tire Alfa Romeo Giulia 2017 Owner's Guide

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2017, Model line: Giulia, Model: Alfa Romeo Giulia 2017Pages: 268, PDF Size: 18.64 MB

Page 194 of 268

TIRE REPAIR KIT —

IF EQUIPPED

Description

If a tire is punctured, you can make a

first emergency repair using the Tire

Repair Kit located in the rear storage

area under the load platform.

The Tire Repair Kit includes:

Sealant cartridge containing the

sealing fluid.

Filler tube.

Adhesive label with the writing "Max.

50 mph (80 km/h)”, to be attached in a

position easily visible to the driver (eg.

on the dashboard) after repairing the

tire.

Air compressor, complete with

pressure gauge and connectors.

An instruction leaflet for reference in

prompt and correct use of the Tire

Repair Kit, which must be then given to

the personnel dealing with the

sealant-treated tire.

A pair of protective gloves.

Some adaptors, for inflating different

elements.

Note: The sealing fluid is effective with

external temperatures of between -40°F

(-40°C) and 122°F (50°C). The sealing

fluid has an expiration date. To use the Tire Repair Kit, proceed as

follows:

1. Stop the vehicle in a position where

you can repair the tire safely. You

should be as far as possible from the

side of the road, and in a position that

is not dangerous for oncoming traffic.

Engage the hazard warning flashers,

remove the safety triangle from the

luggage compartment, and place it at a

suitable distance from the vehicle to

make other drivers aware of your

presence.

2. Verify that the valve stem (on the

wheel with the deflated tire) is in a

position that is near to the ground. This

will allow the tire repair kit hoses to

reach the valve stem and keep the tire

repair kit flat on the ground.

3. Shift the gear selector to PARK (P).

4. Apply the electric parking brake and

turn the engine OFF.

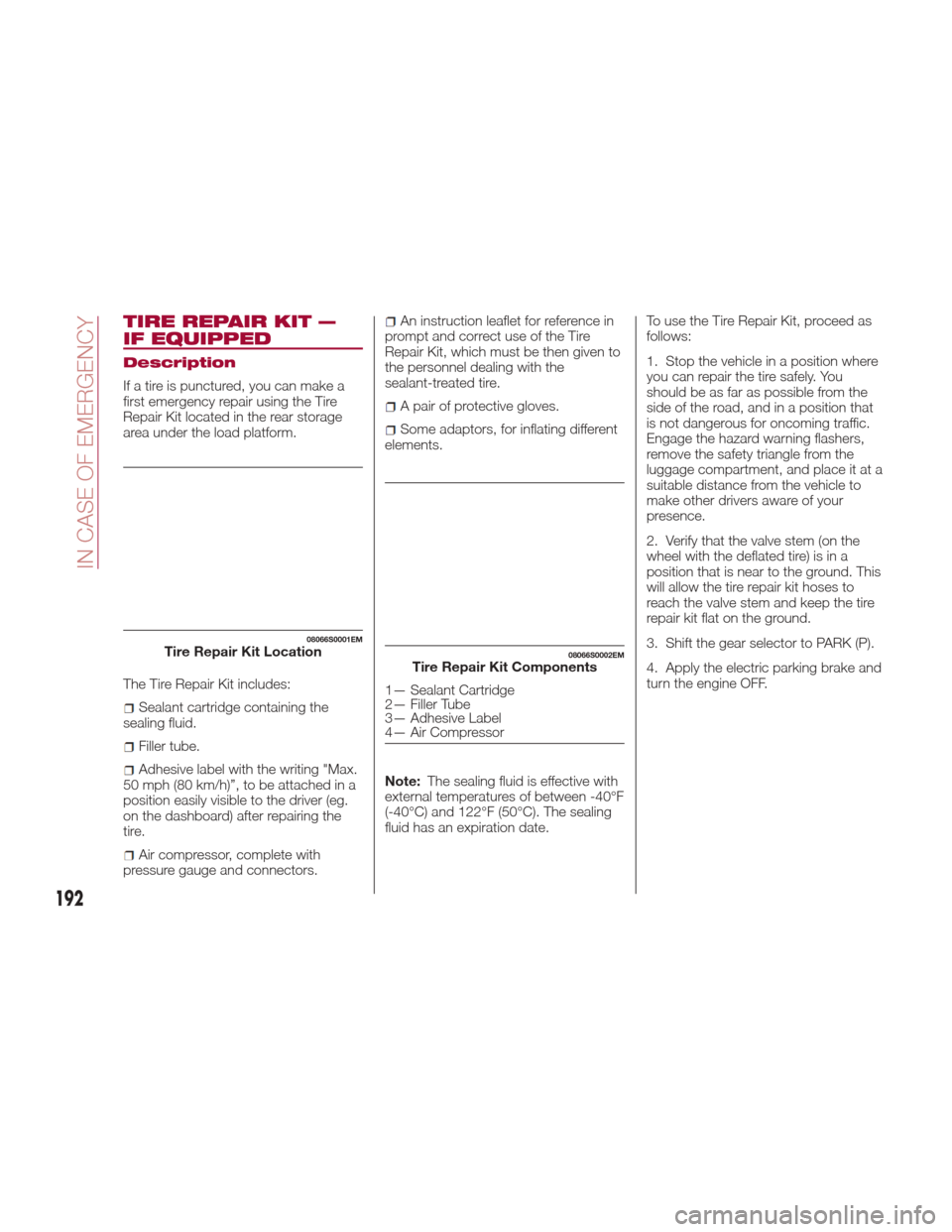

08066S0001EMTire Repair Kit Location08066S0002EMTire Repair Kit Components

1— Sealant Cartridge

2— Filler Tube

3— Adhesive Label

4— Air Compressor

192

IN CASE OF EMERGENCY

Page 195 of 268

Inflation Procedure

Warning!

