ECU ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 75 of 1771

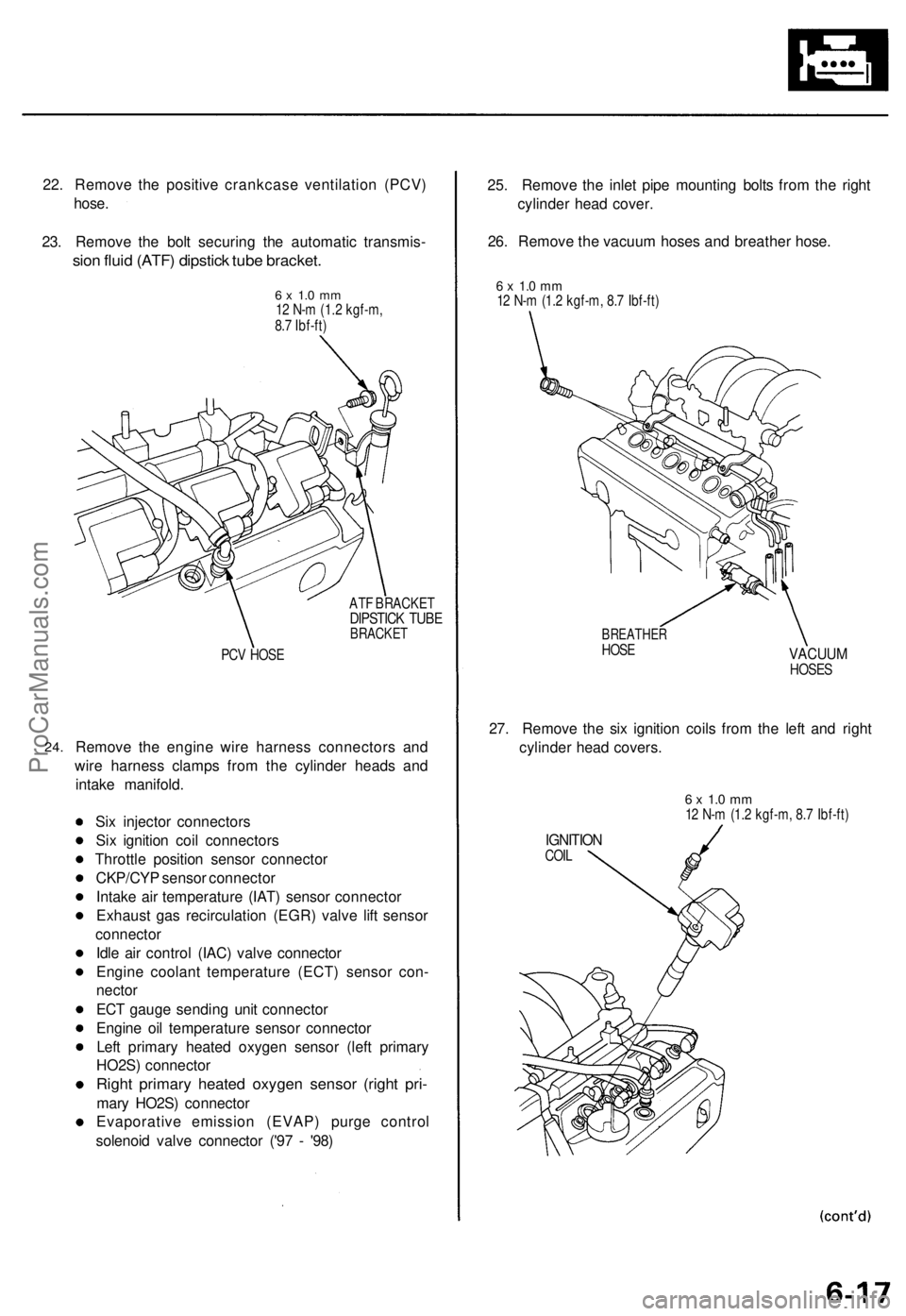

22. Remove the positive crankcase ventilation (PCV)

hose.

23. Remove the bolt securing the automatic transmis-

sion fluid (ATF) dipstick tube bracket.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ATF BRACKET

DIPSTICK TUBE

BRACKET

PCV HOSE

24.

Remove the engine wire harness connectors and

wire harness clamps from the cylinder heads and

intake manifold.

Six injector connectors

Six ignition coil connectors

Throttle position sensor connector

CKP/CYP sensor connector

Intake air temperature (IAT) sensor connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Idle air control (IAC) valve connector

Engine coolant temperature (ECT) sensor con-

nector

ECT gauge sending unit connector

Engine oil temperature sensor connector

Left primary heated oxygen sensor (left primary

HO2S) connector

Right primary heated oxygen sensor (right pri-

mary HO2S) connector

Evaporative emission (EVAP) purge control

solenoid valve connector ('97 - '98)

25. Remove the inlet pipe mounting bolts from the right

cylinder head cover.

26. Remove the vacuum hoses and breather hose.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

BREATHER

HOSE

VACUUM

HOSES

27. Remove the six ignition coils from the left and right

cylinder head covers.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

IGNITION

COILProCarManuals.com

Page 78 of 1771

Cylinder Heads

Removal (cont'd)

36. Remove the three bolts securing the alternator

bracket.

