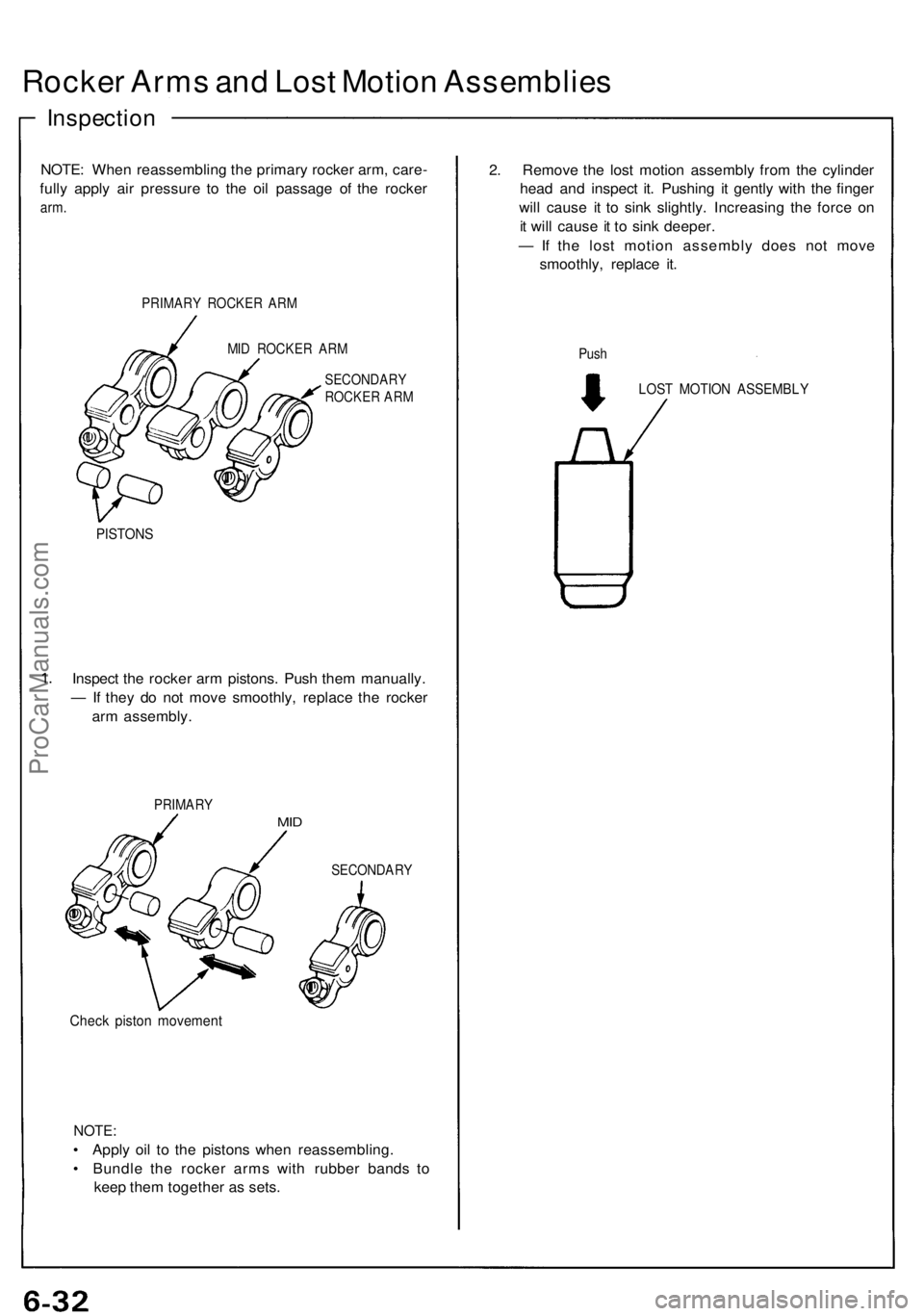

Rocker Arm s an d Los t Motio n Assemblie s

Inspection

NOTE: Whe n reassemblin g th e primar y rocke r arm , care -

full y appl y ai r pressur e t o th e oi l passag e o f th e rocke r

arm.

PRIMAR Y ROCKE R AR M

MI D ROCKE R AR M

SECONDAR Y

ROCKE R AR M

PISTON S

Inspect th e rocke r ar m pistons . Pus h the m manually .

