sensor ACURA RL KA9 1996 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 272 of 1954

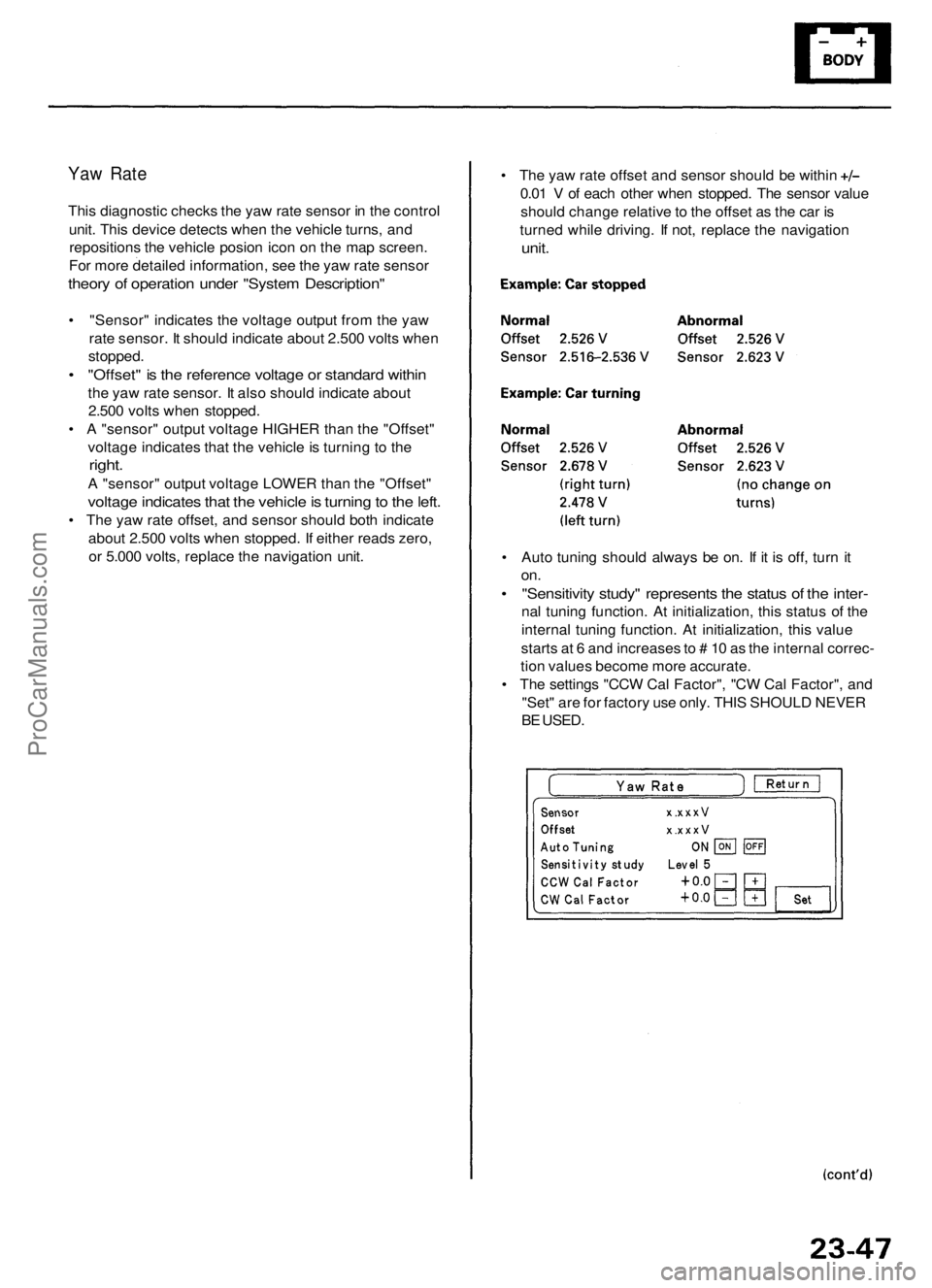

Yaw Rate

This diagnostic checks the yaw rate sensor in the control

unit. This device detects when the vehicle turns, and

repositions the vehicle posion icon on the map screen.

For more detailed information, see the yaw rate sensor

theory of operation under "System Description"

• "Sensor" indicates the voltage output from the yaw

rate sensor. It should indicate about 2.500 volts when

stopped.

• "Offset" is the reference voltage or standard within

the yaw rate sensor. It also should indicate about

2.500 volts when stopped.

• A "sensor" output voltage HIGHER than the "Offset"

voltage indicates that the vehicle is turning to the

right.

A "sensor" output voltage LOWER than the "Offset"

voltage indicates that the vehicle is turning to the left.

• The yaw rate offset, and sensor should both indicate

about 2.500 volts when stopped. If either reads zero,

or 5.000 volts, replace the navigation unit.

• The yaw rate offset and sensor should be within

0.01 V of each other when stopped. The sensor value

should change relative to the offset as the car is

turned while driving. If not, replace the navigation

unit.

• Auto tuning should always be on. If it is off, turn it

on.

• "Sensitivity study" represents the status of the inter-

nal tuning function. At initialization, this status of the

internal tuning function. At initialization, this value

starts at 6 and increases to # 10 as the internal correc-

tion values become more accurate.

