key ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 144 of 1503

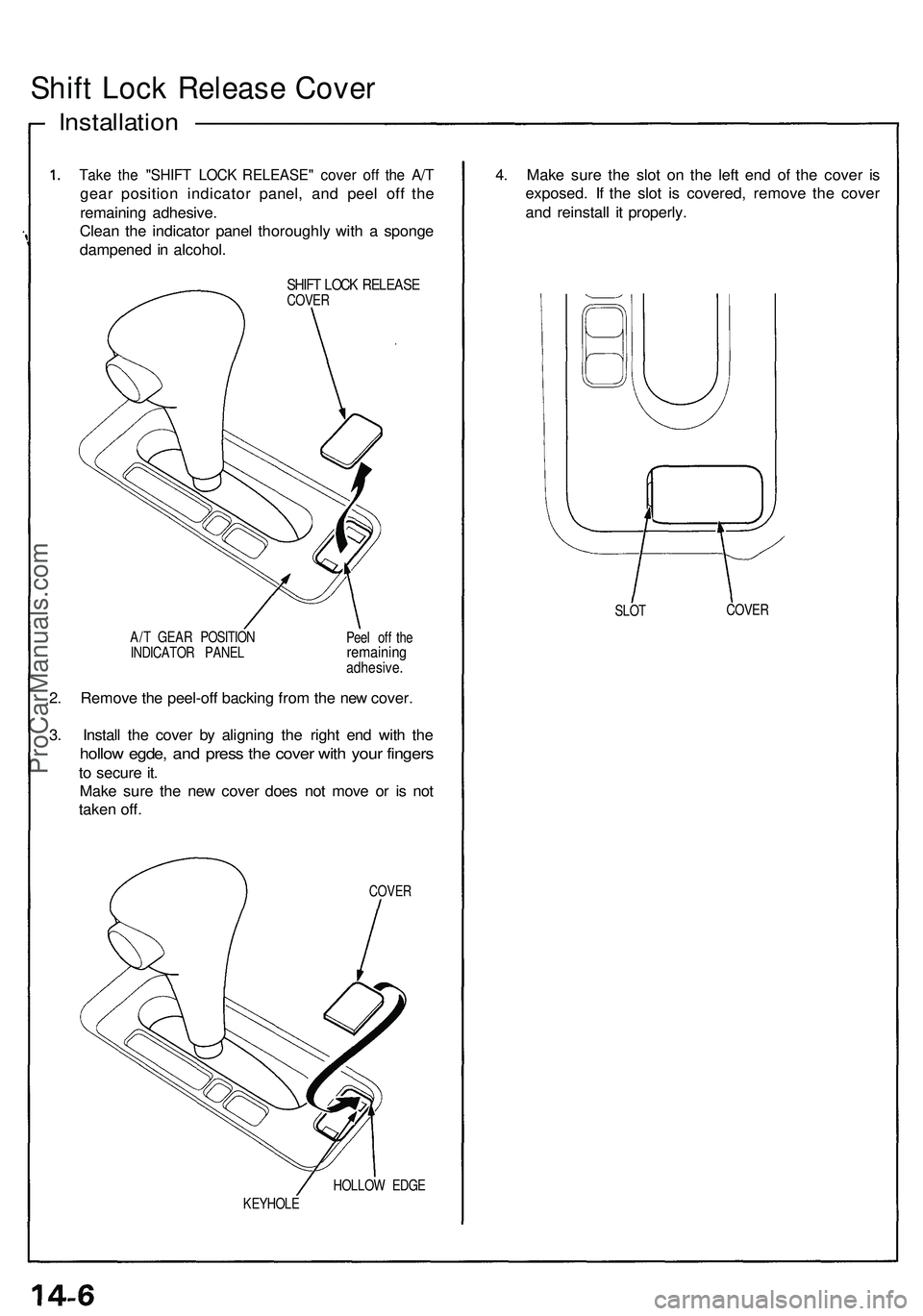

Shift Loc k Releas e Cove r

Installatio n ——————————

Take th e "SHIF T LOC K RELEASE " cove r of f th e A/ T

gea r positio n indicato r panel , an d pee l of f th e

remainin g adhesive .

Clea n th e indicato r pane l thoroughl y wit h a spong e

dampene d in alcohol .

SHIFT LOC K RELEAS ECOVER

A/ T GEA R POSITIO N

INDICATO R PANE L Pee

l of f th e

remainin gadhesive .

2. Remov e th e peel-of f backin g fro m th e ne w cover .

3 . Instal l th e cove r b y alignin g th e righ t en d wit h th e

hollo w egde , an d pres s th e cove r wit h you r finger s

to secur e it .

Mak e sur e th e ne w cove r doe s no t mov e o r i s no t

take n off .

COVE R

HOLLO W EDG E

KEYHOL E

4. Mak e sur e th e slo t o n th e lef t en d o f th e cove r i s

exposed . I f th e slo t i s covered , remov e th e cove r

an d reinstal l i t properly .

