clock ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 130 of 1503

II. Engine Control Module (ECM) Reset Procedure

Either of the following actions, will reset the ECM.

• Using the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

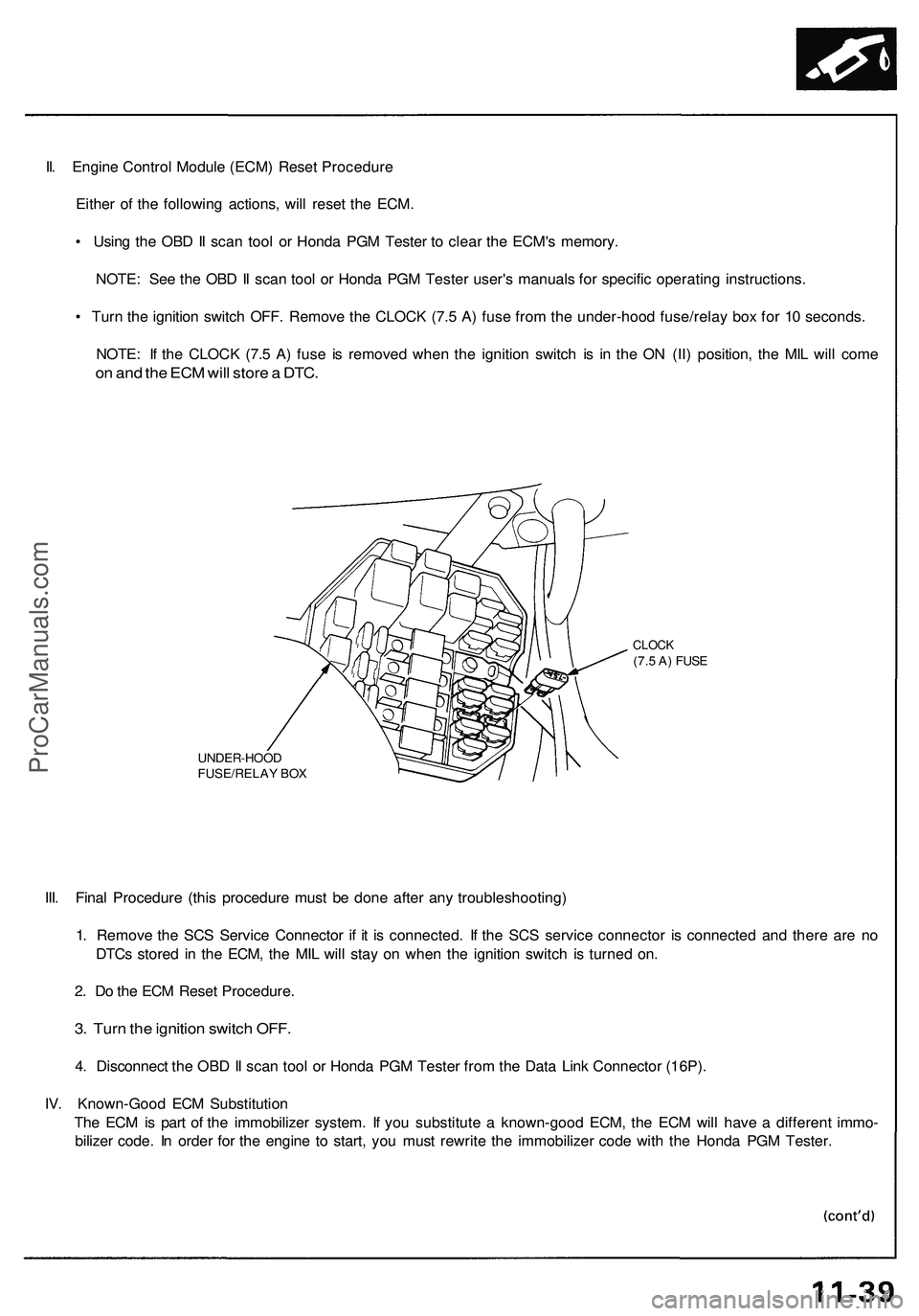

• Turn the ignition switch OFF. Remove the CLOCK (7.5 A) fuse from the under-hood fuse/relay box for 10 seconds.

NOTE: If the CLOCK (7.5 A) fuse is removed when the ignition switch is in the ON (II) position, the MIL will come

on and the ECM will store a DTC.

UNDER-HOOD

FUSE/RELAY BOX

CLOCK

(7.5 A) FUSE

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected. If the SCS service connector is connected and there are no

DTCs stored in the ECM, the MIL will stay on when the ignition switch is turned on.

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).

IV. Known-Good ECM Substitution

The ECM is part of the immobilizer system. If you substitute a known-good ECM, the ECM will have a different immo-

bilizer code. In order for the engine to start, you must rewrite the immobilizer code with the Honda PGM Tester.ProCarManuals.com

