length ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 292 of 1503

Overhaul (Cont'd )

Manual Steerin g

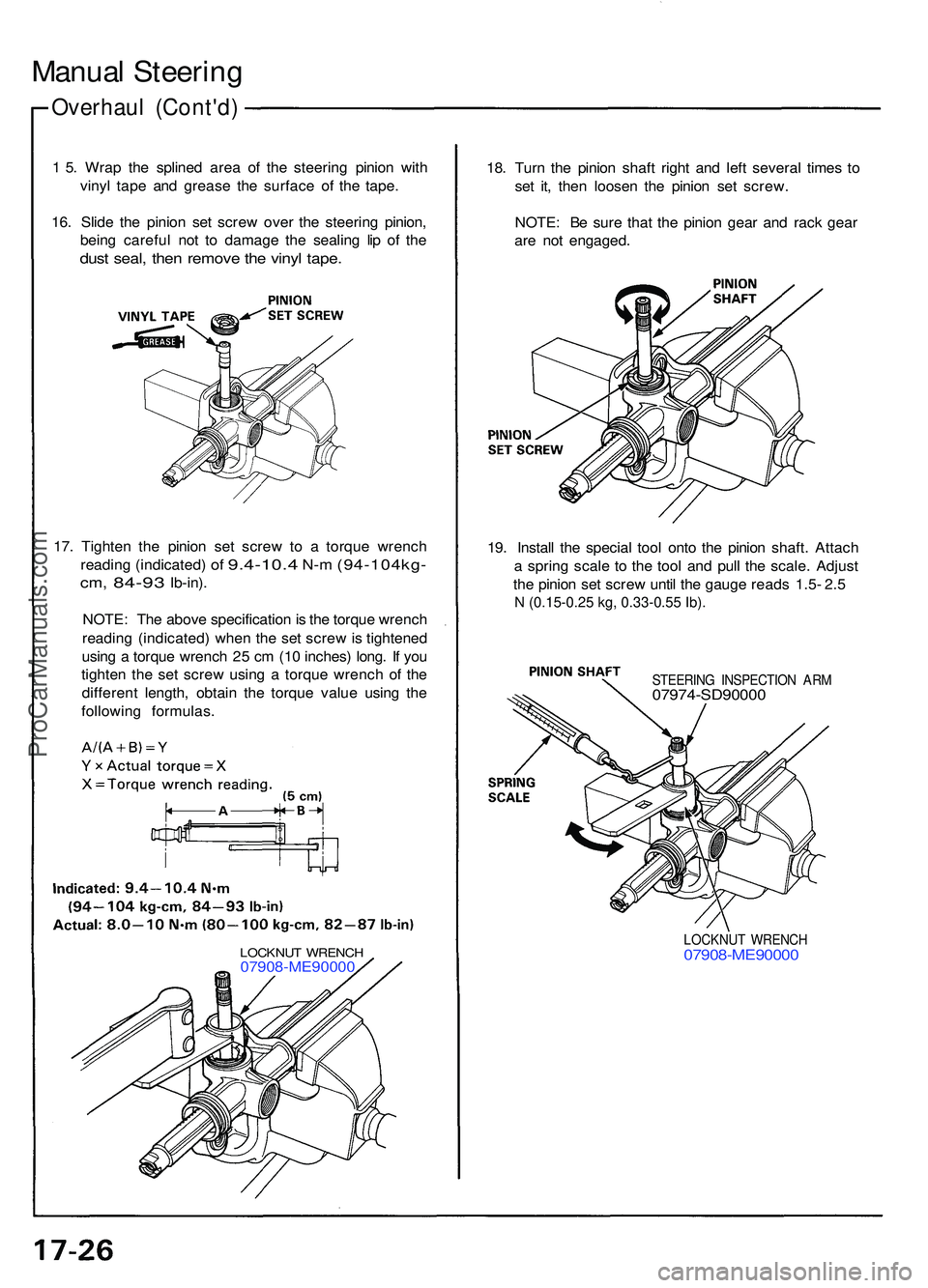

1 5 . Wra p th e spline d are a o f th e steerin g pinio n wit h

viny l tap e an d greas e th e surfac e o f th e tape .

16 . Slid e th e pinio n se t scre w ove r th e steerin g pinion ,

bein g carefu l no t t o damag e th e sealin g li p o f th e

dus t seal , the n remov e th e viny l tape .

18. Tur n th e pinio n shaf t righ t an d lef t severa l time s t o

se t it , the n loose n th e pinio n se t screw .

NOTE : B e sur e tha t th e pinio n gea r an d rac k gea r

ar e no t engaged .

19 . Instal l th e specia l too l ont o th e pinio n shaft . Attac h

a sprin g scal e t o th e too l an d pul l th e scale . Adjus t

th e pinio n se t scre w unti l th e gaug e read s 1. 5- 2. 5

N (0.15-0.25 kg, 0.33-0.55 Ib).

STEERIN G INSPECTIO N AR M07974-SD9000 0

LOCKNUT WRENC H07908-ME9000 0

17. Tighte n th e pinio n se t scre w t o a torqu e wrenc h

readin g (indicated )

of 9.4-10. 4 N-m (94-104kg -

cm, 84-9 3 Ib-in) .

NOTE : Th e abov e specificatio n is th e torqu e wrenc h

readin g (indicated ) whe n th e se t scre w is tightene d

usin g a torqu e wrenc h 2 5 c m (1 0 inches ) long . I f yo u

tighte n th e se t scre w usin g a torqu e wrenc h o f th e

differen t length , obtai n th e torqu e valu e usin g th e

followin g formulas .

