cap Alfa Romeo 159 2006 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2006, Model line: 159, Model: Alfa Romeo 159 2006Pages: 299, PDF Size: 4.64 MB

Page 186 of 299

184

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

The space-saver spare

wheel (for versions/

markets where applicable) is

specific to your car; do not use

it on other models, or use the

spare wheel of other models

on your car. The space-saver

spare wheel shall only be used

in an emergency. It shall only

be used for the distance nec-

essary to reach a service point

and the car speed shall not ex-

ceed 80 Km/h. The spare

wheel has a sticker that sum-

marises the main cautions for

use and limitations. The stick-

er should never be removed or

covered!. Never fit a wheel

cap on a space-saver spare

wheel.

WARNING

When driving with a

space-saver spare

wheel fitted, the driving per-

formance of the car changes.

Avoid accelerating or braking

sharply, abrupt turns or fast

cornerings. The life of the

spare wheel is approx. 3000

Km, after this distance it

should be replaced with an-

other of the same type. Nev-

er attempt to fit a conven-

tional tyre on a rim designed

for use as a space-saver spare

wheel. Have the punctured

wheel repaired and refitted as

soon as possible. Two or more

space-saver spare wheels

should never be used togeth-

er. Do not grease the threads

of bolts before installing them:

they might slip out.

WARNING

The jack shall only be

used for changing

wheels on the car with which

it is provided or on cars of the

same model. It must not be used

for other purposes such as for

instance raising cars of other

models. In no case should it be

used for repairs under the car.

Incorrect positioning of the jack

may cause the jacked car to fall.

Do not use the jack for higher

capacities than stated on its la-

bel. Snow chains cannot be fit-

ted to the space-saver spare

wheel. So, if a front (drive)

wheel is punctured and chains

are needed, a rear wheel should

be fitted to the front of the car

and the spare wheel should be

fitted to the rear. This way with

two normal drive wheels, snow

chains can be fitted to them to

solve an emergency.

WARNING

Page 188 of 299

186

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

❒Loosen the bolts of the wheel to be

replaced by about one turn with the

wrench provided A-fig. 5; if the car

is fitted with alloy rims, shake the car

to facilitate removing this rim from

the wheel hub;❒Remove the wheel cap A-fig. 6

(only versions with steel rims);❒Take out the tool container fig. 4;

A0E0134mfig. 4A0E0206mfig. 5A0E0207mfig. 6

Page 191 of 299

189

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

REFITTING A

NORMAL WHEEL

Following the procedure described pre-

viously, raise the car and remove the

spare wheel.

Versions with steel rims

Proceed as follows:

❒Make sure the contact surfaces be-

tween standard wheel and hub are

clean so that the fastening bolts will not

come loose;

❒Fit the standard wheel taking into ac-

count that pin B-fig. 10shall coin-

cide with one of the holes A;

❒Place the wheel cap on the wheel rim

making symbol

C, (marked inside the

wheel cap), coincide with the inflation

valvefig. 12;

❒Using the wrench provided, tighten the

fastening bolts;

❒ Lower the car and remove the jack;

❒Using the wrench provided, fully tight-

en the bolts in the sequence shown

infig. 11;

A0E0211mfig. 13

Versions with alloy rims

Proceed as follows:

❒tighten pin A-fig. 13in one of the

holes of the wheel hub fastening

bolts;

❒insert the wheel on the pin and, us-

ing the wrench provided, tighten the

four bolts available;

❒loosen pin A-fig. 13and tighten

the last fastening bolt;

❒lower the car and remove the jack,

then, using the wrench provided tight-

en the bolts according to the sequence

previously shown for the space-saver

spare wheel fig. 11.When you have finished:

❒Stow the spare wheel in the space

provided in the boot;

❒Fit the jack partially open in its con-

tainer forcing it lightly to prevent it

from vibrating when travelling;

❒Put the tools back into their places in

the container;

❒Arrange the container complete with

tools on the space-saver spare wheel;

❒Reposition properly the boot stiff cov-

ering.

A0E0236mfig. 12

Page 194 of 299

192

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

Proceed as follows:

❒set the wheel to be repaired with

valveA-fig. 16in the position

shown in the figure, then pull up

the handbrake, take the quick

tyre repair kit and put it on the

ground near the wheel to be repaired;

❒loosen tyre inflation valve cap, take

out the filler hose A-fig. 17and

screw the ring nut B-fig. 18on the

tyre valve;

A0E0116mfig. 17

A0E0214mfig. 18

INFLATING PROCEDURE

A0E0212mfig. 16

Put on the protection

gloves provided to-

gether with quick tyre repair

kit.