— If the y d o no t mov e smoothly , replac e th e rocke r

ar m assembly .

PRIMARYMID

SECONDAR Y

Check pisto n movemen t

NOTE:

• Appl y oi l t o th e piston s whe n reassembling .

• Bundl e th e rocke r arm s wit h rubbe r band s t o

kee p the m togethe r a s sets . 2

. Remov e th e los t motio n assembl y fro m th e cylinde r

hea d an d inspec t it . Pushin g i t gentl y wit h th e finge r

wil l caus e i t t o sin k slightly . Increasin g th e forc e o n

i t wil l caus e i t t o sin k deeper .

— If th e los t motio n assembl y doe s no t mov e

smoothly , replac e it .

Pus h

LOS T MOTIO N ASSEMBL Y

ProCarManuals.com

Page 111 of 1640

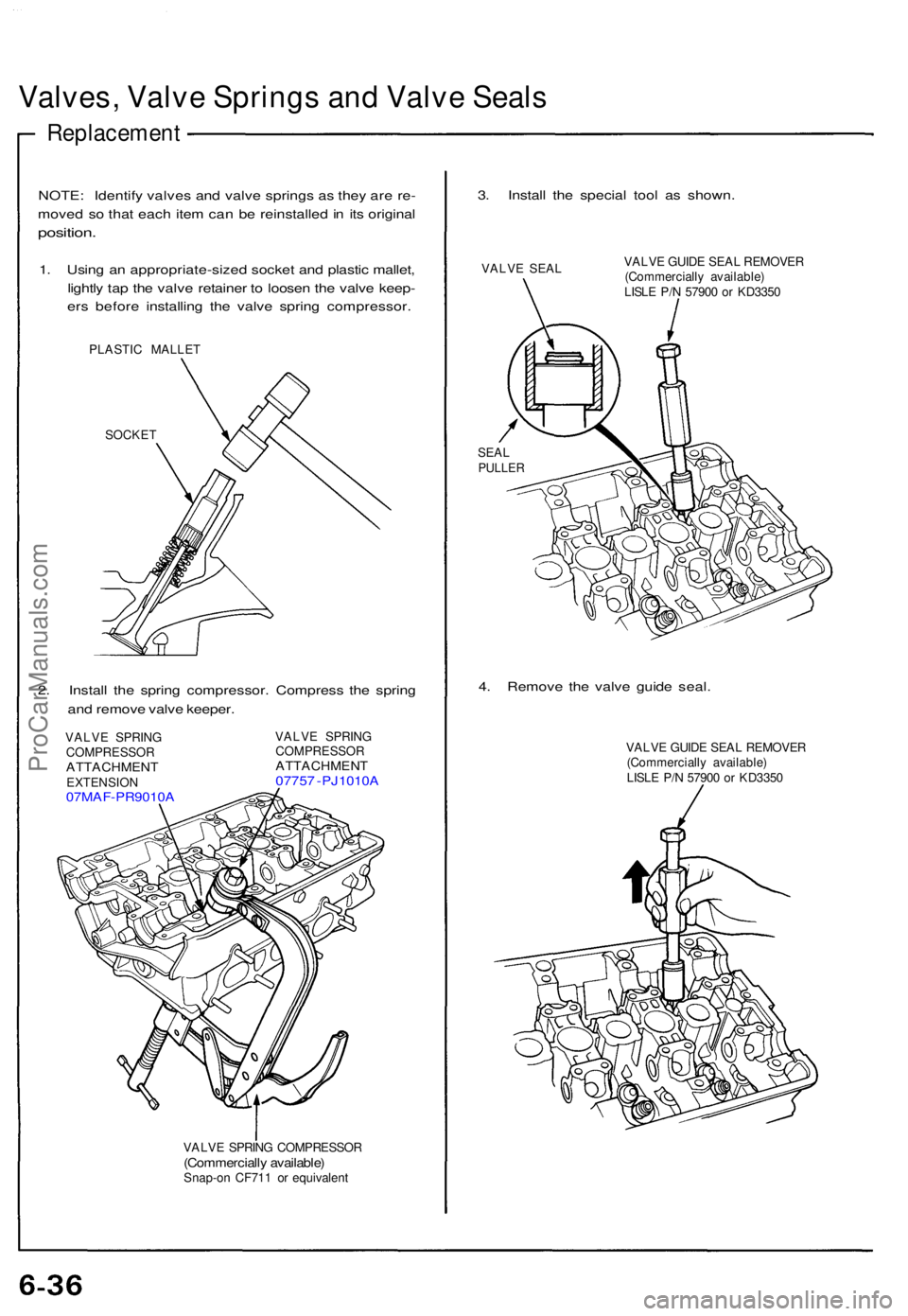

Valves, Valv e Spring s an d Valv e Seal s

Replacemen t

NOTE: Identif y valve s an d valv e spring s a s the y ar e re -

move d s o tha t eac h ite m ca n b e reinstalle d in it s origina l

position .

1. Usin g a n appropriate-size d socke t an d plasti c mallet ,

lightl y ta p th e valv e retaine r t o loose n th e valv e keep -

er s befor e installin g th e valv e sprin g compressor .

PLASTIC MALLE T

SOCKE T

2. Instal l th e sprin g compressor . Compres s th e sprin g

an d remov e valv e keeper .

VALVE SPRIN G

COMPRESSO R

ATTACHMENTEXTENSION07MAF-PR9010 A

VALVE SPRIN G

COMPRESSO R

ATTACHMENT07757 - PJ1010 A

VALVE SPRIN G COMPRESSO R(Commercially available )Snap-on CF71 1 o r equivalen t

3. Instal l th e specia l too l a s shown .

VALVE SEA L VALV

E GUID E SEA L REMOVE R

(Commerciall y available )

LISL E P/ N 5790 0 o r KD335 0

SEALPULLE R

4. Remov e th e valv e guid e seal .

VALV E GUID E SEA L REMOVE R

(Commerciall y available )