LOCKNUT WRENC H07908-ME9000 0

ProCarManuals.com

Page 294 of 1503

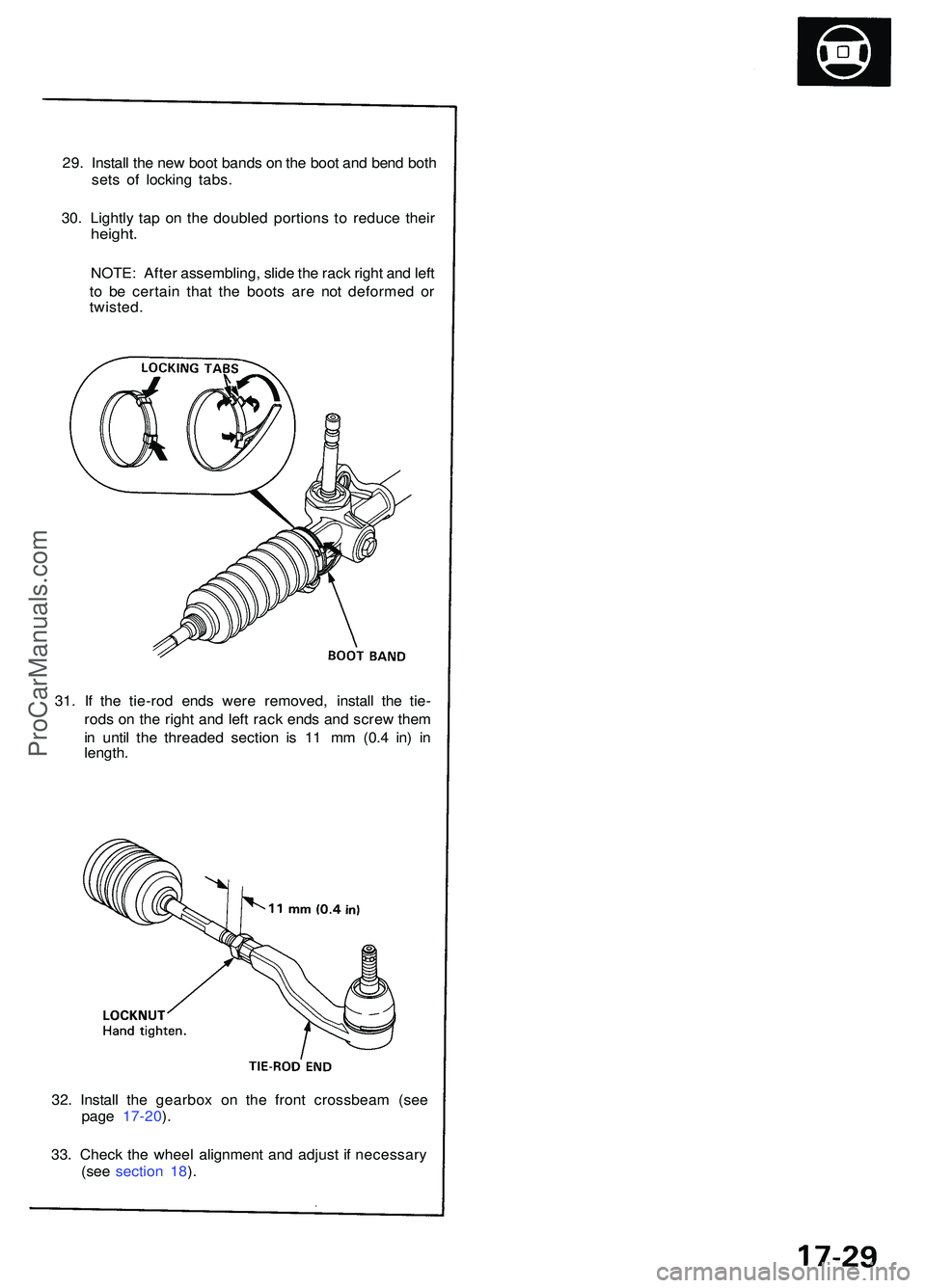

29. Instal l th e ne w boo t band s o n th e boo t an d ben d bot h

set s o f lockin g tabs .

30 . Lightl y ta p o n th e double d portion s t o reduc e thei r

height .

NOTE : Afte r assembling , slid e th e rac k righ t an d lef t

t o b e certai n tha t th e boot s ar e no t deforme d o r

twisted .

32 . Instal l th e gearbo x o n th e fron t crossbea m (se e

pag e 17-20 ).

33 . Chec k th e whee l alignmen t an d adjus t i f necessar y

(se e sectio n 18 ).

31

. I f th e tie-ro d end s wer e removed , instal l th e tie -

rod s o n th e righ t an d lef t rac k end s an d scre w the m

i n unti l th e threade d sectio n i s 1 1 m m (0. 4 in ) i n

length .

