brakes ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1 of 1503

General Info

Specifications

Maintenance

Engine

Cooling

Fuel and Emissions

*Transaxle

SteeringSuspension

*Brakes (Including ABS)

*Body

*Heating, Ventilation and

Air Conditioning

*Body Electrical

*Engine Electrical

*SRS

1997-200 5 NSX Main Menu

As sections w/ * include SRS components,

special precautions are required when servicing.

ProCarManuals.com

Page 370 of 1503

3-15

T

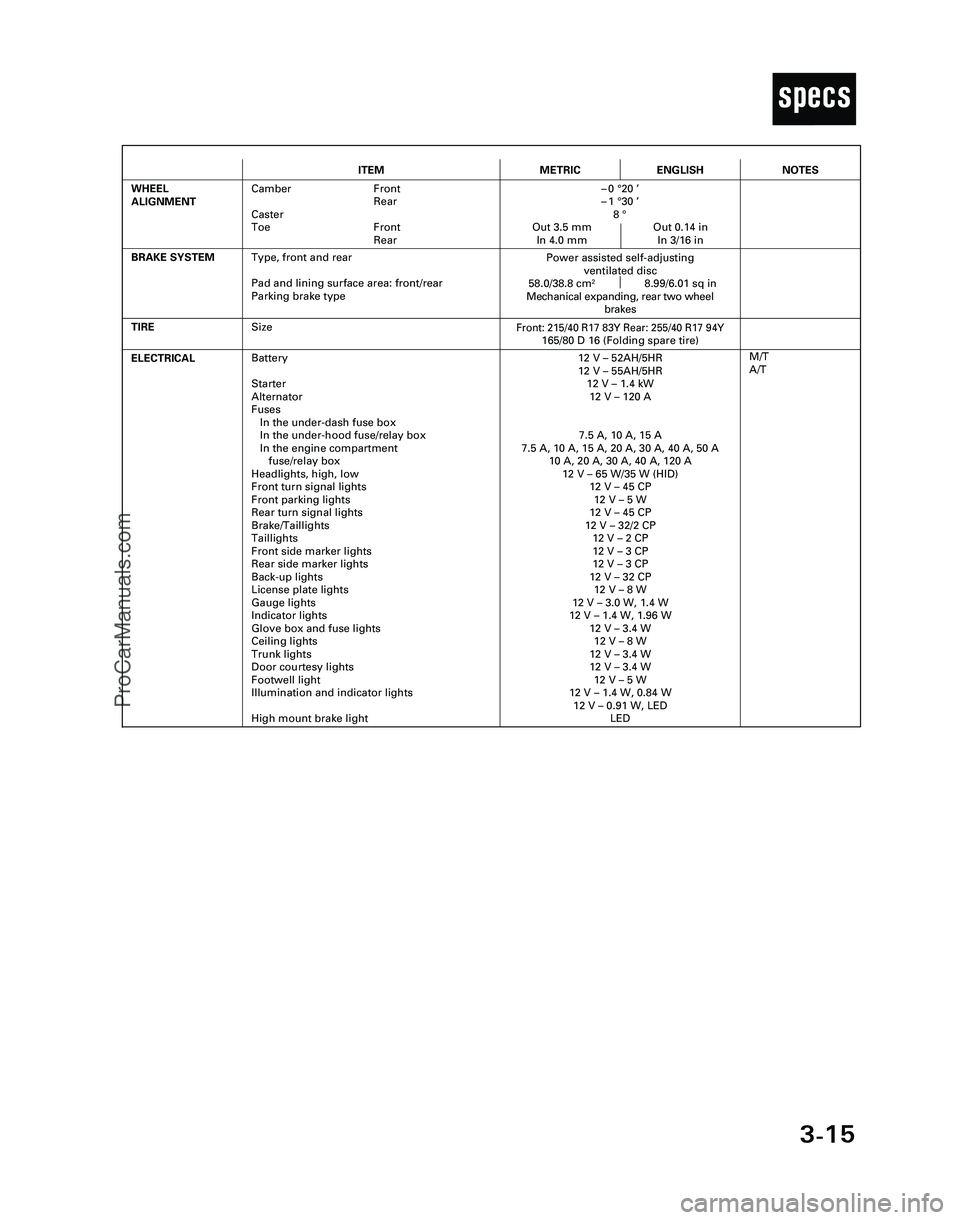

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 982 of 1503

Inspection and Adjustment

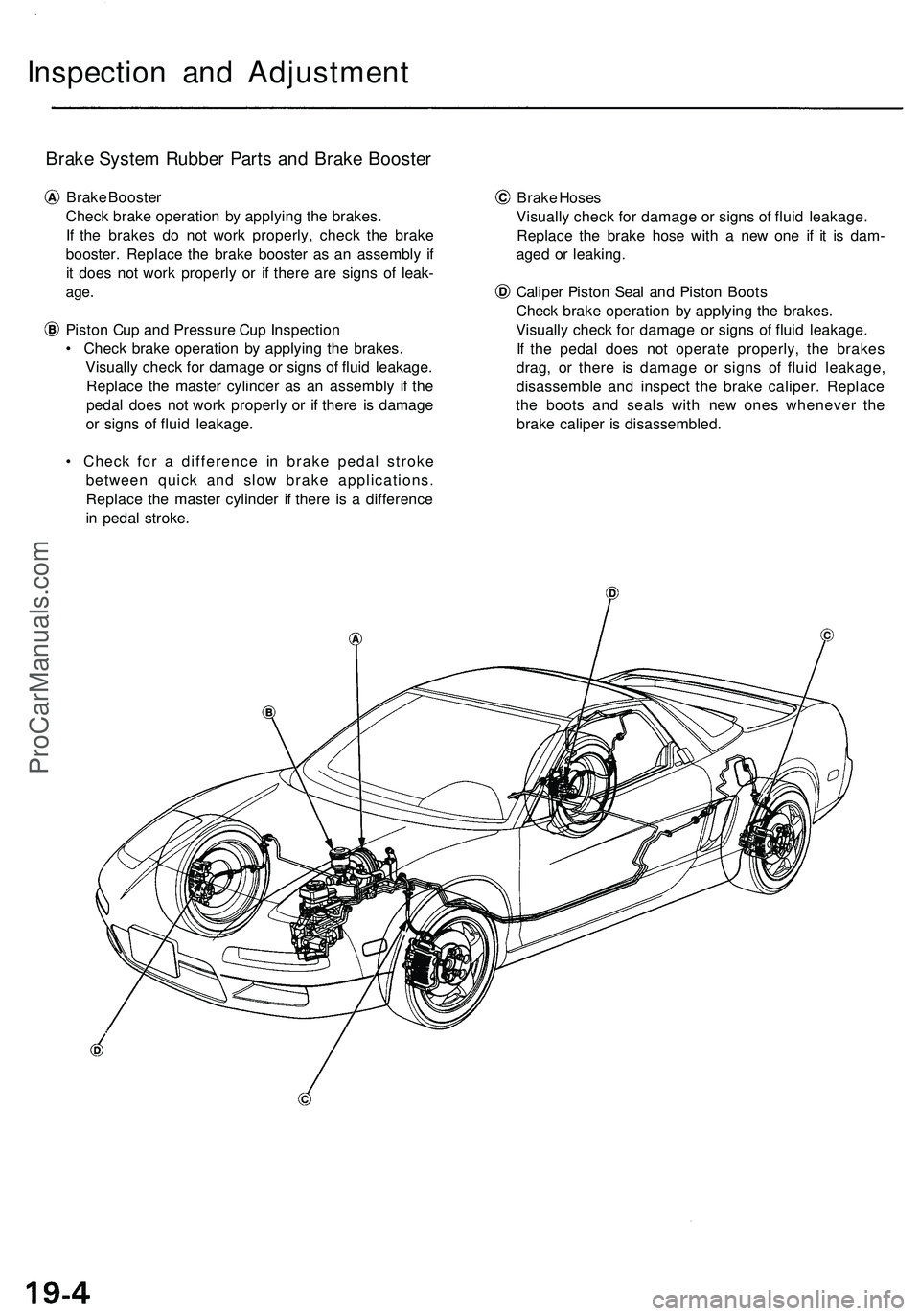

Brake System Rubber Parts and Brake Booster

Brake Booster

Check brake operation by applying the brakes.

If the brakes do not work properly, check the brake

booster. Replace the brake booster as an assembly if

it does not work properly or if there are signs of leak-

age.

Piston Cup and Pressure Cup Inspection

• Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

Replace the master cylinder as an assembly if the

pedal does not work properly or if there is damage

or signs of fluid leakage.

• Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a difference

in pedal stroke.

Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is dam-

aged or leaking.

