boot Alfa Romeo GT 2005 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2005, Model line: GT, Model: Alfa Romeo GT 2005Pages: 307, PDF Size: 6.05 MB

Page 199 of 307

GETTING TO KNOW YOUR CAR

197

BOSE HI-FI

SOUND SYSTEM

(upon request for

versions/markets where

applicable)

The BOSE HI-FI system has been accurately

designed for

Alfa GT, to offer out-

standing sound quality and reproduce the

musical realism of a live concert, for all the

seats in the passenger compartment.

The system feature include outstandingly

faithful reproduction of crystalline treble

tones and full, rich basses which among oth-

er things, make the Loudness function su-

perfluous. In addition, the complete range

of the sounds is reproduced in the whole pas-

senger compartment enveloping the occu-

pants with the natural spatial sensation that

is felt when listening to live music.

The components adopted are patented and

are the result of the most sophisticated tech-

nology, but at the same time they are easy

and intuitive to use, so that even less expert

people can use the system.

fig. 163

A0A0642b

fig. 161

A0A0336b

fig. 162

A0A0337b

TECHNICAL INFORMATION

(fig. 161-162-163)

System comprises:

– four high efficiency woofers (A) with di-

ameter

165 mm, two at the front and two at the

back, each having a coaxial tweeter inside;– a bass box with a volume of 12 dm

3

(B) housed on the left-hand side of the

boot;

– a high power HI-FI amplifier (150W)

with 6 channels, analogue equalising in am-

plitude signal phase and with 130 mm di-

ameter sub-woofer.

Page 201 of 307

GETTING TO KNOW YOUR CAR

199

ENVIRONMENTAL

PROTECTION

The devices used to reduce petrol engine

emissions are:

– trivalent catalytic converter (catalytic si-

lencer);

– Lambda sensors;

– anti-evaporation system.

If one or more spark plugs are discon-

nected, do not run the engine, even for a

test.

The devices used to reduce diesel fuel en-

gine emissions are:

– oxidising catalyst;

– exhaust gas re-circulation system

(E. G. R.). Do not go near the fuel

filler with naked flames or

lit cigarettes: danger of

fire. Avoid going too near the fuel

filler with your face, to avoid in-

haling harmful vapours.

In the case of need, only

replace the fuel cap with

another genuine one, or the

efficiency of the fuel vapour re-

covery system could be adversely

affected.