ProCarManuals.com

Page 367 of 1503

3-2

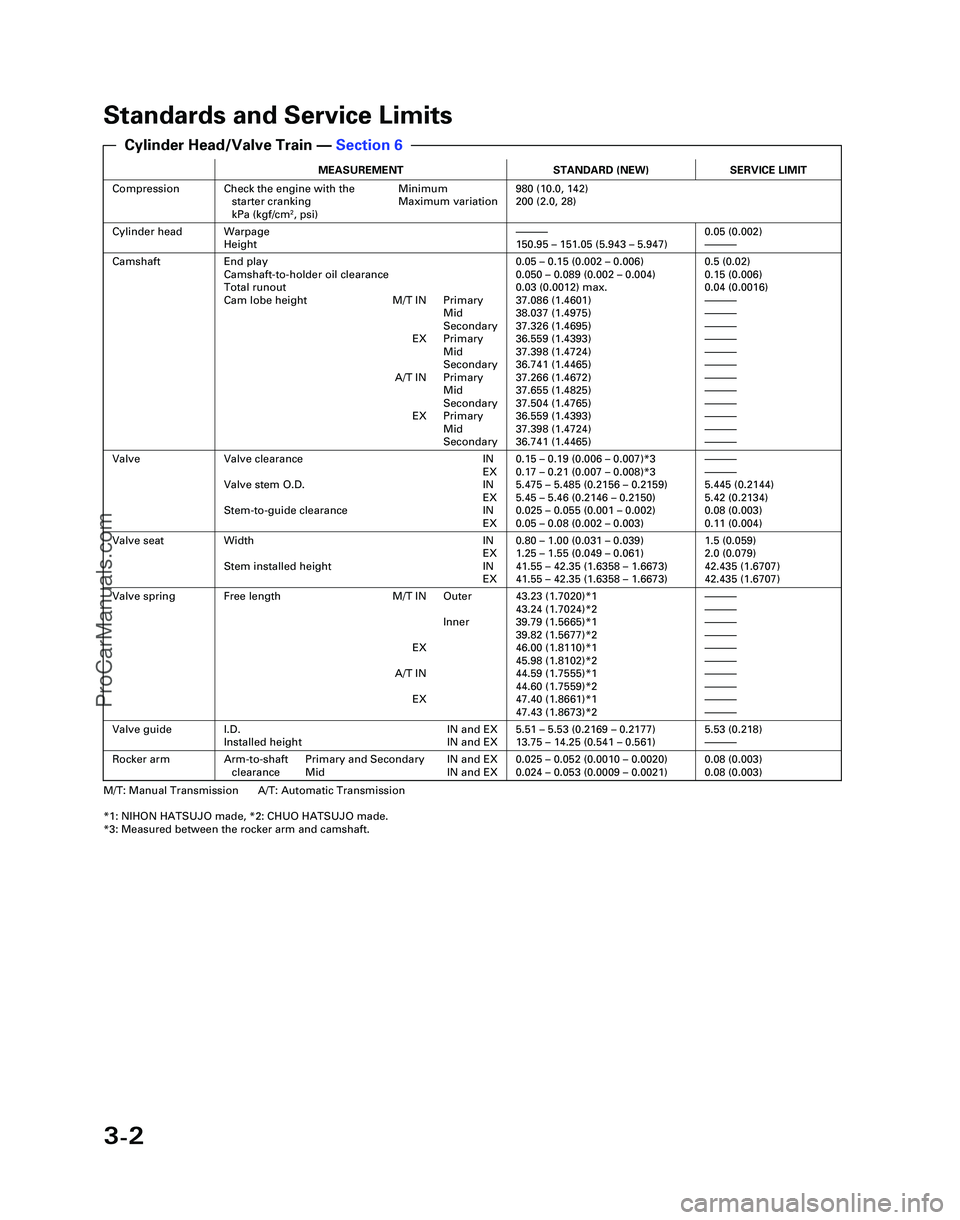

Standards and Service Limits

MEASUREMENTSTANDARD (NEW)SERVICE LIMIT

CompressionCheck the engine with the Minimumstarter cranking Maximum variation

kPa (kgf/cm

2, psi)

980 (10.0, 142)

200 (2.0, 28)

Cylinder headWarpage

Height—150.95 – 151.05 (5.943 – 5.947)0.05 (0.002)—

CamshaftEnd play

Camshaft-to-holder oil clearance

Total runout

Cam lobe height M/T IN Primary Mid

Secondary

EX Primary Mid

Secondary

A/T IN Primary Mid

Secondary

EX Primary Mid

Secondary0.05 – 0.15 (0.002 – 0.006)

0.050 – 0.089 (0.002 – 0.004)

0.03 (0.0012) max.

37.086 (1.4601)

38.037 (1.4975)

37.326 (1.4695)

36.559 (1.4393)

37.398 (1.4724)

36.741 (1.4465)

37.266 (1.4672)

37.655 (1.4825)

37.504 (1.4765)

36.559 (1.4393)

37.398 (1.4724)

36.741 (1.4465)0.5 (0.02)

0.15 (0.006)

0.04 (0.0016)

—

—

—

—

—

—

—

—

—

—

—

—

ValveValve clearance IN EX

Valve stem O.D. IN EX

Stem-to-guide clearance IN EX0.15 – 0.19 (0.006 – 0.007)*3

0.17 – 0.21 (0.007 – 0.008)*3

5.475 – 5.485 (0.2156 – 0.2159)

5.45 – 5.46 (0.2146 – 0.2150)

0.025 – 0.055 (0.001 – 0.002)

0.05 – 0.08 (0.002 – 0.003)—

—

5.445 (0.2144)

5.42 (0.2134)

0.08 (0.003)

0.11 (0.004)

Valve seatWidth INEX

Stem installed height IN EX0.80 – 1.00 (0.031 – 0.039)

1.25 – 1.55 (0.049 – 0.061)

41.55 – 42.35 (1.6358 – 1.6673)

41.55 – 42.35 (1.6358 – 1.6673)1.5 (0.059)

2.0 (0.079)

42.435 (1.6707)

42.435 (1.6707)

Valve springFree length M/T IN Outer

Inner

EX

A/T IN EX43.23 (1.7020)*1

43.24 (1.7024)*2

39.79 (1.5665)*1

39.82 (1.5677)*2

46.00 (1.8110)*1

45.98 (1.8102)*2

44.59 (1.7555)*1

44.60 (1.7559)*2

47.40 (1.8661)*1

47.43 (1.8673)*2—

—

—

—

—

—

—

—

—

—

Valve guideI.D. IN and EX

Installed height IN and EX5.51 – 5.53 (0.2169 – 0.2177)

13.75 – 14.25 (0.541 – 0.561)5.53 (0.218)—

Rocker armArm-to-shaft Primary and Secondary IN and EXclearance Mid IN and EX0.025 – 0.052 (0.0010 – 0.0020)

0.024 – 0.053 (0.0009 – 0.0021)0.08 (0.003)

0.08 (0.003)

M/T: Manual Transmission A/T: Automatic Transmission

*1: NIHON HATSUJO made, *2: CHUO HATSUJO made.

*3: Measured between the rocker arm and camshaft.

Cylinder Head/Valve Train — Section 6

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:48 PM Page 3-2

ProCarManuals.com

Page 368 of 1503

3-13

TDesign Specifications

(cont’d)

