oil temperature ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 97 of 1640

![ACURA NSX 1991 Service Repair Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N ACURA NSX 1991 Service Repair Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N](/img/32/56988/w960_56988-96.png)

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

NOTE: Use new O-rings and gaskets when reassembling.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

REAR VARIABLE VALVE TIMING

AND VALVE LIFT ELECTRONIC CONTROL

SYSTEM (VTEC) SOLENOID VALVE

Troubleshooting, page 6-3 ('91-'93) or ('94-'96)

EXHAUST GAS

RECIRCULATI0N (EGR) VALVE

6 x 1 .0 mm

12 N·m

(1.2 kg-m.

9 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

ENGINE COOLANT

TEMPERATURE (ECT) SENSOR

18 N·m (1.8 kg-m, 13 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 lb-ft)

FRONT VTEC SOLENOID VALVE

Troubleshooting. page 6-3

SEALING BOLTS

60 N·m

(6.0 kg-m,

43 lb-ft)

OIL PRESSURE

GAUSE SENDING

UNIT (section 23)

ROCKER

SHAFTS

WASHERS

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,16 Ib-ft)

DOWEL PIN

0-RING

Replace.

ECT SWITCH

28 N·m

12.8 kg-m.

20 lb-ft

O-RING

Replace.

O-RING

Replace.

ROCKER ARM ASSEMBLY[PRIMARY. MID, SECONDARY]

Inspection, page 6-32 ('91-'93) or ('94-'96)

ROCKER SHAFT

OIL CONTROL

ORIFICE

Remove with 5 mm

boit and clean.

FILTER

Replace.

GASKET

Replace.

O-RING

Replace.ProCarManuals.com

Page 99 of 1640

Cylinder Heads

Removal

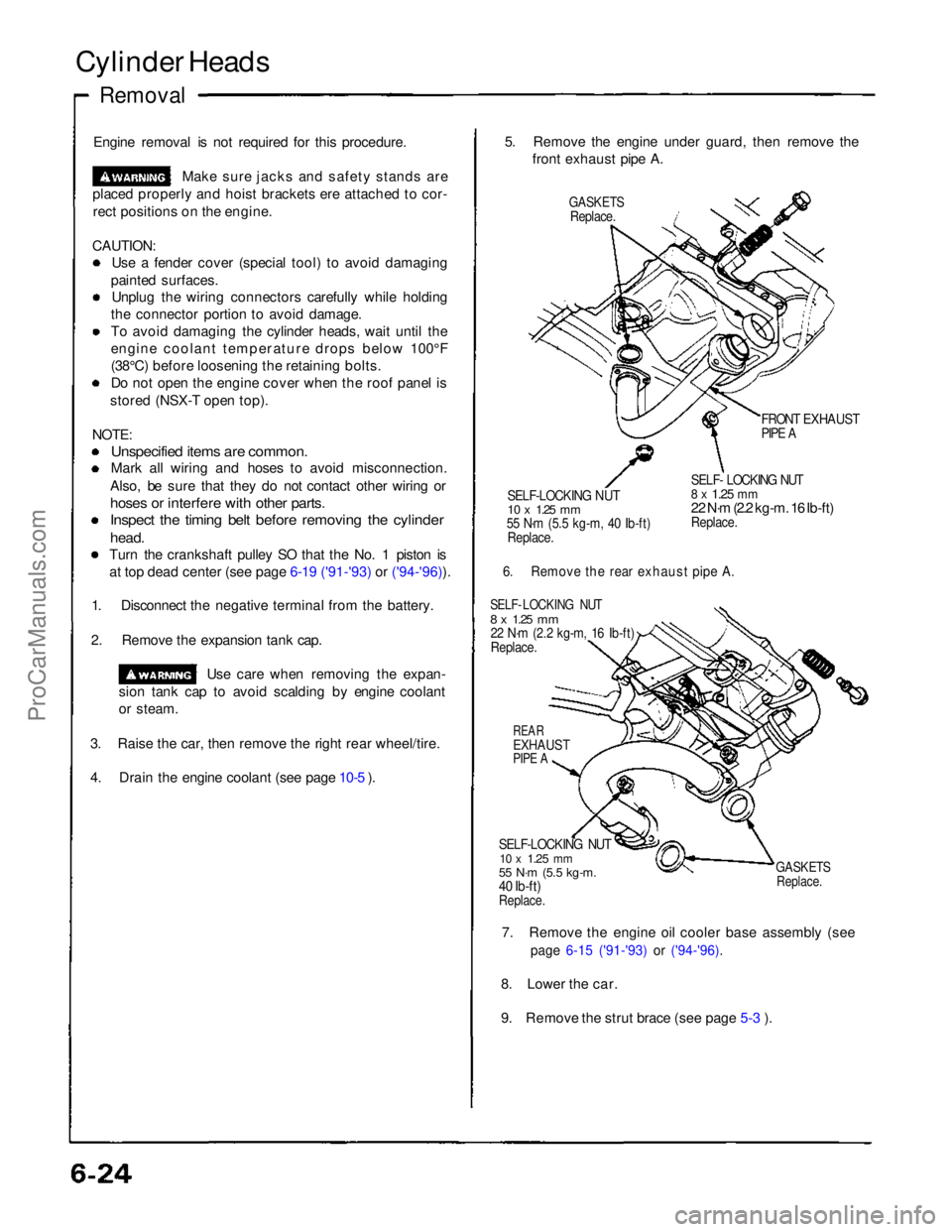

Engine removal is not required for this procedure. Make sure jacks and safety stands are

placed properly and hoist brackets ere attached to cor- rect positions on the engine.

CAUTION: Use a fender cover (special tool) to avoid damaging

painted surfaces. Unplug the wiring connectors carefully while holding

the connector portion to avoid damage.

