timing belt ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 375 of 1503

4-6

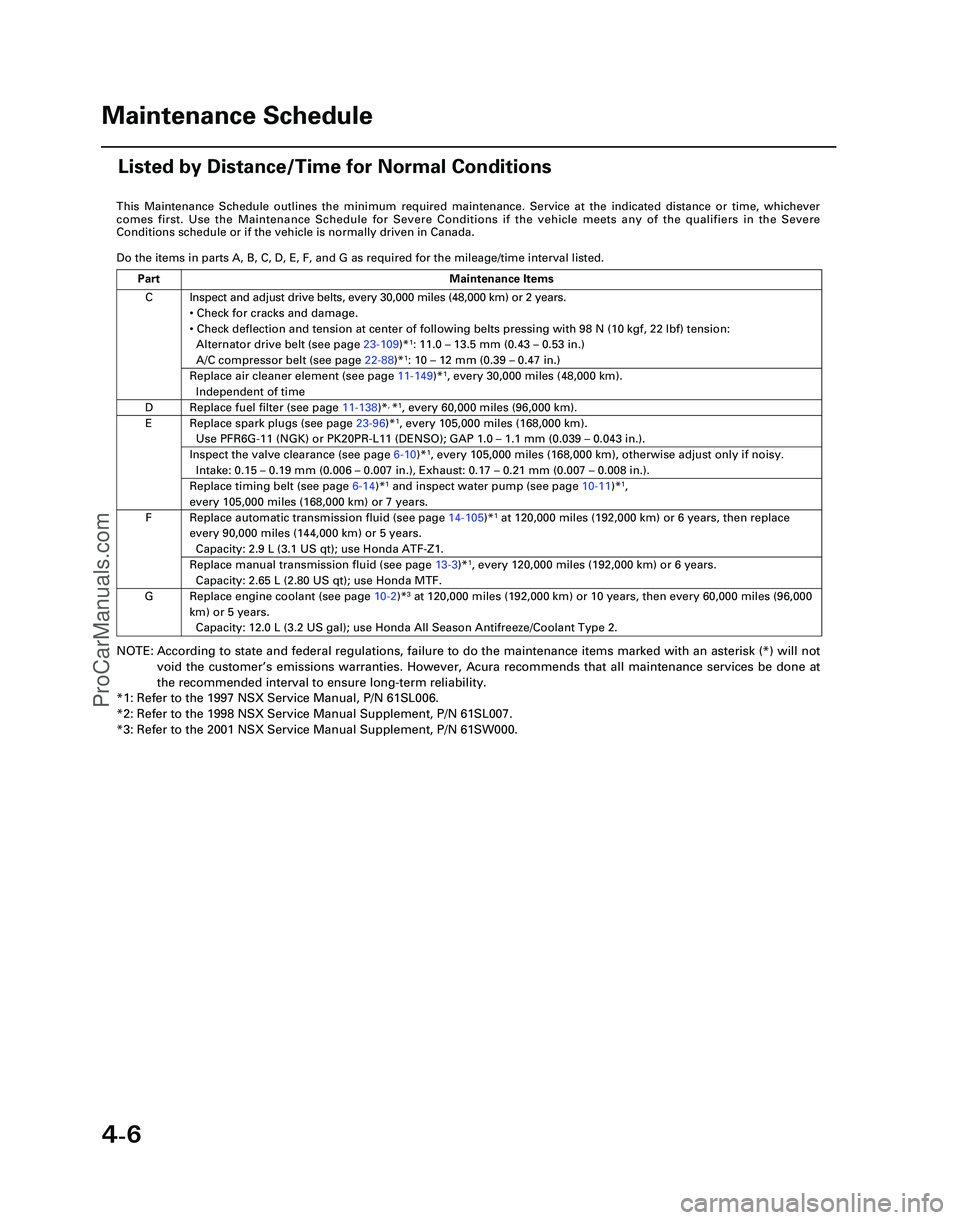

This Maintenance Schedule outlines the minimum required maintenance. Ser\

vice at the indicated distance or time, whichever

comes first. Use the Maintenance Schedule for Severe Conditions if the v\

ehicle meets any of the qualifiers in the Severe

Conditions schedule or if the vehicle is normally driven in Canada.

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

C

D

E

F

G Inspect and adjust drive belts, every 30,000 miles (48,000 km) or 2 ye\

ars.

•

Check for cracks and damage.

• Check deflection and tension at center of following belts pressing with\

98 N (10 kgf, 22 lbf) tension:

Alternator drive belt (see page 23-109)*

1: 11.0 – 13.5 mm (0.43 – 0.53 in.)

A/C compressor belt (see page 22-88)*1: 10 – 12 mm (0.39 – 0.47 in.)

Replace air cleaner element (see page 11-149)*1, every 30,000 miles (48,000 km).

Independent of time

Replace fuel filter (see page 11-138)*, *1, every 60,000 miles (96,000 km).

Replace spark plugs (see page 23-96)*1, every 105,000 miles (168,000 km).

Use PFR6G-11 (NGK) or PK20PR-L11 (DENSO); GAP 1.0 – 1.1 mm (0.039 – 0.043 in.).

Inspect the valve clearance (see page 6-10)*1, every 105,000 miles (168,000 km), otherwise adjust only if noisy.

Intake: 0.15 – 0.19 mm (0.006 – 0.007 in.), Exhaust: 0.17 – 0.21 mm (0.007 – 0.008 in.).

