change time ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 570 of 1503

Troubleshooting

Troubleshooting Procedures (cont'd)

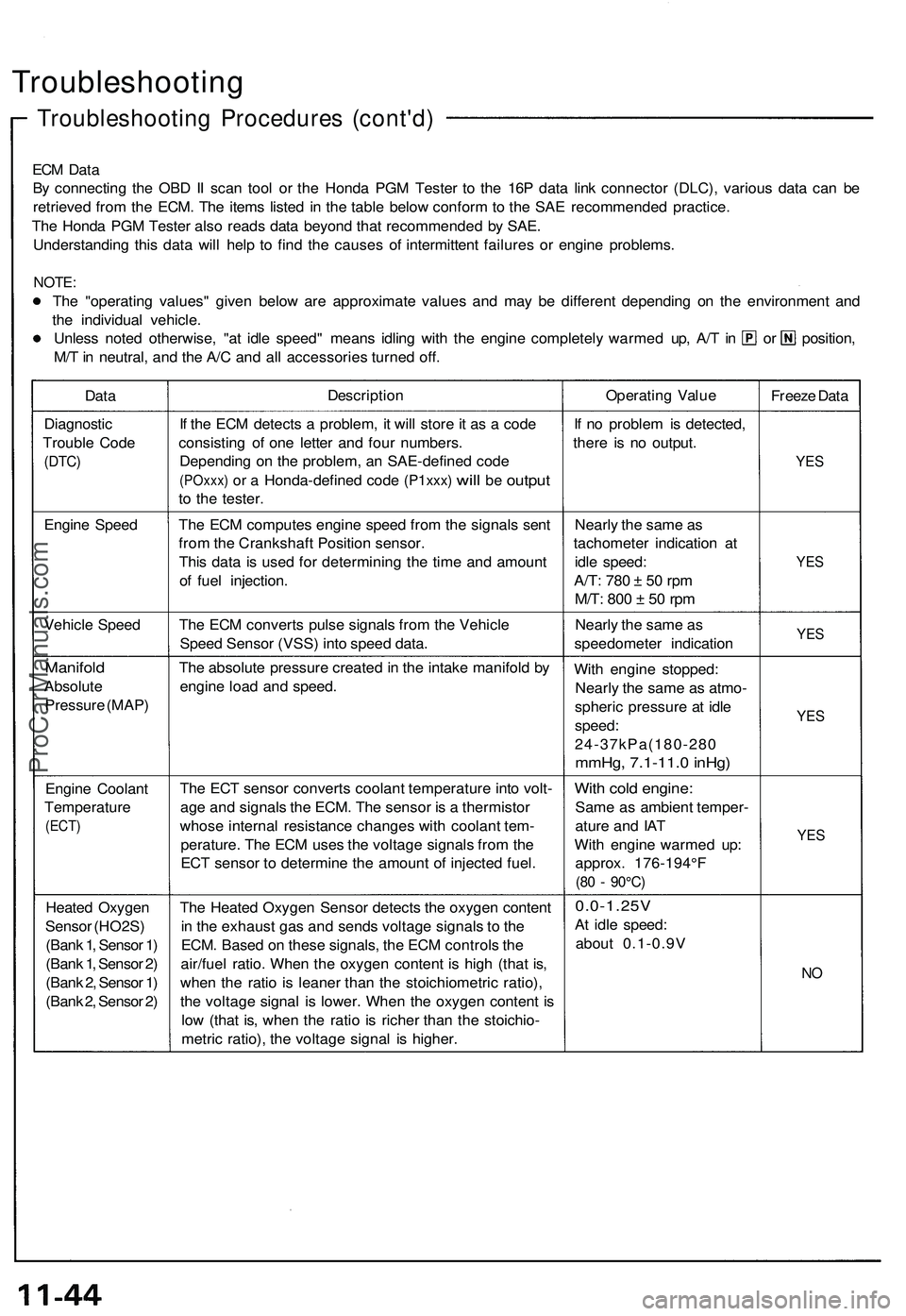

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, A/T in or position,

M/T in neutral, and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(POxxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

YES

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication at

idle speed:

A/T:

780 ± 50 rpm

M/T:

800 ± 50 rpm

YES

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

YES

Manifold

Absolute

Pressure (MAP)

The absolute pressure created in the intake manifold by

engine load and speed.

With engine stopped:

Nearly the same as atmo-

spheric pressure at idle

speed:

24-37kPa(180-280

mmHg, 7.1-11.0 inHg)

YES

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant tem-

perature. The ECM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

approx. 176-194°F

(80 - 90°C)

YES

Heated Oxygen

Sensor (HO2S)

(Bank 1, Sensor 1)

(Bank 1, Sensor 2)

(Bank 2, Sensor 1)

(Bank 2, Sensor 2)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9V

NOProCarManuals.com

Page 903 of 1503

System Description

Function and Operation (cont'd)