SLOT COVE

R

ProCarManuals.com

Page 277 of 1503

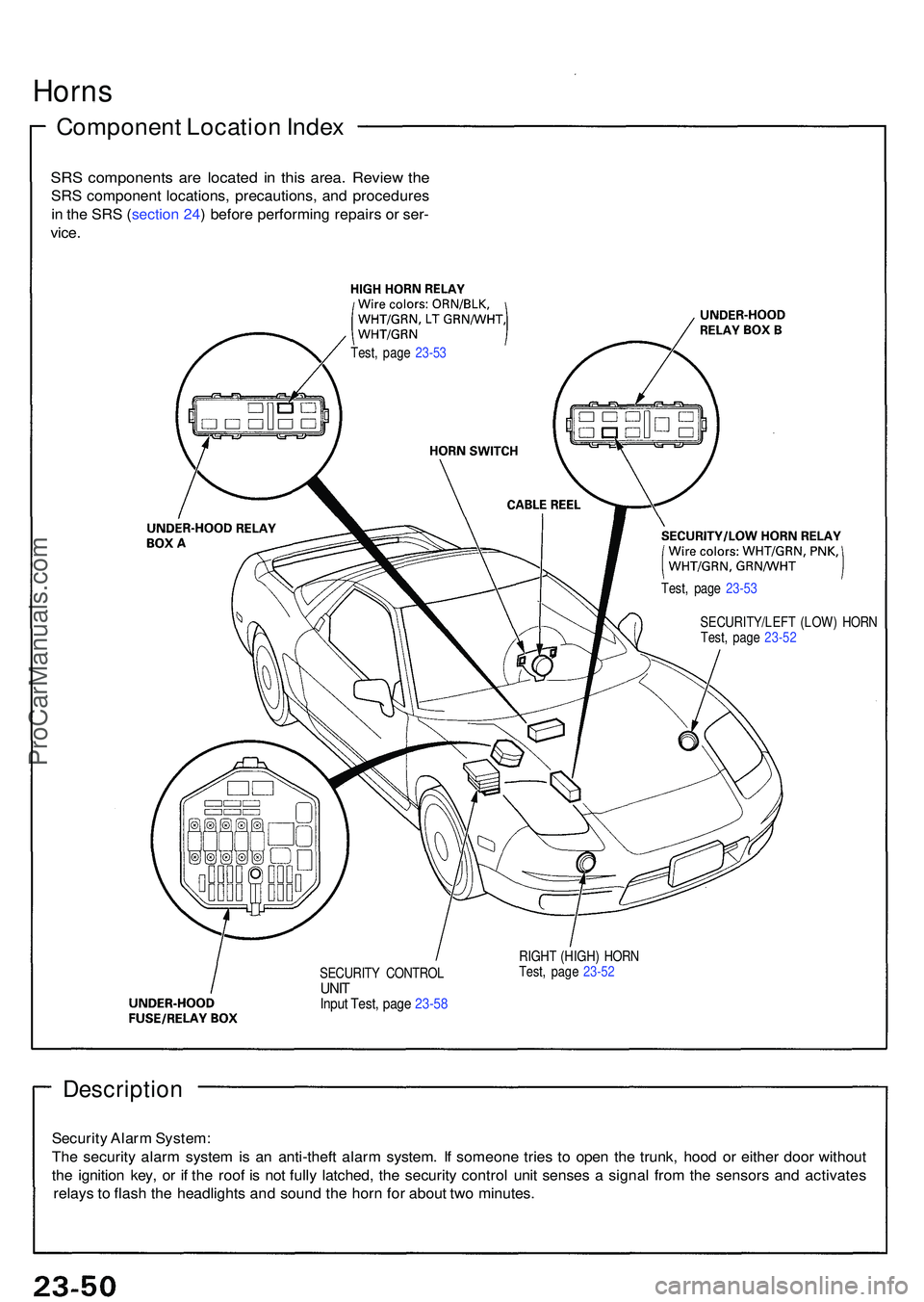

Description

Security Alar m System :

Th e securit y alar m syste m is a n anti-thef t alar m system . I f someon e trie s t o ope n th e trunk , hoo d o r eithe r doo r withou t

th e ignitio n key , o r i f th e roo f i s no t full y latched , th e securit y contro l uni t sense s a signa l fro m th e sensor s an d activate s

relay s t o flas h th e headlight s an d soun d th e hor n fo r abou t tw o minutes .

