air condition ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 47 of 1771

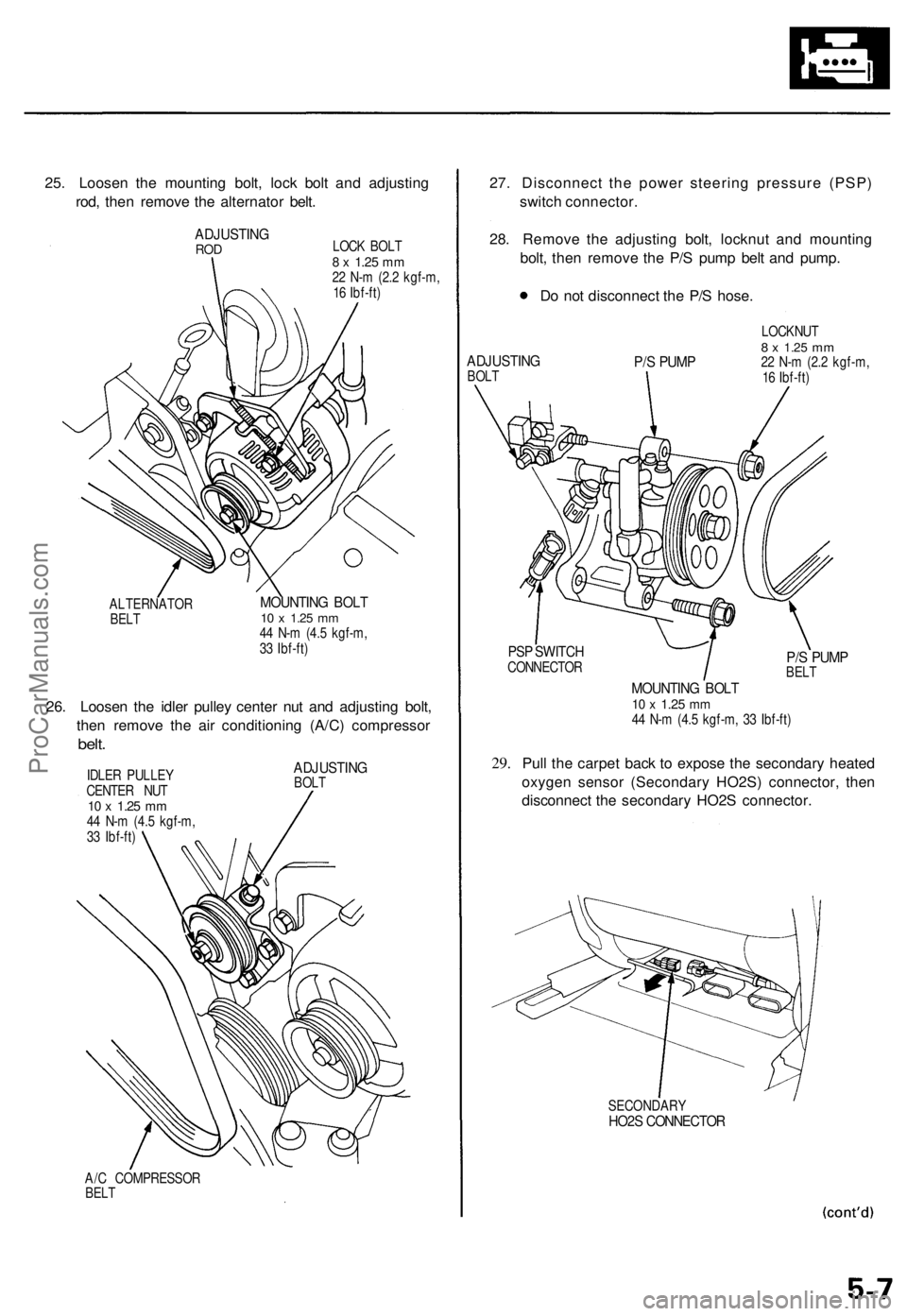

25. Loosen the mounting bolt, lock bolt and adjusting

rod, then remove the alternator belt.

ADJUSTING

ROD

LOCK BOLT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

26. Loosen the idler pulley center nut and adjusting bolt,

then remove the air conditioning (A/C) compressor

belt.

IDLER PULLEY

CENTER NUT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ADJUSTING

BOLT

A/C COMPRESSOR

BELT

27. Disconnect the power steering pressure (PSP)

switch connector.

28. Remove the adjusting bolt, locknut and mounting

bolt, then remove the P/S pump belt and pump.

Do not disconnect the P/S hose.

ADJUSTING

BOLT

P/S PUMP

LOCKNUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

PSP SWITCH

CONNECTOR

29.

P/S PUMP

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

Pull the carpet back to expose the secondary heated

oxygen sensor (Secondary HO2S) connector, then

disconnect the secondary HO2S connector.

SECONDARY

HO2S CONNECTORProCarManuals.com

Page 184 of 1771

Troubleshooting

Troubleshootin g Procedure s (cont'd )