To avoid damaging the cylinder heads, wait until the

engine coolant temperature drops below 100°F

(38°C) before loosening the retaining bolts. Do not open the engine cover when the roof panel is

stored (NSX-T open top).

NOTE:

Unspecified items are common.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses or interfere with other parts.

Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley SO that the No. 1 piston is at top dead center (see page 6-19 ('91-'93) or ('94-'96)).

1. Disconnect the negative terminal from the battery.

2. Remove the expansion tank cap. Use care when removing the expan-

sion tank cap to avoid scalding by engine coolant

or steam.

3. Raise the car, then remove the right rear wheel/tire.

4. Drain the engine coolant (see page 10-5 ). 5. Remove the engine under guard, then remove the

front exhaust pipe A.

GASKETS

Replace.

FRONT EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m, 40 Ib-ft)

Replace.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 Ib-ft)

Replace.

6. Remove the rear exhaust pipe A.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

Replace.

REAR

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m.

40 Ib-ft)

Replace.

GASKETS

Replace.

7. Remove the engine oil cooler base assembly (see

page 6-15 ('91-'93) or ('94-'96).

8. Lower the car.

9. Remove the strut brace (see page 5-3 ).ProCarManuals.com

Page 102 of 1640

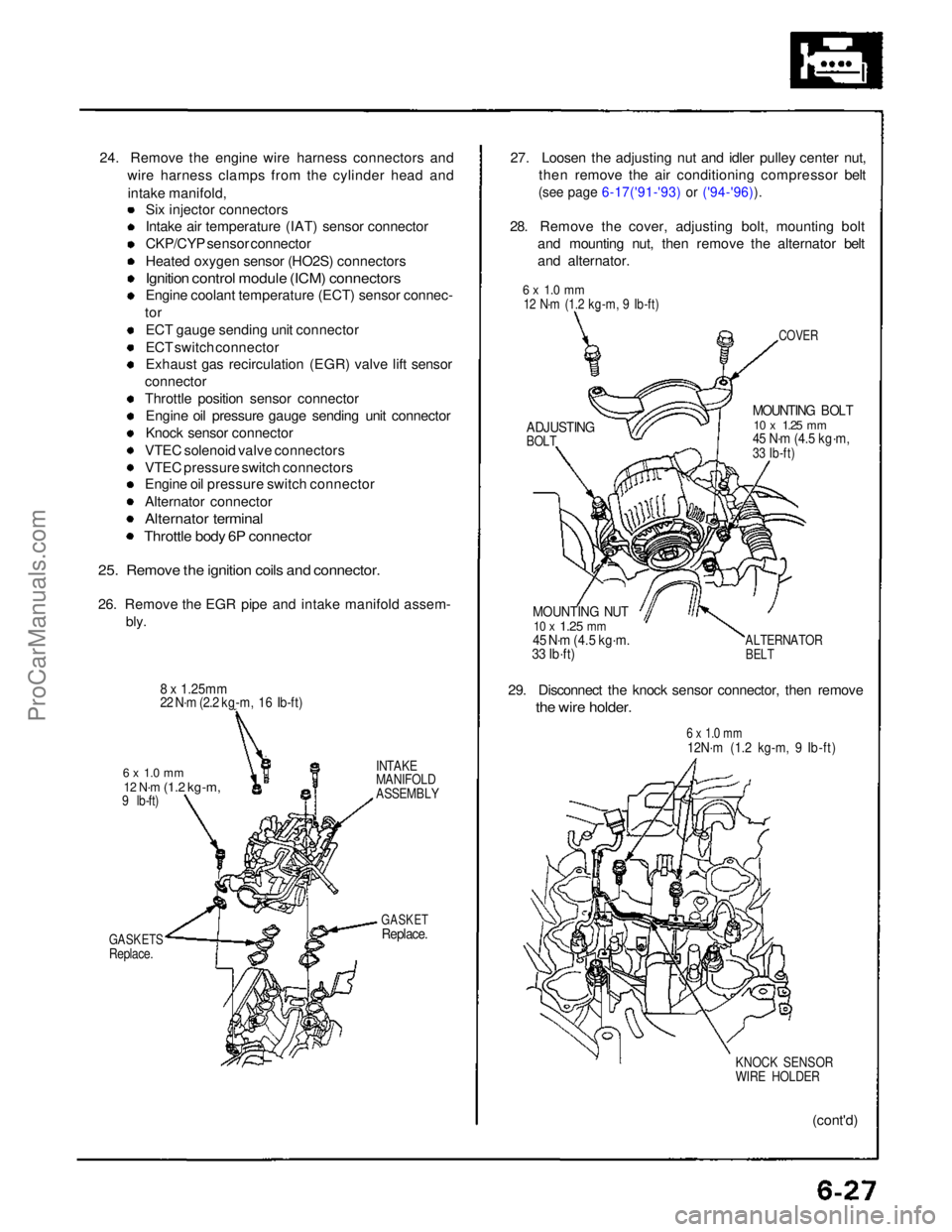

24. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and

intake manifold, Six injector connectors

Intake air temperature (IAT) sensor connector

CKP/CYP sensor connector

Heated oxygen sensor (HO2S) connectors

Ignition control module (ICM) connectors

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Throttle position sensor connector Engine oil pressure gauge sending unit connector

Knock sensor connector

VTEC solenoid valve connectors

VTEC pressure switch connectors

Engine oil pressure switch connector

Alternator connector

Alternator terminal

Throttle body 6P connector

25. Remove the ignition coils and connector.

26. Remove the EGR pipe and intake manifold assem- bly.

8 x 1.25mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

GASKETS

Replace. INTAKE

MANIFOLD

ASSEMBLY

GASKET

Replace.

