ESP ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 481 of 1771

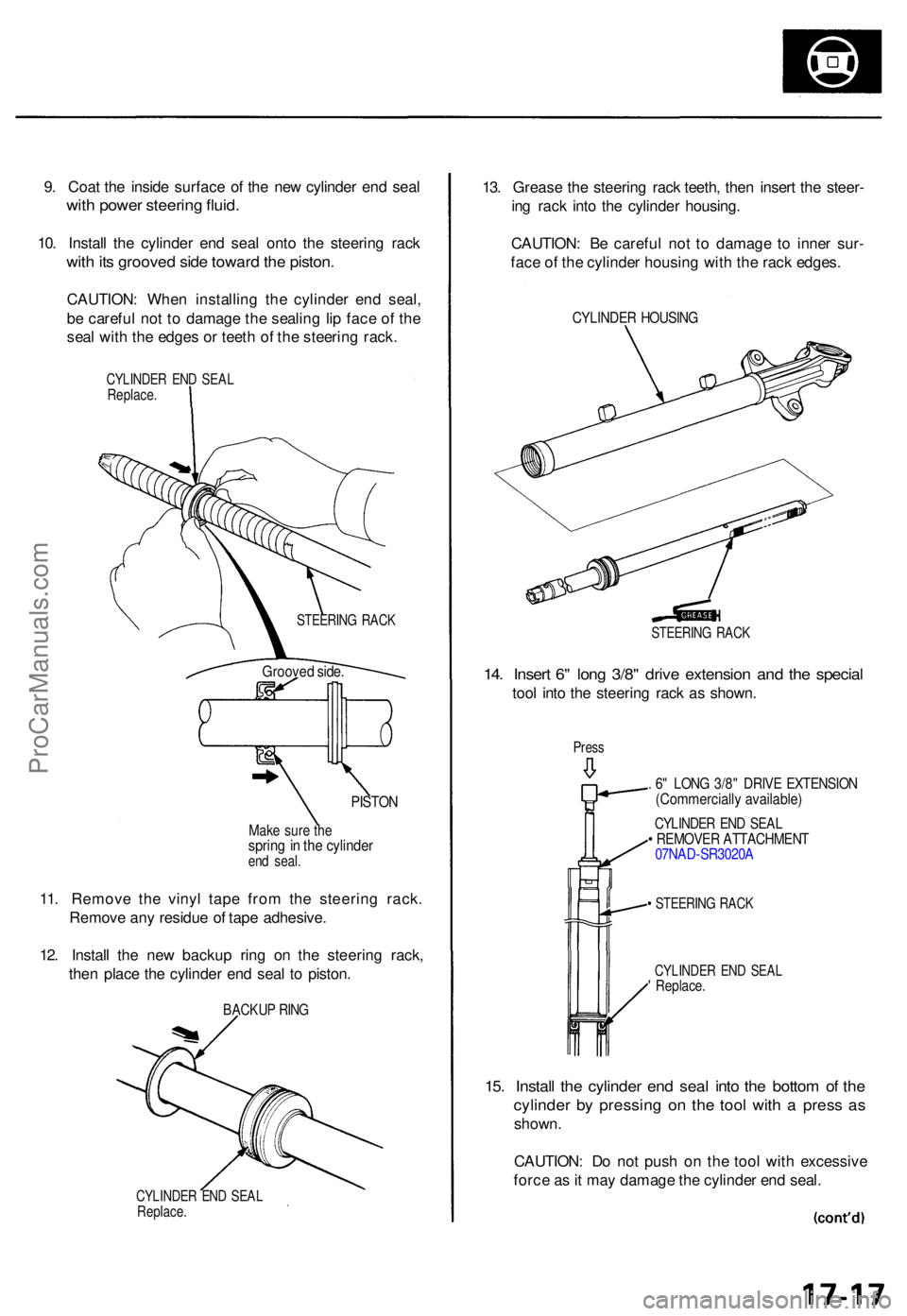

9. Coa t th e insid e surfac e o f th e ne w cylinde r en d sea l

with powe r steerin g fluid .

10. Instal l th e cylinde r en d sea l ont o th e steerin g rac k

with it s groove d sid e towar d th e piston .

CAUTION : Whe n installin g th e cylinde r en d seal ,

b e carefu l no t t o damag e th e sealin g li p fac e o f th e

sea l wit h th e edge s o r teet h o f th e steerin g rack .

CYLINDE R EN D SEA LReplace .

PISTON

CYLINDE R EN D SEA LReplace .

13. Greas e th e steerin g rac k teeth , the n inser t th e steer -

in g rac k int o th e cylinde r housing .

CAUTION : B e carefu l no t t o damag e t o inne r sur -

fac e o f th e cylinde r housin g wit h th e rac k edges .

CYLINDE R HOUSIN G

STEERIN G RAC K

14. Inser t 6 " lon g 3/8 " driv e extensio n an d th e specia l

tool int o th e steerin g rac k a s shown .

Press

. 6 " LON G 3/8 " DRIV E EXTENSIO N(Commerciall y available )

CYLINDER EN D SEA L• REMOVE R ATTACHMEN T07NAD-SR3020 A

• STEERIN G RAC K

CYLINDE R EN D SEA L' Replace .

15. Instal l th e cylinde r en d sea l int o th e botto m o f th e

cylinde r b y pressin g o n th e too l with a press a s

shown .

CAUTION : D o no t pus h o n th e too l wit h excessiv e

forc e a s it ma y damag e th e cylinde r en d seal .

STEERIN G RAC K

Groove d side .

Make sur e th esprin g in th e cylinde rend seal .

11. Remov e th e viny l tap e fro m th e steerin g rack .

Remov e an y residu e o f tap e adhesive .

12 . Instal l th e ne w backu p rin g o n th e steerin g rack ,

the n plac e th e cylinde r en d sea l t o piston .