Page 269 of 1503

Lighting Syste m

HID Bulb Removal

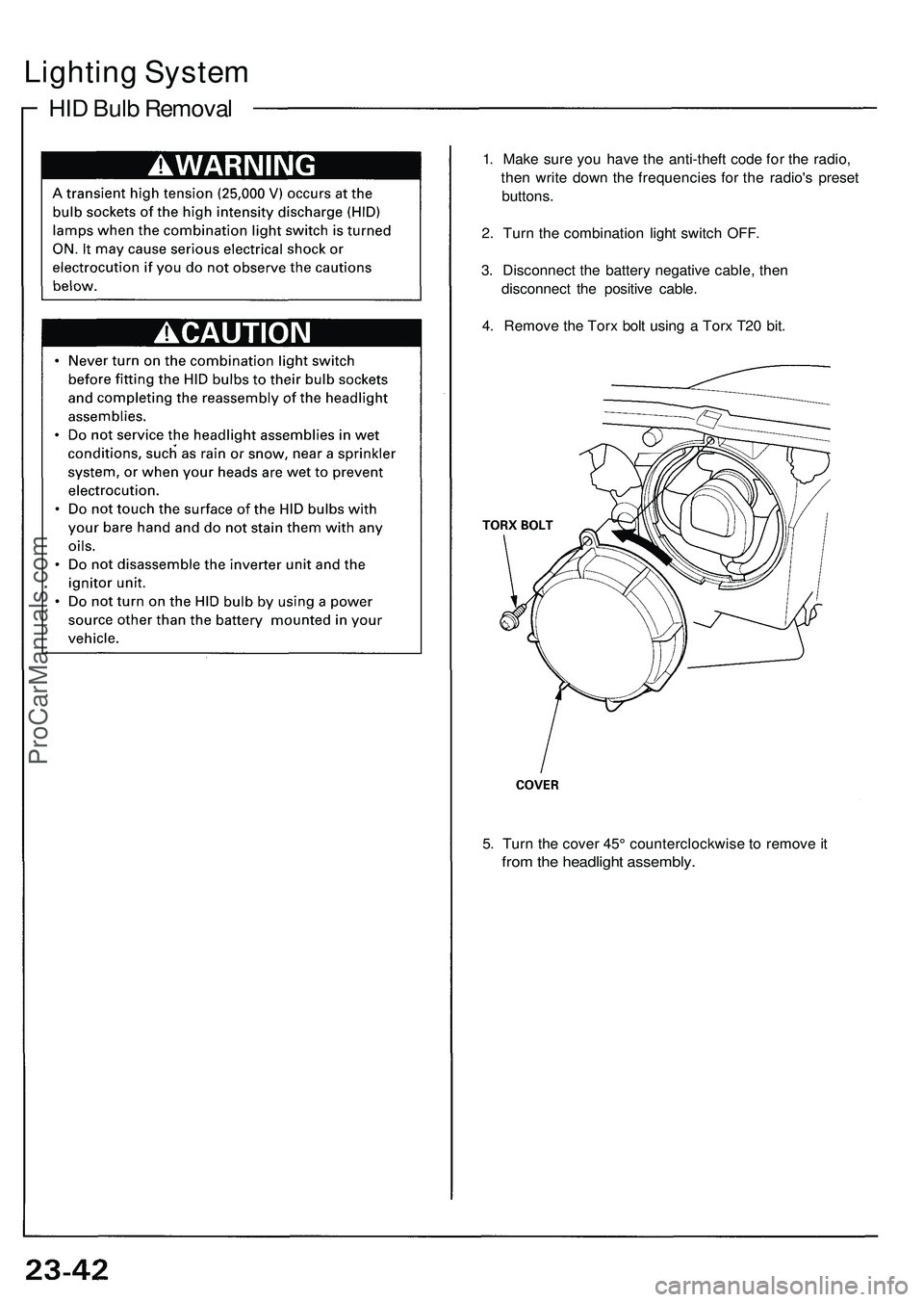

1. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s prese t

buttons .

2 . Tur n th e combinatio n ligh t switc h OFF .

3 . Disconnec t th e batter y negativ e cable , the n

disconnec t th e positiv e cable .

4 . Remov e th e Tor x bol t usin g a Tor x T2 0 bit .

5 . Tur n th e cove r 45 ° counterclockwis e to remov e it

fro m th e headligh t assembly .

ProCarManuals.com

Page 270 of 1503

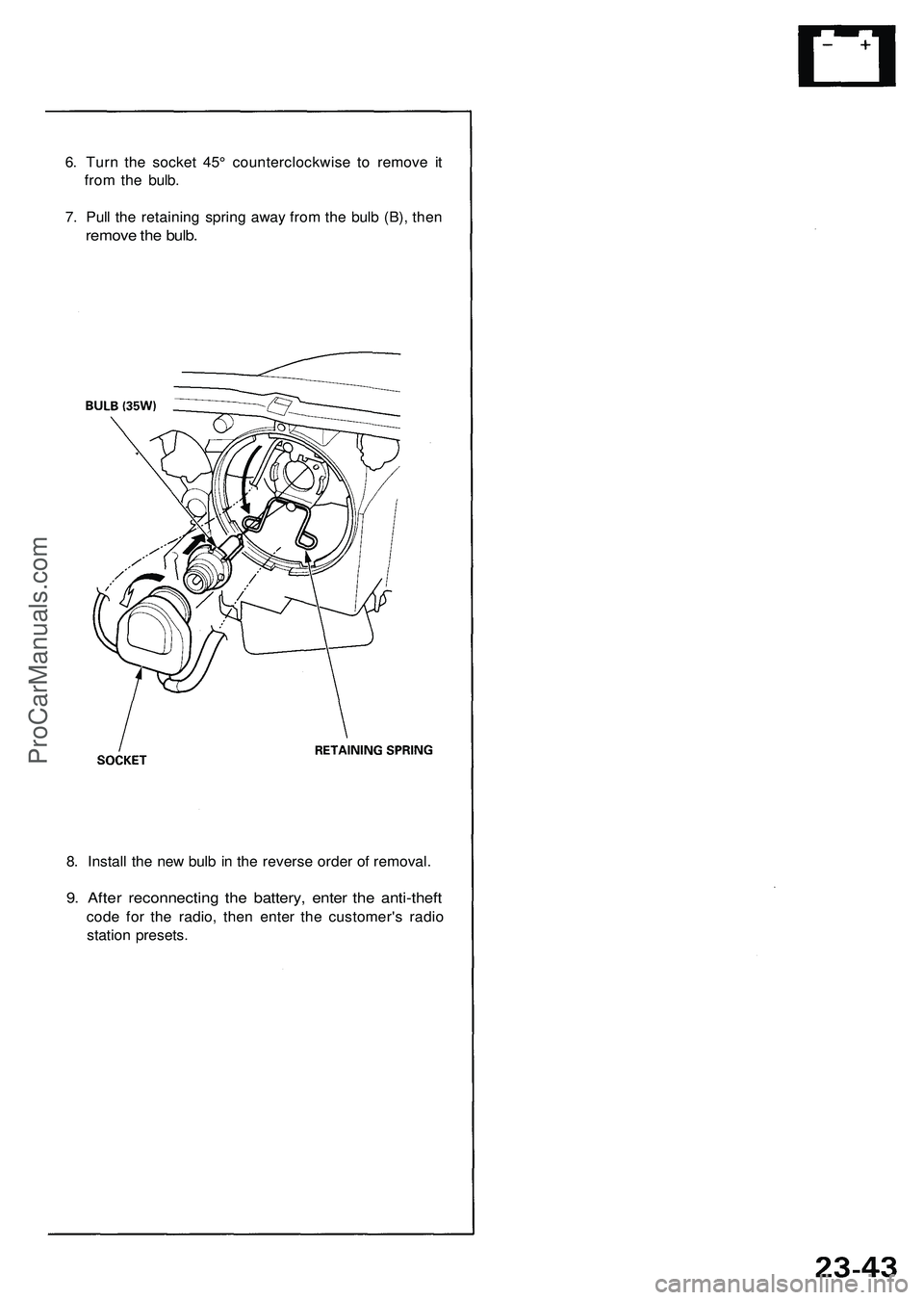

6. Turn the socket 45° counterclockwise to remove it

from the bulb.