Do not attempt to seal a tire on the side

of the vehicle closest to traffic. Pull far

enough off the road to avoid the danger of

being hit when using the Tire Service Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving

on a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open

flames or heat sources.

A loose Tire Service Kit thrown forward

in a collision or hard stop could endanger

the occupants of the vehicle. Always stow

the Tire Service Kit in the place provided.

Failure to follow these warnings can result

in injuries that are serious or fatal to you,

your passengers, and others around you.

Take care not to allow the contents of

Tire Service Kit to come in contact with

hair, eyes, or clothing. Tire Service Kit

sealant is harmful if inhaled, swallowed, or

absorbed through the skin. It causes skin,

eye, and respiratory irritation. Flush

immediately with plenty of water if there is

any contact with eyes or skin. Change

clothing as soon as possible, if there is any

contact with clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If

swallowed, rinse mouth immediately with

plenty of water and drink plenty of water.

Do not induce vomiting! Consult a

physician immediately.

To use your Tire Repair Kit, proceed as

follows:

1. Engage the electric parking brake.

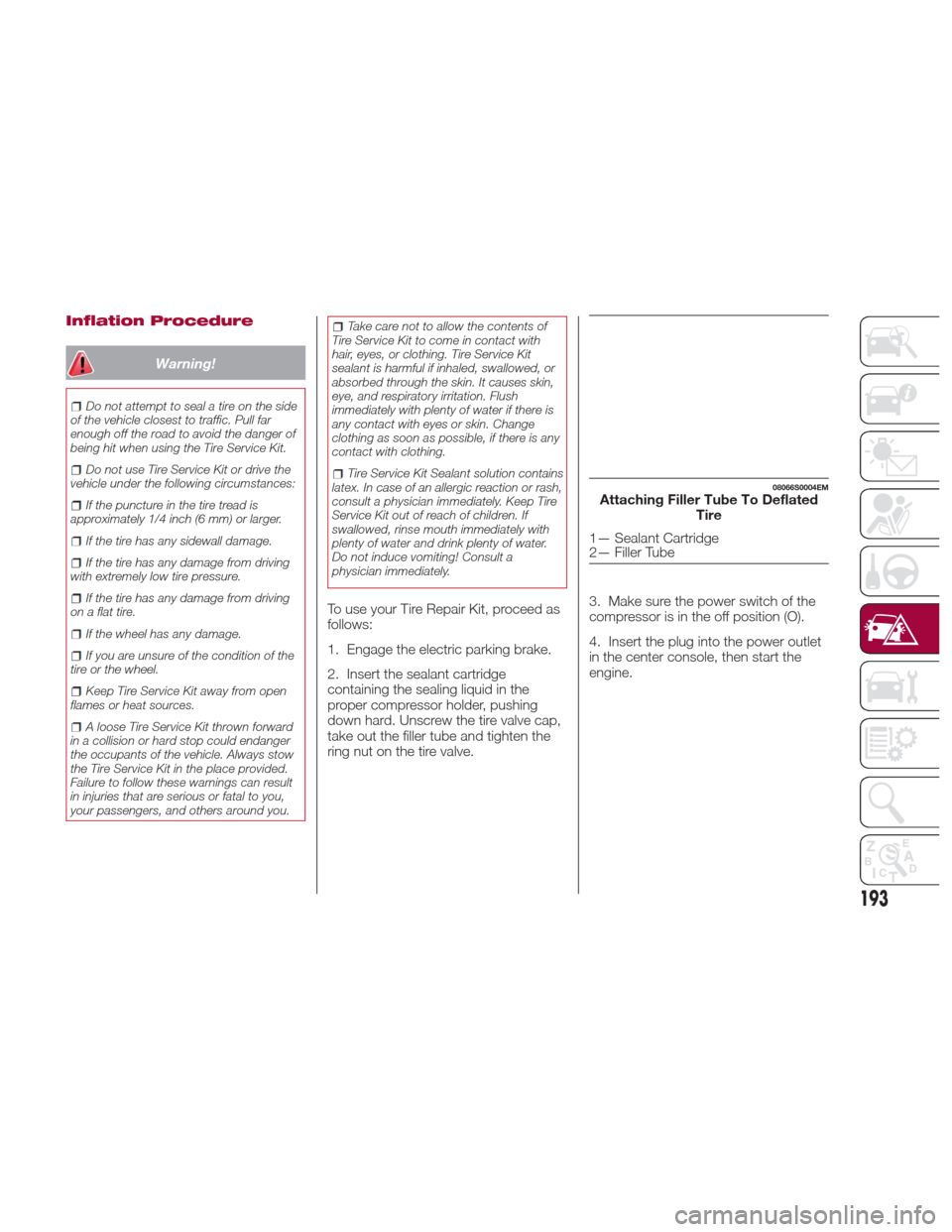

2. Insert the sealant cartridge

containing the sealing liquid in the

proper compressor holder, pushing

down hard. Unscrew the tire valve cap,

take out the filler tube and tighten the

ring nut on the tire valve. 3. Make sure the power switch of the

compressor is in the off position (O).