Caliper Piston Seal and Piston Boots

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

If the pedal does not operate properly, the brakes

drag, or there is damage or signs of fluid leakage,

disassemble and inspect the brake caliper. Replace

the boots and seals with new ones whenever the

brake caliper is disassembled.ProCarManuals.com

Page 984 of 1503

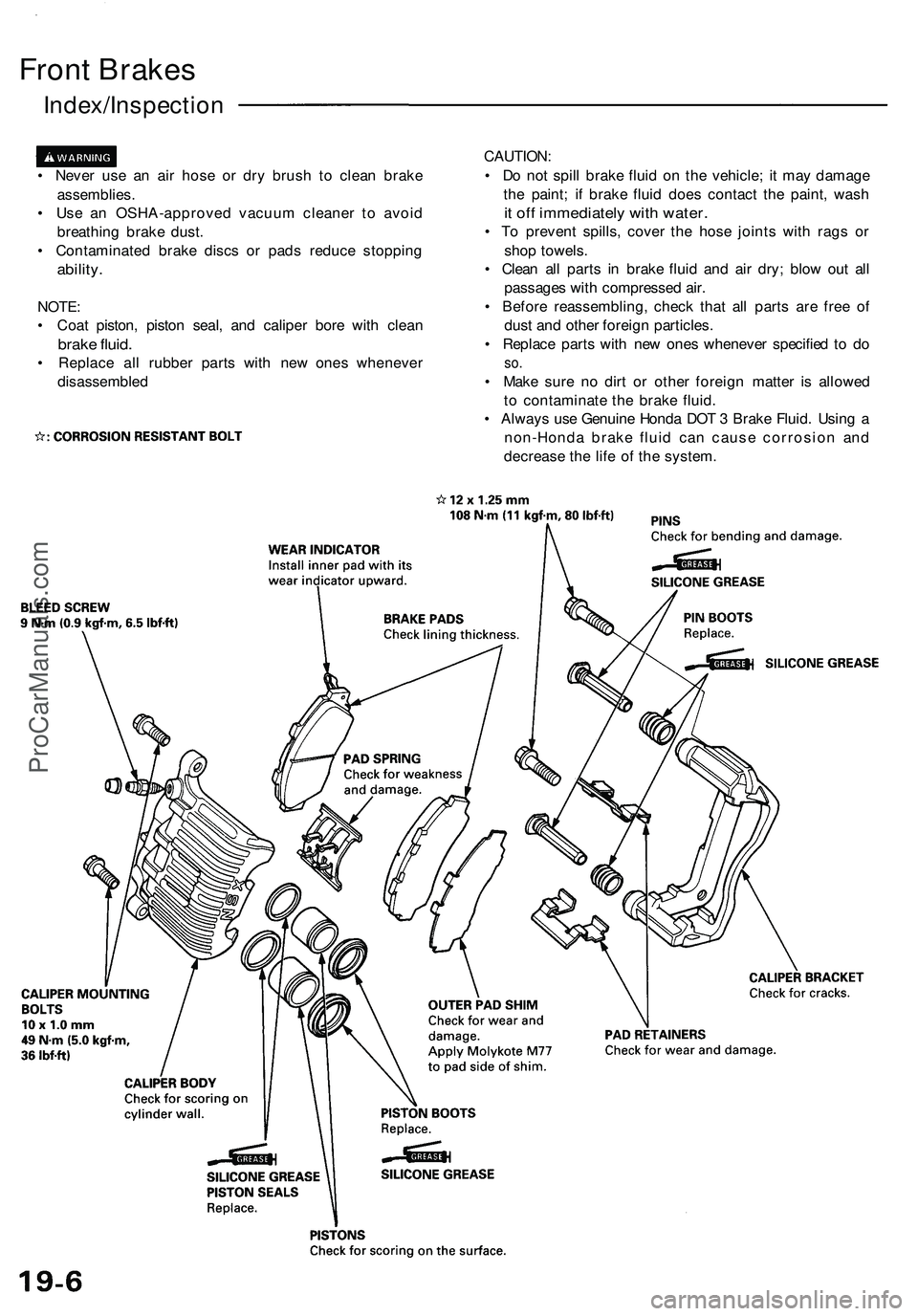

Front Brakes

Index/Inspection

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

• Contaminated brake discs or pads reduce stopping

ability.

NOTE:

• Coat piston, piston seal, and caliper bore with clean

brake fluid.

• Replace all rubber parts with new ones whenever

disassembled

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

• Before reassembling, check that all parts are free of

dust and other foreign particles.

• Replace parts with new ones whenever specified to do

so.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Always use Genuine Honda DOT 3 Brake Fluid. Using a

