brake light ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 171 of 1954

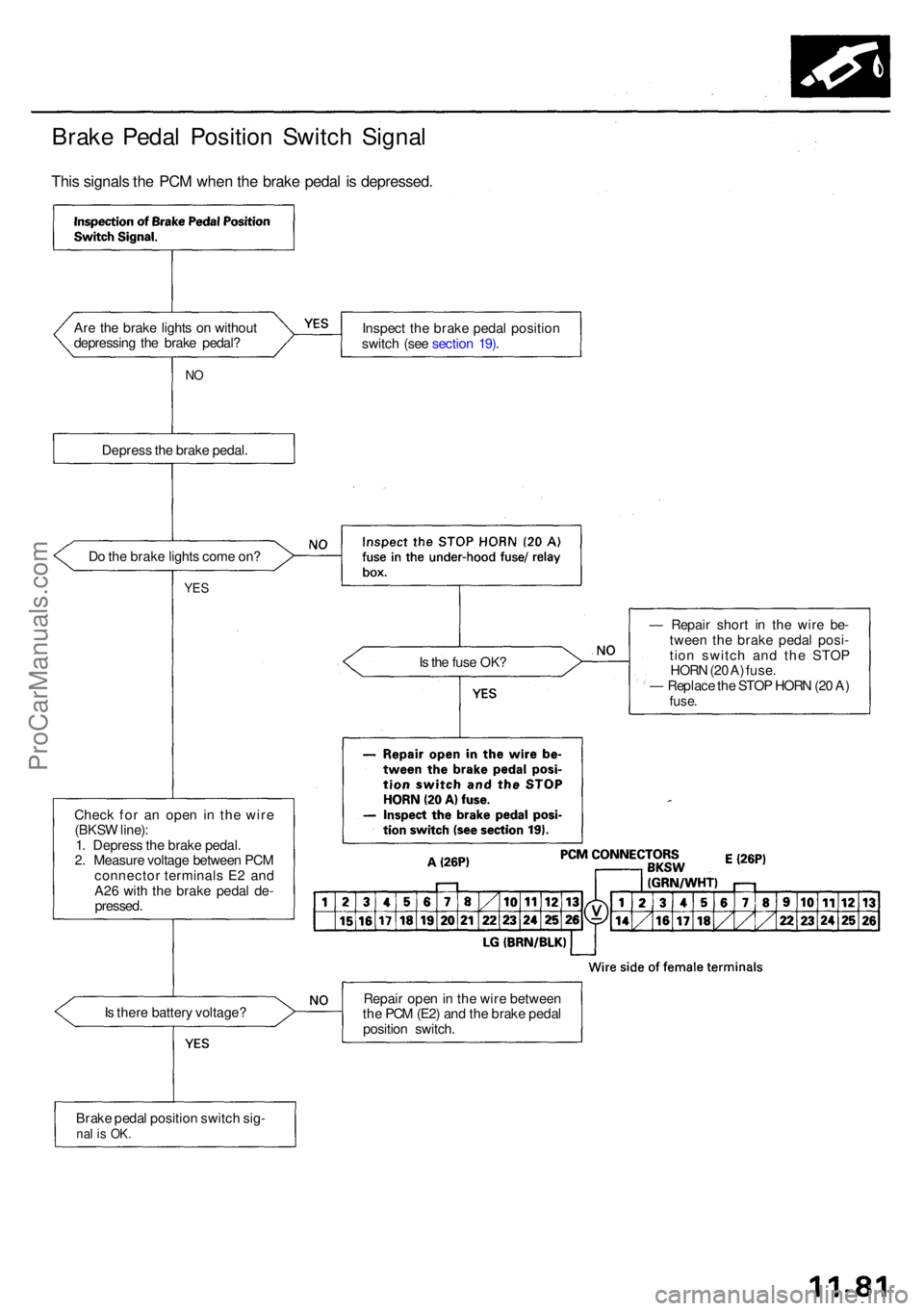

Brake Peda l Positio n Switc h Signa l

This signal s th e PC M whe n th e brak e peda l i s depressed .

Are th e brak e light s o n withou t

depressin g th e brak e pedal ? Inspec

t th e brak e peda l positio n

switc h (se e sectio n 19) .

NO

Depres s th e brak e pedal .

D o th e brak e light s com e on ?

YES

Is th e fus e OK ?

Chec k fo r a n ope n i n th e wir e

(BKS W line) :

1 . Depres s th e brak e pedal .

2 . Measur e voltag e betwee n PC M

connecto r terminal s E 2 an d

A2 6 wit h th e brak e peda l de -

pressed . —

Repai r shor t i n th e wir e be -

twee n th e brak e peda l posi -

tio n switc h an d th e STO P

HOR N (2 0 A ) fuse .

— Replac e th e STO P HOR N (2 0 A )

fuse .

Is ther e batter y voltage ? Repai

r ope n in th e wir e betwee n

th e PC M (E2 ) an d th e brak e peda l

positio n switch .

Brak e peda l positio n switc h sig -

nal i s OK .

ProCarManuals.com

Page 356 of 1954

Cruise Control

Control Unit Input Test (cont'd)

Cavity Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

3

13

7

6

14

12

2

5

10

9

11

1

BLK

LT GRN

LT GRN/BLK

LT GRN/RED

PNK

BLU/WHT

GRY

GRN/WHT

BLU/YEL

BRN

BRN/BLK

BRN/WHT

Under all conditions

Ignition switch ON (II) and

main switch ON

Resume button pushed

Cancel button pushed

Set button pushed

Cancel button pushed

Shift lever in , or

Ignition switch ON (II), and

main switch ON; raise the

front of the vehicle, and rotate

one wheel slowly while

holding the other wheel.

Ignition switch ON (II), main

switch ON; brake pedal

pressed, then released

Brake pedal pressed then

released

Ignition switch ON (II)

Under all conditions

Under all conditions

Under all conditions

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be no voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be no voltage on terminal No. 7.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be voltage on terminal No. 7.

Check for continuity to ground:

There should be continuity.

NOTE: There should be no continuity

when the shift lever is in other positions.

Check for voltage between the

BLU/ WHT and BLK terminals:

There should be cycle 0 - 5 V or

battery voltage.

Check for voltage to ground:

There should be 0 V with the pedal

pressed, and battery voltage with

the pedal released.

Check for voltage to ground:

There should be battery voltage with

the pedal pressed, and 0 V with the

pedal released.

Attach to ground:

The cruise light in the gauge assembly

should come on.