LISL E P/ N 5790 0 o r KD335 0

ProCarManuals.com

Page 125 of 1640

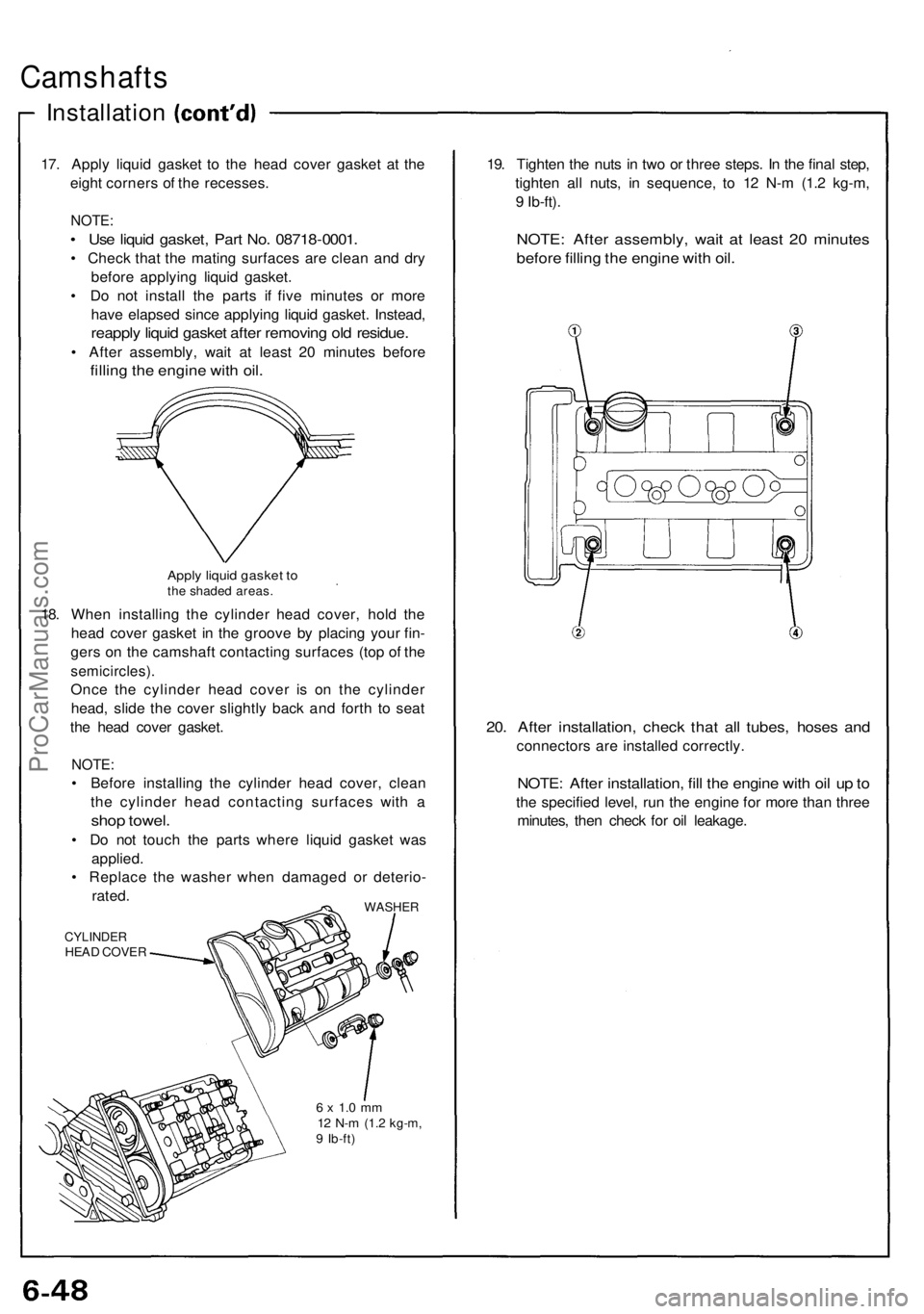

Camshafts

Installation

17. Appl y liqui d gaske t t o th e hea d cove r gaske t a t th e

eigh t corner s o f th e recesses .

NOTE:

• Us e liqui d gasket , Par t No . 0871 8-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d dr y

befor e applyin g liqui d gasket .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket . Instead ,

reapply liqui d gaske t afte r removin g ol d residue .

• Afte r assembly , wai t a t leas t 2 0 minute s befor e

filling th e engin e wit h oil .

Appl y liqui d gaske t t oth e shade d areas .

18. Whe n installin g th e cylinde r hea d cover , hol d th e

hea d cove r gaske t i n th e groov e b y placin g you r fin -

ger s o n th e camshaf t contactin g surface s (to p o f th e

semicircles) .

Once th e cylinde r hea d cove r i s o n th e cylinde r

head , slid e th e cove r slightl y bac k an d fort h t o sea t

th e hea d cove r gasket .

NOTE:

• Befor e installin g th e cylinde r hea d cover , clea n

th e cylinde r hea d contactin g surface s wit h a

sho p towel .

• D o no t touc h th e part s wher e liqui d gaske t wa s

applied .

• Replac e th e washe r whe n damage d o r deterio -

rated .

WASHE R

CYLINDE RHEAD COVE R

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

19. Tighte n th e nut s i n tw o o r thre e steps . I n th e fina l step ,

tighte n al l nuts , i n sequence , t o 1 2 N- m (1. 2 kg-m ,

9 Ib-ft) .

NOTE : Afte r assembly , wai t a t leas t 2 0 minute s

before fillin g th e engin e wit h oil .

20. Afte r installation , chec k tha t al l tubes , hose s an d

connector s ar e installe d correctly .

NOTE: Afte r installation , fil l th e engin e wit h oi l u p to

th e specifie d level , ru n th e engin e fo r mor e tha n thre e

minutes , the n chec k fo r oi l leakage .

