parking brake ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 370 of 1503

3-15

T

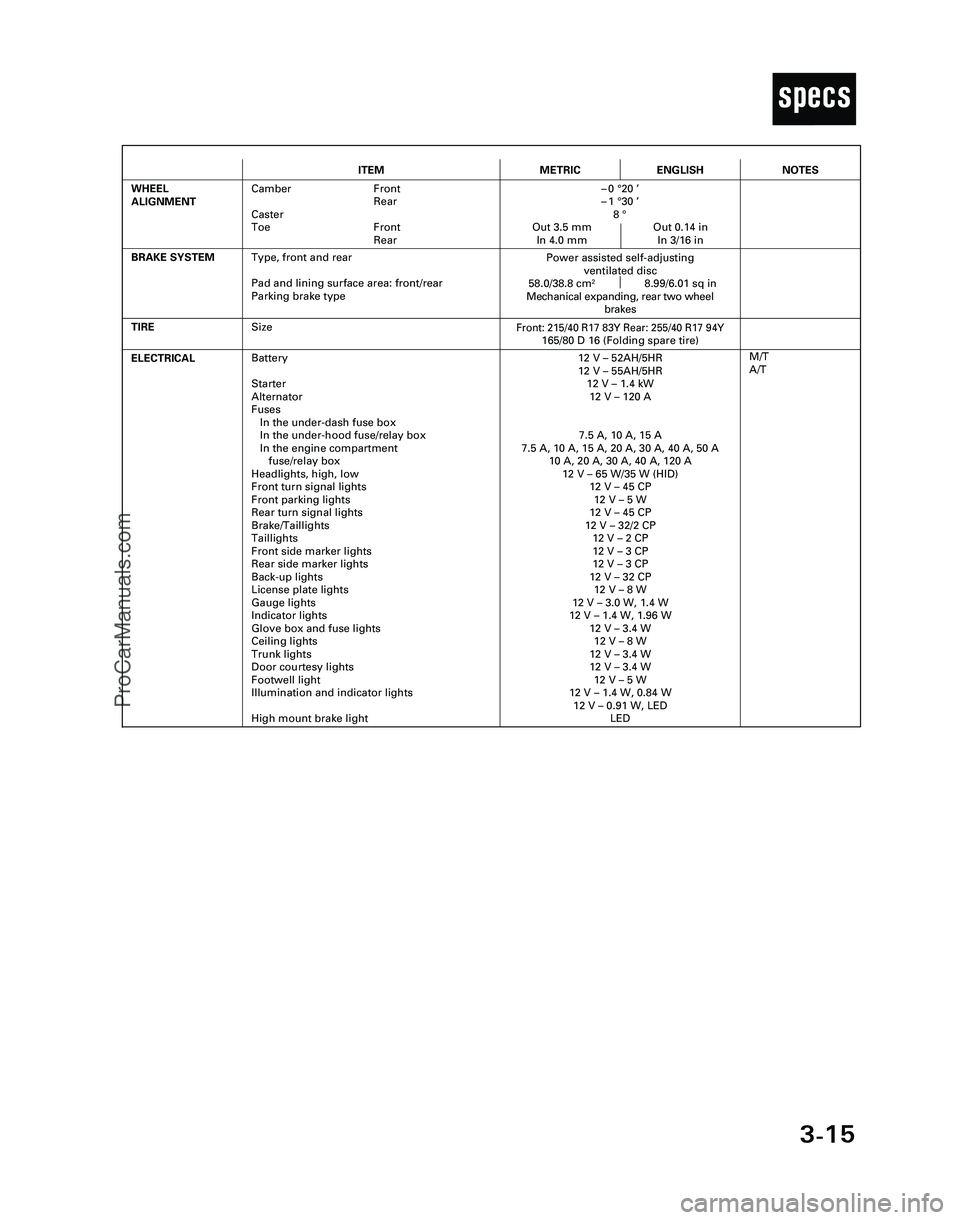

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 371 of 1503

4-2

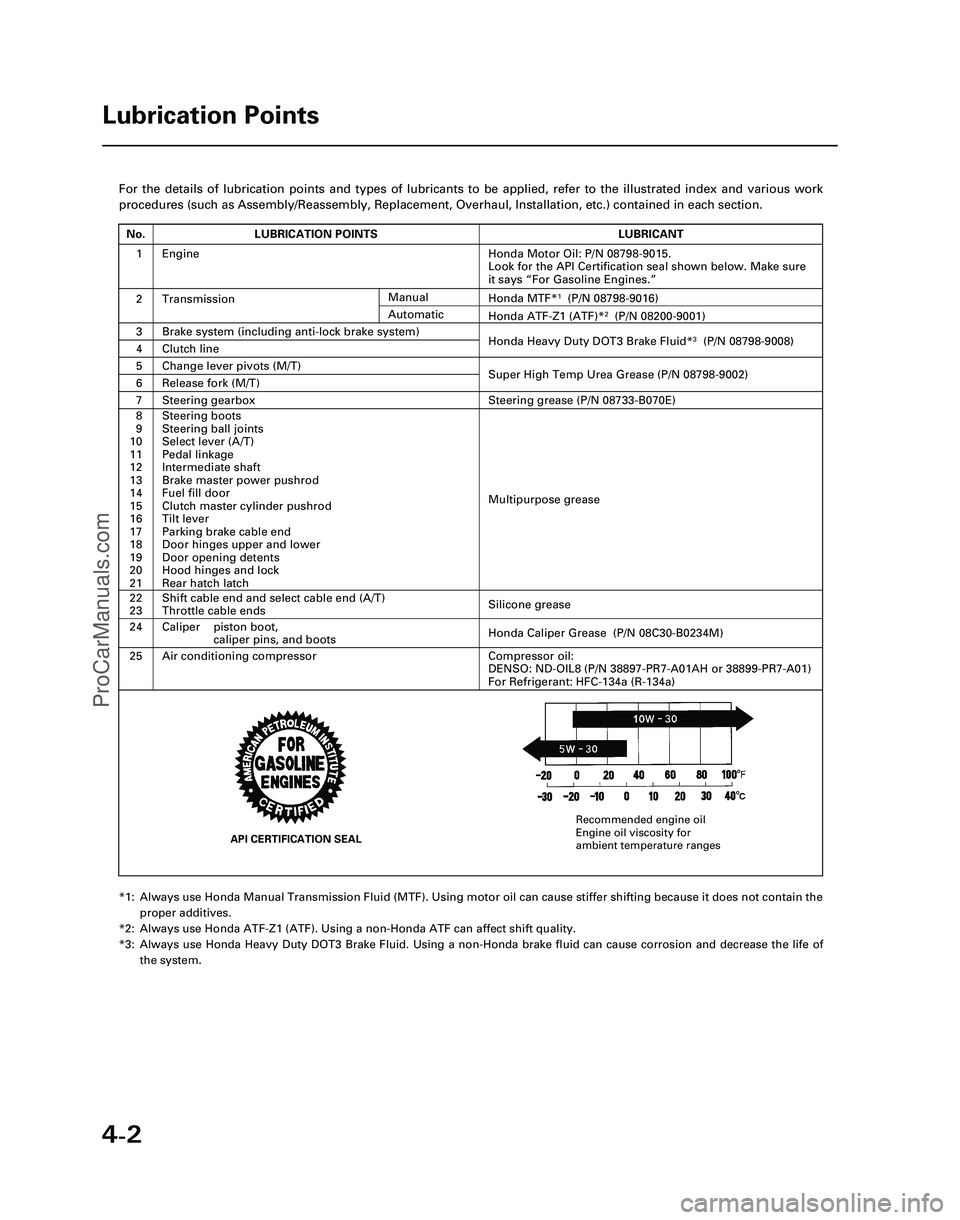

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 374 of 1503

4-5

Y

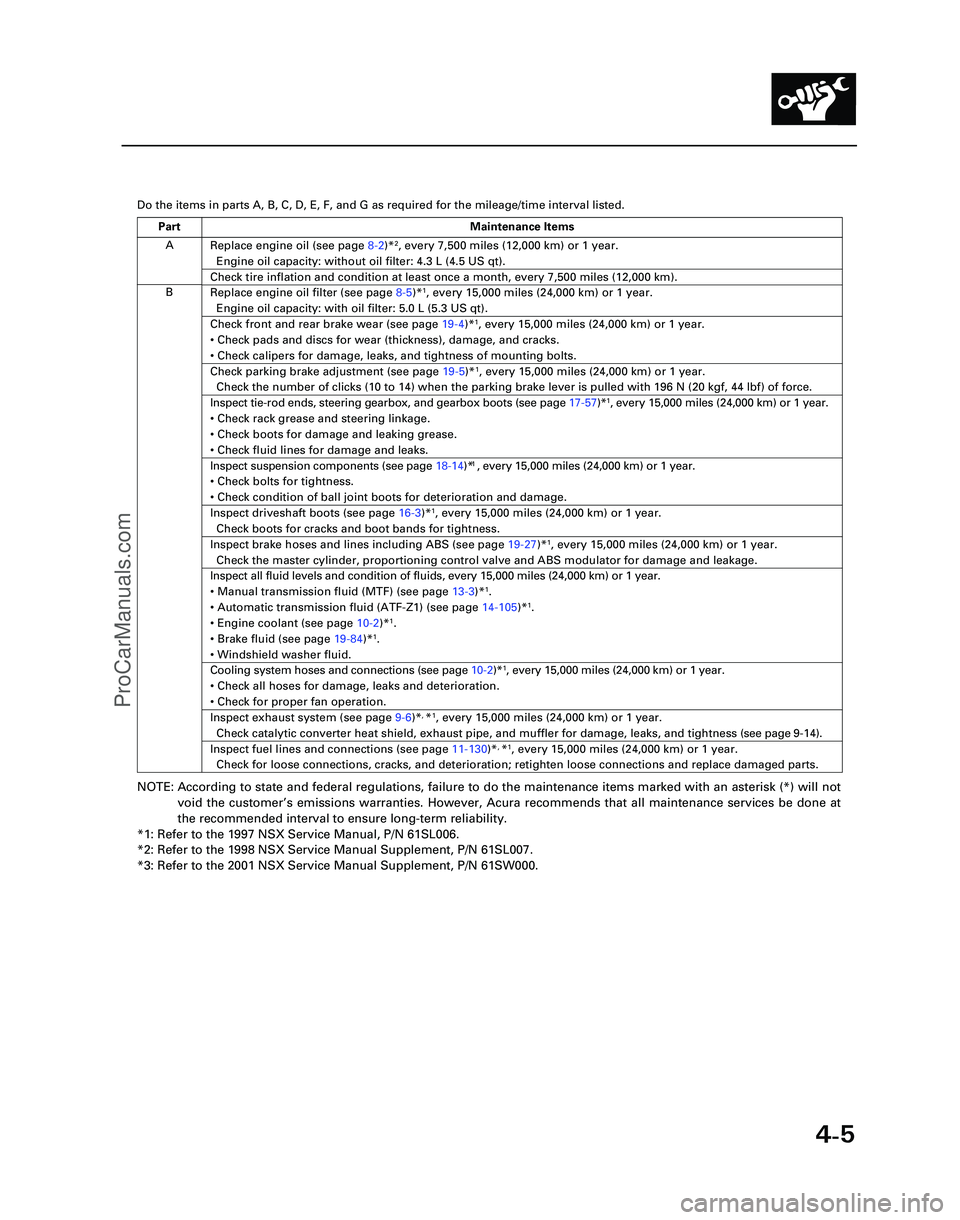

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

A

B Replace engine oil (see page

8-2)*

2, every 7,500 miles (12,000 km) or 1 year.

Engine oil capacity: without oil filter: 4.3 L (4.5 US qt).

Check tire inflation and condition at least once a month, every 7,500 mi\

les (12,000 km).

Replace engine oil filter (see page 8-5)*1, every 15,000 miles (24,000 km) or 1 year.

Engine oil capacity: with oil filter: 5.0 L (5.3 US qt).