Check for resistance to ground:

There should be 80 -120

Check for resistance to ground:

There should be 70 -110

Check for resistance to ground:

There should be 40 - 60

• Poor ground (G401, G402)

• An open in the wire

• Blown No. 20 (20 A) fuse in the

under-dash fuse/relay box

• Faulty main switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Faulty A/T gear position switch

• Poor ground (G401, G402)

• An open in the wire

• Faulty vehicle speed sensor (VSS)

• An open in the wire

• Short to ground

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown bulb

• Faulty gauge circuit

• An open in the wire

• Faulty actuator solenoid

• An open in the wireProCarManuals.com

Page 621 of 1954

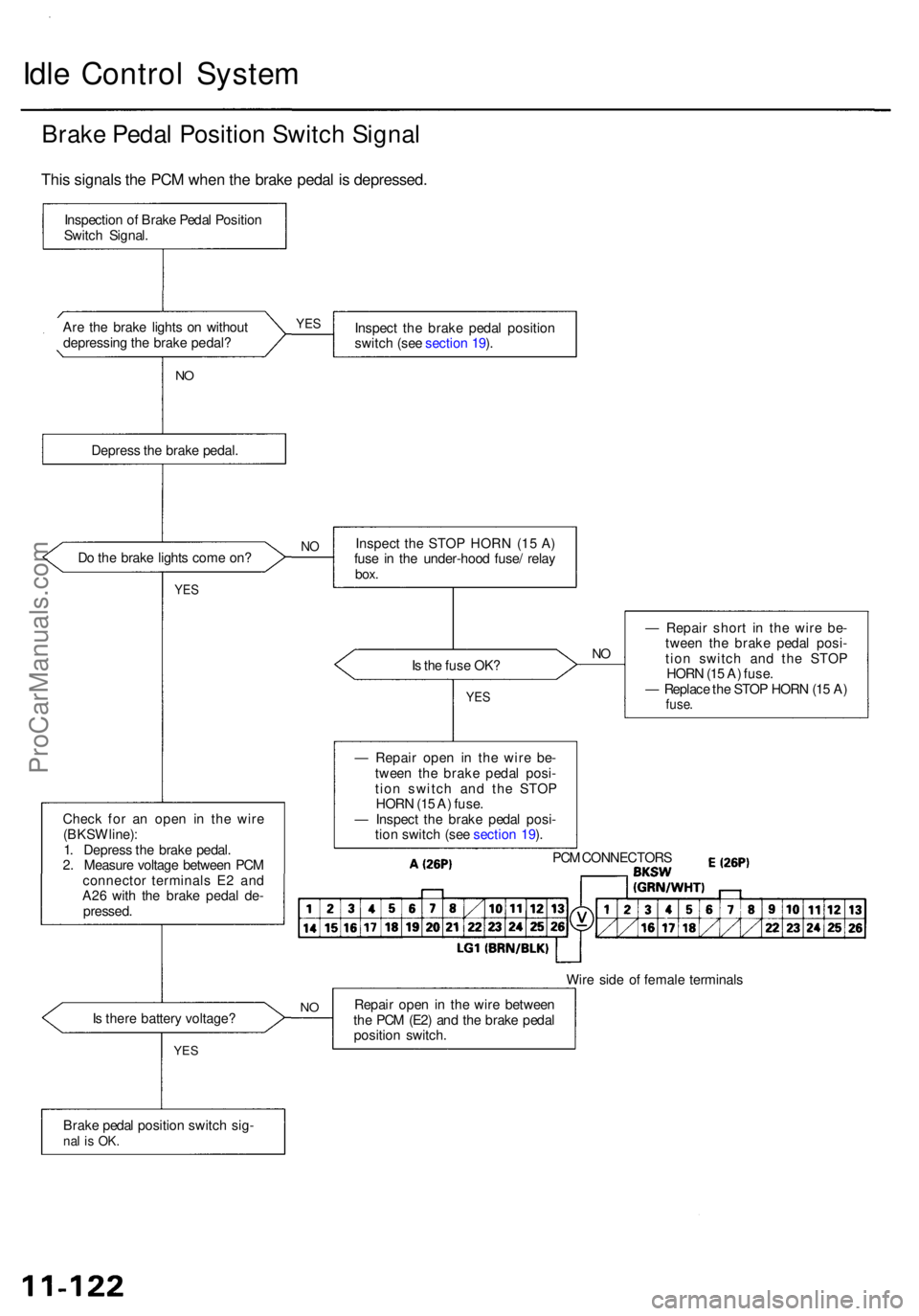

Idle Contro l Syste m

Brake Peda l Positio n Switc h Signa l

Are th e brak e light s o n withou t

depressin g th e brak e pedal ? Inspec

t th e brak e peda l positio n

switc h (se e sectio n 19 ).

N O

Depres s th e brak e pedal .

D o th e brak e light s com e on ?

YES

Is th e fus e OK ?NO

Chec k fo r a n ope n i n th e wir e

(BKS W line) :

1 . Depres s th e brak e pedal .

2 . Measur e voltag e betwee n PC M

connecto r terminal s E 2 an d

A2 6 wit h th e brak e peda l de -

pressed . —

Repai r shor t i n th e wire be-

twee n th e brak e peda l posi -

tio n switc h an d th e STO P

HOR N (1 5 A ) fuse .

— Replac e th e STO P HOR N (1 5 A )

fuse .

Wire sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r ope n in th e wir e betwee n

th e PC M (E2 ) an d th e brak e peda l

positio n switch .

Brak e peda l positio n switc h sig -

nal i s OK .

YES

NO

— Repai r ope n i n th e wir e be -

twee n th e brak e peda l posi -

tio n switc h an d th e STO P

HOR N (1 5 A ) fuse .

— Inspec t th e brak e peda l posi -

tio n switc h (se e sectio n 19 ).

PC M CONNECTOR S

YES

NOInspec t th e STO P HOR N (1 5 A )

fus e i n th e under-hoo d fuse / rela y

box.

YES

Inspectio n o f Brak e Peda l Positio n

Switc h Signal .

This signal s th e PC M whe n th e brak e peda l i s depressed .