ALTERNATOR

BRACKET

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

37. Remove the two bolts securing the P/S pump bracket.

P/S PUMP

BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

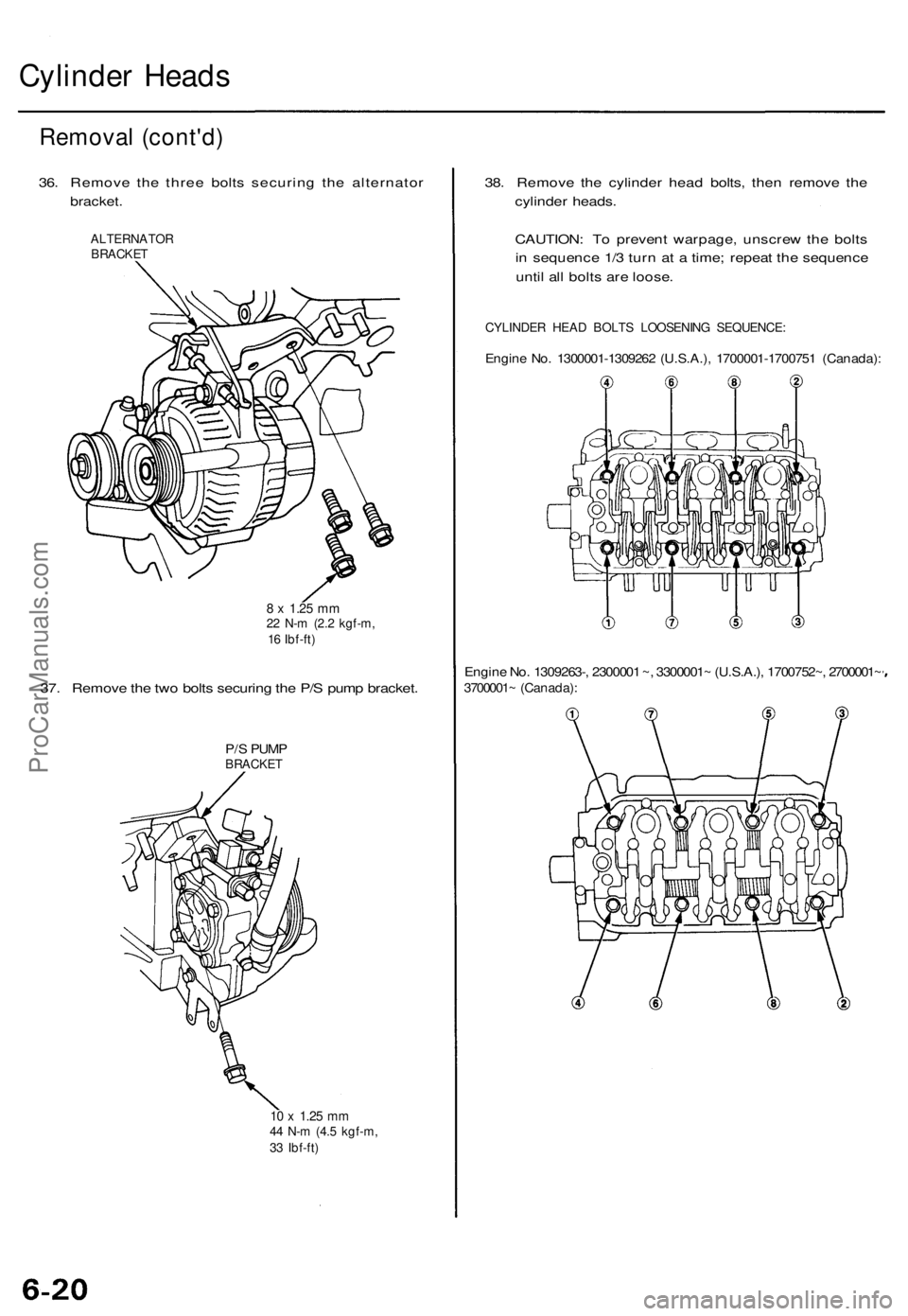

38. Remove the cylinder head bolts, then remove the

cylinder heads.

CAUTION: To prevent warpage, unscrew the bolts

in sequence 1/3 turn at a time; repeat the sequence

until all bolts are loose.

CYLINDER HEAD BOLTS LOOSENING SEQUENCE:

Engine No. 1300001-1309262 (U.S.A.), 1700001-1700751 (Canada):

Engine No. 1309263-, 2300001 ~, 3300001~ (U.S.A.), 1700752~, 2700001~

3700001~ (Canada):ProCarManuals.com

Page 97 of 1771

Cylinder Heads

Installation (cont'd)