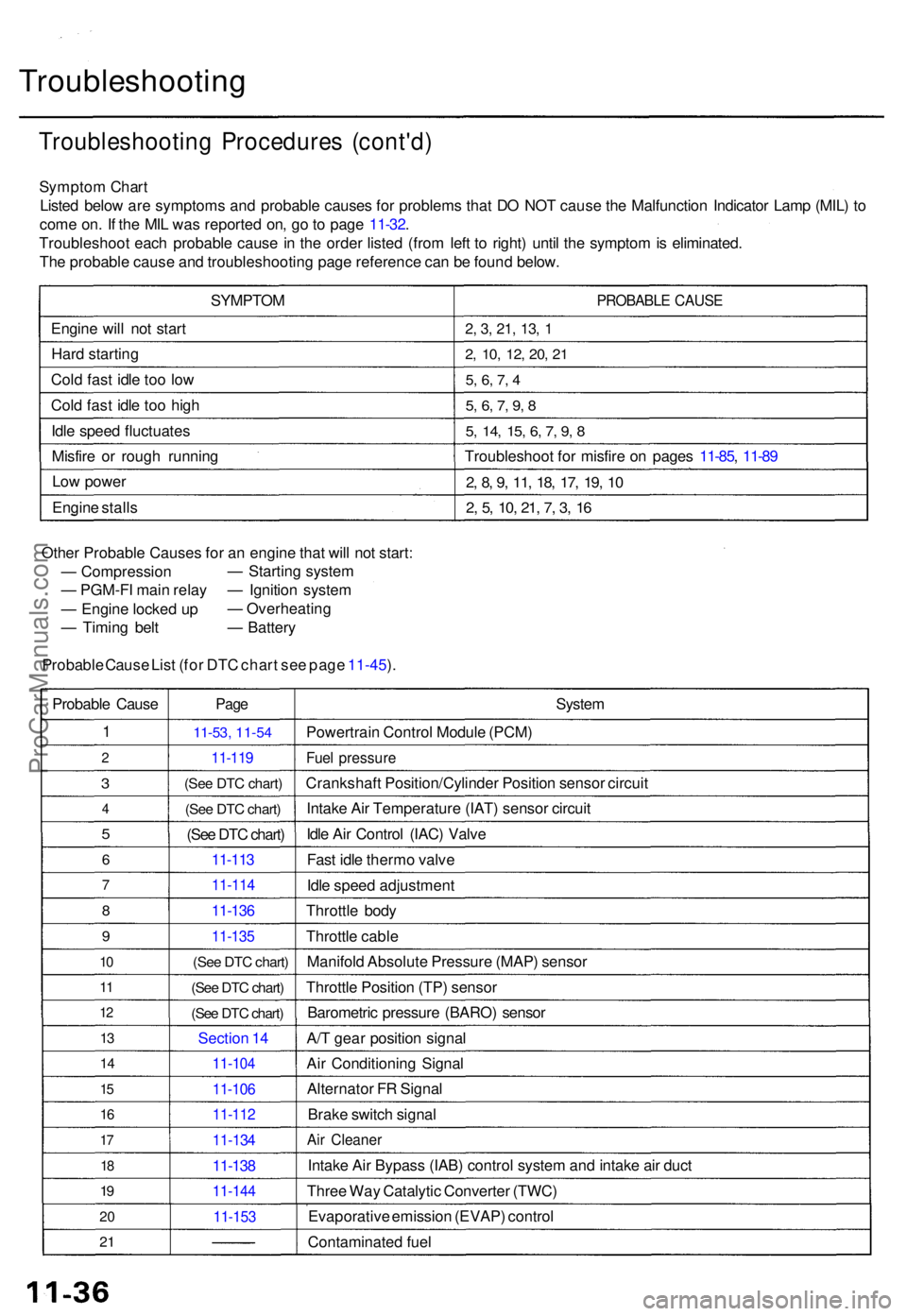

Sympto m Char t

Liste d belo w ar e symptom s an d probabl e cause s fo r problem s tha t D O NO T caus e th e Malfunctio n Indicato r Lam p (MIL ) t o

com e on . I f th e MI L wa s reporte d on , g o to pag e 11-32 .

Troubleshoo t eac h probabl e caus e in th e orde r liste d (fro m lef t t o right ) unti l th e sympto m is eliminated .

Th e probabl e caus e an d troubleshootin g pag e referenc e ca n b e foun d below .

SYMPTO M

Engin e wil l no t star t

Har d startin g

Col d fas t idl e to o lo w

Col d fas t idl e to o hig h

Idl e spee d fluctuate s

Misfir e o r roug h runnin g

Lo w powe r

Engin e stall s

PROBABL E CAUS E

2, 3 , 21 , 13 , 1

2 , 10 , 12 , 20 , 2 1

5, 6 , 7 , 4

5 , 6 , 7 , 9 , 8

5 , 14 , 15 , 6 , 7 , 9 , 8

Troubleshoo t fo r misfir e o n page s 11-85 , 11-8 9

2, 8 , 9 , 11 , 18 , 17 , 19 , 1 0

2, 5 , 10 , 21 , 7 , 3 , 1 6

Othe r Probabl e Cause s fo r a n engin e tha t wil l no t start :

— Compressio n

— PGM-F I mai n rela y

— Engin e locke d u p

— Timin g bel t

Probabl e Caus e Lis t (for DTC chart see page 11-45).

—

Startin g syste m

— Ignitio n syste m

— Overheatin g

— Batter y

Probabl e Caus e

1

2

3

4

5

6

7

8

9

10

1 1

1 2

13

1 4

15

1 6

17

18

19

2 0

2 1

Pag e

11-5 3, 11-54

11-11 9

(See DTC chart)

(See DTC chart)

(See DTC chart)

11-113

11-11 4

11-136

11-13 5

(See DTC chart)

(See DTC chart)

(See DTC chart)

Sectio n 1 4

11-10 4

11-106

11-112

11-13 4

11-138

11-14 4

11-153

System

Powertrai n Contro l Modul e (PCM )

Fuel pressur e

Crankshaf t Position/Cylinde r Positio n senso r circui t

Intak e Ai r Temperatur e (IAT ) senso r circui t

Idl e Ai r Contro l (IAC ) Valv e

Fas t idl e therm o valv e

Idl e spee d adjustmen t

Throttl e bod y

Throttl e cabl e

Manifol d Absolut e Pressur e (MAP ) senso r

Throttl e Positio n (TP ) senso r

Barometri c pressur e (BARO ) senso r

A/ T gea r positio n signa l

Ai r Conditionin g Signa l

Alternato r F R Signa l

Brak e switc h signa l

Air Cleane r

Intake Ai r Bypas s (IAB ) contro l syste m an d intak e ai r duc t

Thre e Wa y Catalyti c Converte r (TWC )

Evaporativ e emissio n (EVAP ) contro l

Contaminate d fue l

ProCarManuals.com

Page 186 of 1771

Troubleshooting

Troubleshooting Procedure s (cont'd )