WARNING

The compressor shall

not be operated for

more than 20 minutes. Risk of

overheating!. Tyres repaired

with the quick tyre repair kit

shall be used temporarily only.

WARNING

Replace the cylinder if

sealer has run out. Do

not throw away the

cylinder and the sealing fluid.

Have the sealing fluid and the

cylinder disposed of in compli-

ance with national and local reg-

ulations.

Page 201 of 299

199

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCYMain beam headlights

(halogen bulbs)

To change the bulb, proceed as follows:

❒remove cover A-fig. 25by turning

it counter-clockwise;

❒disconnect the electric connectorA-

fig. 25;

❒release the bulb holder catch B;

IF AN EXTERIOR

LIGHT BURNS OUT

For the type of bulb and power rating,

see “When needing to change a bulb”.

FRONT LIGHT UNITS

The front light units contain main beam,

sidelights, direction indicator and dipped

beam bulbs.

To change the bulbs, turn cap counter-

clockwise and then remove it.

The bulbs are arranged inside the light

unitfig. 25as follows:

AMain beam headlights

BSidelights/direction indicators

CDipped beam headlights

A0E0191mfig. 25

After replacement, re-

fit the covers correctly

checking that they are proper-

ly secured.

WARNING

A0E0223mfig. 26

❒remove the bulb and replace it;

❒fit the new bulb and refit bulb hold-

er catch B-fig. 26;

❒reconnect the electrical connector A;

❒refit the protective cover properly.

Page 229 of 299

227

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

CAR

MAINTENANCE

USE OF THE CAR

UNDER HEAVY

CONDITIONS

Should prevailing use of the car be un-

der one of the following specially heavy

conditions:

❒ trailer or caravan towing;

❒ dusty roads;

❒ short distances (less than 7-8 km)

and repeated with external temper-

atures below zero;

❒ frequently idling engines or long dis-

tance low speed driving (e.g.: door-

to-door deliveries) or in case of a long

term inactivity;

❒ urban routes;

carry out checks more frequently than

required on Service Schedule:

❒ check front disk brake pad conditions

and wear;

❒ check cleanness of bonnet and boot

locks and lever cleanness and lubri-

cation;

❒ sight inspect the conditions of: en-

gine, gearbox, transmission, pipes

and hoses (exhaust - fuel - brakes),

rubber parts (boots, sleeves, bushes,

etc.);

❒ check battery charge and fluid level

(electrolyte);

❒ visual check on various drive belt con-

ditions;

❒ change engine oil and oil filter, if re-

quired;

❒ check and replace pollen filter, if re-

quired;

❒ check and replace air cleaner, if re-

quired.

PERIODICAL CHECKS

Every 1,000 km or before long jour-

neys, check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒ tyre pressure and conditions.

❒ check light system operation (head-

lights, direction indicators, hazard

lights, etc.);

❒ check windscreen wiper/washer op-

eration and windscreen/rear window

blade position/wear;

Every 3,000 km check and top up if re-

quired: engine oil level.

You are recommended to use FL Se-

leniaproducts, designed and produced

specifically for Alfa Romeo cars (see

table “Capacities” in section “Techni-

cal specifications”).