27. Loosen the adjusting nut and idler pulley center nut,

then remove the air conditioning compressor belt

(see page 6-17('91-'93) or ('94-'96)).

28. Remove the cover, adjusting bolt, mounting bolt and mounting nut, then remove the alternator belt

and alternator.

COVER

MOUNTING BOLT

10 x

1.25

mm

45 N·m (4.5 kg·m,

33 Ib-ft)

MOUNTING NUT

10 x

1.25

mm

45 N·m (4.5 kg·m.

33 Ib·ft)

ALTERNATOR

BELT

29. Disconnect the knock sensor connector, then remove

the wire holder.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

KNOCK SENSOR

WIRE HOLDER

(cont'd)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

ADJUSTING

BOLTProCarManuals.com

Page 146 of 1640

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

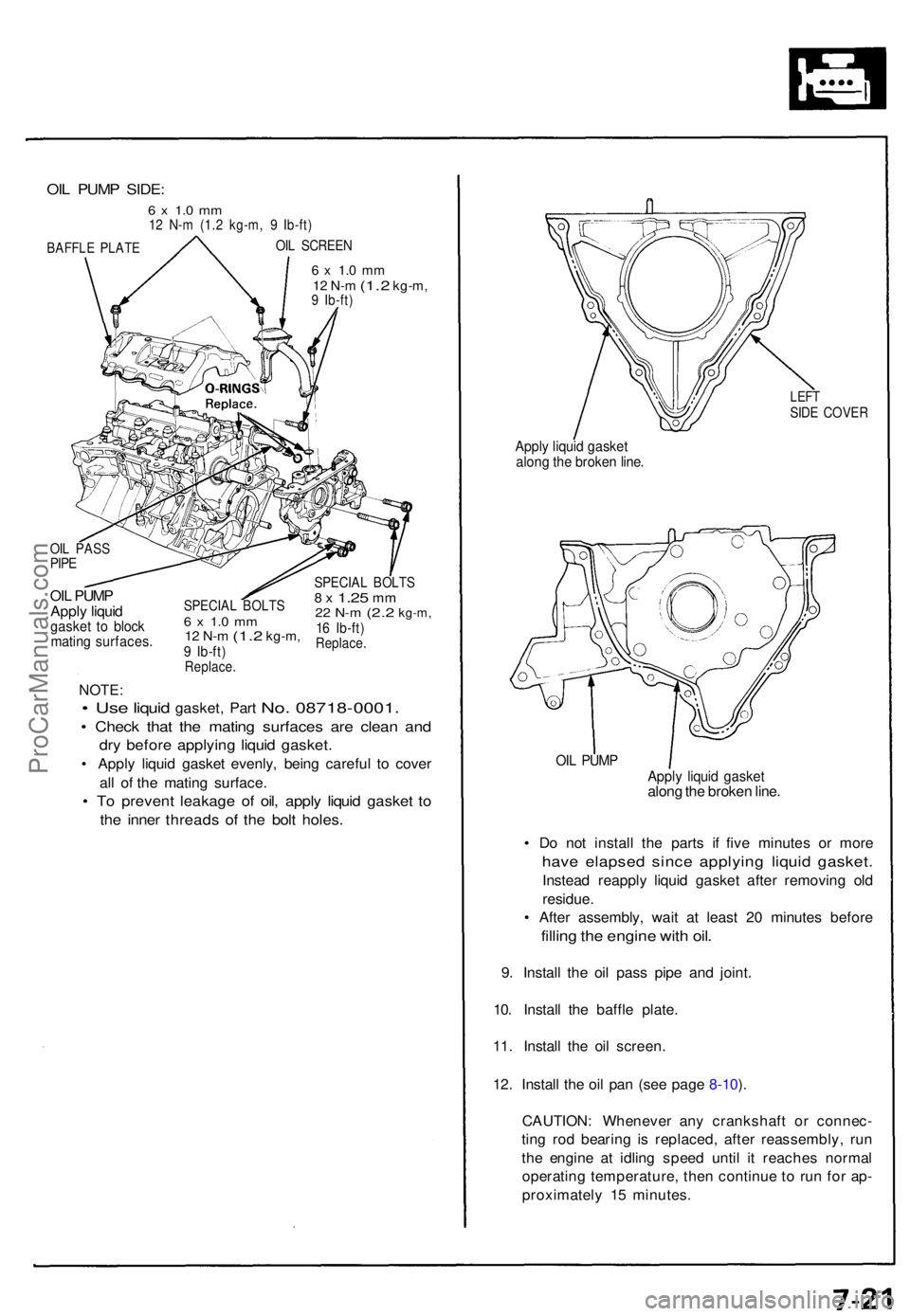

OIL PUM P

Appl y liqui d

gaske t t o bloc kmatin g surfaces .

SPECIAL BOLT S6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )Replace .

SPECIAL BOLT S8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )Replace .

NOTE:

• Use liqui d gasket , Par t No. 08718-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d

dry befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , bein g carefu l t o cove r

al l o f th e matin g surface .

• T o preven t leakag e o f oil , appl y liqui d gaske t t o

th e inne r thread s of the bol t holes .

LEFTSIDE COVE R

Apply liqui d gaske talong th e broke n line .

OIL PUM PApply liqui d gaske talong th e broke n line .

• D o no t instal l th e part s i f fiv e minute s o r mor e

have elapse d sinc e applyin g liqui d gasket .

Instead reappl y liqui d gaske t afte r removin g ol d

residue .

• Afte r assembly , wai t a t leas t 2 0 minute s befor e

filling th e engin e wit h oil .

9. Instal l th e oi l pas s pip e an d joint .

10 . Instal l th e baffl e plate .