Replace timing belt (see page 6-14)*1 and inspect water pump (see page 10-11)*1,

every 105,000 miles (168,000 km) or 7 years.

Replace automatic transmission fluid (see page 14-105)*1 at 120,000 miles (192,000 km) or 6 years, then replace

every 90,000 miles (144,000 km) or 5 years.

Capacity: 2.9 L (3.1 US qt); use Honda ATF-Z1.

Replace manual transmission fluid (see page 13-3)*1, every 120,000 miles (192,000 km) or 6 years.

Capacity: 2.65 L (2.80 US qt); use Honda MTF.

Replace engine coolant (see page 10-2 )*3 at 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (9\

6,000

km) or 5 years. Capacity: 12.0 L (3.2 US gal); use Honda All Season Antifreeze/Coolant\

Type 2.

Part Maintenance Items

Maintenance Schedule

Listed by Distance/Time for Normal Conditions

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-6

ProCarManuals.com

Page 430 of 1503

Timing Bel t

Illustrate d Inde x

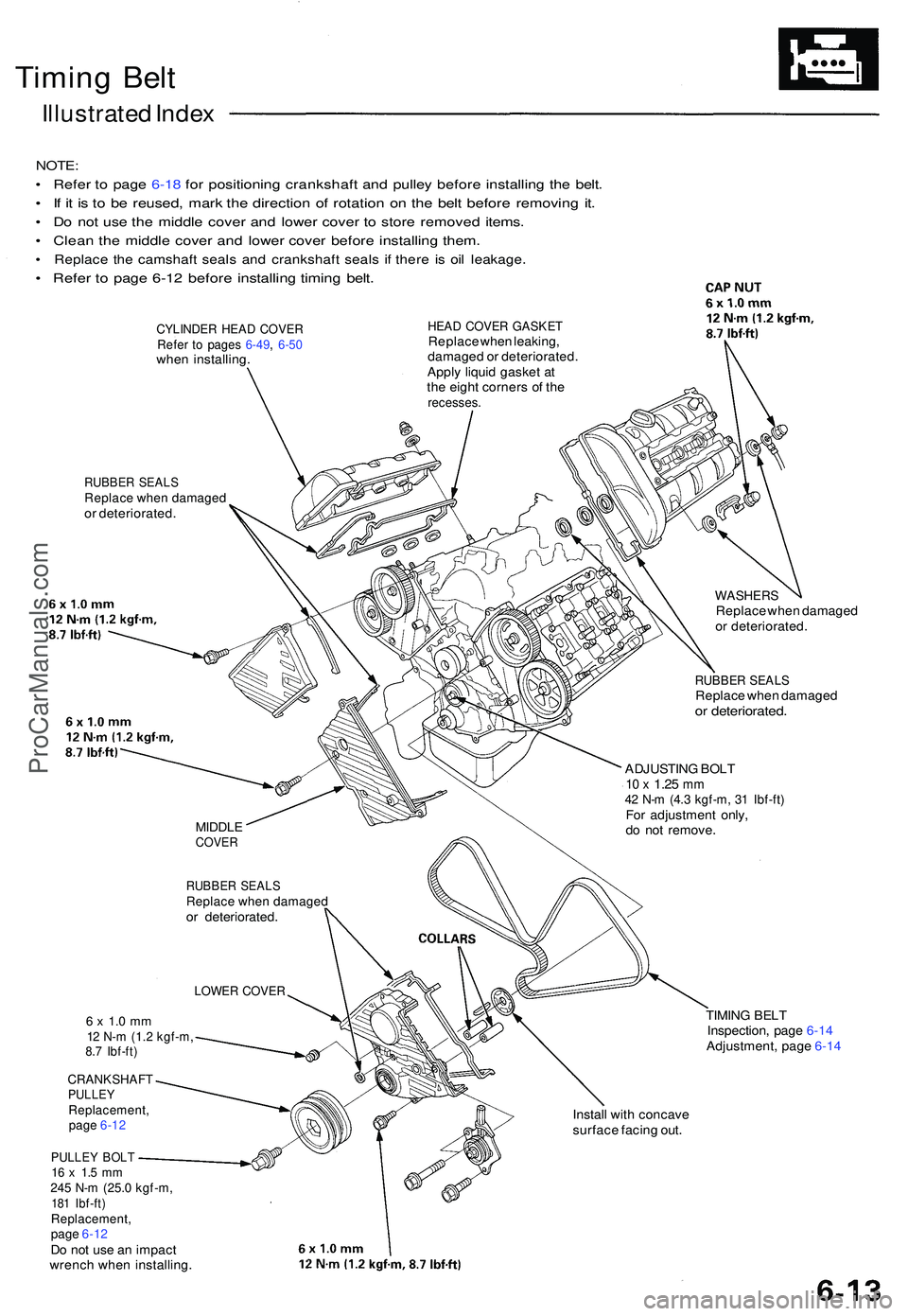

NOTE :

• Refe r t o pag e 6-1 8 fo r positionin g crankshaf t an d pulle y befor e installin g th e belt .

• I f i t i s t o b e reused , mar k th e directio n o f rotatio n o n th e bel t befor e removin g it .

• D o no t us e th e middl e cove r an d lowe r cove r t o stor e remove d items .

• Clea n th e middl e cove r an d lowe r cove r befor e installin g them .

• Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e i s oi l leakage .

• Refe r t o pag e 6-1 2 befor e installin g timin g belt .

