battery replacement ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 358 of 1503

Power Door Locks

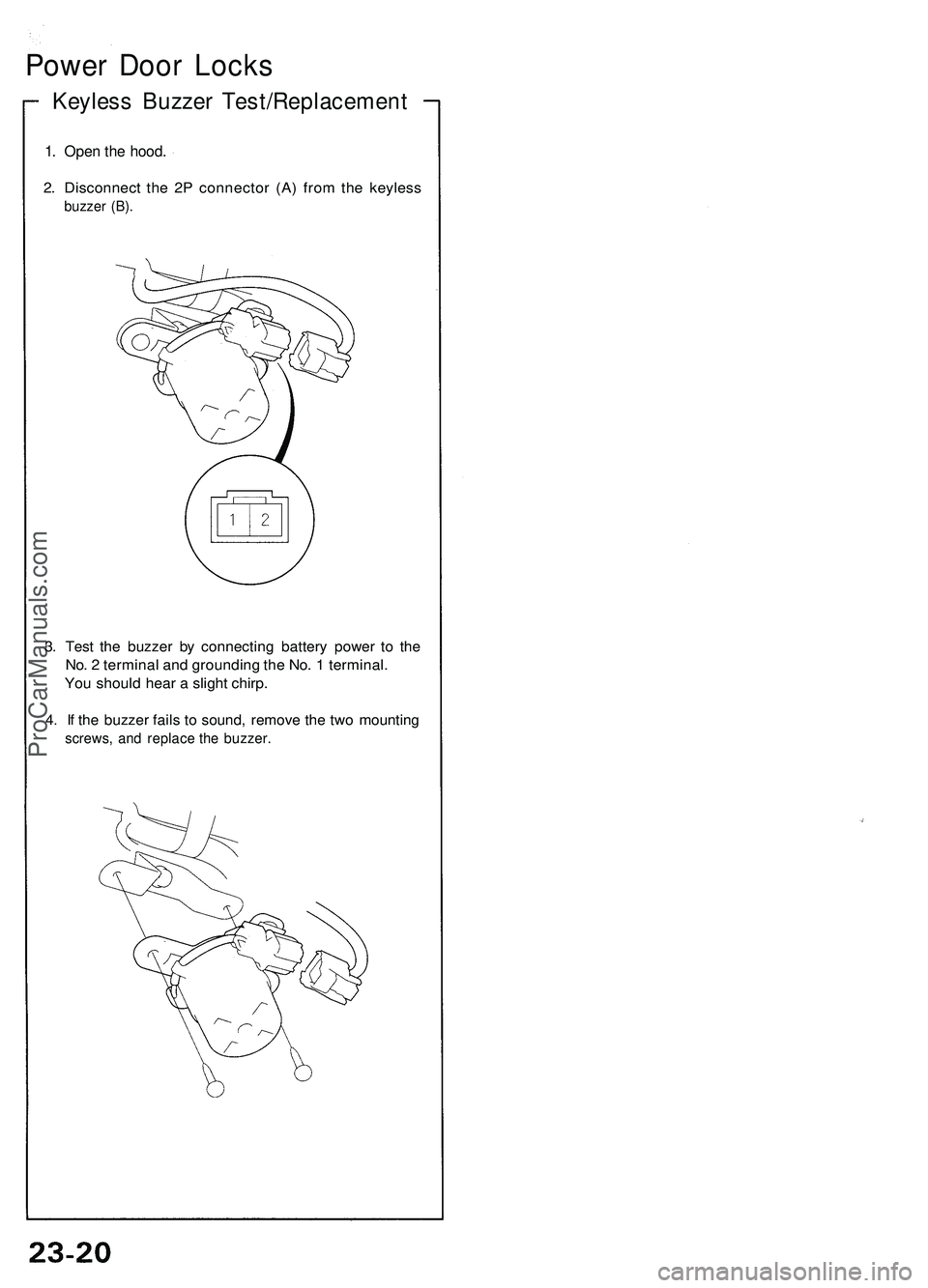

Keyless Buzzer Test/Replacement

1. Open the hood.

2. Disconnect the 2P connector (A) from the keyless

buzzer (B).

3. Test the buzzer by connecting battery power to the

No. 2 terminal and grounding the No. 1 terminal.

You should hear a slight chirp.