4. Insert the plug into the power outlet

in the center console, then start the

engine.

08066S0004EMAttaching Filler Tube To Deflated

Tire

1— Sealant Cartridge

2— Filler Tube

193

Page 196 of 268

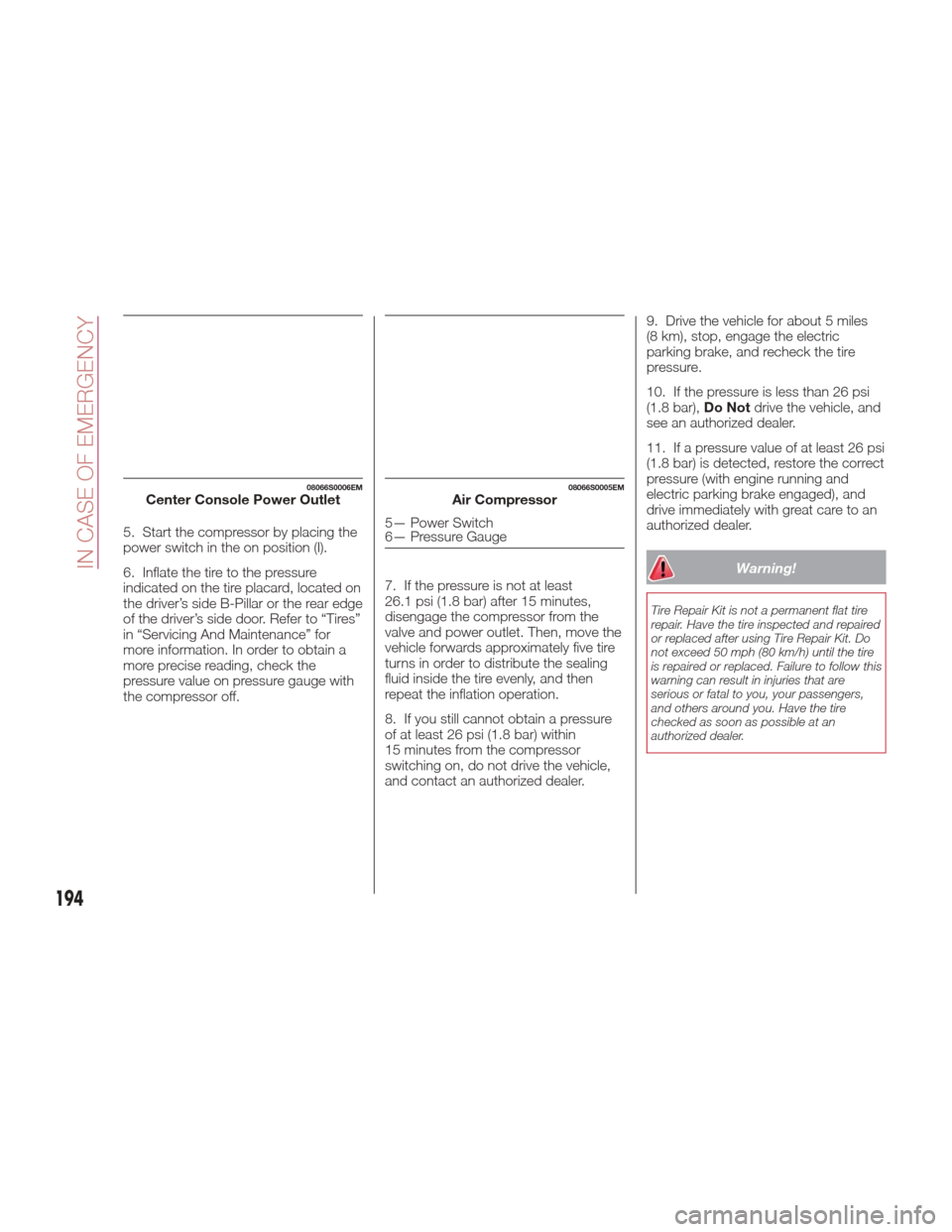

5. Start the compressor by placing the

power switch in the on position (I).

6. Inflate the tire to the pressure

indicated on the tire placard, located on

the driver’s side B-Pillar or the rear edge

of the driver’s side door. Refer to “Tires”

in “Servicing And Maintenance” for

more information. In order to obtain a

more precise reading, check the

pressure value on pressure gauge with

the compressor off.7. If the pressure is not at least

26.1 psi (1.8 bar) after 15 minutes,

disengage the compressor from the

valve and power outlet. Then, move the

vehicle forwards approximately five tire

turns in order to distribute the sealing

fluid inside the tire evenly, and then

repeat the inflation operation.