• The settings "CCW Cal Factor", "CW Cal Factor", and

"Set" are for factory use only. THIS SHOULD NEVER

BE USED.ProCarManuals.com

Page 274 of 1954

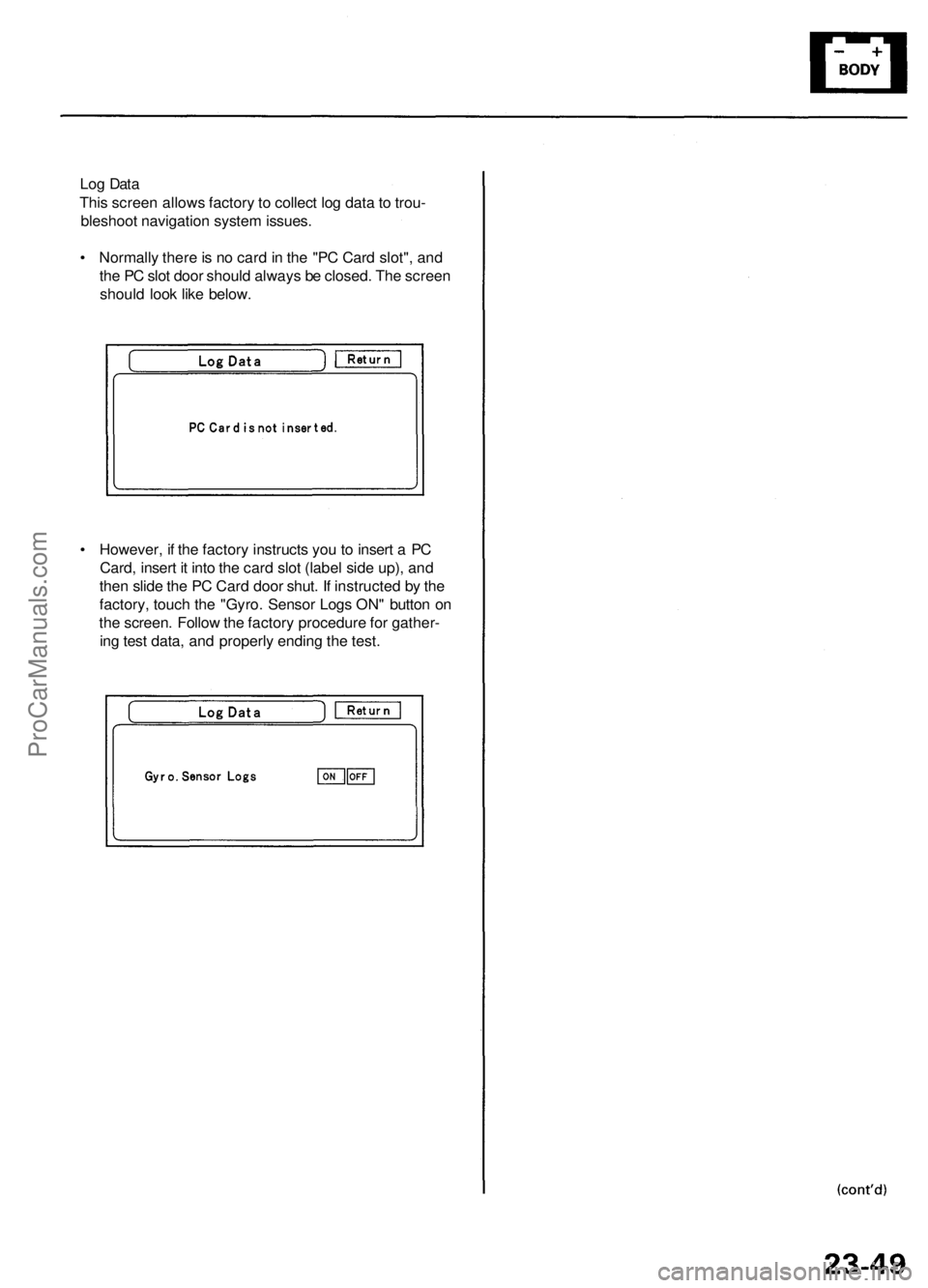

Log Data

This screen allows factory to collect log data to trou-

bleshoot navigation system issues.

• Normally there is no card in the "PC Card slot", and

the PC slot door should always be closed. The screen

should look like below.

• However, if the factory instructs you to insert a PC

Card, insert it into the card slot (label side up), and

then slide the PC Card door shut. If instructed by the

factory, touch the "Gyro. Sensor Logs ON" button on

the screen. Follow the factory procedure for gather-

ing test data, and properly ending the test.ProCarManuals.com

Page 356 of 1954

Cruise Control

Control Unit Input Test (cont'd)

Cavity Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

3

13

7

6

14

12

2

5

10

9

11

1

BLK

LT GRN

LT GRN/BLK

LT GRN/RED

PNK

BLU/WHT

GRY

GRN/WHT

BLU/YEL

BRN

BRN/BLK

BRN/WHT

Under all conditions

Ignition switch ON (II) and

main switch ON

Resume button pushed

Cancel button pushed

Set button pushed

Cancel button pushed

Shift lever in , or

Ignition switch ON (II), and

main switch ON; raise the

front of the vehicle, and rotate

one wheel slowly while

holding the other wheel.

Ignition switch ON (II), main

switch ON; brake pedal

pressed, then released

Brake pedal pressed then

released

Ignition switch ON (II)

Under all conditions

Under all conditions

Under all conditions

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be no voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be no voltage on terminal No. 7.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be voltage on terminal No. 7.

Check for continuity to ground:

There should be continuity.

NOTE: There should be no continuity

when the shift lever is in other positions.

Check for voltage between the

BLU/ WHT and BLK terminals:

There should be cycle 0 - 5 V or

battery voltage.

Check for voltage to ground:

There should be 0 V with the pedal

pressed, and battery voltage with

the pedal released.

Check for voltage to ground:

There should be battery voltage with

the pedal pressed, and 0 V with the

pedal released.

Attach to ground:

The cruise light in the gauge assembly

should come on.