4. If the buzzer fails to sound, remove the two mounting

screws, and replace the buzzer.ProCarManuals.com

Page 659 of 1503

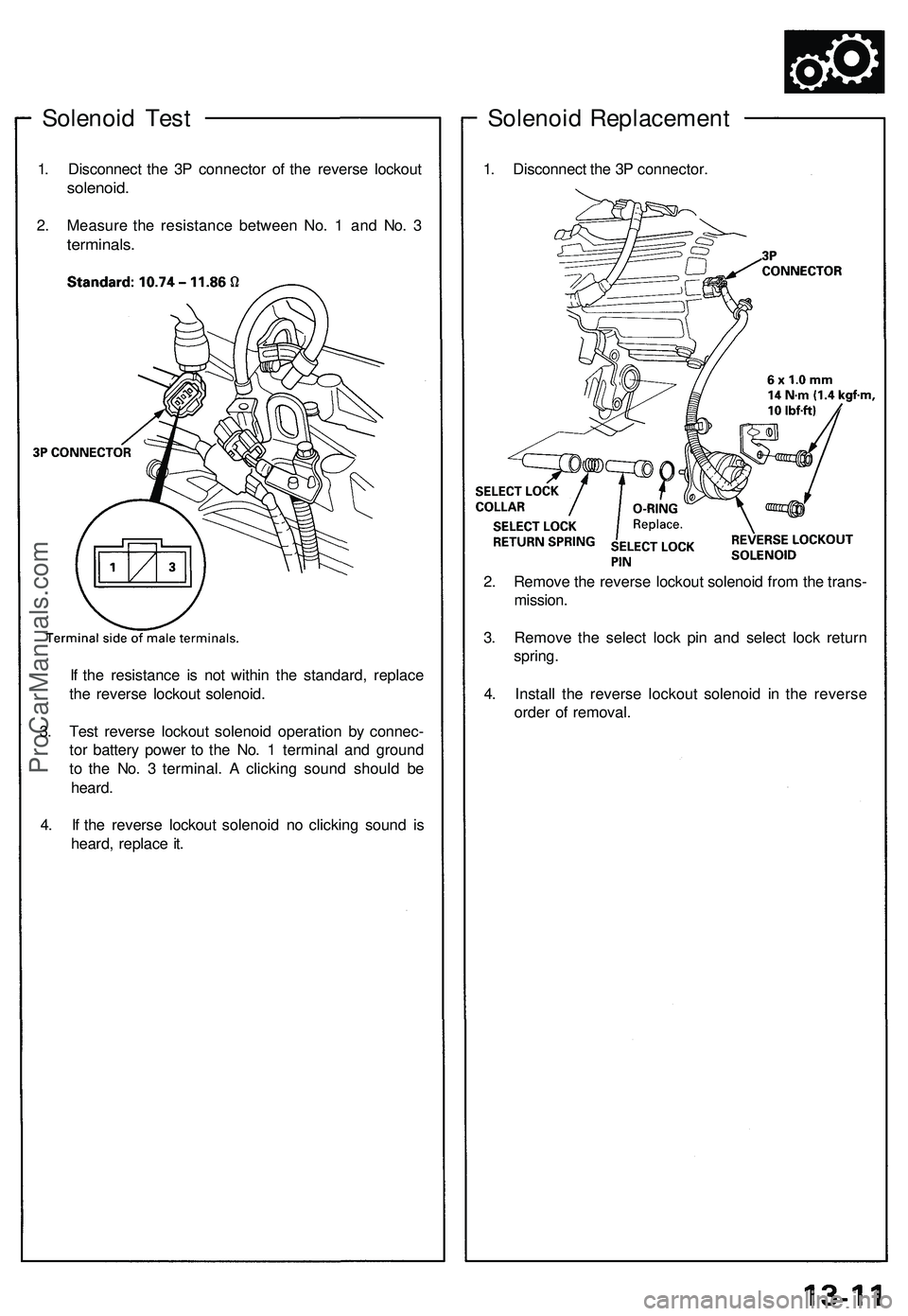

Solenoid Test

1. Disconnect the 3P connector of the reverse lockout

solenoid.

2. Measure the resistance between No. 1 and No. 3

terminals.

If the resistance is not within the standard, replace

the reverse lockout solenoid.

3. Test reverse lockout solenoid operation by connec-

tor battery power to the No. 1 terminal and ground

to the No. 3 terminal. A clicking sound should be

heard.

4. If the reverse lockout solenoid no clicking sound is

heard, replace it.

