engine valve Alfa Romeo 159 2006 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2006, Model line: 159, Model: Alfa Romeo 159 2006Pages: 299, PDF Size: 4.64 MB

Page 124 of 299

122

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

The car can be equipped with the

T.P.M.S. (Tyre Pressure Monitoring Sys-

tem). This system consists of a radio-fre-

quency sensor, installed on each wheel

(on the rim inside the tyre) that sends

pressure information to the control unit.IMPORTANT NOTES

Failure indications will not be stored and

therefore will not be displayed when

turning the engine off and on again. If

failure persists, the control unit will send

warning indications to the instrument

panel only after a few seconds when the

car is moving.

Tyre pressure should be checked with

tyres cold. Should it become necessary

for whatever reason to check pressure

with hot tyres, do not reduce pressure

although it is higher than the prescribed

value but repeat the check when tyres

are cold (see section “Wheels” in sec-

tion “Technical Specifications”).

TYRE PRESSURE MONITORING SYSTEM -

T.P.M.S. (where provided)

The T.P.M.S. does not

exempt the driver from

checking tyre pressure, includ-

ing the space-saver spare

wheel (where provided) at

regular intervals.

WARNING

T.P.M.S. cannot indicate sudden tyre

pressure drops (e.g.: tyre burst). In this

event, brake the car cautiously and

avoid sudden steering.

The T.P.M.S. system requires special

equipment. Consult Alfa Romeo Autho-

rized Services to know what type of ac-

cessories are compatible with the sys-

tem (wheels, wheel caps, etc.). Using

other accessories could cause system

malfunctioning. Due to inflation valve

special characteristics, use only tyre re-

pair sealants approved by Alfa Romeo;

other sealants could cause system mal-

functioning.

Page 187 of 299

185

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

Please note:

❒the jack weight is 1.76 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired. If it

breaks it must be replaced with a

new jack;

❒no tool other than its cranking device

may be fitted on the jack.To change a wheel proceed as follows:

❒Stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

ground should be flat and adequate-

ly firm;

❒Turn the engine off, pull up the hand-

brake and engage first gear or re-

verse;

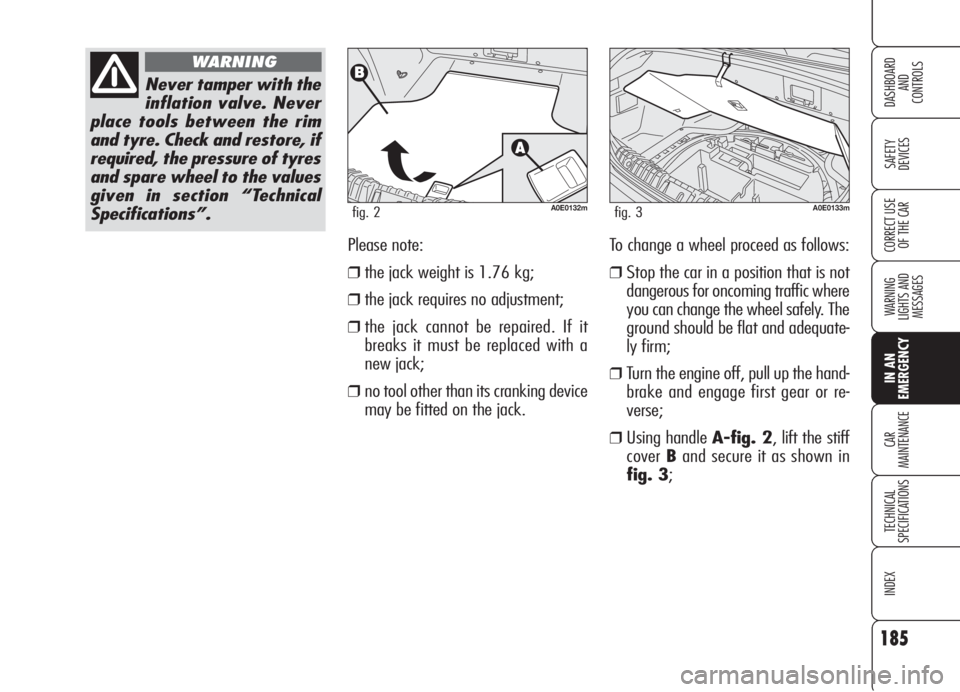

❒Using handle A-fig. 2, lift the stiff

coverBand secure it as shown in

fig. 3;

Never tamper with the

inflation valve. Never

place tools between the rim

and tyre. Check and restore, if

required, the pressure of tyres

and spare wheel to the values

given in section “Technical

Specifications”.