BACKU P RIN G

ProCarManuals.com

Page 483 of 1771

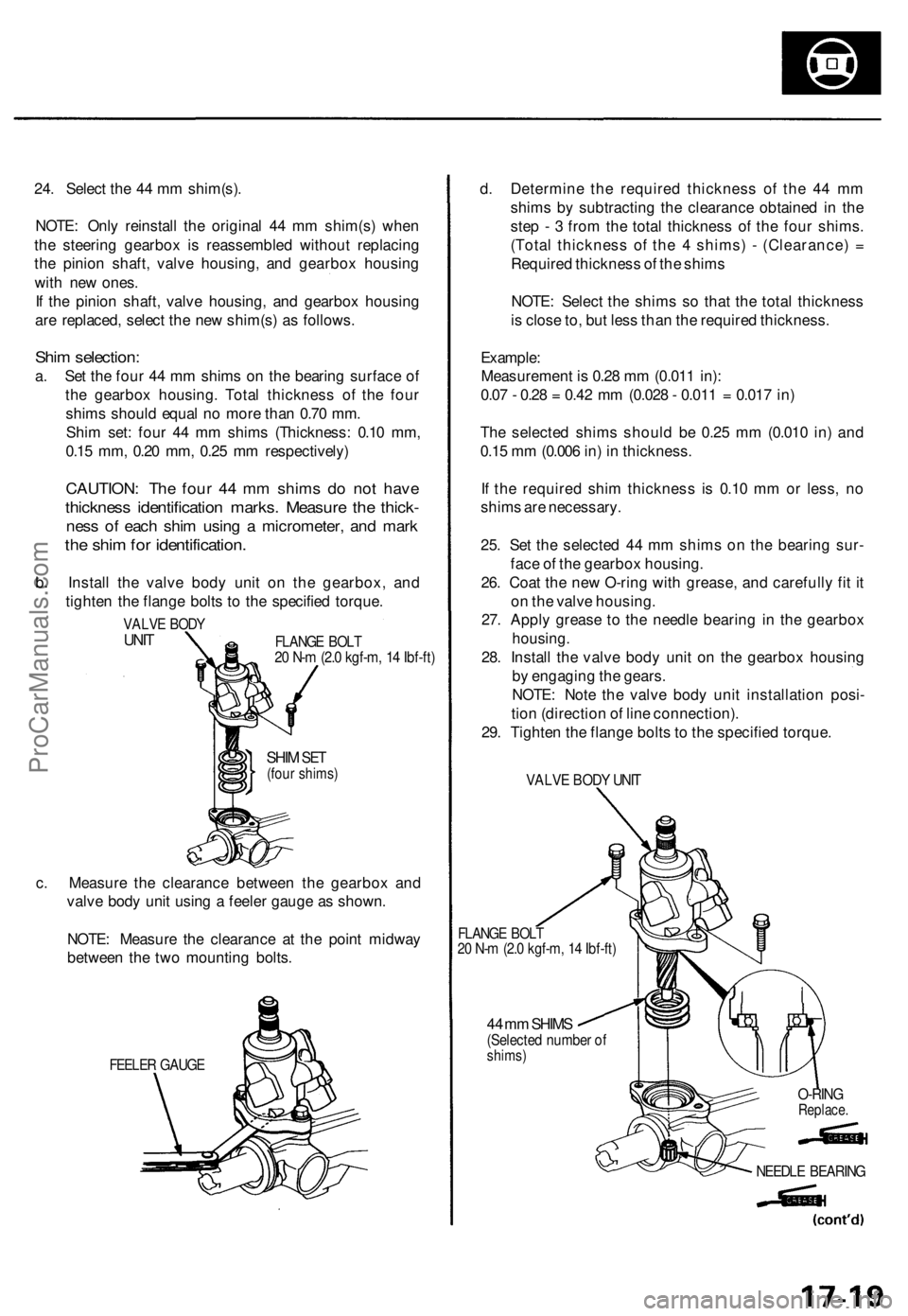

24. Selec t th e 4 4 m m shim(s) .

NOTE : Onl y reinstal l th e origina l 4 4 m m shim(s ) whe n

th e steerin g gearbo x i s reassemble d withou t replacin g

th e pinio n shaft , valv e housing , an d gearbo x housin g

wit h ne w ones .

I f th e pinio n shaft , valv e housing , an d gearbo x housin g

ar e replaced , selec t th e ne w shim(s ) a s follows .

Shim selection :

a. Se t th e fou r 4 4 m m shim s o n th e bearin g surfac e o f

th e gearbo x housing . Tota l thicknes s o f th e fou r

shim s shoul d equa l n o mor e tha n 0.7 0 mm .

Shi m set : fou r 4 4 m m shim s (Thickness : 0.1 0 mm ,

0.1 5 mm , 0.2 0 mm , 0.2 5 m m respectively )

CAUTION: Th e fou r 4 4 m m shim s d o no t hav e

thicknes s identificatio n marks . Measur e th e thick -

ness o f eac h shi m usin g a micrometer , an d mar k

the shi m fo r identification .

b. Instal l th e valv e bod y uni t o n th e gearbox , an d

tighte n th e flang e bolt s t o th e specifie d torque .

VALVE BOD YUNITFLANG E BOL T20 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

SHIM SET(fou r shims )

c. Measur e th e clearanc e betwee n th e gearbo x an d

valv e bod y uni t usin g a feele r gaug e a s shown .

NOTE : Measur e th e clearanc e a t th e poin t midwa y

betwee n th e tw o mountin g bolts .

FEELE R GAUG E

d. Determin e th e require d thicknes s o f th e 4 4 m m

shim s b y subtractin g th e clearanc e obtaine d in th e

ste p - 3 fro m th e tota l thicknes s o f th e fou r shims .

(Tota l thicknes s o f th e 4 shims ) - (Clearance ) =

Require d thicknes s o f th e shim s

NOTE : Selec t th e shim s s o tha t th e tota l thicknes s

i s clos e to , bu t les s tha n th e require d thickness .

Example :

Measuremen t i s 0.2 8 m m (0.01 1 in) :

0.0 7 - 0.2 8 = 0.4 2 m m (0.02 8 - 0.01 1 = 0.01 7 in )

Th e selecte d shim s shoul d b e 0.2 5 m m (0.01 0 in ) an d

0.1 5 m m (0.00 6 in ) i n thickness .

I f th e require d shi m thicknes s i s 0.1 0 m m o r less , n o

shim s ar e necessary .

25 . Se t th e selecte d 4 4 m m shim s o n th e bearin g sur -

fac e o f th e gearbo x housing .

26 . Coa t th e ne w O-rin g wit h grease , an d carefull y fi t i t

o n th e valv e housing .

27 . Appl y greas e t o th e needl e bearin g i n th e gearbo x

housing.

28. Instal l th e valv e bod y uni t o n th e gearbo x housin g

b y engagin g th e gears .

NOTE : Not e th e valv e bod y uni t installatio n posi -

tio n (directio n o f lin e connection) .

29 . Tighte n th e flang e bolt s to th e specifie d torque .

VALVE BOD Y UNI T

FLANG E BOL T20 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

44 m m SHIM S(Selecte d numbe r o fshims )

O-RINGReplace .