Check front and rear brake wear (see page 19-4)*1, every 15,000 miles (24,000 km) or 1 year.

• Check pads and discs for wear (thickness), damage, and cracks.

• Check calipers for damage, leaks, and tightness of mounting bolts.

Check parking brake adjustment (see page 19-5)*1, every 15,000 miles (24,000 km) or 1 year.

Check the number of clicks (10 to 14) when the parking brake lever is pulled with 196 N (20 kgf,\

44 lbf) of force.

Inspect tie-rod ends, steering gearbox, and gearbox boots (see page 17-57)*1, every 15,000 miles (24,000 km) or 1 year.

• Check rack grease and steering linkage.

• Check boots for damage and leaking grease.

• Check fluid lines for damage and leaks.1

• Check bolts for tightness.

• Check condition of ball joint boots for deterioration and damage.

Inspect driveshaft boots (see page 16-3)*1, every 15,000 miles (24,000 km) or 1 year.

Check boots for cracks and boot bands for tightness.

Inspect brake hoses and lines including ABS (see page 19-27)*1, every 15,000 miles (24,000 km) or 1 year.

Check the master cylinder, proportioning control valve and ABS modulator\

for damage and leakage.

Inspect all fluid levels and condition of fluids, every 15,000 miles (2\

4,000 km) or 1 year.

• Manual transmission fluid (MTF) (see page 13-3)*

1.

• Automatic transmission fluid (ATF-Z1) (see page 14-105)*1.

• Engine coolant (see page 10-2)*1.

• Brake fluid (see page 19-84)*1.

• Windshield washer fluid.

Cooling system hoses and connections (see page 10-2)*1, every 15,000 miles (24,000 km) or 1 year.

• Check all hoses for damage, leaks and deterioration.

• Check for proper fan operation.

Inspect exhaust system (see page 9-6)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check catalytic converter heat shield, exhaust pipe, and muffler for dam\

age, leaks, and tightness ( see page 9-14 ).

Inspect fuel lines and connections (see page 11-130)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check for loose connections, cracks, and deterioration; retighten loose \

connections and replace damaged parts.

Part Maintenance Items

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-5

Inspect suspension components (see page 18-14)* , every 15,000 miles (24,000 km) or 1 year.

ProCarManuals.com

Page 384 of 1503

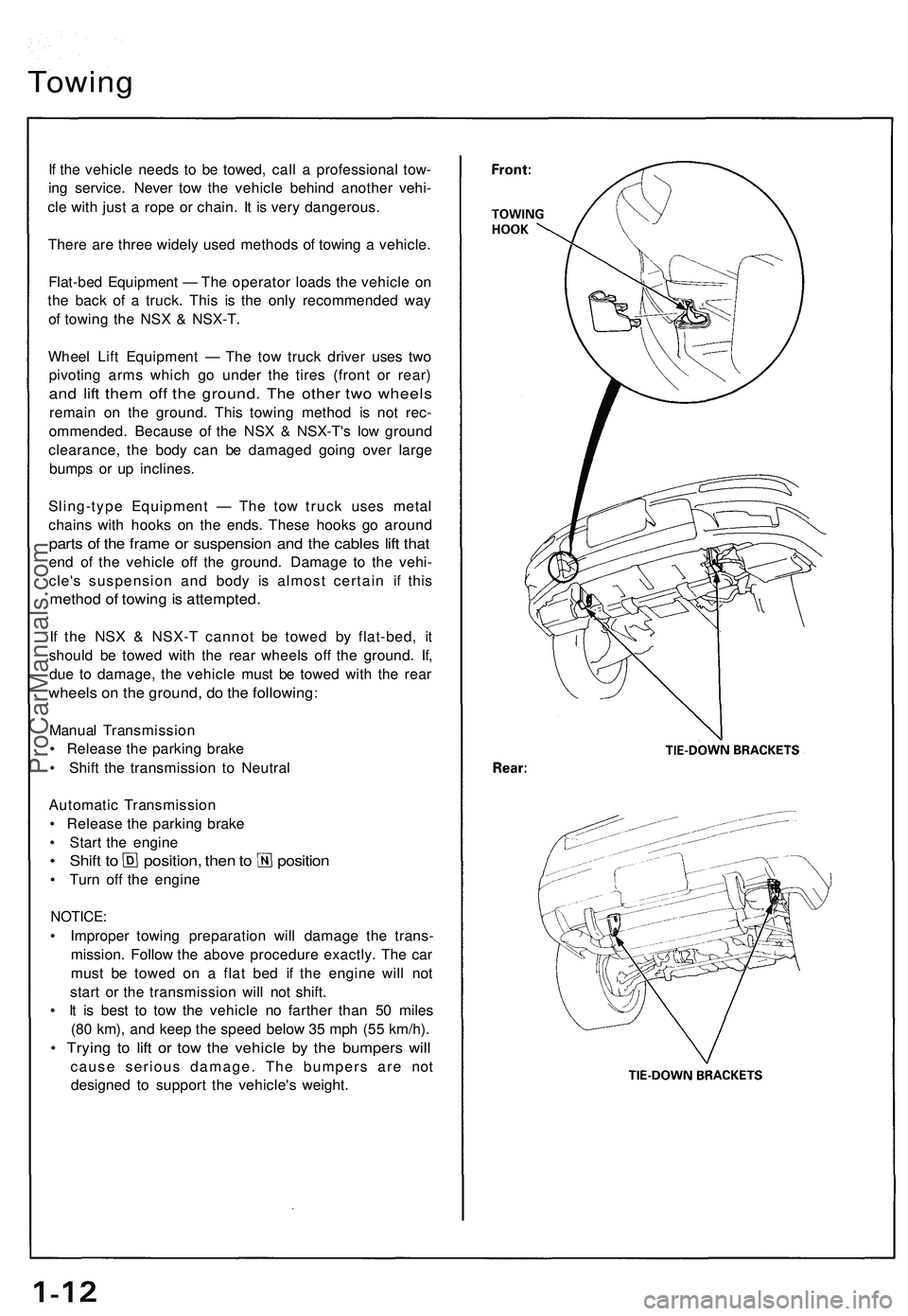

Towing

If the vehicle needs to be towed, call a professional tow-

ing service. Never tow the vehicle behind another vehi-

cle with just a rope or chain. It is very dangerous.