SECURIT Y CONTRO LUNITInpu t Test , pag e 23-5 8

RIGH T (HIGH ) HOR N

Test , pag e 23-5 2

Horn s

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

Test , pag e 23-5 3

Test, pag e 23-5 3

SECURITY/LEF T (LOW ) HOR N

Test , pag e 23-5 2

ProCarManuals.com

Page 353 of 1503

+

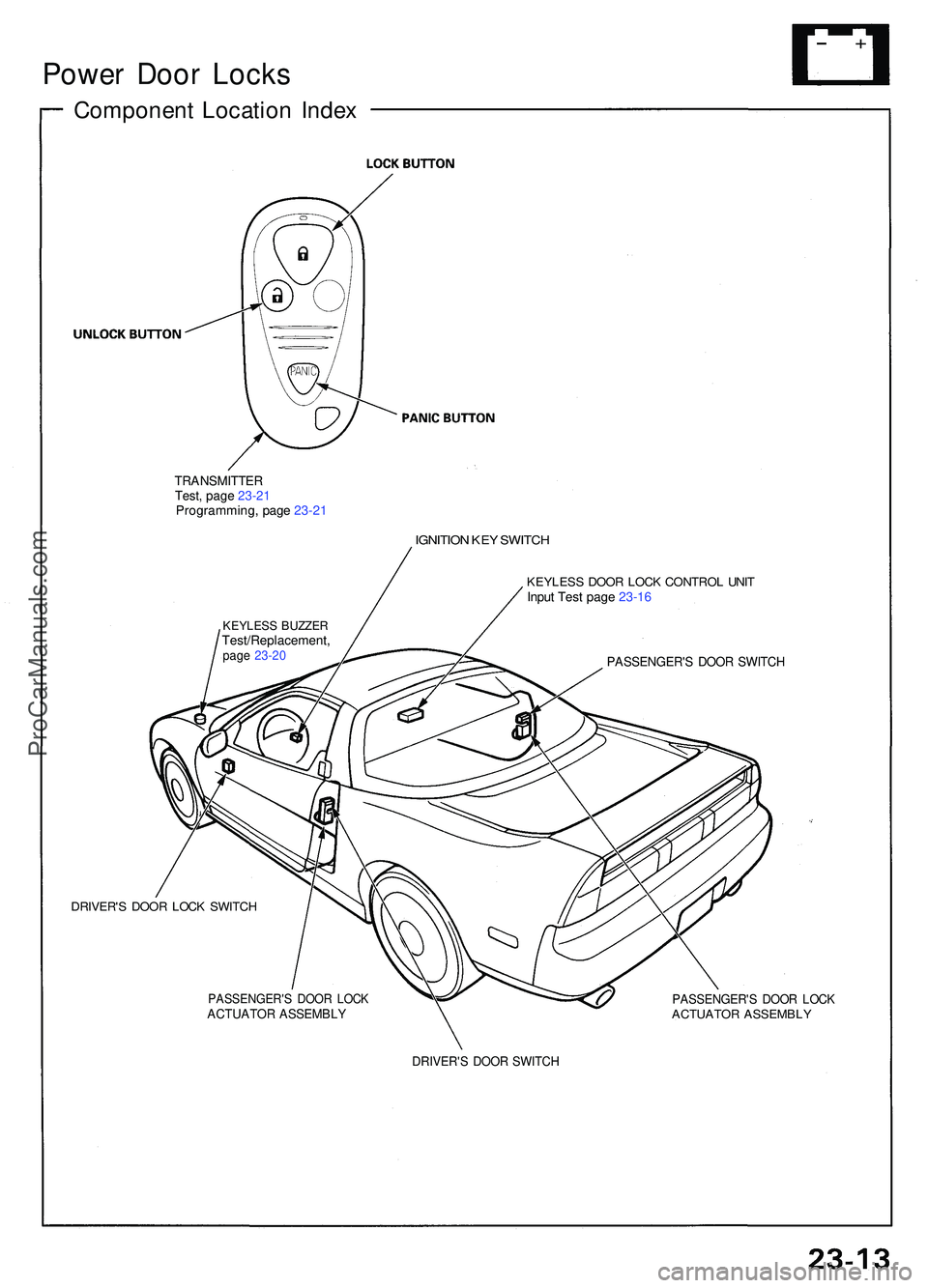

Power Doo r Lock s

Componen t Locatio n Inde x

TRANSMITTE RTest, pag e 23-2 1Programming , pag e 23-2 1

IGNITIO N KE Y SWITC H

KEYLES S DOO R LOC K CONTRO L UNI TInput Tes t pag e 23-1 6

PASSENGER' S DOO R SWITC H

DRIVER' S DOO R LOC K SWITC H

PASSENGER' S DOO R LOC KACTUATO R ASSEMBL YPASSENGER' S DOO R LOC KACTUATO R ASSEMBL Y

DRIVER'S DOO R SWITC H

KEYLES S BUZZE RTest/Replacement ,page 23-2 0

ProCarManuals.com

Page 358 of 1503

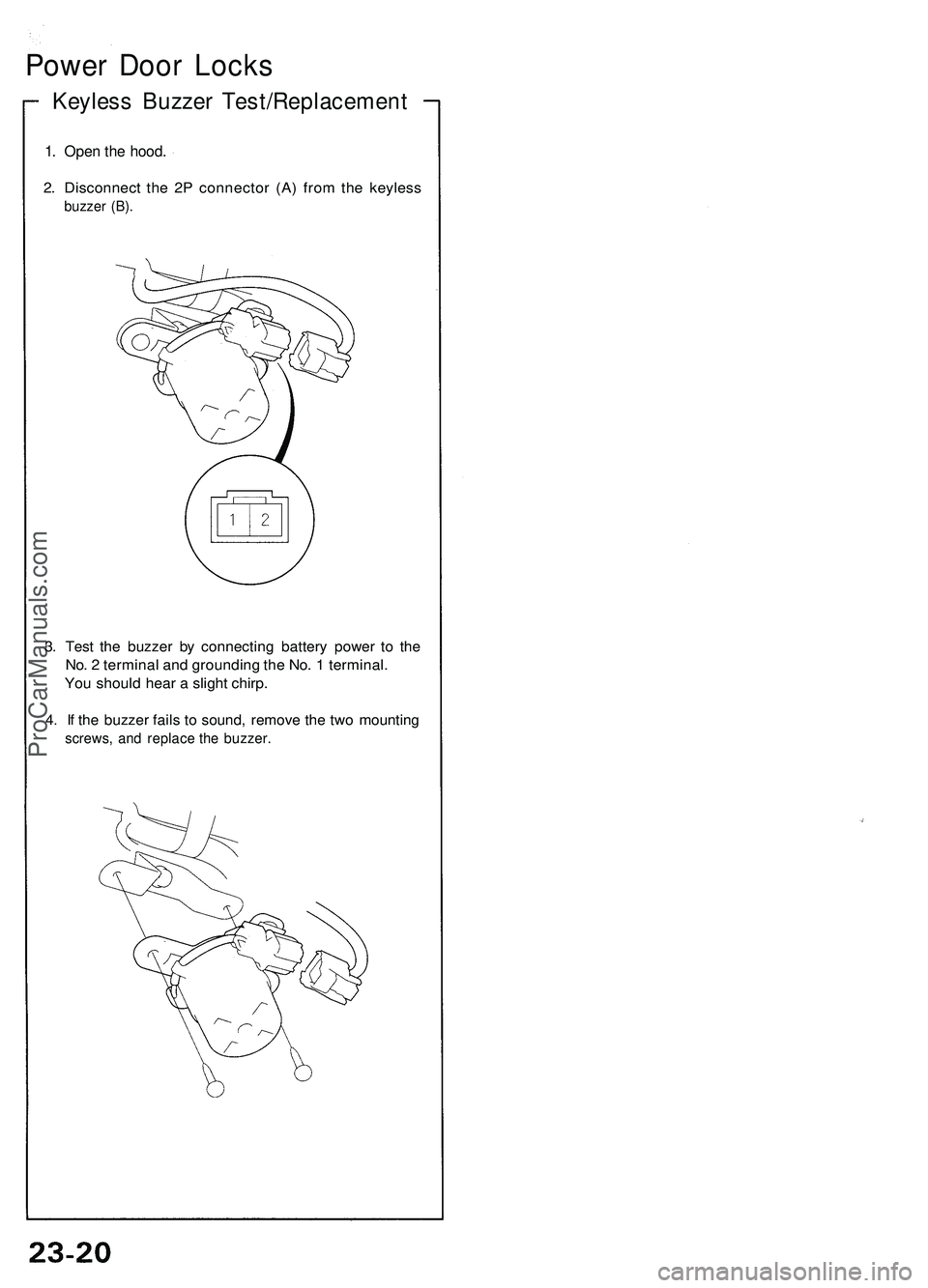

Power Door Locks

Keyless Buzzer Test/Replacement

1. Open the hood.

2. Disconnect the 2P connector (A) from the keyless

buzzer (B).

3. Test the buzzer by connecting battery power to the

No. 2 terminal and grounding the No. 1 terminal.

You should hear a slight chirp.