11 . Instal l th e oi l screen .

12 . Instal l th e oi l pa n (se e pag e 8-10 ).

CAUTION : Wheneve r an y crankshaf t o r connec -

tin g ro d bearin g i s replaced , afte r reassembly , ru n

th e engin e a t idlin g spee d unti l i t reache s norma l

operatin g temperature , the n continu e t o ru n fo r ap -

proximatel y 1 5 minutes .

OIL PUM P SIDE :

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

OIL SCREE NBAFFLE PLAT E

OIL PAS SPIPE

ProCarManuals.com

Page 763 of 1640

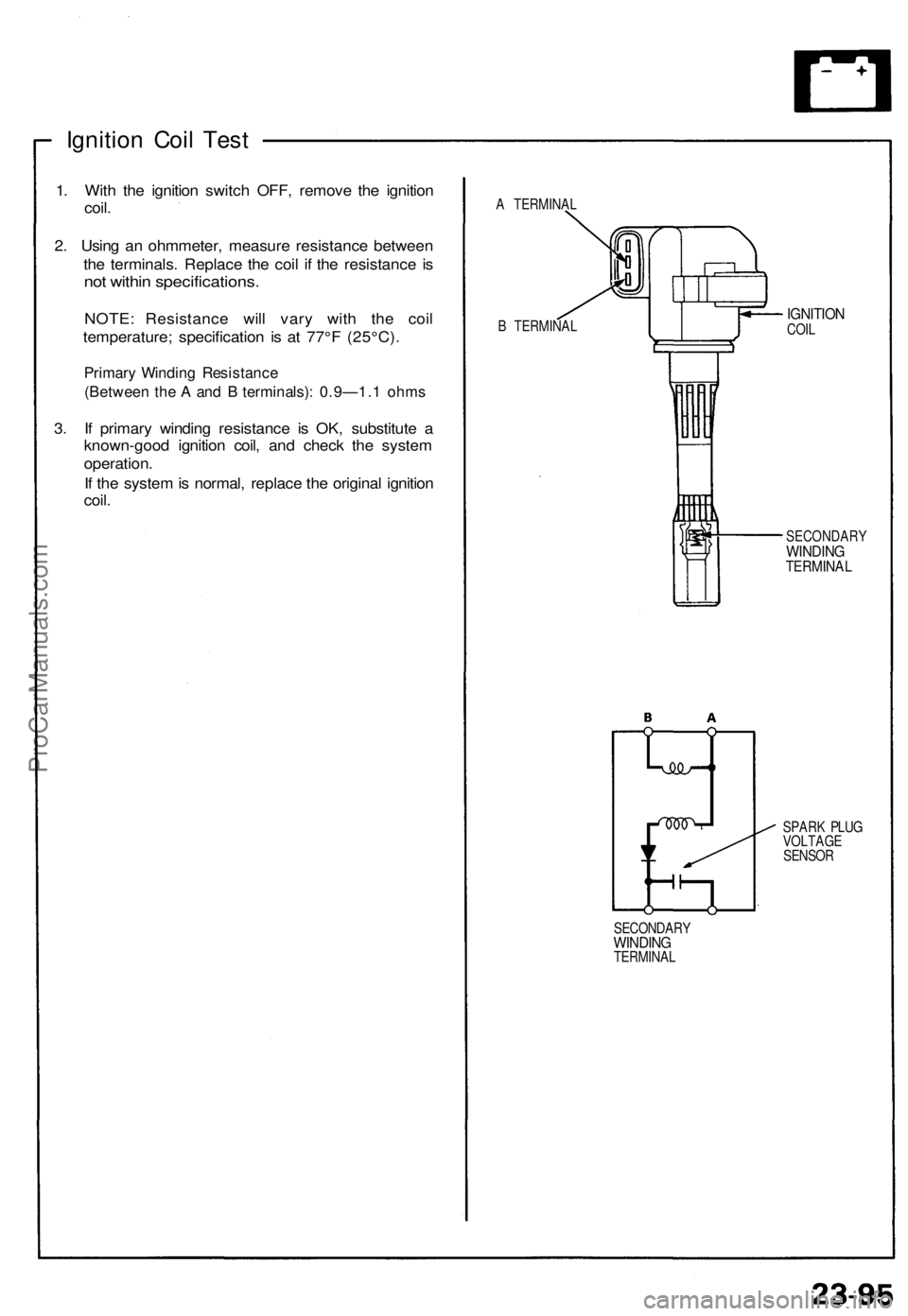

Ignition Coil Test

1. With the ignition switch OFF, remove the ignition

coil.

2. Using an ohmmeter, measure resistance between

the terminals. Replace the coil if the resistance is

not within specifications.

NOTE: Resistance will vary with the coil

temperature; specification is at 77°F (25°C).

Primary Winding Resistance

(Between the A and B terminals): 0.9—1.1 ohms

3. If primary winding resistance is OK, substitute a

known-good ignition coil, and check the system

operation.

If the system is normal, replace the original ignition

coil.