CYLINDE R HEA D COVE RRefer t o page s 6-49 , 6-5 0whe n installing .

HEAD COVE R GASKE TReplace whe n leaking ,

damage d o r deteriorated .

Appl y liqui d gaske t a t

th e eigh t corner s o f th e

recesses .

RUBBER SEAL SReplac e whe n damage dor deteriorated .

WASHERSReplace whe n damage d

o r deteriorated .

RUBBER SEAL SReplac e whe n damage dor deteriorated .

MIDDLECOVER

RUBBE R SEAL SReplac e whe n damage dor deteriorated . ADJUSTIN

G BOL T

10 x 1.2 5 mm42 N- m (4. 3 kgf-m , 3 1 Ibf-ft )For adjustmen t only ,

d o no t remove .

LOWER COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

CRANKSHAF TPULLEYReplacement ,page 6-1 2

PULLE Y BOL T16 x 1. 5 m m245 N- m (25. 0 kgf-m ,181 Ibf-ft )Replacement ,page 6-1 2Do no t us e a n impac t

wrenc h whe n installing . TIMIN

G BEL T

Inspection , pag e 6-1 4

Adjustment , pag e 6-1 4

Instal l wit h concav e

surfac e facin g out .

ProCarManuals.com

Page 431 of 1503

Timing Bel t

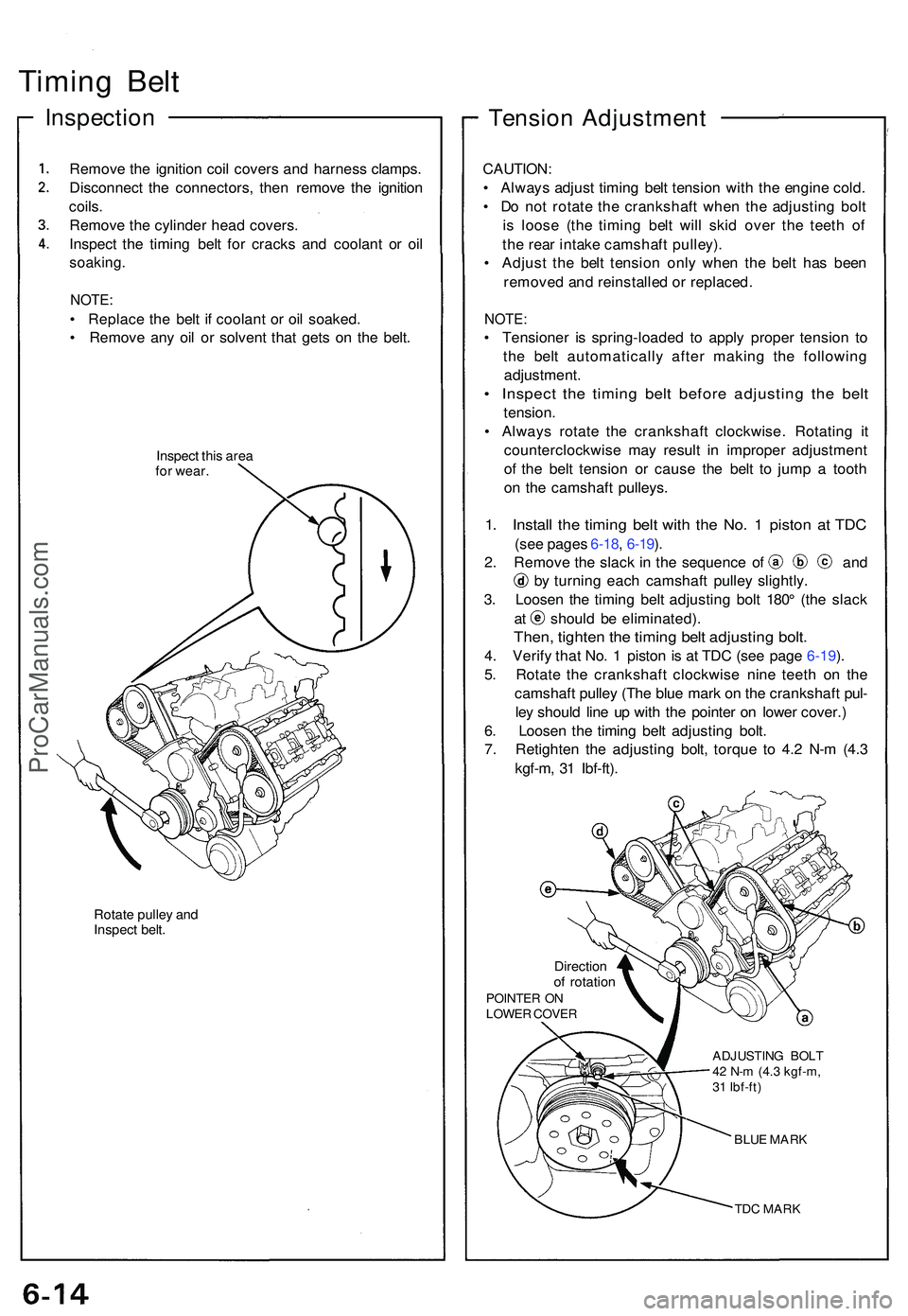

Inspectio n

Remove th e ignitio n coi l cover s an d harnes s clamps .

Disconnec t th e connectors , the n remov e th e ignitio n

coils .

Remov e th e cylinde r hea d covers .

Inspec t th e timin g bel t fo r crack s an d coolan t o r oi l

soaking .

