technical specifications Alfa Romeo 147 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2007, Model line: 147, Model: Alfa Romeo 147 2007Pages: 291, PDF Size: 5.52 MB

Page 7 of 291

5

THE SYMBOLS USED IN THIS BOOKLET

The symbols illustrated in these pages show the subjects

which should, in particular, be closely studied.

This indicates the correct procedures

to be followed to prevent the vehicle from

damaging the environment. Warning. Partially or

fully ignoring these rules may lead to

serious injury.Warning. Partially or fully ignoring these

rules may lead to serious damage being

caused to the vehicle which, in some

circumstances, may cause forfeiture

of the warranty cover.

PERSONAL

SAFETYPROTECTING THE

ENVIRONMENTVEHICLE

SAFETY

The texts, illustrations and specifications given in this booklet refer to the vehicle

at the time of going to press.

As part of our ongoing striving to improve our products, Alfa Romeo may introduce technical changes during

production, therefore the specifications and fittings may be altered without prior notice.

For details on this subject, please apply to the manufacturer’s sales network.

Page 132 of 291

GETTING TO KNOW YOUR CAR

130fig. 132

A0A0437m

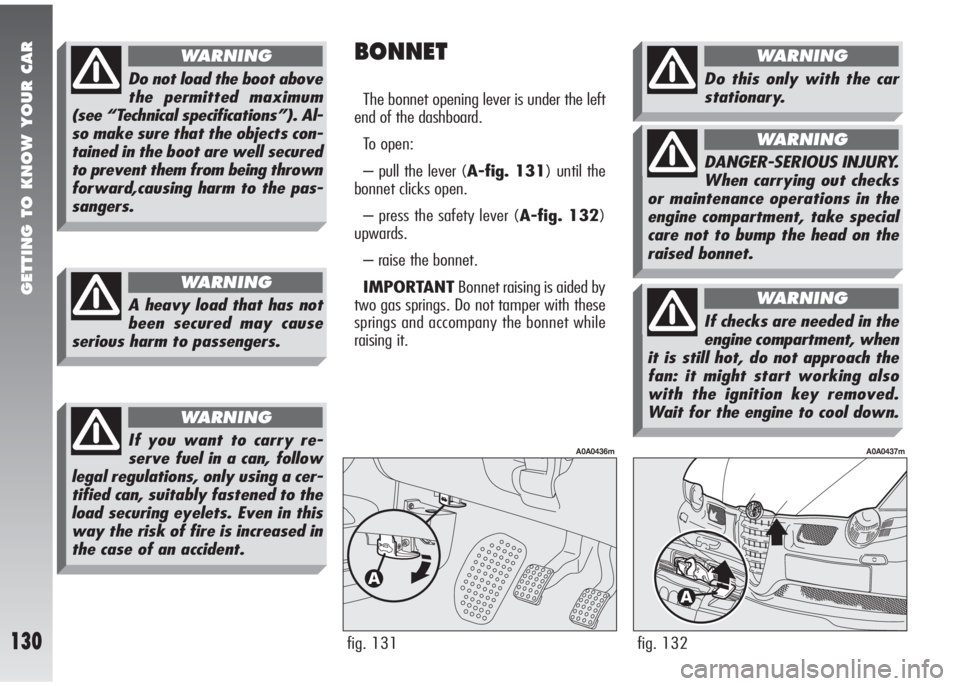

BONNET

The bonnet opening lever is under the left

end of the dashboard.

To open:

– pull the lever (A-fig. 131) until the

bonnet clicks open.

– press the safety lever (A-fig. 132)

upwards.

– raise the bonnet.

IMPORTANTBonnet raising is aided by

two gas springs. Do not tamper with these

springs and accompany the bonnet while

raising it.

fig. 131

A0A0436m

A heavy load that has not

been secured may cause

serious harm to passengers.

WARNING

Do not load the boot above

the permitted maximum

(see “Technical specifications”). Al-

so make sure that the objects con-

tained in the boot are well secured

to prevent them from being thrown

forward,causing harm to the pas-

sangers.

WARNING

If you want to carry re-

serve fuel in a can, follow

legal regulations, only using a cer-

tified can, suitably fastened to the

load securing eyelets. Even in this

way the risk of fire is increased in

the case of an accident.