Check for resistance to ground:

There should be 80 -120

Check for resistance to ground:

There should be 70 -110

Check for resistance to ground:

There should be 40 - 60

• Poor ground (G401, G402)

• An open in the wire

• Blown No. 20 (20 A) fuse in the

under-dash fuse/relay box

• Faulty main switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Faulty A/T gear position switch

• Poor ground (G401, G402)

• An open in the wire

• Faulty vehicle speed sensor (VSS)

• An open in the wire

• Short to ground

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown bulb

• Faulty gauge circuit

• An open in the wire

• Faulty actuator solenoid

• An open in the wireProCarManuals.com

Page 371 of 1954

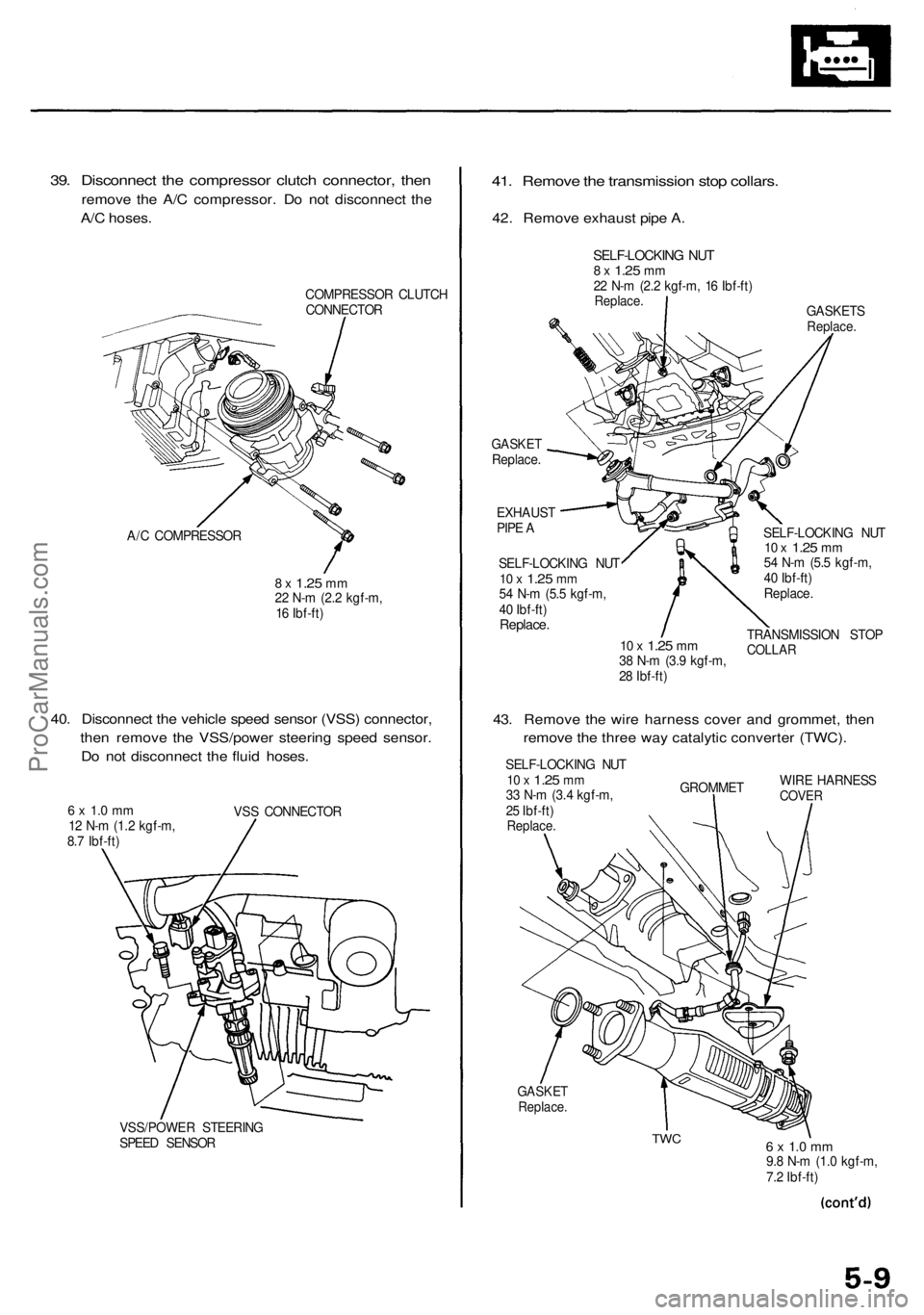

39. Disconnect the compressor clutch connector, then

remove the A/C compressor. Do not disconnect the

A/C hoses.

COMPRESSOR CLUTCH

CONNECTOR

A/C COMPRESSOR

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

40. Disconnect the vehicle speed sensor (VSS) connector,

then remove the VSS/power steering speed sensor.

Do not disconnect the fluid hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

VSS CONNECTOR

VSS/POWER STEERING

SPEED SENSOR

41. Remove the transmission stop collars.

42. Remove exhaust pipe A.

GASKETS

Replace.

GASKET

Replace.

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

TRANSMISSION STOP

COLLAR

43. Remove the wire harness cover and grommet, then

remove the three way catalytic converter (TWC).

SELF-LOCKING NUT

10 x

1.25

mm

33 N-m (3.4 kgf-m,

25 Ibf-ft)

Replace.

GROMMET

WIRE HARNESS

COVER

GASKET

Replace.