ProCarManuals.com

Page 161 of 1640

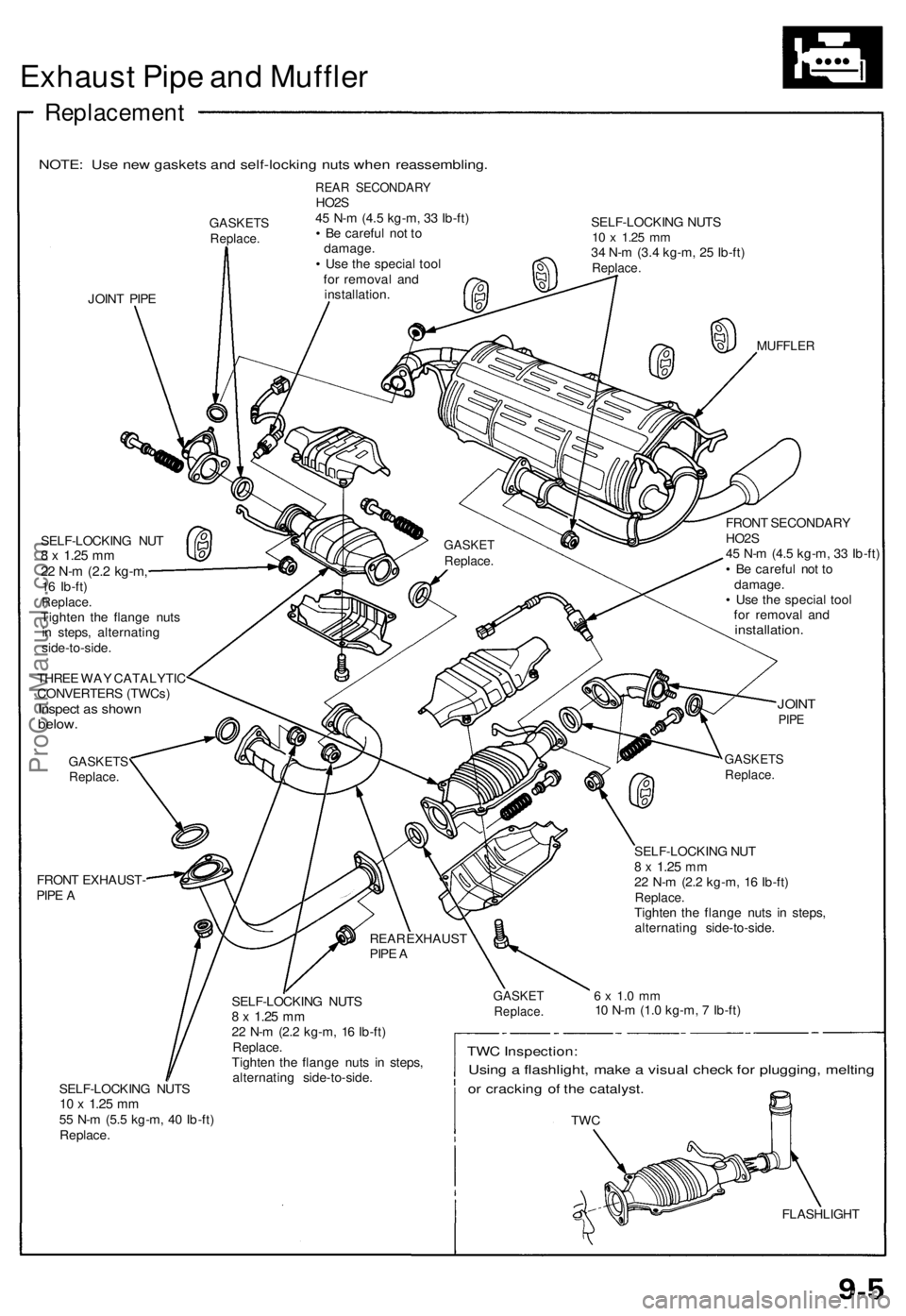

Exhaust Pip e an d Muffle r

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

GASKETSReplace.

JOINT PIP E

REA R SECONDAR YHO2S

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

• B e carefu l no t t o

damage .

• Us e th e specia l too l

fo r remova l an d

installation . SELF-LOCKIN

G NUT S

10 x 1.2 5 mm34 N- m (3. 4 kg-m , 2 5 Ib-ft )Replace .

MUFFLE R

SELF-LOCKIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )Replace .Tighten th e flang e nut s

i n steps , alternatin g

side-to-side .

THRE E WA Y CATALYTI C

CONVERTER S (TWCs )

Inspect a s show nbelow.

GASKET SReplace.

FRONT EXHAUST -

PIP E A FRON

T SECONDAR Y

HO2 S

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

• B e carefu l no t t o

damage .

• Us e th e specia l too l

fo r remova l an d

installation .

JOINTPIPE

SELF-LOCKIN G NUT S10 x 1.2 5 mm55 N- m (5. 5 kg-m , 4 0 Ib-ft )

Replace . SELF-LOCKIN

G NUT S

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )Replace .Tighten th e flang e nut s i n steps ,

alternatin g side-to-side .

GASKETSReplace.

SELF-LOCKIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )Replace .Tighten th e flang e nut s i n steps ,

alternatin g side-to-side .

