ECT Alfa Romeo Stelvio 2018 Owner's Manual

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2018, Model line: Stelvio, Model: Alfa Romeo Stelvio 2018Pages: 276, PDF Size: 5.79 MB

Page 195 of 276

3. Install bulb, making sure that it is

correctly inserted fully.

4. Close the protective cover on the lens.

5. Install liftgate lamp in the correct

position, inserting it first on one side, and

then pressing on the other side until it

clicks into place.

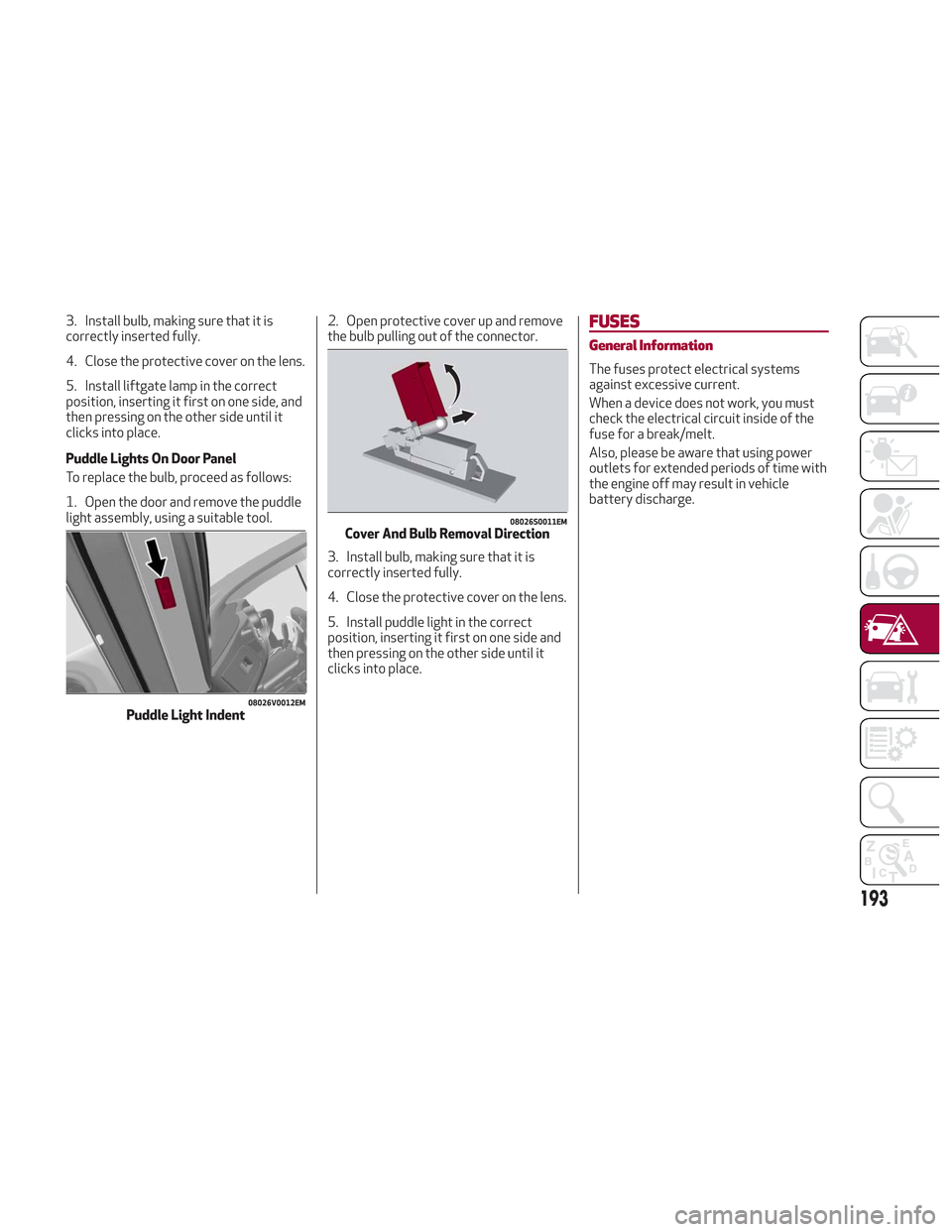

Puddle Lights On Door Panel

To replace the bulb, proceed as follows:

1. Open the door and remove the puddle

light assembly, using a suitable tool.2. Open protective cover up and remove

the bulb pulling out of the connector.