NOTE:

• Replac e th e bel t i f coolan t o r oi l soaked .

• Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s are a

fo r wear .

Rotate pulle y an d

Inspec t belt .

Tensio n Adjustmen t

CAUTION:

• Alway s adjus t timin g bel t tensio n wit h th e engin e cold .

• D o no t rotat e th e crankshaf t whe n th e adjustin g bol t

i s loos e (th e timin g bel t wil l ski d ove r th e teet h o f

th e rea r intak e camshaf t pulley) .

• Adjus t th e bel t tensio n onl y whe n th e bel t ha s bee n

remove d an d reinstalle d o r replaced .

NOTE:

• Tensione r i s spring-loade d t o appl y prope r tensio n t o

th e bel t automaticall y afte r makin g th e followin g

adjustment .

• Inspec t th e timin g bel t befor e adjustin g th e bel t

tension .

• Alway s rotat e th e crankshaf t clockwise . Rotatin g i t

counterclockwis e ma y resul t i n imprope r adjustmen t

o f th e bel t tensio n o r caus e th e bel t t o jum p a toot h

o n th e camshaf t pulleys .

1. Instal l th e timin g bel t wit h th e No . 1 pisto n a t TD C

(see page s 6-18 , 6-19 ).

2 . Remov e th e slac k i n th e sequenc e o f an d

by turnin g eac h camshaf t pulle y slightly .

3 . Loose n th e timin g bel t adjustin g bol t 180 ° (th e slac k

at shoul d b e eliminated) .

Then, tighte n th e timin g bel t adjustin g bolt .

4. Verif y tha t No . 1 pisto n i s a t TD C (se e pag e 6-19 ).

5 . Rotat e th e crankshaf t clockwis e nin e teet h o n th e

camshaf t pulle y (Th e blu e mar k o n th e crankshaf t pul -

le y shoul d lin e u p wit h th e pointe r o n lowe r cover. )

6 . Loose n th e timin g bel t adjustin g bolt .

7 . Retighte n th e adjustin g bolt , torqu e t o 4. 2 N- m (4. 3

kgf-m , 3 1 Ibf-ft) .

Directio nof rotatio nPOINTE R O NLOWE R COVE R

ADJUSTING BOL T

42 N- m (4. 3 kgf-m ,

3 1 Ibf-ft )