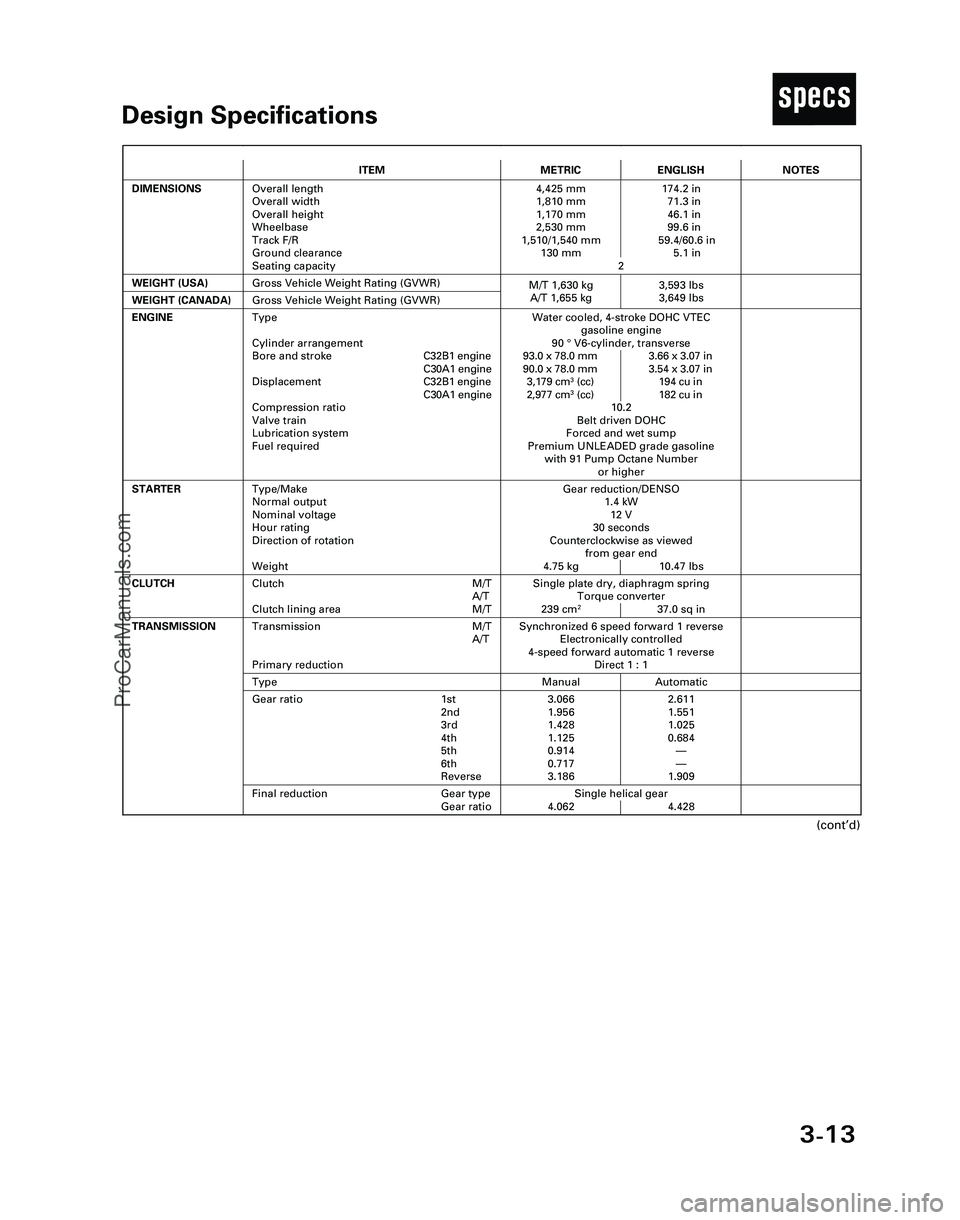

ITEMMETRICENGLISH

DIMENSIONSOverall length

Overall width

Overall height

Wheelbase

Track F/R

Ground clearance

Seating capacity4,425 mm 174.2 in

1,810 mm 71.3 in

1,170 mm 46.1 in

2,530 mm 99.6 in

1,510/1,540 mm 59.4/60.6 in

130 mm 5.1 in

2

WEIGHT (USA)

Single plate dry, diaphragm spring

Torque converter

239 cm

237.0 sq in

CLUTCHClutch M/T

A/T

Clutch lining area M/T

Gross Vehicle Weight Rating (GVWR)

NOTES

Gear reduction/DENSO

1.4 kW

12 V

30 seconds

Counterclockwise as viewed

from gear end

4.75 kg 10.47 lbs

ENGINEWater cooled, 4-stroke DOHC VTEC

gasoline engine

90 °V6-cylinder, transverse

93.0 x 78.0 mm 3.66 x 3.07 in

90.0 x 78.0 mm 3.54 x 3.07 in

3,179 cm

3(cc) 194 cu in

2,977 cm3(cc) 182 cu in

10.2

Belt driven DOHC

Forced and wet sump

Premium UNLEADED grade gasoline

with 91 Pump Octane Number

or higher

STARTERType/Make

Normal output

Nominal voltage

Hour rating

Direction of rotation

Weight

WEIGHT (CANADA)Gross Vehicle Weight Rating (GVWR)

