Alfa Romeo 156 2006 Owner handbook (in English)

Manufacturer: ALFA ROMEO, Model Year: 2006, Model line: 156, Model: Alfa Romeo 156 2006Pages: 357, PDF Size: 5.04 MB

Page 181 of 357

GETTING TO KNOW YOUR CAR

179

If the

x

low brake fluid

warning light comes on (to-

gether with the message + symbol

shown by the display), stop the car

immediately and contact the near-

est Alfa Romeo Authorized Ser-

vices. Indeed, any leak of fluid

from the hydraulic system com-

promises the effectiveness of both

the conventional brake system and

the system with antilock system.

WARNING

The turning on of the

>

warning light (together

with the message + symbol shown

by the display) with the engine

running normally indicates an ABS

system fault. In this case the brak-

ing system preserves its effec-

tiveness, without however making

use of the antilock device. Under

these circumstances, the EBD sys-

tem may fail to give top perfor-

mance. In this case, too, you are

recommended to contact Alfa

Romeo Authorized Services imme-

diately, driving in such a way as to

avoid abrupt braking, to have the

system checked.

WARNING

VDC AND ASR

SYSTEMS(where required)VDC SYSTEM (VEHICLE

DYNAMICS CONTROL):

GENERALThe VDC is an electronic vehicle stability

control system which, acting on the torque

and braking the wheels in a differentiated

manner, helps to bring the car back to the

correct course in the event of loss of grip.

While travelling the car is subjected to lat-

eral and longitudinal forces that may be

controlled by the driver up to when the

tyres offer adequate road-holding; when

this falls below the minimum level, the car

starts to deviate from the course required

by the driver.

Above all on rough surfaces (such as cob-

bles, or due to the presence of water, ice

or soil), changes in speed (when accelerat-

ing or braking) and/or course (bends or the

need to avoid obstacles) can cause the tyres

to lose grip.When the sensors detect the conditions

that would lead to skidding, the VDC system

acts on the engine and brakes generating

a stabilising torque.

The system performance

levels, in terms of active

safety, should not induce the dri-

ver to run pointless and unjustified

risks. Driving conduct should al-

ways be suited to the conditions of

the road surface, vision and traf-

fic. The responsibility for road

safety is always and anyway the

vehicle driver’s concern.

The VDC system helps the driver

to keep control of the car in the

event of loss of tyre grip.

The forces induced by the VDC sys-

tem to control the lack of stability

of the car always and anyway de-

pend on the grip between the tyre

and the road surface.

WARNING

Page 182 of 357

GETTING TO KNOW YOUR CAR

180

The heart of the VDC system is the VDC

control unit which with the data supplied by

the sensors installed on the car, calculates

the centrifugal forces generated when the

car is cornering. The yawing sensor detects

the rotations of the car around its own ver-

tical axis. The centrifugal forces generated

when the car is cornering are detected by

a highly sensitive lateral acceleration sensor.

The stabilising action of the VDC system is

based on calculations made by the

system’s electronic control unit which

processes the signals received from the

steering wheel rotation, lateral acceleration

and individual wheel rotation sensors. These

signals allow the control unit to recognise

the manoeuvre the driver intends to do

when turning the steering wheel.

The control unit processes the information

received from the sensors and is therefore

capable of detecting the position of the car

and comparing it with the trajectory the dri-

ver would like to follow instant by instant.

In the event of a discrepancy, the control

unit chooses and commands the most suit-

able action to bring the car back to the re-

quired course within a fraction of a second:

braking one or more wheels at a different

braking force and, if necessary it reduces the

power transmitted by the engine. The corrective actions are changed and con-

trolled continuously until the car returns to

the required course.

The action of the VDC system considerably

increases the active safety of the vehicle un-

der many critical situations and it is partic-

ularly useful also when the road surface grip

conditions change.

For the VDC, ASR and ABS

systems to work correctly,

the tyres must be of the same

brand and type on all wheels, in

perfect conditions and above all of

the specified type, brand and size.

WARNING

During use of the compact

spare wheel, the VDC sys-

tem continues working. It should be

borne in mind that the spare wheel

is smaller than a normal tyre,

therefore its grip is lower than that

of the other tyres of the car.