NEEDLE BEARIN G

ProCarManuals.com

Page 493 of 1771

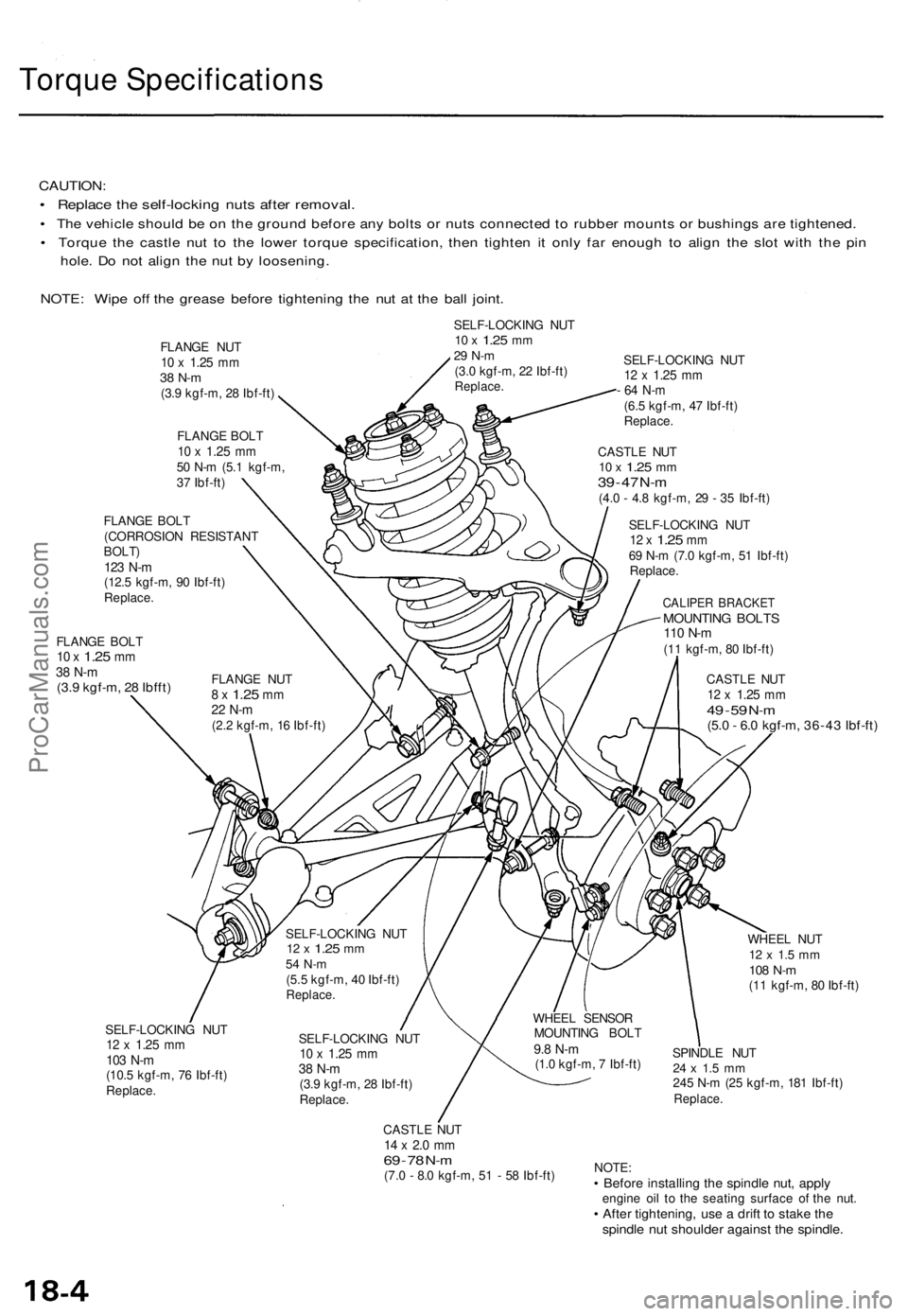

Torque Specification s

CAUTION:

• Replac e th e self-lockin g nut s afte r removal .

• Th e vehicl e shoul d b e o n th e groun d befor e an y bolt s o r nut s connecte d t o rubbe r mount s o r bushing s ar e tightened .

• Torqu e th e castl e nu t t o th e lowe r torqu e specification , the n tighte n i t onl y fa r enoug h t o alig n th e slo t wit h th e pi n

hole . D o no t alig n th e nu t b y loosening .

NOTE : Wip e of f th e greas e befor e tightenin g th e nu t a t th e bal l joint .

SELF-LOCKIN G NU T10 x 1.2 5 mm29 N- m(3.0 kgf-m , 2 2 Ibf-ft )Replace .

FLANGE BOL T10 x 1.2 5 mm38 N- m(3.9 kgf-m , 2 8 Ibfft )

SELF-LOCKIN G NU T12 x 1.2 5 mm

- 6 4 N- m

(6.5 kgf-m , 4 7 Ibf-ft )Replace .

CASTLE NU T10 x 1.2 5 mm39 - 4 7 N- m(4. 0 - 4. 8 kgf-m , 2 9 - 3 5 Ibf-ft )

SELF-LOCKIN G NU T

12 x 1.2 5 mm69 N- m (7. 0 kgf-m , 5 1 Ibf-ft )

Replace .

CALIPER BRACKE TMOUNTING BOLT S110 N- m(11 kgf-m , 8 0 Ibf-ft )

CASTL E NU T

12 x 1.2 5 mm49 - 5 9 N- m(5. 0 - 6. 0 kgf-m , 36-4 3 Ibf-ft )

SELF-LOCKIN G NU T12 x 1.2 5 mm103 N- m(10. 5 kgf-m , 7 6 Ibf-ft )Replace .

SELF-LOCKIN G NU T10 x 1.2 5 mm38 N- m(3.9 kgf-m , 2 8 Ibf-ft )Replace .

CASTLE NU T14 x 2. 0 m m69 - 7 8 N- m(7. 0 - 8. 0 kgf-m , 5 1 - 5 8 Ibf-ft ) WHEE

L NU T

12 x 1. 5 m m108 N- m(11 kgf-m , 8 0 Ibf-ft )

SPINDL E NU T

24 x 1. 5 m m245 N- m (2 5 kgf-m , 18 1 Ibf-ft )Replace .

NOTE:• Befor e installin g th e spindl e nut , appl yengin e oi l t o th e seatin g surfac e o f th e nut .• Afte r tightening , us e a drif t t o stak e th espindl e nu t shoulde r agains t th e spindle .

FLANGE NU T10 x 1.2 5 mm38 N- m(3.9 kgf-m , 2 8 Ibf-ft )

FLANG E BOL T

10 x 1.2 5 mm50 N- m (5. 1 kgf-m ,

3 7 Ibf-ft )

FLANG E NU T

8 x 1.2 5 mm22 N- m(2.2 kgf-m , 1 6 Ibf-ft )

FLANG

E BOL T

(CORROSIO N RESISTAN T

BOLT)123 N- m(12. 5 kgf-m , 9 0 Ibf-ft )Replace .

WHEEL SENSO R

MOUNTIN G BOL T

9.8 N- m(1.0 kgf-m , 7 Ibf-ft )

SELF-LOCKIN

G NU T

12 x 1.2 5 mm54 N- m(5.5 kgf-m , 4 0 Ibf-ft )Replace .