non-Honda brake fluid can cause corrosion and

decrease the life of the system.ProCarManuals.com

Page 996 of 1503

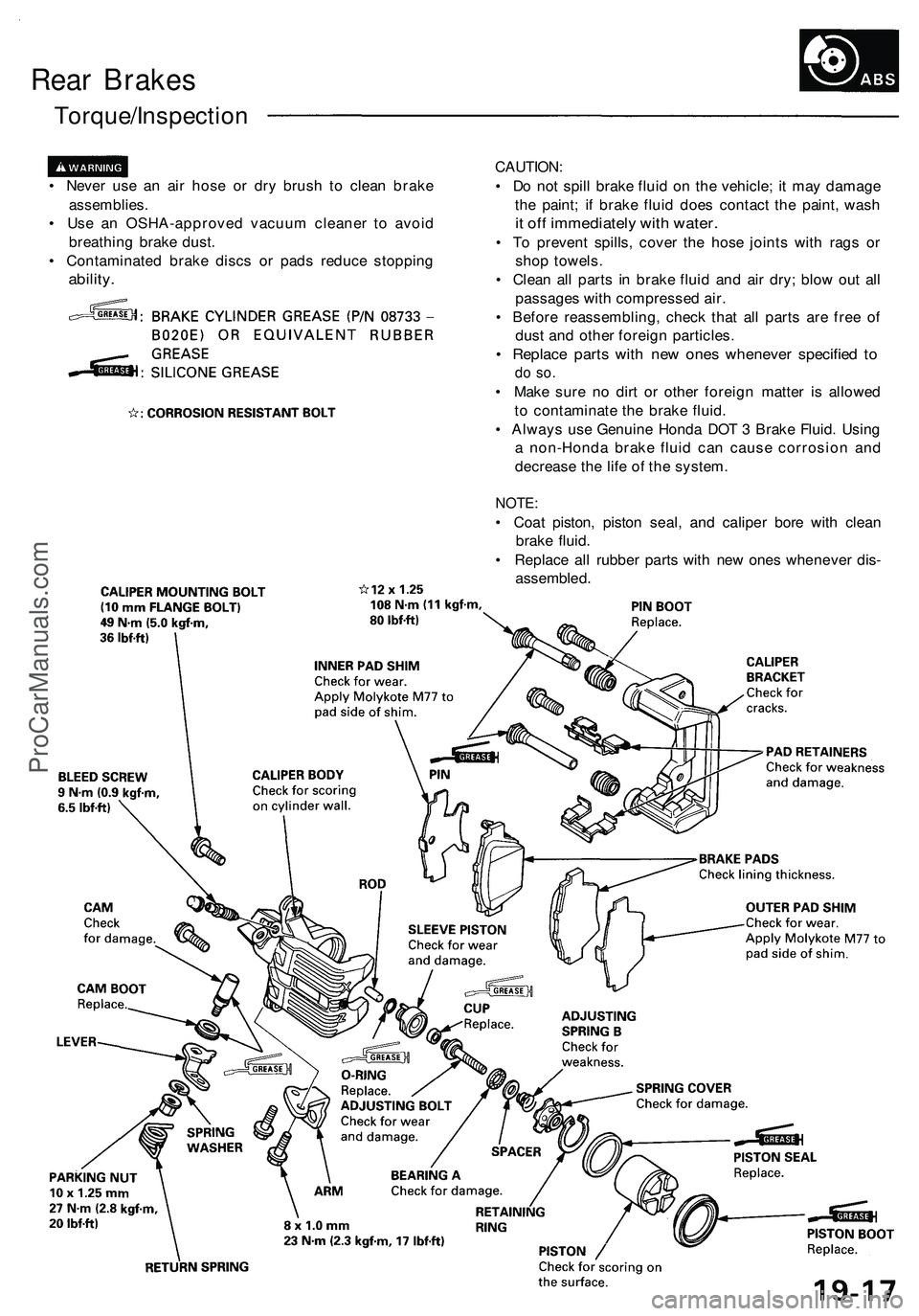

Rear Brakes

Torque/Inspection

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

• Contaminated brake discs or pads reduce stopping

ability.

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

• Before reassembling, check that all parts are free of

dust and other foreign particles.

• Replace parts with new ones whenever specified to

do so.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the system.

NOTE:

• Coat piston, piston seal, and caliper bore with clean

brake fluid.