7. Pull the retaining spring away from the bulb (B), then

remove the bulb.

8. Install the new bulb in the reverse order of removal.

9. After reconnecting the battery, enter the anti-theft

code for the radio, then enter the customer's radio

station presets.ProCarManuals.com

Page 276 of 1503

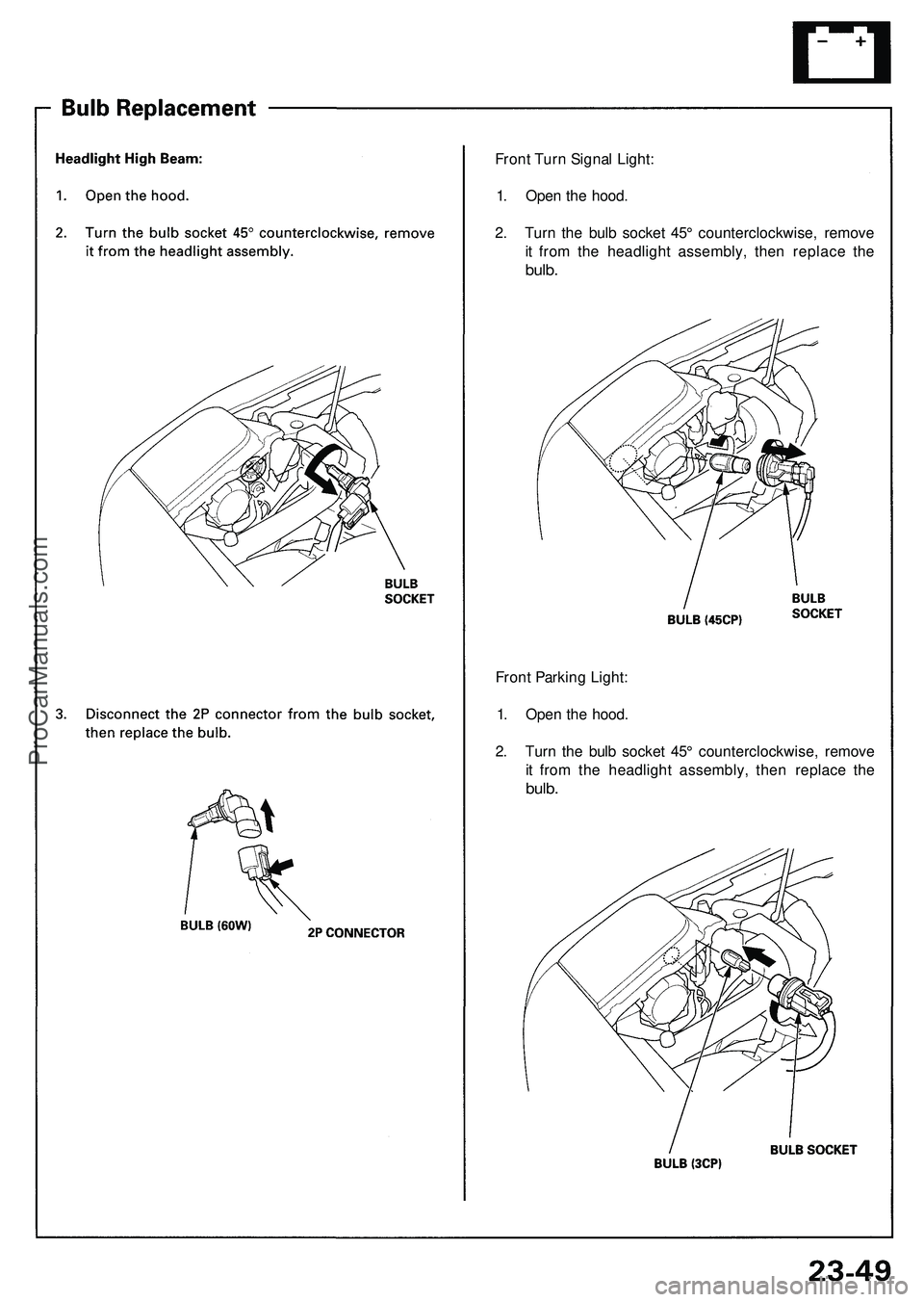

Front Turn Signal Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.

Front Parking Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.ProCarManuals.com