ProCarManuals.com

Page 495 of 1771

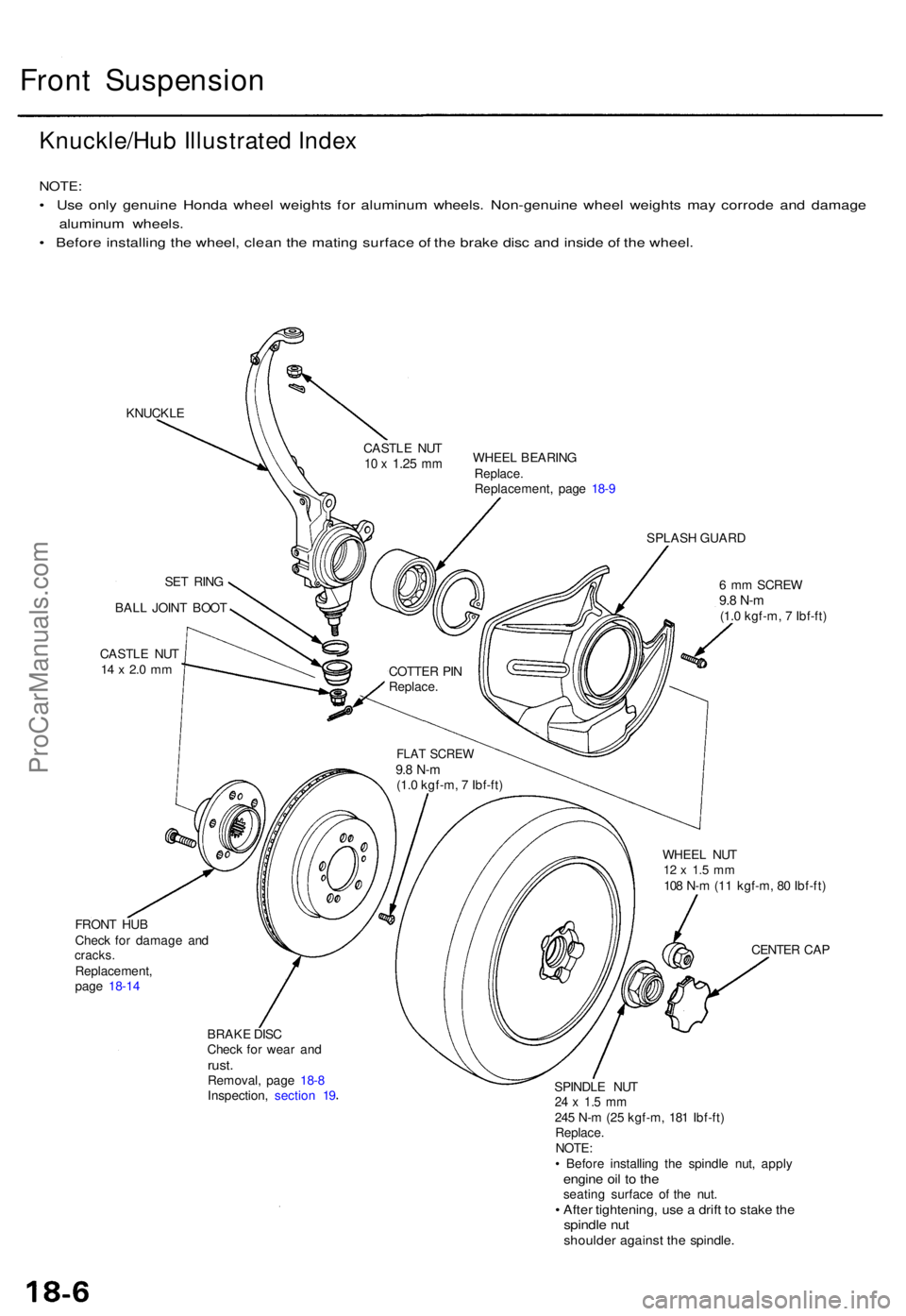

Front Suspensio n

Knuckle/Hu b Illustrated Index

NOTE :

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e whee l weight s ma y corrod e an d damag e

aluminu m wheels .

• Befor e installin g th e wheel , clea n th e matin g surfac e o f th e brak e dis c an d insid e o f th e wheel .

KNUCKL E

SET RIN G

BAL L JOIN T BOO T

CASTL E NU T

14 x 2. 0 m m

FRON T HU B

Chec k fo r damag e an d

cracks .Replacement ,

pag e 18-1 4 WHEE

L BEARIN G

Replace.Replacement , pag e 18- 9

SPLAS H GUAR D

6 m m SCRE W

9.8 N- m(1.0 kgf-m , 7 Ibf-ft )

WHEE L NU T

12 x 1. 5 m m108 N- m (1 1 kgf-m , 8 0 Ibf-ft )

CENTE R CA P

BRAK E DIS C

Chec k fo r wea r an d

rust .Removal , pag e 18- 8

Inspection , sectio n 1 9 SPINDL

E NU T

24 x 1. 5 m m245 N- m (2 5 kgf-m , 18 1 Ibf-ft )

Replace .

NOTE :

• Befor e installin g th e spindl e nut , appl y

engine oi l t o th eseatin g surfac e o f th e nut .• Afte r tightening , us e a drif t t o stak e th espindl e nu tshoulde r agains t th e spindle .

CASTLE NU T10 x 1.2 5 mm

COTTE R PI N

Replace .

FLAT SCRE W9.8 N- m(1.0 kgf-m , 7 Ibf-ft )