Page 234 of 299

232

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

CAR

MAINTENANCE

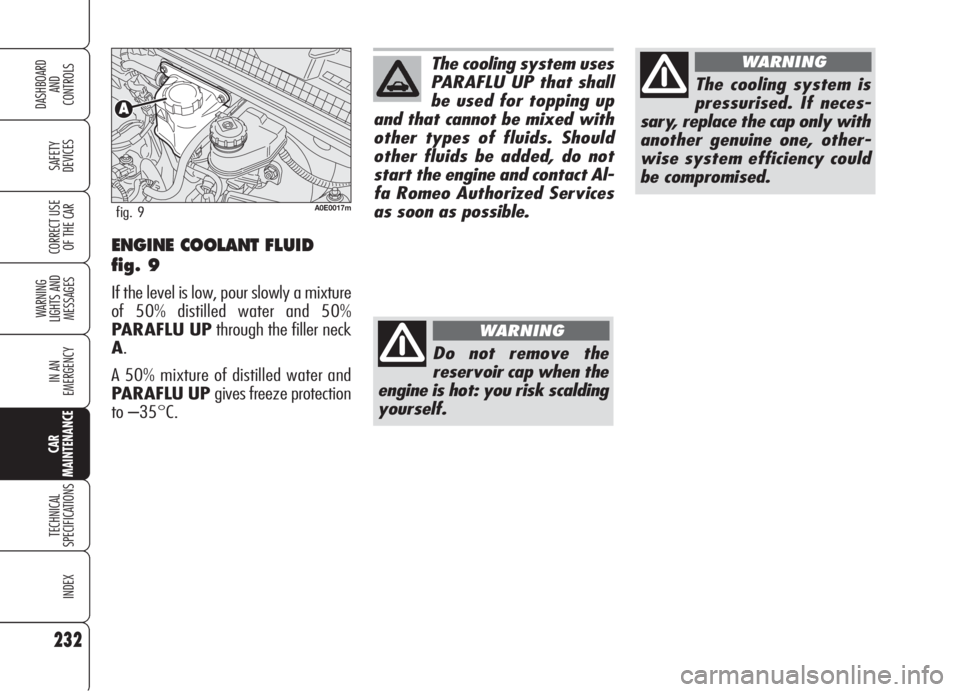

ENGINE COOLANT FLUID

fig. 9

If the level is low, pour slowly a mixture

of 50% distilled water and 50%

PARAFLU UPthrough the filler neck

A.

A 50% mixture of distilled water and

PARAFLU UP gives freeze protection

to –35°C.

A0E0017mfig. 9

The cooling system uses

PARAFLU UP that shall

be used for topping up

and that cannot be mixed with

other types of fluids. Should

other fluids be added, do not

start the engine and contact Al-

fa Romeo Authorized Services

as soon as possible.

Do not remove the

reservoir cap when the

engine is hot: you risk scalding

yourself.

WARNING

The cooling system is

pressurised. If neces-

sary, replace the cap only with

another genuine one, other-

wise system efficiency could

be compromised.

WARNING

Page 235 of 299

233

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

CAR

MAINTENANCE

WINDSCREEN/HEADLIGHT

WASHER FLUID fig. 10

To top up, remove the cap Aand then

pour a mixture of water and TUTELA

PROFESSIONAL SC 35, in the fol-

lowing concentrations:

❒30%TUTELA PROFESSIONAL

SC 35and 70% water in summer;

❒50%TUTELA PROFESSIONAL

SC 35 and 50% water in winter.

In case of temperatures below –20°C,

use undiluted TUTELA PROFES-

SIONAL SC 35.

A0E0029mfig. 10

Do not travel with the

windscreen washer

reservoir empty. The wind-

screen washer is fundamental

for improving visibility.

WARNING

Certain commercial ad-

ditives for windscreen

washers are inflammable. The

engine compartment contains

hot components which may set

it on fire.

WARNING

Page 236 of 299

234

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

CAR

MAINTENANCE

POWER STEERING FLUID

fig. 11-12

Check that the fluid level in the reservoir

is at maximum level: this operation shall

be carried out with the car on level sur-

face, engine not running and cold.

Check that the fluid level is at the MAX

mark on the reservoir or at the top mark

(maximum level) shown on the dipstick

under the reservoir cap.

A0E0027mfig. 11 1.9 JTS - 2.2 JTS - 2.4 JTDMversions

A0E0234mfig. 12 3.2 JTS -

1.9 JTDM8V- 1.9 JTDM16Vversions

If the fluid level in the reservoir is below

the specified level, top up as follows:

❒start the engine and wait until the flu-

id level in the reservoir has stabilized;

❒with the engine started, turn repeat-

edly the steering wheel fully right-

wards and leftwards;

❒top up until reaching the MAXmark

then refit the cap.IMPORTANTFor this operation it is

however recommended to always con-

tact Alfa Romeo Authorized Services.

Do not allow the pow-

er steering fluid to

touch the hot parts of the en-

gine: it is inflammable.

WARNING

Page 237 of 299

235

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

CAR

MAINTENANCE

BRAKE FLUID fig. 13

Unscrew cap Aand check that the flu-

id level in the reservoir is at maximum.

Fluid level in the reservoir shall not ex-

ceed the MAXmark.

IMPORTANTFor this operation it is

however recommended to always con-

tact Alfa Romeo Authorized Services.

A0E0016mfig. 13

Make sure that the high-

ly corrosive brake fluid

does not drip onto the

paintwork. If it does, wash it off

immediately with water.From time to time, check the instrument

panel warning light

x: pressing on cap

A(with key fitted into the ignition de-

vice) the warning light shall turn on.

IMPORTANTBrake fluid absorbs

moisture. For this reason, if the car is

mainly used in areas with a high degree

of atmospheric humidity, the fluid should

be replaced at more frequent intervals

than specified in the Service schedule.