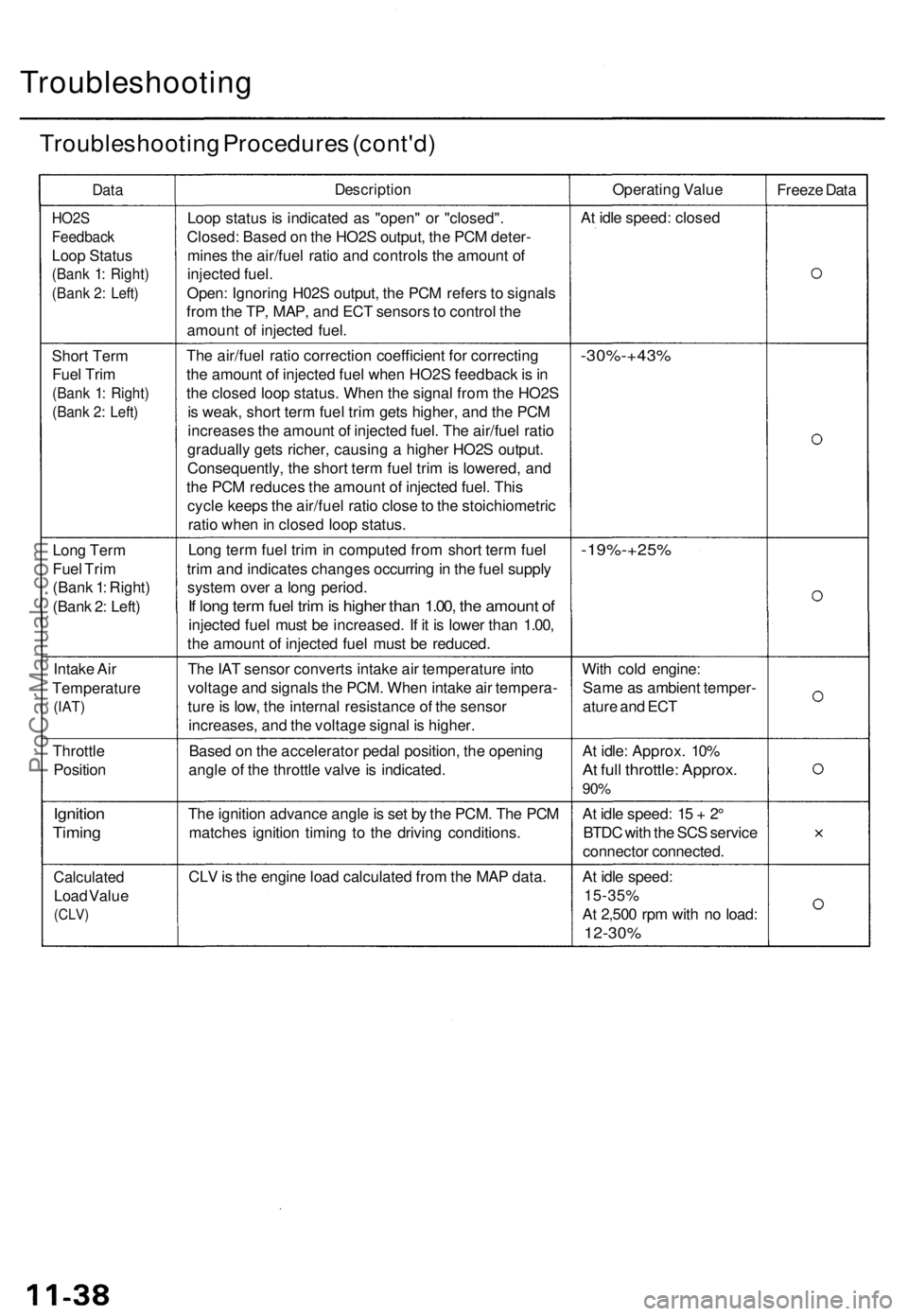

DataDescriptio nOperating Valu e

Freeze Dat a

HO2 S

Feedbac k

Loop Statu s

(Bank 1 : Right )

(Bank 2 : Left )

Loop statu s i s indicate d a s "open " o r "closed" .

Closed: Based o n th e HO2 S output , th e PC M deter -

mine s th e air/fue l rati o an d control s th e amoun t o f

injecte d fuel .

Open : Ignorin g H02 S output , th e PC M refer s t o signal s

fro m th e TP , MAP , an d EC T sensor s to contro l th e

amoun t o f injecte d fuel . A

t idl e speed : close d

Shor t Ter m

Fue l Tri m

(Ban k 1 : Right )

(Bank 2 : Left )

The air/fue l rati o correctio n coefficien t fo r correctin g

th e amoun t o f injecte d fue l whe n HO2 S feedbac k is in

th e close d loo p status . Whe n th e signa l fro m th e HO2 S

i s weak , shor t ter m fue l tri m get s higher , an d th e PC M

increase s th e amoun t o f injecte d fuel . Th e air/fue l rati o

graduall y get s richer , causin g a highe r HO2 S output .

Consequently , th e shor t ter m fue l tri m is lowered , an d

th e PC M reduce s th e amoun t o f injecte d fuel . Thi s

cycl e keep s th e air/fue l rati o close to th e stoichiometri c

rati o whe n in close d loo p status .-30%-+43 %

Long Ter m

Fue l Tri m

(Ban k 1 : Right )

(Ban k 2 : Left ) Lon

g ter m fue l tri m in compute d fro m shor t ter m fue l

tri m an d indicate s change s occurrin g in th e fue l suppl y

syste m ove r a lon g period .

If lon g ter m fue l tri m is highe r tha n 1.00 , th e amoun t o f

injecte d fue l mus t b e increased . I f i t i s lowe r tha n 1.00 ,

th e amoun t o f injecte d fue l mus t b e reduced .

-19%-+25 %

Intake Ai r

Temperatur e

(IAT)

The IA T senso r convert s intak e ai r temperatur e int o

voltag e an d signal s th e PCM . Whe n intak e ai r tempera -

tur e is low , th e interna l resistanc e o f th e senso r

increases , an d th e voltag e signa l i s higher . Wit

h col d engine :

Sam e a s ambien t temper -

atur e an d EC T

Throttl e

Positio n Base

d o n th e accelerato r peda l position , th e openin g

angl e o f th e throttl e valv e is indicated . A

t idle : Approx . 10 %

At ful l throttle : Approx .

90%

Ignitio n

Timing

The ignitio n advanc e angl e is se t b y th e PCM . Th e PC M

matche s ignitio n timin g t o th e drivin g conditions .A

t idl e speed : 1 5 + 2°

BTD C wit h th e SC S servic e

connecto r connected .

Calculated

Load Valu e

(CLV )

CLV is th e engin e loa d calculate d fro m th e MA P data . At idl e speed :

15-35 %

A t 2,50 0 rp m wit h n o load :