8. If you still cannot obtain a pressure

of at least 26 psi (1.8 bar) within

15 minutes from the compressor

switching on, do not drive the vehicle,

and contact an authorized dealer.9. Drive the vehicle for about 5 miles

(8 km), stop, engage the electric

parking brake, and recheck the tire

pressure.

10. If the pressure is less than 26 psi

(1.8 bar),

Do Notdrive the vehicle, and

see an authorized dealer.

11. If a pressure value of at least 26 psi

(1.8 bar) is detected, restore the correct

pressure (with engine running and

electric parking brake engaged), and

drive immediately with great care to an

authorized dealer.

Warning!

Tire Repair Kit is not a permanent flat tire

repair. Have the tire inspected and repaired

or replaced after using Tire Repair Kit. Do

not exceed 50 mph (80 km/h) until the tire

is repaired or replaced. Failure to follow this

warning can result in injuries that are

serious or fatal to you, your passengers,

and others around you. Have the tire

checked as soon as possible at an

authorized dealer.

08066S0006EMCenter Console Power Outlet08066S0005EMAir Compressor

5— Power Switch

6— Pressure Gauge

194

IN CASE OF EMERGENCY

Page 197 of 268

12. Apply the adhesive label from the

sealant bottle where it can be easily

seen by the driver as a reminder that

the tire has been treated with a Tire

Repair Kit, as well as not to exceed the

speed restriction for the treated tire.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

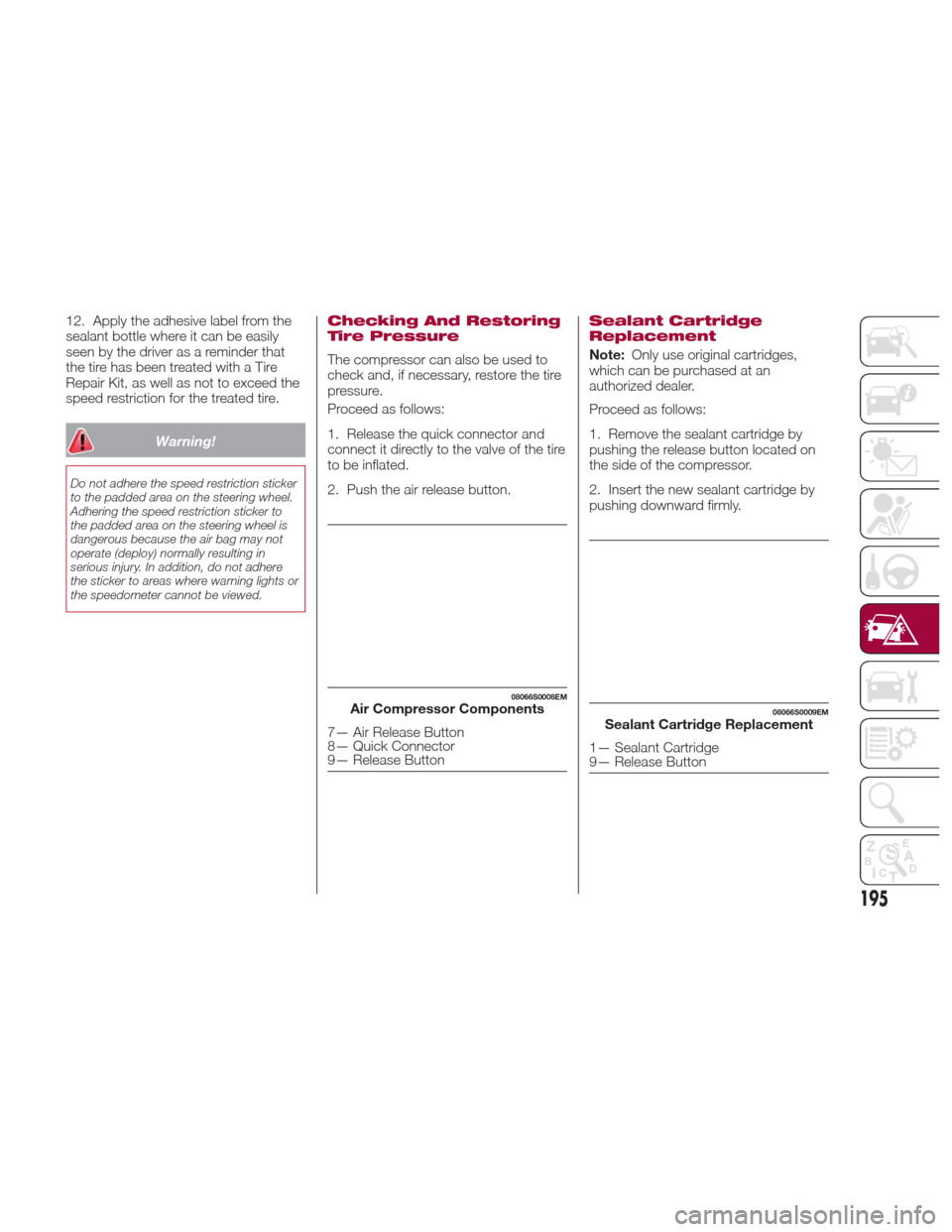

Checking And Restoring

Tire Pressure

The compressor can also be used to

check and, if necessary, restore the tire

pressure.