BLUE MAR K

TDC MAR K

ProCarManuals.com

Page 433 of 1503

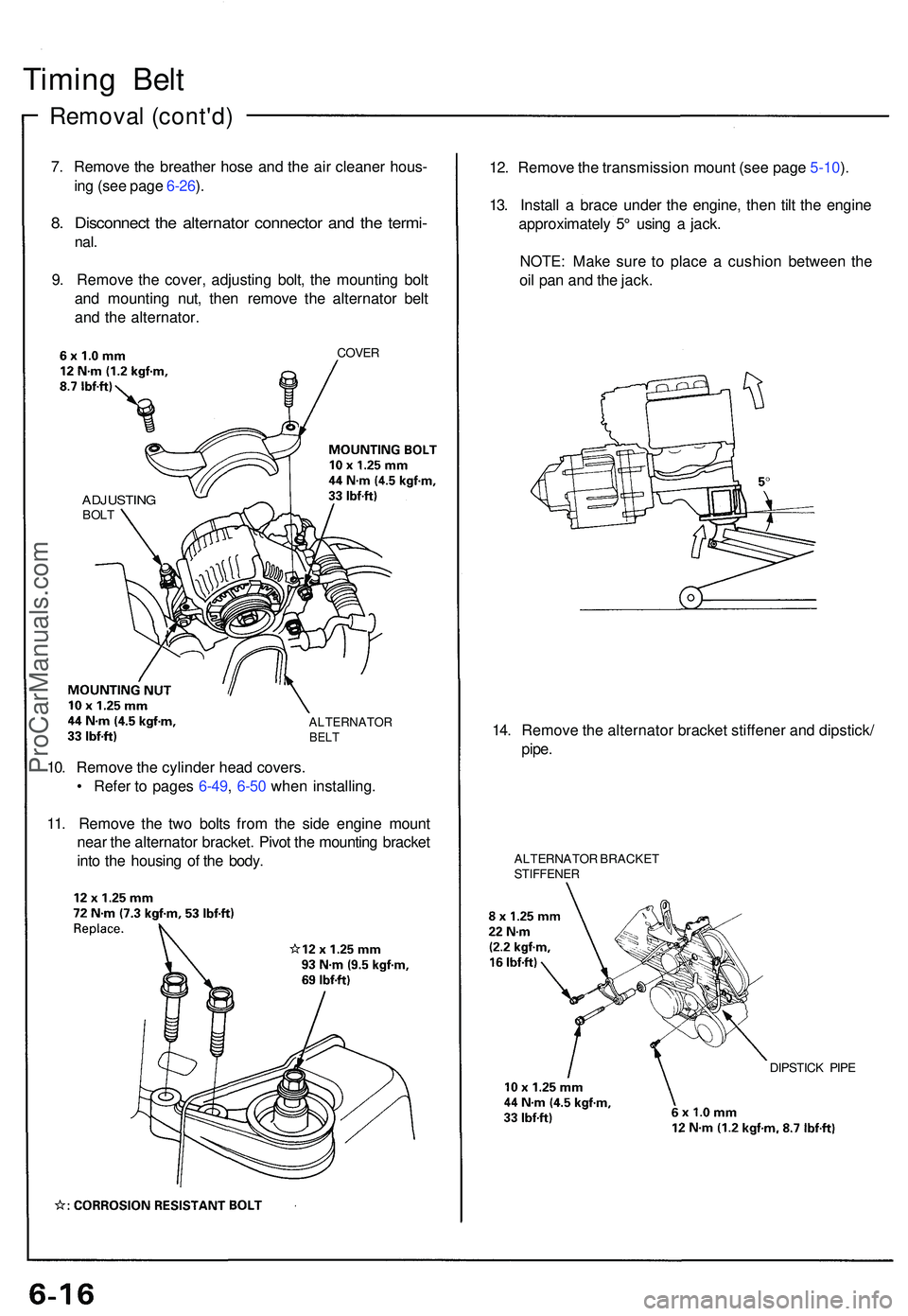

Timing Bel t

Remova l (cont'd )

7. Remov e th e breathe r hos e an d th e ai r cleaner hous-

in g (se e pag e 6-26 ).

8 . Disconnec t th e alternato r connecto r an d th e termi -

nal.

9. Remov e th e cover , adjustin g bolt , th e mountin g bol t

an d mountin g nut , the n remov e th e alternato r bel t

an d th e alternator .

COVER

ADJUSTIN GBOLT

ALTERNATO RBELT

12. Remov e th e transmissio n moun t (se e pag e 5-10 ).

13 . Instal l a brac e unde r th e engine , the n til t th e engin e

approximatel y 5 ° usin g a jack .

NOTE : Mak e sur e t o plac e a cushio n betwee n th e

oi l pa n an d th e jack .

14 . Remov e th e alternato r bracke t stiffene r an d dipstick /

pipe .

ALTERNATO R BRACKE TSTIFFENE R

DIPSTICK PIP E

10. Remov e th e cylinde r hea d covers .

• Refe r t o page s 6-49 , 6-5 0 whe n installing .

11 . Remov e th e tw o bolt s fro m th e sid e engin e moun t

nea r th e alternato r bracket . Pivo t th e mountin g bracke t

int o th e housin g o f th e body .

ProCarManuals.com

Page 435 of 1503

Timing Belt

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here.

NOTE: Clean the middle and lower covers before instal-

lation.