WARNING

Do this only with the car

stationary.

WARNING

DANGER-SERIOUS INJURY.

When carrying out checks

or maintenance operations in the

engine compartment, take special

care not to bump the head on the

raised bonnet.

WARNING

If checks are needed in the

engine compartment, when

it is still hot, do not approach the

fan: it might start working also

with the ignition key removed.

Wait for the engine to cool down.

WARNING

Page 133 of 291

GETTING TO KNOW YOUR CAR

131

To close:

– lower the bonnet until approx. 20 cm

from the engine compartment and then let

it drop, ensuring that it is fully closed and

not just held in position by the safety catch.

If the bonnet does not close properly do

not push it down but open it again and re-

peat the above procedure.

Scarves, ties and other loose

clothing might be pulled by

moving parts.

WARNING

For safety reasons the

bonnet shall always be

perfectly closed when travelling.

Always check for proper bonnet

locking. If the bonnet is left inad-

vertently open, stop the car im-

mediately and close the bonnet.

WARNING

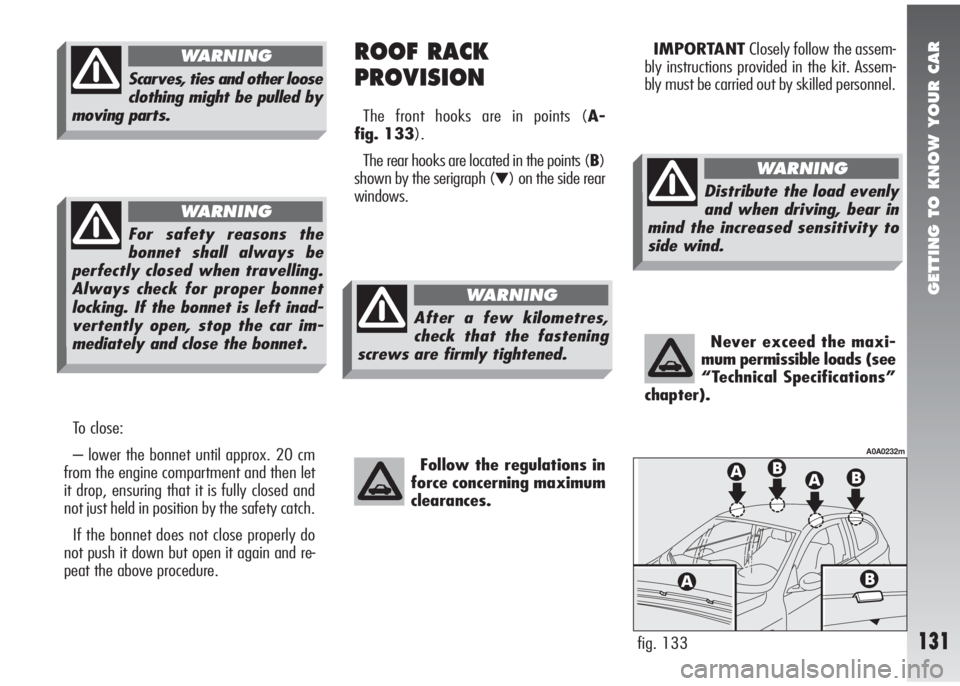

ROOF RACK

PROVISION

The front hooks are in points (A-

fig. 133).

The rear hooks are located in the points (B)

shown by the serigraph (

▼) on the side rear

windows.

Follow the regulations in

force concerning maximum

clearances.

IMPORTANTClosely follow the assem-

bly instructions provided in the kit. Assem-

bly must be carried out by skilled personnel.

Never exceed the maxi-

mum permissible loads (see

“Technical Specifications”

chapter).

fig. 133

A0A0232m

After a few kilometres,

check that the fastening

screws are firmly tightened.

WARNING

Distribute the load evenly

and when driving, bear in

mind the increased sensitivity to

side wind.

WARNING

Page 187 of 291

CORRECT USE OF THE CAR

185

IMPORTANTWhen winter tyres are

used with a maximum speed index below

the one that can be reached by the vehicle

(increased by 5%), place a notice in the pas-

senger compartment, plainly in the driver’s

view which states the maximum permissi-

ble speed of the winter tyres (as per CE Di-

rective).