WARNING

VDC SYSTEM OPERATIONThe VDC system turns on automatically

when the car is started and cannot be

switched off. It is however possible to cut

off operation of the ASR system pressing the

corresponding button on the centre console.

The main components of the VDC system

are:

– an electronic control unit which

processes the signals received from the var-

ious sensors and brings about the most ap-

propriate strategy;

– a sensor that detects the position of the

steering wheel;

– four sensors that detect the rotation

speed of each wheel;

– a sensor that detects rotation of the car

around the vertical axis;

– a sensor that detects lateral acceleration

(centrifugal force).

Page 183 of 357

GETTING TO KNOW YOUR CAR

181

ASR FUNCTION (ANTISLIP

REGULATION): GENERALThe ASR system integrates the VDC sys-

tem controlling the vehicle drive and com-

ing into operation automatically each time

one or both driving wheels skid.

Two different control systems are activated,

depending on the skidding conditions:

– If skidding concerns both driving wheels,

because it is caused by the excessive power

transmitted, the ASR system cuts in reduc-

ing the power transmitted by the engine.

– If skidding concerns only one driving

wheel, the ASR system cuts in automatically

braking the skidding wheel, with an effect

similar to that of a self-locking differential.The action of the ASR system is particularly

helpful under the following conditions:

– Skidding of the inner wheel on a bend,

due to the effect of the dynamic changes of

the load or over-accelerating.

– Excessive power transmitted to the

wheels, also in relation to the conditions of

the road surface.

– Acceleration on slippery, snowy or icy

surfaces.

– In the case of loss of grip on a wet sur-

face (aquaplaning).

CUTTING IN OF THE VDC

SYSTEMThe cutting in of the VDC system is indi-

cated by the flashing of the warning lightá

on the instrument cluster, to inform the

driver that the car is in critical conditions of

stability and grip.

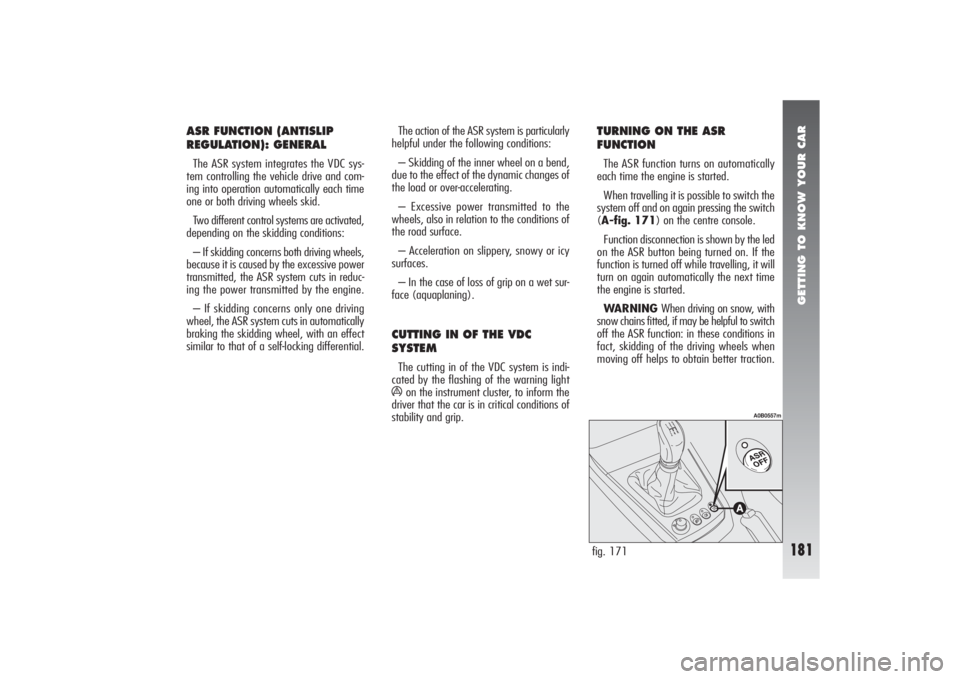

TURNING ON THE ASR

FUNCTIONThe ASR function turns on automatically

each time the engine is started.