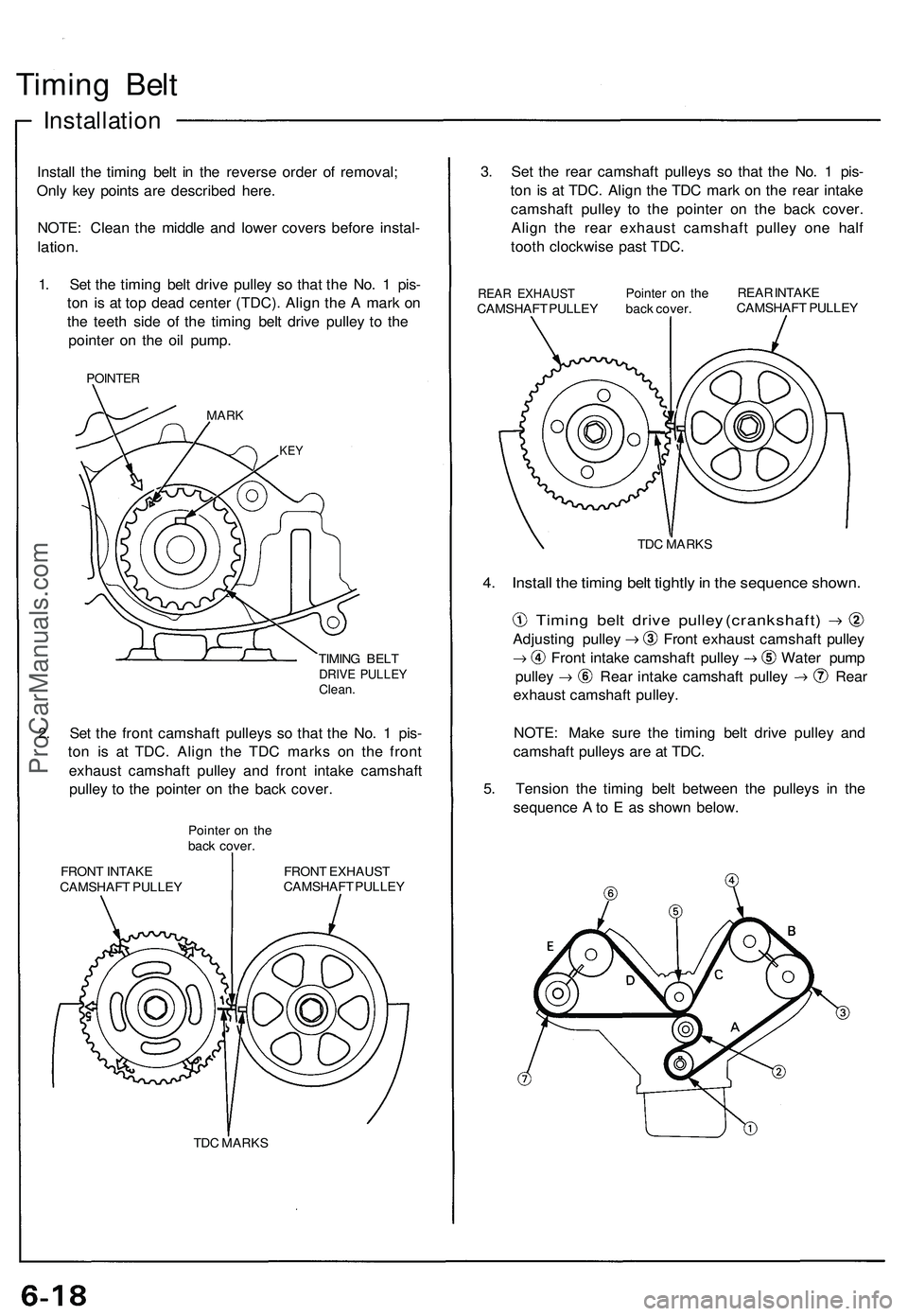

1. Set the timing belt drive pulley so that the No. 1 pis-

ton is at top dead center (TDC). Align the A mark on

the teeth side of the timing belt drive pulley to the

pointer on the oil pump.

POINTER

MARK

KEY

TIMING BELT

DRIVE PULLEY

Clean.

2. Set the front camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC marks on the front

exhaust camshaft pulley and front intake camshaft

pulley to the pointer on the back cover.

Pointer on the

back cover.

FRONT INTAKE

CAMSHAFT PULLEY

FRONT EXHAUST

CAMSHAFT PULLEY

TDC MARKS

3. Set the rear camshaft pulleys so that the No. 1 pis-

ton is at TDC. Align the TDC mark on the rear intake

camshaft pulley to the pointer on the back cover.

Align the rear exhaust camshaft pulley one half

tooth clockwise past TDC.

REAR EXHAUST

CAMSHAFT PULLEY

Pointer on the

back cover.

REAR INTAKE

CAMSHAFT PULLEY

TDC MARKS

4. Install the timing belt tightly in the sequence shown.

Timing belt drive pulley (crankshaft)

Adjusting pulley Front exhaust camshaft pulley

Front intake camshaft pulley Water pump

pulley Rear intake camshaft pulley Rear

exhaust camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

5. Tension the timing belt between the pulleys in the

sequence A to E as shown below.ProCarManuals.com

Page 437 of 1503

CKP/CYP Senso r

Replacemen t

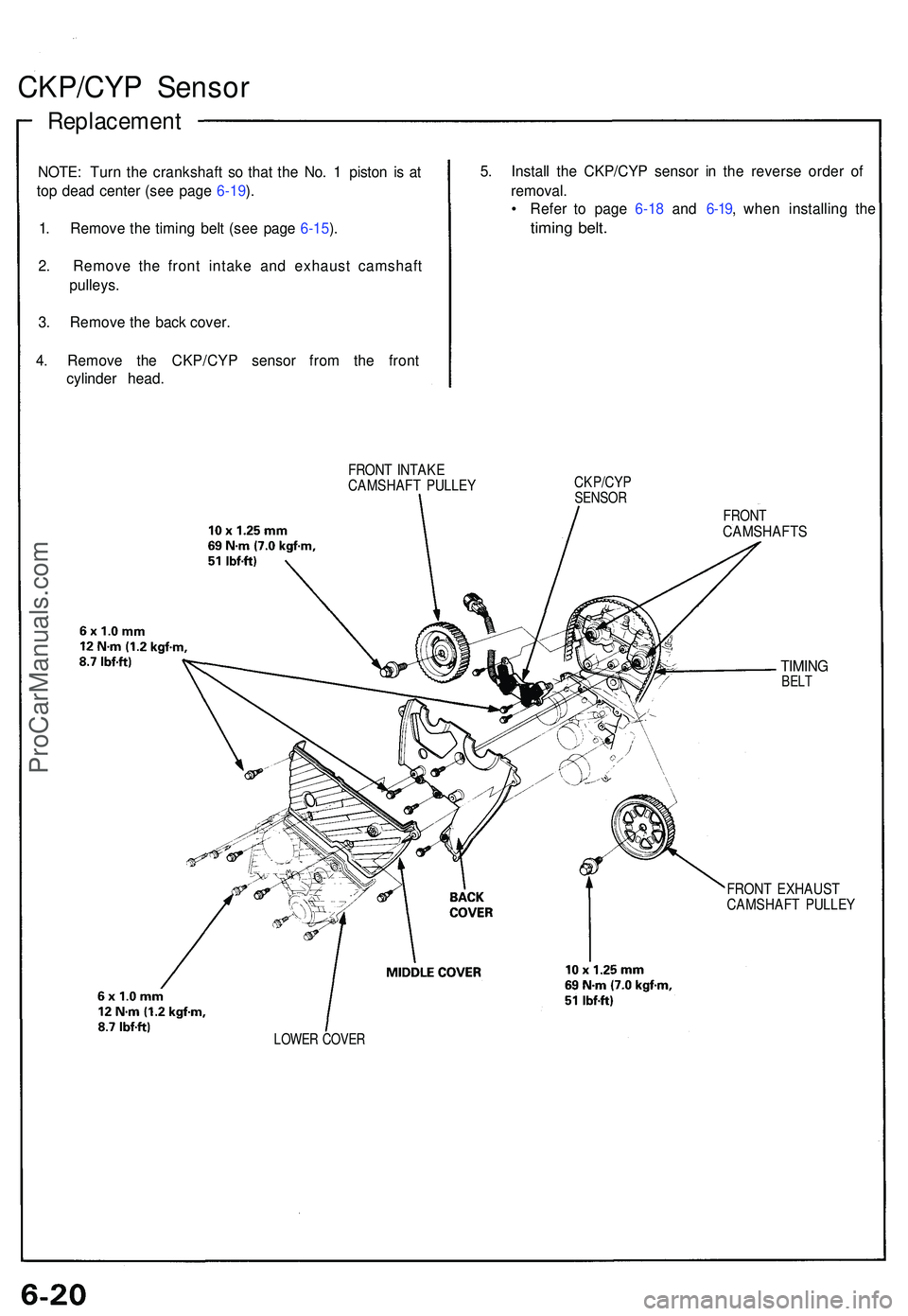

NOTE: Tur n th e crankshaf t s o tha t th e No . 1 pisto n i s a t

to p dea d cente r (se e pag e 6-19 ).