Page 368 of 1503

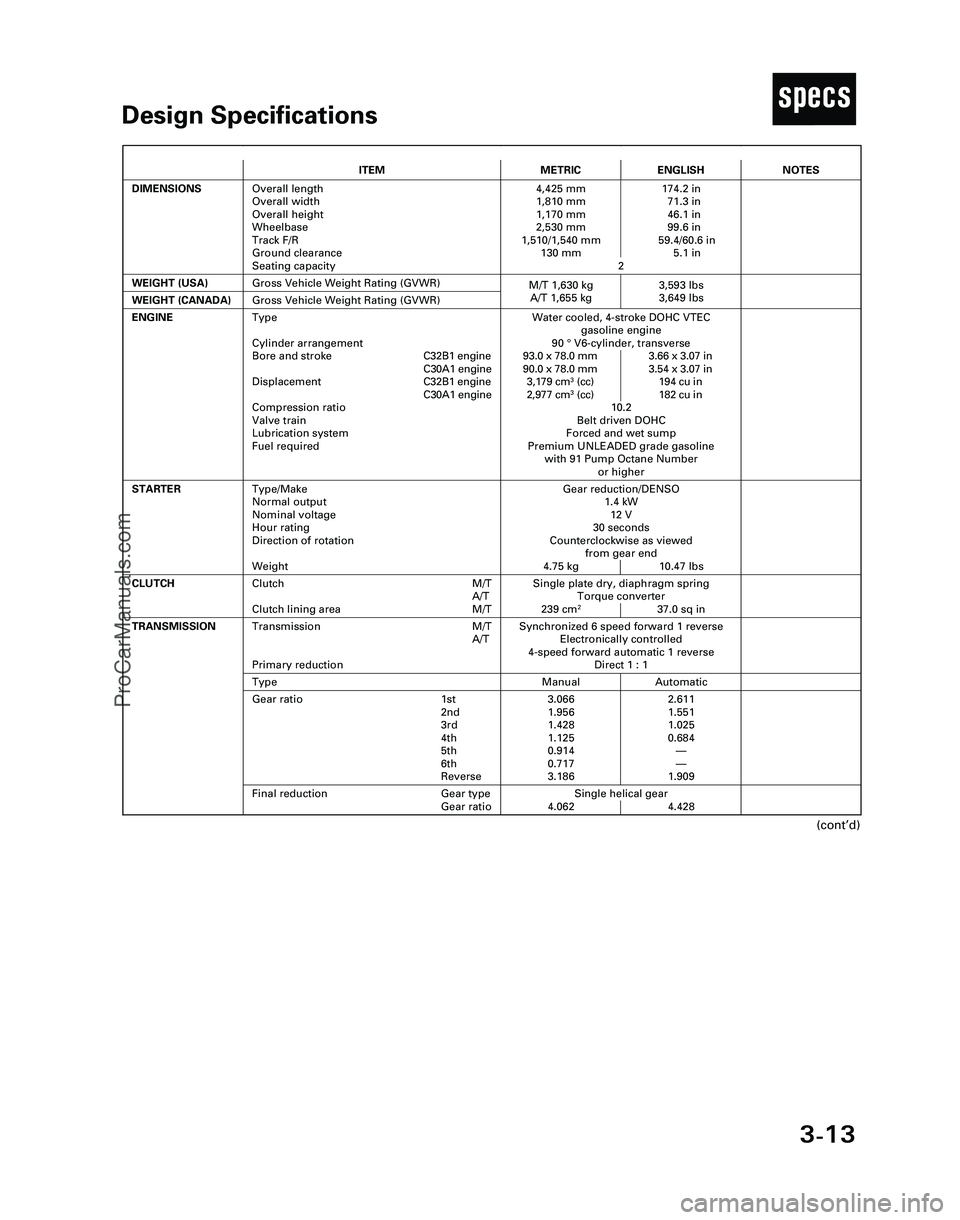

3-13

TDesign Specifications

(cont’d)

ITEMMETRICENGLISH

DIMENSIONSOverall length

Overall width

Overall height

Wheelbase

Track F/R

Ground clearance

Seating capacity4,425 mm 174.2 in

1,810 mm 71.3 in

1,170 mm 46.1 in

2,530 mm 99.6 in

1,510/1,540 mm 59.4/60.6 in

130 mm 5.1 in

2

WEIGHT (USA)

Single plate dry, diaphragm spring

Torque converter

239 cm

237.0 sq in

CLUTCHClutch M/T

A/T

Clutch lining area M/T

Gross Vehicle Weight Rating (GVWR)

NOTES

Gear reduction/DENSO

1.4 kW

12 V

30 seconds

Counterclockwise as viewed

from gear end

4.75 kg 10.47 lbs

ENGINEWater cooled, 4-stroke DOHC VTEC

gasoline engine

90 °V6-cylinder, transverse

93.0 x 78.0 mm 3.66 x 3.07 in

90.0 x 78.0 mm 3.54 x 3.07 in

3,179 cm

3(cc) 194 cu in

2,977 cm3(cc) 182 cu in

10.2

Belt driven DOHC

Forced and wet sump

Premium UNLEADED grade gasoline

with 91 Pump Octane Number

or higher

STARTERType/Make

Normal output

Nominal voltage

Hour rating

Direction of rotation

Weight

WEIGHT (CANADA)Gross Vehicle Weight Rating (GVWR)