WARNING

A0E0132mfig. 2A0E0133mfig. 3

Page 195 of 299

193

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

❒after reaching the tyre pressure spec-

ified in paragraph “Wheels” in sec-

tion “Technical Specifications”, start

driving immediately;

❒if after 5 minutes it is still impossi-

ble to reach at least 1.5 bar, disen-

gage compressor from valve and cur-

rent outlet, then move the car forth

for approx. 10 metres in order to dis-

tribute the sealing fluid inside the tyre

evenly, then repeat the inflation op-

eration;

❒If after this operation it is still im-

possible after 5 minutes to reach at

least 1.8 bar, do start driving since

the tyre is excessively damaged and

the quick tyre repair kit cannot guar-

antee suitable sealing, contact Alfa

Romeo Authorized Services;

❒make sure the compressor switch A-

fig. 19is set to 0(off), start the

engine and fit plug A-fig. 20into

the outlet/cigar lighter on the front

console and then turn on the com-

pressor by setting switch A-fig. 19

toI(on);

❒Inflate the tyre to the pressure speci-

fied in paragraph “Wheels” in section

“Technical Specifications”. Check tyre

pressure on gauge B-fig. 19 with

compressor off to obtain precise read-

ing;

A0E0213mfig. 19A0E0217mfig. 20Apply the sticker in a

visible position for the

driver to indicate that the tyre

has been treated with the

quick tyre repair kit. Drive

carefully especially when cor-

nering and do not exceed 80

km/h. Avoid heavy braking

and accelerating.

WARNING

Page 196 of 299

194

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

You shall absolutely

communicate that the

tyre has been repaired with

the quick tyre repair kit. Hand

the instruction brochure to the

personnel charged with treat-

ing the tyre repaired with the

kit.

WARNING

A0E0215mfig. 21

A0E0216mfig. 22

CHECKING AND RESTORING

PRESSURE ONLY

The compressor can be also used just for

restoring pressure. Disconnect the quick

connectionA-fig. 21and connect it

directly to the tyre valve fig. 22; in this

way the cylinder is not connected to

compressor and the sealing fluid will not

flow into the tyre.

If pressure falls below

1.8 bar, stop the car

since the tyre is excessively

damaged and the quick tyre

repair kit Fix & Go automatic

cannot guarantee suitable

sealing, contact Alfa Romeo

Authorized Services.

WARNING

❒after driving for about 10 minutes

stop and check again the tyre pres-

sure;pull up the handbrake;❒if at least 1.8 bar pressure is read, re-

store proper pressure (with engine

running and handbrake on) and

restart;

❒drive with the utmost care to the

nearest Alfa Romeo Authorized

Service.