ProCarManuals.com

Page 684 of 1771

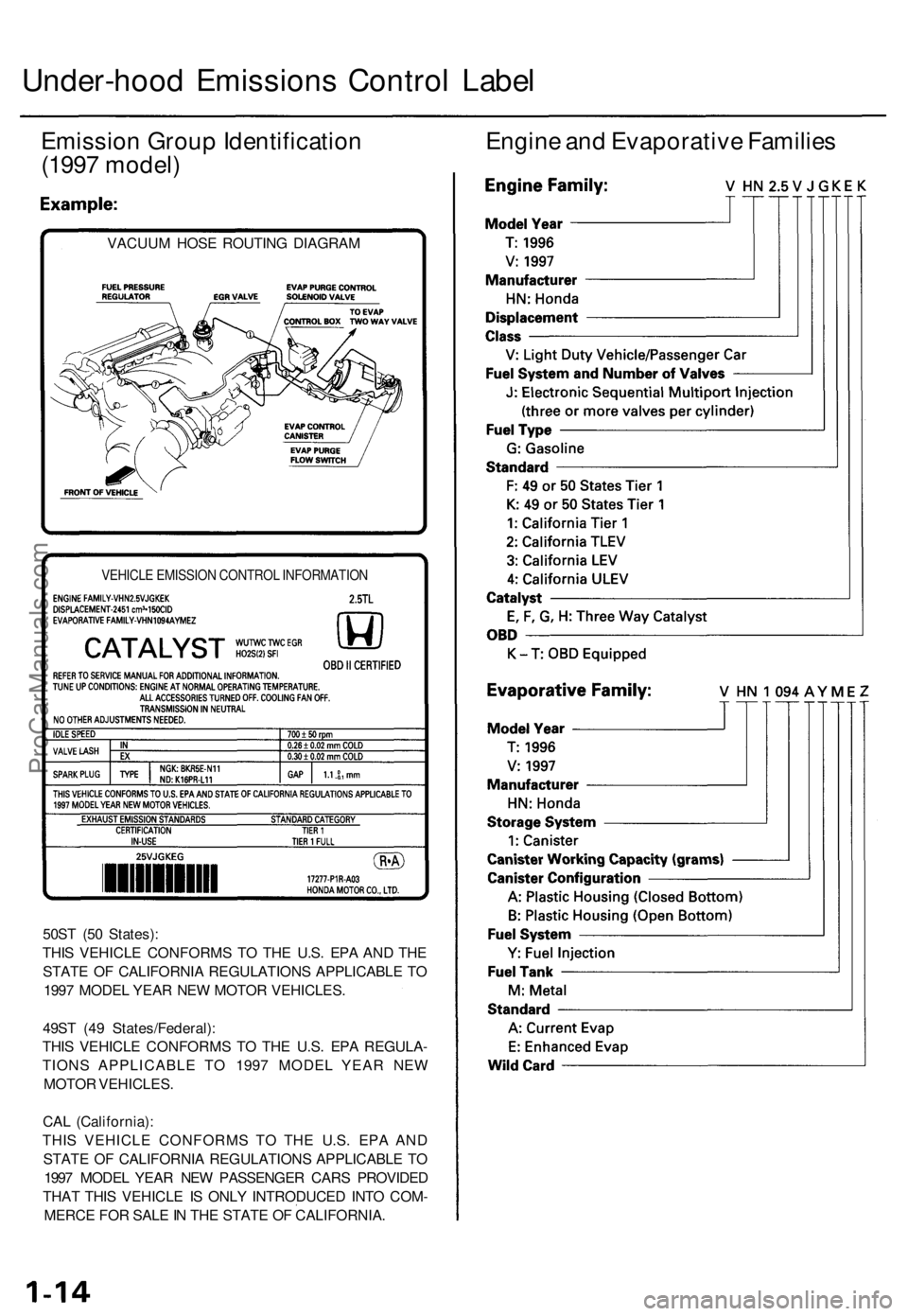

Under-hood Emissions Control Label

VACUUM HOSE ROUTING DIAGRAM

Emission Group Identification

(1997 model)

VEHICLE EMISSION CONTROL INFORMATION

50ST (50 States):

THIS VEHICLE CONFORMS TO THE U.S. EPA AND THE

STATE OF CALIFORNIA REGULATIONS APPLICABLE TO

1997 MODEL YEAR NEW MOTOR VEHICLES.

49ST (49 States/Federal):

THIS VEHICLE CONFORMS TO THE U.S. EPA REGULA-

TIONS APPLICABLE TO 1997 MODEL YEAR NEW

MOTOR VEHICLES.

CAL (California):

THIS VEHICLE CONFORMS TO THE U.S. EPA AND

STATE OF CALIFORNIA REGULATIONS APPLICABLE TO

1997 MODEL YEAR NEW PASSENGER CARS PROVIDED

THAT THIS VEHICLE IS ONLY INTRODUCED INTO COM-

MERCE FOR SALE IN THE STATE OF CALIFORNIA.

Engine and Evaporative FamiliesProCarManuals.com

Page 787 of 1771

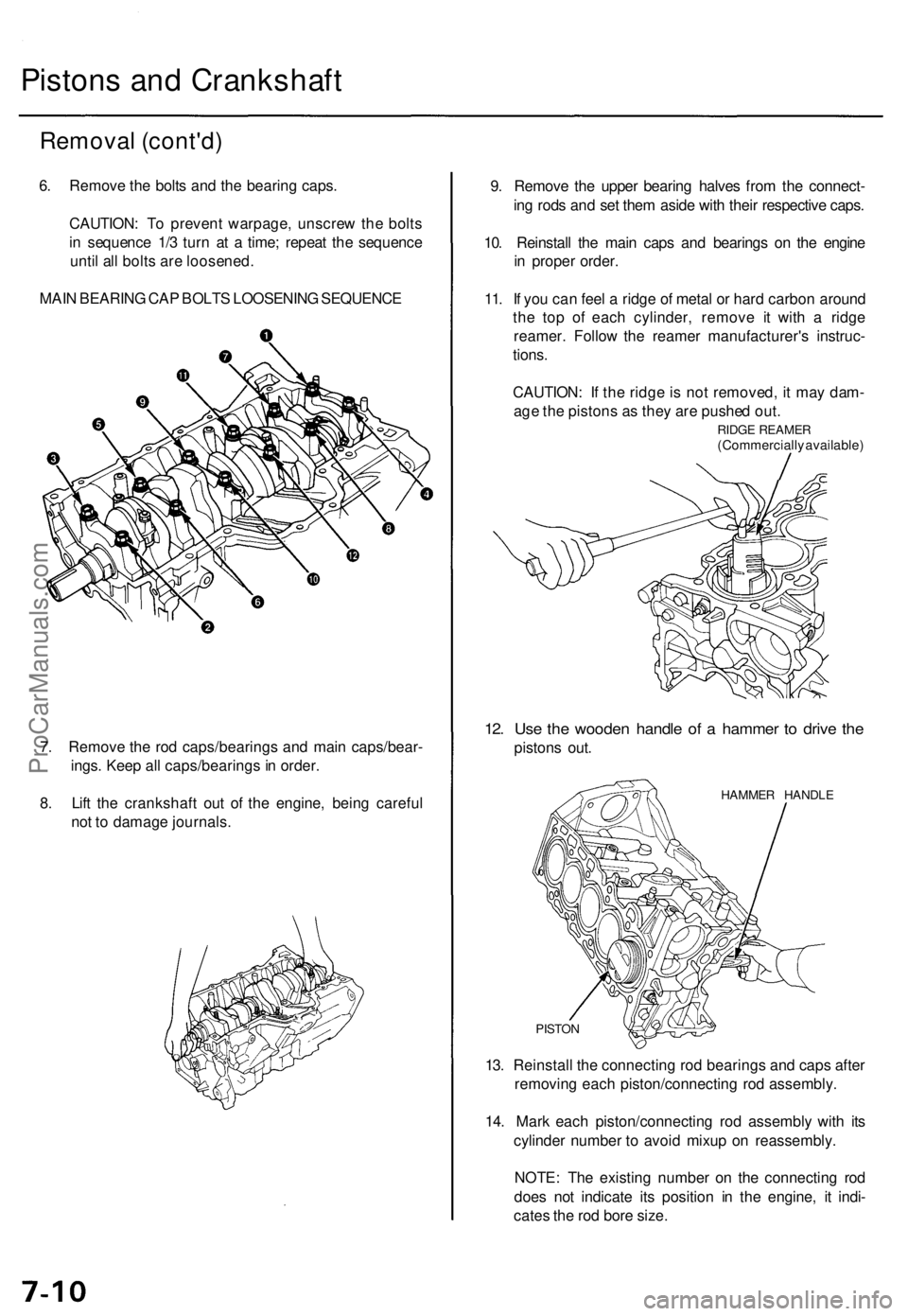

Pistons an d Crankshaf t

Removal (cont'd )

6. Remov e th e bolt s an d th e bearin g caps .

CAUTION : T o preven t warpage , unscre w th e bolt s

i n sequenc e 1/ 3 tur n a t a time ; repea t th e sequenc e

unti l al l bolt s ar e loosened .