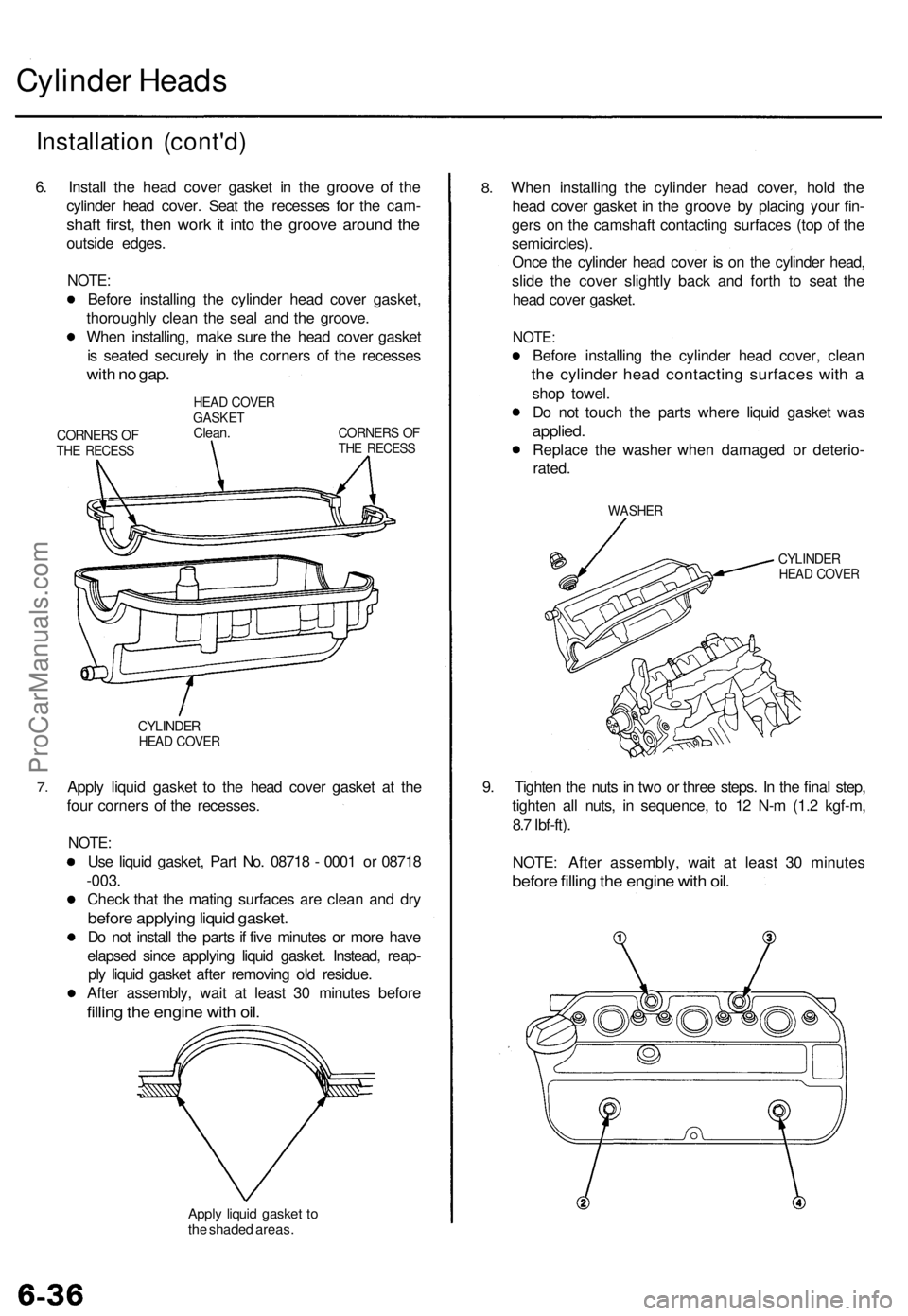

6. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the cam-

shaft first, then work it into the groove around the

outside edges.

NOTE:

Before installing the cylinder head cover gasket,

thoroughly clean the seal and the groove.

When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

CORNERS OF

THE RECESS

HEAD COVER

GASKET

Clean.

CORNERS OF

THE RECESS

7.

CYLINDER

HEAD COVER

Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

-003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Do not install the parts if five minutes or more have

elapsed since applying liquid gasket. Instead, reap-

ply liquid gasket after removing old residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket to

the shaded areas.

8.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder head,

slide the cover slightly back and forth to seat the

head cover gasket.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

Do not touch the parts where liquid gasket was

applied.

Replace the washer when damaged or deterio-

rated.