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

TWC Inspection :

Using a flashlight , mak e a visua l chec k fo r plugging , meltin g

or crackin g o f th e catalyst .

TWC

FLASHLIGH T

REA

R EXHAUS T

PIP E A

GASKE TReplace .

GASKETReplace .

ProCarManuals.com

Page 210 of 1640

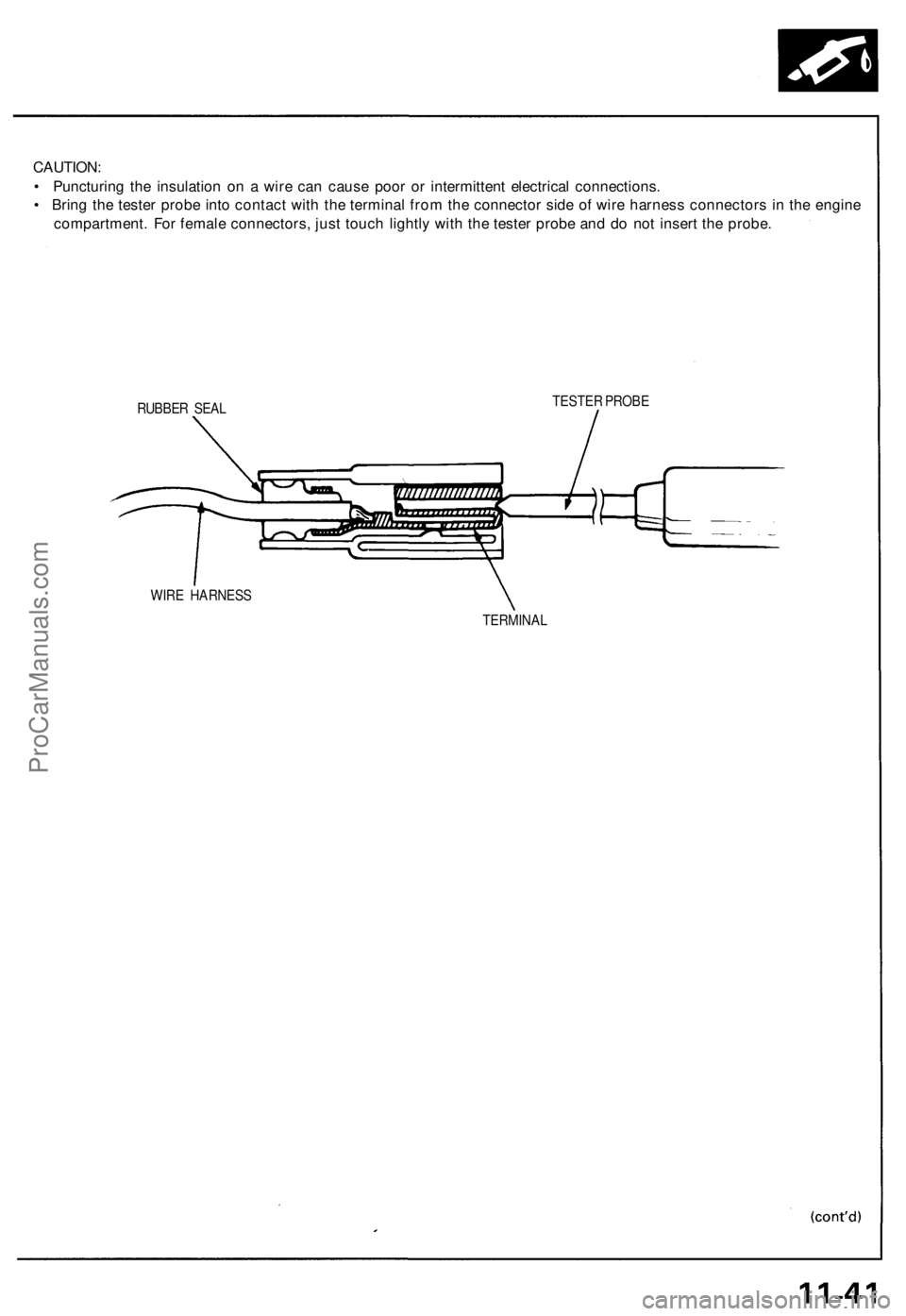

CAUTION:

• Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

• Bring the tester probe into contact with the terminal from the connector side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

TESTER PROBE

WIRE HARNESS

TERMINALProCarManuals.com

Page 229 of 1640

PGM-FI Syste m

System Descriptio n

3. Fue l Cut-of f Contro l

• Durin g deceleratio n wit h th e throttl e valv e closed , curren t t o th e fue l injector s i s cu t of f t o improv e fue l econom y a t

speed s ove r 1,50 0 rpm .