ProCarManuals.com

Page 1051 of 1954

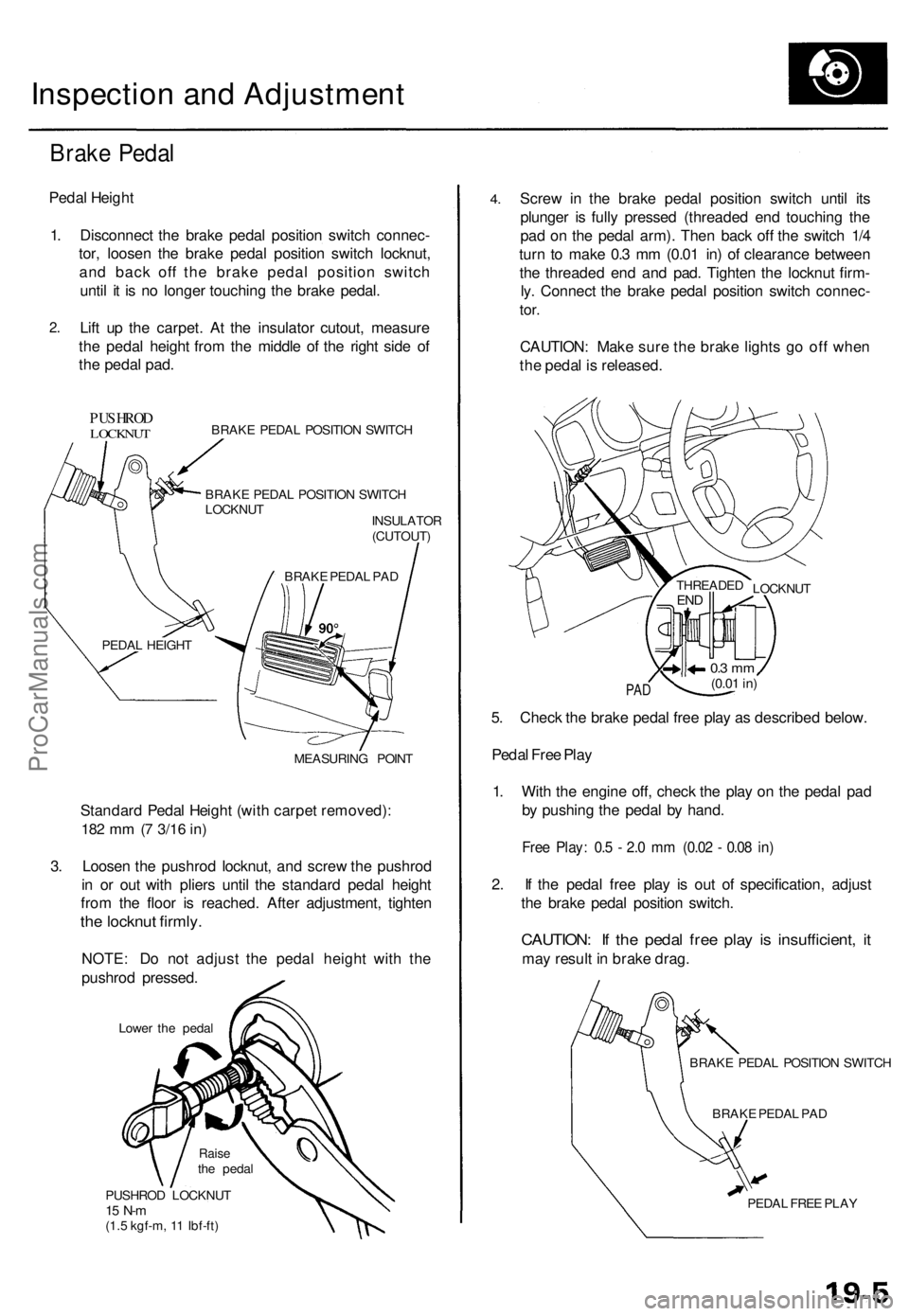

Inspection and Adjustment

Brake Pedal

Pedal Height

1. Disconnect the brake pedal position switch connec-

tor, loosen the brake pedal position switch locknut,

and back off the brake pedal position switch

until it is no longer touching the brake pedal.

2.

Lift up the carpet. At the insulator cutout, measure

the pedal height from the middle of the right side of

the pedal pad.

PUSHROD

LOCKNUT

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL POSITION SWITCH

LOCKNUT

INSULATOR

(CUTOUT)

MEASURING POINT

Standard Pedal Height (with carpet removed):

182 mm (7

3/16

in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly.

NOTE: Do not adjust the pedal height with the

pushrod pressed.

Lower the pedal

PUSHROD LOCKNUT

15 N-m

(1.5 kgf-m, 11 Ibf-ft)

4.

Screw in the brake pedal position switch until its

plunger is fully pressed (threaded end touching the

pad on the pedal arm). Then back off the switch 1/4

turn to make 0.3 mm (0.01 in) of clearance between

the threaded end and pad. Tighten the locknut firm-

ly. Connect the brake pedal position switch connec-

tor.

CAUTION: Make sure the brake lights go off when

the pedal is released.

PAD

5. Check the brake pedal free play as described below.

Pedal Free Play

1. With the engine off, check the play on the pedal pad

by pushing the pedal by hand.

Free Play: 0.5 - 2.0 mm (0.02 - 0.08 in)

2. If the pedal free play is out of specification, adjust

the brake pedal position switch.

CAUTION: If the pedal free play is insufficient, it

may result in brake drag.

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL PAD

PEDAL FREE PLAY

LOCKNUT

THREADED

END

0.3 mm

(0.01

in)