Fit the same type of tyre on all four wheels

(brand and profile) to ensure higher driving

safety when braking and good handling.

Remember that it is inappropriate to

change the direction of rotation of tyres. WINTER TYRES

These tyres are specially designed for dri-

ving on snow and ice, to be fitted in re-

placement of those fitted on the car.

Use winter tyres of the same size as the

normal tyres provided on the car.

Alfa Romeo Authorised Services will be

pleased to advise you on the choice of the

car most suited to the use the Customer in-

tends to make of it.

For the type of tyre to be used, inflation

pressures and the specifications of winter

tyres, follow the instructions given in the

“Technical Specifications” chapter.

The winter features of these tyres are re-

duced considerably when the tread depth

is below 4 mm. In this case, they should be

replaced.

Due to the winter features, under normal

conditions of use or on long motorway jour-

neys, the performance of these tyres is low-

er than that of normal tyres.

It is necessary therefore to limit their use to

the purposes for which they are certified.

TRAILER TOWING

The car does not have the approval to tow

trailers.

Page 231 of 291

VEHICLE MAINTENANCE

229

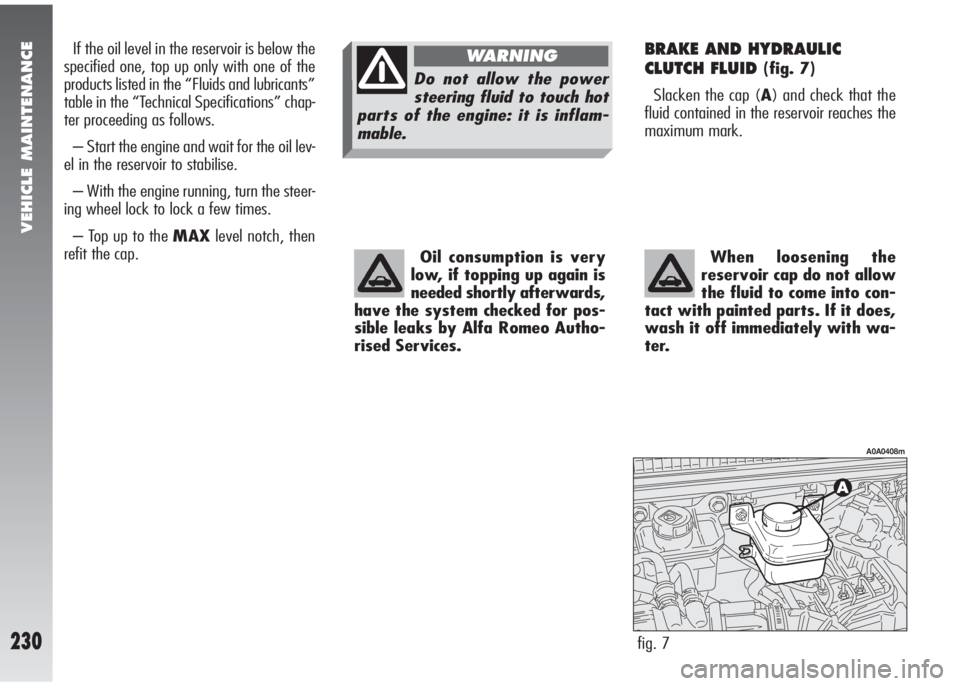

POWER STEERING FLUID

(fig. 6)

Check that the level of the oil in the reser-

voir is at maximum.

This operation should be carried out with

the vehicle on a level surface and the en-

gine switched off and cold.

Check that the level reaches the MAX

mark on the reservoir or coincides with the

upper notch (maximum level) on the dip-

stick (A) integral with the reservoir cap. The cooling system is

pressurised. If necessary,

replace the cap only with

another genuine one, otherwise

system efficiency could be compro-

mised.