WASHER

CYLINDER

HEAD COVER

9. Tighten the nuts in two or three steps. In the final step,

tighten all nuts, in sequence, to 12 N-m (1.2 kgf-m,

8.7 Ibf-ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.ProCarManuals.com

Page 116 of 1771

Pistons

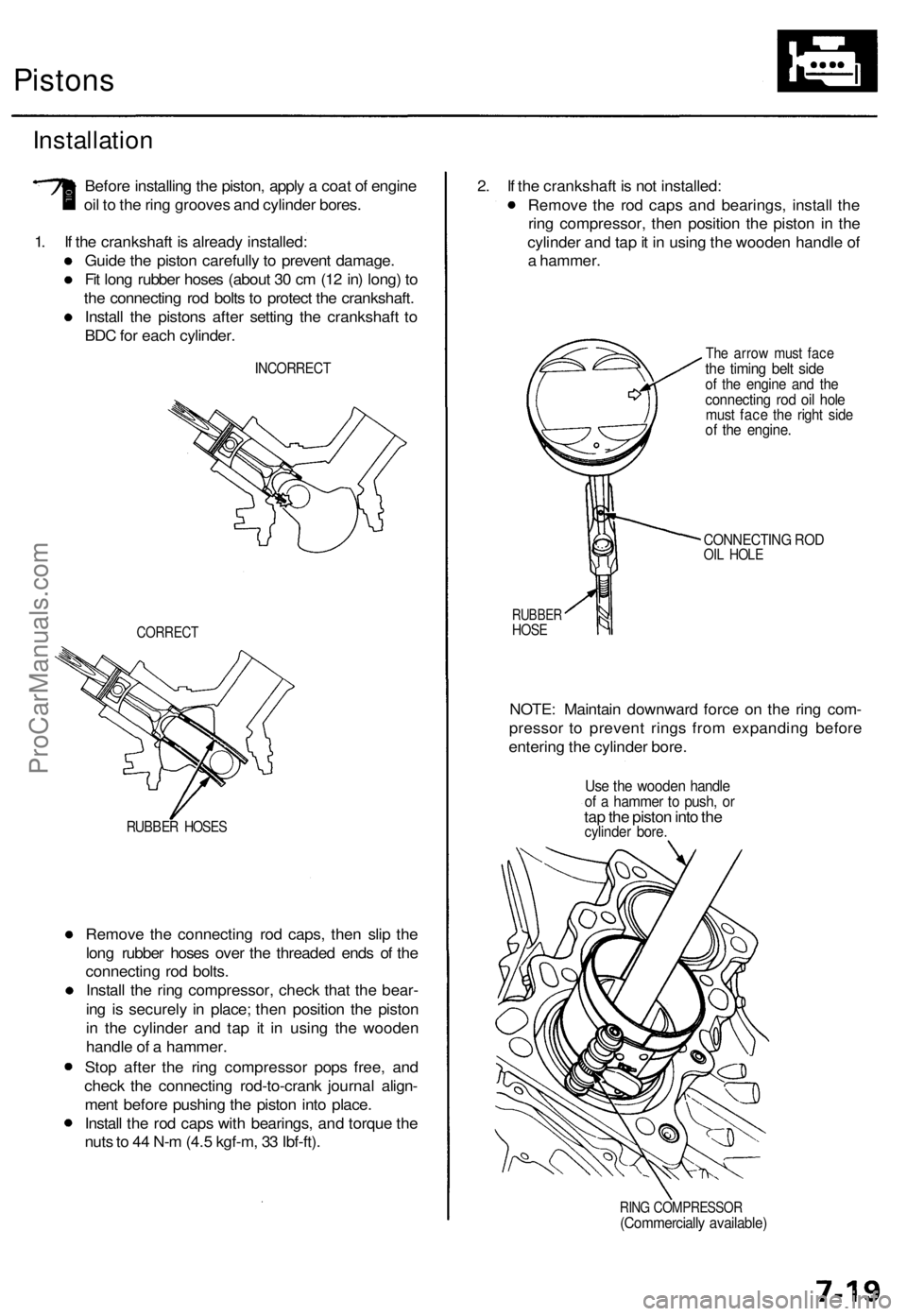

Installation

Before installing the piston, apply a coat of engine

oil to the ring grooves and cylinder bores.

1. If the crankshaft is already installed:

Guide the piston carefully to prevent damage.

Fit long rubber hoses (about 30 cm (12 in) long) to

the connecting rod bolts to protect the crankshaft.

Install the pistons after setting the crankshaft to

BDC for each cylinder.

INCORRECT

CORRECT

RUBBER HOSES

Remove the connecting rod caps, then slip the

long rubber hoses over the threaded ends of the

connecting rod bolts.

Install the ring compressor, check that the bear-

ing is securely in place; then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place.

Install the rod caps with bearings, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

2. If the crankshaft is not installed:

Remove the rod caps and bearings, install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a hammer.

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the right side

of the engine.

CONNECTING ROD

OIL HOLE

RUBBER

HOSE

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING COMPRESSOR

(Commercially available)ProCarManuals.com

Page 143 of 1771

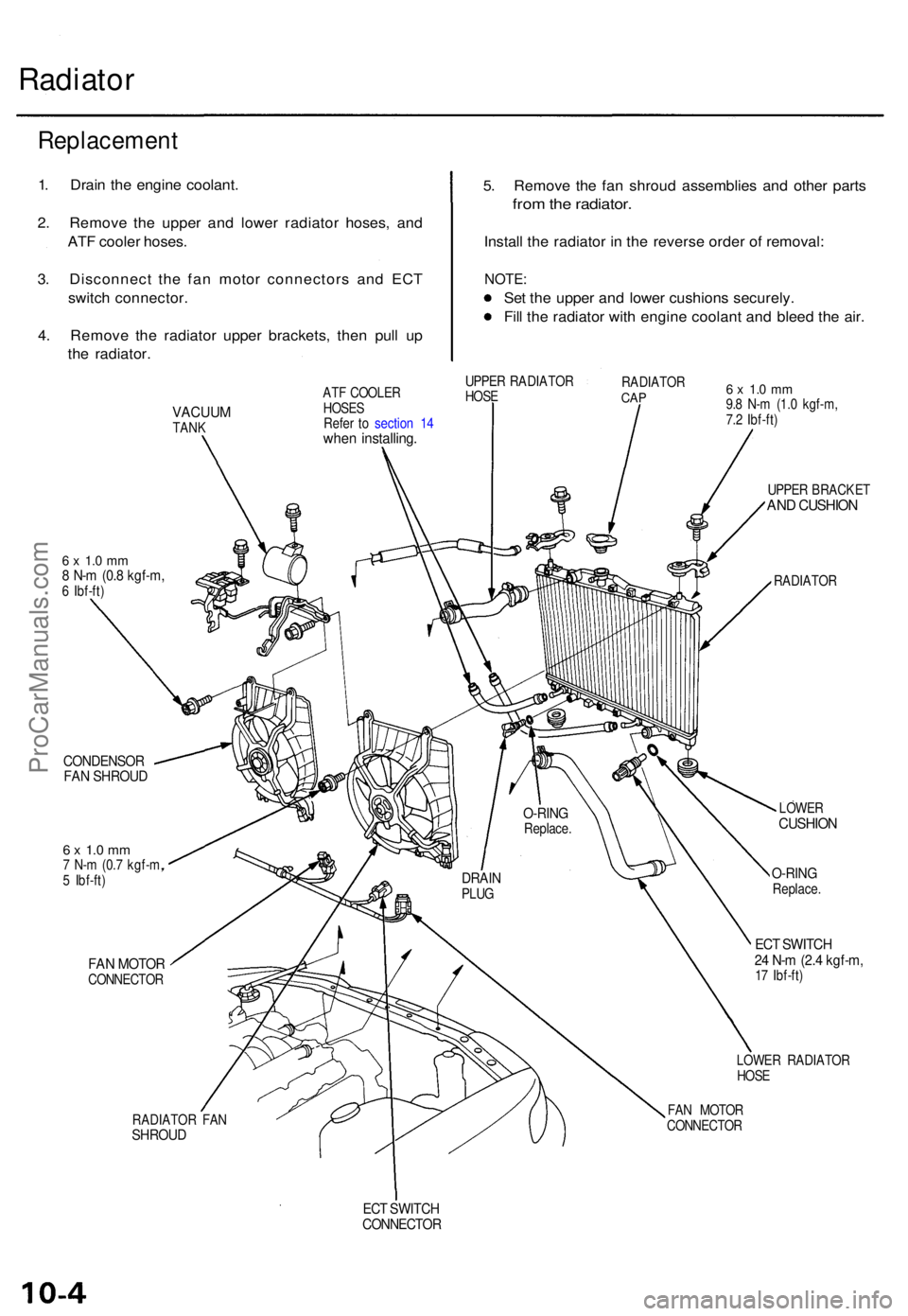

Radiator

5. Remov e th e fa n shrou d assemblie s an d othe r part s

from th e radiator .