TWC

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SELF-LOCKING NUT

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

Replace.ProCarManuals.com

Page 493 of 1954

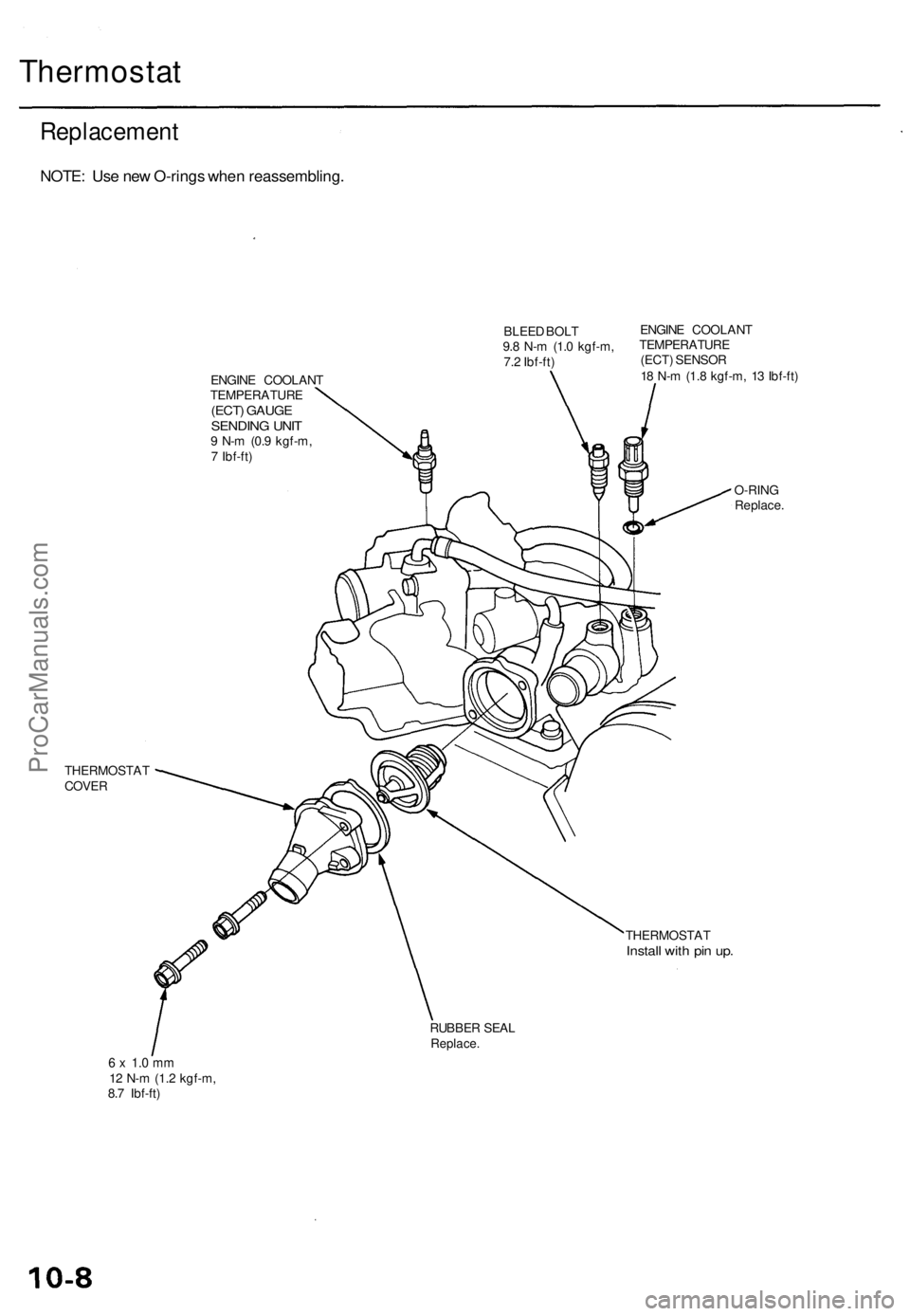

Thermostat

Replacement

NOTE: Use new O-rings when reassembling.

BLEED BOLT

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) GAUGE

SENDING UNIT

9 N-m (0.9 kgf-m,

7 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

18 N-m (1.8 kgf-m, 13 Ibf-ft)

THERMOSTAT

COVER

O-RING

Replace.

THERMOSTAT

Install with pin up.

RUBBER SEAL

Replace.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 498 of 1954

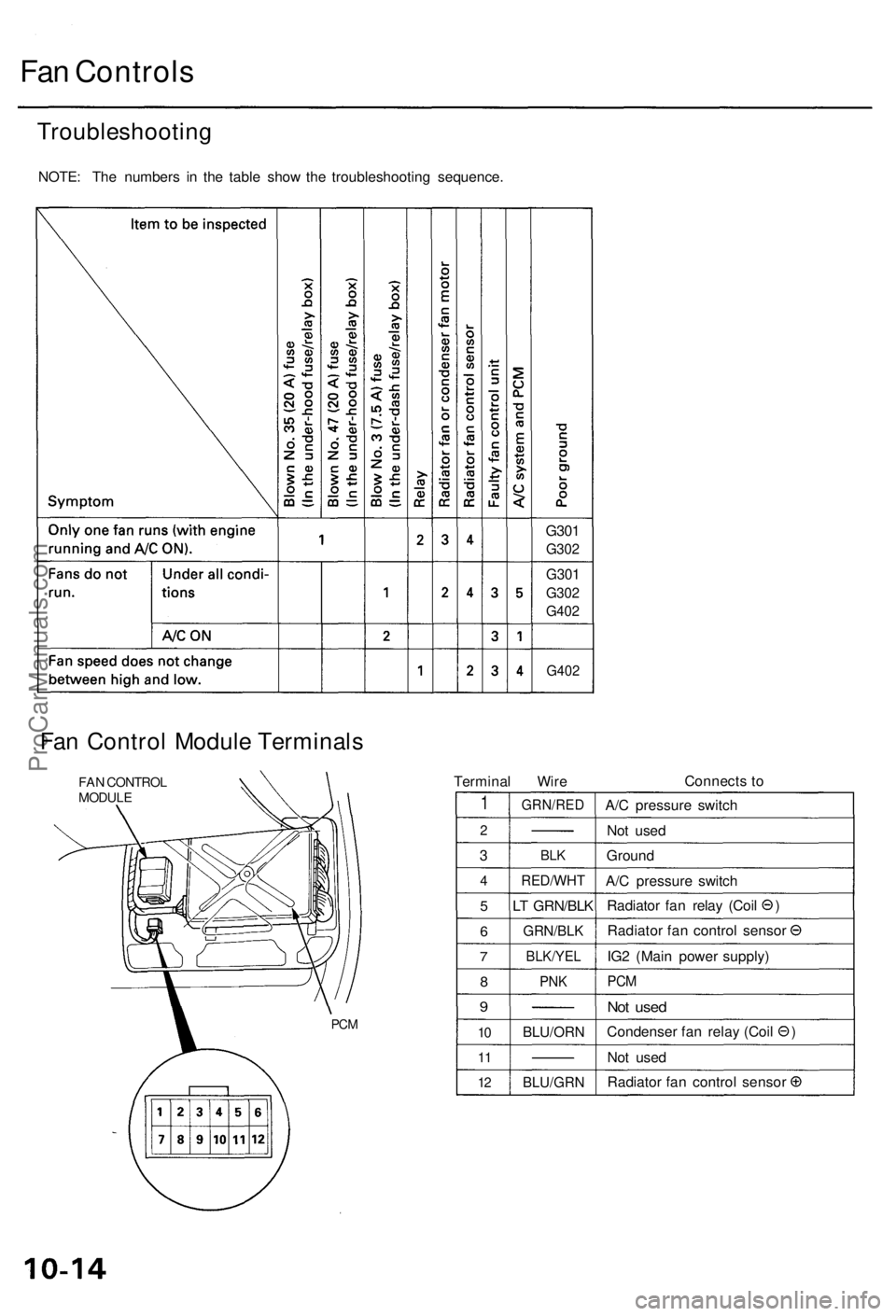

Fan Controls

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.