Top up only with the same

fluid contained in the cool-

ing circuit. PARAFLU UP

(red) cannot be mixed with

PARAFLU 11 (blue) or with other

fluids. Should this take place, do

not start the engine and contact Al-

fa Romeo Authorized Service.

fig. 6

A0A0407m

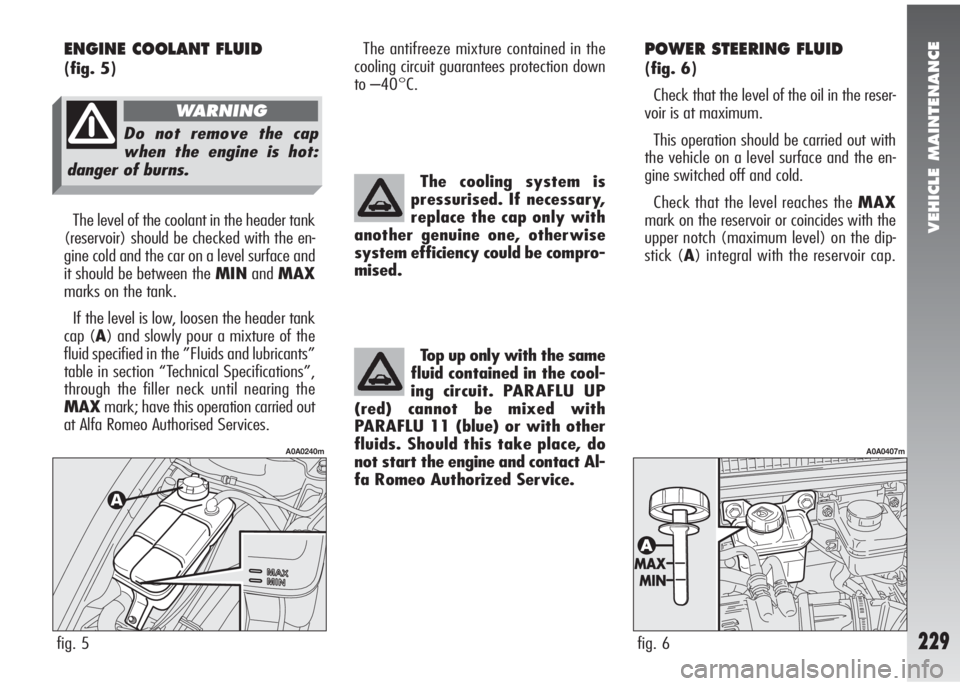

ENGINE COOLANT FLUID

(fig. 5)

The level of the coolant in the header tank

(reservoir) should be checked with the en-

gine cold and the car on a level surface and

it should be between the MINandMAX

marks on the tank.

If the level is low, loosen the header tank

cap (A) and slowly pour a mixture of the

fluid specified in the ”Fluids and lubricants”

table in section “Technical Specifications”,

through the filler neck until nearing the

MAXmark; have this operation carried out

at Alfa Romeo Authorised Services.

fig. 5

A0A0240m

The antifreeze mixture contained in the

cooling circuit guarantees protection down

to –40°C.

Do not remove the cap

when the engine is hot:

danger of burns.

WARNING

Page 232 of 291

VEHICLE MAINTENANCE

230

If the oil level in the reservoir is below the

specified one, top up only with one of the

products listed in the “Fluids and lubricants”

table in the “Technical Specifications” chap-

ter proceeding as follows.

– Start the engine and wait for the oil lev-

el in the reservoir to stabilise.

– With the engine running, turn the steer-

ing wheel lock to lock a few times.

– Top up to the MAXlevel notch, then

refit the cap.