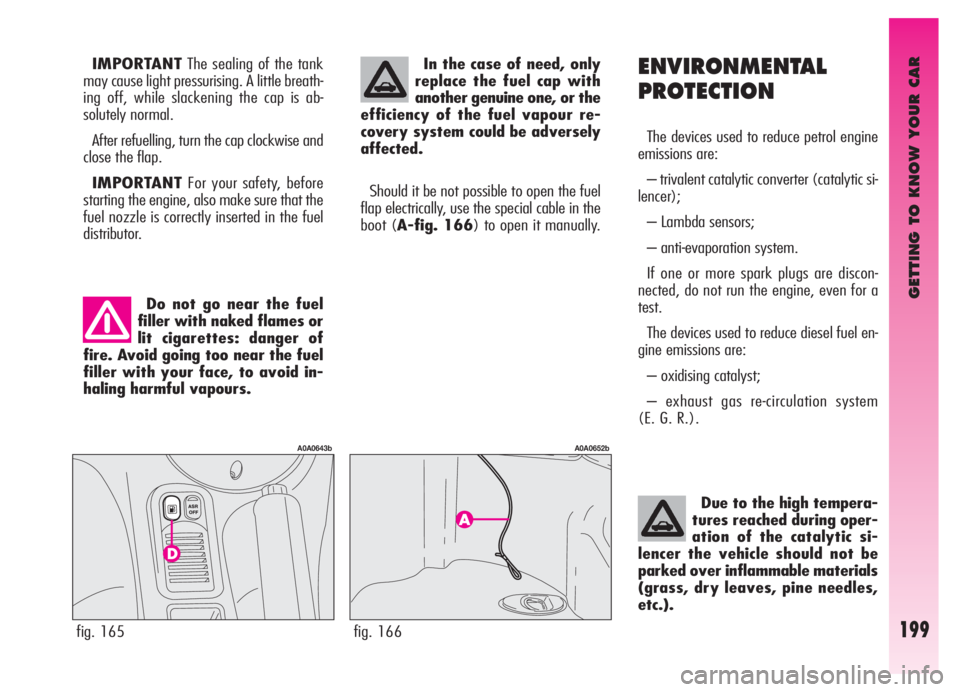

Should it be not possible to open the fuel

flap electrically, use the special cable in the

boot (A-fig. 166) to open it manually.

Due to the high tempera-

tures reached during oper-

ation of the catalytic si-

lencer the vehicle should not be

parked over inflammable materials

(grass, dry leaves, pine needles,

etc.).

fig. 165

A0A0643b

fig. 166

A0A0652b

IMPORTANTThe sealing of the tank

may cause light pressurising. A little breath-

ing off, while slackening the cap is ab-

solutely normal.

After refuelling, turn the cap clockwise and

close the flap.

IMPORTANTFor your safety, before

starting the engine, also make sure that the

fuel nozzle is correctly inserted in the fuel

distributor.

Page 205 of 307

Never leave children

unattended in the vehicle.

Always remove the igni-

tion key when leaving the vehicle

and take it with you.To avoid useless con-

sumption of power and

possible draining of the

battery, never leave the ignition

key in the MAR position when

the engine is not running.

CORRECT USE OF THE CAR

203

PARKING

When the vehicle is parked, proceed as

follows:

– Switch off the engine.

– Engage the handbrake.

– Engage first gear if the vehicle is faced

uphill or reverse if the vehicle is facing

downhill.

– Turn the front wheels so that the vehi-

cle will immediately come to a halt if the

handbrake slips.

REDUCING RUNNING

COSTS AND

ENVIRONMENT

POLLUTION

By following a few simple guidelines, it

is possible to save vehicle running costs

and reduce harmful emissions.

GENERAL CONSIDERATIONS

Vehicle maintenance

To take care of the car maintenance

have the checks and adjustments carried

out in accordance with the “Scheduled

Maintenance Programme”.

Tyres

Check the pressure of the tyres routinely

at an interval of no more than 4 weeks: if

the pressure is too low consumption levels

increase as resistance to rolling is higher.

Useless loads

Never travel with an overload in the

boot. The weight of the vehicle (especial-

ly in urban traffic), and its geometry heav-

ily affect consumption levels and stability.Electric services

Use electric devices only for the amount

of time needed. Rearscreen heating, addi-

tional headlights, windscreen wipers and

heater fan need a considerable amount of

energy, therefore increasing the require-

ment of current increases fuel consump-

tion (up to +25% in the urban cycle).

Climate control system

The climate control system is a further

load bearing heavily on the engine induc-

ing higher consumption levels(up to

+20% on average). Outside temperature

permitting, preferably use the air vents.

Aerodynamic items

The use of non-certified aerodynamic

items may adversely affect air drag and

consumption levels.

Page 218 of 307

IN AN EMERGENCY

216

– Using the wrench provided, tighten

the fastening bolts.

– Lower the car and remove the jack.

– Using the wrench provided, fully tight-

en the bolts in the sequence shown previ-

ously for the compact spare wheel fig. 8.

– Place the cap near the wheel so that

the inflation valve can come through the

slot provided on the cap.

– Press the circumference of the cap,

starting from the parts nearest to the infla-

tion valve until it is inserted completely.

IMPORTANTIncorrect fitting may

cause the wheel cap to come off when the

car is travelling.For versions with alloy rims:

– Tighten the pin (A-fig. 9) in one of

the fastening bolt holes on the wheel hub.