G301

G302

G301

G302

G402

G402

Fan Control Module Terminals

FAN CONTROL

MODULE

Terminal Wire

Connects to

1

2

3

4

5

6

7

8

9

10

11

12

GRN/RED

BLK

RED/WHT

LT GRN/BLK

GRN/BLK

BLK/YEL

PNK

BLU/ORN

BLU/GRN

A/C pressure switch

Not used

Ground

A/C pressure switch

Radiator fan relay (Coil )

Radiator fan control sensor

IG2 (Main power supply)

PCM

Not used

Condenser fan relay (Coil )

Not used

Radiator fan control sensor

PCMProCarManuals.com

Page 499 of 1954

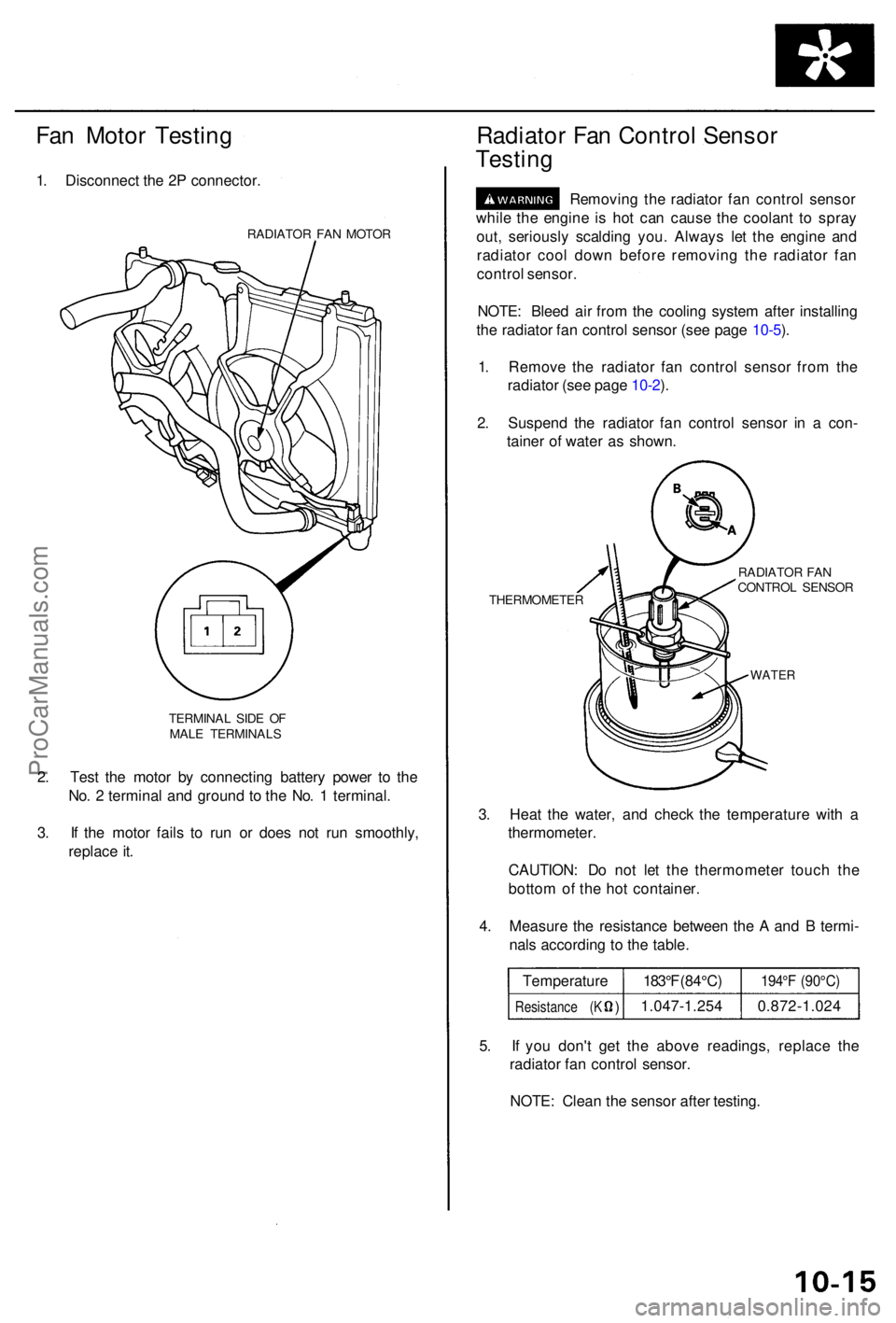

Fan Moto r Testin g

1. Disconnec t th e 2 P connector .

RADIATOR FA N MOTO R

TERMINA L SID E O F

MAL E TERMINAL S

2. Tes t th e moto r b y connectin g batter y powe r t o th e

No . 2 termina l an d groun d t o th e No . 1 terminal .

3 . I f th e moto r fail s t o ru n o r doe s no t ru n smoothly ,

replac e it .

Radiato r Fa n Contro l Senso r

Testin g

Removin g th e radiato r fa n contro l senso r

whil e th e engin e i s ho t ca n caus e th e coolan t t o spra y

out , seriousl y scaldin g you . Alway s le t th e engin e an d

radiato r coo l dow n befor e removin g th e radiato r fa n

contro l sensor .