When travelling it is possible to switch the

system off and on again pressing the switch

(A-fig. 171

) on the centre console.

Function disconnection is shown by the led

on the ASR button being turned on. If the

function is turned off while travelling, it will

turn on again automatically the next time

the engine is started.

WARNING When driving on snow, with

snow chains fitted, if may be helpful to switch

off the ASR function: in these conditions in

fact, skidding of the driving wheels when

moving off helps to obtain better traction.

fig. 171

A0B0557m

Page 184 of 357

GETTING TO KNOW YOUR CAR

182

EOBD SYSTEMThe EOBD (European On Board Diagnosis)

system fitted in the car conforms with the

98/69/EC (EURO 3) Directive and the

2001/1/EC Directive, level B (EURO4) for

2.0 JTS, 2.0 JTS Selespeed and JTD 20V

Multijet versions.

This system continuously monitors the

components of the vehicle related to emis-

sions; it also indicates, when the warning

light

U

comes on on the instrument panel

(together with the message + symbol

shown by the display) that the components

in question are in poor conditions.

The objective is the following:

– to keep under control the efficiency of

the system;

– to indicate when a malfunction causes

an increase in the emissions beyond the

threshold established by European regula-

tions;

– to indicate the need to replace the de-

teriorated components.

The system also has a diagnostic connec-

tor, which can be interfaced with adequate in-

struments, that enables the error codes stored

in the control unit to be read, together with

a series of specific parameters concerning the

operation and diagnosis of the engine.This check can also be made by the traf-

fic control agents.

If, when the ignition key

is turned to MAR, the

U

warning light does not

come on or if, when driving, it

lights up and emits a fixed light or

a flashing one (together with the

message + symbol shown by the

display), contact an Alfa Romeo

Authorized Service Station as soon

as possible. The operation of the

U

warning light can also be

checked by means of special equip-

ment available to the traffic con-

trol officers. Comply with the reg-

ulations in force in country where

you drive your car.

WARNINGAfter the problem has beel

resolved, to completely check the system,

the Alfa Romeo Authorized Services must

carry out tests on a test bench and, if nec-

essary, road tests that could be long.

WARNING LIGHT ON

INSTRUMENT PANELWhen the ignition key is turned to MAR,

the dial warning light

á

comes on but must

go out after a few seconds.

If the warning light does not go out, or if it

stays on (together with the message + sym-

bol on the display and the coming on of the

ASR button led) when the vehicle is running,

contact Alfa Romeo Authorized Services.

The flashing of the warning lamp when the

vehicle is running indicates the actuation of

the VDC system.

VDC system failure warning

In the event of a failure the VDC system

disengages automatically and the

á

warn-

ing light on the instrument cluster turns on

glowing steadily (together with the message

+ symbol shown on the display and the com-

ing on of the ASR button led).

In the event of a VDC system failure the

car behaves like a vehicle not fitted with this

system: in any case it is advisable to con-

tact Alfa Romeo Authorized Services as soon

as possible.

Page 185 of 357

GETTING TO KNOW YOUR CAR

183

SOUND SYSTEM(where applicable)

The fixed sound system, with cassette

player (radio with cassette player) or CD

player with parametric sound equalizer (ra-

dio with CD player) has been designed to

suit the specific characteristics of the pas-

senger compartment, with a personalised

design that matches the style of the dash-

board. The sound system instructions for use

are described in the attached supplement.

SOUND SYSTEM

PRESETTING SYSTEM(for versions/markets where

applicable)

The car, if not delivered with sound sys-

tem, is fitted with a glove compartment

(fig. 172) on the instrument panel.

Sound system presetting system includes

the following:

– sound system power cables;

– front and rear speaker power cables;

– aerial power cable;

– sound system housing;

– aerial on car roof (where provided).The sound system shall be installed in the

proper housing occupied by the glove com-

partment that can be removed by pressing

the two retaining tabs in the glove com-

partment: here are the power cables.