Proceed as follows:

1. Release the quick connector and

connect it directly to the valve of the tire

to be inflated.

2. Push the air release button.

Sealant Cartridge

Replacement

Note:Only use original cartridges,

which can be purchased at an

authorized dealer.

Proceed as follows:

1. Remove the sealant cartridge by

pushing the release button located on

the side of the compressor.

2. Insert the new sealant cartridge by

pushing downward firmly.

08066S0008EMAir Compressor Components

7— Air Release Button

8— Quick Connector

9— Release Button

08066S0009EMSealant Cartridge Replacement

1— Sealant Cartridge

9— Release Button

195

Page 206 of 268

SERVICING AND MAINTENANCE

Correct servicing permits the

performance of the vehicle to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SCHEDULED SERVICING.......205

ENGINECOMPARTMENT ......209

BATTERY RECHARGING .......212

DEALER SERVICE ...........214

RAISING THE VEHICLE ........220

TIRES .................. .221DEPARTMENT OF

TRANSPORTATION UNIFORM TIRE

QUALITY GRADES

...........233

STORING THE VEHICLE .......234

BODYWORK...............235

INTERIORS ............... .237

204

SERVICING AND MAINTENANCE

Page 207 of 268

SCHEDULED

SERVICING

Correct servicing is crucial for

guaranteeing a long life for the vehicle

under the best conditions.

For this reason, Alfa Romeo has

planned a series of checks and services

for your vehicle at fixed intervals based

on distance and time, as described in

the Scheduled Servicing Plan.

Before each service, it is always

necessary to carefully follow the

instructions in the Scheduled Servicing

Plan (e.g. periodically check level of

fluids, tire pressure, etc.).

Scheduled Servicing is offered by an

authorized dealer according to a set

time schedule. If, during each

operation, in addition to the ones

scheduled, the need arises for further

replacements or repairs, these may be

carried out with owners explicit consent

only.

Note:

Scheduled Servicing intervals are

required by the Manufacturer. Failure to

have them carried out may invalidate

the New Vehicle Limited Warranty.

You are advised to inform your

authorized dealer of any small operating

irregularities without waiting for the next

service.

Periodic Checks

Every month or every600miles

( 1,000 km) or before long trips check

and, if necessary, top off:

Engine coolant level.

Brake fluid level (if insufficient, see

your authorized dealer as soon as

possible).

Windshield washer fluid level.

Tire inflation pressure and condition.

Operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.).

Operation of windshield

washing/wiping system and

positioning/wear of wiper blades.

Every 2,000 miles ( 3,000km), check

and top off if required:

Engine oil level.

Heavy Usage Of The Car

If the vehicle is used under one of the

following conditions:

Dusty roads.

Short, repeated journeys less than

4 miles (7-8 km) at sub-zero outside

temperatures.

Engine often idling or driving long

distances at low speeds or long periods

of inactivity.

In the event of a long period of

inactivity. The following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

Check cleanliness of hood and trunk

locks, cleanliness and lubrication of

linkage.

Visually inspect conditions of: engine,

transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (sleeves/bushes, etc.).

Check battery charge and battery

fluid level (electrolyte).

Visually inspect conditions of the

accessory drive belts.

Check and, if necessary, change

engine oil and replace oil filter.

Check and, if necessary, replace

cabin air filter.

Check and, if necessary, replace air

cleaner.