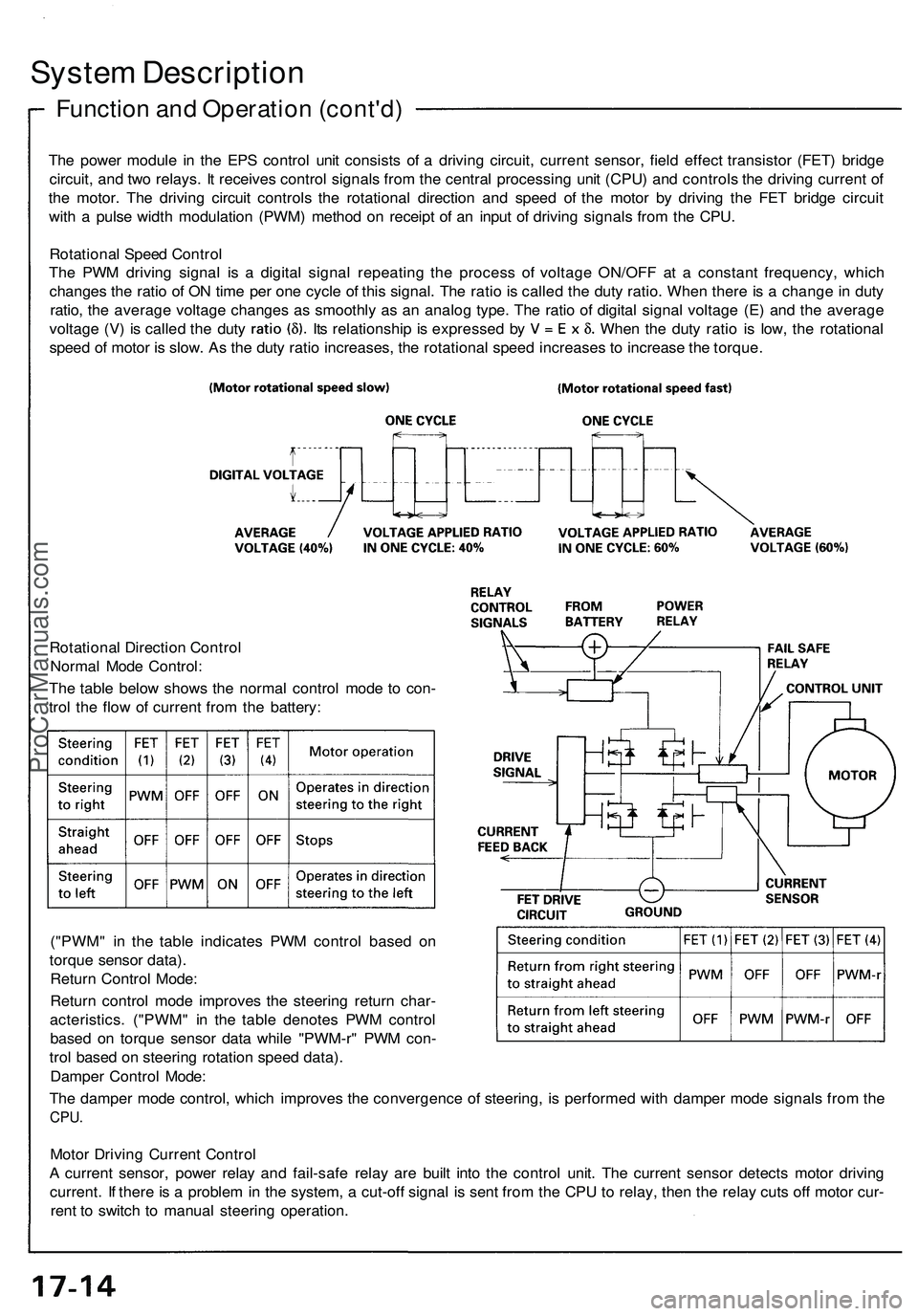

The power module in the EPS control unit consists of a driving circuit, current sensor, field effect transistor (FET) bridge

circuit, and two relays. It receives control signals from the central processing unit (CPU) and controls the driving current of

the motor. The driving circuit controls the rotational direction and speed of the motor by driving the FET bridge circuit

with a pulse width modulation (PWM) method on receipt of an input of driving signals from the CPU.

Rotational Speed Control

The PWM driving signal is a digital signal repeating the process of voltage ON/OFF at a constant frequency, which

changes the ratio of ON time per one cycle of this signal. The ratio is called the duty ratio. When there is a change in duty

ratio, the average voltage changes as smoothly as an analog type. The ratio of digital signal voltage (E) and the average

voltage (V) is called the duty Its relationship is expressed by When the duty ratio is low, the rotational

speed of motor is slow. As the duty ratio increases, the rotational speed increases to increase the torque.

Rotational Direction Control

Normal Mode Control:

The table below shows the normal control mode to con-

trol the flow of current from the battery:

("PWM" in the table indicates PWM control based on

torque sensor data).

Return Control Mode:

Return control mode improves the steering return char-

acteristics. ("PWM" in the table denotes PWM control

based on torque sensor data while "PWM-r" PWM con-

trol based on steering rotation speed data).

Damper Control Mode:

The damper mode control, which improves the convergence of steering, is performed with damper mode signals from the

CPU.

Motor Driving Current Control

A current sensor, power relay and fail-safe relay are built into the control unit. The current sensor detects motor driving

current. If there is a problem in the system, a cut-off signal is sent from the CPU to relay, then the relay cuts off motor cur-

rent to switch to manual steering operation.ProCarManuals.com

Page 994 of 1503

Tests

Brake Booster

Functional Test

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. If

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve, or

calipers) is leaking.

2. Start the engine with the pedal depressed. If the

pedal sinks slightly, the vacuum booster is operat-

ing normally, if the pedal height does not vary, the

booster or check valve is faulty.

3. With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. If the brake pedal

sinks more than 10 mm (3/8 in.) in three minutes,

the master cylinder is faulty. A slight change in

pedal height when the A/C compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. If the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. If the pedal rises, the booster is

faulty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When the

pedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. If the pedal position does not vary, check

the booster check valve.

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster or at the booster side of the valve.

2. Start the engine and let it idle. There should be vac-

uum. If no vacuum is available, the check valve is

not working properly. Replace the check valve and

retest.ProCarManuals.com