Synchronized 6 speed forward 1 reverse

Electronically controlled

4-speed forward automatic 1 reverse

Direct 1 : 1Transmission M/T

A/T

Primary reduction

Manual AutomaticType

3.066 2.611

1.956 1.551

1.428 1.025

1.125 0.684

0.914—

0.717—

3.186 1.909Gear ratio 1st

2nd

3rd

4th

5th

6th

Reverse

Single helical gear

4.062 4.428

TRANSMISSION

Final reduction Gear type

Gear ratio

Type

Cylinder arrangement

Bore and strokeC32B1 engine

C30A1 engine

DisplacementC32B1 engine

C30A1 engine

Compression ratio

Valve train

Lubrication system

Fuel required

M/T 1,630 kg 3,593 lbs

A/T 1,655 kg 3,649 lbs

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-13

ProCarManuals.com

Page 883 of 1503

Driveshafts

Reassembly

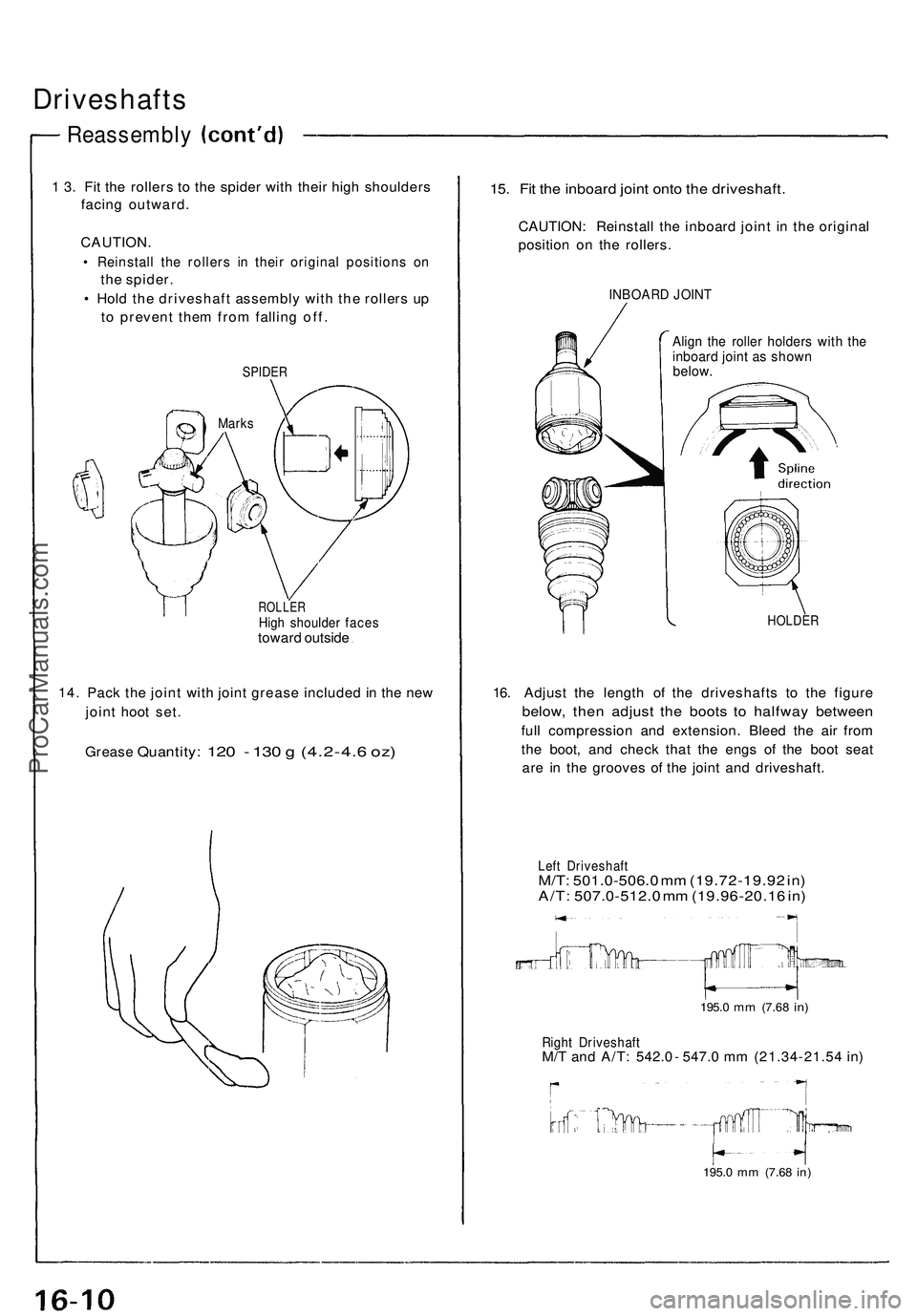

1 3. Fit the rollers to the spider with their high shoulders

facing outward.

CAUTION.

• Reinstall the rollers in their original positions on

the spider.

• Hold the driveshaft assembly with the rollers up

to prevent them from falling off.

SPIDER

ROLLER

High shoulder faces

toward outside

14. Pack the joint with joint grease included in the new

joint hoot set.

Grease

Quantity:

120 - 130 g

(4.2-4.6

oz)

15. Fit the inboard joint onto the driveshaft.

CAUTION: Reinstall the inboard joint in the original

position on the rollers.

INBOARD JOINT

Align the roller holders with the

inboard joint as shown

below.

HOLDER

16. Adjust the length of the driveshafts to the figure

below, then adjust the boots to halfway between

full compression and extension. Bleed the air from

the boot, and check that the engs of the boot seat

are in the grooves of the joint and driveshaft.

Left Driveshaft

M/T: 501.0-506.0 mm (19.72-19.92 in)

A/T: 507.0-512.0 mm (19.96-20.16 in)

195.0

mm

(7.68

in)

Right Driveshaft

M/T and A/T: 542.0 - 547.0 mm (21.34-21.54 in)

195.0

mm

(7.68

in)

MarksProCarManuals.com

Page 932 of 1503

Steering Gearbo x

Inspectio n (cont'd )

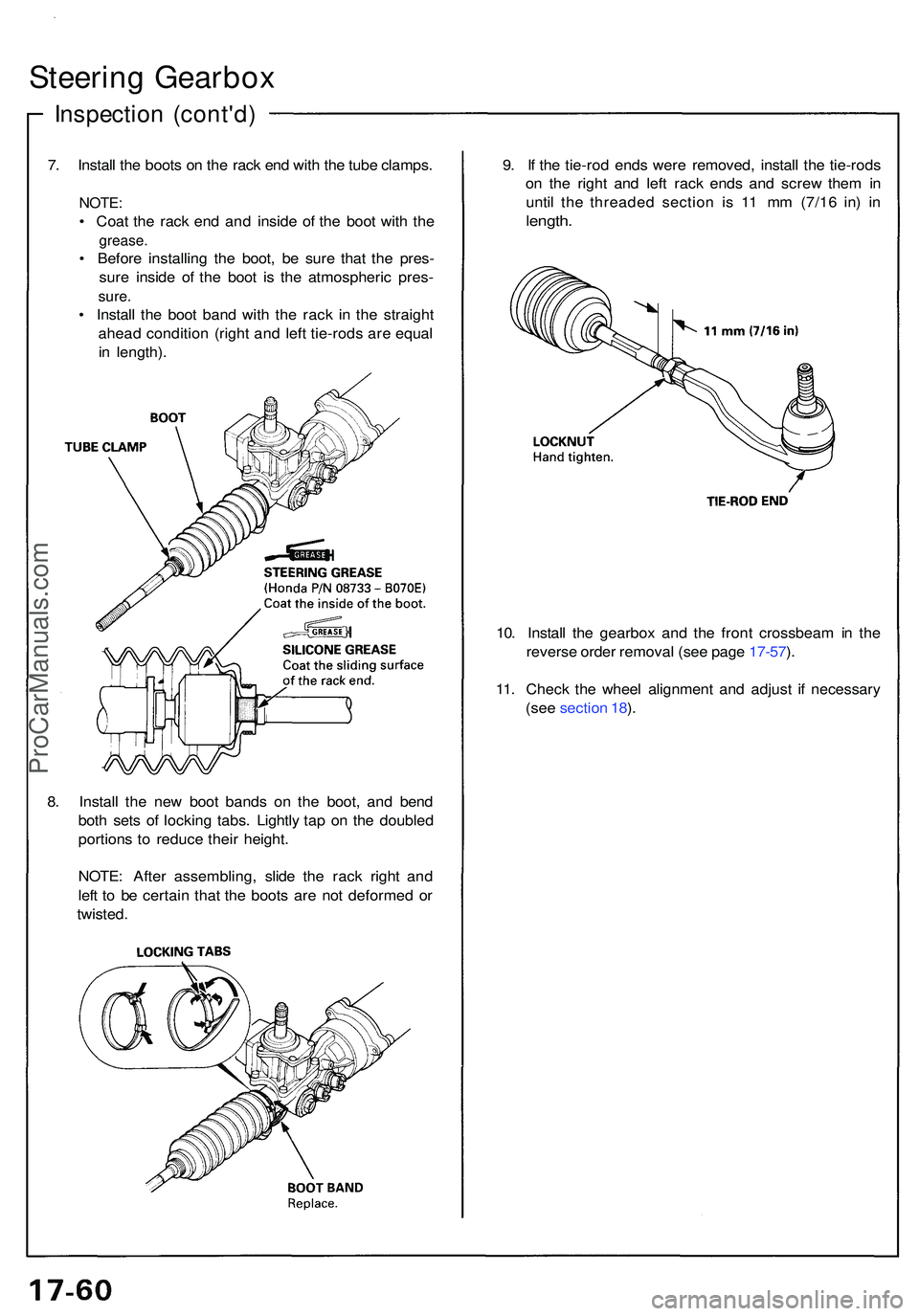

7. Instal l th e boot s o n th e rac k en d wit h th e tub e clamps .

NOTE:

• Coa t th e rac k en d an d insid e o f th e boo t wit h th e

grease .