4. If the buzzer fails to sound, remove the two mounting

screws, and replace the buzzer.ProCarManuals.com

Page 359 of 1503

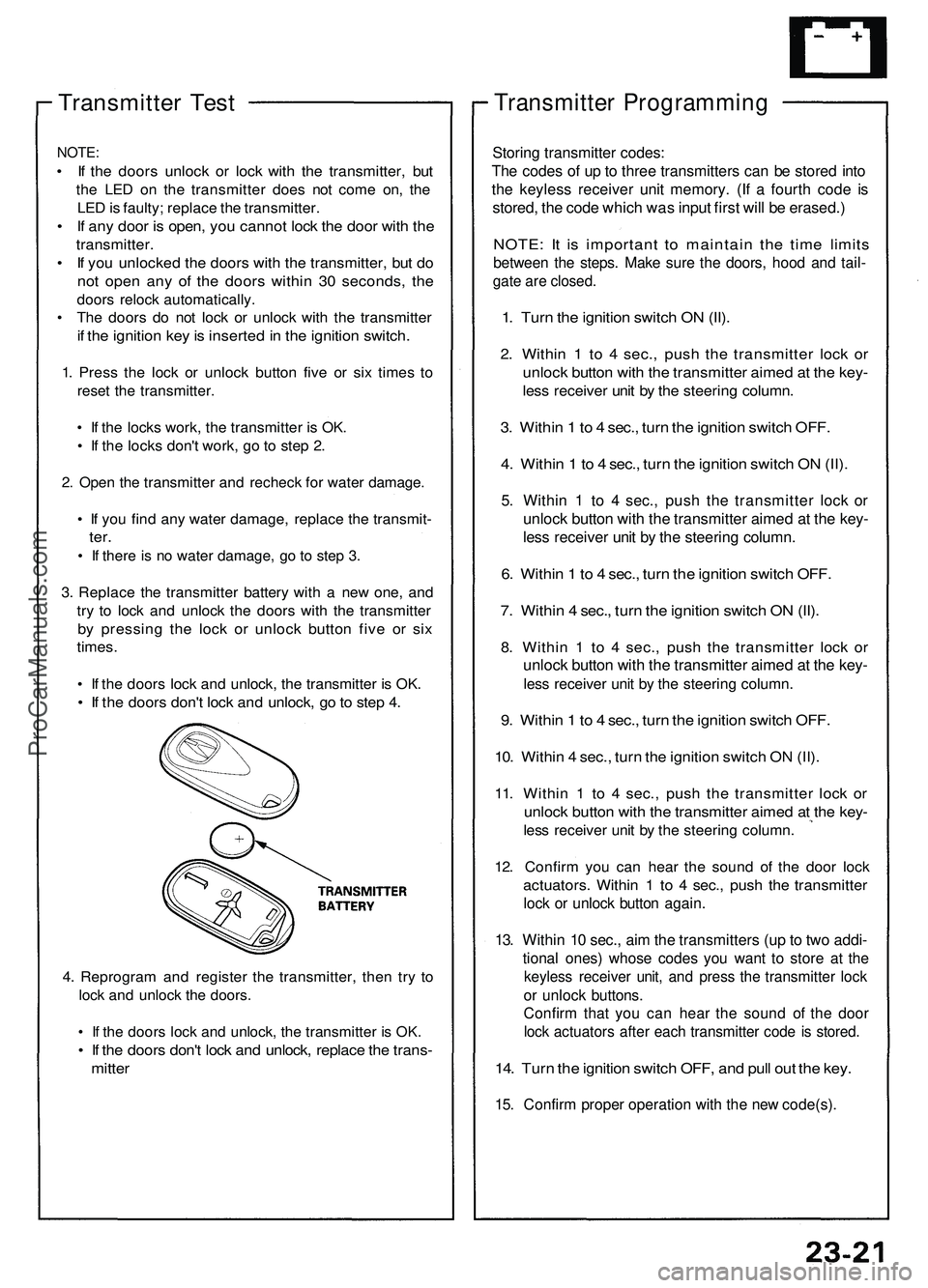

Transmitter Test

NOTE:

• If the doors unlock or lock with the transmitter, but

the LED on the transmitter does not come on, the

LED is faulty; replace the transmitter.

• If any door is open, you cannot lock the door with the

transmitter.

• If you unlocked the doors with the transmitter, but do

not open any of the doors within 30 seconds, the

doors relock automatically.

• The doors do not lock or unlock with the transmitter

if the ignition key is inserted in the ignition switch.

1. Press the lock or unlock button five or six times to

reset the transmitter.

• If the locks work, the transmitter is OK.

• If the locks don't work, go to step 2.

2. Open the transmitter and recheck for water damage.

• If you find any water damage, replace the transmit-

ter.

• If there is no water damage, go to step 3.

3. Replace the transmitter battery with a new one, and

try to lock and unlock the doors with the transmitter

by pressing the lock or unlock button five or six

times.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, go to step 4.

4. Reprogram and register the transmitter, then try to

lock and unlock the doors.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, replace the trans-

mitter

Transmitter Programming

Storing transmitter codes:

The codes of up to three transmitters can be stored into

the keyless receiver unit memory. (If a fourth code is

stored, the code which was input first will be erased.)

NOTE: It is important to maintain the time limits

between the steps. Make sure the doors, hood and tail-

gate are closed.

1. Turn the ignition switch ON (II).

2. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

3. Within 1 to 4 sec., turn the ignition switch OFF.

4. Within 1 to 4 sec., turn the ignition switch ON (II).

5. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

6. Within 1 to 4 sec., turn the ignition switch OFF.

7. Within 4 sec., turn the ignition switch ON (II).

8. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

9. Within 1 to 4 sec., turn the ignition switch OFF.

10. Within 4 sec., turn the ignition switch ON (II).

11. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

12. Confirm you can hear the sound of the door lock

actuators. Within 1 to 4 sec., push the transmitter

lock or unlock button again.

13. Within 10 sec., aim the transmitters (up to two addi-

tional ones) whose codes you want to store at the

keyless receiver unit, and press the transmitter lock

or unlock buttons.

Confirm that you can hear the sound of the door

lock actuators after each transmitter code is stored.