1 . Remov e th e timin g bel t (se e pag e 6-15 ).

2 . Remov e th e fron t intak e an d exhaus t camshaf t

pulleys .

3 . Remov e th e bac k cover .

4 . Remov e th e CKP/CY P senso r fro m th e fron t

cylinde r head . 5

. Instal l th e CKP/CY P senso r i n th e revers e orde r o f

removal .

• Refe r t o pag e 6-1 8 an d 6-19 , whe n installin g th e

timin g belt .

FRON T INTAK ECAMSHAF T PULLE YCKP/CY PSENSOR

LOWER COVE R

FRONTCAMSHAFT S

TIMINGBELT

FRON T EXHAUS TCAMSHAF T PULLE Y

ProCarManuals.com

Page 470 of 1503

Camshafts

Installation (cont'd)

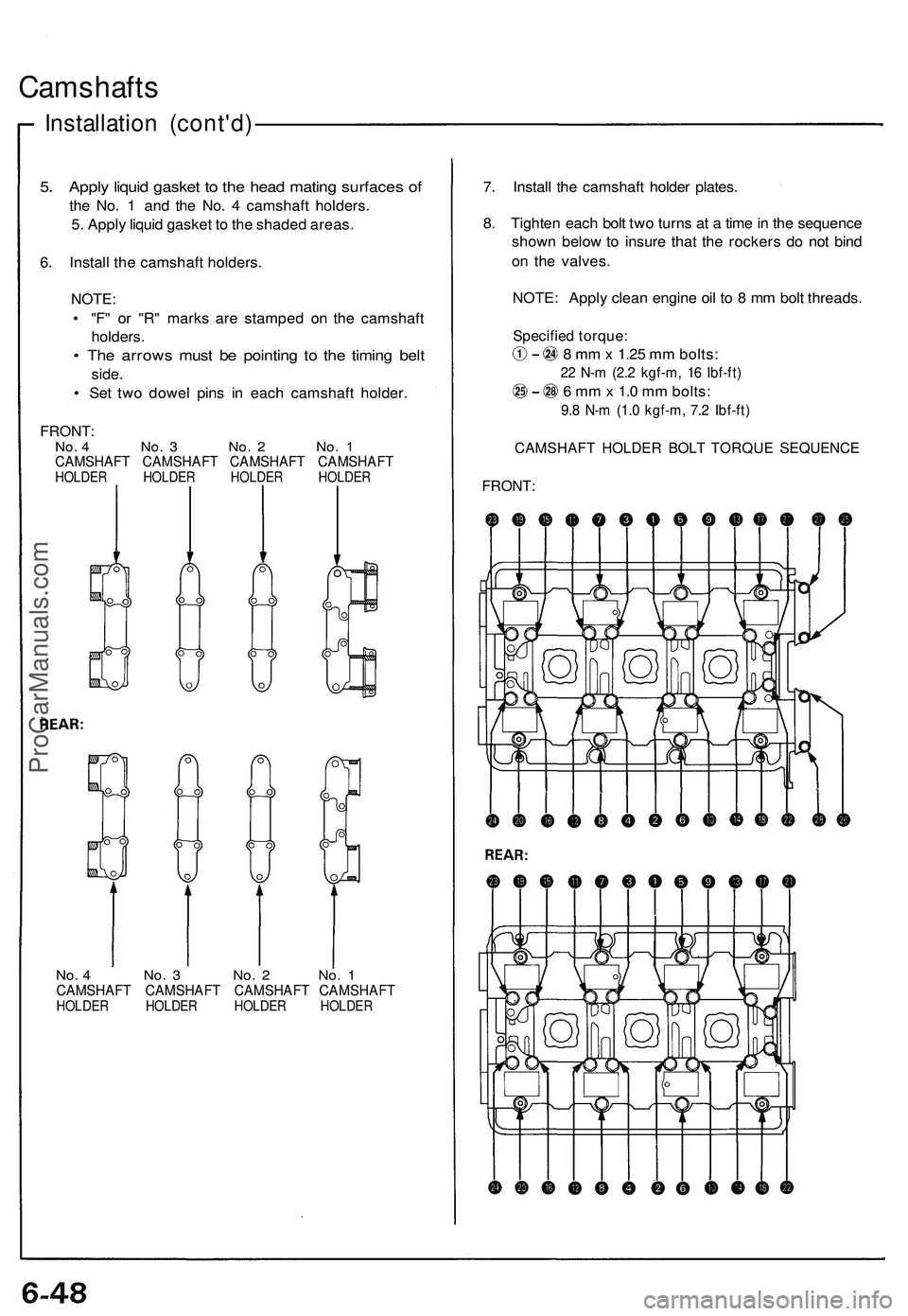

5. Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 4 camshaft holders.