There are three widely used methods of towing a vehicle.

Flat-bed Equipment — The operator loads the vehicle on

the back of a truck. This is the only recommended way

of towing the NSX & NSX-T.

Wheel Lift Equipment — The tow truck driver uses two

pivoting arms which go under the tires (front or rear)

and lift them off the ground. The other two wheels

remain on the ground. This towing method is not rec-

ommended. Because of the NSX & NSX-T's low ground

clearance, the body can be damaged going over large

bumps or up inclines.

Sling-type Equipment — The tow truck uses metal

chains with hooks on the ends. These hooks go around

parts of the frame or suspension and the cables lift that

end of the vehicle off the ground. Damage to the vehi-

cle's suspension and body is almost certain if this

method of towing is attempted.

If the NSX & NSX-T cannot be towed by flat-bed, it

should be towed with the rear wheels off the ground. If,

due to damage, the vehicle must be towed with the rear

wheels on the ground, do the following:

Manual Transmission

• Release the parking brake

• Shift the transmission to Neutral

Automatic Transmission

• Release the parking brake

• Start the engine

• Shift to position, then to position

• Turn off the engine

NOTICE:

• Improper towing preparation will damage the trans-

mission. Follow the above procedure exactly. The car

must be towed on a flat bed if the engine will not

start or the transmission will not shift.

• It is best to tow the vehicle no farther than 50 miles

(80 km), and keep the speed below 35 mph (55 km/h).

• Trying to lift or tow the vehicle by the bumpers will

cause serious damage. The bumpers are not

designed to support the vehicle's weight.ProCarManuals.com

Page 771 of 1503

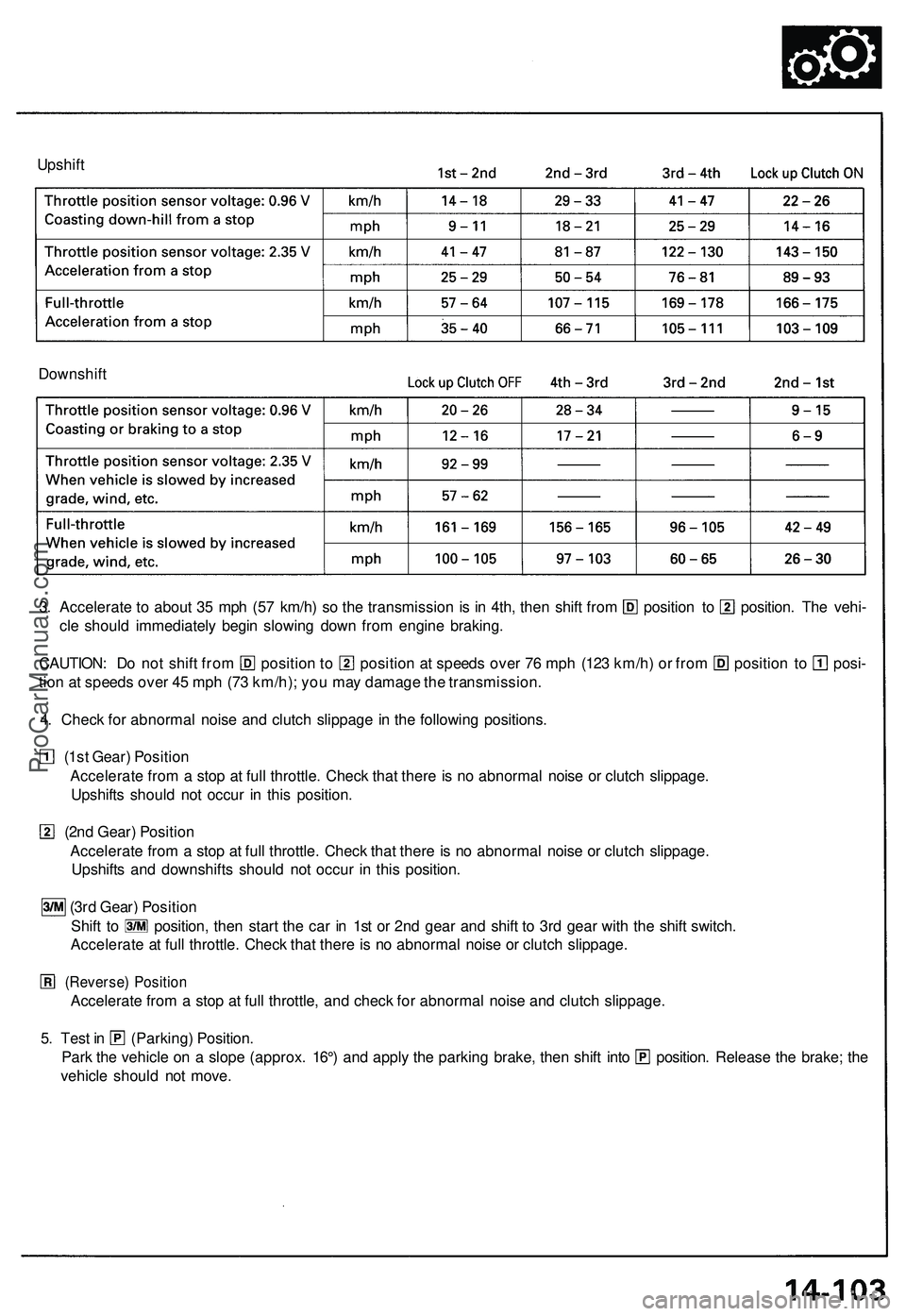

Upshift

Downshift

3. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th, then shift from position to position. The vehi-

cle should immediately begin slowing down from engine braking.

CAUTION: Do not shift from position to position at speeds over 76 mph (123 km/h) or from position to posi-

tion at speeds over 45 mph (73 km/h); you may damage the transmission.

4. Check for abnormal noise and clutch slippage in the following positions.

(1st Gear) Position

Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

Upshifts should not occur in this position.