• Replace all rubber parts with new ones whenever dis-

assembled.ProCarManuals.com

Page 999 of 1503

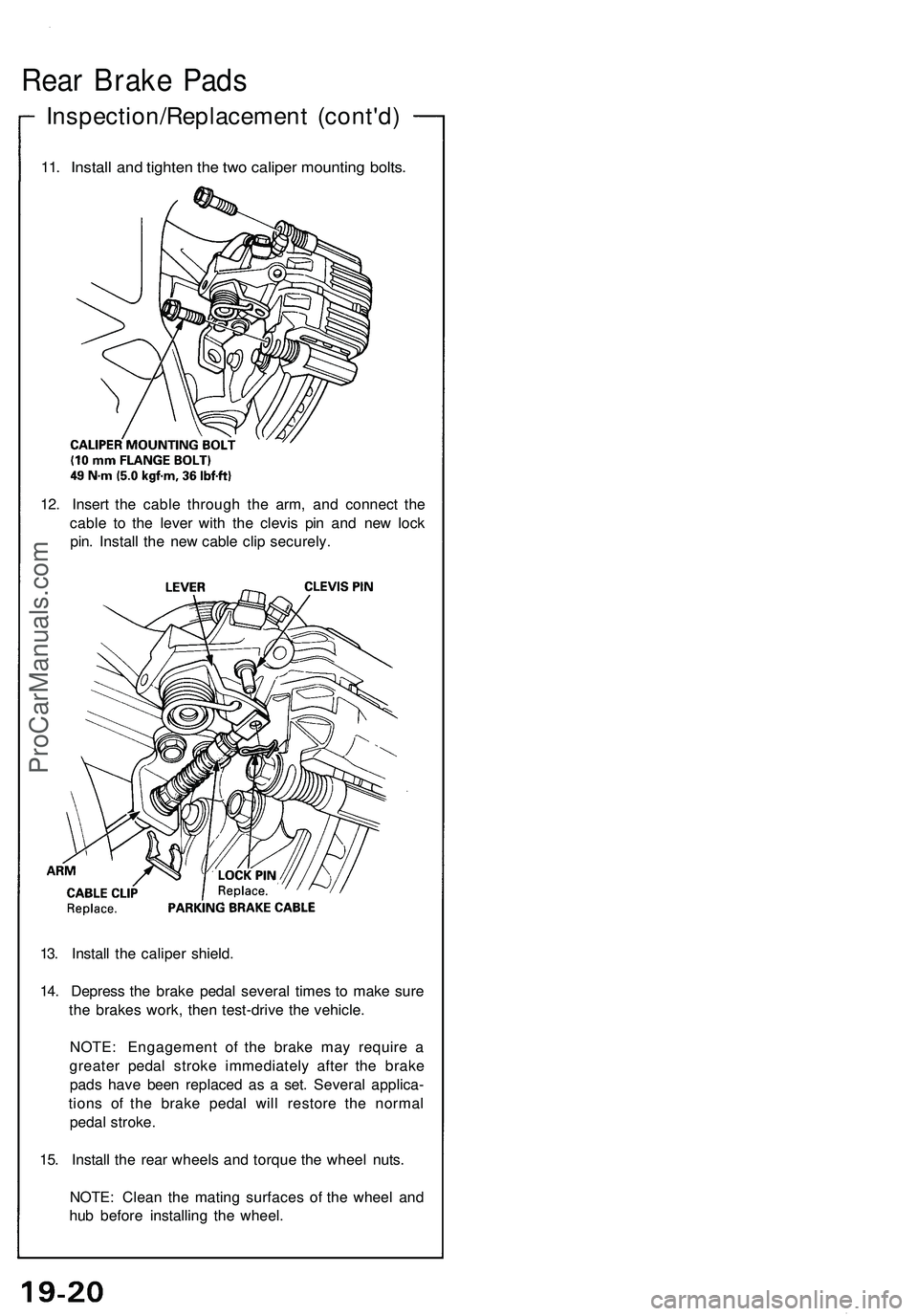

Inspection/Replacement (cont'd)

Rear Brake Pads

11. Install and tighten the two caliper mounting bolts.

12. Insert the cable through the arm, and connect the

cable to the lever with the clevis pin and new lock

pin. Install the new cable clip securely.

13. Install the caliper shield.

14. Depress the brake pedal several times to make sure

the brakes work, then test-drive the vehicle.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