Synchronized 6 speed forward 1 reverse

Electronically controlled

4-speed forward automatic 1 reverse

Direct 1 : 1Transmission M/T

A/T

Primary reduction

Manual AutomaticType

3.066 2.611

1.956 1.551

1.428 1.025

1.125 0.684

0.914—

0.717—

3.186 1.909Gear ratio 1st

2nd

3rd

4th

5th

6th

Reverse

Single helical gear

4.062 4.428

TRANSMISSION

Final reduction Gear type

Gear ratio

Type

Cylinder arrangement

Bore and strokeC32B1 engine

C30A1 engine

DisplacementC32B1 engine

C30A1 engine

Compression ratio

Valve train

Lubrication system

Fuel required

M/T 1,630 kg 3,593 lbs

A/T 1,655 kg 3,649 lbs

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-13

ProCarManuals.com

Page 426 of 1503

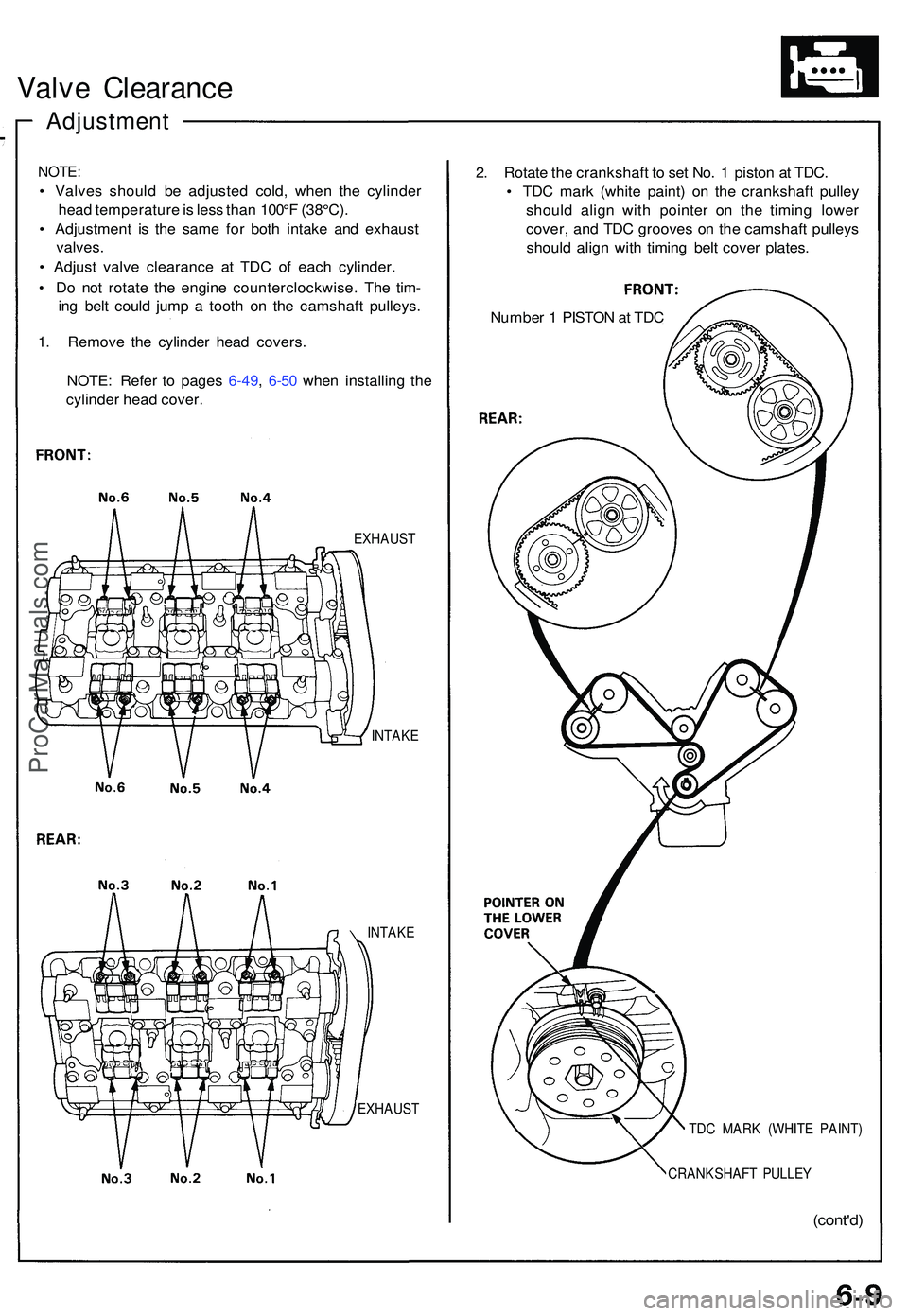

Valve Clearanc e

Adjustmen t

NOTE:

• Valve s shoul d b e adjuste d cold , whe n th e cylinde r

hea d temperatur e is les s tha n 100° F (38°C) .

• Adjustmen t i s th e sam e fo r bot h intak e an d exhaus t

valves .

• Adjus t valv e clearanc e a t TD C o f eac h cylinder .

• D o no t rotat e th e engin e counterclockwise . Th e tim -

in g bel t coul d jum p a toot h o n th e camshaf t pulleys .

1 . Remov e th e cylinde r hea d covers .

NOTE : Refe r t o page s 6-49 , 6-5 0 whe n installin g th e

cylinde r hea d cover .

EXHAUS T

INTAK E

INTAK E

EXHAUS T

2. Rotat e th e crankshaf t t o se t No . 1 pisto n a t TDC .

• TD C mar k (whit e paint ) o n th e crankshaf t pulle y

shoul d alig n wit h pointe r o n th e timin g lowe r

cover , an d TD C groove s o n th e camshaf t pulley s

shoul d alig n wit h timin g bel t cove r plates .

Numbe r 1 PISTO N a t TD C

TDC MAR K (WHIT E PAINT )

CRANKSHAF T PULLE Y

(cont'd)