14. Turn the ignition switch OFF, and pull out the key.

15. Confirm proper operation with the new code(s).ProCarManuals.com

Page 435 of 1503

Timing Belt

Installation

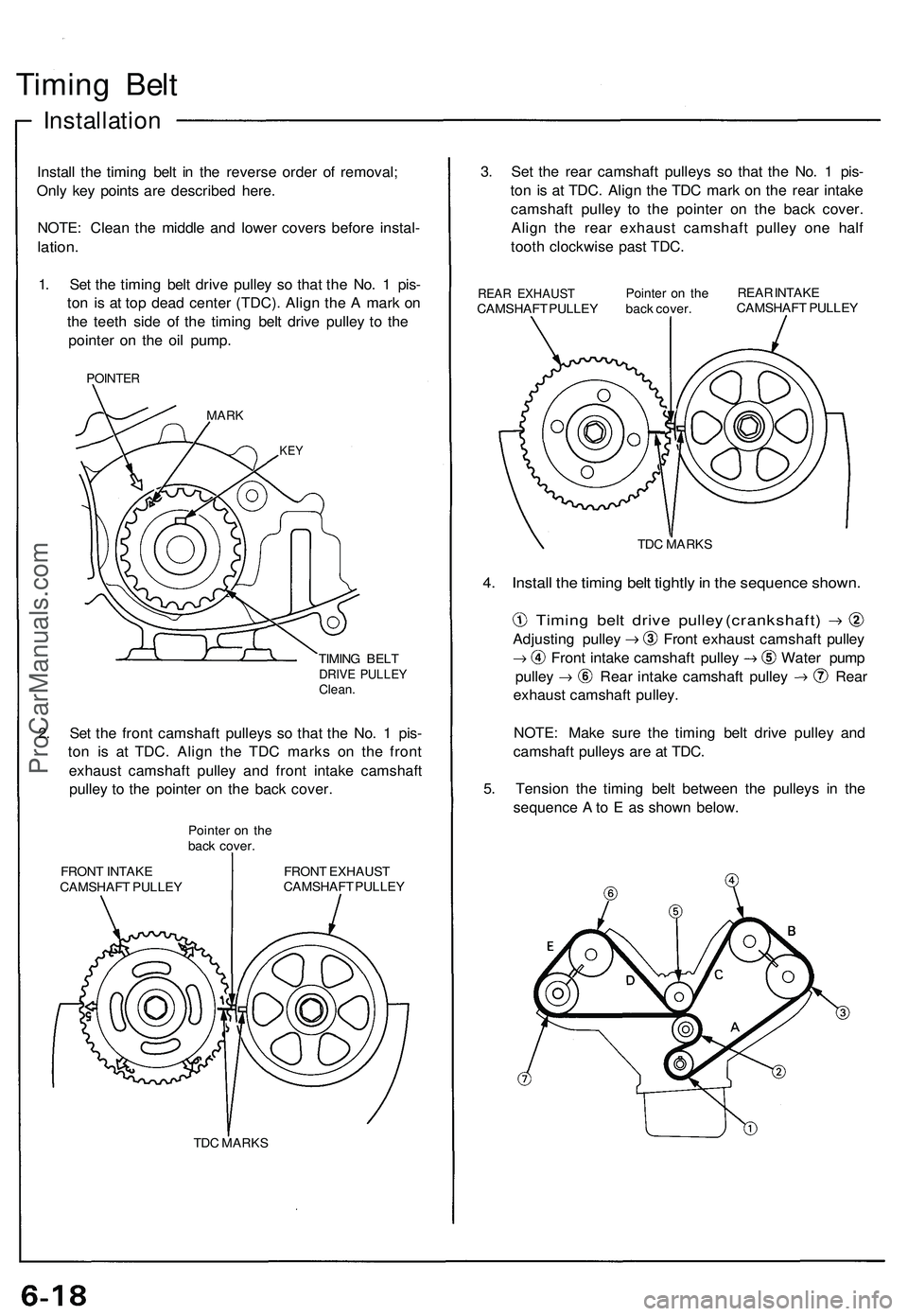

Install the timing belt in the reverse order of removal;

Only key points are described here.

NOTE: Clean the middle and lower covers before instal-

lation.

1. Set the timing belt drive pulley so that the No. 1 pis-

ton is at top dead center (TDC). Align the A mark on

the teeth side of the timing belt drive pulley to the

pointer on the oil pump.

POINTER

MARK

KEY

TIMING BELT

DRIVE PULLEY

Clean.

2. Set the front camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC marks on the front

exhaust camshaft pulley and front intake camshaft

pulley to the pointer on the back cover.

Pointer on the

back cover.

FRONT INTAKE

CAMSHAFT PULLEY

FRONT EXHAUST

CAMSHAFT PULLEY

TDC MARKS

3. Set the rear camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC mark on the rear intake

camshaft pulley to the pointer on the back cover.

Align the rear exhaust camshaft pulley one half

tooth clockwise past TDC.

REAR EXHAUST

CAMSHAFT PULLEY

Pointer on the

back cover.

REAR INTAKE

CAMSHAFT PULLEY

TDC MARKS

4. Install the timing belt tightly in the sequence shown.

Timing belt drive pulley (crankshaft)