Severe Duty All Models

Change Engine Oil at 4,000 miles

(6,500 km) if the vehicle is operated in a

dusty and off-road environment or is

operated predominately at idle or only

very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

205

Page 208 of 268

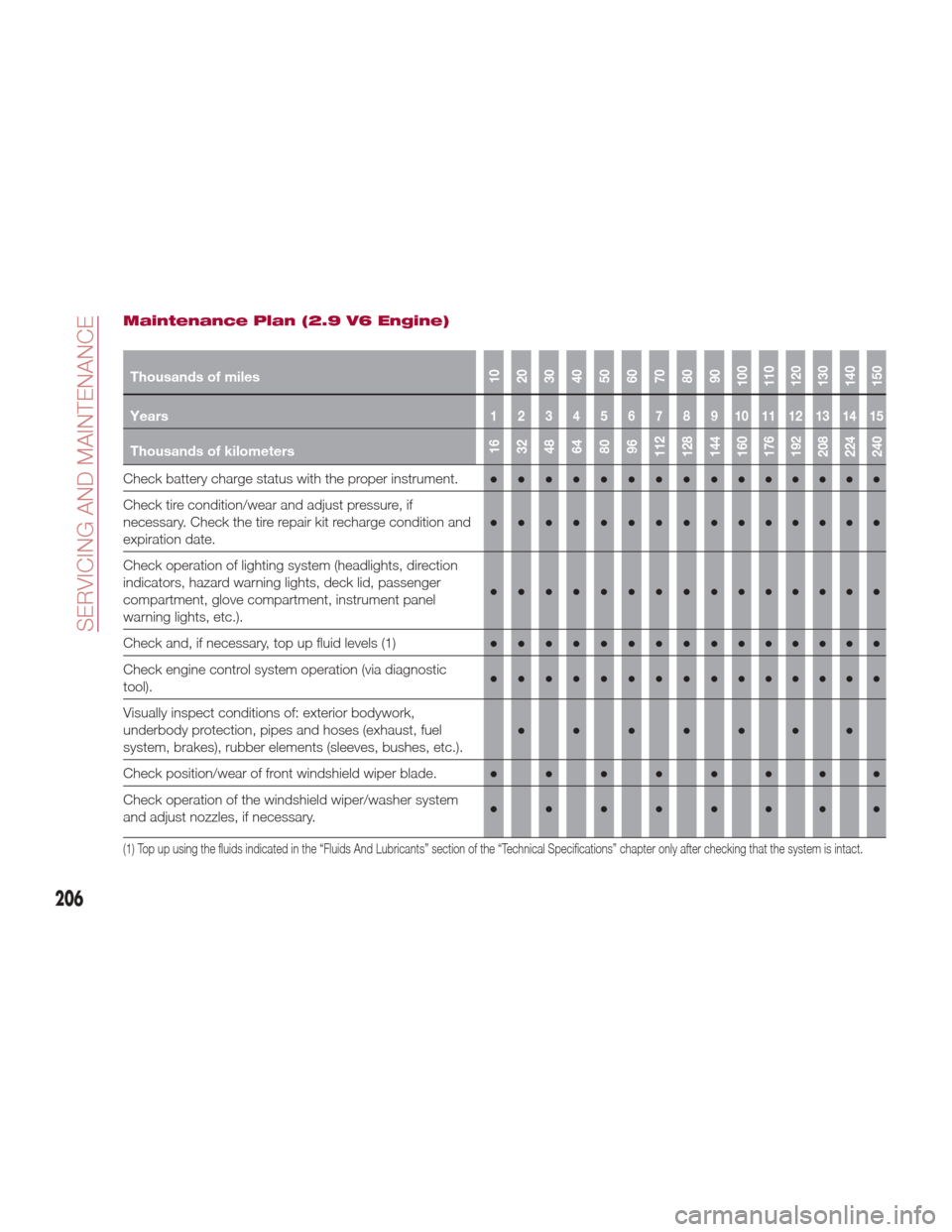

Maintenance Plan (2.9 V6 Engine)

Thousands of miles10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

Years123456789101112131415

Thousands of kilometers16

32

48

64

80

96

112

128

144

160

176

192

208

224

240

Check battery charge status with the proper instrument. ●●●●●●●●●●●●●●●

Check tire condition/wear and adjust pressure, if

necessary. Check the tire repair kit recharge condition and

expiration date. ●●●●●●●●●

●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, deck lid, passenger

compartment, glove compartment, instrument panel

warning lights, etc.). ●●●●●●●●●

●●●●●●

Check and, if necessary, top up fluid levels

(1)●●●●●●●●● ●●●●●●

Check engine control system operation (via diagnostic

tool). ●●●●●●●●●

●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (sleeves, bushes, etc.). ●●●●●●●

Check position/wear of front windshield wiper blade. ●●●●●●●●

Check operation of the windshield wiper/washer system

and adjust nozzles, if necessary. ●●●●●●●●

(1) Top up using the fluids indicated in the “Fluids And Lubricants” section of the “Technical Specifications” chapter only after checking that the system is intact.