– Insert the wheel on the pin and, using

the wrench provided, tighten the four bolts

available. This is facilitated by the exten-

sion provided (B).

– Remove the pin (A-fig. 9) and tight-

en the last fastening bolt.

– Lower the car and remove the jack.

– Using the wrench provided, tighten

the bolts in the sequence shown previous-

ly for the compact spare wheel fig. 8.After refitting a wheel:

– stow the spare wheel in the space pro-

vided in the boot

– insert the jack in its container forcing

it lightly to prevent it from vibrating when

travelling

– place the tools used in the housings in

the container

– stow the container complete with tools

on the spare wheel and secure everything

with the clamping device (A-fig. 3)

– correctly re-position the stiff cover.

fig. 7

A0A0155b

fig. 8

A0A0156b

fig. 9

A0A0693b

Page 219 of 307

IN AN EMERGENCY

217

QUICK TYRE REPAIR

KIT FIX&GO automatic

The car is provided with the quick tyre re-

pair kit “FIX&GO automatic”, instead of the

traditional tool kit and space-saver spare

wheel.

The kit fig. 10, is placed in the boot. In

this container are also housed the screw-

driver and the tow hitch. The quick tyre repair kit includes:

– a bottle A-fig. 10containing the seal-

er, fitted with:

– filling pipe B

– sticker Cbearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel) af-

ter fixing the tyre;

– compressor Dwith pressure gauge and

fittings;– instruction brochure fig. 11, to be used

for prompt and proper use of the quick re-

pair kit and to be then handed to the per-

sonnel charged with handling the tyre treat-

ed with the tyre repair kit;

– a pair of protection gloves located in the

side space of the compressor;

– adapters for inflating different elements.

fig. 10

A0A1095b

fig. 11

A0A1096b

Page 227 of 307

IN AN EMERGENCY

225

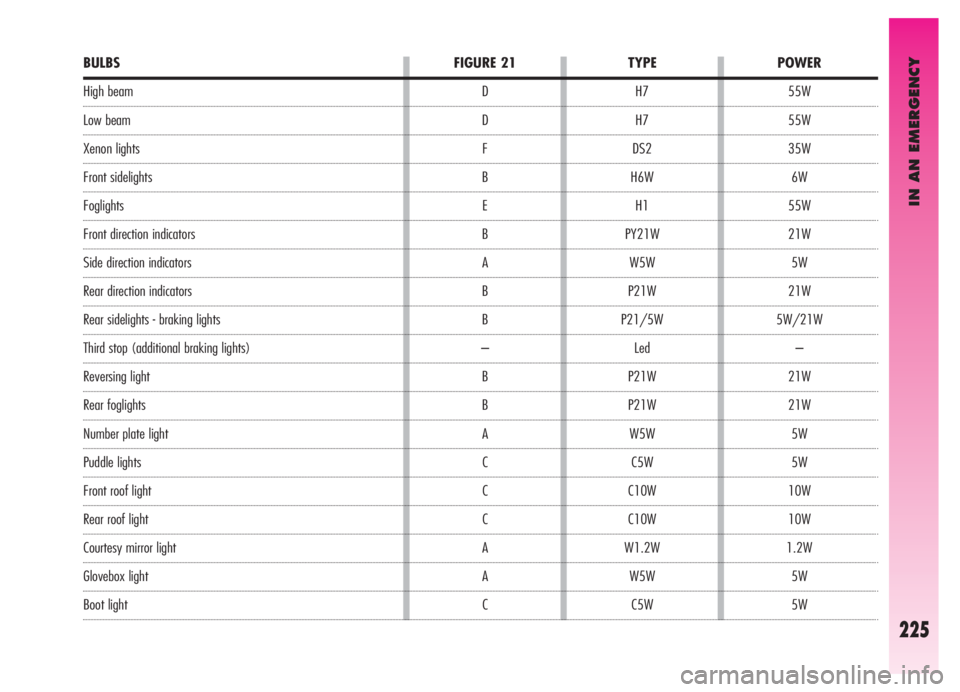

BULBS

High beam

Low beam

Xenon lights

Front sidelights

Foglights

Front direction indicators

Side direction indicators

Rear direction indicators

Rear sidelights - braking lights

Third stop (additional braking lights)