MAI N BEARIN G CA P BOLT S LOOSENIN G SEQUENC E

7 . Remov e th e ro d caps/bearing s an d mai n caps/bear -

ings . Kee p al l caps/bearing s in order .

8 . Lif t th e crankshaf t ou t o f th e engine , bein g carefu l

no t t o damag e journals . 9

. Remov e th e uppe r bearin g halve s fro m th e connect -

in g rod s an d se t the m asid e wit h thei r respectiv e caps .

10 . Reinstal l th e mai n cap s an d bearing s o n th e engin e

i n prope r order .

11 . I f yo u ca n fee l a ridg e o f meta l o r har d carbo n aroun d

th e to p o f eac h cylinder , remov e i t wit h a ridg e

reamer . Follo w th e reame r manufacturer' s instruc -

tions .

CAUTION : I f th e ridg e is no t removed , i t ma y dam -

ag e th e piston s a s the y ar e pushe d out .

RIDG E REAME R(Commerciall y available )

12. Us e th e woode n handl e o f a hamme r t o driv e th e

piston s out .

HAMME R HANDL E

PISTON

13. Reinstal l th e connectin g ro d bearing s an d cap s afte r

removin g eac h piston/connectin g ro d assembly .

14 . Mar k eac h piston/connectin g ro d assembl y wit h it s

cylinde r numbe r t o avoi d mixu p o n reassembly .

NOTE : Th e existin g numbe r o n th e connectin g ro d

doe s no t indicat e it s positio n i n th e engine , i t indi -

cate s th e ro d bor e size .

ProCarManuals.com

Page 883 of 1771

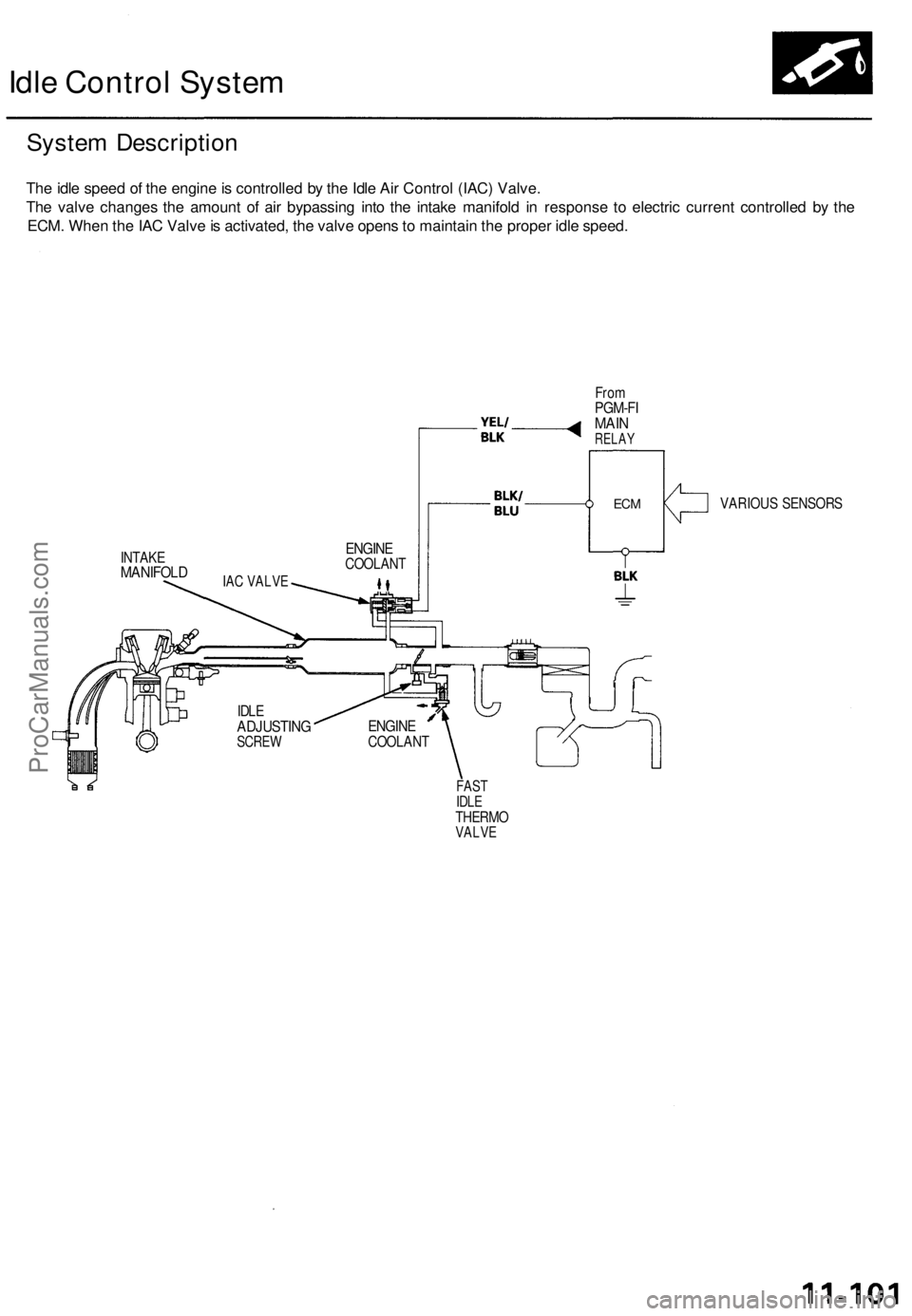

Idle Control System

System Description

The idle speed of the engine is controlled by the Idle Air Control (IAC) Valve.

The valve changes the amount of air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated, the valve opens to maintain the proper idle speed.

From

PGM-FI

MAIN

RELAY

INTAKE

MANIFOLD

VARIOUS SENSORS

FAST

IDLE

THERMO

VALVE

IDLE

ADJUSTING

SCREW

ENGINE

COOLANT

ENGINE

COOLANT

IAC VALVE

ECMProCarManuals.com

Page 936 of 1771

Description

The automatic transmission is a combination of a 3-element torque converter and a dual-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 reverse. The entire unit is positioned in line with the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the drive plate is a ring gear which meshes with the starter pinion when the engine is being started.

The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in line with the engine

crankshaft.