• Befor e installin g th e boot , b e sur e tha t th e pres -

sur e insid e of the boo t i s th e atmospheri c pres -

sure.

• Instal l th e boo t ban d wit h th e rac k i n th e straigh t

ahea d conditio n (righ t an d lef t tie-rod s ar e equa l

i n length) . 9

. I f th e tie-ro d end s wer e removed , instal l th e tie-rod s

o n th e righ t an d lef t rac k end s an d scre w the m in

until the threade d sectio n i s 1 1 m m (7/1 6 in ) i n

length .

10. Instal l th e gearbo x an d th e fron t crossbea m in th e

revers e orde r remova l (se e pag e 17-57 ).

11 . Chec k th e whee l alignmen t an d adjus t i f necessar y

(se e sectio n 18 ).

8 . Instal l th e ne w boo t band s o n th e boot , an d ben d

bot h set s o f lockin g tabs . Lightl y ta p o n th e double d

portion s t o reduc e thei r height .

NOTE : Afte r assembling , slid e th e rac k righ t an d

lef t t o b e certai n tha t th e boot s ar e no t deforme d o r

twisted .

ProCarManuals.com

Page 945 of 1503

Wheel Alignmen t

Rear Whee l Alignmen t Adjustin g Procedur e

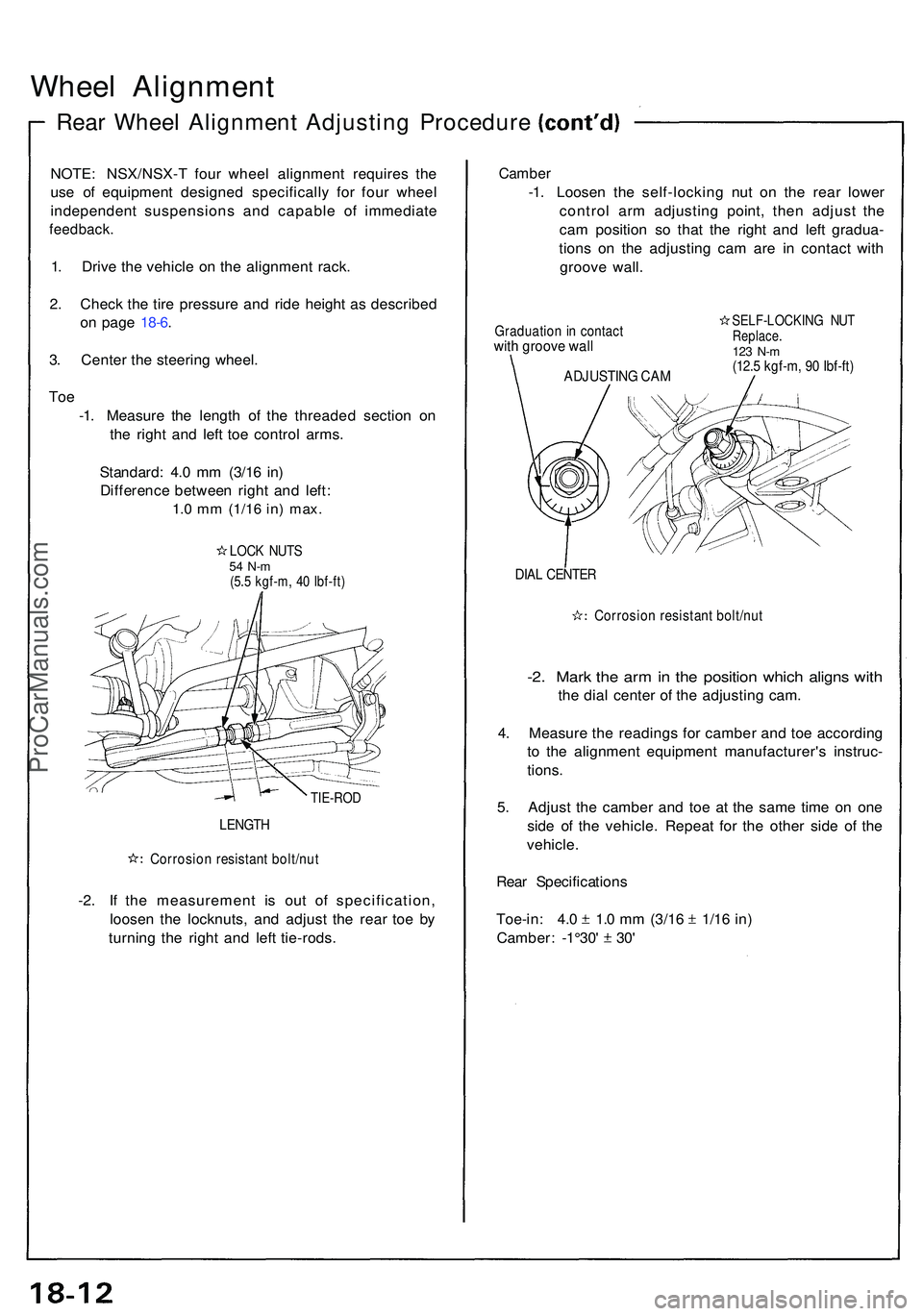

NOTE: NSX/NSX- T fou r whee l alignmen t require s th e

us e o f equipmen t designe d specificall y fo r fou r whee l

independen t suspension s an d capabl e o f immediat e

feedback.

1. Driv e th e vehicl e o n th e alignmen t rack .

2 . Chec k th e tir e pressur e an d rid e heigh t a s describe d

o n pag e 18-6 .

3 . Cente r th e steerin g wheel .

Toe

-1. Measur e th e lengt h o f th e threade d sectio n o n

th e righ t an d lef t to e contro l arms .

Standard : 4. 0 m m (3/1 6 in )

Differenc e betwee n righ t an d left :

1.0 m m (1/1 6 in) max .

LOCK NUT S54 N- m(5.5 kgf-m , 4 0 Ibf-ft )

TIE-RO D

LENGTH

Corrosio n resistan t bolt/nu t

-2. I f th e measuremen t i s ou t o f specification ,

loose n th e locknuts , an d adjus t th e rea r to e b y

turnin g th e righ t an d lef t tie-rods .

Camber

-1. Loose n th e self-lockin g nu t o n th e rea r lowe r

contro l ar m adjustin g point , the n adjus t th e

ca m positio n s o tha t th e righ t an d lef t gradua -

tion s o n th e adjustin g ca m ar e i n contac t wit h

groov e wall .