BRAKE PEDAL PAD

PEDAL HEIGHT

Raise

the pedalProCarManuals.com

Page 1052 of 1954

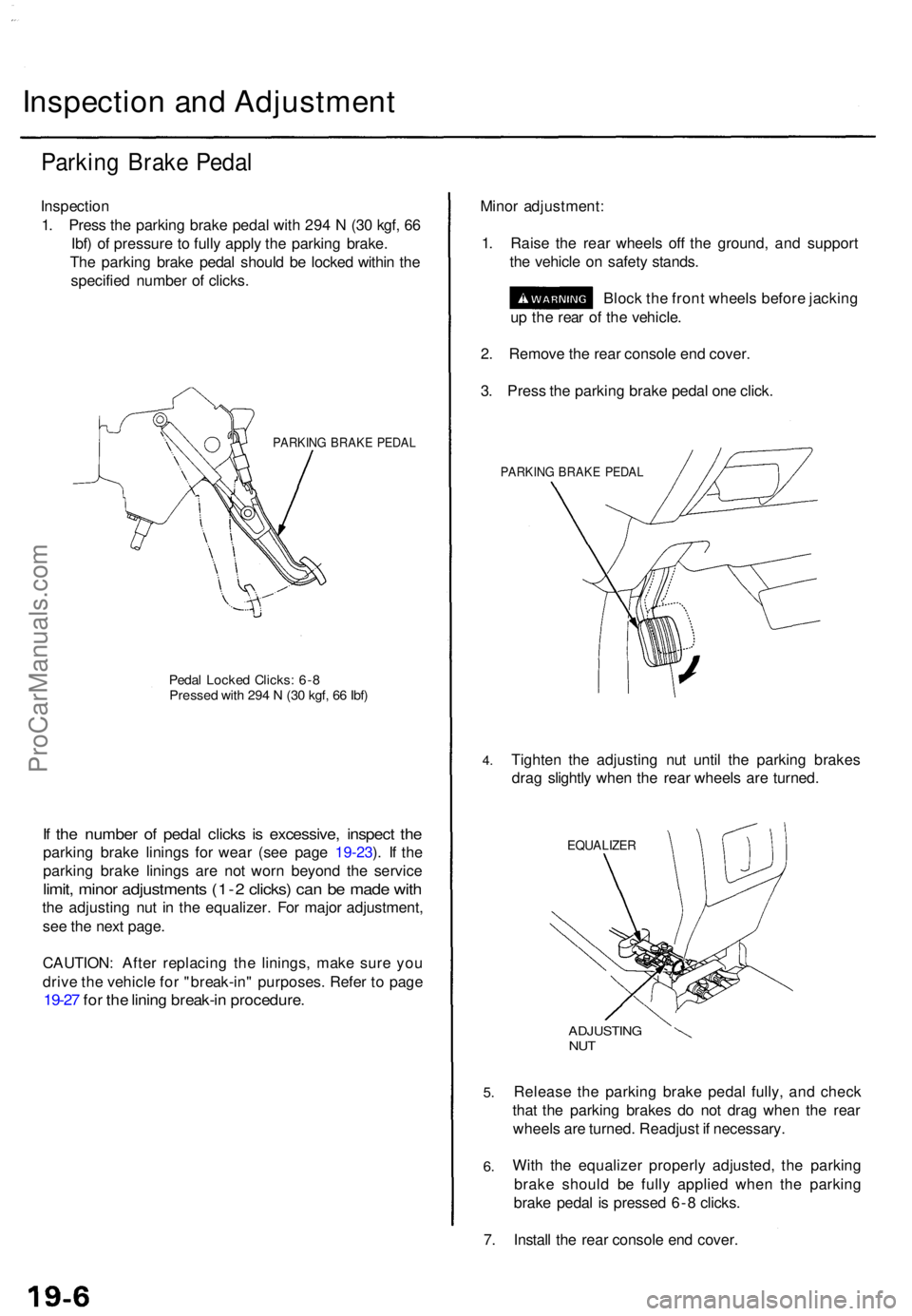

Inspection an d Adjustmen t

Parking Brak e Peda l

Inspectio n

1 . Pres s th e parkin g brak e peda l wit h 29 4 N (3 0 kgf , 6 6

Ibf ) o f pressur e to full y appl y th e parkin g brake .

Th e parkin g brak e peda l shoul d b e locke d withi n th e

specifie d numbe r o f clicks .

PARKIN G BRAK E PEDA L

Pedal Locke d Clicks : 6- 8Presse d wit h 29 4 N (3 0 kgf , 6 6 Ibf )

If th e numbe r o f peda l click s i s excessive , inspec t th e

parkin g brak e lining s fo r wea r (se e pag e 19-23 ). I f th e

parkin g brak e lining s ar e no t wor n beyon d th e servic e

limit, mino r adjustment s (1- 2 clicks ) ca n b e mad e wit h

the adjustin g nu t i n th e equalizer . Fo r majo r adjustment ,

se e th e nex t page .

CAUTION : Afte r replacin g th e linings , mak e sur e yo u

driv e th e vehicl e fo r "break-in " purposes . Refe r t o pag e

19-27 fo r th e linin g break-i n procedure .

Minor adjustment :

1 . Rais e th e rea r wheel s of f th e ground , an d suppor t

th e vehicl e o n safet y stands .

Bloc k th e fron t wheel s befor e jackin g

u p th e rea r o f th e vehicle .

2 . Remov e th e rea r consol e en d cover .

3 . Pres s th e parkin g brak e peda l on e click .

PARKIN G BRAK E PEDA L

4.Tighte n th e adjustin g nu t unti l th e parkin g brake s

dra g slightl y whe n th e rea r wheel s ar e turned .

EQUALIZE R

5.

6.

ADJUSTIN GNUT

Releas e th e parkin g brak e peda l fully , an d chec k

tha t th e parkin g brake s d o no t dra g whe n th e rea r

wheel s ar e turned . Readjus t i f necessary .

Wit h th e equalize r properl y adjusted , th e parkin g

brak e shoul d b e full y applie d whe n th e parkin g

brak e peda l i s presse d 6- 8 clicks .

7 . Instal l th e rea r consol e en d cover .