Solenoid Replacement

1. Disconnect the 3P connector.

2. Remove the reverse lockout solenoid from the trans-

mission.

3. Remove the select lock pin and select lock return

spring.

4. Install the reverse lockout solenoid in the reverse

order of removal.ProCarManuals.com

Page 1197 of 1503

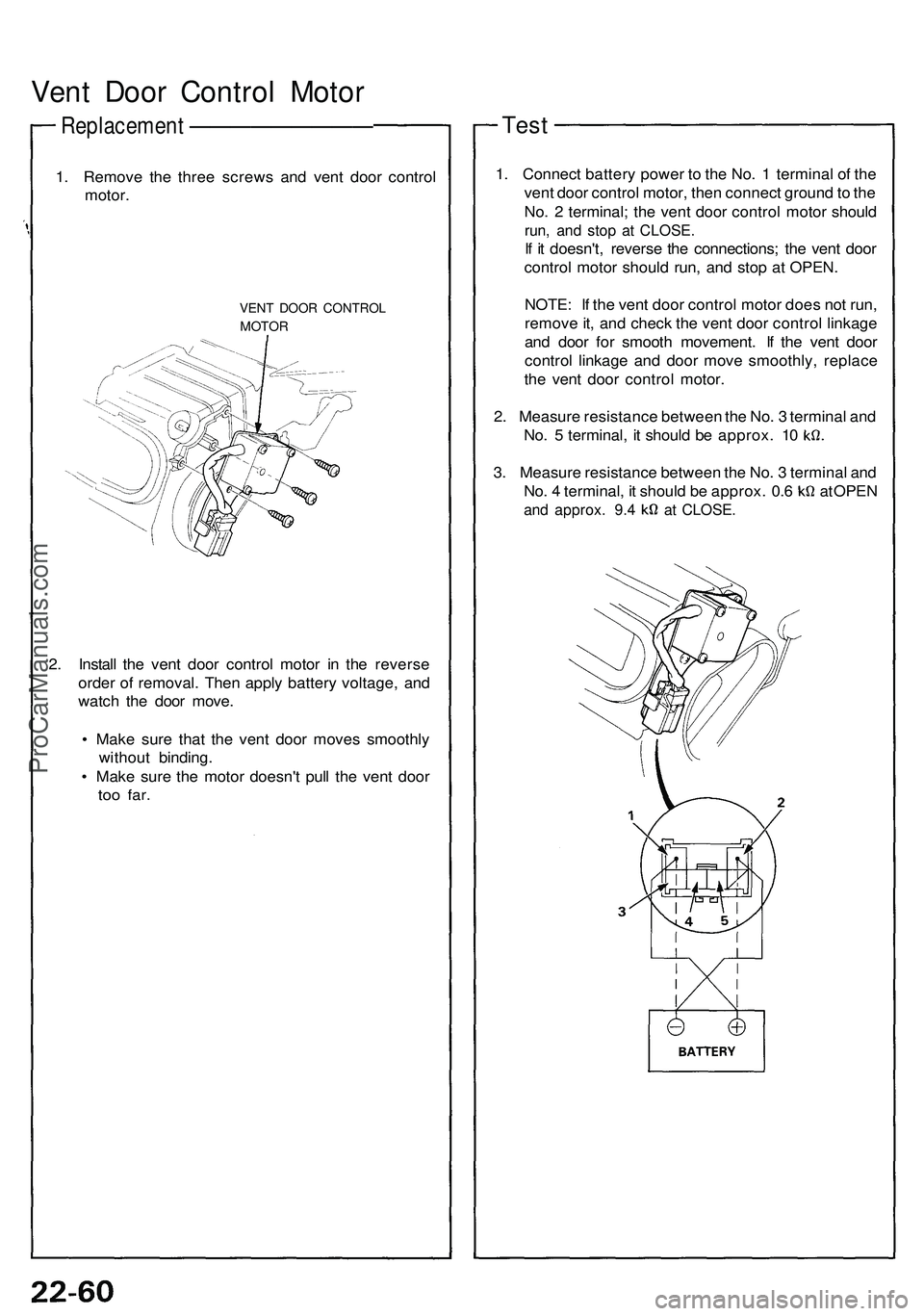

Vent Door Control Motor

Replacement —————————

1. Remove the three screws and vent door control

motor.