(2nd Gear) Position

Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

Upshifts and downshifts should not occur in this position.

(3rd Gear) Position

Shift to position, then start the car in 1st or 2nd gear and shift to 3rd gear with the shift switch.

Accelerate at full throttle. Check that there is no abnormal noise or clutch slippage.

(Reverse) Position

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

5. Test in (Parking) Position.

Park the vehicle on a slope (approx. 16°) and apply the parking brake, then shift into position. Release the brake; the

vehicle should not move.ProCarManuals.com

Page 779 of 1503

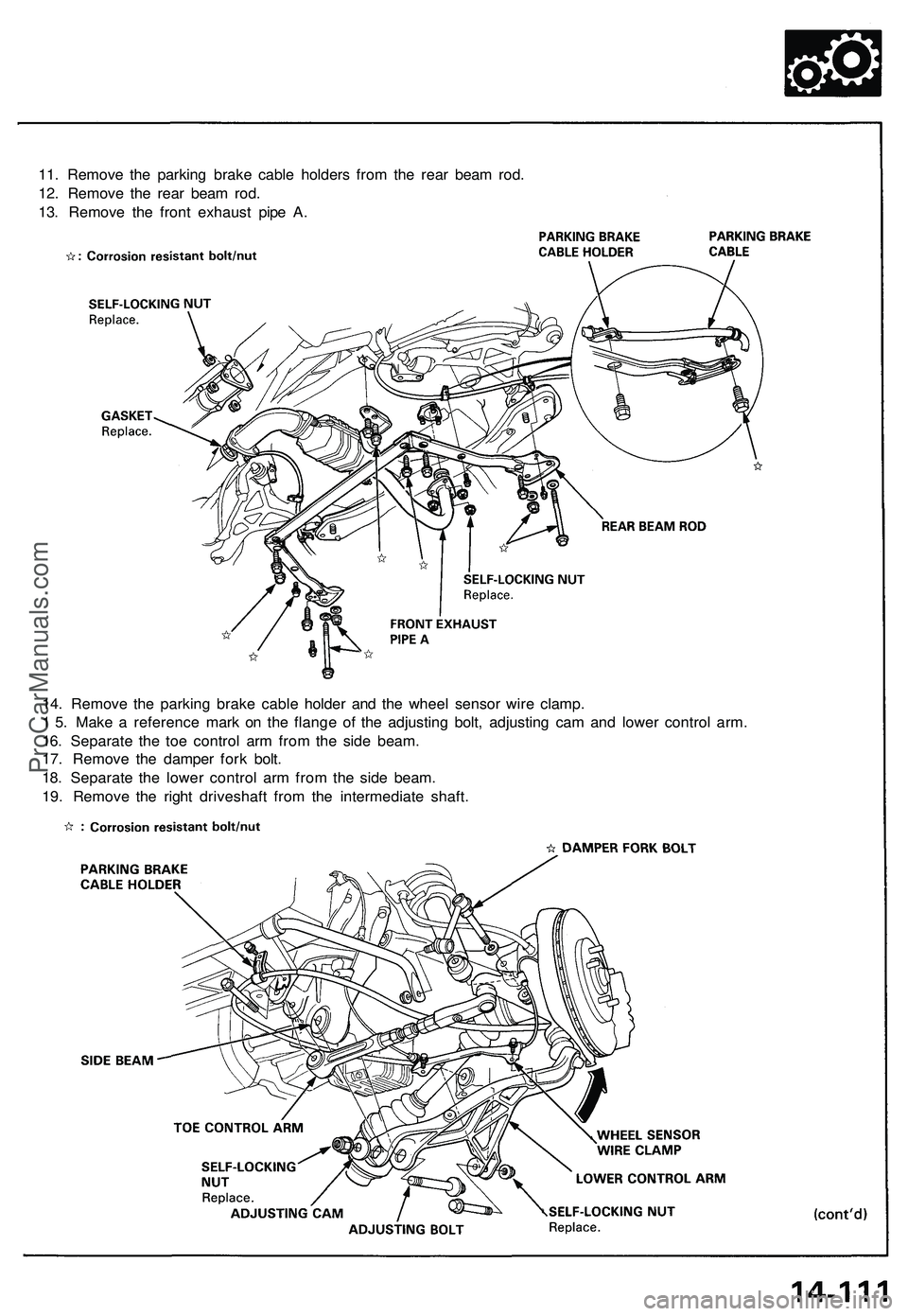

11. Remove the parking brake cable holders from the rear beam rod.

12. Remove the rear beam rod.

13. Remove the front exhaust pipe A.

14. Remove the parking brake cable holder and the wheel sensor wire clamp.

1 5. Make a reference mark on the flange of the adjusting bolt, adjusting cam and lower control arm.

