wheel bolt torque ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 385 of 1503

Service Precautions

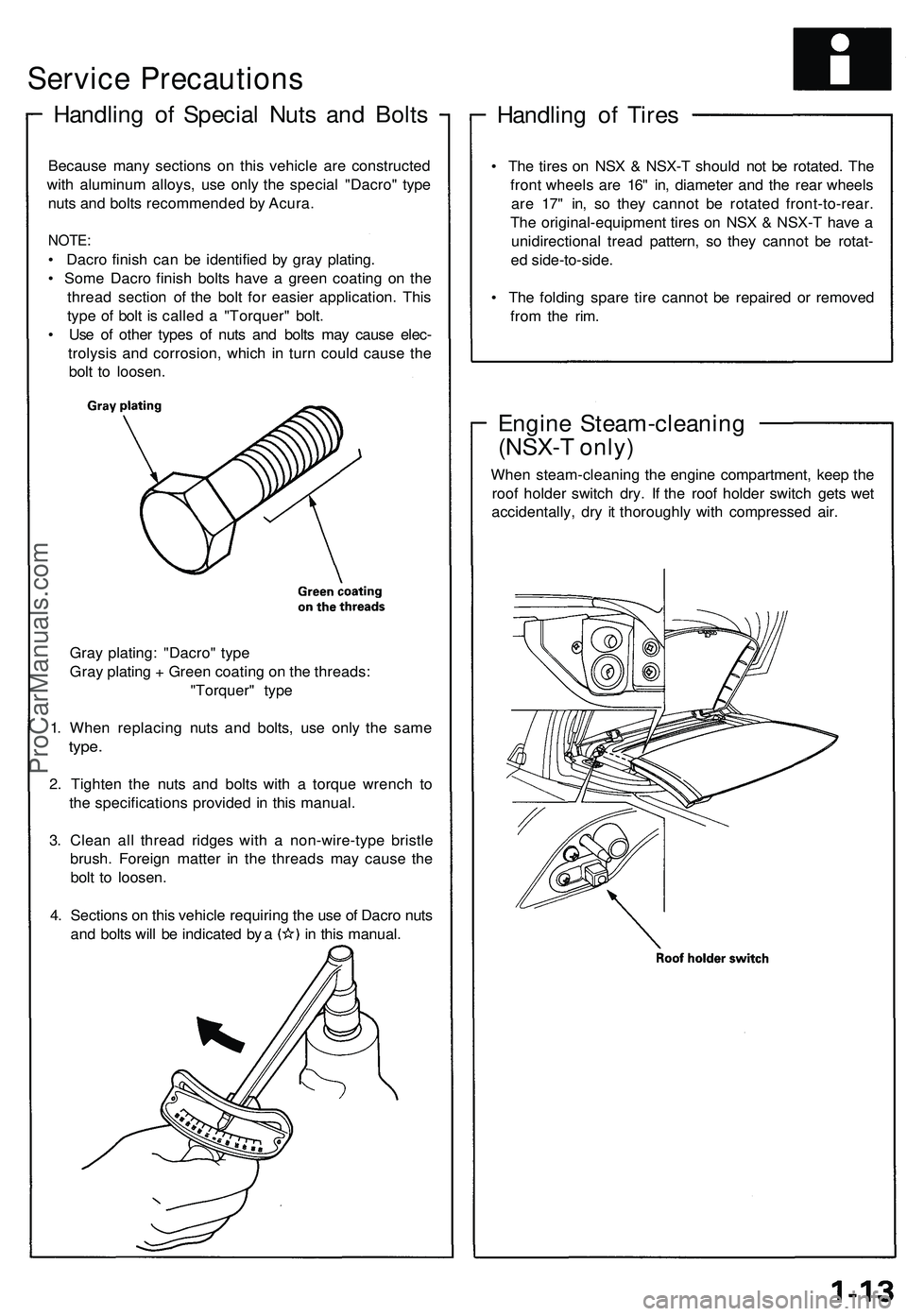

Handling of Special Nuts and Bolts

Handling of Tires

• The tires on NSX & NSX-T should not be rotated. The

front wheels are 16" in, diameter and the rear wheels

are 17" in, so they cannot be rotated front-to-rear.