12-30 %

ProCarManuals.com

Page 198 of 1771

Troubleshooting

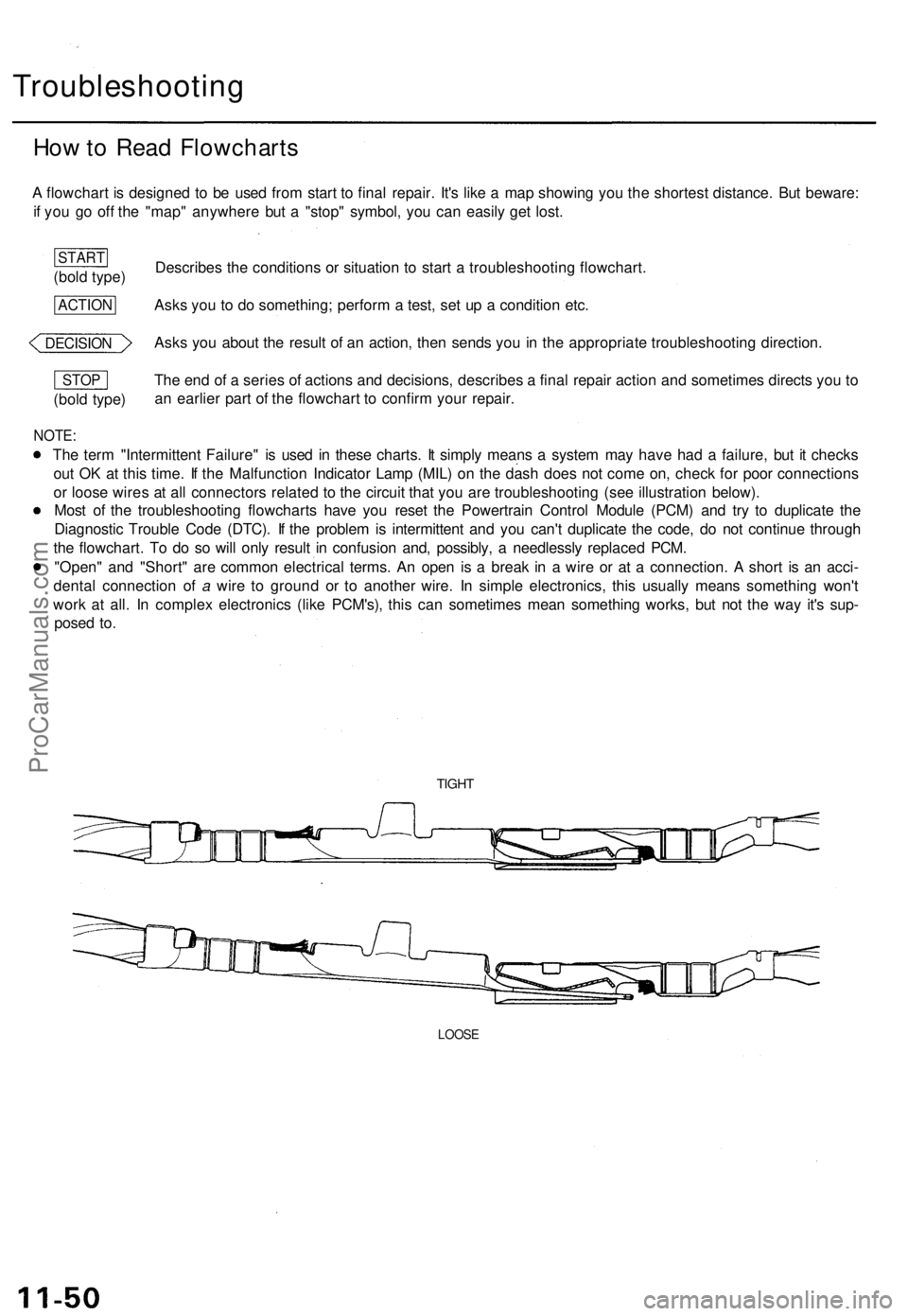

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But beware:

if you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

an earlier part of the flowchart to confirm your repair.

NOTE:

The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK at this time. If the Malfunction Indicator Lamp (MIL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

Most of the troubleshooting flowcharts have you reset the Powertrain Control Module (PCM) and try to duplicate the

Diagnostic Trouble Code (DTC). If the problem is intermittent and you can't duplicate the code, do not continue through

the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced PCM.

"Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like PCM's), this can sometimes mean something works, but not the way it's sup-

posed to.

TIGHT

LOOSE

(bold type)

STOP

DECISION

ACTION

(bold type)

STARTProCarManuals.com

Page 199 of 1771

PGM-FI Syste m

System Descriptio n

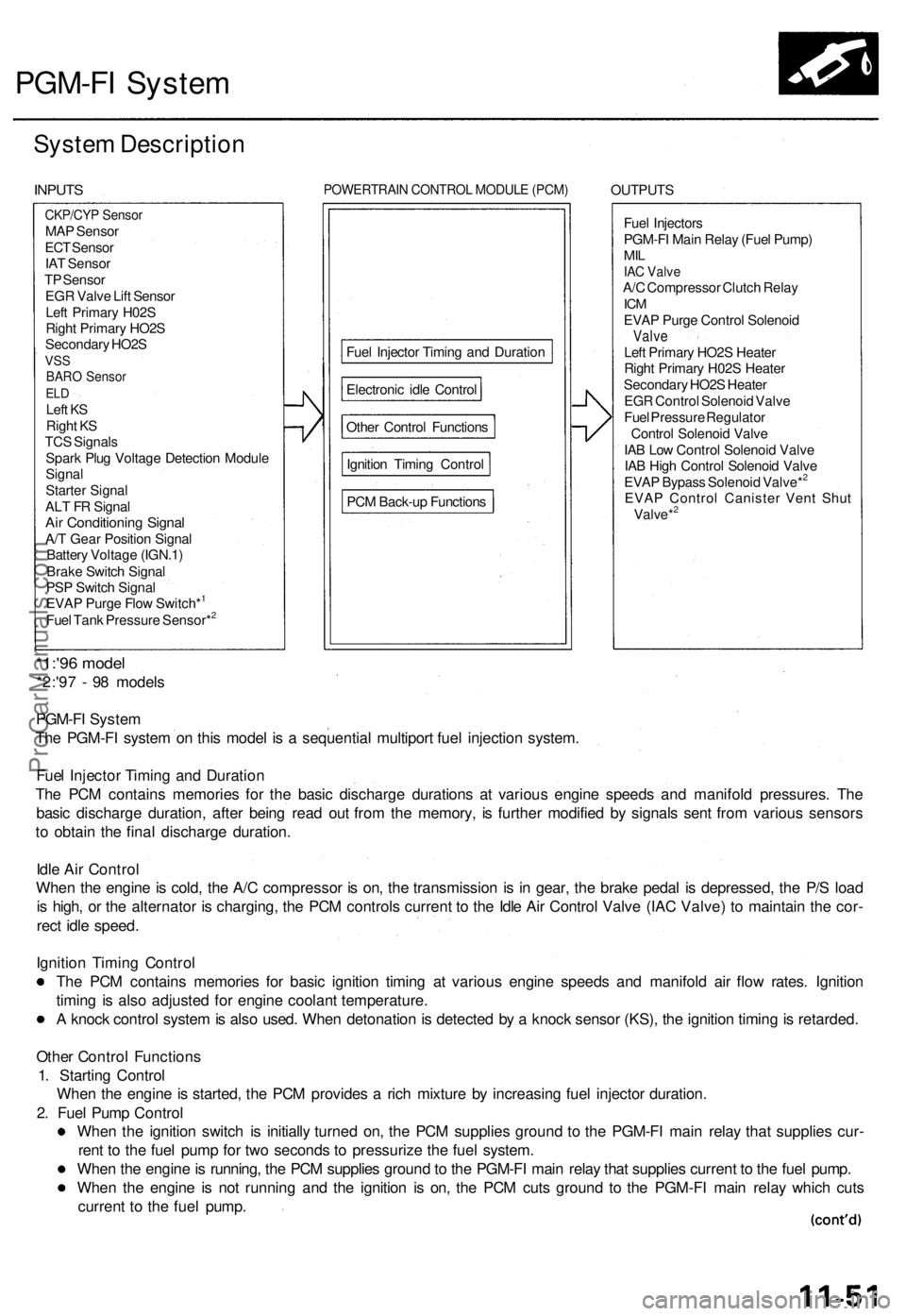

INPUTS POWERTRAI N CONTRO L MODUL E (PCM ) OUTPUT S

Fue l Injector s

PGM-F I Mai n Rela y (Fue l Pump )