Graduatio n i n contac twith groov e wal l

SELF-LOCKIN G NU TReplace .123 N- m(12. 5 kgf-m , 9 0 Ibf-ft )

DIAL CENTE R

Corrosio n resistan t bolt/nu t

-2. Mar k th e ar m in th e positio n whic h align s wit h

the dia l cente r o f th e adjustin g cam .

4 . Measur e th e reading s fo r cambe r an d to e accordin g

t o th e alignmen t equipmen t manufacturer' s instruc -

tions .

5 . Adjus t th e cambe r an d to e a t th e sam e tim e o n on e

sid e o f th e vehicle . Repea t fo r th e othe r sid e o f th e

vehicle .

Rea r Specification s

Toe-in: 4. 0 1. 0 m m (3/1 6 1/1 6 in )

Camber : -1°30 ' 30 '

ADJUSTIN G CA M

ProCarManuals.com

Page 1143 of 1503

Roof

Roof Sid e Seal/Retaine r Replacemen t (cont'd )

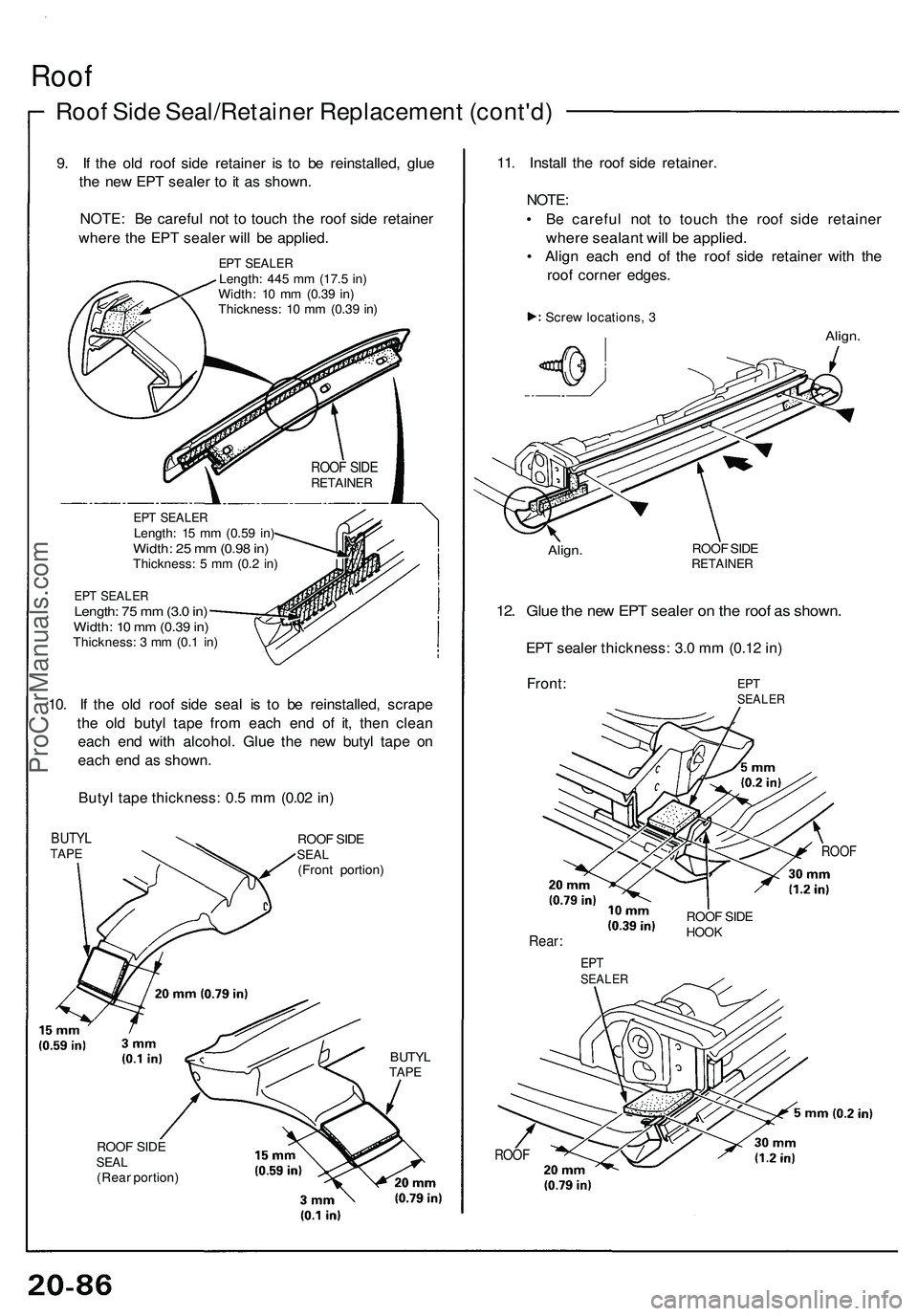

9. I f th e ol d roo f sid e retaine r i s t o b e reinstalled , glu e

th e ne w EP T seale r t o it a s shown .

NOTE : B e carefu l no t t o touc h th e roo f sid e retaine r

wher e th e EP T seale r wil l b e applied .

EPT SEALE RLength: 44 5 m m (17. 5 in )

Width : 1 0 m m (0.3 9 in )

Thickness : 1 0 m m (0.3 9 in )

EP T SEALE RLength: 1 5 m m (0.5 9 in )Width : 2 5 m m (0.9 8 in )Thickness : 5 m m (0. 2 in )

EP T SEALE RLength: 7 5 m m (3. 0 in )Width : 1 0 m m (0.3 9 in )Thickness : 3 m m (0. 1 in )

10. I f th e ol d roo f sid e sea l i s t o b e reinstalled , scrap e

th e ol d buty l tap e fro m eac h en d of it, the n clea n

eac h en d wit h alcohol . Glu e th e ne w buty l tap e o n

eac h en d a s shown .

Buty l tap e thickness : 0. 5 m m (0.0 2 in )

BUTY LTAPEROO F SID ESEA L(Fron t portion )

BUTYLTAPE

ROO F SID ESEA L(Rea r portion )

11. Instal l th e roo f sid e retainer .

NOTE :

• B e carefu l no t t o touc h th e roo f sid e retaine r

where sealan t wil l b e applied .

• Alig n eac h en d o f th e roo f sid e retaine r wit h th e

roo f corne r edges .

Screw locations , 3

Align .