3. Install bulb, making sure that it is

correctly inserted fully.

4. Close the protective cover on the lens.

5. Install puddle light in the correct

position, inserting it first on one side and

then pressing on the other side until it

clicks into place.FUSES

General Information

The fuses protect electrical systems

against excessive current.

When a device does not work, you must

check the electrical circuit inside of the

fuse for a break/melt.

Also, please be aware that using power

outlets for extended periods of time with

the engine off may result in vehicle

battery discharge.

08026V0012EMPuddle Light Indent

08026S0011EMCover And Bulb Removal Direction

193

Page 196 of 276

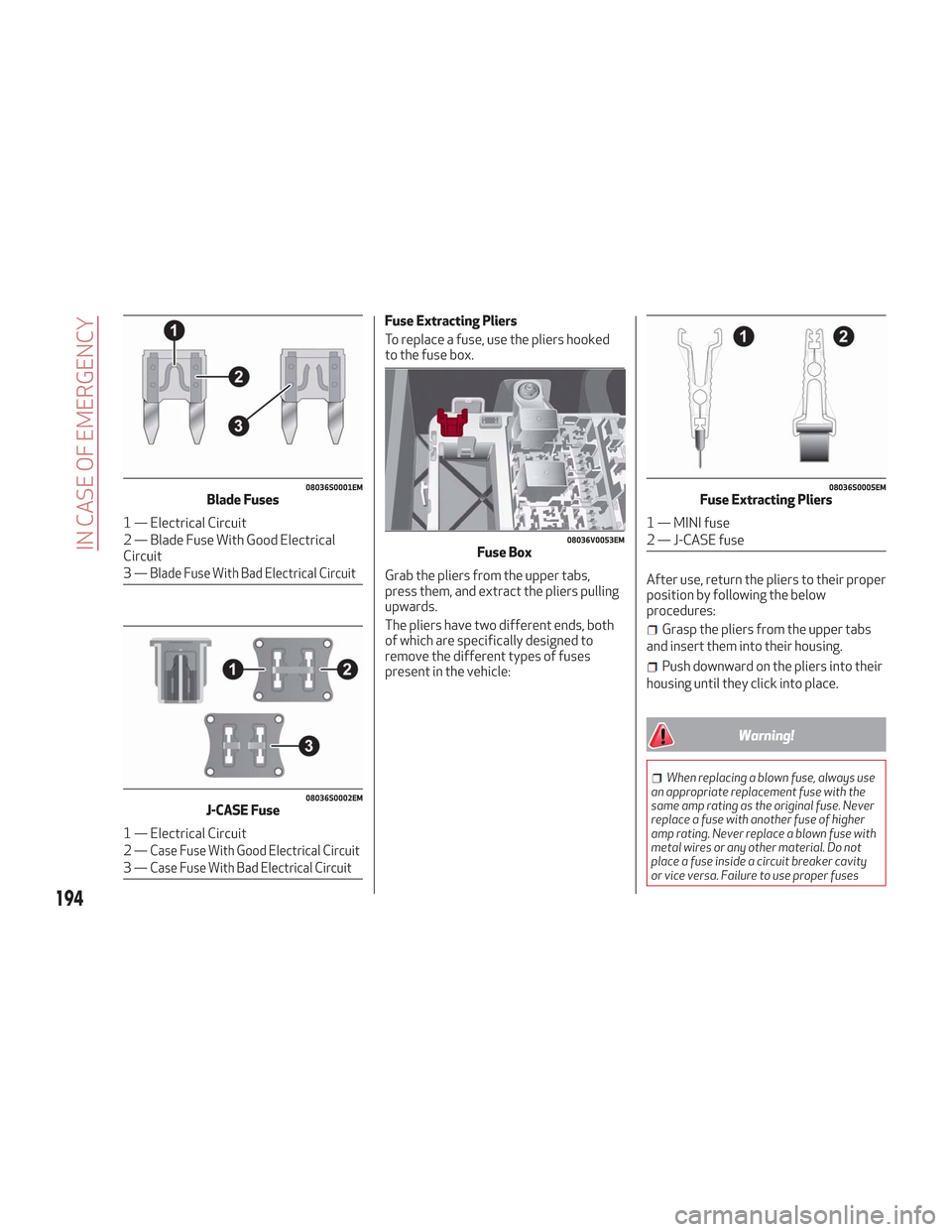

Fuse Extracting Pliers

To replace a fuse, use the pliers hooked

to the fuse box.