ProCarManuals.com

Page 428 of 1503

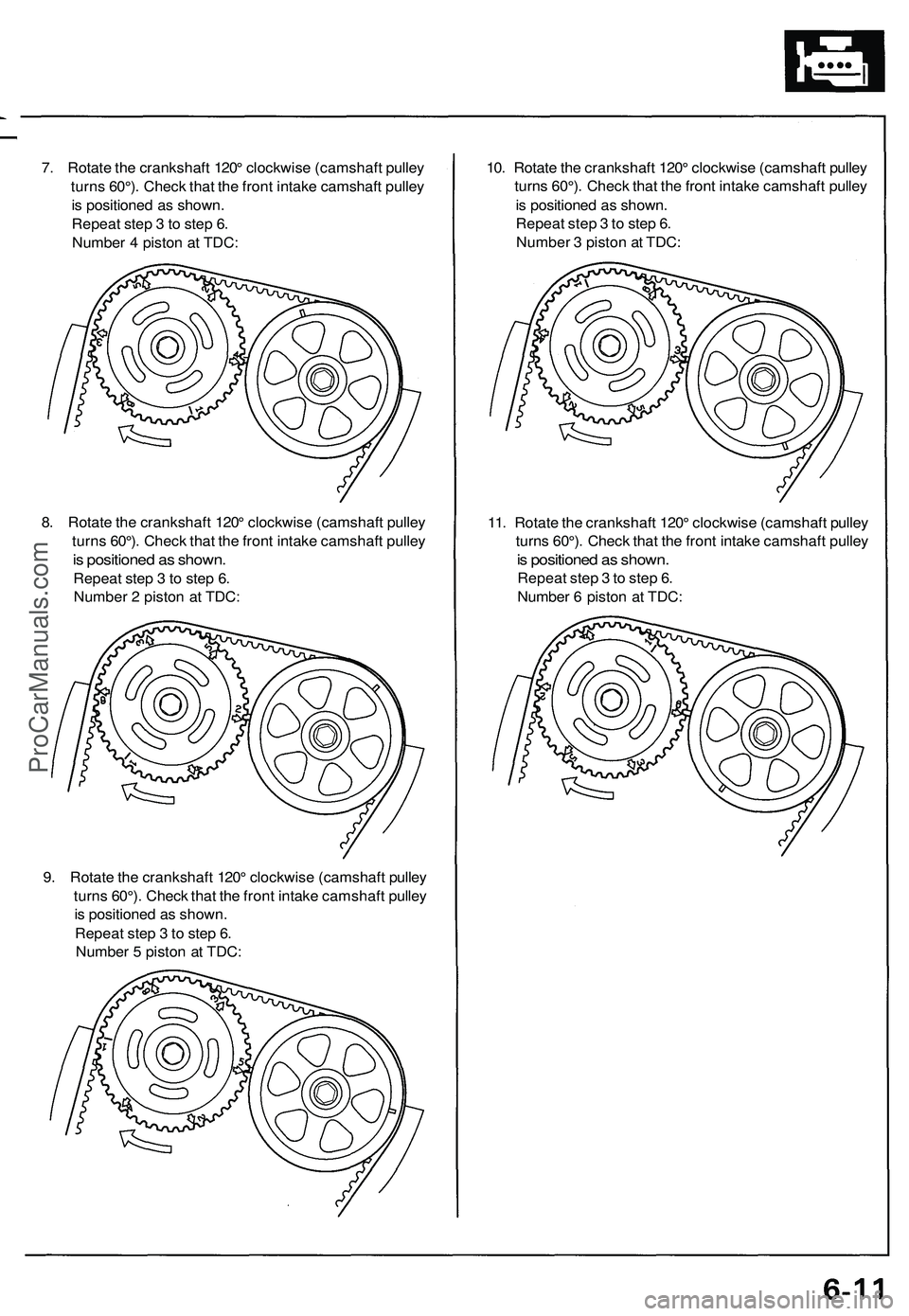

7. Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 4 pisto n a t TDC :

8 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

is positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 2 pisto n a t TDC :

9 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 5 pisto n a t TDC : 10

. Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 3 pisto n a t TDC :

11 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

is positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 6 pisto n a t TDC :

ProCarManuals.com

Page 431 of 1503

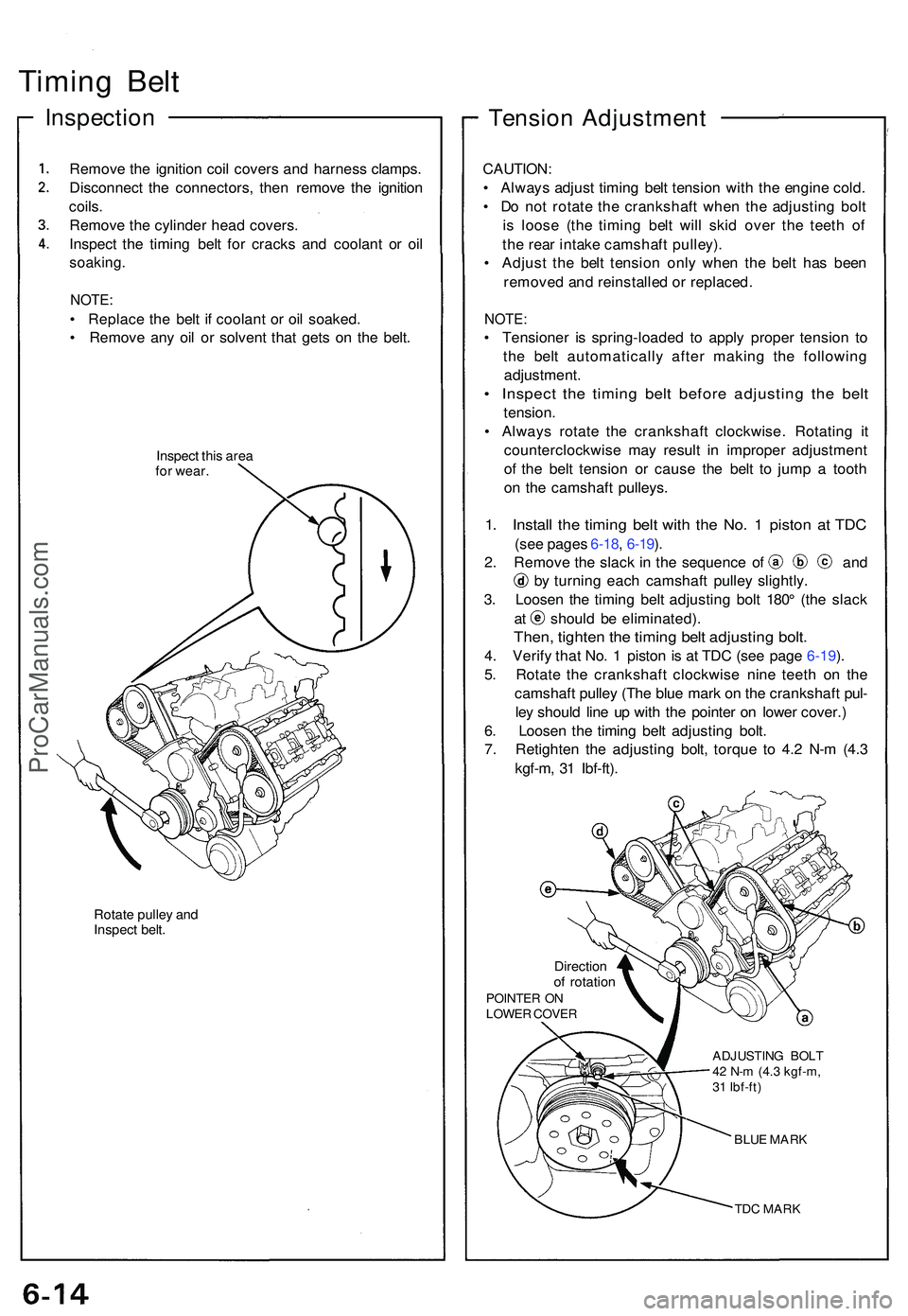

Timing Bel t

Inspectio n

Remove th e ignitio n coi l cover s an d harnes s clamps .