NOTE : Blee d ai r fro m th e coolin g syste m afte r installin g

th e radiato r fa n contro l senso r (se e pag e 10-5 ).

1 . Remov e th e radiato r fa n contro l senso r fro m th e

radiato r (se e pag e 10-2 ).

2 . Suspen d th e radiato r fa n contro l senso r i n a con -

taine r o f wate r a s shown .

THERMOMETE R RADIATO

R FA N

CONTRO L SENSO R

WATER

3. Hea t th e water , an d chec k th e temperatur e wit h a

thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m o f th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g t o th e table .

Temperatur e

Resistance ( K ) 183°

F (84°C )

1.047-1.25 4

194°F (90°C )

0.872-1.02 4

5 . I f yo u don' t ge t th e abov e readings , replac e th e

radiato r fa n contro l sensor .

NOTE : Clea n th e senso r afte r testing .

ProCarManuals.com

Page 502 of 1954

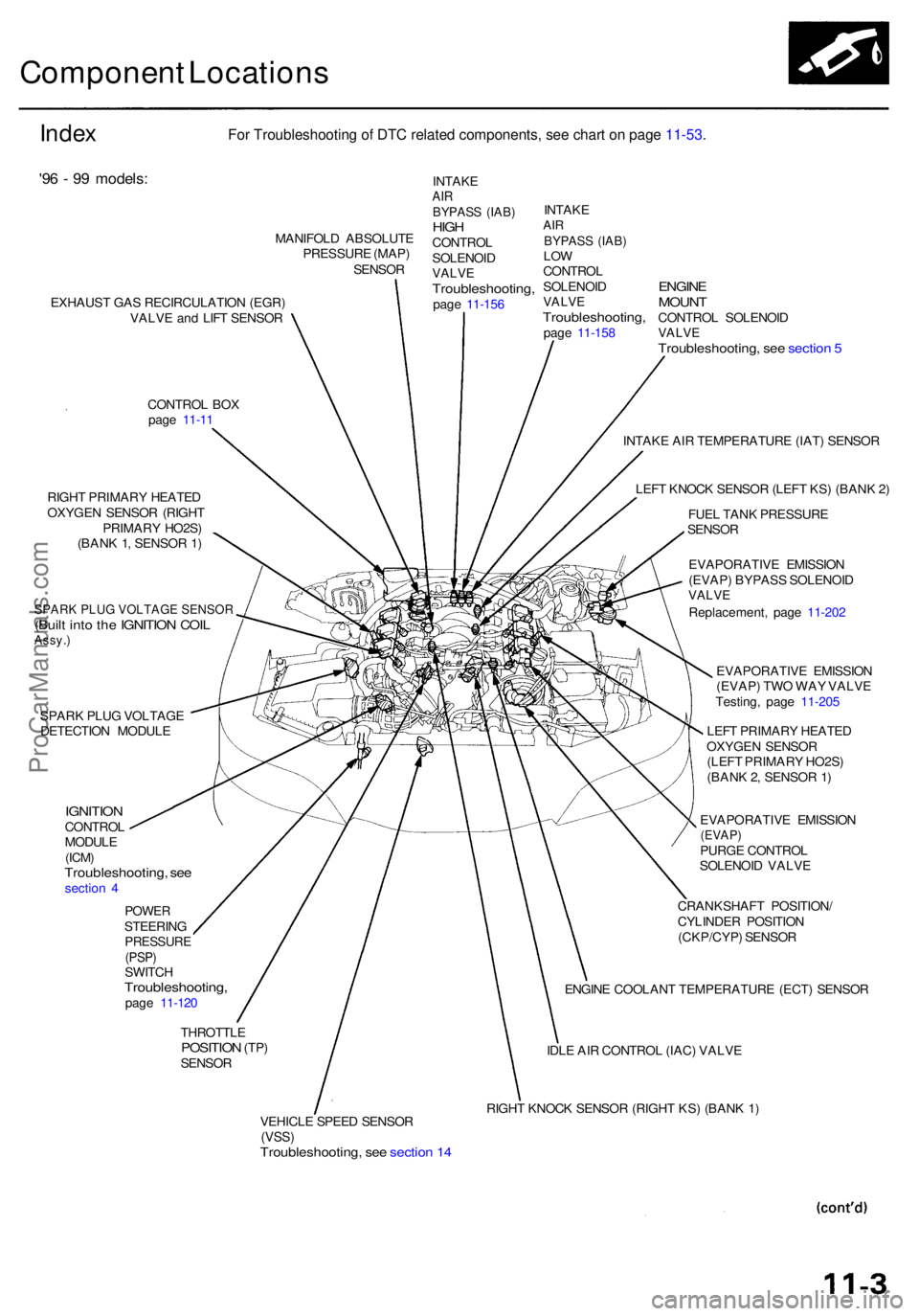

Component Location s

Index

'96 - 9 9 models :

MANIFOL D ABSOLUT E

PRESSUR E (MAP )

SENSO R

EXHAUS T GA S RECIRCULATIO N (EGR )

VALV E an d LIF T SENSO R

CONTRO L BO X

pag e 11-1 1

RIGH T PRIMAR Y HEATE D

OXYGE N SENSO R (RIGH T

PRIMAR Y HO2S )

(BAN K 1 , SENSO R 1 )

SPARK PLUG VOLTAGE SENSOR(Buil t int o th e IGNITIO N COI LAssy. )

INTAK EAIRBYPAS S (IAB )HIGHCONTRO L

SOLENOI D

VALVETroubleshooting ,page 11-15 6 INTAK

E

AIRBYPAS S (IAB )LOWCONTRO L

SOLENOI D

VALVETroubleshooting ,page 11-15 8

SPAR K PLU G VOLTAG E

DETECTIO N MODUL E

ENGINEMOUN TCONTRO L SOLENOI DVALVETroubleshooting , se e sectio n 5

THROTTL EPOSITION (TP)

SENSO R

VEHICL E SPEE D SENSO R

(VSS)Troubleshooting , se e sectio n 1 4

IDL E AI R CONTRO L (IAC ) VALV E

RIGH T KNOC K SENSO R (RIGH T KS ) (BAN K 1 )