16. Separate the toe control arm from the side beam.

17. Remove the damper fork bolt.

18. Separate the lower control arm from the side beam.

19. Remove the right driveshaft from the intermediate shaft.ProCarManuals.com

Page 780 of 1503

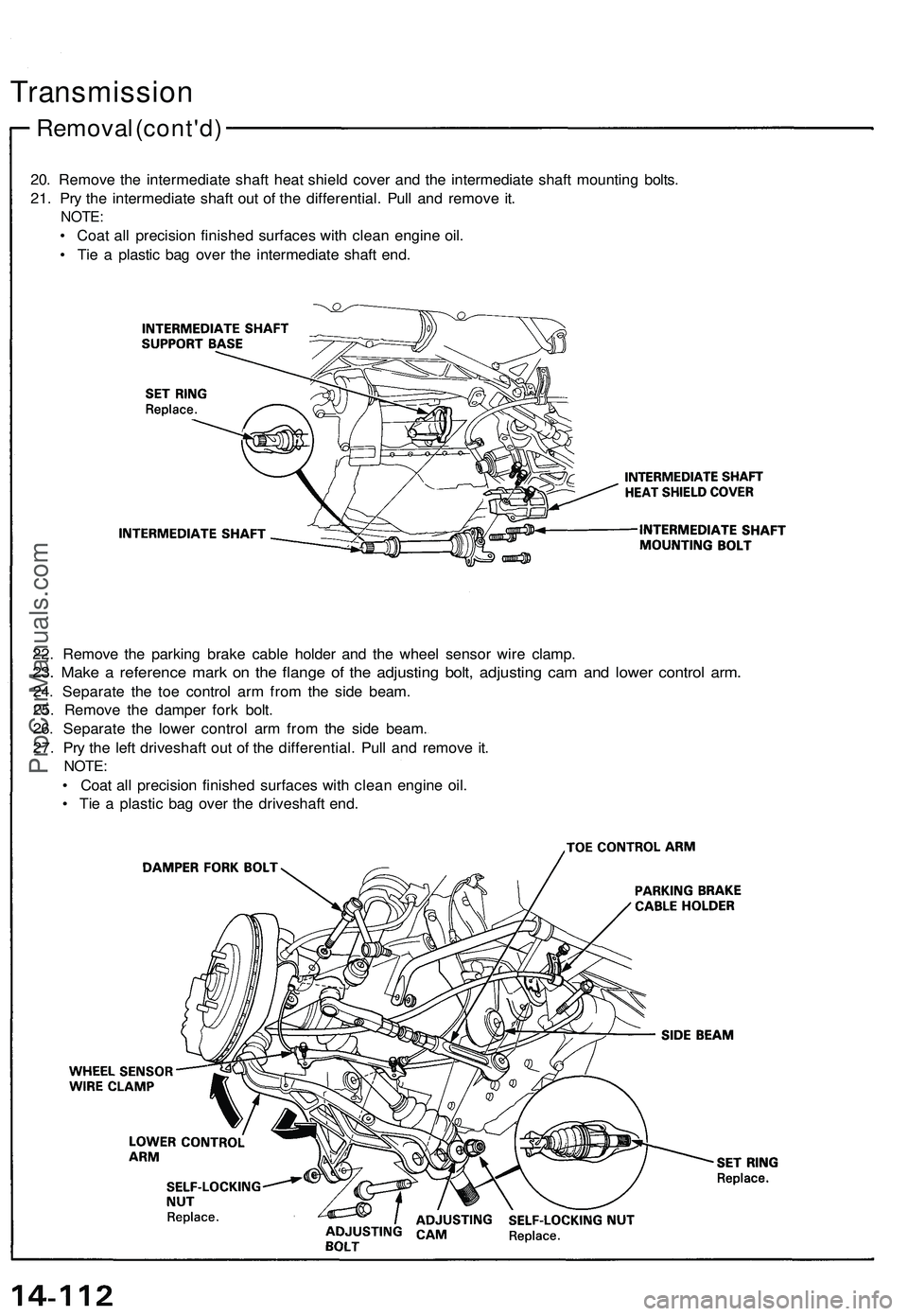

20. Remove the intermediate shaft heat shield cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

• Coat all precision finished surfaces with clean engine oil.

• Tie a plastic bag over the intermediate shaft end.

Removal (cont'd)

Transmission

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Make a reference mark on the flange of the adjusting bolt, adjusting cam and lower control arm.

24. Separate the toe control arm from the side beam.

25. Remove the damper fork bolt.

26. Separate the lower control arm from the side beam.

27. Pry the left driveshaft out of the differential. Pull and remove it.

NOTE:

• Coat all precision finished surfaces with clean engine oil.

• Tie a plastic bag over the driveshaft end.ProCarManuals.com

Page 836 of 1503

Installation (cont'd)