A TERMINAL

B TERMINAL

IGNITION

COIL

SECONDARY

WINDING

TERMINAL

SPARK PLUG

VOLTAGE

SENSOR

SECONDARY

WINDING

TERMINALProCarManuals.com

Page 786 of 1640

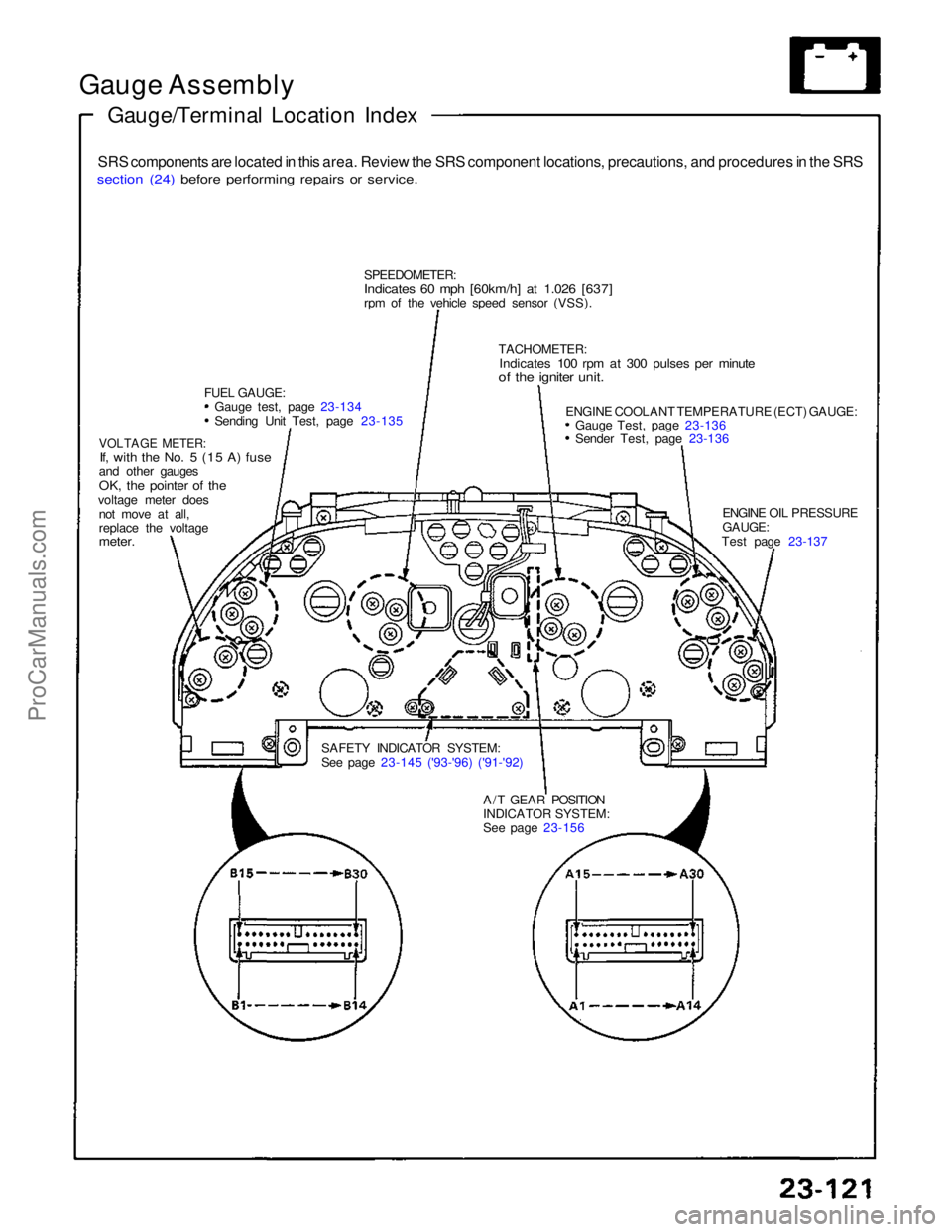

Gauge Assembly

Gauge/Terminal Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

SPEEDOMETER:

Indicates 60 mph [60km/h] at 1.026 [637]

rpm of the vehicle speed sensor (VSS).

FUEL GAUGE: Gauge test, page 23-134 Sending Unit Test, page 23-135

VOLTAGE METER:

If, with the No. 5 (15 A) fuse

and other gauges

OK, the pointer of the

voltage meter does not move at all,

replace the voltage

meter.

SAFETY INDICATOR SYSTEM:

See page 23-145 ('93-'96) ('91-'92)A/T GEAR POSITION

INDICATOR SYSTEM:

See page 23-156 ENGINE OIL PRESSURE

GAUGE:

Test page 23-137

ENGINE COOLANT TEMPERATURE (ECT) GAUGE:

Gauge Test, page 23-136 Sender Test, page 23-136

TACHOMETER:

Indicates 100 rpm at 300 pulses per minute

of the igniter unit.ProCarManuals.com

Page 790 of 1640

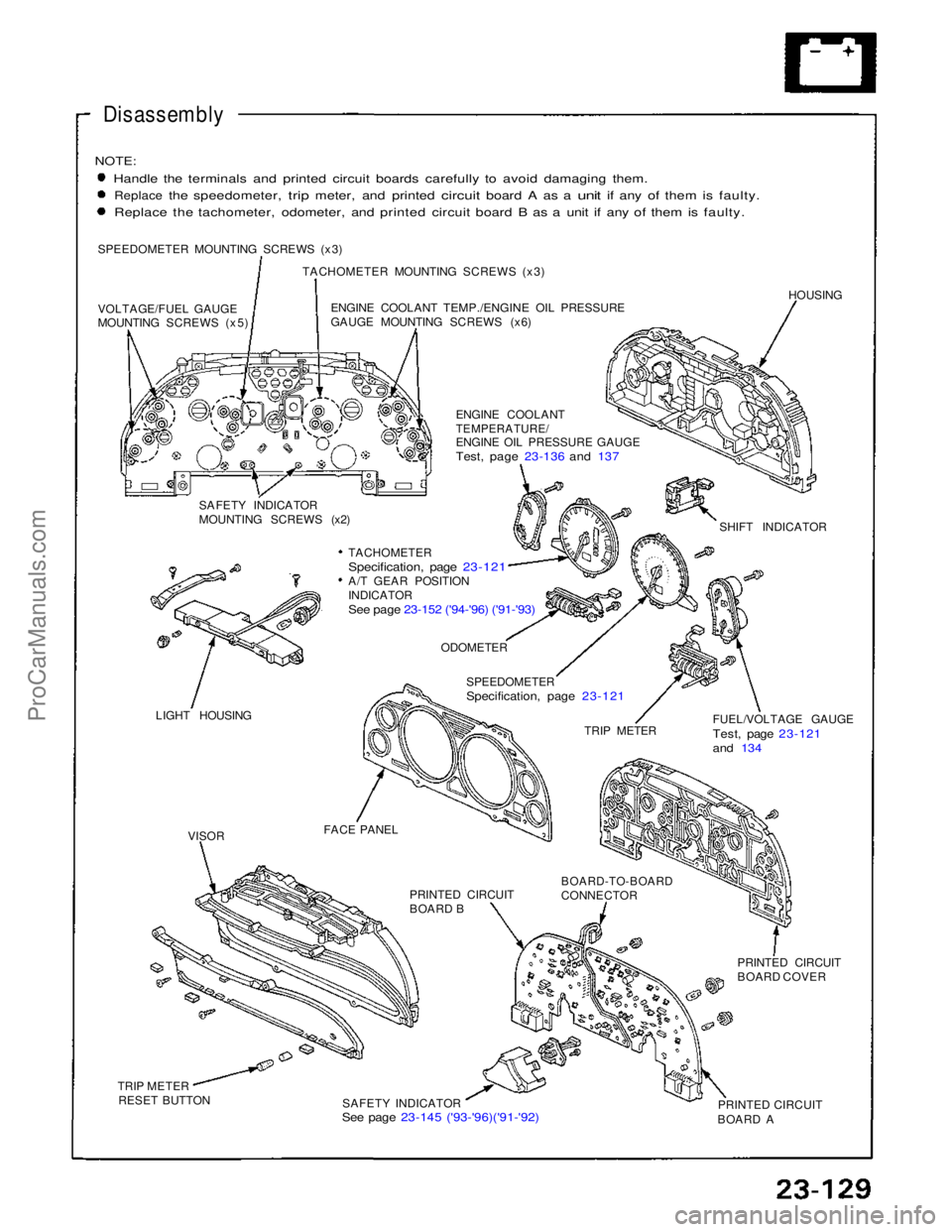

Disassembly

NOTE:

Handle the terminals and printed circuit boards carefully to avoid damaging them.

Replace

the

speedometer,

trip

meter,

and

printed

circuit

board

A as a

unit

if any of

them

is

faulty. Replace the tachometer, odometer, and printed circuit board B as a unit if any of them is faulty.

SPEEDOMETER MOUNTING SCREWS (x3) TACHOMETER MOUNTING SCREWS (x3)

VOLTAGE/FUEL GAUGE

MOUNTING SCREWS (x5) ENGINE COOLANT TEMP./ENGINE OIL PRESSURE

GAUGE MOUNTING SCREWS (x6)

HOUSING

ENGINE COOLANT

TEMPERATURE/

ENGINE OIL PRESSURE GAUGE

Test, page 23-136 and 137

SAFETY INDICATOR

MOUNTING SCREWS (x2) SHIFT INDICATOR

TACHOMETER

Specification, page 23-121

A/T GEAR POSITION

INDICATOR

See page 23-152 ('94-'96) ('91-'93)

LIGHT HOUSING

ODOMETER

SPEEDOMETER

Specification, page 23-121

TRIP METER FUEL/VOLTAGE GAUGE

Test, page 23-121

and 134

FACE PANEL PRINTED CIRCUIT

BOARD B

BOARD-TO-BOARD

CONNECTOR

PRINTED CIRCUIT

BOARD COVER

PRINTED CIRCUIT

BOARD A

SAFETY INDICATOR

See page 23-145 ('93-'96)('91-'92)

TRIP METER

RESET BUTTON

VISORProCarManuals.com

Page 965 of 1640

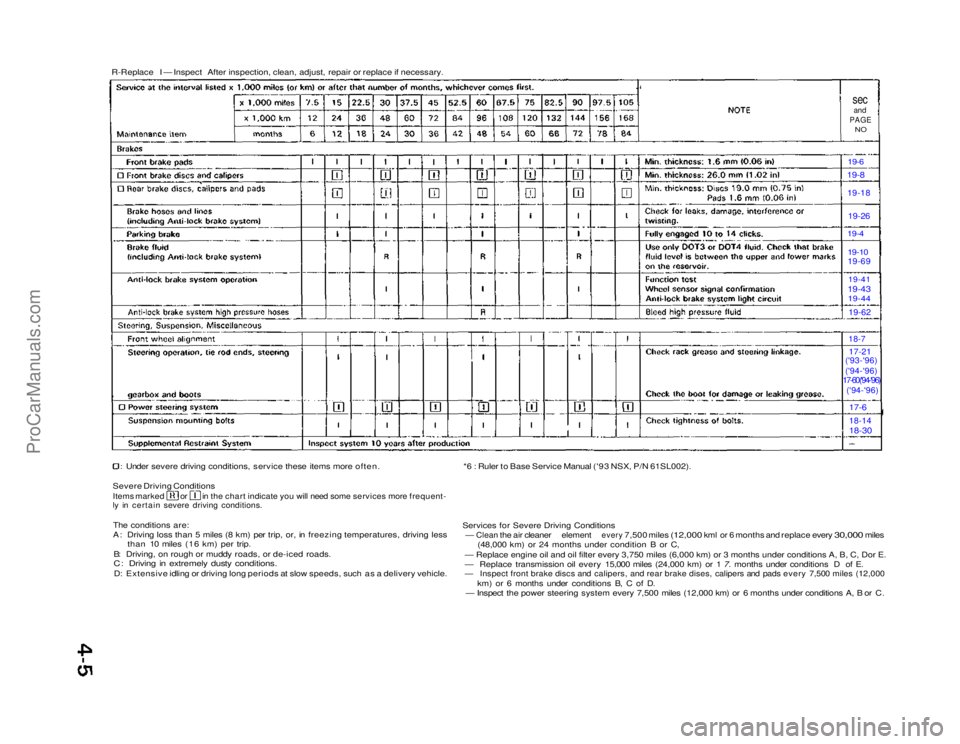

R-Replace I — Inspect After inspection, clean, adjust, repair or replace if necessary.