Adjusting pulley Front exhaust camshaft pulley

Front intake camshaft pulley Water pump

pulley Rear intake camshaft pulley Rear

exhaust camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

5. Tension the timing belt between the pulleys in the

sequence A to E as shown below.ProCarManuals.com

Page 469 of 1503

Camshafts

Installation

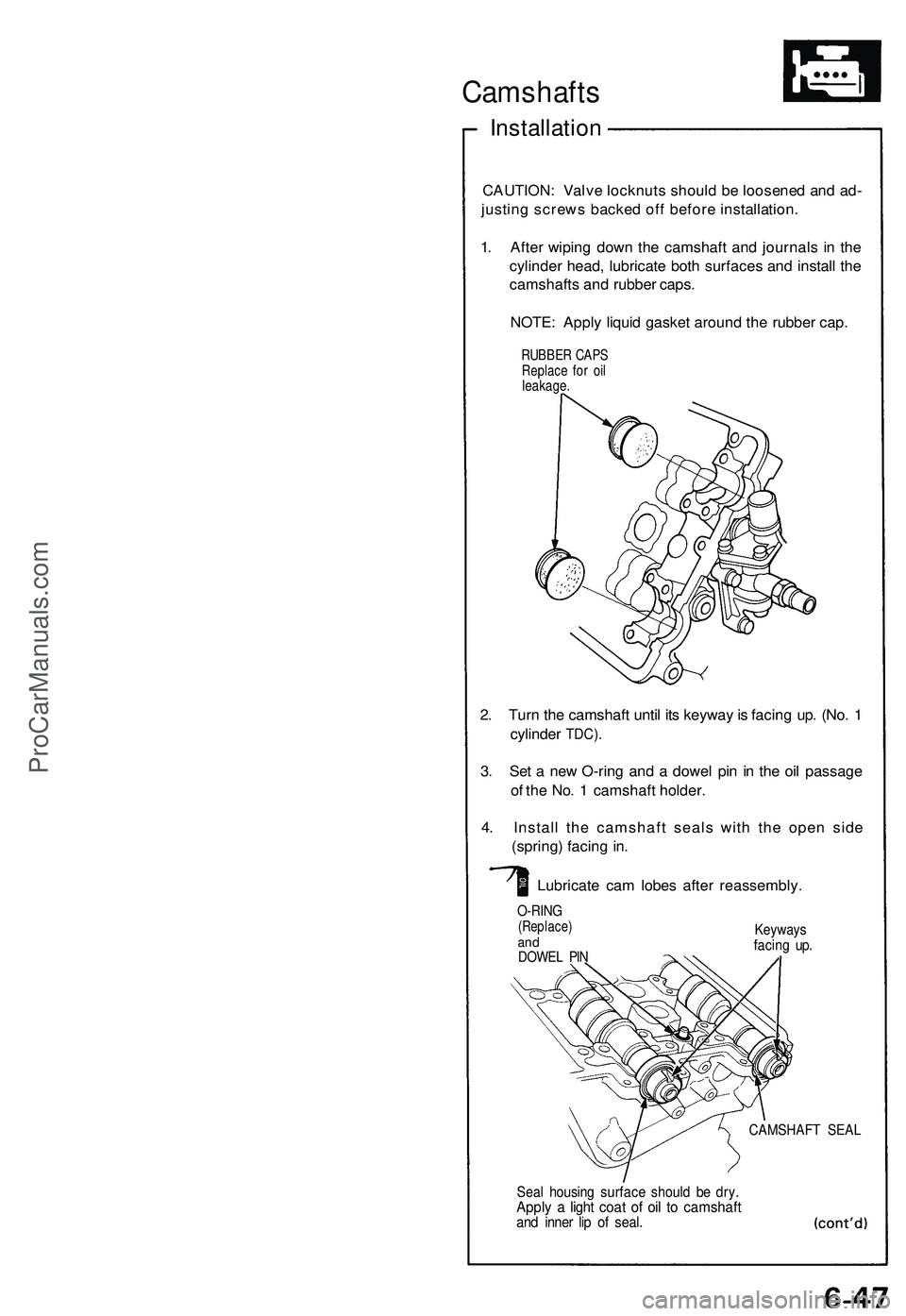

CAUTION: Valve locknuts should be loosened and ad-

justing screws backed off before installation.

1. After wiping down the camshaft and journals in the

cylinder head, lubricate both surfaces and install the

camshafts and rubber caps.

NOTE: Apply liquid gasket around the rubber cap.

2. Turn the camshaft until its keyway is facing up. (No. 1

cylinder

TDC).

3. Set a new O-ring and a dowel pin in the oil passage

of the No. 1 camshaft holder.

4. Install the camshaft seals with the open side

(spring) facing in.

Lubricate cam lobes after reassembly.

O-RING

(Replace)

and

DOWEL PIN

Keyways

facing up.

CAMSHAFT SEAL

Seal housing surface should be dry.

Apply a light coat of oil to camshaft

and inner lip of seal.

RUBBER CAPS

Replace for oil

leakage.ProCarManuals.com

Page 482 of 1503

Crankshaft

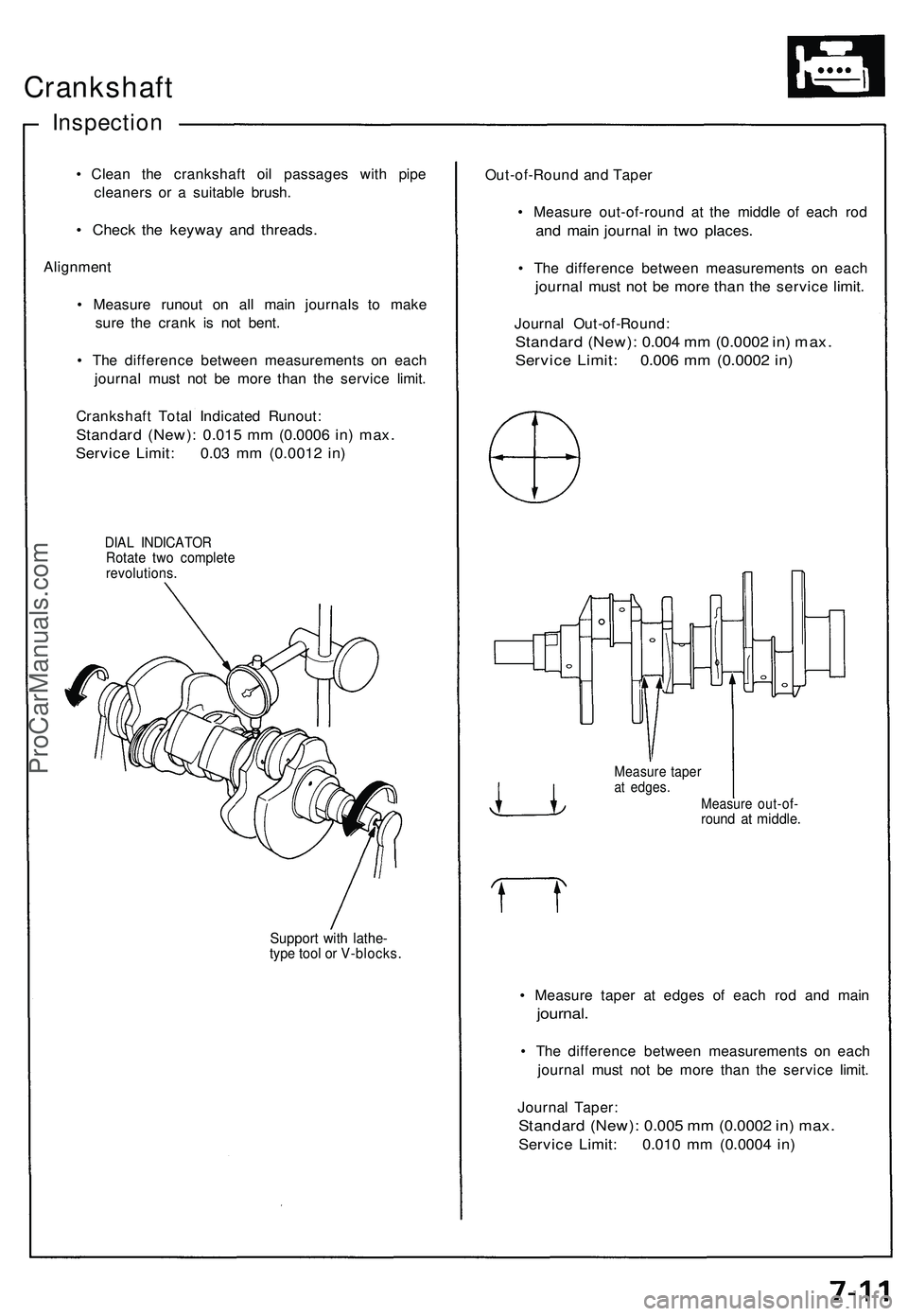

Inspection

• Clea n th e crankshaf t oi l passage s wit h pip e

cleaner s o r a suitabl e brush .