VENT DOOR CONTROL

MOTOR

2. Install the vent door control motor in the reverse

order of removal. Then apply battery voltage, and

watch the door move.

• Make sure that the vent door moves smoothly

without binding.

• Make sure the motor doesn't pull the vent door

too

far.

Test

1. Connect battery power to the No. 1 terminal of the

vent door control motor, then connect ground to the

No. 2 terminal; the vent door control motor should

run, and stop at CLOSE.

If it doesn't, reverse the connections; the vent door

control motor should run, and stop at OPEN.

NOTE: If the vent door control motor does not run,

remove it, and check the vent door control linkage

and door for smooth movement. If the vent door

control linkage and door move smoothly, replace

the vent door control motor.

2. Measure resistance between the No. 3 terminal and

No. 5 terminal, it should be approx. 10

3. Measure resistance between the No. 3 terminal and

No. 4 terminal, it should be approx. 0.6 at OPEN

and approx. 9.4 at CLOSE.ProCarManuals.com

Page 1216 of 1503

Replacement

1. Disconnec t th e negativ e cabl e fro m th e battery .

2 . Remov e th e fron t bumpe r (se e sectio n 20 ).

3 . Recove r th e refrigeran t usin g a R-134 a refrigeran t

Recover/Recycling/Chargin g Syste m (se e pag e

22-73 ).

4 . Disconnec t th e discharg e lin e C an d th e condense r

line s fro m th e condenser . Ca p th e ope n fitting s

immediatel y t o kee p moistur e an d dir t ou t o f th e

system .

(Right Condenser )

(Left Condenser )

CONDENSER

LIN E C

CONDENSE R

LIN E A

CONDENSE RLINE A

DISCHARG ELINEC

5. Disconnec t th e connecto r fro m th e condense r fan ,

remov e th e tw o mountin g bolt s an d nut , the n

remov e th e condenser .

CORROSIO N RESISTAN T BOL T

(Righ t Condenser )

RIGHT CONDENSE R

MOUNTING BOLT S6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

(Left Condenser )CONNECTORNUT

LEF T CONDENSE R

MOUNTING BOLT S6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

6. Instal l th e condense r i n th e revers e orde r o f

removal ; and :

• I f you'r e installin g a ne w condenser , ad d

refrigeran t oi l (ND-OI L 8 ) (se e pag e 22-69 ).

• Replac e O-ring s wit h ne w one s a t eac h fitting ,

an d appl y refrigeran t oi l t o them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r

R-134 a t o avoi d leakage .

• Charg e th e syste m (se e pag e 22-91 ), an d tes t it s

performanc e (se e pag e 22-70 ).