Install th e radiato r i n th e revers e orde r o f removal :

NOTE:

Set th e uppe r an d lowe r cushion s securely .

Fil l th e radiato r wit h engin e coolan t an d blee d th e air .

VACUU MTANK

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,6 Ibf-ft )

CONDENSO RFAN SHROU D

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,

5 Ibf-ft )

FAN MOTO RCONNECTO R

RADIATO R FA N

SHROU D

ATF COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

UPPER RADIATO R

HOS E RADIATO

RCAP6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

UPPE R BRACKE T

AND CUSHIO N

RADIATO R

LOWE R

CUSHIO N

O-RINGReplace .

ECT SWITC H24 N- m (2. 4 kgf-m ,17 Ibf-ft )

LOWE R RADIATO R

HOS E

FA N MOTO R

CONNECTO R

ECT SWITC HCONNECTO R

DRAINPLUG

O-RIN GReplace .

Replacemen t

1. Drai n th e engin e coolant .

2 . Remov e th e uppe r an d lowe r radiato r hoses , an d

AT F coole r hoses .

3 . Disconnec t th e fa n moto r connector s an d EC T

switc h connector .

4 . Remov e th e radiato r uppe r brackets , the n pul l u p

th e radiator .

ProCarManuals.com

Page 144 of 1771

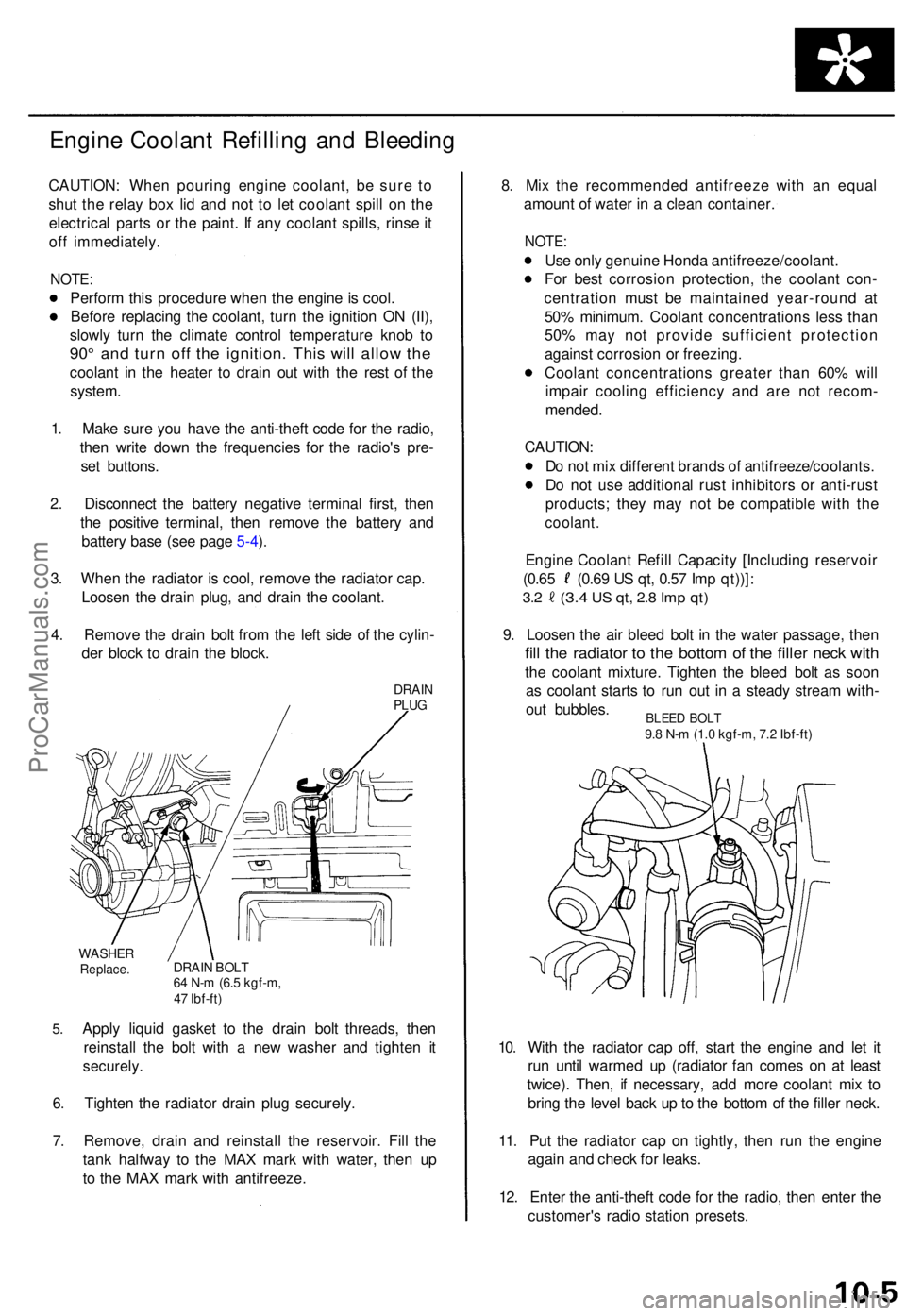

Engine Coolan t Refillin g an d Bleedin g

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90 ° an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

se t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal , the n remov e th e batter y an d

batter y bas e (se e pag e 5-4 ).

3 . Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

4 . Remov e th e drai n bol t fro m th e lef t sid e o f th e cylin -

de r bloc k t o drai n th e block .

DRAINPLUG

5.

WASHE RReplace .DRAIN BOL T64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

Apply liqui d gaske t t o th e drai n bol t threads , the n

reinstal l th e bol t wit h a ne w washe r an d tighte n i t

securely .