Grab the pliers from the upper tabs,

press them, and extract the pliers pulling

upwards.

The pliers have two different ends, both

of which are specifically designed to

remove the different types of fuses

present in the vehicle:After use, return the pliers to their proper

position by following the below

procedures:

Grasp the pliers from the upper tabs

and insert them into their housing.

Push downward on the pliers into their

housing until they click into place.

Warning!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

08036S0001EMBlade Fuses

1 — Electrical Circuit

2 — Blade Fuse With Good Electrical

Circuit

3—

Blade Fuse With Bad Electrical Circuit

08036S0002EMJ-CASE Fuse

1 — Electrical Circuit

2—

Case Fuse With Good Electrical Circuit

3—Case Fuse With Bad Electrical Circuit

08036V0053EMFuse Box

08036S0005EMFuse Extracting Pliers

1 — MINI fuse

2 — J-CASE fuse

194

IN CASE OF EMERGENCY

Page 197 of 276

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or

disengaged.

If the replaced fuse blows again, contact

an authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system,

transmission system) or steering system

blows, contact an authorized dealer.

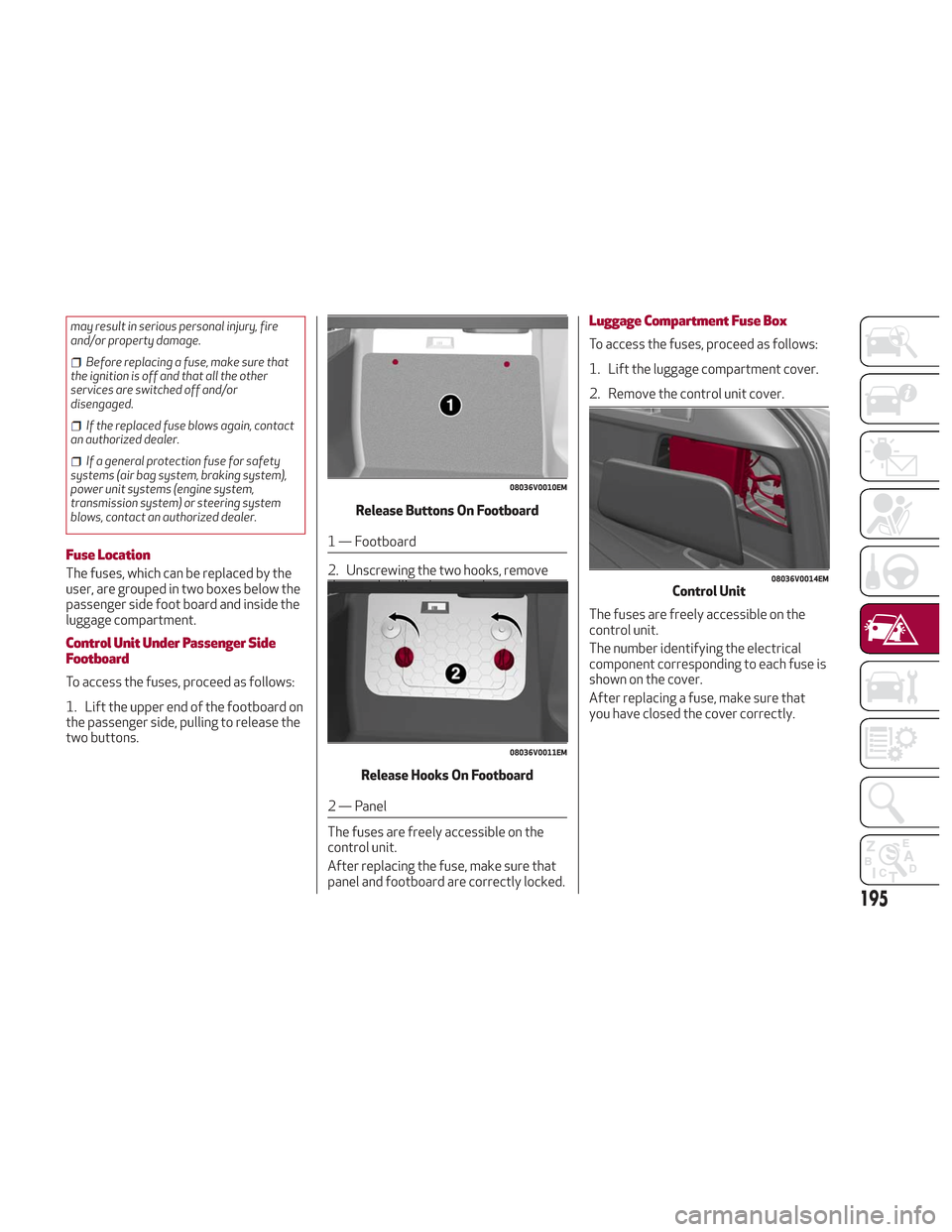

Fuse Location

The fuses, which can be replaced by the

user, are grouped in two boxes below the

passenger side foot board and inside the

luggage compartment.

Control Unit Under Passenger Side

Footboard

To access the fuses, proceed as follows:

1. Lift the upper end of the footboard on

the passenger side, pulling to release the

two buttons. Release Buttons On Footboard

1 — Footboard

2. Unscrewing the two hooks, remove

the panel pulling downward.

Release Hooks On Footboard

2 — Panel

The fuses are freely accessible on the

control unit.

After replacing the fuse, make sure that

panel and footboard are correctly locked.

Luggage Compartment Fuse Box

To access the fuses, proceed as follows:

1. Lift the luggage compartment cover.

2. Remove the control unit cover.

The fuses are freely accessible on the

control unit.

The number identifying the electrical

component corresponding to each fuse is

shown on the cover.

After replacing a fuse, make sure that

you have closed the cover correctly.