NU TCONNECTO R

ProCarManuals.com

Page 1220 of 1503

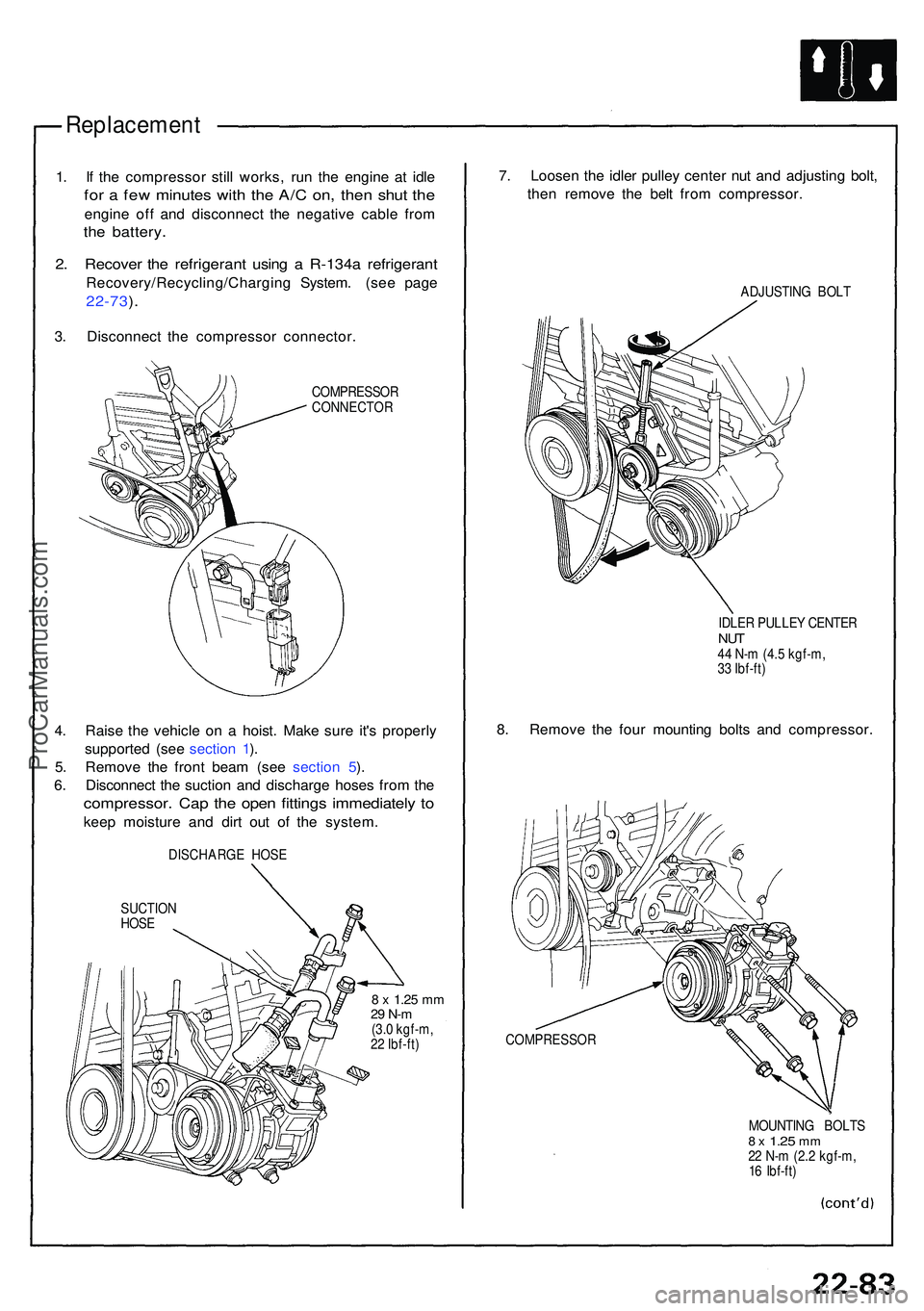

Replacement

1. I f th e compresso r stil l works , ru n th e engin e a t idl e

for a fe w minute s wit h th e A/ C on , the n shu t th e

engin e of f an d disconnec t th e negativ e cabl e fro m

the battery .

2. Recove r th e refrigeran t usin g a R-134 a refrigeran t

Recovery/Recycling/Chargin g System . (se e pag e

22-73 ).

3 . Disconnec t th e compresso r connector .

COMPRESSO R

CONNECTO R

4. Rais e th e vehicl e o n a hoist . Mak e sur e it' s properl y

supporte d (se e sectio n 1 ).

5 . Remov e th e fron t bea m (se e sectio n 5 ).

6 . Disconnec t th e suctio n an d discharg e hose s fro m th e

compressor . Ca p th e ope n fitting s immediatel y t o

kee p moistur e an d dir t ou t o f th e system .

DISCHARG E HOS E

SUCTIO N

HOS E

8 x 1.2 5 mm29 N- m(3.0 kgf-m ,

2 2 Ibf-ft )

7. Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e bel t fro m compressor .

ADJUSTING BOL T

IDLE R PULLE Y CENTE R

NUT44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

8. Remov e th e fou r mountin g bolt s an d compressor .

COMPRESSO R

MOUNTING BOLT S8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 1240 of 1503