The original-equipment tires on NSX & NSX-T have a

unidirectional tread pattern, so they cannot be rotat-

ed side-to-side.

• The folding spare tire cannot be repaired or removed

from the rim.

Engine Steam-cleaning

(NSX-T only)

When steam-cleaning the engine compartment, keep the

roof holder switch dry. If the roof holder switch gets wet

accidentally, dry it thoroughly with compressed air.

Because many sections on this vehicle are constructed

with aluminum alloys, use only the special "Dacro" type

nuts and bolts recommended by Acura.

NOTE:

• Dacro finish can be identified by gray plating.

• Some Dacro finish bolts have a green coating on the

thread section of the bolt for easier application. This

type of bolt is called a "Torquer" bolt.

• Use of other types of nuts and bolts may cause elec-

trolysis and corrosion, which in turn could cause the

bolt to loosen.

Gray plating: "Dacro" type

Gray plating + Green coating on the threads:

"Torquer" type

1. When replacing nuts and bolts, use only the same

type.

2. Tighten the nuts and bolts with a torque wrench to

the specifications provided in this manual.

3. Clean all thread ridges with a non-wire-type bristle

brush. Foreign matter in the threads may cause the

bolt to loosen.

4. Sections on this vehicle requiring the use of Dacro nuts

and bolts will be indicated by a in this manual.ProCarManuals.com

Page 713 of 1503

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 979 of 1503

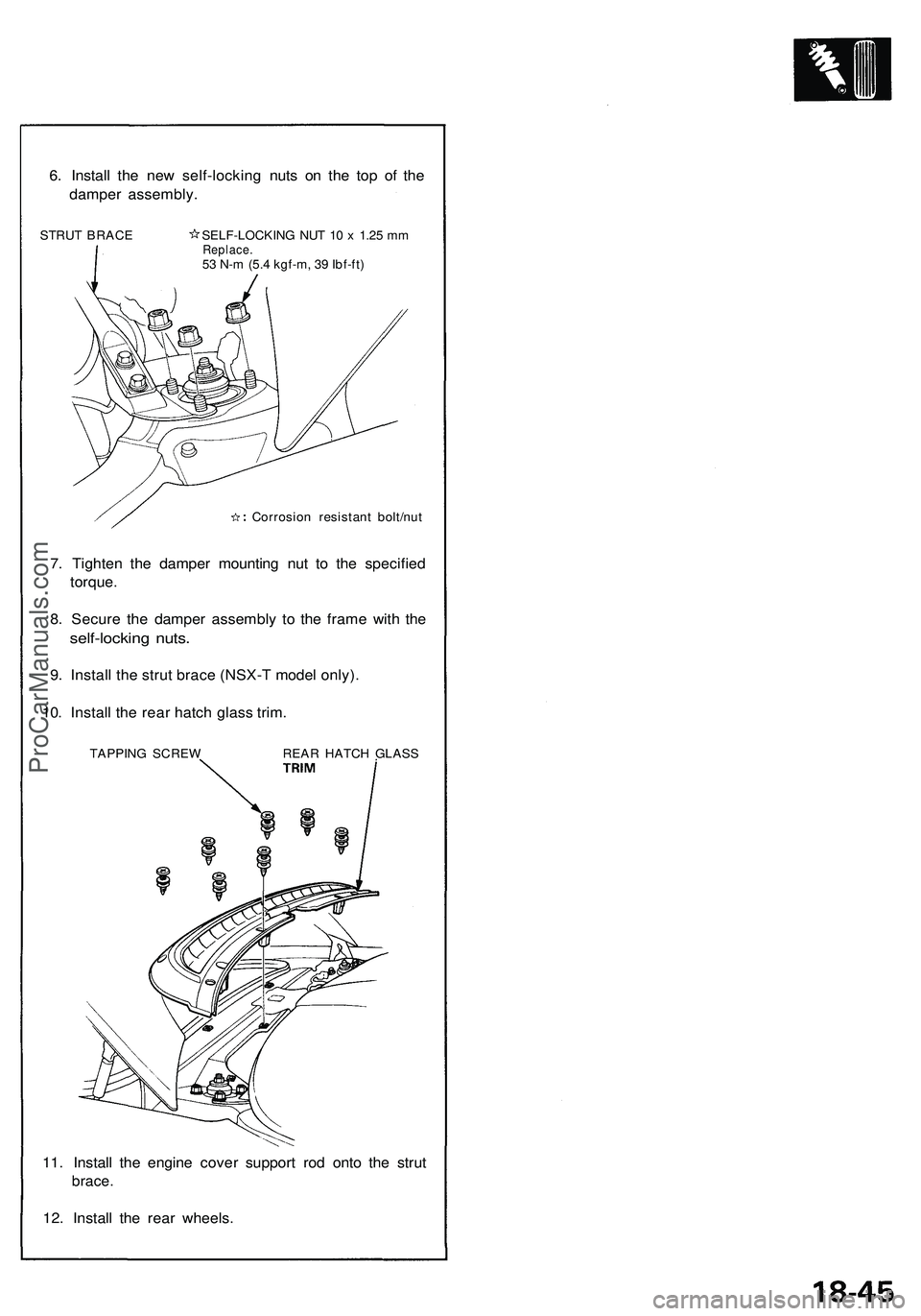

6. Install the new self-locking nuts on the top of the

damper assembly.

STRUT BRACE SELF-LOCKING NUT 10 x 1.25 mm

Replace.

53 N-m (5.4 kgf-m, 39 Ibf-ft)

Corrosion resistant bolt/nut

7. Tighten the damper mounting nut to the specified

torque.

8. Secure the damper assembly to the frame with the

self-locking nuts.

9. Install the strut brace (NSX-T model only).

10. Install the rear hatch glass trim.

TAPPING SCREW REAR HATCH GLASS

11. Install the engine cover support rod onto the strut

brace.