MILIAC Valv eA/C Compresso r Clutc h Rela yICMEVA P Purg e Contro l Solenoi dValveLeft Primar y HO2 S Heate r

Righ t Primar y H02 S Heate r

Secondar y HO2 S Heate r

EG R Contro l Solenoi d Valv e

Fue l Pressur e Regulato r

Contro l Solenoi d Valv e

IA B Lo w Contro l Solenoi d Valv e

IA B Hig h Contro l Solenoi d Valv e

EVA P Bypas s Solenoi d Valve*

2

EVA P Contro l Caniste r Ven t Shu t

Valve*2

*1:'9 6 mode l

*2:'97 - 9 8 model s

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Fue l Injecto r Timin g an d Duratio n

Th e PC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Idl e Ai r Contro l

Whe n th e engin e is cold , th e A/ C compresso r i s on , th e transmissio n i s i n gear , th e brak e peda l i s depressed , th e P/ S loa d

i s high , o r th e alternato r i s charging , th e PC M control s curren t t o th e Idl e Ai r Contro l Valv e (IA C Valve ) t o maintai n th e cor -

rec t idl e speed .

Ignitio n Timin g Contro l

Th e PC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d ai r flo w rates . Ignitio n

timin g i s als o adjuste d fo r engin e coolan t temperature .

A knoc k contro l syste m is als o used . Whe n detonatio n is detecte d b y a knoc k senso r (KS) , th e ignitio n timin g is retarded .

Othe r Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e PC M provide s a ric h mixtur e b y increasin g fue l injecto r duration .

2 . Fue l Pum p Contro l

Whe n th e ignitio n switc h i s initiall y turne d on , th e PC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s cur -

ren t t o th e fue l pum p fo r tw o second s t o pressuriz e th e fue l system .

Whe n th e engin e is running , th e PC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s curren t t o th e fue l pump .

Whe n th e engin e i s no t runnin g an d th e ignitio n i s on , th e PC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

CKP/CY P Senso rMAP Senso r

EC T Senso r

IA T Senso r

T P Senso r

EG R Valv e Lif t Senso r

Lef t Primar y H02 S

Righ t Primar y HO2 S

Secondar y HO2 S

VSSBAR O Senso rELDLef t K S

Righ t K S

TC S Signal s

Spar k Plu g Voltag e Detectio n Modul e

Signa l

Starte r Signa l

AL T F R Signa l

Air Conditionin g Signa lA/T Gea r Positio n Signa l

Batter y Voltag e (IGN.1 )

Brak e Switc h Signa l

PS P Switc h Signa l

EVA P Purg e Flo w Switch*

1

Fue l Tan k Pressur e Sensor*2

PC M Back-u p Function s

Ignitio

n Timin g Contro l

Othe

r Contro l Function s

Electroni

c idl e Contro l

Fue

l Injecto r Timin g an d Duratio n

ProCarManuals.com

Page 200 of 1771

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,000 rpm.

Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay .

When the PCM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure a smooth transition to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

'96 model: When the engine coolant temperature is below 158°F (70°C), the PCM controls the EVAP purge control

solenoid valve which cuts vacuum to the EVAP purge control canister diaphragm.

'97 - 98 models: When the engine coolant temperature is above 99°F (37°C), the PCM controls the EVAP purge control

solenoid valve which controls vacuum to the EVAP purge control canister.

6. Intake Air Bypass (IAB) Low Control Solenoid Valve, Intake Air Bypass (IAB) High Control Solenoid Valve

When engine speed is below 3,350 rpm, the IAB High Control Solenoid Valve and IAB Low Control Solenoid Valve are

activated by a signal from the PCM. Intake air flows through a long chamber path, increasing torque at low RPM.

When engine speed is 3,350 - 3,950 rpm, the IAB Low Control Solenoid Valve is deactivated by the PCM. Intake air

flows through a short chamber path, increasing mid-range torque.

When the engine rpm is above 3,950 rpm, the IAB Low Control Solenoid Valve and IAB High Control Solenoid Valve are

deactivated by the PCM. This creates a very short intake path and increases high-speed torque.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the PCM controls the EGR control solenoid

valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the PCM ignores that signal and assumes a pre-programmed

value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the PCM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the PCM supplies ground for the MIL and stores the DTC in

erasable memory. When the ignition is initially turned on, the PCM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Driving Cycle Detection Method

To prevent false indications, the two driving cycle detection method is used for the H02S, fuel metering-related, idle

control system, ECT sensor, EGR system, TWC, EVAP control system and other self-diagnostic functions. When an

abnormality occurs, the PCM stores it in its memory. When the same abnormality recurs after the ignition switch is

turned OFF and ON (II) again, the PCM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 207 of 1771