Transmission

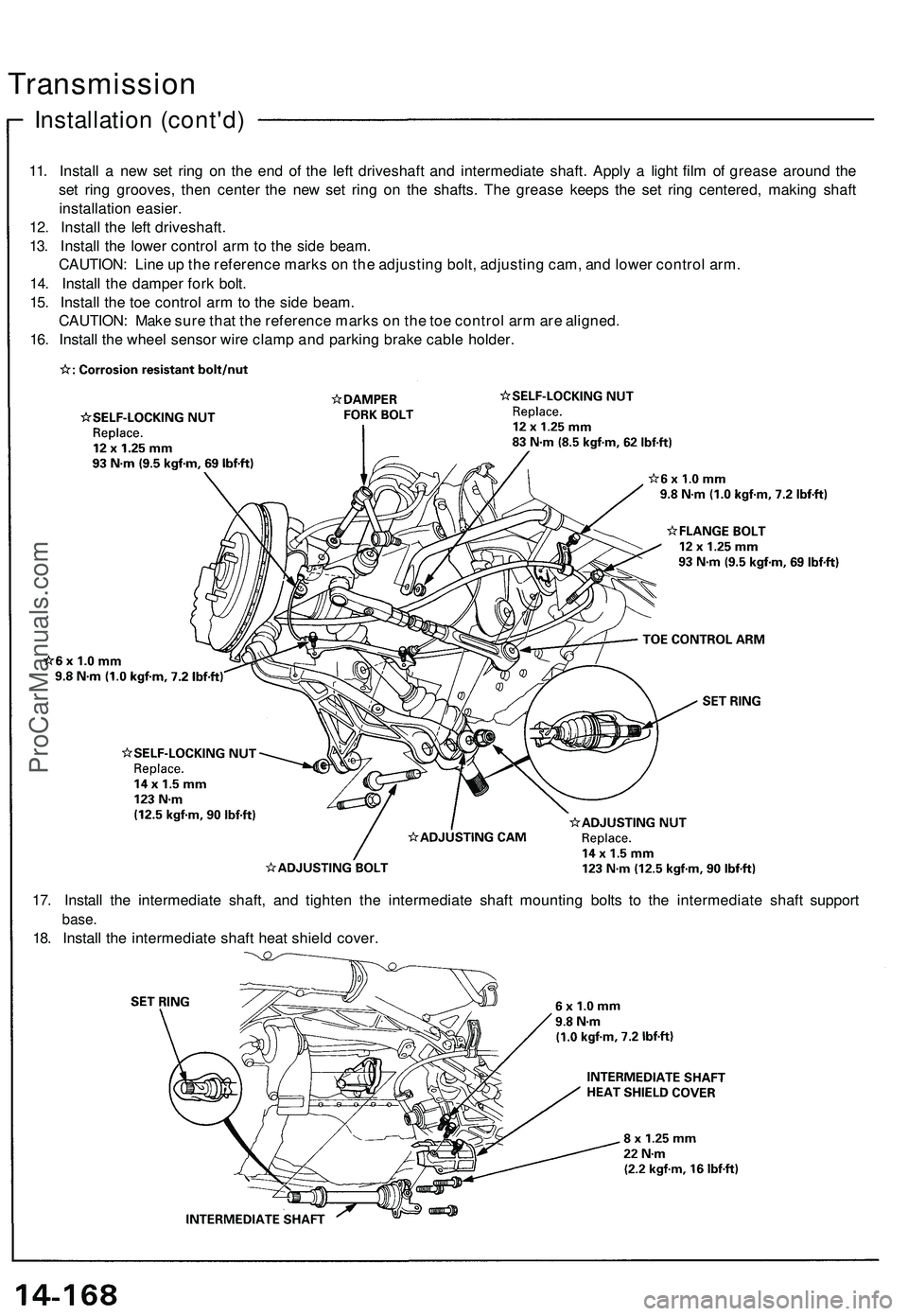

11. Install a new set ring on the end of the left driveshaft and intermediate shaft. Apply a light film of grease around the

set ring grooves, then center the new set ring on the shafts. The grease keeps the set ring centered, making shaft

installation easier.

12. Install the left driveshaft.

13. Install the lower control arm to the side beam.

CAUTION: Line up the reference marks on the adjusting bolt, adjusting cam, and lower control arm.

14. Install the damper fork bolt.

15. Install the toe control arm to the side beam.

CAUTION: Make sure that the reference marks on the toe control arm are aligned.

16. Install the wheel sensor wire clamp and parking brake cable holder.

17. Install the intermediate shaft, and tighten the intermediate shaft mounting bolts to the intermediate shaft support

base.

18. Install the intermediate shaft heat shield cover.ProCarManuals.com

Page 837 of 1503

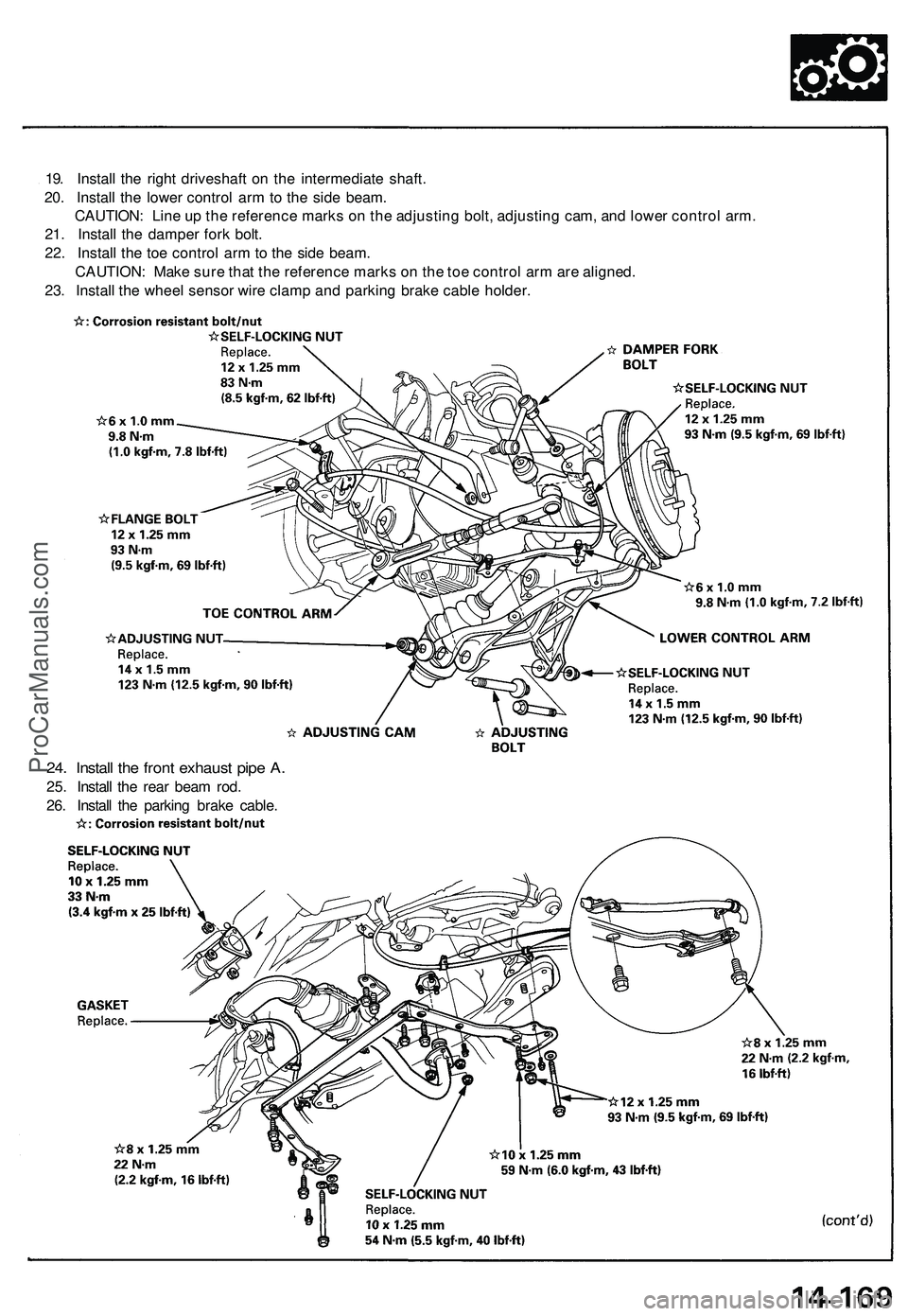

19. Install the right driveshaft on the intermediate shaft.

20. Install the lower control arm to the side beam.

CAUTION: Line up the reference marks on the adjusting bolt, adjusting cam, and lower control arm.