6. Tighte n th e radiato r drai n plu g securely .

7 . Remove , drai n an d reinstal l th e reservoir . Fil l th e

tan k halfwa y t o th e MA X mar k wit h water , the n u p

t o th e MA X mar k wit h antifreeze . 8

. Mi x th e recommende d antifreez e wit h a n equa l

amoun t o f wate r i n a clea n container .

NOTE:

Use onl y genuin e Hond a antifreeze/coolant .

Fo r bes t corrosio n protection , th e coolan t con -

centratio n mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

D o no t mi x differen t brand s o f antifreeze/coolants .

D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

coolant .

Engine Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

3.2 (3. 4 US qt , 2. 8 Im p qt )

9. Loose n th e ai r blee d bol t i n th e wate r passage , the n

fill th e radiato r t o th e botto m o f th e fille r nec k wit h

the coolan t mixture . Tighte n th e blee d bol t a s soo n

a s coolan t start s t o ru n ou t i n a stead y strea m with -

ou t bubbles .

10 . Wit h th e radiato r ca p off , star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e coolan t mi x t o

brin g th e leve l bac k u p to th e botto m o f th e fille r neck .

11 . Pu t th e radiato r cap on tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

12 . Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

BLEED BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 200 of 1771

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,000 rpm.

Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay .

When the PCM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure a smooth transition to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

'96 model: When the engine coolant temperature is below 158°F (70°C), the PCM controls the EVAP purge control

solenoid valve which cuts vacuum to the EVAP purge control canister diaphragm.

'97 - 98 models: When the engine coolant temperature is above 99°F (37°C), the PCM controls the EVAP purge control

solenoid valve which controls vacuum to the EVAP purge control canister.

6. Intake Air Bypass (IAB) Low Control Solenoid Valve, Intake Air Bypass (IAB) High Control Solenoid Valve

When engine speed is below 3,350 rpm, the IAB High Control Solenoid Valve and IAB Low Control Solenoid Valve are

activated by a signal from the PCM. Intake air flows through a long chamber path, increasing torque at low RPM.

When engine speed is 3,350 - 3,950 rpm, the IAB Low Control Solenoid Valve is deactivated by the PCM. Intake air

flows through a short chamber path, increasing mid-range torque.

When the engine rpm is above 3,950 rpm, the IAB Low Control Solenoid Valve and IAB High Control Solenoid Valve are

deactivated by the PCM. This creates a very short intake path and increases high-speed torque.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the PCM controls the EGR control solenoid

valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the PCM ignores that signal and assumes a pre-programmed

value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the PCM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the PCM supplies ground for the MIL and stores the DTC in

erasable memory. When the ignition is initially turned on, the PCM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Driving Cycle Detection Method

To prevent false indications, the two driving cycle detection method is used for the H02S, fuel metering-related, idle

control system, ECT sensor, EGR system, TWC, EVAP control system and other self-diagnostic functions. When an

abnormality occurs, the PCM stores it in its memory. When the same abnormality recurs after the ignition switch is

turned OFF and ON (II) again, the PCM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 239 of 1771