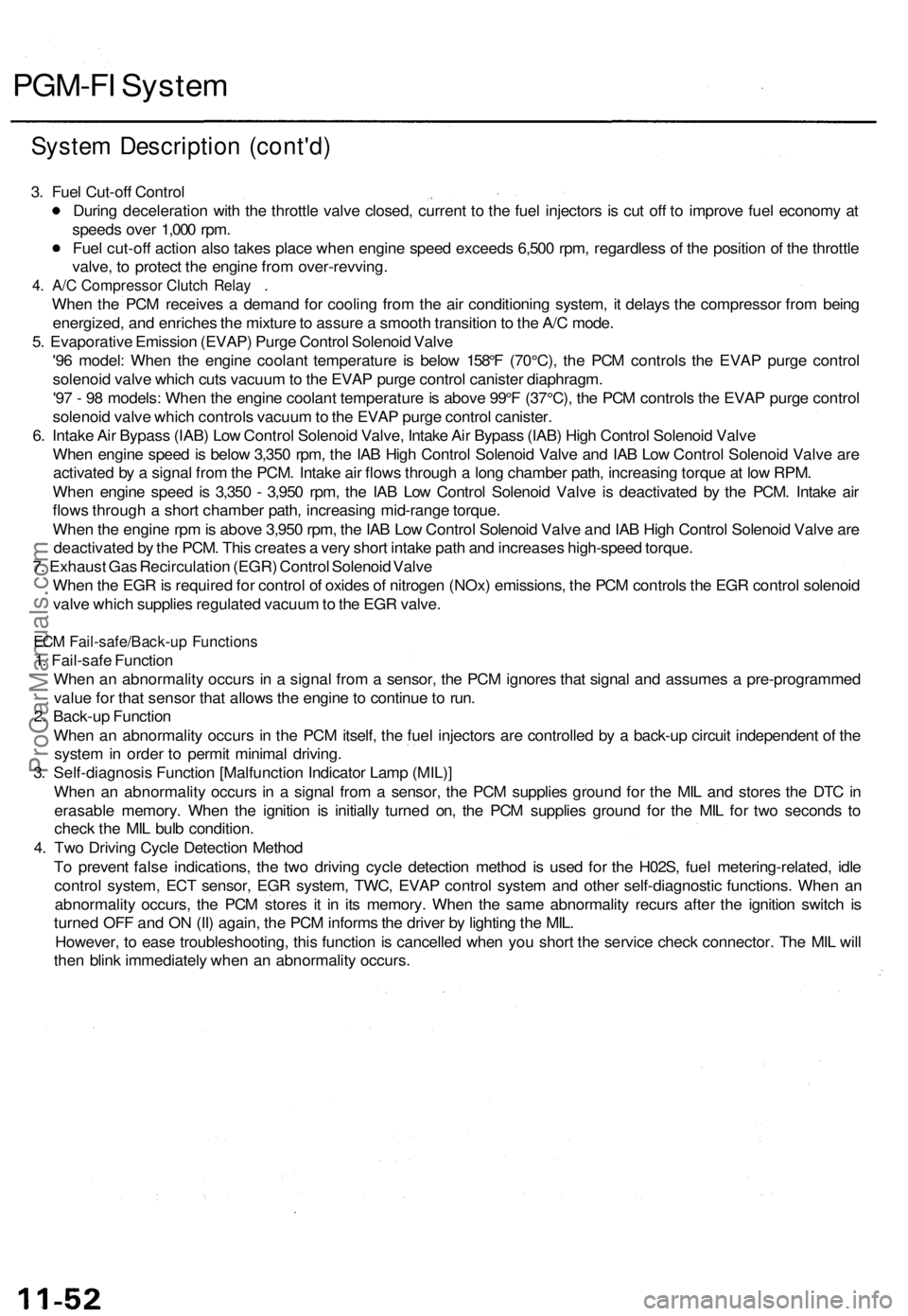

Idle Contro l Syste m

Air Conditionin g Signa l

This signal s th e PC M whe n ther e is a deman d fo r coolin g fro m th e ai r conditionin g system .

Inspectio n o f Ai r Conditionin g

Signal .

Chec k fo r a shor t i n th e wir e

(AC S line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e A/ C pressur e

switc h A connecto r an d radia -

to r fa n diod e connector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n

PC M connecto r terminal s C 2

and A26 .

Is ther e batter y voltage ?

Chec k fo r a n ope n i n th e wir e

(ACC line) :1. Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e A/ C pressur e

switc h A connecto r an d radia -

to r fa n diod e connector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Momentaril y connec t PC M

connecto r terminal s A 8 an d

A2 6 wit h a jumpe r wir e sever -

a l times .

(T o pag e 11-105 )

A (26P)

PCM CONNECTOR S

C (12P )

Wire sid e o f femal e terminal s

Chec k fo r a shor t i n th e wir e (AC S

line):1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e PC M connec -

tor C (12P) .3. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l C2 .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

th e PC M (C2 ) an d th e A/ C pres -

sur e switc h A or radiato r fa n

diode .

Substitut e a known-goo d PC M

an d recheck . I f prescribe d volt -

ag e is no w available , replac e

th e origina l PCM .

Se e th e ai r conditione r inspec -

tio n (se e sectio n 22 ).

PCM CONNECTO R A (26P )