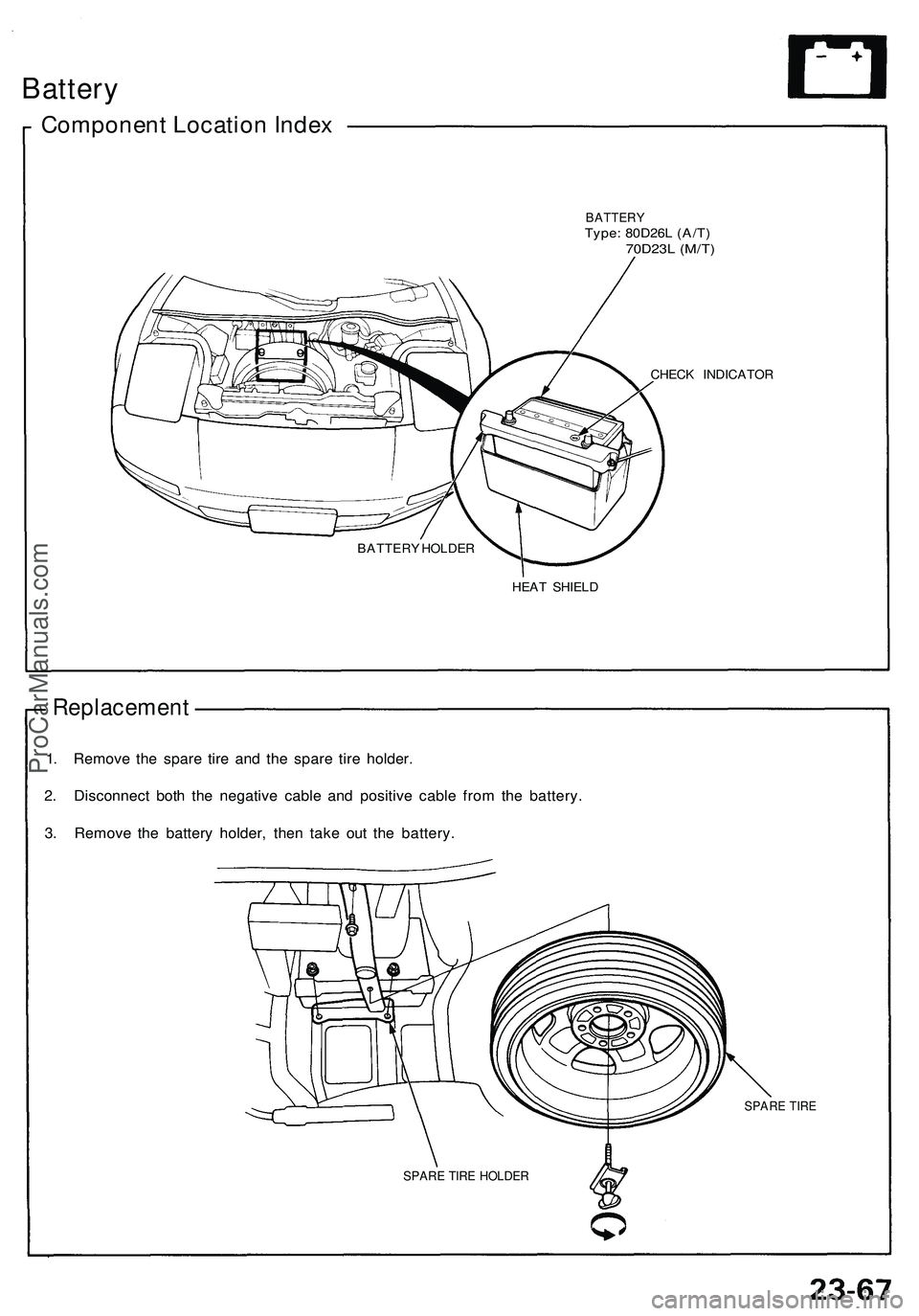

Battery

Component Location Index

BATTERY

Type: 80D26L (A/T)

70D23L (M/T)