Page 217 of 299

215

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

IN AN

EMERGENCY

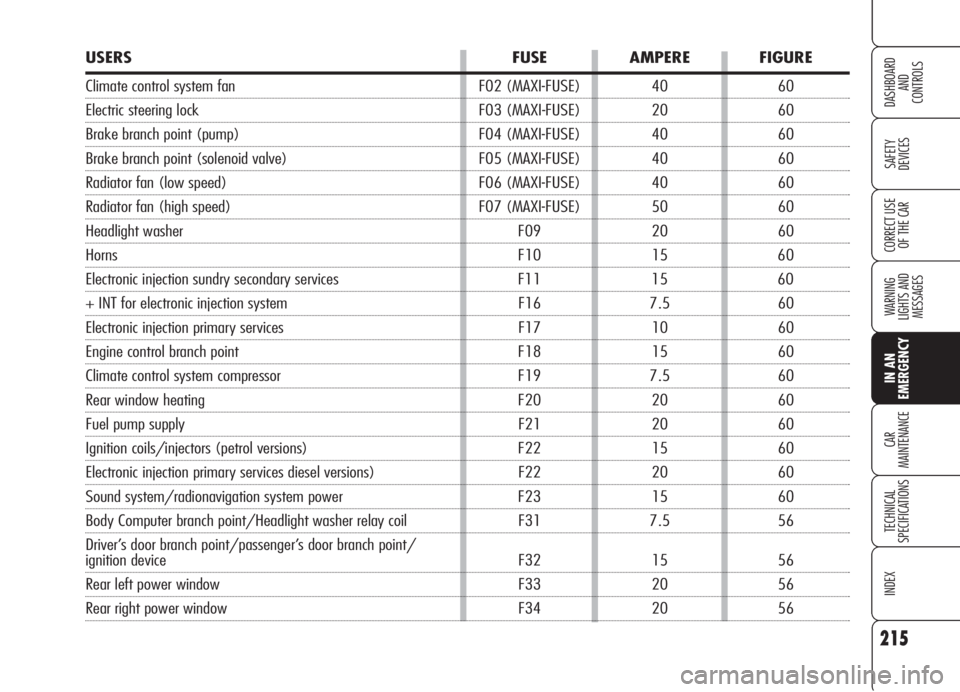

USERS FUSE AMPERE FIGURE

Climate control system fan F02 (MAXI-FUSE) 40 60

Electric steering lock F03 (MAXI-FUSE) 20 60

Brake branch point (pump) F04 (MAXI-FUSE) 40 60

Brake branch point (solenoid valve) F05 (MAXI-FUSE) 40 60

Radiator fan (low speed) F06 (MAXI-FUSE) 40 60

Radiator fan (high speed) F07 (MAXI-FUSE) 50 60

Headlight washer F09 20 60

Horns F10 15 60

Electronic injection sundry secondary services F11 15 60

+ INT for electronic injection system F16 7.5 60

Electronic injection primary services F17 10 60

Engine control branch point F18 15 60

Climate control system compressor F19 7.5 60

Rear window heating F20 20 60

Fuel pump supply F21 20 60

Ignition coils/injectors (petrol versions) F22 15 60

Electronic injection primary services diesel versions) F22 20 60

Sound system/radionavigation system power F23 15 60

Body Computer branch point/Headlight washer relay coil F31 7.5 56

Driver’s door branch point/passenger’s door branch point/

ignition device F32 15 56

Rear left power window F33 20 56

Rear right power window F34 20 56

Page 255 of 299

253

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

TECHNICALSPECIFICATIONS

1.9 JTS

939A6000

Otto

4 in line

4

86 x 80

1859

118

160

6500

190

19.4

4500

NGKFR5CP

Unleaded petrol

95 RON

(Specification EN228)2.2 JTS

939A5000

Otto

4 in line

4

86 X 94.6

2198

136

185

6500

230

23.4

4500

NGKFR5CP

Unleaded petrol

95 RON

(Specification EN228)3.2 JTS

939A000

Otto

6 in 60° V

4

85.6 X 89

3195

191

260

6200

322

32.8

4500

BOSCH

HR7MPP152

Unleaded petrol

95 RON

(Specification EN228)

ENGINE

GENERAL

Engine code

Cycle

Number and layout of cylinders

Valves per cylinder

Piston bore and stroke mm

Total displacement cm3

Maximum power (EEC) kW

HP

corresponding ratio rpm

Maximum torque (EEC) Nm

kgm

corresponding ratio rpm

Spark plugs

Fuel

Page 256 of 299

254

SAFETY

DEVICES

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

INDEX

CORRECT USE

OF THE CAR

DASHBOARD

AND

CONTROLS

TECHNICALSPECIFICATIONS

1.9

JTD

M8v

939A1000

Diesel

4 in line

2

82 x 90.4

1910

88

120

4000

280

28.6

2000

–

Diesel fuel

for motor

vehicles

(Specification

EN590)1.9

JTDM16v

939A2000

Diesel

4 in line

4

82 x 90.4

1910

110

150

4000

320

32.6

2000

–

Diesel fuel

for motor

vehicles

(Specification

EN590)2.4 JTD

M

939A3000

Diesel

5 in line

4

82

X90.4

2387

147

200

4000

400

40.8

2000

–

Diesel fuel

for motor

vehicles

(Specification

EN590)

(*) For specific markets1.9

JTD

M8v (*)

939A7000

Diesel

4 in line

2

82 x 90,4

1910

85

115

4000

275

28

2000

–

Diesel fuel

for motor

vehicles

(Specification

EN590)1.9

JTDM16v (*)

939A8000

Diesel

4 in line

4

82 x 90,4

1910

100

136

4000

305

31

2000

–

Diesel fuel

for motor

vehicles

(Specification

EN590)

GENERAL

Engine code

Cycle

Number and layout of cylinders

Valves per cylinder

Piston bore and stroke mm

Total displacement cm3

Maximum power (EEC) kW

HP

corresponding ratio rpm

Maximum torque (EEC) Nm

kgm

corresponding ratio rpm

Spark plugs

Fuel