Oil consumption is very

low, if topping up again is

needed shortly afterwards,

have the system checked for pos-

sible leaks by Alfa Romeo Autho-

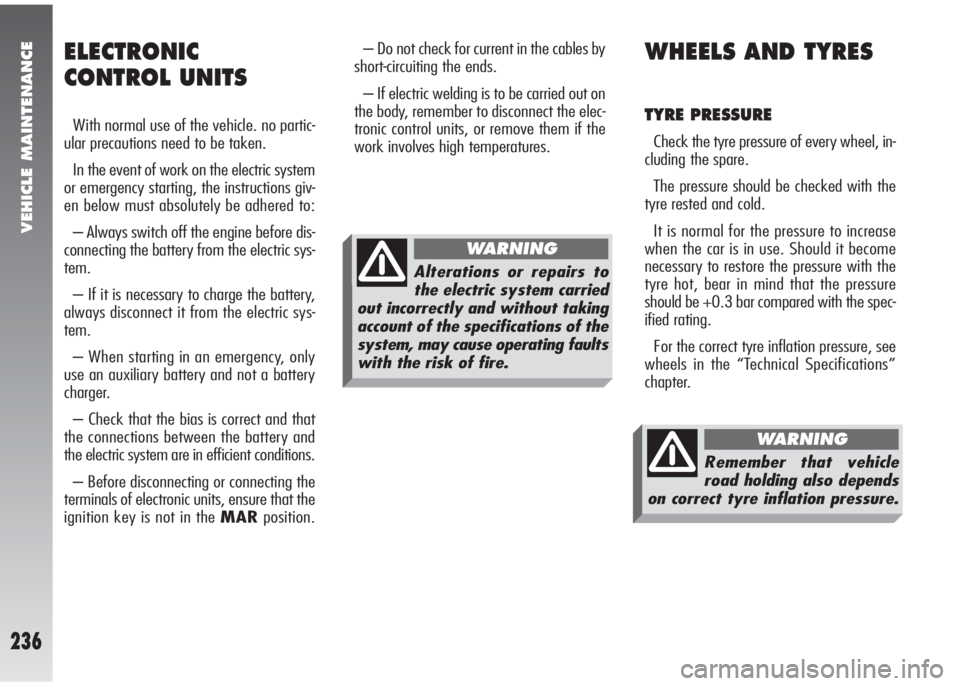

rised Services.BRAKE AND HYDRAULIC

CLUTCH FLUID

(fig. 7)

Slacken the cap (A) and check that the

fluid contained in the reservoir reaches the

maximum mark.

fig. 7

A0A0408m

When loosening the

reservoir cap do not allow

the fluid to come into con-

tact with painted parts. If it does,

wash it off immediately with wa-

ter.

Do not allow the power

steering fluid to touch hot

parts of the engine: it is inflam-

mable.

WARNING

Page 238 of 291

VEHICLE MAINTENANCE

236

– Do not check for current in the cables by

short-circuiting the ends.

– If electric welding is to be carried out on

the body, remember to disconnect the elec-

tronic control units, or remove them if the

work involves high temperatures.ELECTRONIC

CONTROL UNITS

With normal use of the vehicle. no partic-

ular precautions need to be taken.

In the event of work on the electric system

or emergency starting, the instructions giv-

en below must absolutely be adhered to:

– Always switch off the engine before dis-

connecting the battery from the electric sys-

tem.

– If it is necessary to charge the battery,

always disconnect it from the electric sys-

tem.

– When starting in an emergency, only

use an auxiliary battery and not a battery

charger.

– Check that the bias is correct and that

the connections between the battery and

the electric system are in efficient conditions.

– Before disconnecting or connecting the

terminals of electronic units, ensure that the

ignition key is not in the MARposition.

WHEELS AND TYRES

TYRE PRESSURE

Check the tyre pressure of every wheel, in-

cluding the spare.

The pressure should be checked with the

tyre rested and cold.

It is normal for the pressure to increase

when the car is in use. Should it become

necessary to restore the pressure with the

tyre hot, bear in mind that the pressure

should be +0.3 bar compared with the spec-

ified rating.

For the correct tyre inflation pressure, see

wheels in the “Technical Specifications”

chapter.

Alterations or repairs to

the electric system carried

out incorrectly and without taking

account of the specifications of the

system, may cause operating faults

with the risk of fire.

WARNING

Remember that vehicle

road holding also depends

on correct tyre inflation pressure.

WARNING

Page 245 of 291

TECHNICAL SPECIFICATIONS

243

IDENTIFICATION

LABEL

This (fig. 2) is to be found on the front

cross member of the engine compartment.

It contains the following information:

(A)Space for details of national ho-

mologation

(B)Space for punching the consecutive

chassis number

(C)Space available for maximum

weights authorised by various na-

tional regulations

(D)Space for version and any supple-

mentary indications to those speci-

fied(E)Space for smoke coefficient (Diesel

versions)

(F)Space for punching manufacturer’s

name.

BODYWORK LABEL

This is located in the engine bay, to one

side of the upper right shock absorber

(fig. 3) and contains:

– Type of vehicle: ZAR 937.000

– Manufacturer’s serial number (chassis

number).