Disconnec t th e connectors , the n remov e th e ignitio n

coils .

Remov e th e cylinde r hea d covers .

Inspec t th e timin g bel t fo r crack s an d coolan t o r oi l

soaking .

NOTE:

• Replac e th e bel t i f coolan t o r oi l soaked .

• Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s are a

fo r wear .

Rotate pulle y an d

Inspec t belt .

Tensio n Adjustmen t

CAUTION:

• Alway s adjus t timin g bel t tensio n wit h th e engin e cold .

• D o no t rotat e th e crankshaf t whe n th e adjustin g bol t

i s loos e (th e timin g bel t wil l ski d ove r th e teet h o f

th e rea r intak e camshaf t pulley) .

• Adjus t th e bel t tensio n onl y whe n th e bel t ha s bee n

remove d an d reinstalle d o r replaced .

NOTE:

• Tensione r i s spring-loade d t o appl y prope r tensio n t o

th e bel t automaticall y afte r makin g th e followin g

adjustment .

• Inspec t th e timin g bel t befor e adjustin g th e bel t

tension .

• Alway s rotat e th e crankshaf t clockwise . Rotatin g i t

counterclockwis e ma y resul t i n imprope r adjustmen t

o f th e bel t tensio n o r caus e th e bel t t o jum p a toot h

o n th e camshaf t pulleys .

1. Instal l th e timin g bel t wit h th e No . 1 pisto n a t TD C

(see page s 6-18 , 6-19 ).

2 . Remov e th e slac k i n th e sequenc e o f an d

by turnin g eac h camshaf t pulle y slightly .

3 . Loose n th e timin g bel t adjustin g bol t 180 ° (th e slac k

at shoul d b e eliminated) .

Then, tighte n th e timin g bel t adjustin g bolt .

4. Verif y tha t No . 1 pisto n i s a t TD C (se e pag e 6-19 ).

5 . Rotat e th e crankshaf t clockwis e nin e teet h o n th e

camshaf t pulle y (Th e blu e mar k o n th e crankshaf t pul -

le y shoul d lin e u p wit h th e pointe r o n lowe r cover. )

6 . Loose n th e timin g bel t adjustin g bolt .

7 . Retighte n th e adjustin g bolt , torqu e t o 4. 2 N- m (4. 3

kgf-m , 3 1 Ibf-ft) .

Directio nof rotatio nPOINTE R O NLOWE R COVE R

ADJUSTING BOL T

42 N- m (4. 3 kgf-m ,

3 1 Ibf-ft )

BLUE MAR K

TDC MAR K

ProCarManuals.com

Page 435 of 1503

Timing Belt

Installation

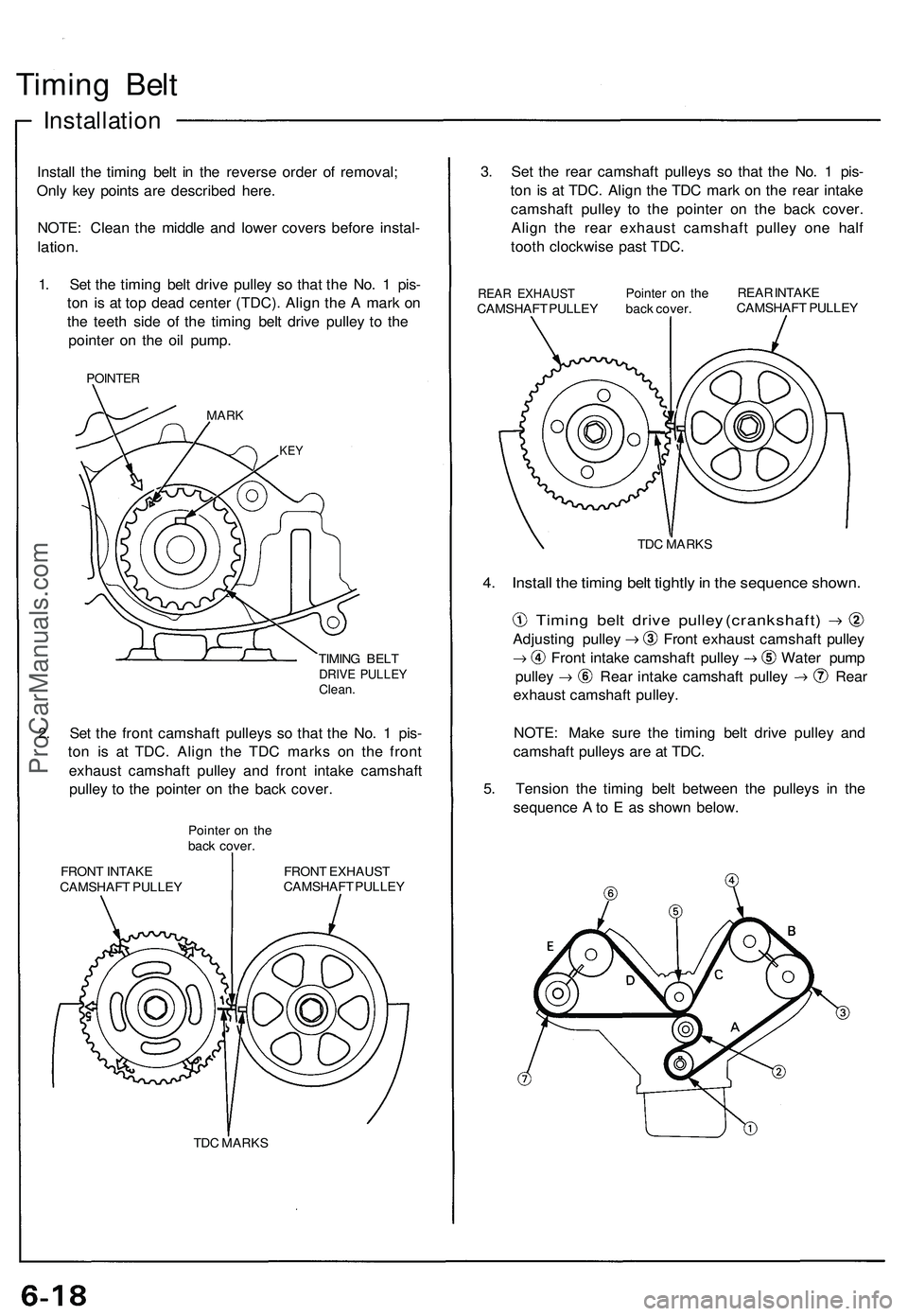

Install the timing belt in the reverse order of removal;

Only key points are described here.