sec

and

PAGE

NO

19-6 19-8

19-18

19-26

19-4

19-10

19-69

19-41

19-43 19-44

19-62

18-7

17-21

('93-'96)

('94-'96)

17-60('94-'96)

('94-'96)

17-6

18-14

18-30

Under severe driving conditions, service these items more often.

Severe Driving Conditions

Items marked or in the chart indicate you will need some services more frequent-

ly in certain severe driving conditions.

The conditions are:

A: Driving loss than 5 miles (8 km) per trip, or, in freezing temperatures, driving less than 10 miles (16 km) per trip.

B: Driving, on rough or muddy roads, or de-iced roads.

C: Driving in extremely dusty conditions.

D: Extensive idling or driving long periods at slow speeds, such as a delivery vehicle. *6 : Ruler to Base Service Manual ('93 NSX, P/N 61SL002).

Services for Severe Driving Conditions

—

Clean

the air

cleaner

element

every

7,500 miles

(12,000

kml or 6

months

and

replace every

30,000

miles (48,000 km) or 24 months under condition B or C,

— Replace engine oil and oil filter every 3,750 miles (6,000 km) or\

3 months under conditions A, B, C, Dor E.

— Replace transmission oil every 15,000 miles (24,000 km) or 1 7. months under conditions D of E.

— Inspect front brake discs and calipers, and rear brake dises, calipers and pads every 7,500 miles (12,000

km) or 6 months under conditions B, C of D.

— Inspect the power steering system every 7,500 miles (12,000 km) or 6 months under conditions A, B or C.ProCarManuals.com