ENGIN

E COOLAN T TEMPERATUR E (ECT ) SENSO R

CRANKSHAF

T POSITION /

CYLINDE R POSITIO N

(CKP/CYP ) SENSO R

EVAPORATIV

E EMISSIO N

(EVAP)PURGE CONTRO L

SOLENOI D VALV E

LEF

T PRIMAR Y HEATE D

OXYGE N SENSO R

(LEF T PRIMAR Y HO2S )

(BAN K 2, SENSO R 1 )

POWE RSTEERIN GPRESSUR E(PSP)SWITC HTroubleshooting ,page 11-12 0

IGNITIO NCONTRO L

MODUL E

(ICM)Troubleshooting , se esectio n 4 EVAPORATIV

E EMISSIO N

(EVAP ) TW O WA Y VALV E

Testing , pag e 11-20 5

EVAPORATIV

E EMISSIO N

(EVAP ) BYPAS S SOLENOI D

VALVEReplacement , pag e 11-20 2

FUE

L TAN K PRESSUR E

SENSO R

LEF

T KNOC K SENSO R (LEF T KS ) (BAN K 2 )

INTAK

E AI R TEMPERATUR E (IAT ) SENSO R

For Troubleshooting of DTC related components, see chart on page 11-53.

ProCarManuals.com

Page 512 of 1954

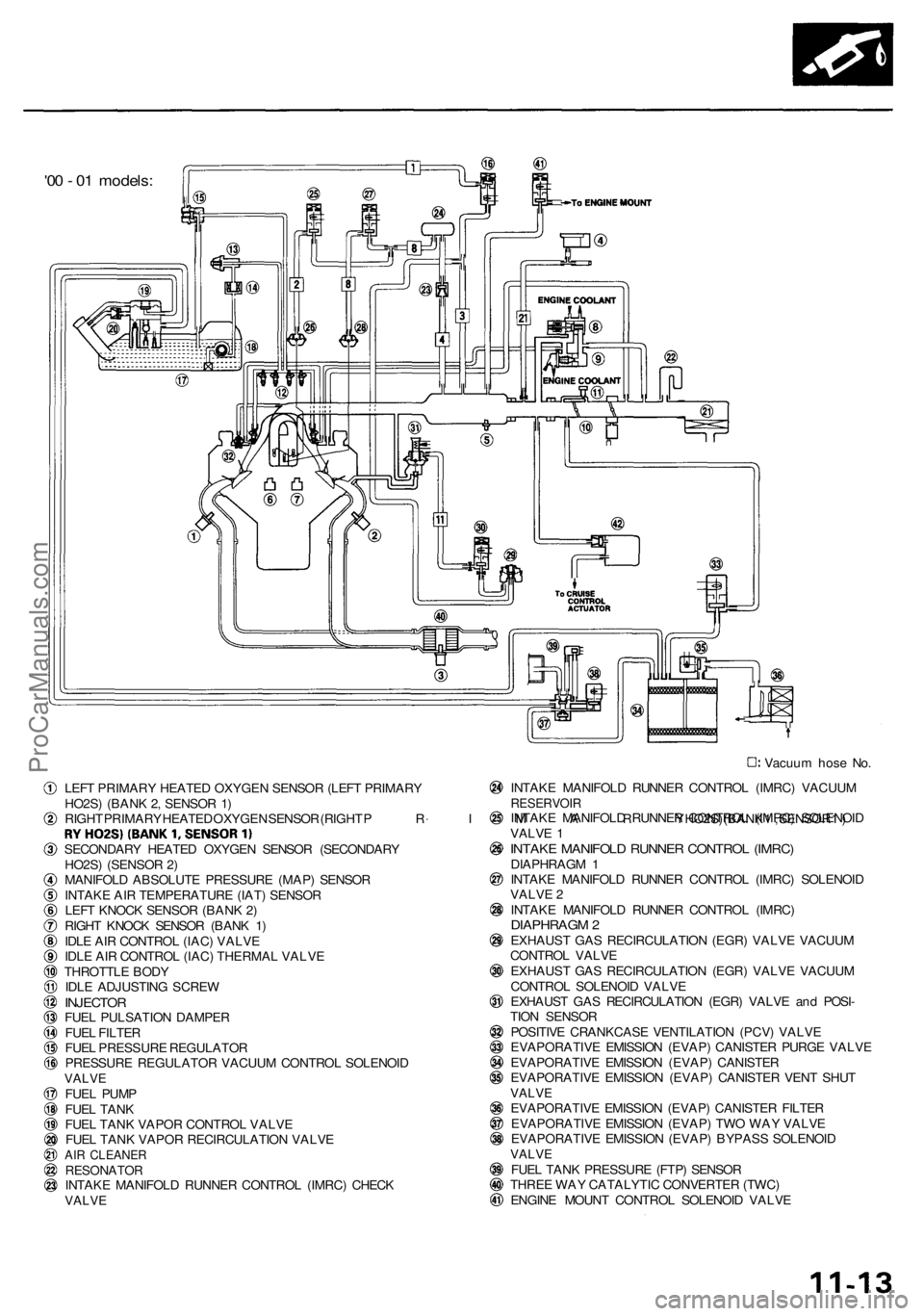

'00 - 01 models:

Vacuum hose No.