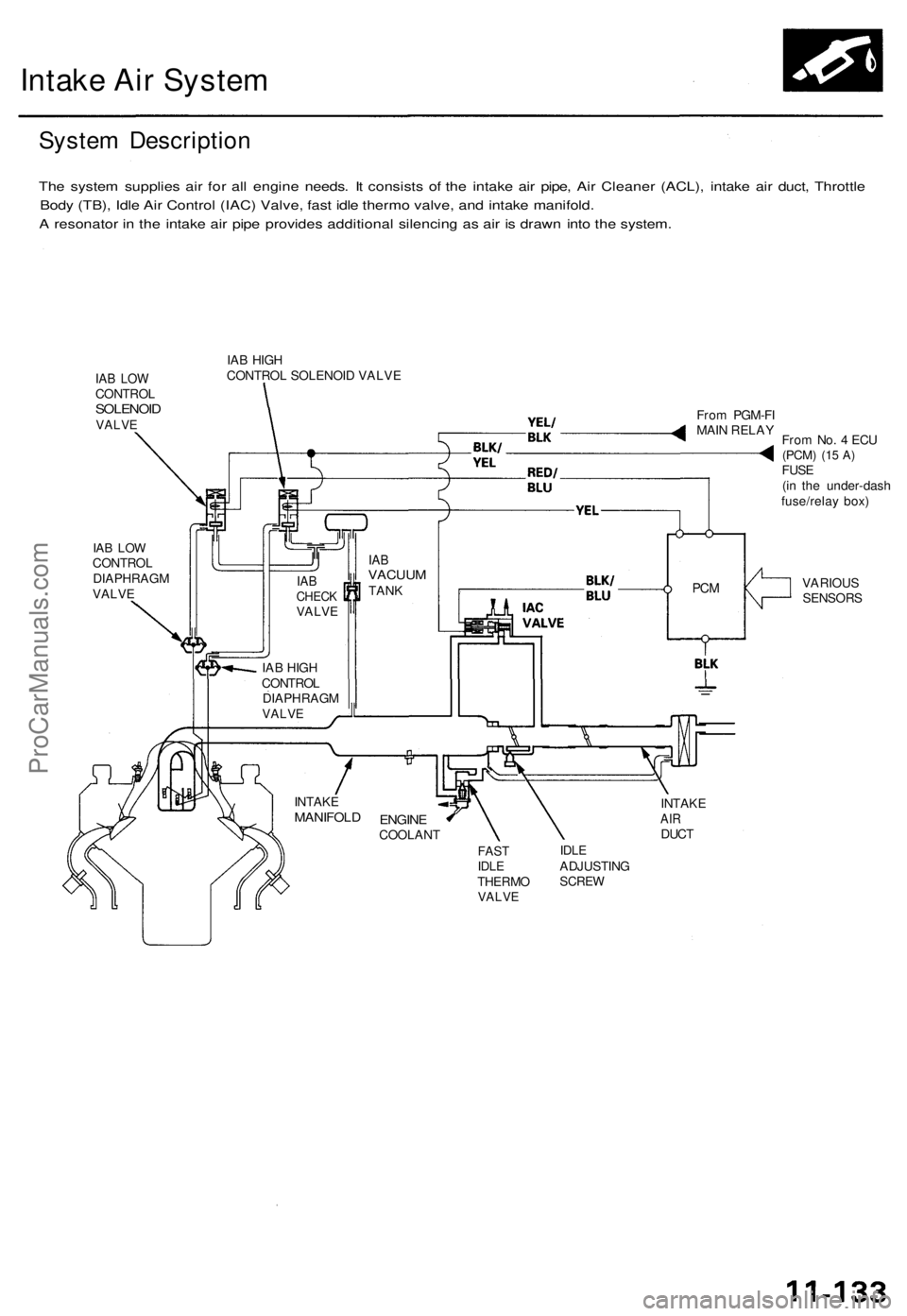

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe, Air Cleaner (ACL), intake air duct, Throttle

Body (TB), Idle Air Control (IAC) Valve, fast idle thermo valve, and intake manifold.

A resonator in the intake air pipe provides additional silencing as air is drawn into the system.

IAB LOW

CONTROL

SOLENOID

VALVE

IAB HIGH

CONTROL SOLENOID VALVE

IAB LOW

CONTROL

DIAPHRAGM

VALVE

From PGM-FI

MAIN RELAY

From No. 4 ECU

(PCM)

(15 A)

FUSE

(in the under-dash

fuse/relay box)

VARIOUS

SENSORS

INTAKE

AIR

DUCT

FAST

IDLE

THERMO

VALVE

IDLE

ADJUSTING

SCREW

ENGINE

COOLANT

INTAKE

MANIFOLD

PCM

IAB

VACUUM

TANK

IAB

CHECK

VALVE

IAB HIGH

CONTROL

DIAPHRAGM

VALVEProCarManuals.com

Page 251 of 1771

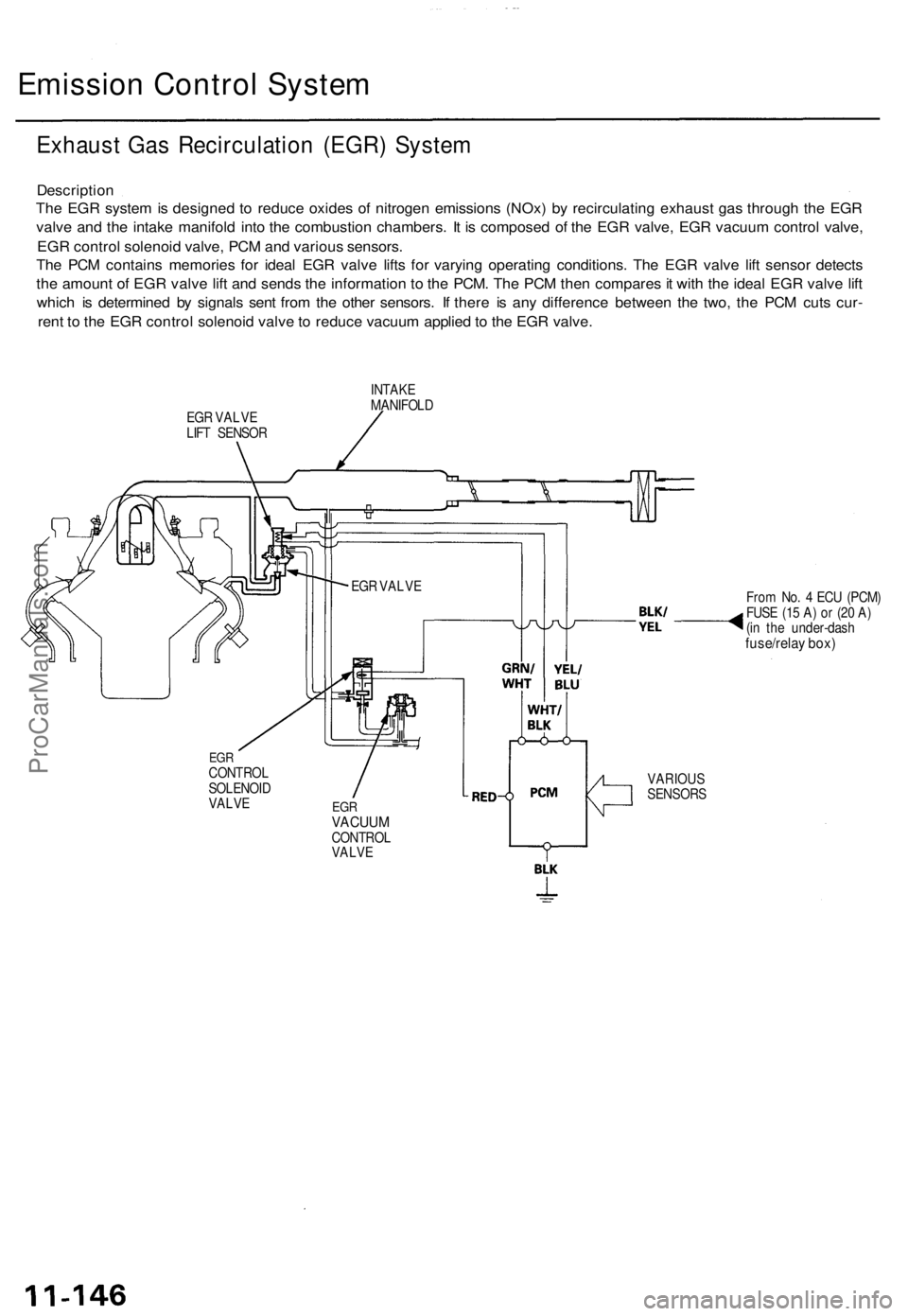

Emission Control System

Exhaust Gas Recirculation (EGR) System

Description

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGR

valve and the intake manifold into the combustion chambers. It is composed of the EGR valve, EGR vacuum control valve,

EGR control solenoid valve, PCM and various sensors.