If after buying the car you

want to install the sound

system, contact first Alfa

Romeo Authorised Services whose

qualified personnel, in addition to

suggesting the most suitable de-

vices, will evaluate the overall

electric absorption to safeguard the

battery. Excessive loadless ab-

sorption could damage the battery

and lose warranty.fig. 172

A0B742m

Page 186 of 357

GETTING TO KNOW YOUR CAR

184

The wiring diagram is the following (fig.

173):

Connector A

A1N.C.

A2N.C.

A3N.C.

A4+ 30 (battery-powered)

A5Aerial power supply

A6Light

A7+ 15 (key-powered)

A8Ground

Connector B

B1RH rear speaker

B2RH rear speaker

B3RH front speaker

B4RH front speaker

B5LH front speaker

B6LH front speaker

B7LH rear speaker

B8LH rear speaker

TECHNICAL INFORMATIONSpeakers (fig. 174-175)

For cars fitted with presetting system, the

sound system includes the following:

– 2 tweeters (A-fig. 174), with 30W

power;

– 4 speakers (B-fig. 174) and (A-fig.

175), 165 mm diameter (2 front and 2

rear), with 40W power.Aerial

For versions/markets where applicable,

the aerial can be built into the rear heated

window or can be located on the car roof.fig. 173

A0B741m

fig. 174

A0B387m

fig. 175

A0B237m

Page 187 of 357

GETTING TO KNOW YOUR CAR

185

REFUELLING PETROL ENGINESIn order to prevent the vehicle being filled

with leaded petrol, the diameter of the filler

neck is smaller than the nozzle used on

pumps delivering leaded petrol.At low temperatures, the degree of fluid-

ity of fuel oil may become insufficient due

to the formation of paraffins leading to dan-

ger of clogging the fuel oil filter.

Therefore, to avoid inconveniences, sum-

mer and winter fuel oils are normally dis-

tributed depending on the season.

However, during the intermediate season,

characterised by a large difference between

outside temperatures (0°C to 15°C), the

quality of the fuel oil distributed to the

pumps may not be adequate.

In this case, and above all if the use of the

car involves stopping and then starting again

at low temperatures (e.g. mountains),

make sure the car is filled with winter fuel

oil; if not, you are advised to mix the fuel

oil with a DIESEL MIXadditive in the pro-

portions stated on the can, pouring first the

antifreeze and then the fuel oil into the tank.

TheDIESEL MIXantifreeze should be

mixed with the fuel oil before reactions due

to cold take place. Adding it too late will

prove pointless. The anti-pollution devices

present on the vehicle im-

pose the use of four-star

unleaded fuel with an octane num-

ber (R.O.N.) above 95.

Under no circumstances

should conventional leaded

petrol be used, as this

would irreparably damage the cat-

alyst. If the tank is accidentally

filled with leaded fuel, even in

minute quantities, DO NOT START

THE ENGINE. Do not attempt to di-

lute the petrol with lead free fuel.

Drain the entire fuel circuit and

tank.

If the catalyst is not

working properly, harmful

emissions reach the ex-

haust, resulting in environment pol-

lution.The car must be refuelled

only with fuel oil for motor

vehicles, in conformity with

European specification EN590. The

use of other products or mixtures

may damage the engine irrepara-

bly, resulting in invalidation of the

warranty for the damage caused.

If the tank is accidentally filled

with another type of fuel, do not

start the engine but drain the tank.

If the engine has been run even for

a brief period, the tank must be

drained together with the entire

fuel circuit.

JTD ENGINES

Page 188 of 357

GETTING TO KNOW YOUR CAR

186

FUEL CAP

(fig. 176)

The fuel flap is released from inside the

car, raising the front part of the lever (A).

The fuel cap (A-fig. 177) has a catch

to prevent misplacing it (B) that fastens it

to the flap (C).

WARNINGThe fuel tank is sealed her-

metically and pressure may build up inside.

Any noise of rushing air when the cap is re-

moved is perfectly normal.

fig. 176

A0B0044m

fig. 177

A0B0045m

In case of need, replace

the fuel cap only with an

original one; otherwise,

the efficiency of the petrol vapour

recovery system could be badly af-

fected.