Wir e sid e o f femal e

terminal s

JUMPERWIRE

ProCarManuals.com

Page 240 of 1771

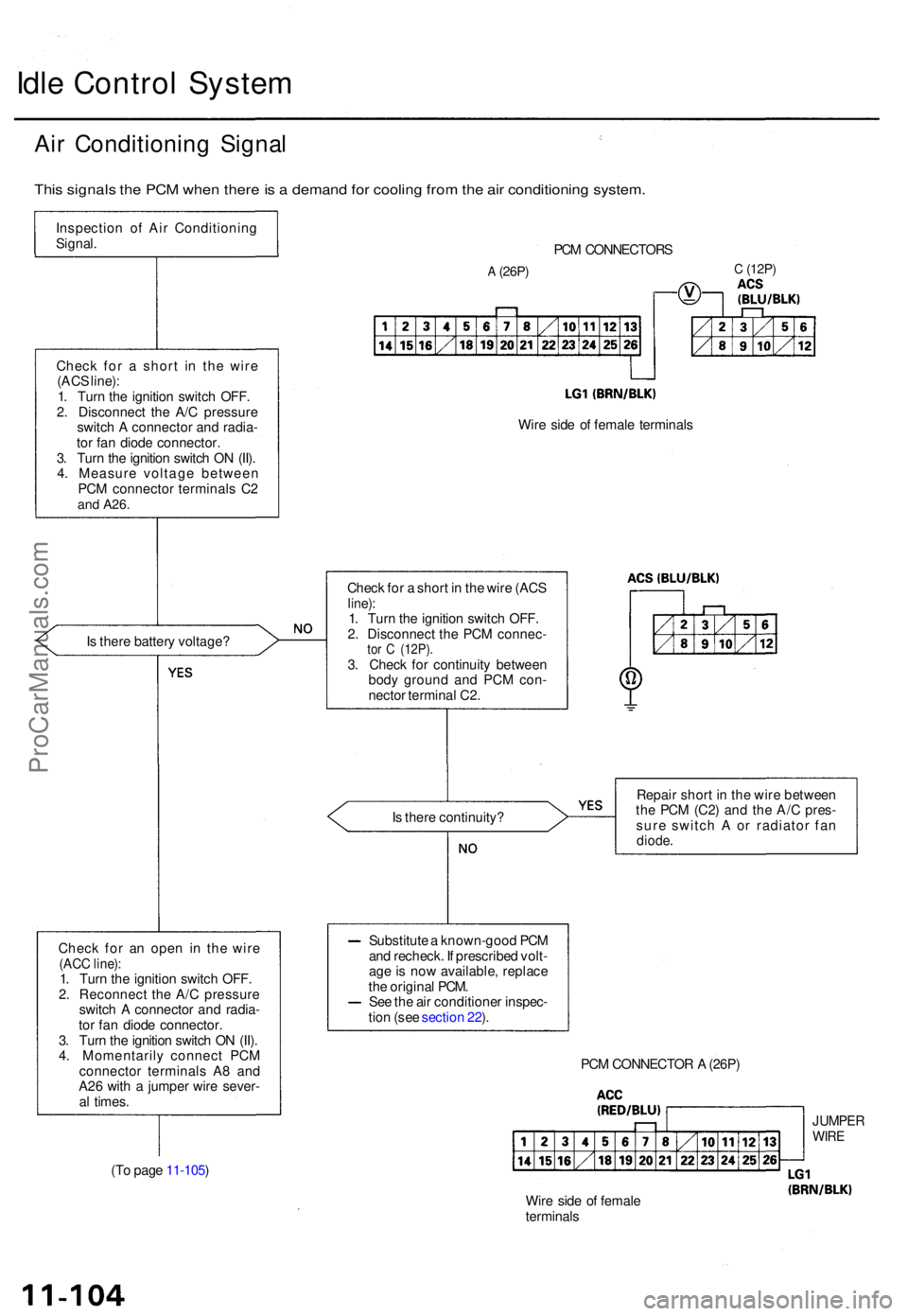

Intake Ai r Syste m

Air Cleane r (ACL )

ACL Elemen t Replacemen t

ACL HOUSIN GCOVER

ACL ELEMEN T

Norma l conditions :

Replac e ai r cleane r elemen t ever y

30,00 0 mile s (48,00 0 km ) o r 2 4

month s whicheve r come s first .

Sever e conditions :

Clea n ai r cleane r elemen t ever y

15,00 0 mile s (24,00 0 km ) o r 1 2

month s an d replace every 30,00 0

mile s (48,00 0 km ) o r 2 4 month s

whicheve r come s first .

ACL HOUSIN G

ProCarManuals.com

Page 336 of 1771

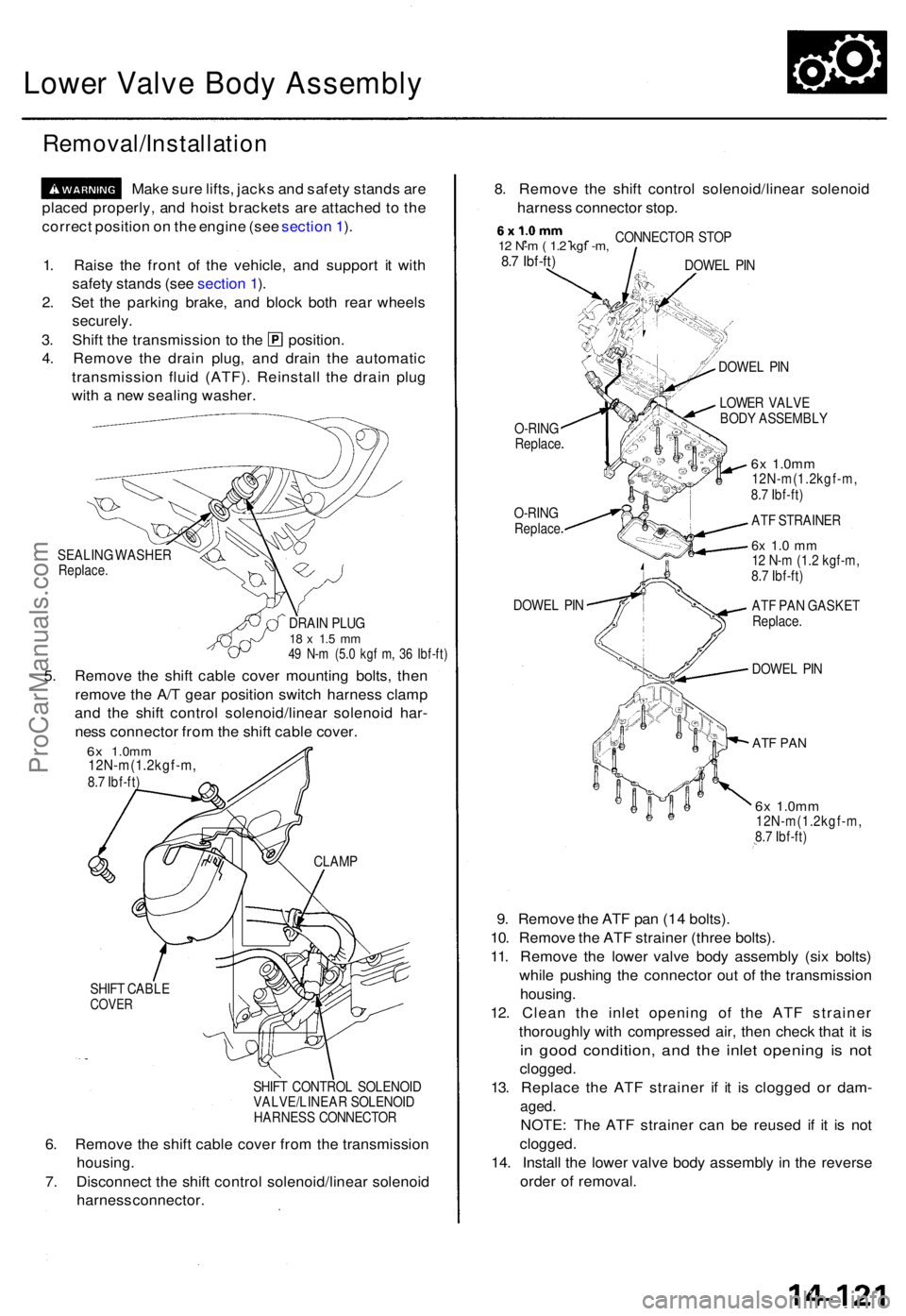

Lower Valv e Bod y Assembl y

Removal/Installatio n

Make sur e lifts , jack s an d safet y stand s ar e

place d properly , an d hois t bracket s ar e attache d to th e

correc t positio n o n th e engin e (se e sectio n 1 ).

SEALIN G WASHE RReplace.

DRAIN PLU G18 x 1. 5 m m49 N- m (5. 0 kg f m , 3 6 Ibf-ft )

5. Remov e th e shif t cabl e cove r mountin g bolts , the n

remov e th e A/ T gea r positio n switc h harnes s clam p

an d th e shif t contro l solenoid/linea r solenoi d har -

nes s connecto r fro m th e shif t cabl e cover .

6x 1.0m m12N-m(1.2kgf-m ,8.7 Ibf-ft )

SHIF T CABL E

COVER

SHIFT CONTRO L SOLENOI D

VALVE/LINEA R SOLENOI D

HARNES S CONNECTO R

6. Remov e th e shif t cabl e cove r fro m th e transmissio n

housing.