15. Install the rear wheels and torque the wheel nuts.

NOTE: Clean the mating surfaces of the wheel and

hub before installing the wheel.ProCarManuals.com

Page 1015 of 1503

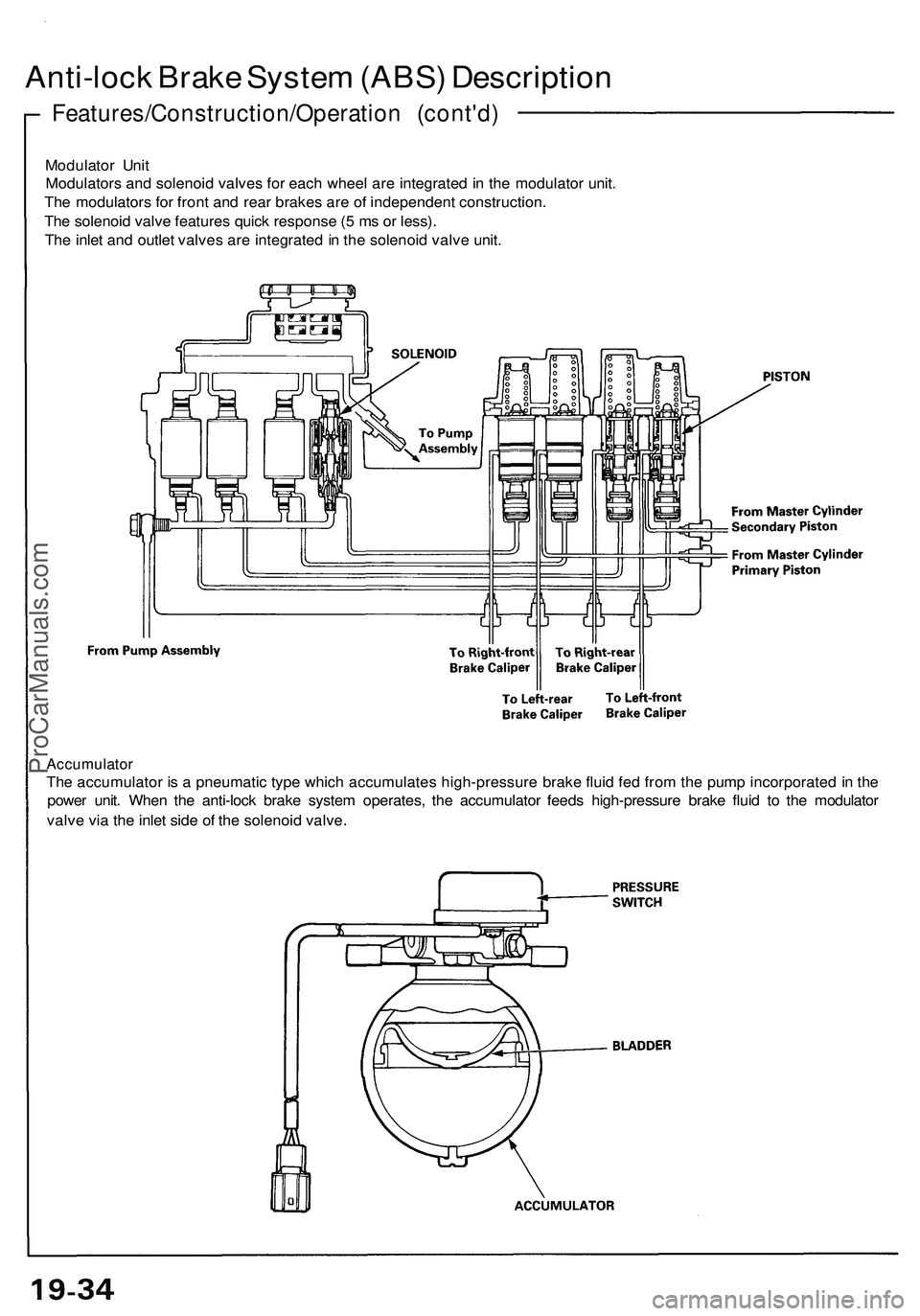

Accumulator

The accumulator is a pneumatic type which accumulates high-pressure brake fluid fed from the pump incorporated in the

power unit. When the anti-lock brake system operates, the accumulator feeds high-pressure brake fluid to the modulator

valve via the inlet side of the solenoid valve.

Modulator Unit

Modulators and solenoid valves for each wheel are integrated in the modulator unit.

The modulators for front and rear brakes are of independent construction.

The solenoid valve features quick response (5 ms or less).

The inlet and outlet valves are integrated in the solenoid valve unit.

Features/Construction/Operation (cont'd)