The mainshaft includes the 1st, 2nd and 4th clutches, and gears for 4th, 2nd, 1st and reverse (3rd gear is integral with the

mainshaft, while the reverse gear is integral with 4th gear).

The countershaft includes the 3rd, and 1st-hold clutches, and gears for 3rd, 4th, 1st, 2nd, reverse, and parking. The sec-

ondary drive gear is integrated with the countershaft.

The gears on the mainshaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide and positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the glove box on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the servo body and the shift control solenoid valves. They

are bolted on the lower part of the transmission housing.

Other valve bodies, the regulator valve body, the ATF pump body, the 2nd accumulator body, and the throttle valve body,

are bolted to the torque converter housing.

The main valve body contains the manual valve, the 1 - 2 shift valve, the 2 - 3 shift valve, the 3 - 4 shift valve, the 4th kick-

down valve, the 2 - 3 orifice control valve, the 3 - 4 orifice control valve, the 4th exhaust valve, the servo control valve,

and the main orifice control valve.

The servo body contains the servo valve, 3rd and 4th accumulator pistons.

The regulator valve body contains the regulator valve, the lock-up shift valve, and the cooler relief valve.

Fluid from the regulator passes through the manual valve to the various control valves.

The throttle valve body includes the throttle valve which is bolted onto the 2nd accumulator body. The 2nd accumulator

piston is assembled in the 2nd accumulator body.

The linear solenoid is joined with the throttle valve body.

The ATF pump body contains the modulator valve, the lock-up control valve, the lock-up timing valve, and the relief valve.

The torque converter check valve is located in the torque converter housing under the ATF pump body.

The 1st and 1st-hold accumulator pistons are assembled in the rear cover.

The clutches receive fluid from their respective feed pipes or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position, in 2nd, 3rd and 4th, and in position in 3rd, pressurized fluid is drained from the back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place,

the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid

valves A and B, and throttle valve. When lock-up control solenoid valves A and B activate, the modulator pressure changes.

The lock-up control solenoid valves A and B are mounted on the torque converter housing, and are controlled by the TCM.ProCarManuals.com

Page 954 of 1771

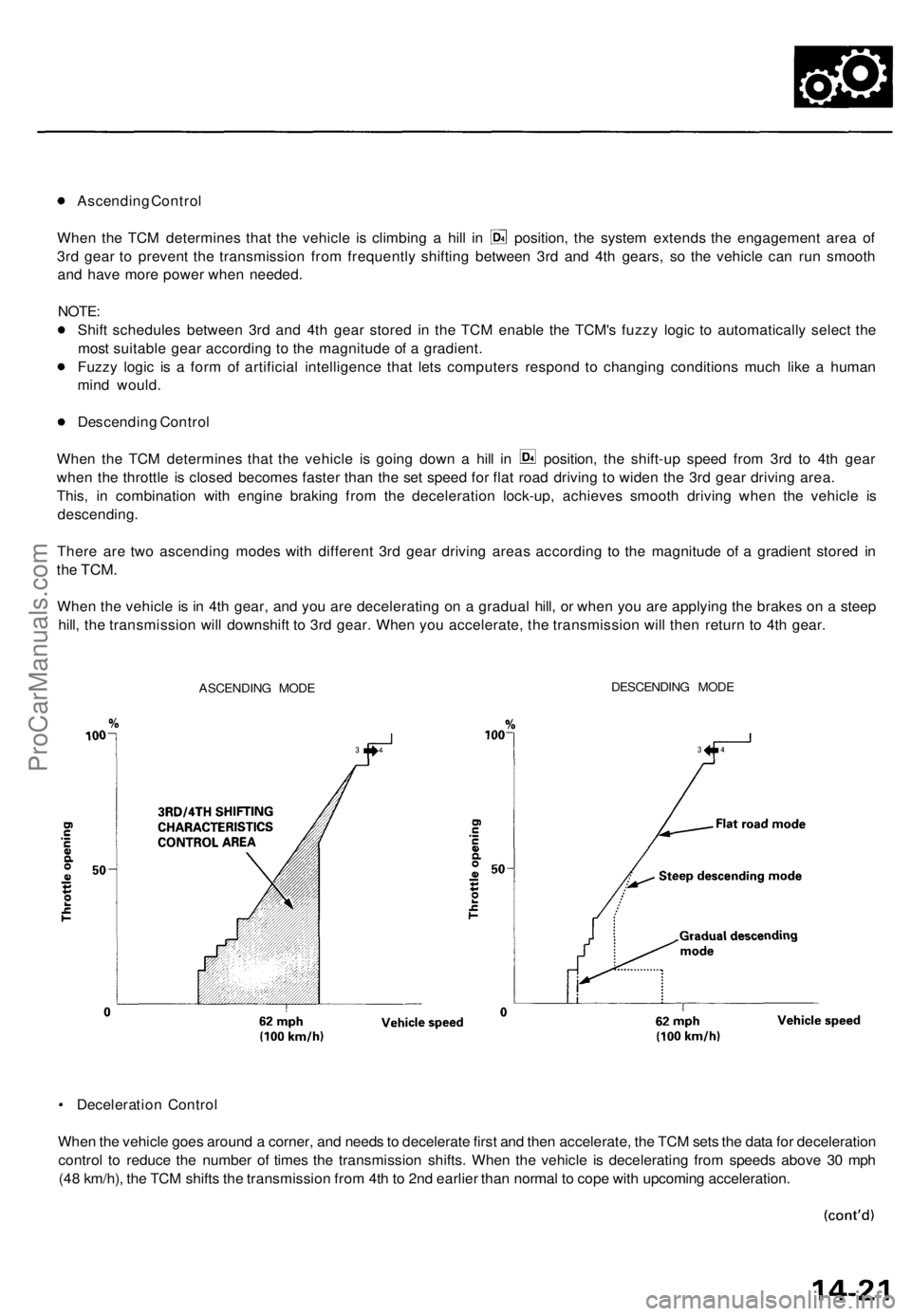

Ascending Control

When the TCM determines that the vehicle is climbing a hill in position, the system extends the engagement area of

3rd gear to prevent the transmission from frequently shifting between 3rd and 4th gears, so the vehicle can run smooth

and have more power when needed.

NOTE:

Shift schedules between 3rd and 4th gear stored in the TCM enable the TCM's fuzzy logic to automatically select the

most suitable gear according to the magnitude of a gradient.

Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a human

mind would.

Descending Control

When the TCM determines that the vehicle is going down a hill in position, the shift-up speed from 3rd to 4th gear

when the throttle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.

This, in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle is

descending.

There are two ascending modes with different 3rd gear driving areas according to the magnitude of a gradient stored in

the

TCM.

When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you are applying the brakes on a steep

hill, the transmission will downshift to 3rd gear. When you accelerate, the transmission will then return to 4th gear.