Reversing light

Rear foglights

Number plate light

Puddle lights

Front roof light

Rear roof light

Courtesy mirror light

Glovebox light

Boot lightFIGURE 21

D

D

F

B

E

B

A

B

B

–

B

B

A

C

C

C

A

A

CPOWER

55W

55W

35W

6W

55W

21W

5W

21W

5W/21W

–

21W

21W

5W

5W

10W

10W

1.2W

5W

5W TYPE

H7

H7

DS2

H6W

H1

PY21W

W5W

P21W

P21/5W

Led

P21W

P21W

W5W

C5W

C10W

C10W

W1.2W

W5W

C5W

Page 232 of 307

IN AN EMERGENCY

230

REVERSING LIGHT

AND REAR FOG GUARDS

(fig. 31-32)

The reversing light and rear fog guard are

in the tail light unit fastened to the tailgate;

they are to be found respectively one on the

right and the other on the left of the vehicle

facing forwards.

To change the bulb, proceed as follows:

– from the bumper lower side (fig. 31),

operate on the bulb holder (A-fig 32) turn-

ing it counter-clockwise and remove it. Take

care not to get burnt if the muffler is still hot;

fig. 31

A0A0627b

fig. 33

A0A0629b

– Remove the bulb pushing gently and

turning counter-clockwise;

– Replace the bulb, then refit the bulb

holder.

Anyway, you are advised to have this

operation carried out by Alfa Romeo

Authorised Services.REAR DIRECTION INDICATORS

AND REAR SIDELIGHTS-

BRAKING LIGHTS

(fig. 33-34)

The rear direction indicators and the side-

lights-braking lights are in the tail light

unit fastened to the body.

To change the bulb, proceed as follows:

– From inside the boot, open the com-

partment (A-fig. 33) and then the door

(B) through the tab (C);

– Turn the bulb for sidelight and braking

light counter-clockwise (D-fig. 34),

or the bulb for the direction indicator (E-

fig. 34) and remove it;

fig. 32

A0A0628b

Page 237 of 307

IN AN EMERGENCY

235

BOOT LIGHT (fig. 47-48)

To change the bulb, proceed as follows:

– Open the tailgate;

– Remove the light unit (A-fig. 47)

levering in the point shown by the arrow; – Refit the light unit inserting it in its cor-

rect position firstly on one end and then

on the other until it clicks into place.– Replace the bulb (B-fig. 48) releas-

ing it from the side contacts, making sure

that the new bulb is correctly clamped

between the contacts;

– Refit the light unit inserting it in its cor-

rect position firstly on one end and then

on the other until it clicks into place (C).

fig. 46

A0A0182b

fig. 47

A0A0648b

fig. 48

A0A0649b

Page 246 of 307

IN AN EMERGENCY

244

IF THE VEHICLE IS TO BE TOWED

The tow ring supplied with the vehicle is

housed in the tool box under the boot

mat.

To install the tow ring, proceed as fol-

lows:

– Take the tow ring from the tool box.

– Remove the cover (A) snap-fitted on

the front (fig. 55) or rear (fig. 56)

bumper. To do this, using the flat-bladed

screwdriver provided, protect the tip with

a soft cloth to avoid damaging the car.– Firmly screw the ring in its housing.

fig. 55 - front

A0A0650b

fig. 56 - rear

A0A0670b

Before tightening the

ring carefully clean the

threaded housing. Before

beginning to tow the car, make

sure that the ring is firmly tight-

ened in its threaded housing.

Before starting to tow,

turn the ignition key to

MAR and back to STOP,

again without removing it.