Anti-lock Brake System (ABS) DescriptionProCarManuals.com

Page 1363 of 1503

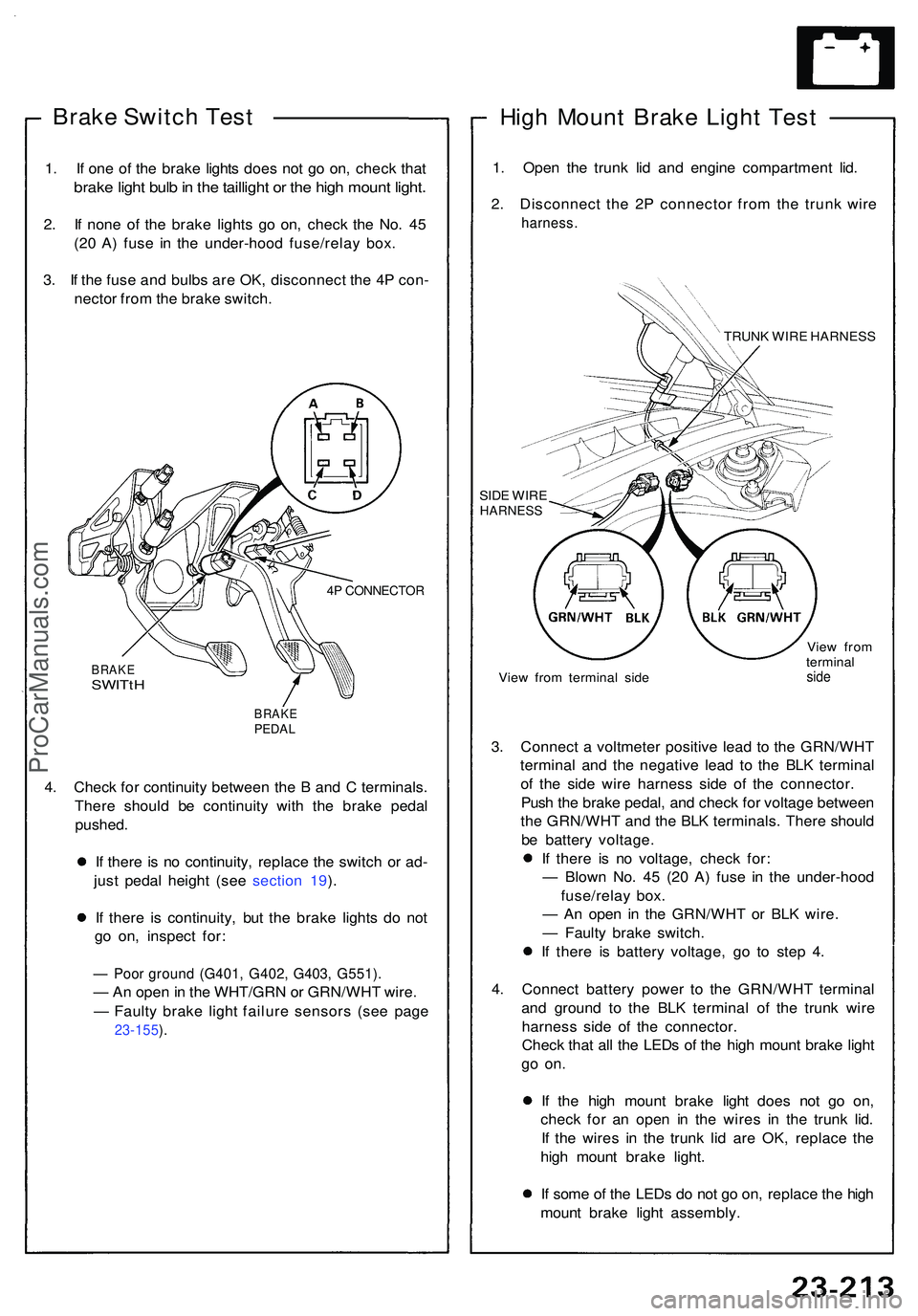

Brake Switc h Tes t

1. I f on e o f th e brak e light s doe s no t g o on , chec k tha t

brak e ligh t bul b in th e tailligh t o r th e hig h moun t light .

2. I f non e o f th e brak e light s g o on , chec k th e No . 4 5

(2 0 A ) fus e i n th e under-hoo d fuse/rela y box .

3 . I f th e fus e an d bulb s ar e OK , disconnec t th e 4 P con -

necto r fro m th e brak e switch .

4P CONNECTO R

BRAKESWITtH

BRAK EPEDAL

4. Chec k fo r continuit y betwee n th e B an d C terminals .

Ther e shoul d b e continuit y wit h th e brak e peda l

pushed .

I f ther e i s n o continuity , replac e th e switc h o r ad -

jus t peda l heigh t (se e sectio n 19 ).

I f ther e i s continuity , bu t th e brak e light s d o no t

g o on , inspec t for :

— Poo r groun d (G401 , G402 , G403 , G551) .

— An ope n in th e WHT/GR N o r GRN/WH T wire .

— Fault y brak e ligh t failur e sensor s (se e pag e

23-155 ).

Hig h Moun t Brak e Ligh t Tes t

1. Ope n th e trun k li d an d engin e compartmen t lid .

2 . Disconnec t th e 2 P connecto r fro m th e trun k wir e

harness .

TRUNK WIR E HARNES S

SID E WIR E

HARNES S

View fro m termina l sid e Vie

w fro m

termina lside

3. Connec t a voltmete r positiv e lea d t o th e GRN/WH T

termina l an d th e negativ e lea d t o th e BL K termina l

o f th e sid e wir e harnes s sid e o f th e connector .

Pus h th e brak e pedal , an d chec k fo r voltag e betwee n

th e GRN/WH T an d th e BL K terminals . Ther e shoul d

b e batter y voltage .

I f ther e i s n o voltage , chec k for :

— Blow n No . 4 5 (2 0 A ) fus e i n th e under-hoo d

fuse/rela y box .

— A n ope n i n th e GRN/WH T o r BL K wire .

— Fault y brak e switch .

I f ther e i s batter y voltage , g o t o ste p 4 .

4 . Connec t batter y powe r t o th e GRN/WH T termina l

an d groun d t o th e BL K termina l o f th e trun k wir e

harnes s sid e o f th e connector .

Chec k tha t al l th e LED s o f th e hig h moun t brak e ligh t

go on .

If th e hig h moun t brak e ligh t doe s no t g o on ,

chec k fo r a n ope n i n th e wire s i n th e trun k lid .

I f th e wire s i n th e trun k li d ar e OK , replac e th e

hig h moun t brak e light .

I f som e o f th e LED s d o no t g o on , replac e th e hig h

moun t brak e ligh t assembly .