Align.ROOF SID ERETAINE R

12. Glu e th e ne w EP T seale r o n th e roo f a s shown .

EPT seale r thickness : 3. 0 m m (0.1 2 in )

Front :

ROOF

Rear :

ROOF

ROOF SID ERETAINE R

EPTSEALE R

ROOF SID EHOO K

EPTSEALE R

ProCarManuals.com

Page 1255 of 1503

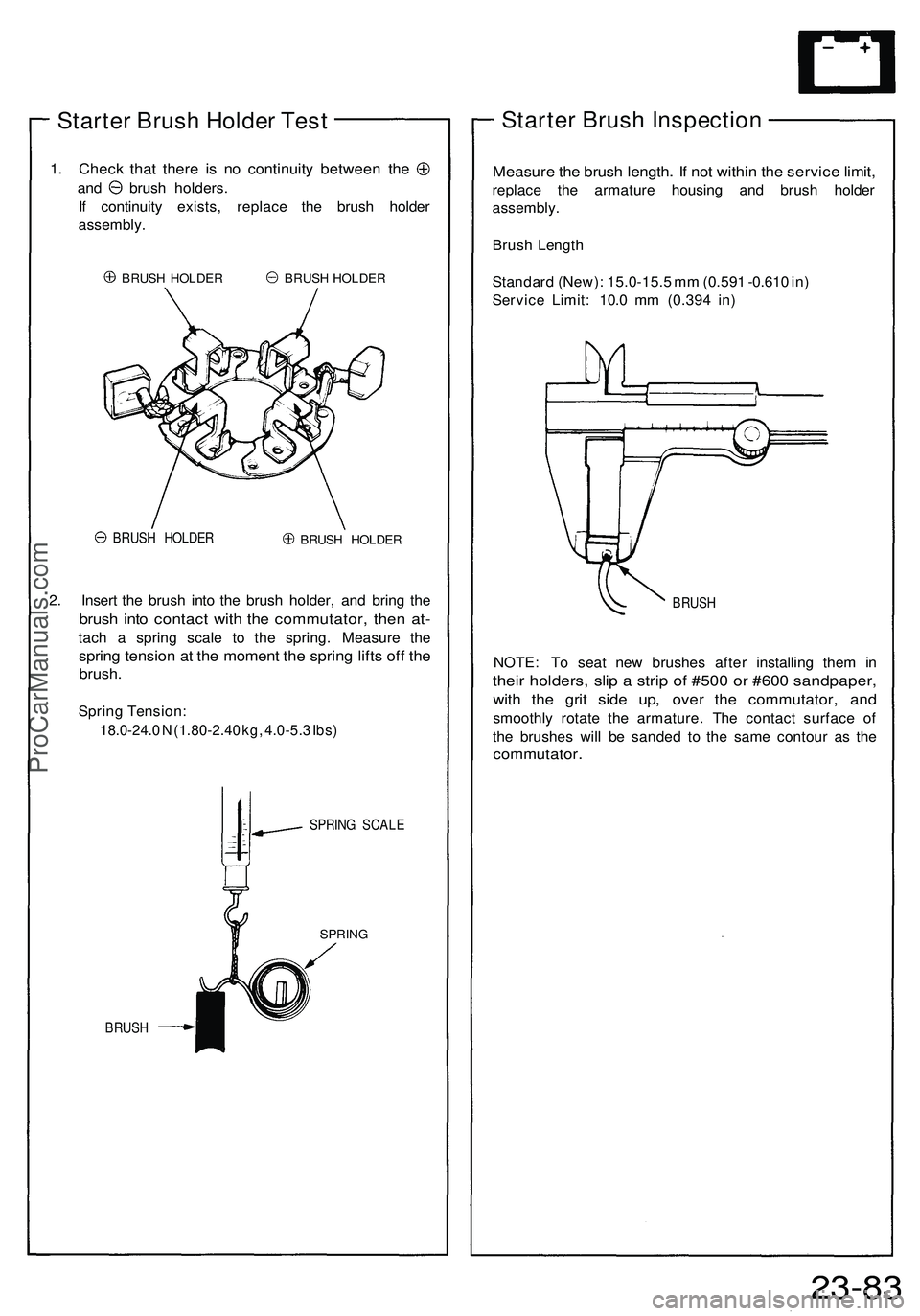

Starter Brus h Holde r Tes t

1. Chec k tha t ther e i s n o continuit y betwee n th e

and brus h holders .

I f continuit y exists , replac e th e brus h holde r

assembly .

BRUSH HOLDE R BRUSH HOLDE R

BRUSH HOLDE RBRUSH HOLDE R

2. Inser t th e brus h int o th e brus h holder , an d brin g th e

brus h int o contac t wit h th e commutator , the n at -

tac h a sprin g scal e t o th e spring . Measur e th e

sprin g tensio n a t th e momen t th e sprin g lift s of f th e

brush .

Spring Tension :

18.0-24.0 N (1.80-2.4 0 kg , 4.0-5. 3 Ibs )

SPRIN G SCAL E

BRUS H

SPRIN G

Starter Brus h Inspectio n

Measure th e brus h length . I f no t withi n th e servic e limit ,

replac e th e armatur e housin g an d brus h holde r

assembly .

Brus h Lengt h

Standar d (New) : 15.0-15. 5 m m (0.59 1 -0.61 0 in )

Servic e Limit : 10. 0 m m (0.39 4 in )

BRUS H

NOTE : T o sea t ne w brushe s afte r installin g the m i n

their holders , sli p a stri p o f #50 0 o r #60 0 sandpaper ,

with th e gri t sid e up , ove r th e commutator , an d

smoothl y rotat e th e armature . Th e contac t surfac e o f

th e brushe s wil l b e sande d t o th e sam e contou r a s th e

commutator .

23-83

ProCarManuals.com

Page 1277 of 1503

Rectifier Test

NOTE: The diodes are designed to allow current to

pass in one direction while blocking it in the opposite

direction. Since the alternator rectifier is made up of

eight diodes (four pairs), each diode must be tested for

continuity in both directions with an ohmmeter that has

diode checking capability; a total of sixteen checks.

1. Check for continuity in each direction, between the

B and P, and between the E (ground) and P ter-

minals of each diode pair. All diodes should have

continuity in only one direction.

E (GROUND)

2. If any of the eight diodes fails, replace the rectifier

assembly. (Diodes are not available separately.)

Alternator Brush Inspection

1. Remove the end cover, then take out the brush

holder by removing its two screws.

2. Measure the length of the brushes with a vernier

caliper.

Alternator Brush Length:

Standard: 10.5 mm (0.41 in)

Service Limit: 3.5 mm (0.14 in)

ALTERNATOR BRUSHES

VERNIER CALIPER

If the brushes are less than the service limit,

replace the assembly.ProCarManuals.com