Removing the key automatically

engages the steering lock result-

ing in the impossibility to steer

the wheels. When towing

remember that without the help

of the engine brake and power

steering greater effort is required

on the pedal and steering wheel.

Do not use flexible cables for

towing and avoid jerks. During

towing operations make sure

that fastening the joint to the car

does not damage the components

in contact with it. When towing

the car, it is compulsory to follow

specific traffic regulations con-

cerning both the towing device

and behaviour on the road.

Page 250 of 307

VEHICLE MAINTENANCE

248

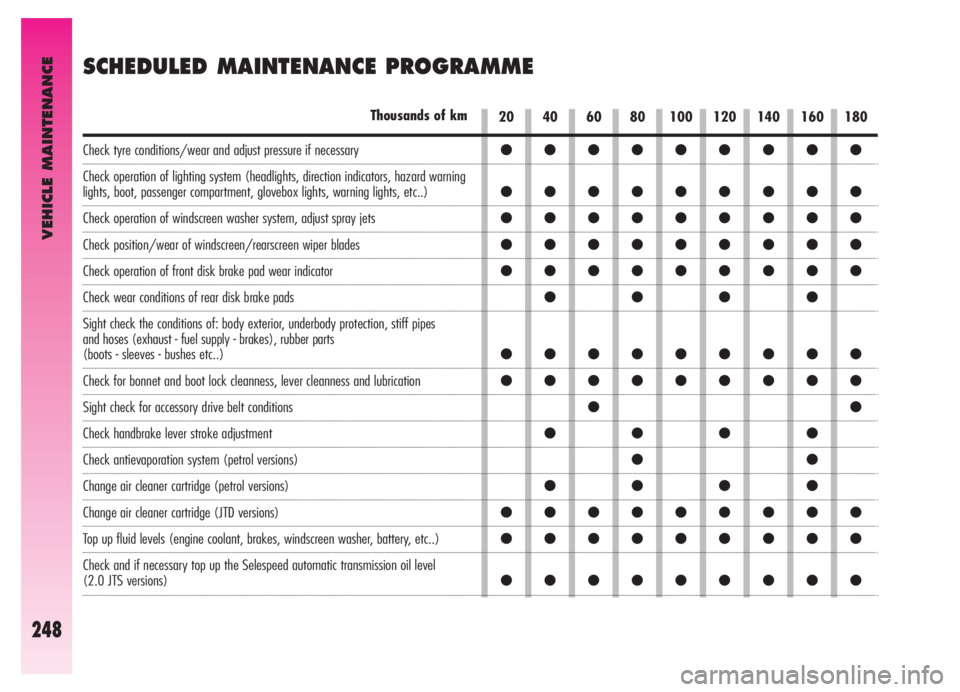

SCHEDULED MAINTENANCE PROGRAMME

20 40 60 80 100 120 140 160 180Thousands of km

Check tyre conditions/wear and adjust pressure if necessary

Check operation of lighting system (headlights, direction indicators, hazard warning

lights, boot, passenger compartment, glovebox lights, warning lights, etc..)

Check operation of windscreen washer system, adjust spray jets

Check position/wear of windscreen/rearscreen wiper blades

Check operation of front disk brake pad wear indicator

Check wear conditions of rear disk brake pads

Sight check the conditions of: body exterior, underbody protection, stiff pipes

and hoses (exhaust - fuel supply - brakes), rubber parts

(boots - sleeves - bushes etc..)

Check for bonnet and boot lock cleanness, lever cleanness and lubrication

Sight check for accessory drive belt conditions

Check handbrake lever stroke adjustment

Check antievaporation system (petrol versions)

Change air cleaner cartridge (petrol versions)

Change air cleaner cartridge (JTD versions)

Top up fluid levels (engine coolant, brakes, windscreen washer, battery, etc..)

Check and if necessary top up the Selespeed automatic transmission oil level

(2.0 JTS versions)

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●

●●●●●●●●●

●●●●●●●●●

●●

●●●●

●●

●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●