ASCENDING MODE

DESCENDING MODE

• Deceleration Control

When the vehicle goes around a corner, and needs to decelerate first and then accelerate, the TCM sets the data for deceleration

control to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 30 mph

(48 km/h), the TCM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration.ProCarManuals.com

Page 997 of 1771

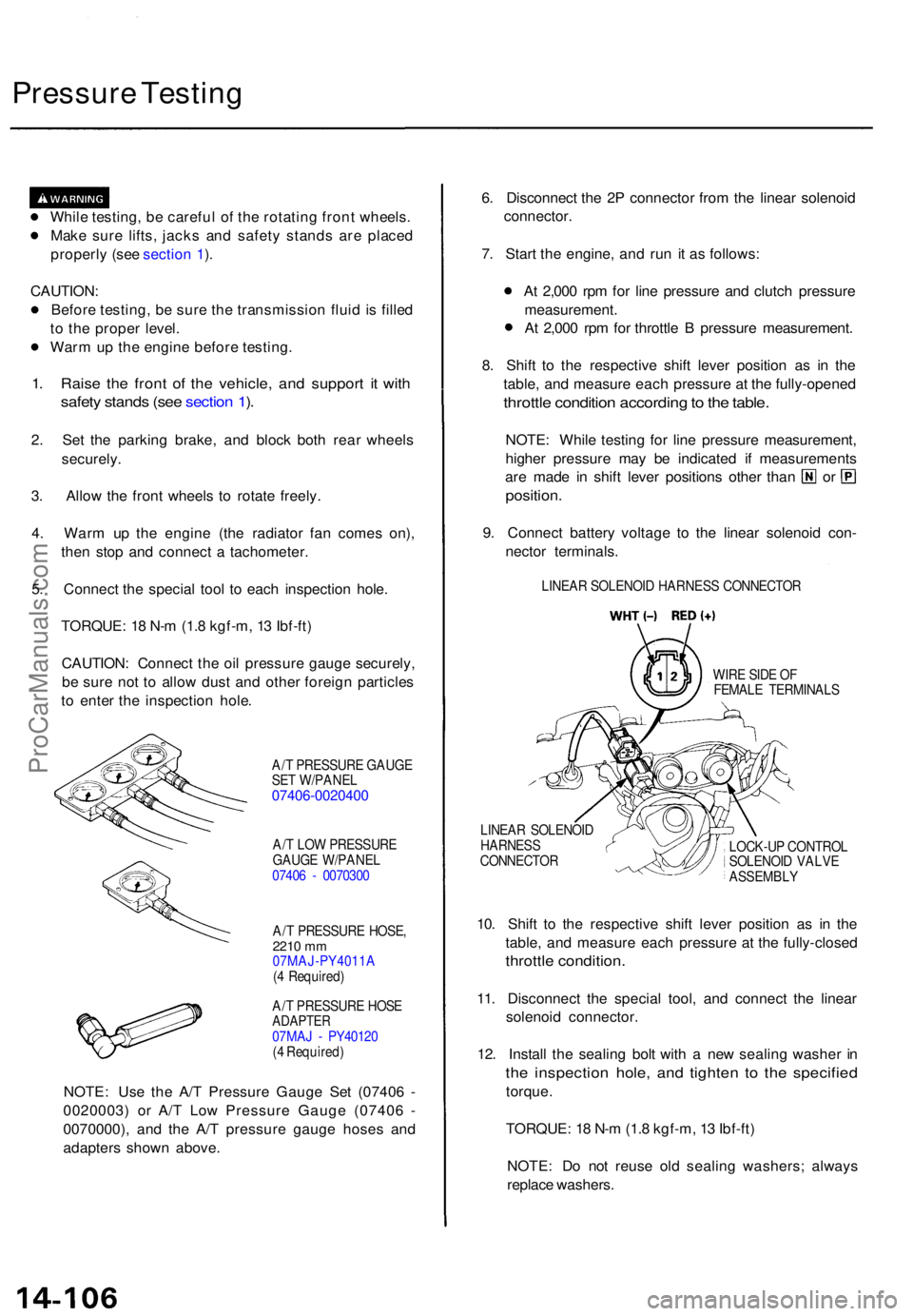

Pressure Testin g

While testing , b e carefu l o f th e rotatin g fron t wheels .

Mak e sur e lifts , jack s an d safet y stand s ar e place d

properl y (se e sectio n 1 ).

CAUTION :

Befor e testing , b e sur e th e transmissio n flui d is fille d

t o th e prope r level .

War m u p th e engin e befor e testing .

1. Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3. Allo w th e fron t wheel s t o rotat e freely .

4 . War m u p th e engin e (th e radiato r fa n come s on) ,

the n sto p an d connec t a tachometer .

5 . Connec t th e specia l too l t o eac h inspectio n hole .

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

CAUTION : Connec t th e oi l pressur e gaug e securely ,

b e sur e no t t o allo w dus t an d othe r foreig n particle s

t o ente r th e inspectio n hole .

A/T PRESSUR E GAUG E

SE T W/PANE L

07406-002040 0

A/T LO W PRESSUR E

GAUG E W/PANE L

0740 6 - 007030 0

A/ T PRESSUR E HOSE ,

2210 mm07MAJ-PY4011 A

( 4 Required )

A/ T PRESSUR E HOS E

ADAPTE R07MAJ - PY4012 0

( 4 Required )

NOTE: Us e th e A/ T Pressur e Gaug e Se t (0740 6 -

0020003 ) o r A/ T Lo w Pressur e Gaug e (0740 6 -

0070000) , an d th e A/ T pressur e gaug e hose s an d

adapter s show n above . 6

. Disconnec t th e 2 P connecto r fro m th e linea r solenoi d

connector .

7 . Star t th e engine , an d ru n i t a s follows :

A t 2,00 0 rp m fo r lin e pressur e an d clutc h pressur e

measurement .

A t 2,00 0 rp m fo r throttl e B pressur e measurement .

8 . Shif t t o th e respectiv e shif t leve r positio n a s i n th e

table , an d measur e eac h pressur e a t th e fully-opene d

throttle conditio n accordin g to th e table .

NOTE : Whil e testin g fo r lin e pressur e measurement ,

highe r pressur e ma y b e indicate d i f measurement s

are mad e i n shif t leve r position s othe r tha n o r

position .

9. Connec t batter y voltag e t o th e linea r solenoi d con -

necto r terminals .

LINEAR SOLENOI D HARNES S CONNECTO R

WIR E SID E O F

FEMAL E TERMINAL S

LINEA R SOLENOI D

HARNES S

CONNECTO R LOCK-U

P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

10. Shif t t o th e respectiv e shif t leve r positio n a s i n th e

table , an d measur e eac h pressur e a t th e fully-close d

throttle condition .

11. Disconnec t th e specia l tool , an d connec t th e linea r

solenoi d connector .

12 . Instal l th e sealin g bol t wit h a ne w sealin g washe r i n

th e inspectio n hole , an d tighte n t o th e specifie d

torque.

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d sealin g washers ; alway s

replac e washers .

ProCarManuals.com