• Chec k th e keywa y an d threads .

Alignmen t

• Measur e runou t o n al l mai n journal s t o mak e

sur e th e cran k i s no t bent .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Crankshaf t Tota l Indicate d Runout :

Standard (New) : 0.01 5 m m (0.000 6 in ) max .

Servic e Limit : 0.0 3 m m (0.001 2 in )

DIA L INDICATO R

Rotat e tw o complet e

revolutions .

Support wit h lathe -type too l o r V-blocks .

Out-of-Roun d an d Tape r

• Measur e out-of-roun d a t th e middl e o f eac h ro d

and mai n journa l i n tw o places .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Journa l Out-of-Round :

Standard (New) : 0.00 4 m m (0.000 2 in ) max .

Servic e Limit : 0.00 6 m m (0.000 2 in )

Measur e out-of -round a t middle .

• Measur e tape r a t edge s o f eac h ro d an d mai n

journal .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Journa l Taper :

Standar d (New) : 0.00 5 m m (0.000 2 in ) max .

Servic e Limit : 0.01 0 m m (0.000 4 in )

Measur e tape rat edges .

ProCarManuals.com

Page 1241 of 1503

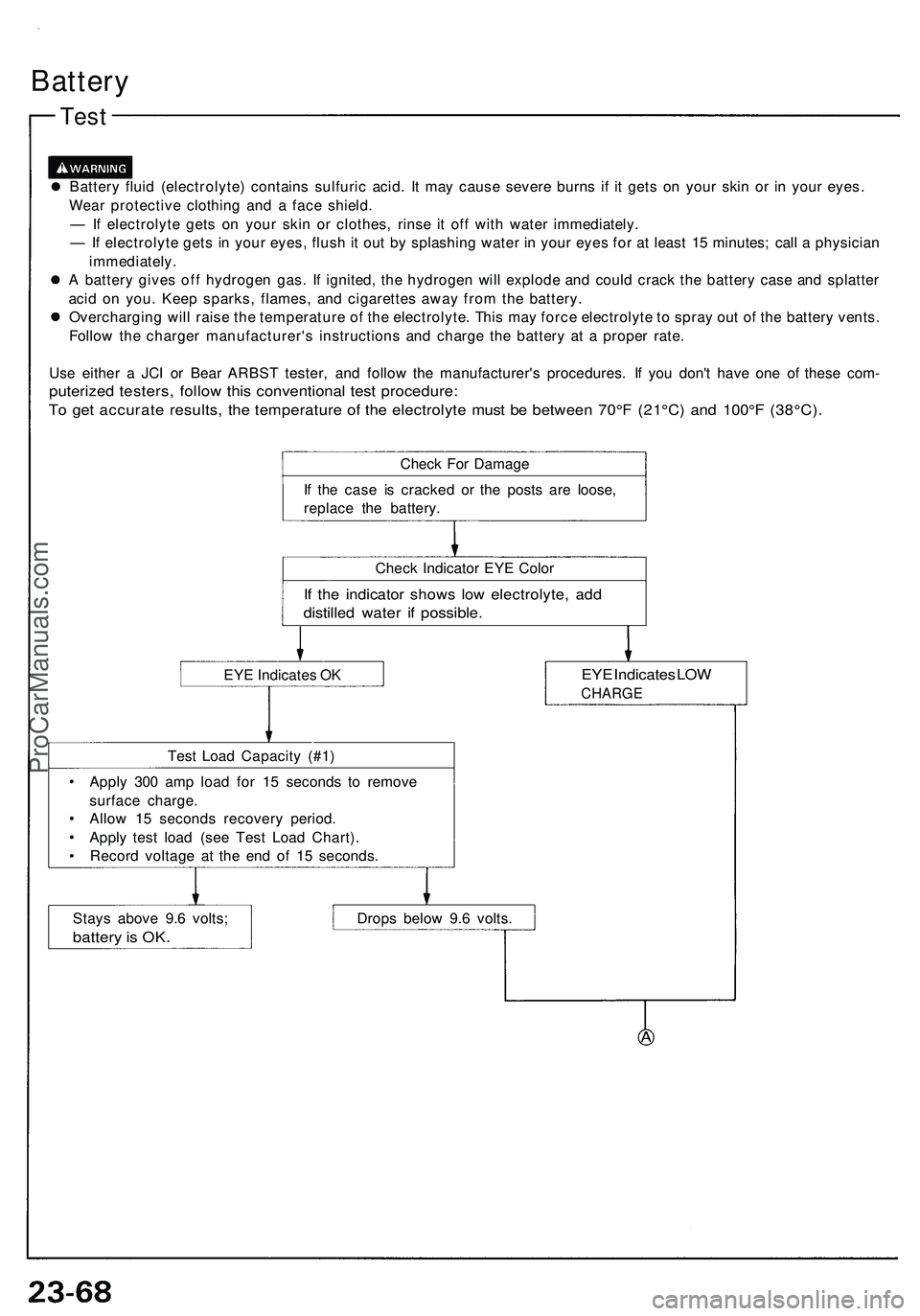

Battery

Test

Batter y flui d (electrolyte ) contain s sulfuri c acid . I t ma y caus e sever e burn s i f i t get s o n you r ski n o r i n you r eyes .

Wea r protectiv e clothin g an d a fac e shield .

— If electrolyt e get s o n you r ski n o r clothes , rins e i t of f wit h wate r immediately .

— If electrolyt e get s in you r eyes , flus h it ou t b y splashin g wate r i n you r eye s fo r a t leas t 1 5 minutes ; cal l a physicia n

immediately .