206

SERVICING AND MAINTENANCE

Page 218 of 268

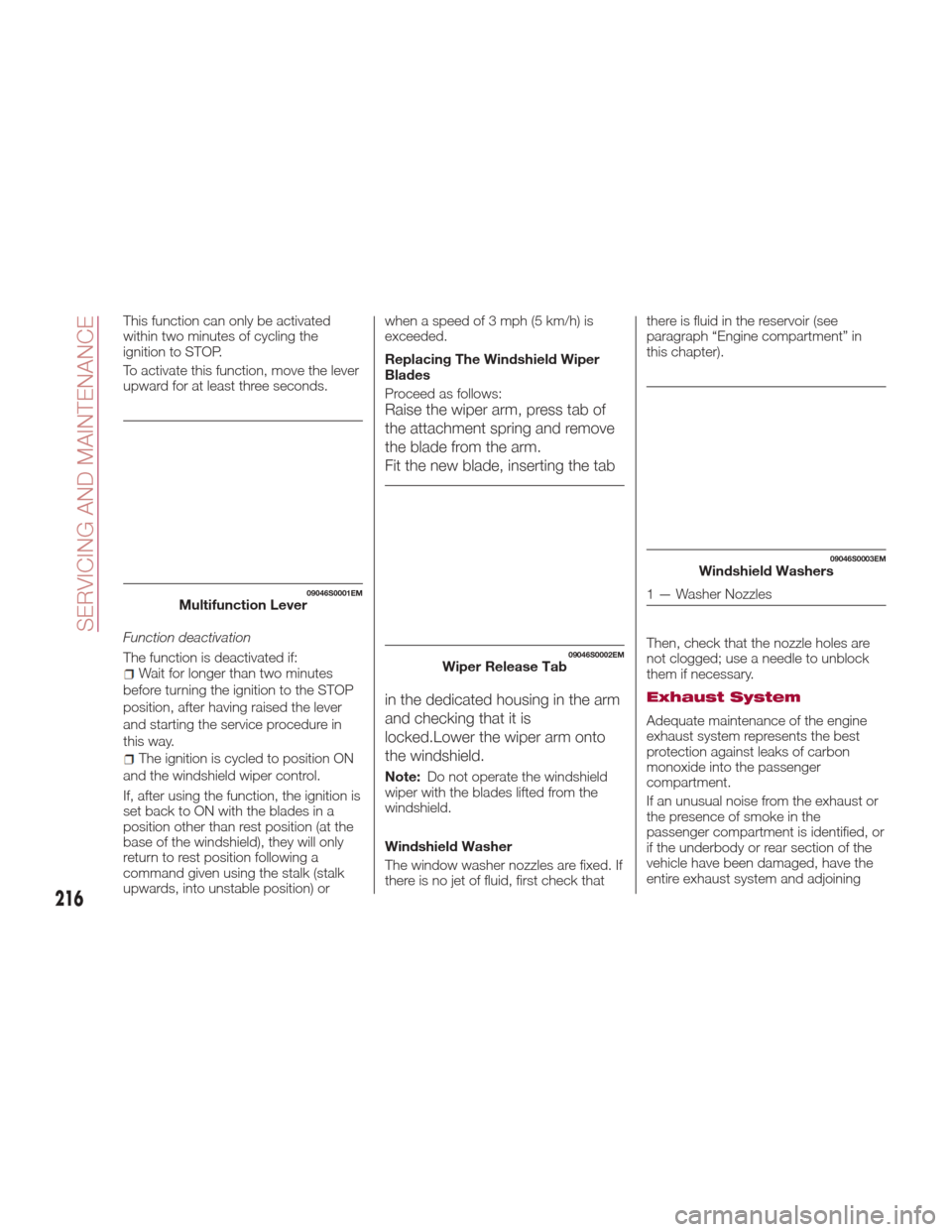

This function can only be activated

within two minutes of cycling the

ignition to STOP.

To activate this function, move the lever

upward for at least three seconds.

Function deactivation

The function is deactivated if:

Wait for longer than two minutes

before turning the ignition to the STOP

position, after having raised the lever

and starting the service procedure in

this way.

The ignition is cycled to position ON

and the windshield wiper control.

If, after using the function, the ignition is

set back to ON with the blades in a

position other than rest position (at the

base of the windshield), they will only

return to rest position following a

command given using the stalk (stalk

upwards, into unstable position) or when a speed of 3 mph (5 km/h) is

exceeded.

Replacing The Windshield Wiper

Blades

Proceed as follows:

Raise the wiper arm, press tab of

the attachment spring and remove

the blade from the arm.

Fit the new blade, inserting the tab

in the dedicated housing in the arm

and checking that it is

locked.Lower the wiper arm onto

the windshield.

Note:

Do not operate the windshield

wiper with the blades lifted from the

windshield.

Windshield Washer

The window washer nozzles are fixed. If

there is no jet of fluid, first check that there is fluid in the reservoir (see

paragraph “Engine compartment” in

this chapter).

Then, check that the nozzle holes are

not clogged; use a needle to unblock

them if necessary.

Exhaust System

Adequate maintenance of the engine

exhaust system represents the best

protection against leaks of carbon

monoxide into the passenger

compartment.

If an unusual noise from the exhaust or

the presence of smoke in the

passenger compartment is identified, or

if the underbody or rear section of the

vehicle have been damaged, have the

entire exhaust system and adjoining

09046S0001EMMultifunction Lever

09046S0002EMWiper Release Tab

09046S0003EMWindshield Washers

1 — Washer Nozzles

216

SERVICING AND MAINTENANCE

Page 223 of 268

TIRES

Tire Safety Information

Tire safety information will cover

aspects of the following information:

Tire Markings, Tire Identification

Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire

Loading.

Tire Markings

Note:

P (Passenger) — Metric tire sizing is

based on U.S. design standards.

P-Metric tires have the letter “P”

molded into the sidewall preceding the

size designation. Example:

P215/65R15 95H.

European — Metric tire sizing is

based on European design standards.

Tires designed to this standard have

the tire size molded into the sidewall

beginning with the section width. The

letter "P" is absent from this tire size

designation. Example: 215/

65R15 96H.

LT (Light Truck) — Metric tire sizing

is based on U.S. design standards.

The size designation for LT-Metric tires

is the same as for P-Metric tires except

for the letters “LT” that are molded into

the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed

for temporary emergency use only.

Temporary high pressure compact

spare tires have the letter “T” or “S”

molded into the sidewall preceding the

size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on

U.S. design standards and it begins

with the tire diameter molded into the

sidewall. Example: 31x10.5 R15 LT.