08036V0010EM

08036V0011EM

08036V0014EMControl Unit

195

Page 200 of 276

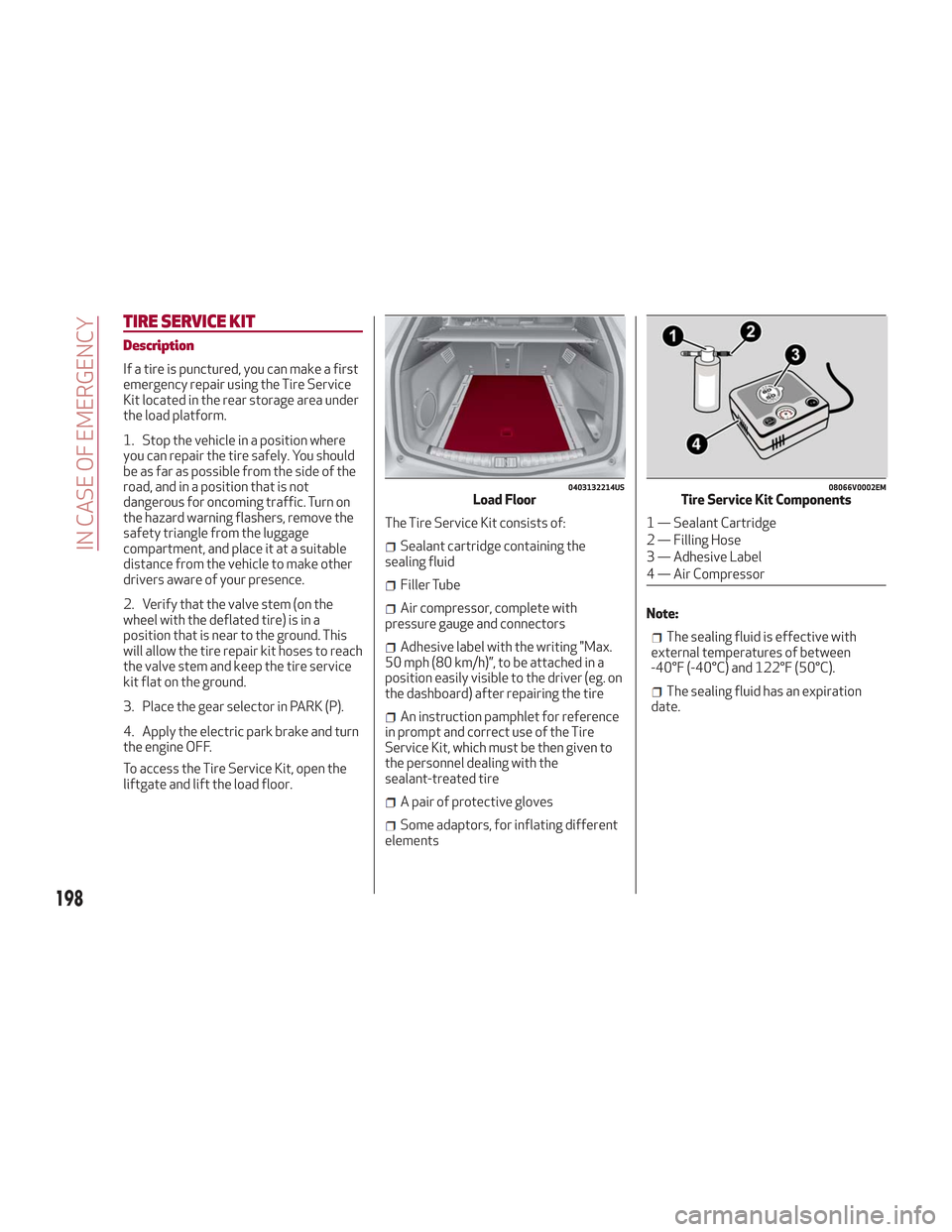

TIRE SERVICE KIT

Description

If a tire is punctured, you can make a first

emergency repair using the Tire Service

Kit located in the rear storage area under

the load platform.

1. Stop the vehicle in a position where

you can repair the tire safely. You should

be as far as possible from the side of the

road, and in a position that is not

dangerous for oncoming traffic. Turn on

the hazard warning flashers, remove the

safety triangle from the luggage

compartment, and place it at a suitable

distance from the vehicle to make other

drivers aware of your presence.

2. Verify that the valve stem (on the

wheel with the deflated tire) is in a

position that is near to the ground. This

will allow the tire repair kit hoses to reach

the valve stem and keep the tire service

kit flat on the ground.

3. Place the gear selector in PARK (P).

4. Apply the electric park brake and turn

the engine OFF.

To access the Tire Service Kit, open the

liftgate and lift the load floor.The Tire Service Kit consists of:

Sealant cartridge containing the

sealing fluid

Filler Tube

Air compressor, complete with

pressure gauge and connectors

Adhesive label with the writing "Max.

50 mph (80 km/h)”, to be attached in a

position easily visible to the driver (eg. on

the dashboard) after repairing the tire

An instruction pamphlet for reference

in prompt and correct use of the Tire

Service Kit, which must be then given to

the personnel dealing with the

sealant-treated tire

A pair of protective gloves