ProCarManuals.com

Page 1450 of 1503

Cruise Contro l

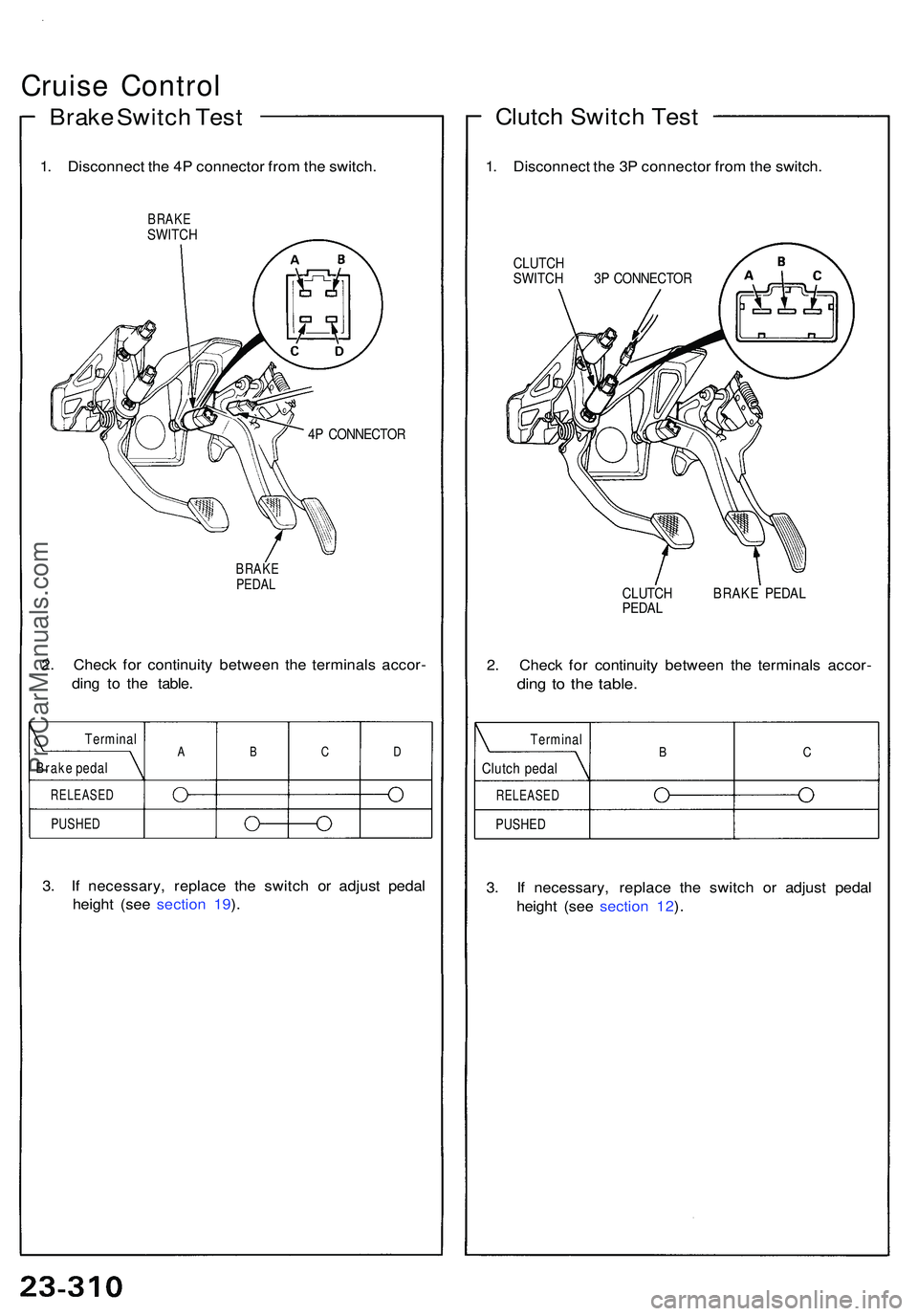

Brake Switc h Tes t

1. Disconnec t th e 4 P connecto r fro m th e switch .

BRAKESWITC H

4P CONNECTO R

BRAKE

PEDA L

2. Chec k fo r continuit y betwee n th e terminal s accor -

din g t o th e table .

3 . I f necessary , replac e th e switc h o r adjus t peda l

heigh t (se e sectio n 19 ).

Clutc h Switc h Tes t

1. Disconnec t th e 3 P connecto r fro m th e switch .

CLUTC H

SWITC H 3 P CONNECTO R

CLUTC H BRAK E PEDA L

PEDA L

2. Chec k fo r continuit y betwee n th e terminal s accor -

ding t o th e table .

3. I f necessary , replac e th e switc h o r adjus t peda l

heigh t (se e sectio n 12 ).

Termina l

Brak e peda l

RELEASE D

PUSHED

ABCDTermina l

Clutch peda l

RELEASE D

PUSHED

BC

ProCarManuals.com