12. Install the rear wheels.ProCarManuals.com

Page 986 of 1503

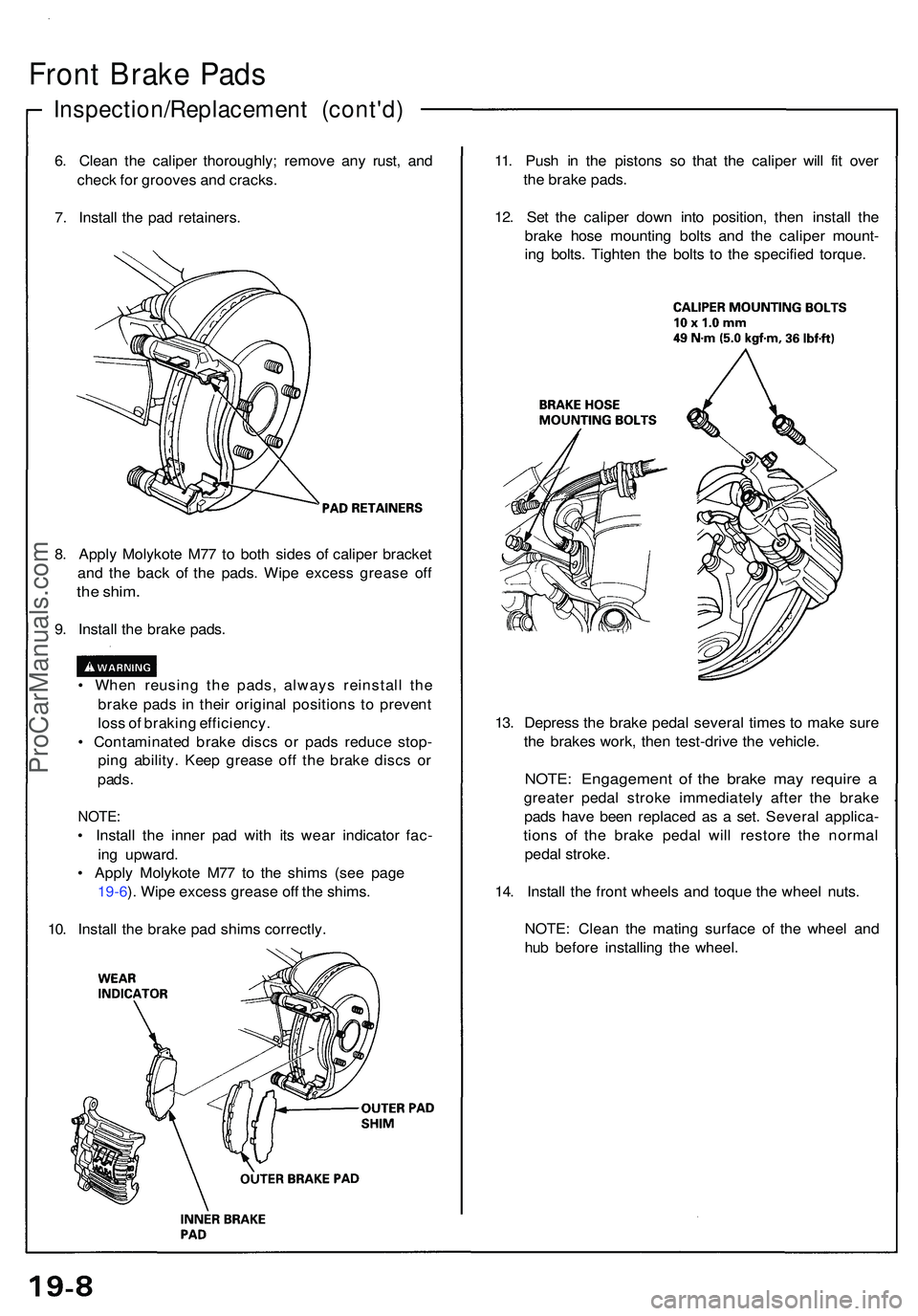

Inspection/Replacement (cont'd )

Front Brak e Pad s

6. Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

7 . Instal l th e pa d retainers . 11

. Pus h i n th e piston s s o tha t th e calipe r wil l fi t ove r

th e brak e pads .

12 . Se t th e calipe r dow n int o position , the n instal l th e

brak e hos e mountin g bolt s an d th e calipe r mount -

in g bolts . Tighte n th e bolt s t o th e specifie d torque .

8 . Appl y Molykot e M7 7 t o bot h side s o f calipe r bracke t

an d th e bac k o f th e pads . Wip e exces s greas e of f

the shim .

9. Instal l th e brak e pads .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e brak e disc s o r

pads .

NOTE :

• Instal l th e inne r pa d wit h it s wea r indicator fac-

in g upward .

• Appl y Molykot e M7 7 t o th e shim s (se e pag e

19-6 ). Wip e exces s greas e of f th e shims .

10 . Instal l th e brak e pa d shim s correctly . 13

. Depres s th e brak e peda l severa l time s t o mak e sur e

th e brake s work , the n test-driv e th e vehicle .

NOTE: Engagemen t o f th e brak e ma y requir e a

greate r peda l strok e immediatel y afte r th e brak e

pad s hav e bee n replace d a s a set . Severa l applica -

tion s of the brak e peda l wil l restor e th e norma l

peda l stroke .

14 . Instal l th e fron t wheel s an d toqu e th e whee l nuts .

NOTE : Clea n th e matin g surfac e o f th e whee l an d

hu b befor e installin g th e wheel .