5. Apply liquid gasket to the shaded areas.

6. Install the camshaft holders.

NOTE:

• "F" or "R" marks are stamped on the camshaft

holders.

• The arrows must be pointing to the timing belt

side.

• Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

7. Install the camshaft holder plates.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm x 1.0 mm bolts:

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:ProCarManuals.com

Page 495 of 1503

Crankshaft

Installation

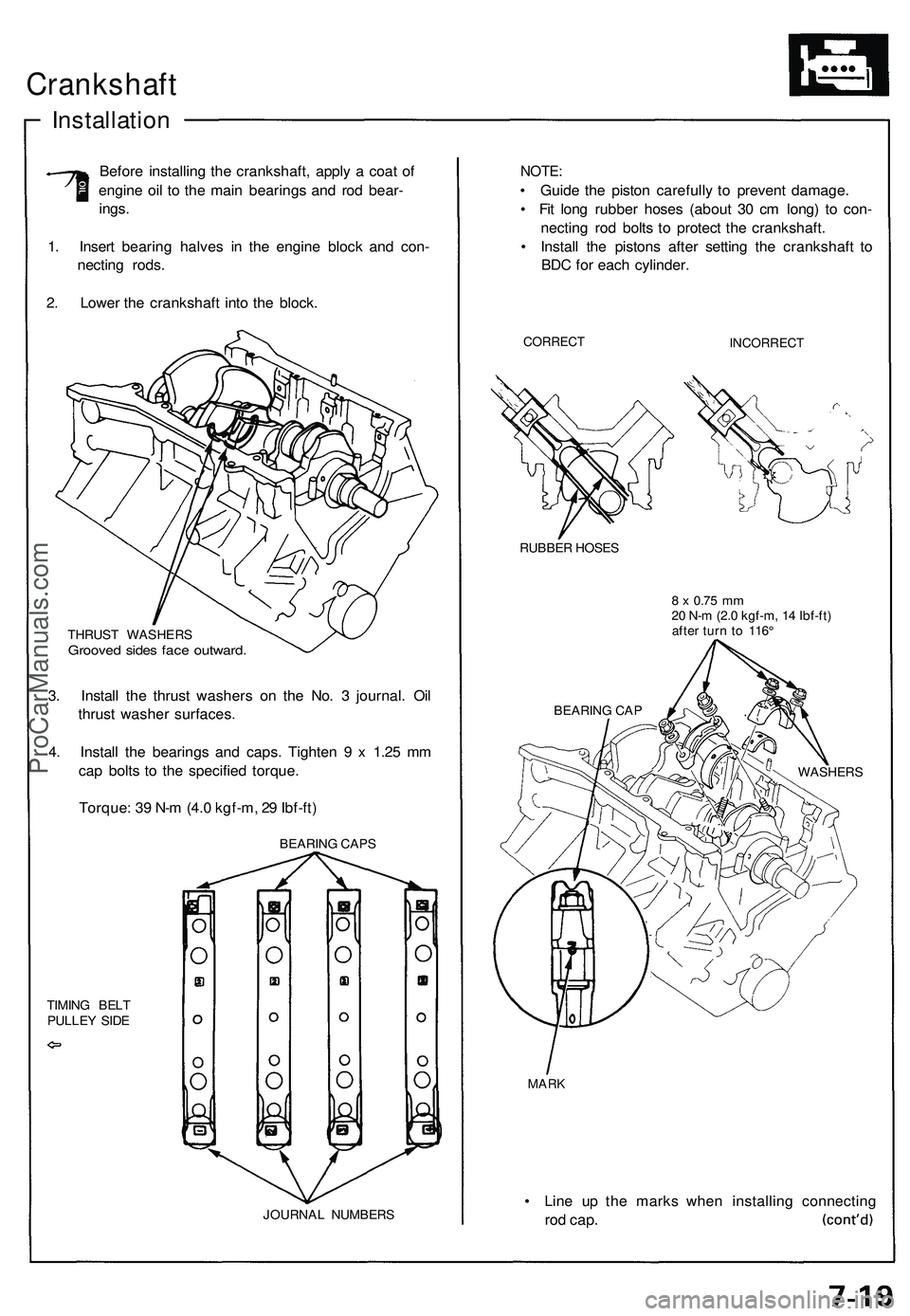

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bear-

ings.

1. Insert bearing halves in the engine block and con-

necting rods.

2. Lower the crankshaft into the block.

THRUST WASHERS

Grooved sides face outward.

3. Install the thrust washers on the No. 3 journal. Oil

thrust washer surfaces.

4. Install the bearings and caps. Tighten 9 x 1.25 mm

cap bolts to the specified torque.

Torque: 39 N-m (4.0 kgf-m, 29 Ibf-ft)

TIMING BELT

PULLEY SIDE

JOURNAL NUMBERS

NOTE:

• Guide the piston carefully to prevent damage.

• Fit long rubber hoses (about 30 cm long) to con-

necting rod bolts to protect the crankshaft.

• Install the pistons after setting the crankshaft to

BDC for each cylinder.

CORRECT

INCORRECT

RUBBER HOSES

8 x

0.75

mm

20 N-m (2.0 kgf-m, 14 Ibf-ft)

after turn to 116°

MARK

• Line up the marks when installing connecting

rod

cap.

BEARING CAP

WASHERS

BEARING CAPSProCarManuals.com