A batter y give s of f hydroge n gas. If ignited , th e hydroge n wil l explod e an d coul d crac k th e batter y cas e an d splatte r

aci d o n you . Kee p sparks , flames , an d cigarette s awa y fro m th e battery .

Overchargin g wil l rais e th e temperatur e o f th e electrolyte . Thi s ma y forc e electrolyt e t o spra y ou t o f th e batter y vents .

Follo w th e charge r manufacturer' s instruction s an d charg e th e batter y a t a prope r rate .

Us e eithe r a JC I o r Bea r ARBS T tester , an d follo w th e manufacturer' s procedures . I f yo u don' t hav e on e of thes e com -

puterize d testers , follo w thi s conventiona l tes t procedure :

To ge t accurat e results , th e temperatur e o f th e electrolyt e mus t b e betwee n 70° F (2 1°C ) an d 100° F (38°C) .

Check Fo r Damag e

I f th e cas e i s cracke d o r th e post s ar e loose ,

replac e th e battery .

Chec k Indicato r EY E Colo r

If th e indicato r show s low electrolyte , ad d

distille d wate r i f possible .

EYE Indicate s O KEY E Indicate s LO W

CHARG E

Test Loa d Capacit y (#1 )

Appl y 30 0 am p loa d fo r 1 5 second s t o remov e

surfac e charge .

Allo w 1 5 second s recover y period .

Appl y tes t loa d (se e Tes t Loa d Chart) .

Recor d voltag e a t th e en d o f 1 5 seconds .

Stay s abov e 9. 6 volts ;

batter y is OK .

Drop s belo w 9. 6 volts .

ProCarManuals.com

Page 1245 of 1503

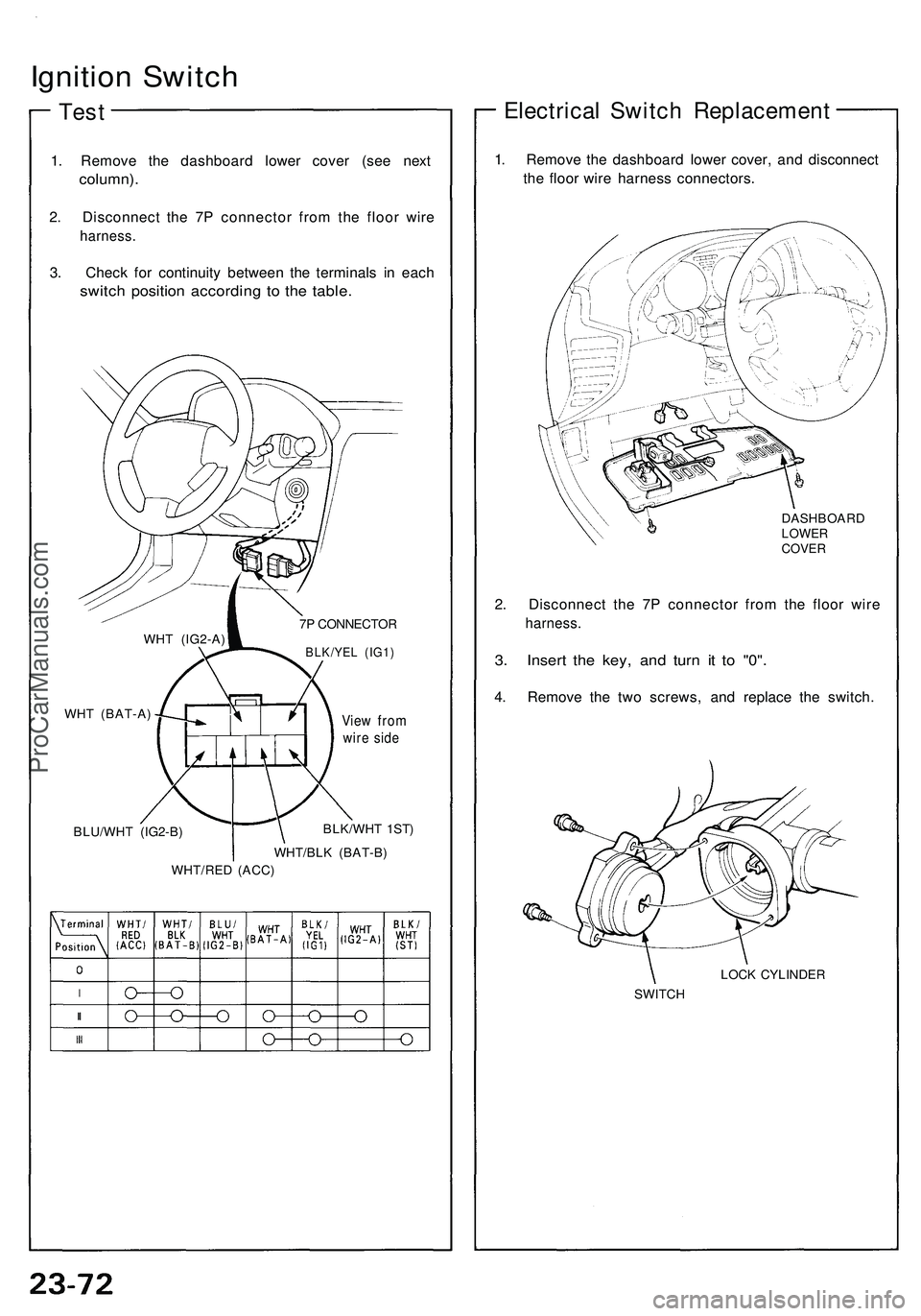

Ignition Switch

Test

1. Remove the dashboard lower cover (see next

column).

2. Disconnect the 7P connector from the floor wire

harness.

3. Check for continuity between the terminals in each

switch position according to the table.

7P CONNECTOR

BLK/YEL (IG1)

BLU/WHT (IG2-B)

View from

wire side

BLK/WHT 1ST)

WHT/BLK (BAT-B)

WHT/RED (ACC)

Electrical Switch Replacement

1. Remove the dashboard lower cover, and disconnect

the floor wire harness connectors.

DASHBOARD

LOWER

COVER

2. Disconnect the 7P connector from the floor wire

harness.

3. Insert the key, and turn it to "0".

4. Remove the two screws, and replace the switch.

LOCK CYLINDER

SWITCH

WHT (IG2-A)

WHT (BAT-A)ProCarManuals.com