Page 966 of 1640

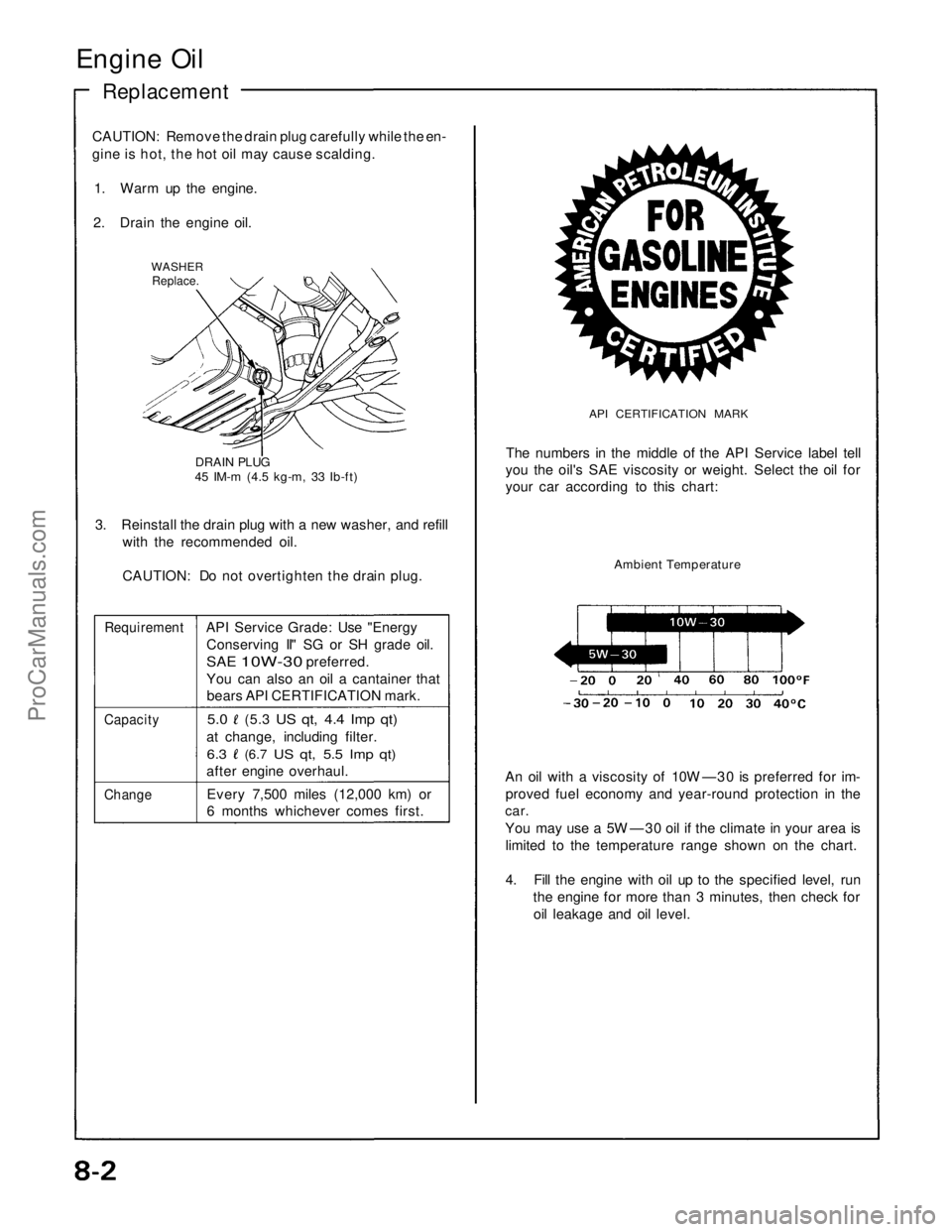

Engine Oil

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 973 of 1640

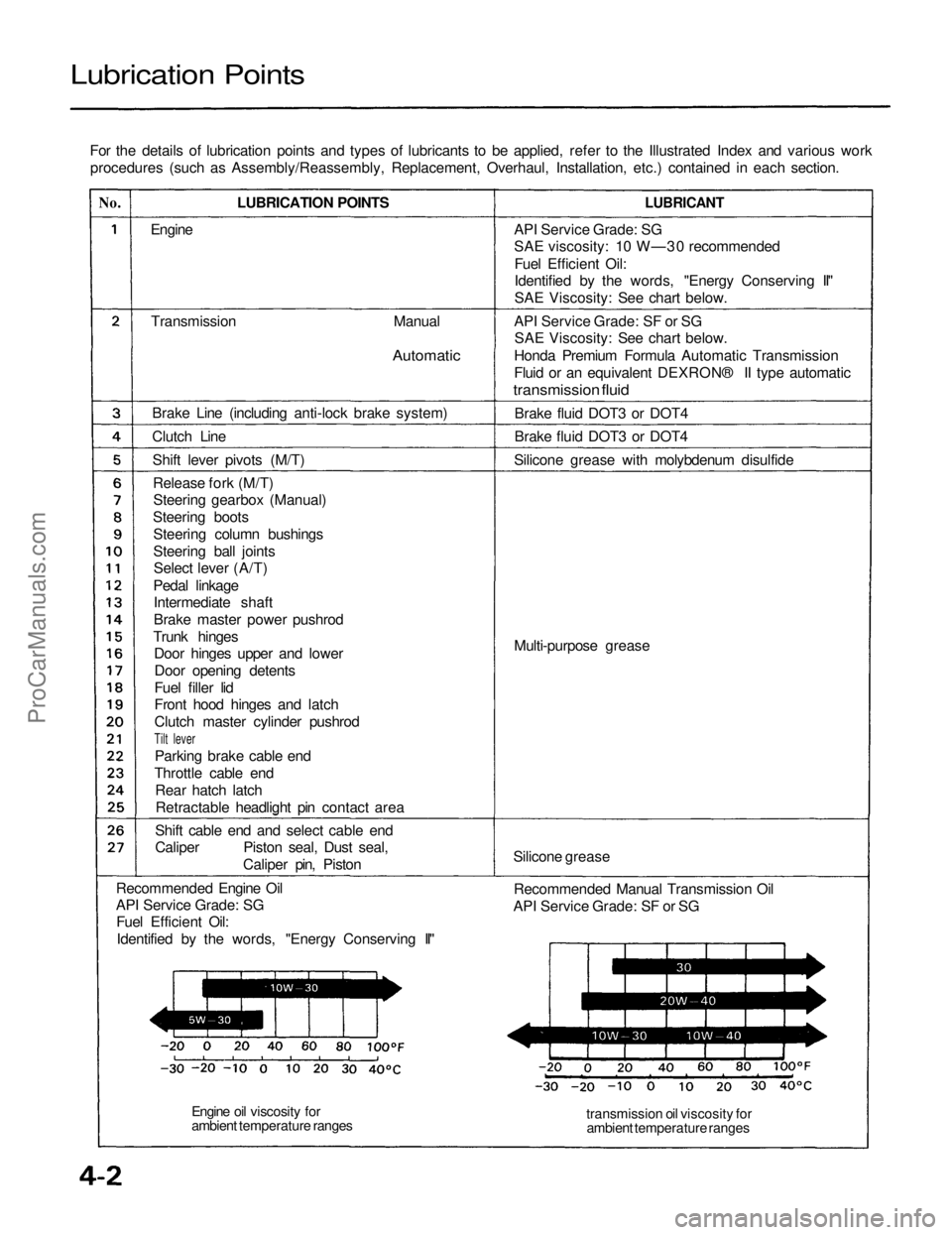

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the Illustrated Index and various workprocedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

LUBRICATION POINTS

LUBRICANT

Engine

Transmission

Manual

Automatic

Brake Line (including anti-lock brake system)

Clutch Line Shift lever pivots (M/T)Release fork (M/T)Steering gearbox (Manual)

Steering boots Steering column bushings

Steering ball jointsSelect lever (A/T)

Pedal linkage Intermediate shaft

Brake master power pushrod

Trunk hinges Door hinges upper and lower

Door opening detents

Fuel filler lid

Front hood hinges and latch

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Throttle cable end Rear hatch latchRetractable headlight pin contact area

Shift cable end and select cable end

Caliper Piston seal, Dust seal, Caliper pin, Piston

Recommended Engine Oil

API Service Grade: SG Fuel Efficient Oil:

Identified by the words, "Energy Conserving II" API Service Grade: SG

SAE viscosity: 10 W—30 recommended

Fuel Efficient Oil:

Identified by the words, "Energy Conserving II"

SAE Viscosity: See chart below.

API Service Grade: SF or SG SAE Viscosity: See chart below.

Honda Premium Formula Automatic Transmission

Fluid or an equivalent DEXRON® II type automatic

transmission fluid

Brake fluid DOT3 or DOT4

Brake fluid DOT3 or DOT4

Silicone grease with molybdenum disulfide

Multi-purpose grease

Silicone grease Recommended Manual Transmission Oil

API Service Grade: SF or SG

transmission oil viscosity forambient temperature ranges

Engine oil viscosity for

ambient temperature rangesProCarManuals.com