• Fue l cut-of f actio n als o take s plac e whe n engin e spee d exceeds , 8,30 0 rpm , regardles s o f th e positio n o f th e throttl e

valve , t o protec t th e engin e fro m over-revving .

4 . A/ C Compresso r Clutc h Rela y

Whe n th e EC M receive s a deman d fo r coolin g fro m th e ai r conditionin g system , i t delay s th e compresso r fro m bein g

energized , an d enriche s th e mixtur e to assur e smoot h translatio n to th e A/ C mode .

5 . Evaporativ e Emissio n (EVAP ) Purg e Contro l Solenoi d Valv e

Whe n th e engin e coolan t temperatur e is belo w 153° F (67°C) , th e EC M control s th e EVA P purg e contro l solenoi d valv e

whic h cut s vacuu m to th e EVA P purg e contro l caniste r diaphragm .

6 . Intak e Ai r Bypas s (IAB ) Contro l Solenoi d Valv e

Whe n th e engin e spee d is belo w 4,80 0 rpm , th e IA B contro l solenoi d valv e is activate d b y a signa l fro m th e ECM . Intak e

ai r the n flow s throug h th e smalle r chamber , an d hig h torqu e is delivered . T o increas e ai r flo w a t engin e speed s highe r

tha n 4,80 0 rpm , th e solenoi d valv e is deactivate d b y th e ECM , an d th e intak e ai r flow s throug h th e large r chamber .

7 . Exhaus t Ga s Recirculatio n (EGR ) Contro l Solenoi d Valv e

Whe n th e EG R is require d fo r contro l o f oxide s o f nitroge n (NOx ) emissions , th e EC M supplie s groun d t o th e EG R

contro l solenoi d valv e whic h supplie s regulate d vacuu m to th e EG R valve .

EC M Fail-safe/Back-u p Function s

1 . Fail-Saf e Functio n

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M ignore s tha t signa l an d assume s a pre-programme d

valv e fo r tha t senso r tha t allow s th e engin e t o continu e t o run .

2 . Back-u p Functio n

Whe n a n abnormalit y occur s i n th e EC M itself , th e fue l injector s ar e controlle d b y a back-u p circui t independen t o f th e

syste m in orde r t o permi t minima l driving .

3 . Self-diagnosi s Functio n [Malfunctio n Indicato r Lam p (MIL) ]

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M light s th e MI L an d store s th e diagnosti c troubl e cod e

i n erasabl e memory . Whe n th e ignitio n i s initiall y turne d on , th e EC M supplie s groun d fo r th e MI L fo r tw o second s t o

chec k th e MI L bul b condition .