The PCM contains memories for ideal EGR valve lifts for varying operating conditions. The EGR valve lift sensor detects

the amount of EGR valve lift and sends the information to the PCM. The PCM then compares it with the ideal EGR valve lift

which is determined by signals sent from the other sensors. If there is any difference between the two, the PCM cuts cur-

rent to the EGR control solenoid valve to reduce vacuum applied to the EGR valve.

EGR VALVE

LIFT SENSOR

INTAKE

MANIFOLD

From No. 4 ECU (PCM)

FUSE (15 A) or (20 A)

(in the under-dash

fuse/relay box)

EGR

CONTROL

SOLENOID

VALVE

EGR

VACUUM

CONTROL

VALVE

VARIOUS

SENSORS

EGR VALVEProCarManuals.com

Page 253 of 1771

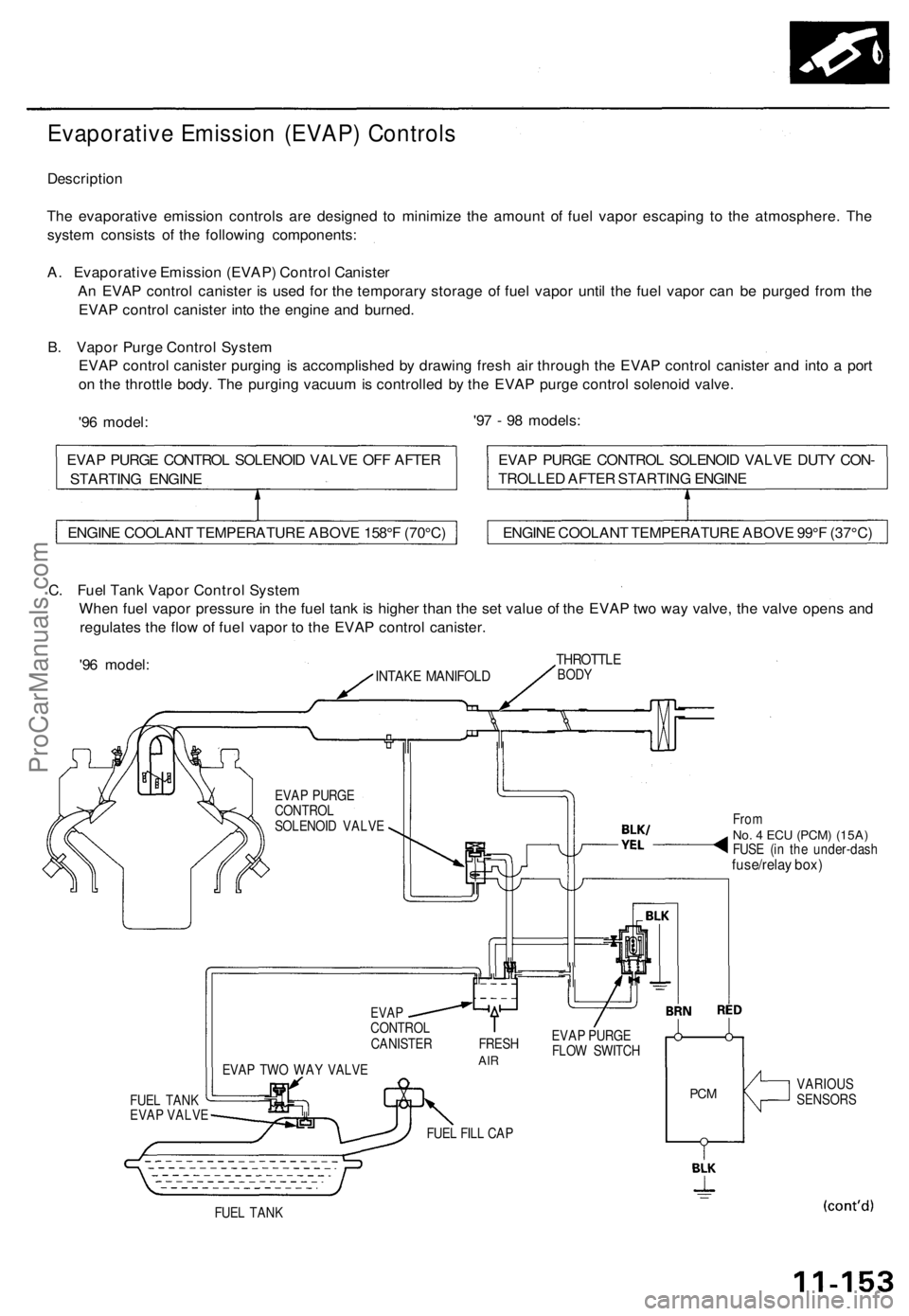

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control solenoid valve.

'96 model:

'97 - 98 models:

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

'96 model:

INTAKE MANIFOLD

THROTTLE

BODY

EVAP PURGE

CONTROL

SOLENOID VALVE

FUEL TANK

EVAP VALVE

EVAP TWO WAY VALVE

From

No. 4 ECU

(PCM) (15A)

FUSE (in the under-dash

fuse/relay box)

EVAP

CONTROL

CANISTER FRESH

AIR

EVAP PURGE

FLOW SWITCH

FUEL FILL CAP

PCM

VARIOUS

SENSORS

FUEL TANK

ENGINE COOLANT TEMPERATURE ABOVE 158°F (70°C)

ENGINE COOLANT TEMPERATURE ABOVE 99°F (37°C)

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINEProCarManuals.com