CHECK INDICATOR

HEAT SHIELD

Replacement

1. Remove the spare tire and the spare tire holder.

2. Disconnect both the negative cable and positive cable from the battery.

3. Remove the battery holder, then take out the battery.

SPARE TIRE

BATTERY HOLDER

SPARE TIRE HOLDERProCarManuals.com

Page 1253 of 1503

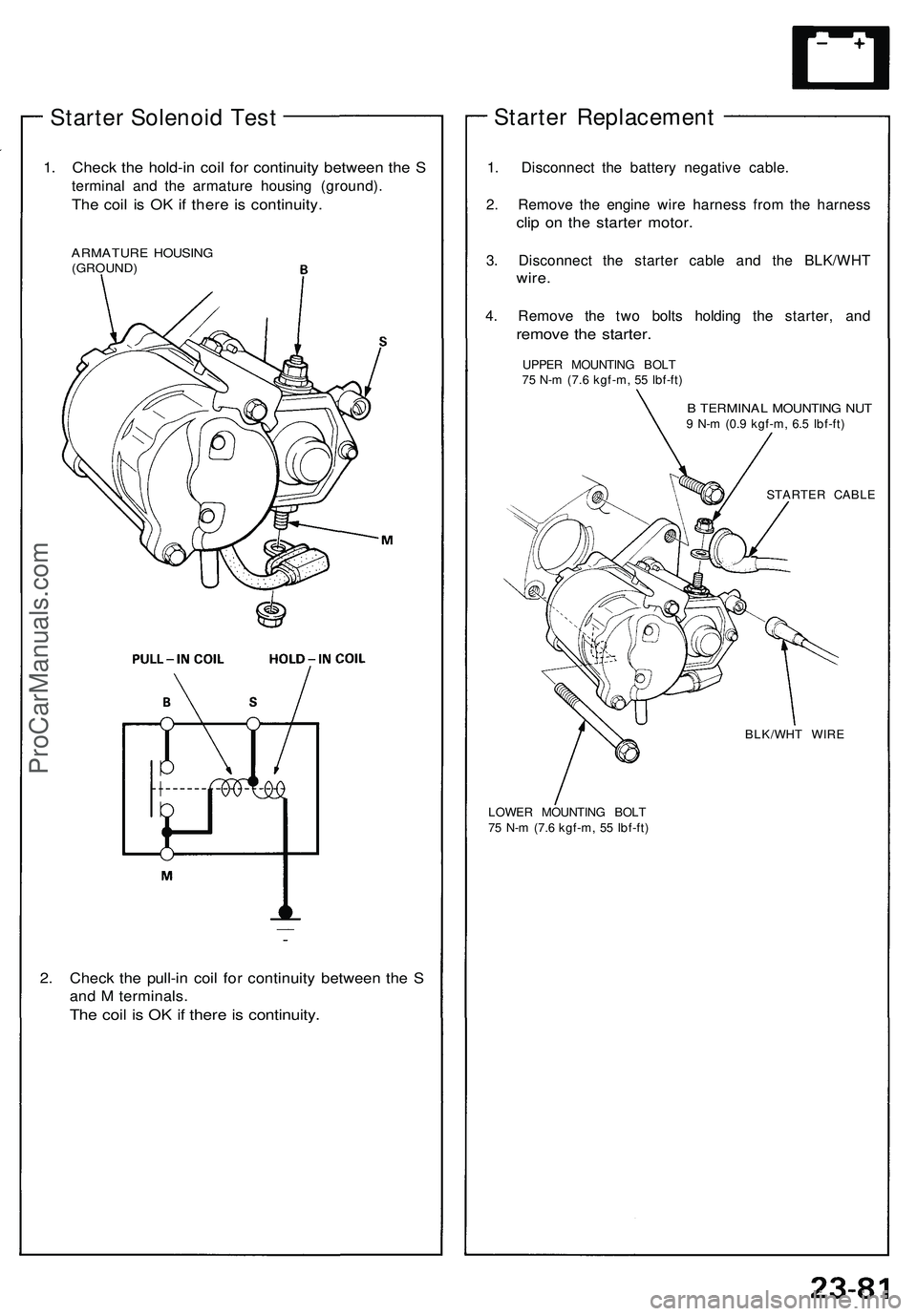

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

B TERMINAL MOUNTING NUT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

BLK/WHT WIREProCarManuals.com

Page 1400 of 1503

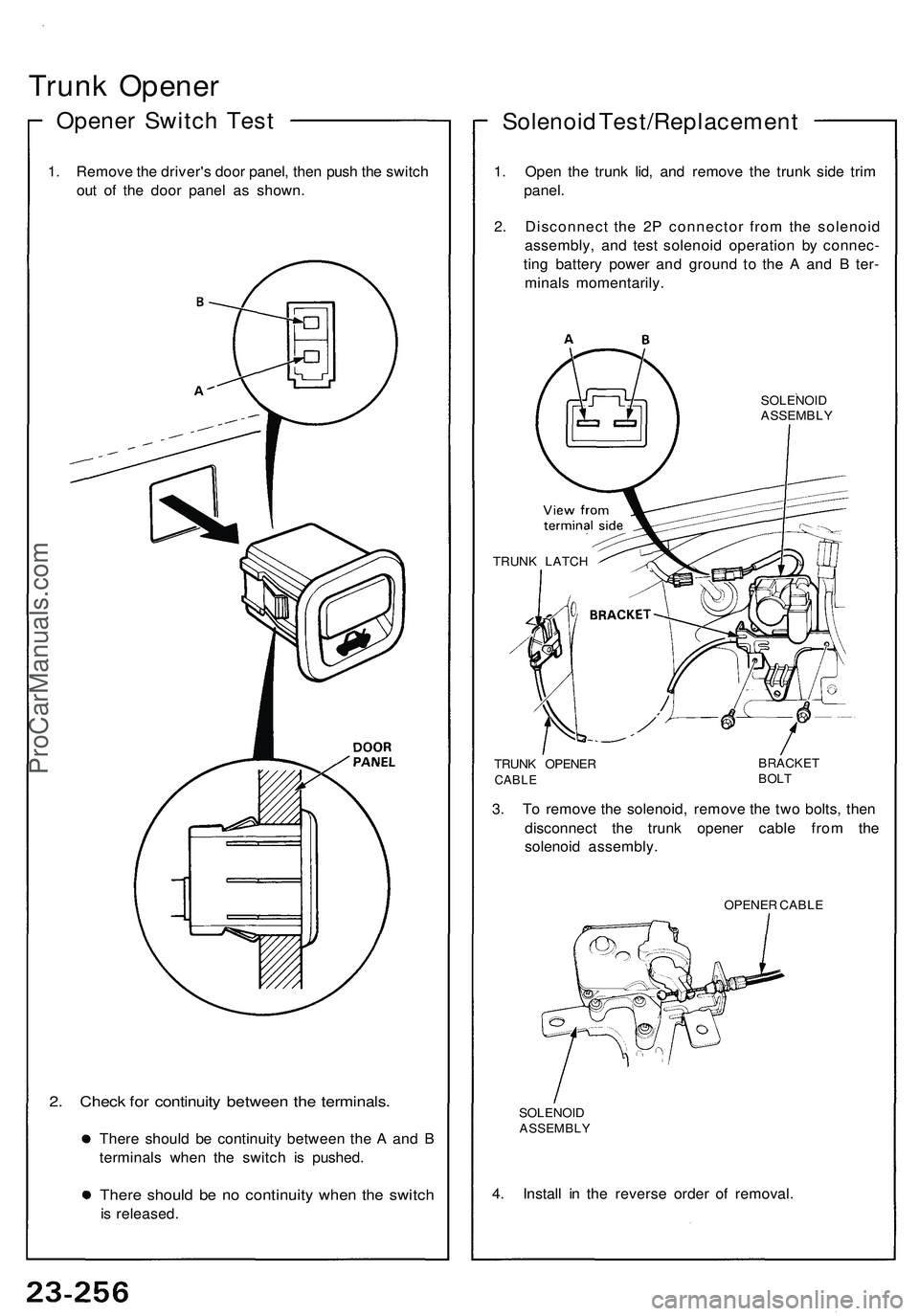

Trunk Opener

Opener Switch Test

1. Remove the driver's door panel, then push the switch

out of the door panel as shown.

2. Check for continuity between the terminals.

There should be continuity between the A and B

terminals when the switch is pushed.

There should be no continuity when the switch

is released.

Solenoid Test/Replacement

1. Open the trunk lid, and remove the trunk side trim

panel.

2. Disconnect the 2P connector from the solenoid

assembly, and test solenoid operation by connec-

ting battery power and ground to the A and B ter-

minals momentarily.

SOLENOID

ASSEMBLY

TRUNK LATCH

TRUNK OPENER

CABLE

BRACKET

BOLT

3. To remove the solenoid, remove the two bolts, then

disconnect the trunk opener cable from the

solenoid assembly.

OPENER CABLE

SOLENOID

ASSEMBLY

4. Install in the reverse order of removal.ProCarManuals.com

Page 1492 of 1503

Damaged Airbag or Tensioner Special Proce-

dure.

If an airbag or tensioner cannot be

deployed or triggered, it should not be treated as

normal scrap; it should still be considered a poten-

tially explosive device that can cause serious

injury.

1. If installed in a vehicle, follow the removal proce-

dures in this section.

2. Intertwine the stripped ends of the two airbag or ten-

sioner wires to make a short circuit.

3. Package the airbag or tensioner in exactly the same

packaging that the new replacement part came in.

4. Mark the outside of the box "DAMAGED AIRBAG

(or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock. If applicable,

also note on the box the VIN of the vehicle from

which it was removed.

5. Contact your Acura District Technical Manager for

how and where to return it for disposal.

Deployment Tool: Check Procedure.

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK; red means the tool is faulty.

3. Disconnect the battery and the yellow clips.ProCarManuals.com