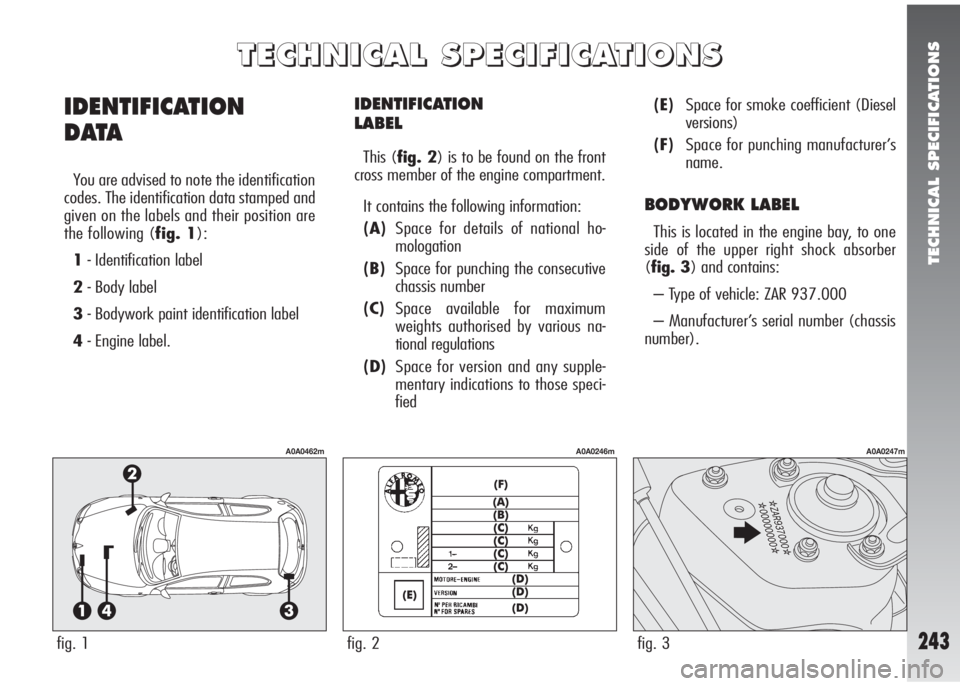

IDENTIFICATION

D ATA

You are advised to note the identification

codes. The identification data stamped and

given on the labels and their position are

the following (fig. 1):

1- Identification label

2- Body label

3- Bodywork paint identification label

4- Engine label.