Tire Identification Number (TIN)

The TIN may be found on one or both

sides of the tire; however, the date code

mayonlybeononeside.Tireswith

white sidewalls will have the full TIN,

including the date code, located on the

white sidewall side of the tire. Look for

the TIN on the outboard side of black

sidewall tires as mounted on the

vehicle. If the TIN is not found on the

outboard side, then you will find it on

the inboard side of the tire.

GUID-0601085395USTire Markings

1 — U.S. DOT Sa-

fety Standards

Code (TIN) 4 — Maximum

Load

2 — Size Designa-

tion 5 — Maximum

Pressure

3 — Service De-

scription 6 — Treadwear,

Traction and Tem-

perature Grades

221

Page 224 of 268

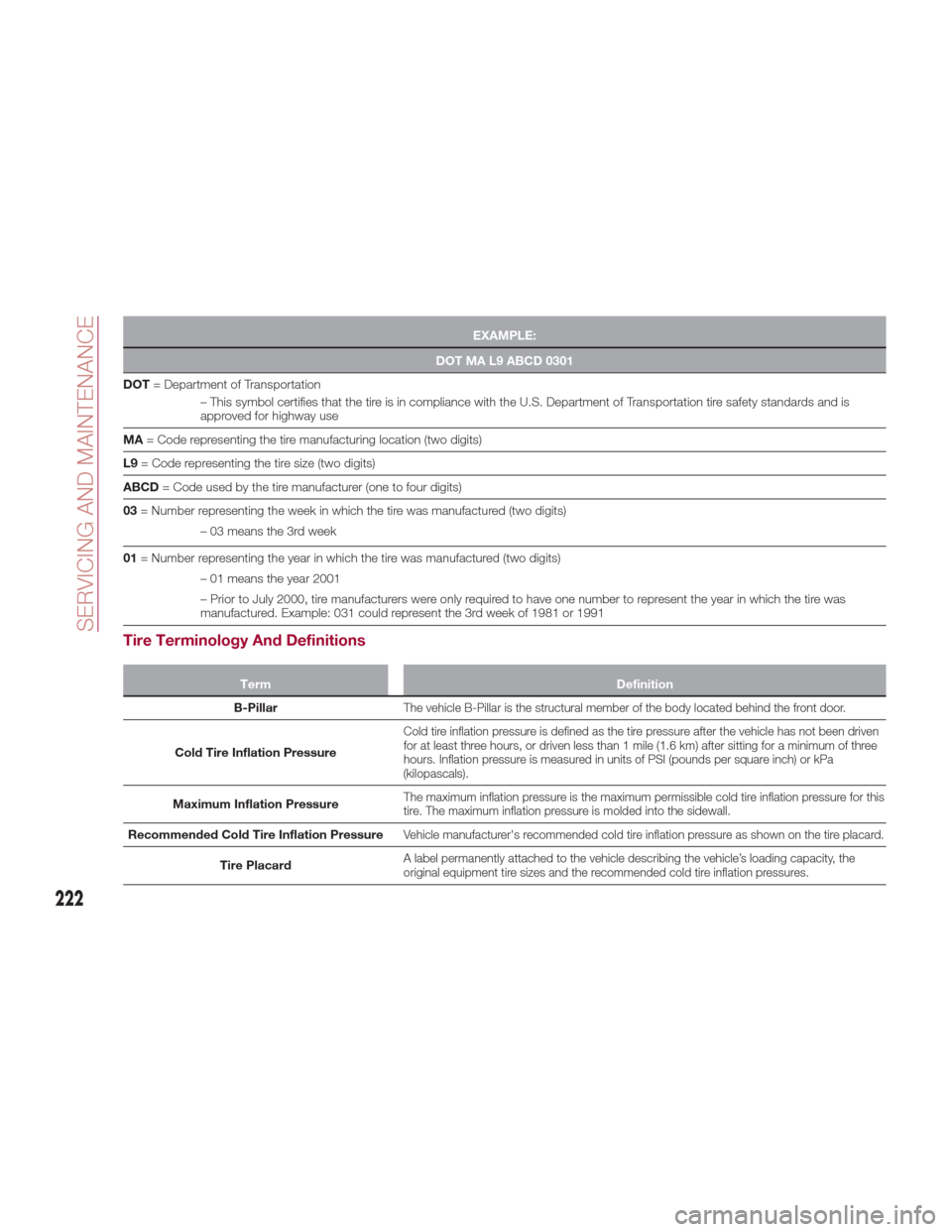

EXAMPLE:

DOT MA L9 ABCD 0301

DOT =

Department of Transportation

– This symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire safety standards and is

approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

– 03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

– 01 means the year 2001

– Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was

manufactured. Example: 031 could represent the 3rd week of 1981 or 1991

Tire Terminology And Definitions

Term Definition

B-Pillar

The vehicle B-Pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure

Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been driven

for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum of three

hours. Inflation pressure is measured in units of PSI (pounds per square inch) or kPa

(kilopascals).

Maximum Inflation PressureThe maximum inflation pressure is the maximum permissible cold tire inflation pressure for this

tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation PressureVehicle manufacturer's recommended cold tire inflation pressure as shown on the tire placard.

Tire PlacardA label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

222

SERVICING AND MAINTENANCE