LEFT PRIMARY HEATED OXYGEN SENSOR (LEFT PRIMARY

HO2S) (BANK 2, SENSOR 1)

RIGHT PRIMARY HEATED OXYGEN SENSOR (RIGHT

PRIMARY

HO2S) (BANK

1,

SENSOR

1)

SECONDARY HEATED OXYGEN SENSOR (SECONDARY

HO2S) (SENSOR 2)

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

INTAKE AIR TEMPERATURE (IAT) SENSOR

LEFT KNOCK SENSOR (BANK 2)

RIGHT KNOCK SENSOR (BANK 1)

IDLE AIR CONTROL (IAC) VALVE

IDLE AIR CONTROL (IAC) THERMAL VALVE

THROTTLE BODY

IDLE ADJUSTING SCREW

INJECTOR

FUEL PULSATION DAMPER

FUEL FILTER

FUEL PRESSURE REGULATOR

PRESSURE REGULATOR VACUUM CONTROL SOLENOID

VALVE

FUEL PUMP

FUEL TANK

FUEL TANK VAPOR CONTROL VALVE

FUEL TANK VAPOR RECIRCULATION VALVE

AIR CLEANER

RESONATOR

INTAKE MANIFOLD RUNNER CONTROL (IMRC) CHECK

VALVE

INTAKE MANIFOLD RUNNER CONTROL (IMRC) VACUUM

RESERVOIR

INTAKE MANIFOLD RUNNER CONTROL (IMRC) SOLENOID

VALVE 1

INTAKE MANIFOLD RUNNER CONTROL (IMRC)

DIAPHRAGM 1

INTAKE MANIFOLD RUNNER CONTROL (IMRC) SOLENOID

VALVE 2

INTAKE MANIFOLD RUNNER CONTROL (IMRC)

DIAPHRAGM 2

EXHAUST GAS RECIRCULATION (EGR) VALVE VACUUM

CONTROL VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE VACUUM

CONTROL SOLENOID VALVE

EXHAUST GAS RECIRCULATION (EGR) VALVE and POSI-

TION SENSOR

POSITIVE CRANKCASE VENTILATION (PCV) VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER PURGE VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER

EVAPORATIVE EMISSION (EVAP) CANISTER VENT SHUT

VALVE

EVAPORATIVE EMISSION (EVAP) CANISTER FILTER

EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

EVAPORATIVE EMISSION (EVAP) BYPASS SOLENOID

VALVE

FUEL TANK PRESSURE (FTP) SENSOR

THREE WAY CATALYTIC CONVERTER (TWC)

ENGINE MOUNT CONTROL SOLENOID VALVEProCarManuals.com

Page 516 of 1954

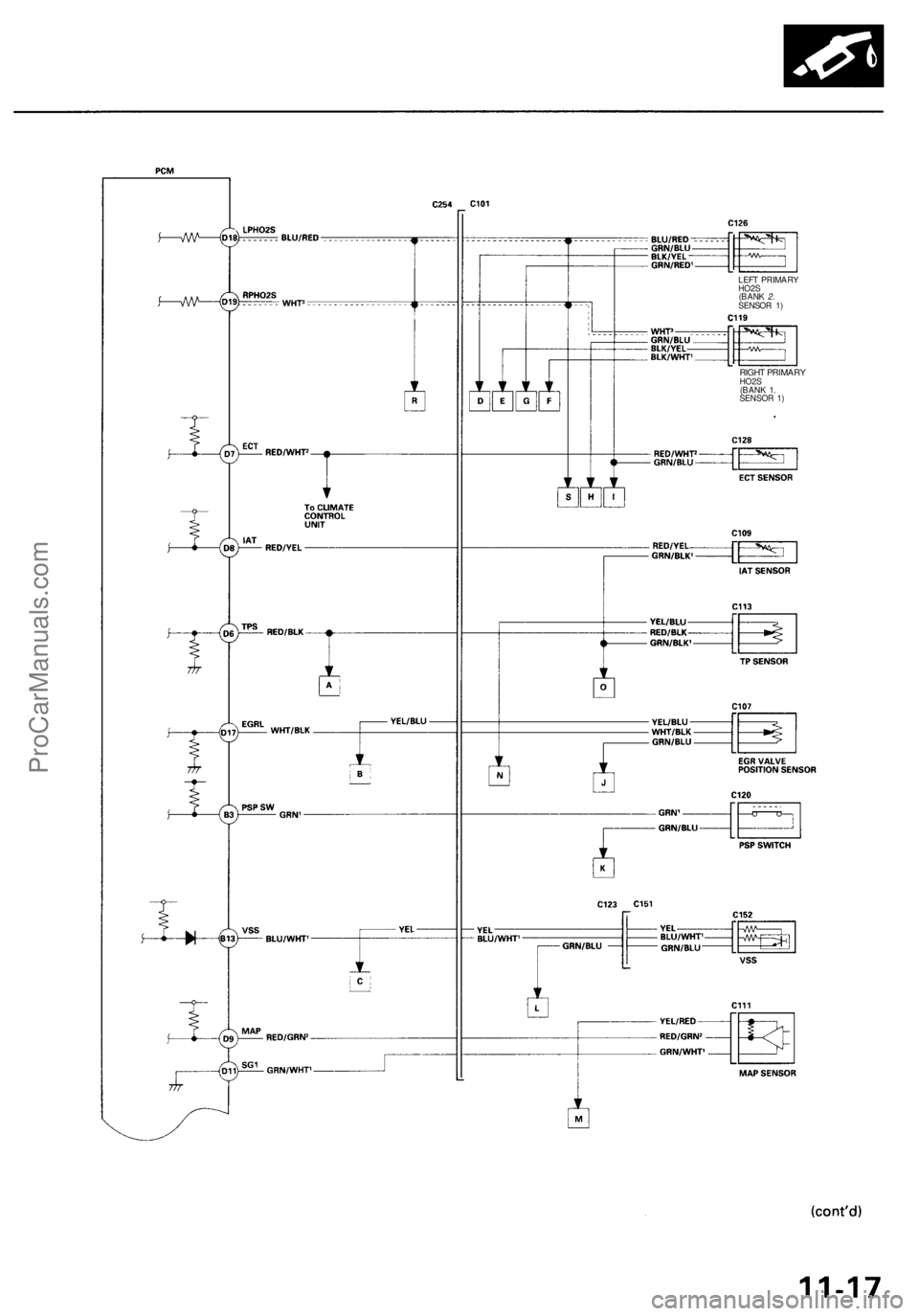

LEFT PRIMARY

HO2S

(BANK 2.

SENSOR 1)

RIGHT PRIMARY

HO2S

(BANK 1.

SENSOR 1)ProCarManuals.com