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

fig. 1

A0A0462m

fig. 2

A0A0246m

fig. 3

A0A0247m

Page 246 of 291

TECHNICAL SPECIFICATIONS

244

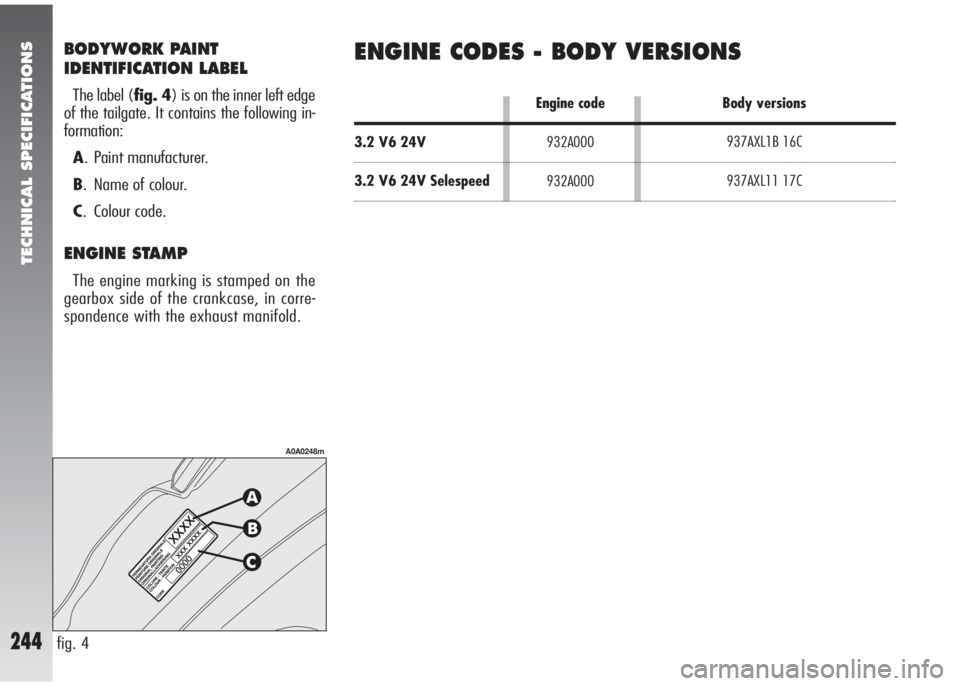

BODYWORK PAINT

IDENTIFICATION LABEL

The label (fig. 4) is on the inner left edge

of the tailgate. It contains the following in-

formation:

A. Paint manufacturer.

B. Name of colour.

C. Colour code.

ENGINE STAMP

The engine marking is stamped on the

gearbox side of the crankcase, in corre-

spondence with the exhaust manifold.

fig. 4

A0A0248m

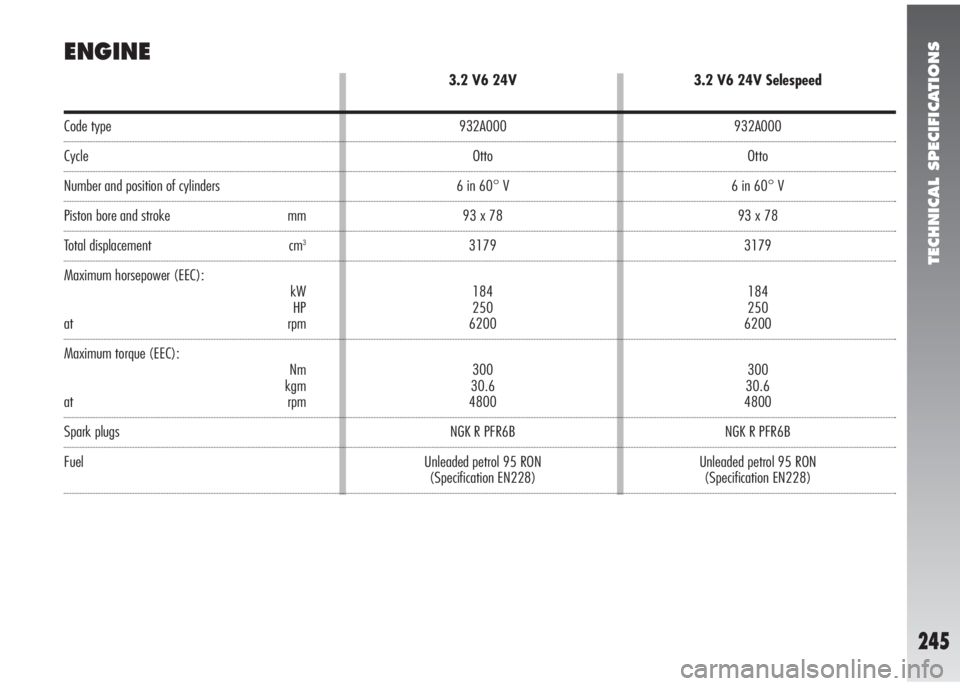

ENGINE CODES - BODY VERSIONS

3.2 V6 24V

3.2 V6 24V Selespeed937AXL1B 16C

937AXL11 17C Engine code

932A000

932A000Body versions

Page 247 of 291

TECHNICAL SPECIFICATIONS

245

Code type

Cycle

Number and position of cylinders

Piston bore and stroke mm

Total displacement cm3

Maximum horsepower (EEC):

kW

HP

at rpm

Maximum torque (EEC):

Nm

kgm

at rpm

Spark plugs

Fuel

ENGINE

3.2 V6 24V

932A000

Otto

6 in 60° V

93 x 78

3179

184

250

6200

300

30.6

4800

NGK R PFR6B

Unleaded petrol 95 RON

(Specification EN228)

3.2 V6 24V Selespeed

932A000

Otto

6 in 60° V

93 x 78

3179

184

250

6200

300

30.6

4800

NGK R PFR6B

Unleaded petrol 95 RON

(Specification EN228)