ProCarManuals.com

Page 1055 of 1954

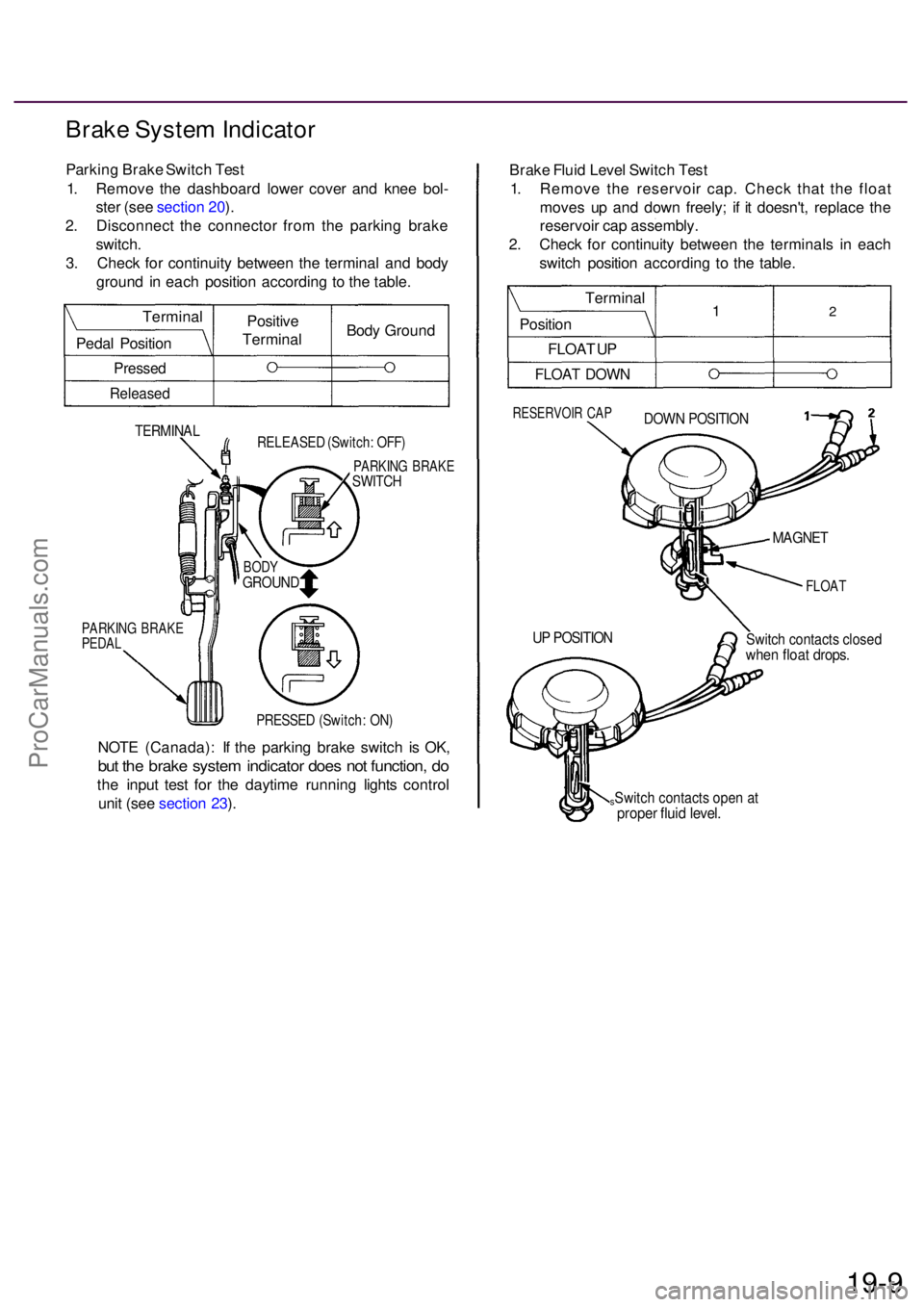

Brake Syste m Indicato r

Parking Brak e Switc h Tes t

1 . Remov e th e dashboar d lowe r cove r an d kne e bol -

ste r (se e sectio n 20 ).

2 . Disconnec t th e connecto r fro m th e parkin g brak e

switch .

3 . Chec k fo r continuit y betwee n th e termina l an d bod y

groun d i n eac h positio n accordin g t o th e table .

TERMINA LRELEASE D (Switch : OFF )

PARKIN G BRAK ESWITCH

PARKIN G BRAK EPEDAL

PRESSE D (Switch : ON )

NOT E (Canada) : I f th e parkin g brak e switc h i s OK ,

but th e brak e syste m indicato r doe s no t function , d o

th e inpu t tes t fo r th e daytim e runnin g light s contro l

uni t (se e sectio n 23 ). Brak

e Flui d Leve l Switc h Tes t

1 . Remov e th e reservoi r cap . Chec k tha t th e floa t

move s u p an d dow n freely ; i f i t doesn't , replac e th e

reservoi r ca p assembly .

2 . Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

RESERVOI R CA PDOW N POSITIO N

FLOAT

Switch contact s close dwhen floa t drops .

sSwitch contact s ope n a tprope r flui d level .

19-9

UP POSITIO N

MAGNET

BODYGROUN D

Positive

Termina lBod

y Groun d

Termina

l

Peda l Positio n

Pressed

Release d

Termina l

Positio n

FLOA T U P

FLOA T DOW N

12

ProCarManuals.com

Page 1056 of 1954

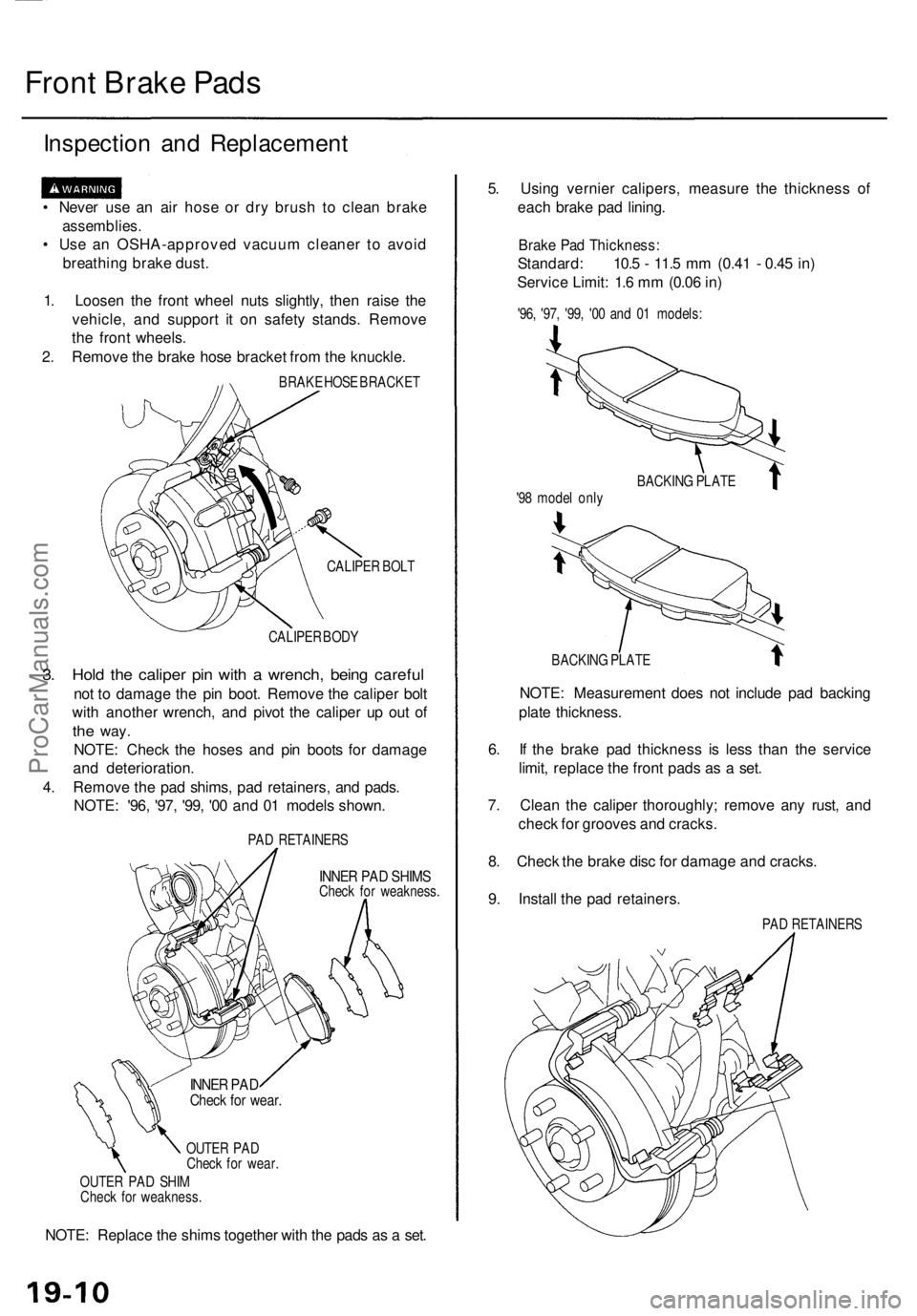

Front Brak e Pad s

Inspectio n an d Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brake

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

th e fron t wheels .

2 . Remov e th e brak e hos e bracke t fro m th e knuckle .

BRAKE HOS E BRACKE T

CALIPE R BOL T

CALIPE R BOD Y

3. Hol d th e calipe r pi n wit h a wrench , bein g carefu l

not t o damag e th e pi n boot . Remov e th e calipe r bol t

wit h anothe r wrench , an d pivo t th e calipe r u p ou t o f

the way .

NOTE : Chec k th e hose s an d pi n boot s fo r damag e

an d deterioration .