EMERGENCY FLAP OPENING

DEVICEIf the lever (A-fig. 176) fails to work,

it is still possible to open the flap by pulling

the cord (A-fig. 178) on the right-hand

side of the luggage compartment.fig. 178

A0B0388m

WARNINGFor your safety, make sure

that the fuelling pump nozzle is inserted cor-

rectly into the housing, before starting the

engine.

Do not get near the fuel

filler with naked flames or

lit cigarettes: danger of fire. Also

avoid going too near the filler with

the face to avoid inhaling harmful

vapours.

WARNING

Page 189 of 357

GETTING TO KNOW YOUR CAR

187

ENVIRONMENTAL

PROTECTIONThe design and construction of the vehi-

cle have not only been developed with the

traditional aspects of performance and

safety in mind, but also take into account

the increasingly pressing problems tied to

protecting the environment.

The choice of materials, techniques and

particular parts are the result of work which

has made it possible to drastically reduce

the harmful effects on the environment and

guarantee respect for the severest interna-

tional norms.USE OF NON-TOXIC

MATERIALSNone of the components of the vehicle con-

tains asbestos. The padding and the climate

control system do not contain CFCs which

are held to be responsible for the depletion

of the ozone layer.

The colouring agents and the corrosion in-

hibitors used on the nuts, screws and bolts

do not contain cadmium any more, which

could pollute the atmosphere or water tables.

PARKING SENSORS

(WHERE PROVIDED)(optional for versions/markets

where applicable)

The parking system detects and informs

the driver (through an intermittent acoustic

signal) about the presence of obstacles in

the rear part of the car (fig. 179). ACTIVATIONThe sensors are automatically activated

when the reverse gear is engaged.

The sound produced by the acoustic alarm

becomes continuous when the distance be-

tween the car and the obstacle is less that

30 cm.

ACOUSTIC SIGNALWhen the reverse gear is engaged an in-

termittent acoustic signal is automatically

activated.

The acoustic signal:

– raises with the reduction of distance be-

tween the car and the obstacle;

– becomes continuous when the distance

between the car and the obstacle is less that

30 cm and stops if the distance raises.

– is constant if the distance is unvaried.

If this situation takes place for side sensors,

the signal is stopped after about 3 seconds

to prevent sound indications when per-

forming manoeuvres near walls.fig. 179

A0B0609m

Page 190 of 357

GETTING TO KNOW YOUR CAR

188

EMISSION REDUCING DEVICES

(petrol engines)Trivalent catalytic converter

(catalytic silencer)

The exhaust system is fitted with a cat-

alyzer formed of alloys of noble metals. It

is housed in a stainless steel container which

is able to resist the high operating temper-

atures.

The catalyzer converts the unburnt hydro-

carbons, carbon monoxide and nitrogen ox-

ides present in the exhaust gas (even if in

small quantities thanks to the electronic in-

jection and ignition system) into harmless

compounds.Lambda probe

A sensor (lambda probe) measures the

content of oxygen present in the exhaust

gas. The signal transmitted by the lambda

probe is use by the injection and ignition

electronic control unit to adjust the air-fuel

mixture.

Anti-evaporation system

As it is impossible, even when the engine

is switched off, to prevent the formation of

fuel vapours, a system has been devised

which imprisons the vapours in a special ac-

tivated carbon container.

During operation of the engine, these

vapours are sucked up and sent to com-

bustion.

EMISSION REDUCING DEVICES

(JTD engines )Oxidising catalytic converter

Converts the polluting substances present

in the exhaust gases (carbon monoxide, un-

burned hydrocarbons and particulate) into

harmless substances, thus reducing the

fumes and smell that are typical of diesel

engines.

The catalytic converter consists of a stain-

less steel case that houses a ceramic hon-

eycomb body coated with noble metal used

as a catalyst.

Exhaust gas recirculation system

(E.G.R.)

This system recycles, i.e. re-uses, a vary-

ing percentage of the exhaust gases, de-

pending on engine operating conditions.

It is used, when necessary, to control ni-

tric oxides.

Due to the high tempera-

tures reached during oper-

ation of the catalytic converter, the

vehicle should not be parked over

inflammable materials (paper, fuel

oils, grass, dry leaves, etc.).

WARNING