ProCarManuals.com

Page 999 of 1503

Inspection/Replacement (cont'd)

Rear Brake Pads

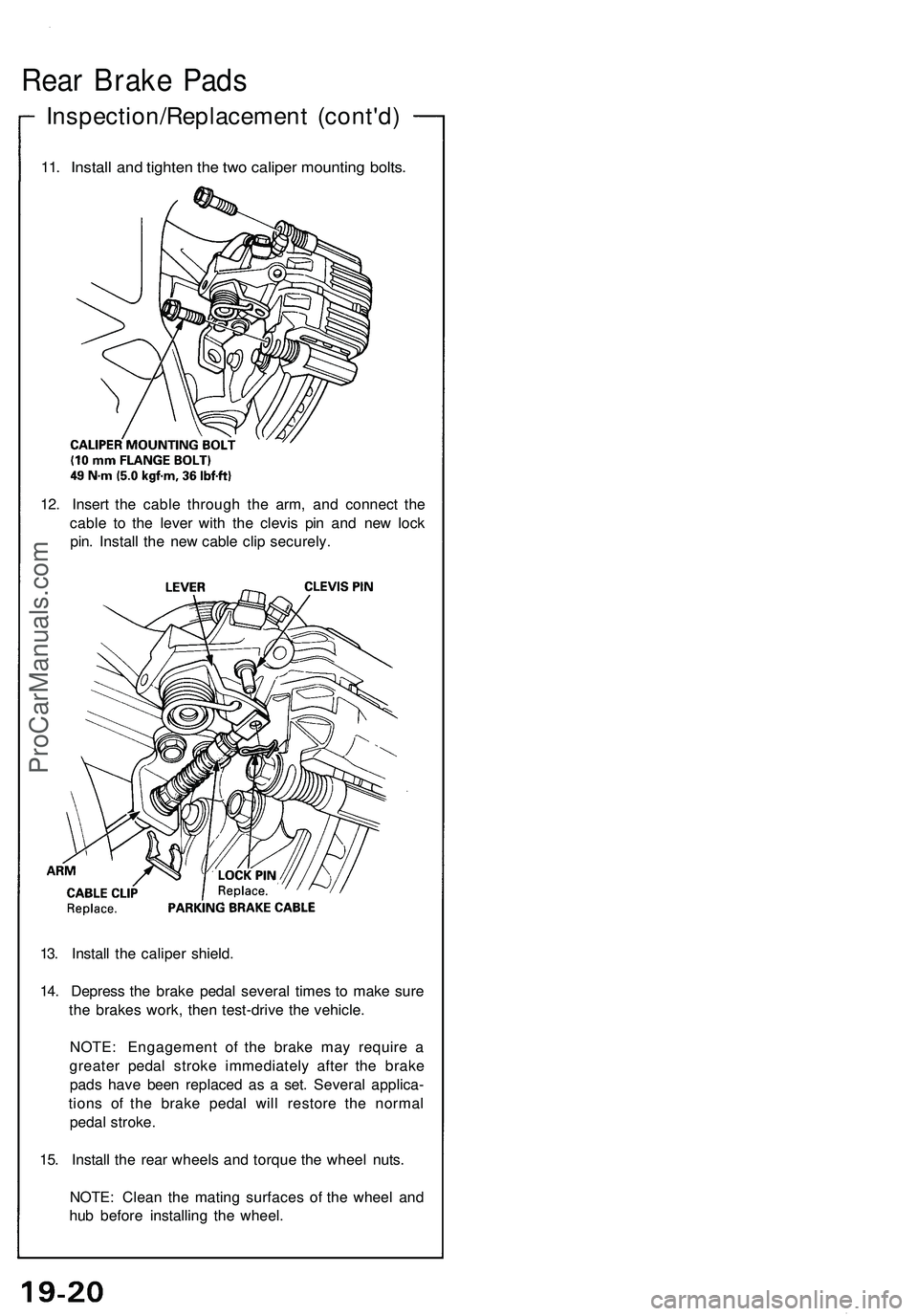

11. Install and tighten the two caliper mounting bolts.

12. Insert the cable through the arm, and connect the

cable to the lever with the clevis pin and new lock

pin. Install the new cable clip securely.

13. Install the caliper shield.

14. Depress the brake pedal several times to make sure

the brakes work, then test-drive the vehicle.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

15. Install the rear wheels and torque the wheel nuts.

NOTE: Clean the mating surfaces of the wheel and

hub before installing the wheel.ProCarManuals.com