4 . Remov e th e pa d shims , pa d retainers , an d pads .

NOTE : '96 , '97 , '99 , '0 0 an d 0 1 model s shown .

PAD RETAINER S

INNER PA D SHIM SCheck fo r weakness .

OUTE R PA D

Chec k fo r wear .

OUTE R PA D SHI M

Chec k fo r weakness .

NOTE: Replac e th e shim s togethe r wit h th e pad s a s a set . 5

. Usin g vernie r calipers , measur e th e thicknes s of

eac h brak e pa d lining .

Brake Pa d Thickness :

Standard: 10. 5 - 11. 5 m m (0.4 1 - 0.4 5 in )

Servic e Limit : 1. 6 m m (0.0 6 in )

'96 , '97 , '99 , '0 0 an d 0 1 models :

BACKIN G PLAT E

NOTE: Measuremen t doe s no t includ e pa d backin g

plat e thickness .

6 . I f th e brak e pa d thicknes s i s les s tha n th e servic e

limit , replac e th e fron t pad s a s a set .

7 . Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

8 . Chec k th e brak e dis c fo r damag e an d cracks .

9 . Instal l th e pa d retainers .

PAD RETAINER S

BACKIN

G PLAT E

'9 8 mode l onl y

INNE R PA DChec k fo r wear .

ProCarManuals.com

Page 1058 of 1954

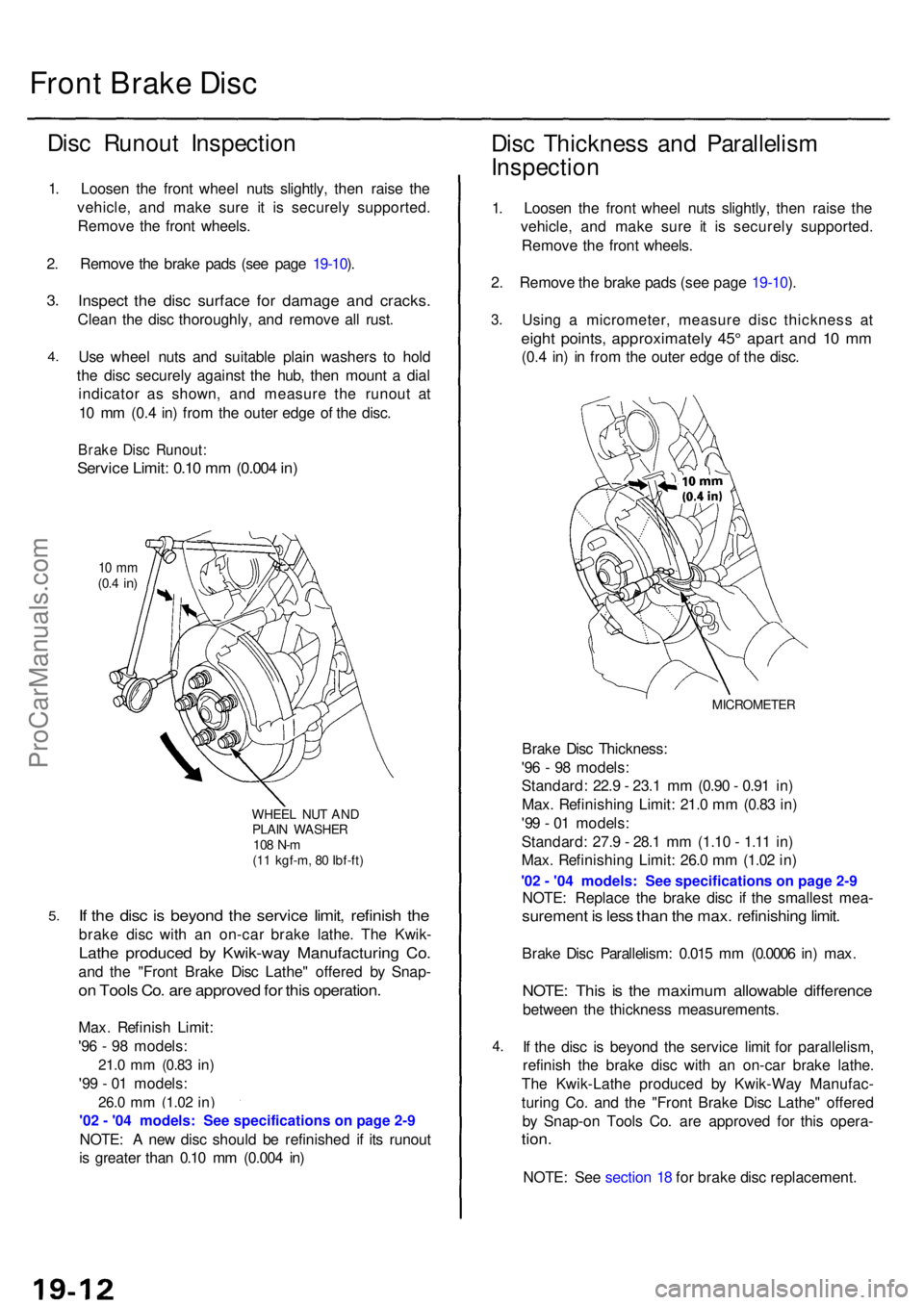

Front Brak e Dis c

Disc Runou t Inspectio n

1. Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d mak e sur e i t i s securel y supported .

Remov e th e fron t wheels .

2 . Remov e th e brak e pad s (se e pag e 19-10 ).

3 .

4 .

5 .

Inspec t th e dis c surfac e fo r damag e an d cracks .

Clean th e dis c thoroughly , an d remov e al l rust .

Us e whee l nut s an d suitabl e plai n washer s t o hol d

th e dis c securel y agains t th e hub , the n moun t a dia l

indicato r a s shown , an d measur e th e runou t a t

1 0 m m (0. 4 in ) fro m th e oute r edg e o f th e disc .

Brak e Dis c Runout :

Service Limit : 0.1 0 m m (0.00 4 in )

10 m m(0.4 in )

WHEE L NU T AN DPLAI N WASHE R108 N- m(11 kgf-m , 8 0 Ibf-ft )

If th e dis c i s beyon d th e servic e limit , refinis h th e

brak e dis c wit h a n on-ca r brak e lathe . Th e Kwik -

Lathe produce d b y Kwik-wa y Manufacturin g Co .

and th e "Fron t Brak e Dis c Lathe " offere d b y Snap -

on Tool s Co . ar e approve d fo r thi s operation .

Max. Refinis h Limit :

'9 6 - 9 8 models :

21.0 mm (0.8 3 in)

'99 - 0 1 models :

26.0 mm (1.0 2 in)

NOTE : A ne w dis c shoul d b e refinishe d i f it s runou t

i s greate r tha n 0.1 0 m m (0.00 4 in )

Dis c Thicknes s an d Parallelis m

Inspectio n

1. Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d mak e sur e i t i s securel y supported .