21. Install the damper fork bolt.

22. Install the toe control arm to the side beam.

CAUTION: Make sure that the reference marks on the toe control arm are aligned.

23. Install the wheel sensor wire clamp and parking brake cable holder.

24. Install the front exhaust pipe A.

25. Install the rear beam rod.

26. Install the parking brake cable.ProCarManuals.com

Page 877 of 1503

Driveshafts

Removal

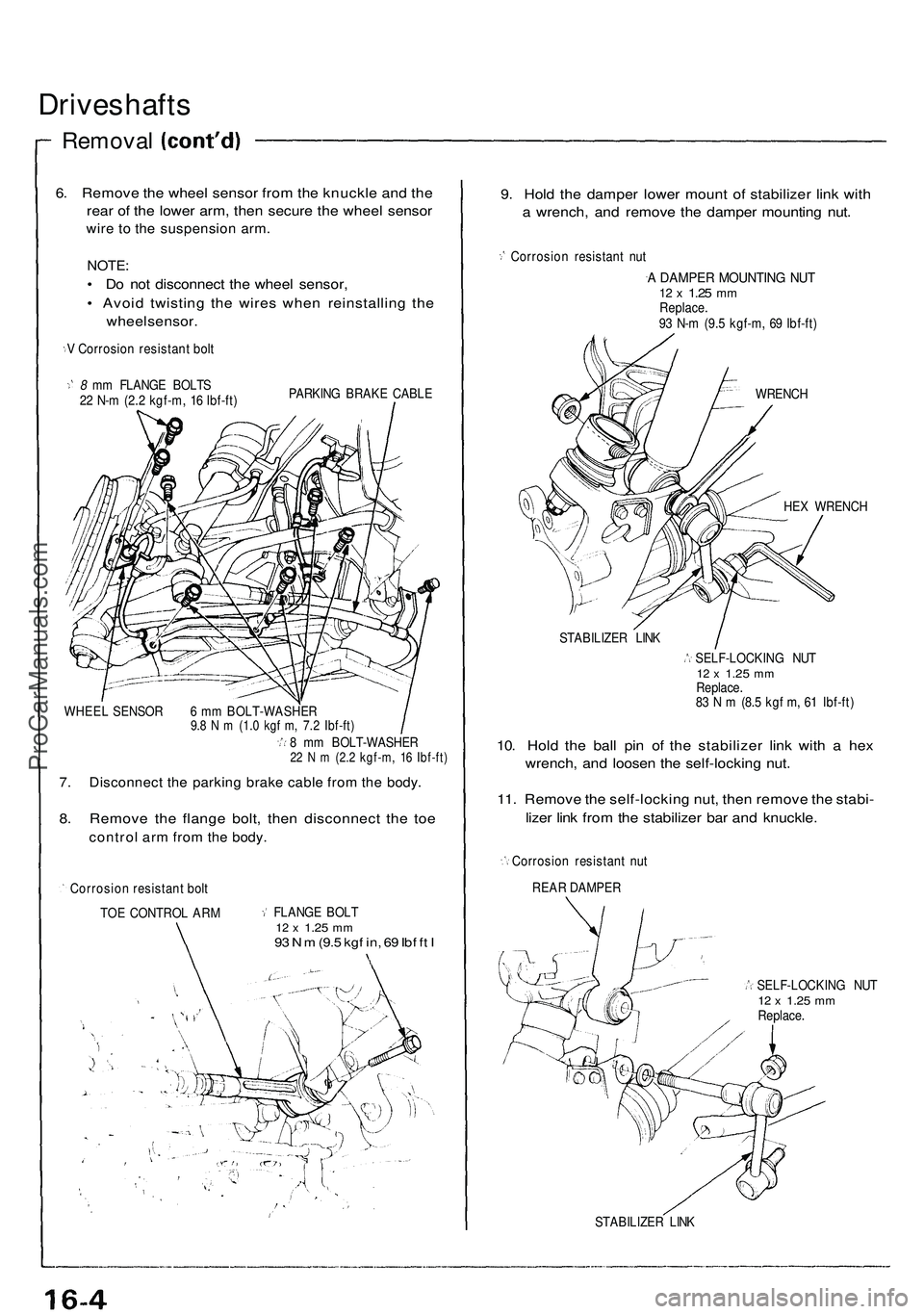

6. Remove the wheel sensor from the knuckle and the

rear of the lower arm, then secure the wheel sensor

wire to the suspension arm.

NOTE:

• Do not disconnect the wheel sensor,

• Avoid twisting the wires when reinstalling the

wheel sensor.

V Corrosion resistant bolt

8 mm FLANGE BOLTS

22 N-m (2.2 kgf-m, 16 Ibf-ft)

PARKING BRAKE CABLE

WHEEL SENSOR 6 mm BOLT-WASHER

9.8 N m (1.0 kgf m, 7.2 Ibf-ft)

8 mm BOLT-WASHER

22 N m (2.2 kgf-m, 16 Ibf-ft)

7. Disconnect the parking brake cable from the body.

8. Remove the flange bolt, then disconnect the toe

control arm from the body.

Corrosion resistant bolt

TOE CONTROL ARM

FLANGE BOLT

12 x

1.25

mm

93 N m

(9.5

kgf in, 69 Ibf ft I

9. Hold the damper lower mount of stabilizer link with

a wrench, and remove the damper mounting nut.

Corrosion resistant nut

A DAMPER MOUNTING NUT

12 x

1.25

mm

Replace.

93 N-m (9.5 kgf-m, 69 Ibf-ft)

WRENCH

HEX WRENCH

STABILIZER LINK

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

83 N m (8.5 kgf m, 61 Ibf-ft)

10. Hold the ball pin of the stabilizer link with a hex

wrench, and loosen the self-locking nut.

11. Remove the self-locking nut, then remove the stabi-

lizer link from the stabilizer bar and knuckle.

Corrosion resistant nut

REAR DAMPER

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

STABILIZER LINKProCarManuals.com