ProCarManuals.com

Page 230 of 1640

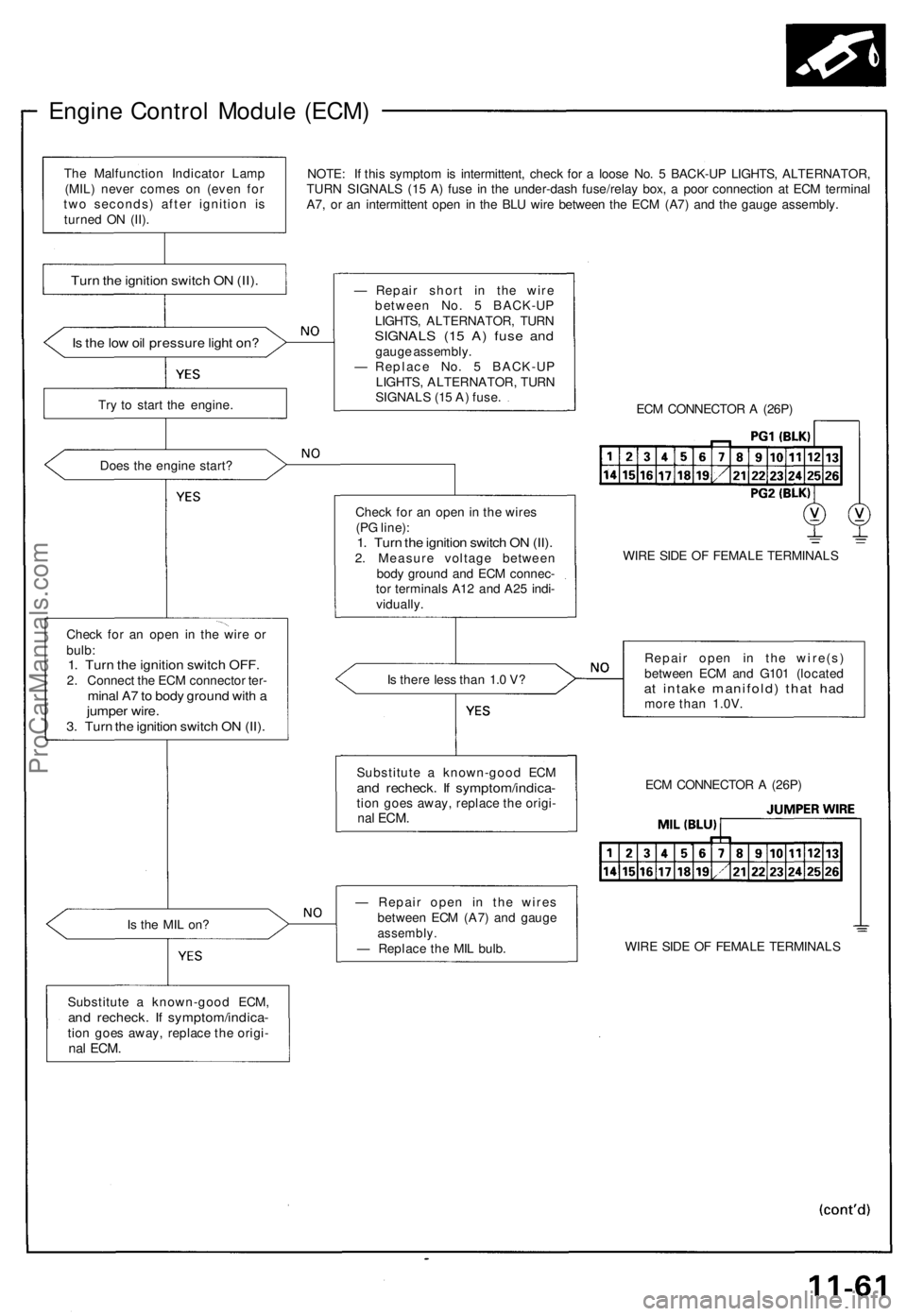

Engine Control Module (ECM)

NOTE: If this symptom is intermittent, check for a loose No. 5 BACK-UP LIGHTS, ALTERNATOR,

TURN SIGNALS (15 A) fuse in the under-dash fuse/relay box, a poor connection at ECM terminal

A7, or an intermittent open in the BLU wire between the ECM (A7) and the gauge assembly.

Is the low oil pressure light on?

Try to start the engine.

Does the engine start?

Check for an open in the wire or

bulb:

1. Turn the ignition switch OFF.

2. Connect the ECM connector ter-

minal A7 to body ground with a

jumper wire.

3. Turn the ignition switch ON (II).

Is the MIL on?

Substitute a known-good ECM,

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

— Repair short in the wire

between No. 5 BACK-UP

LIGHTS, ALTERNATOR, TURN

SIGNALS (15 A) fuse and

gauge assembly.

— Replace No. 5 BACK-UP

LIGHTS, ALTERNATOR, TURN

SIGNALS (15 A) fuse.

ECM CONNECTOR A (26P)

Check for an open in the wires

(PG line):

1. Turn the ignition switch ON (II).

2. Measure voltage between

body ground and ECM connec-

tor terminals A12 and A25 indi-

vidually.

WIRE SIDE OF FEMALE TERMINALS

Is there less than 1.0 V?

Repair open in the wire(s)

between ECM and G101 (located

at intake manifold) that had

more than 1.0V.

— Repair open in the wires

between ECM (A7) and gauge

assembly.

— Replace the MIL bulb.

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR A (26P)

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

Turn the ignition switch ON (II).

The Malfunction Indicator Lamp

(MIL) never comes on (even for

two seconds) after ignition is

turned ON (II).ProCarManuals.com