Remov e th e fron t wheels .

2 . Remov e th e brak e pad s (se e pag e 19-10 ).

3 .

4.

Usin g a micrometer , measur e dis c thicknes s a t

eigh t points , approximatel y 45 ° apar t an d 1 0 m m

(0.4 in ) i n fro m th e oute r edg e o f th e disc .

MICROMETE R

Brake Dis c Thickness :

'9 6 - 9 8 models :

Standard : 22. 9 - 23. 1 m m (0.9 0 - 0.9 1 in )

Max . Refinishin g Limit : 21. 0 m m (0.8 3 in )

'9 9 - 0 1 models :

Standard : 27. 9 - 28. 1 m m (1.1 0 - 1.1 1 in )

Max . Refinishin g Limit : 26. 0 m m (1.0 2 in )

NOTE : Replac e th e brak e dis c i f th e smalles t mea -

suremen t i s les s tha n th e max . refinishin g limit .

Brak e Dis c Parallelism : 0.01 5 m m (0.000 6 in ) max .

NOTE : Thi s i s th e maximu m allowabl e differenc e

between th e thicknes s measurements .

I f th e dis c i s beyon d th e servic e limi t fo r parallelism ,

refinis h th e brak e dis c wit h a n on-ca r brak e lathe .

Th e Kwik-Lath e produce d b y Kwik-Wa y Manufac -

turin g Co . an d th e "Fron t Brak e Dis c Lathe " offere d

b y Snap-o n Tool s Co . ar e approve d fo r thi s opera -

tion.

NOTE : Se e sectio n 1 8 fo r brak e dis c replacement .

ProCarManuals.com

Page 1064 of 1954

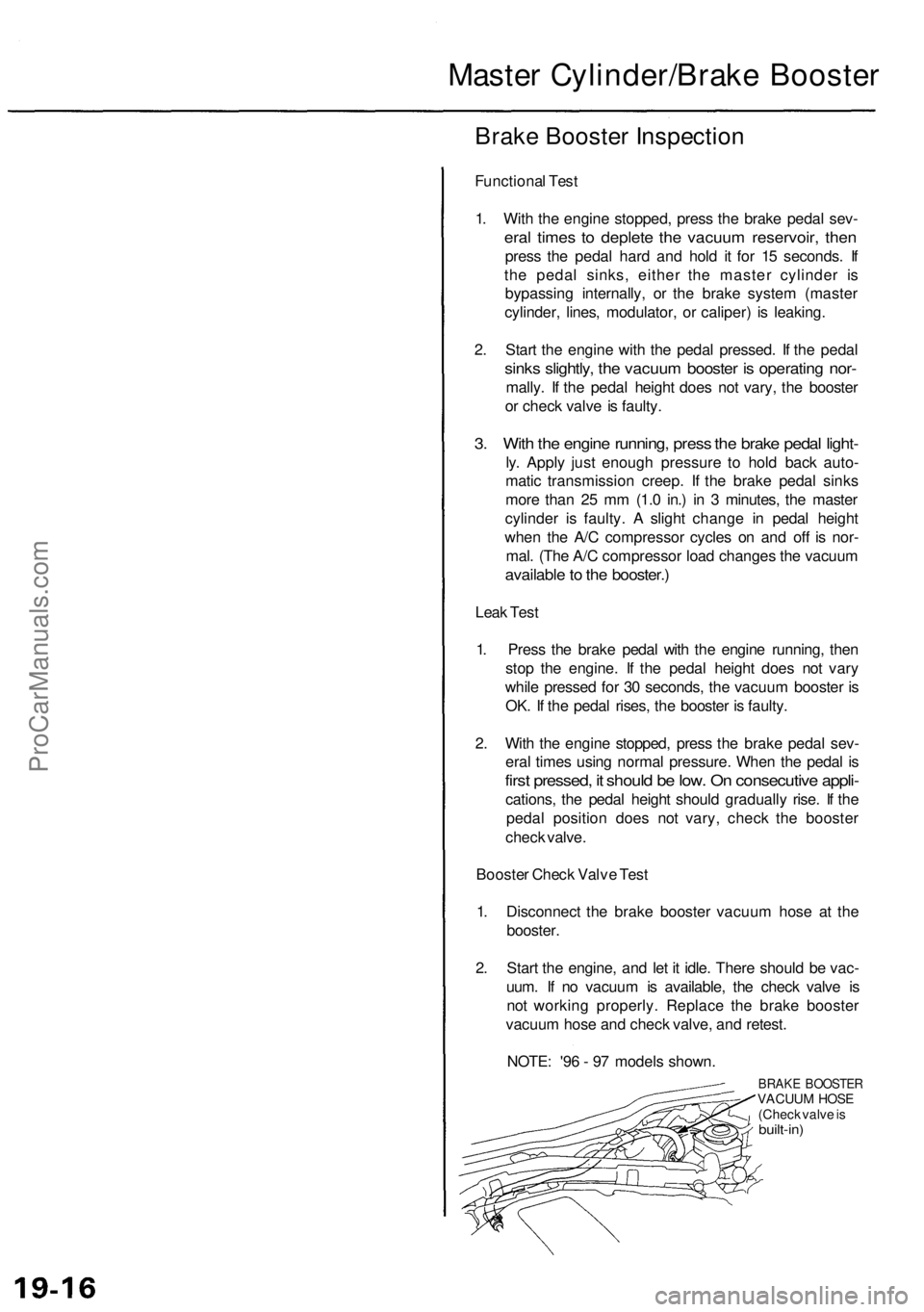

Master Cylinder/Brak e Booste r

Brake Booste r Inspectio n

Functiona l Tes t

1 . Wit h th e engin e stopped , pres s th e brak e peda l sev -

eral time s t o deplet e th e vacuu m reservoir , the n

pres s th e peda l har d an d hol d i t fo r 1 5 seconds . I f

th e peda l sinks , eithe r th e maste r cylinde r i s

bypassin g internally , o r th e brak e syste m (maste r

cylinder , lines , modulator , o r caliper ) i s leaking .

2 . Star t th e engin e wit h th e peda l pressed . I f th e peda l

sinks slightly , th e vacuu m booste r i s operatin g nor -

mally . I f th e peda l heigh t doe s no t vary , th e booste r

o r chec k valv e is faulty .

3. Wit h th e engin e running , pres s th e brak e peda l light -

ly. Appl y jus t enoug h pressur e t o hol d bac k auto -

mati c transmissio n creep . I f th e brak e peda l sink s

mor e tha n 2 5 m m (1. 0 in. ) i n 3 minutes , th e maste r

cylinde r i s faulty . A sligh t chang e i n peda l heigh t

whe n th e A/ C compresso r cycle s o n an d of f i s nor -

mal . (Th e A/ C compresso r loa d change s th e vacuu m

availabl e to th e booster. )

Leak Tes t

1 . Pres s th e brak e peda l wit h th e engin e running , the n

sto p th e engine . I f th e peda l heigh t doe s no t var y

whil e presse d fo r 3 0 seconds , th e vacuu m booste r i s

OK . I f th e peda l rises , th e booste r i s faulty .