7. Disconnec t th e shif t contro l solenoid/linea r solenoi d

harnes s connector . 8

. Remov e th e shif t contro l solenoid/linea r solenoi d

harnes s connecto r stop .

, . .12 N- m ( 1. 2 kg f -m ,8.7 Ibf-ft )

CONNECTO R STO P

DOWE L PI N

O-RIN G

Replac e

O-RINGReplac e

DOWEL PI N DOWE

L PI N

LOWE R VALV E

BOD Y ASSEMBL Y

6x 1.0m m12N-m(1.2kgf-m ,

8. 7 Ibf-ft )

AT F STRAINE R

6x 1. 0 m m12 N- m (1.2 kgf-m ,

8. 7 Ibf-ft )

AT F PA N GASKE T

Replace .

DOWEL PI N

AT F PA N

6x 1.0m m12N-m(1.2kgf-m ,

8. 7 Ibf-ft )

9. Remov e th e AT F pa n (1 4 bolts) .

10 . Remov e th e AT F straine r (thre e bolts) .

11 . Remov e th e lowe r valv e bod y assembl y (si x bolts )

whil e pushin g th e connecto r ou t o f th e transmissio n

housing .

12 . Clea n th e inle t openin g o f th e AT F straine r

thoroughl y wit h compresse d air , the n chec k tha t i t i s

in goo d condition , an d th e inle t openin g i s no t

clogged .

13. Replac e th e AT F straine r i f i t i s clogge d o r dam -

aged.

NOTE : Th e AT F straine r ca n b e reuse d i f i t i s no t

clogged .

14 . Instal l th e lowe r valv e bod y assembly in th e revers e

orde r o f removal .

1

. Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3. Shif t th e transmissio n t o th e position .

4 . Remov e th e drai n plug , an d drai n th e automati c

transmissio n flui d (ATF) . Reinstal l th e drai n plu g

wit h a ne w sealin g washer .

CLAMP

ProCarManuals.com

Page 354 of 1771

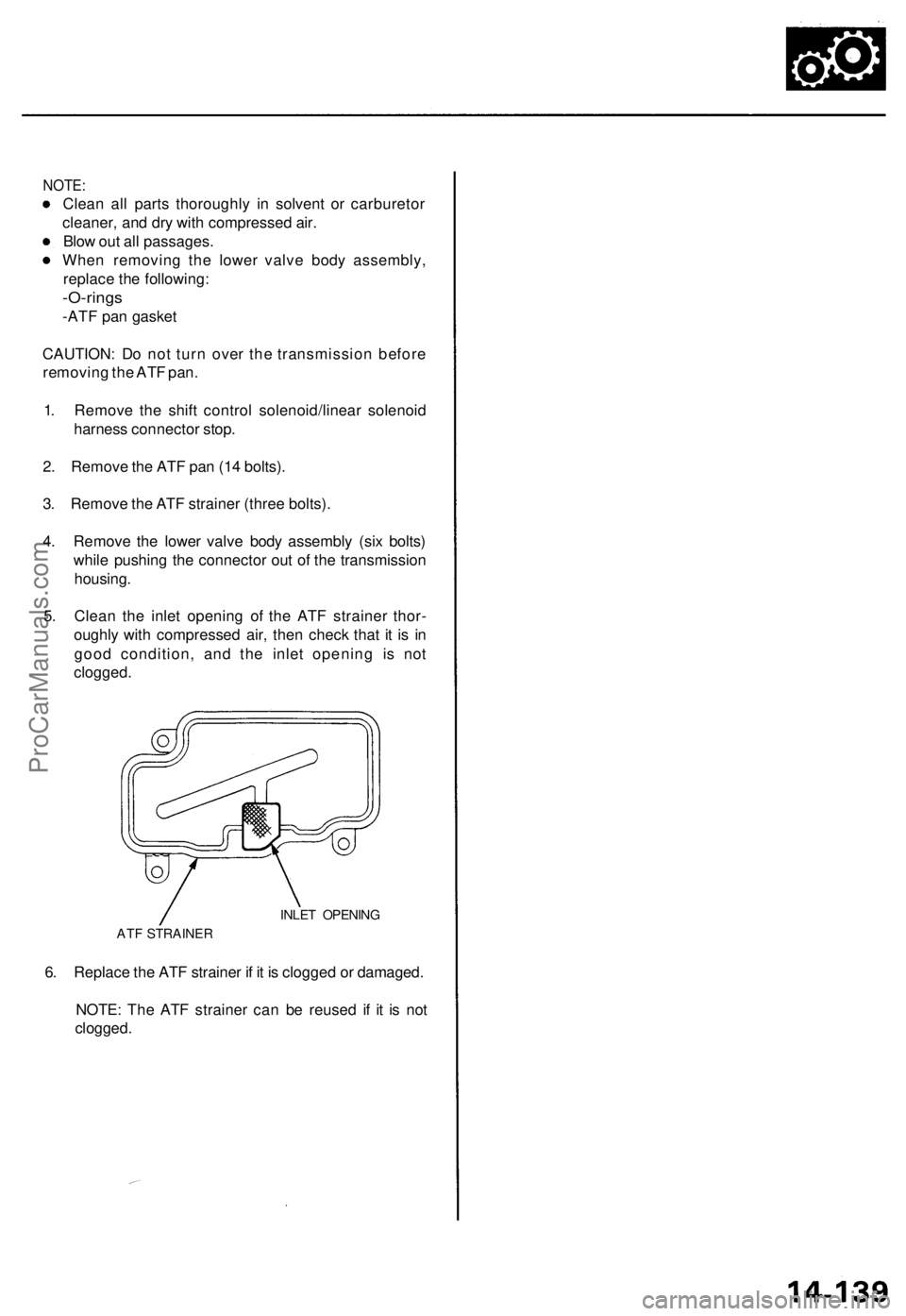

NOTE:

Clean all parts thoroughly in solvent or carburetor

cleaner, and dry with compressed air.

Blow out all passages.

When removing the lower valve body assembly,

replace the following:

-O-rings

-ATF pan gasket

CAUTION: Do not turn over the transmission before

removing the ATF pan.

1. Remove the shift control solenoid/linear solenoid

harness connector stop.

2. Remove the ATF pan (14 bolts).

3. Remove the ATF strainer (three bolts).

4. Remove the lower valve body assembly (six bolts)

while pushing the connector out of the transmission

housing.

5. Clean the inlet opening of the ATF strainer thor-

oughly with compressed air, then check that it is in

good condition, and the inlet opening is not

clogged.

INLET OPENING

ATF STRAINER

6. Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is not

clogged.ProCarManuals.com