NOTE: Clean the middle and lower covers before instal-

lation.

1. Set the timing belt drive pulley so that the No. 1 pis-

ton is at top dead center (TDC). Align the A mark on

the teeth side of the timing belt drive pulley to the

pointer on the oil pump.

POINTER

MARK

KEY

TIMING BELT

DRIVE PULLEY

Clean.

2. Set the front camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC marks on the front

exhaust camshaft pulley and front intake camshaft

pulley to the pointer on the back cover.

Pointer on the

back cover.

FRONT INTAKE

CAMSHAFT PULLEY

FRONT EXHAUST

CAMSHAFT PULLEY

TDC MARKS

3. Set the rear camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC mark on the rear intake

camshaft pulley to the pointer on the back cover.

Align the rear exhaust camshaft pulley one half

tooth clockwise past TDC.

REAR EXHAUST

CAMSHAFT PULLEY

Pointer on the

back cover.

REAR INTAKE

CAMSHAFT PULLEY

TDC MARKS

4. Install the timing belt tightly in the sequence shown.

Timing belt drive pulley (crankshaft)

Adjusting pulley Front exhaust camshaft pulley

Front intake camshaft pulley Water pump

pulley Rear intake camshaft pulley Rear

exhaust camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

5. Tension the timing belt between the pulleys in the

sequence A to E as shown below.ProCarManuals.com

Page 463 of 1503

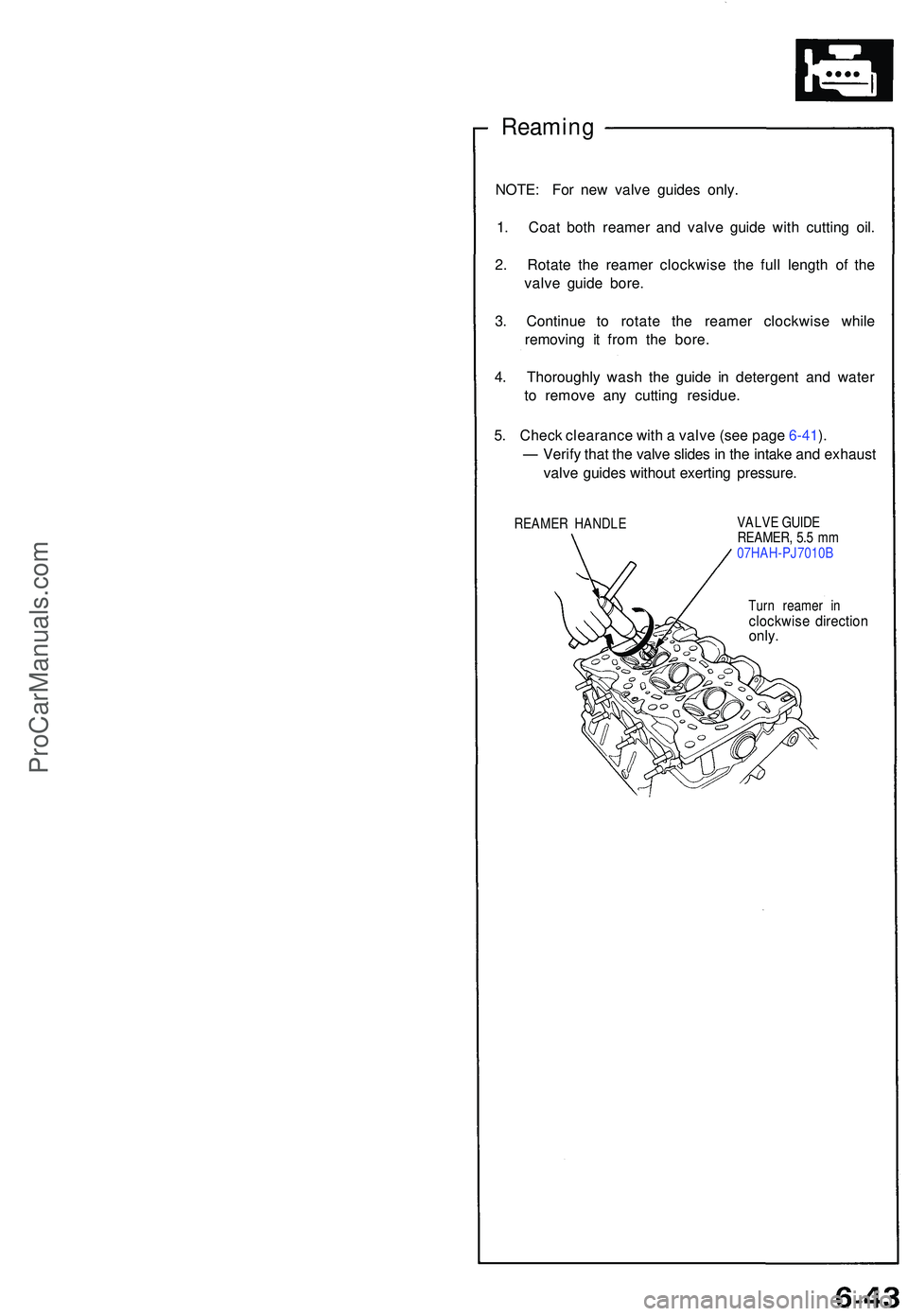

Reaming

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h reame r an d valv e guid e wit h cuttin g oil .

2 . Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e

removin g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k clearanc e wit h a valv e (se e pag e 6-41 ).

— Verif y tha t th e valv e slide s in th e intak e an d exhaus t

valv e guide s withou t exertin g pressure .

REAMER HANDL E VALV

E GUID E

REAMER , 5. 5 m m

07HAH-PJ7010 B

Tur n reame r i n

clockwis e directio nonly.

ProCarManuals.com