2 . Wit h th e engin e stopped , pres s th e brak e peda l sev -

era l time s usin g norma l pressure . Whe n th e peda l i s

firs t pressed , i t shoul d b e low . O n consecutiv e appli -

cations , th e peda l heigh t shoul d graduall y rise . I f th e

peda l positio n doe s no t vary , chec k th e booste r

chec k valve .

Booste r Chec k Valv e Tes t

1 . Disconnec t th e brak e booste r vacuu m hos e a t th e

booster .

2 . Star t th e engine , an d le t i t idle . Ther e shoul d b e vac -

uum . I f n o vacuu m is available , th e chec k valv e i s

no t workin g properly . Replac e th e brak e booste r

vacuu m hos e an d chec k valve , an d retest .

NOTE : '9 6 - 9 7 model s shown .

BRAKE BOOSTE RVACUUM HOS E

(Chec k valv e is

built-in )

ProCarManuals.com

Page 1065 of 1954

Rear Brake Pads

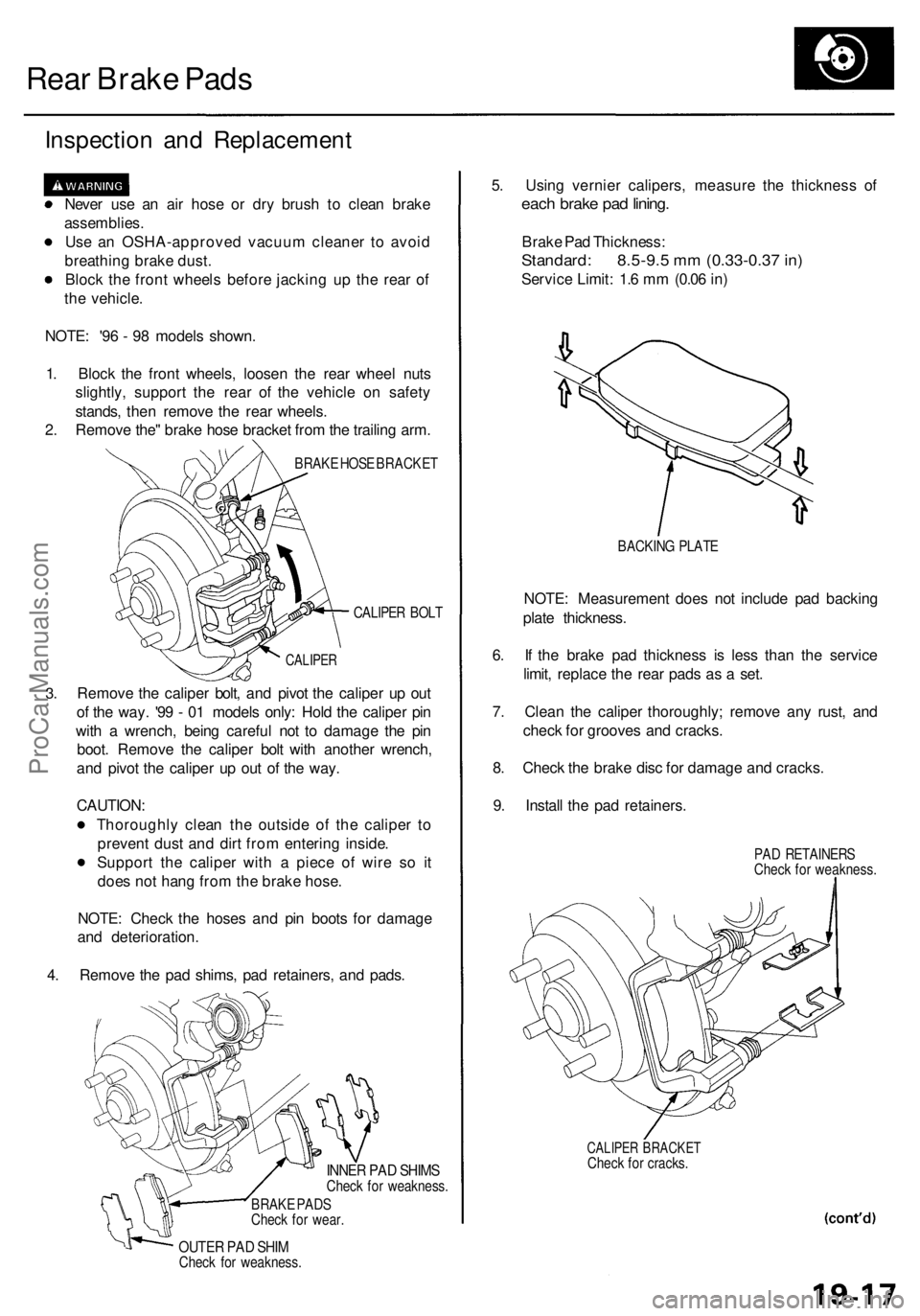

Inspection and Replacement

Never use an air hose or dry brush to clean brake

assemblies.

Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

Block the front wheels before jacking up the rear of

the vehicle.

NOTE: '96 - 98 models shown.

1. Block the front wheels, loosen the rear wheel nuts

slightly, support the rear of the vehicle on safety

stands, then remove the rear wheels.

2. Remove the" brake hose bracket from the trailing arm.

BRAKE HOSE BRACKET

CALIPER BOLT

3.

CALIPER

Remove the caliper bolt, and pivot the caliper up out

of the way. '99 - 01 models only: Hold the caliper pin

with a wrench, being careful not to damage the pin

boot. Remove the caliper bolt with another wrench,

and pivot the caliper up out of the way.

CAUTION:

Thoroughly clean the outside of the caliper to

prevent dust and dirt from entering inside.

Support the caliper with a piece of wire so it

does not hang from the brake hose.

NOTE: Check the hoses and pin boots for damage

and deterioration.

4. Remove the pad shims, pad retainers, and pads.

INNER PAD SHIMS

Check for weakness.

BRAKE PADS

Check for wear.

OUTER PAD SHIM

Check for weakness.

5. Using vernier calipers, measure the thickness of

each brake pad lining.

Brake Pad Thickness:

Standard: 8.5-9.5 mm (0.33-0.37 in)

Service Limit: 1.6 mm (0.06 in)

BACKING PLATE

NOTE: Measurement does not include pad backing

plate thickness.

6. If the brake pad thickness is less than the service

limit, replace the rear pads as a set.

7. Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

8. Check the brake disc for damage and cracks.

9. Install the pad retainers.

PAD RETAINERS

Check for weakness.

CALIPER BRACKET

Check for cracks.ProCarManuals.com