Some adaptors, for inflating different

elements Note:

The sealing fluid is effective with

external temperatures of between

-40°F (-40°C) and 122°F (50°C).

The sealing fluid has an expiration

date.

0403132214USLoad Floor08066V0002EMTire Service Kit Components

1 — Sealant Cartridge

2 — Filling Hose

3 — Adhesive Label

4 — Air Compressor

198

IN CASE OF EMERGENCY

Page 201 of 276

Inflation Procedure

Warning!

Do not attempt to seal a tire on the side of

the vehicle closest to traffic. Pull far enough

off the road to avoid the danger of being hit

when using the Tire Service Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving on

a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open

flames or heat sources.

A loose Tire Service Kit thrown forward in

a collision or hard stop could endanger the

occupants of the vehicle. Always stow the

Tire Service Kit in the place provided. Failure

to follow these warnings can result in

injuries that are serious or fatal to you, your

passengers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair,

eyes, or clothing. Tire Service Kit sealant is

harmful if inhaled, swallowed, or absorbed through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately

with plenty of water if there is any contact

with eyes or skin. Change clothing as soon

as possible, if there is any contact with

clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If

swallowed, rinse mouth immediately with

plenty of water and drink plenty of water.

Do not induce vomiting! Consult a physician

immediately.

To use the Tire Service Kit, proceed as

follows:

1. Apply the electric park brake.

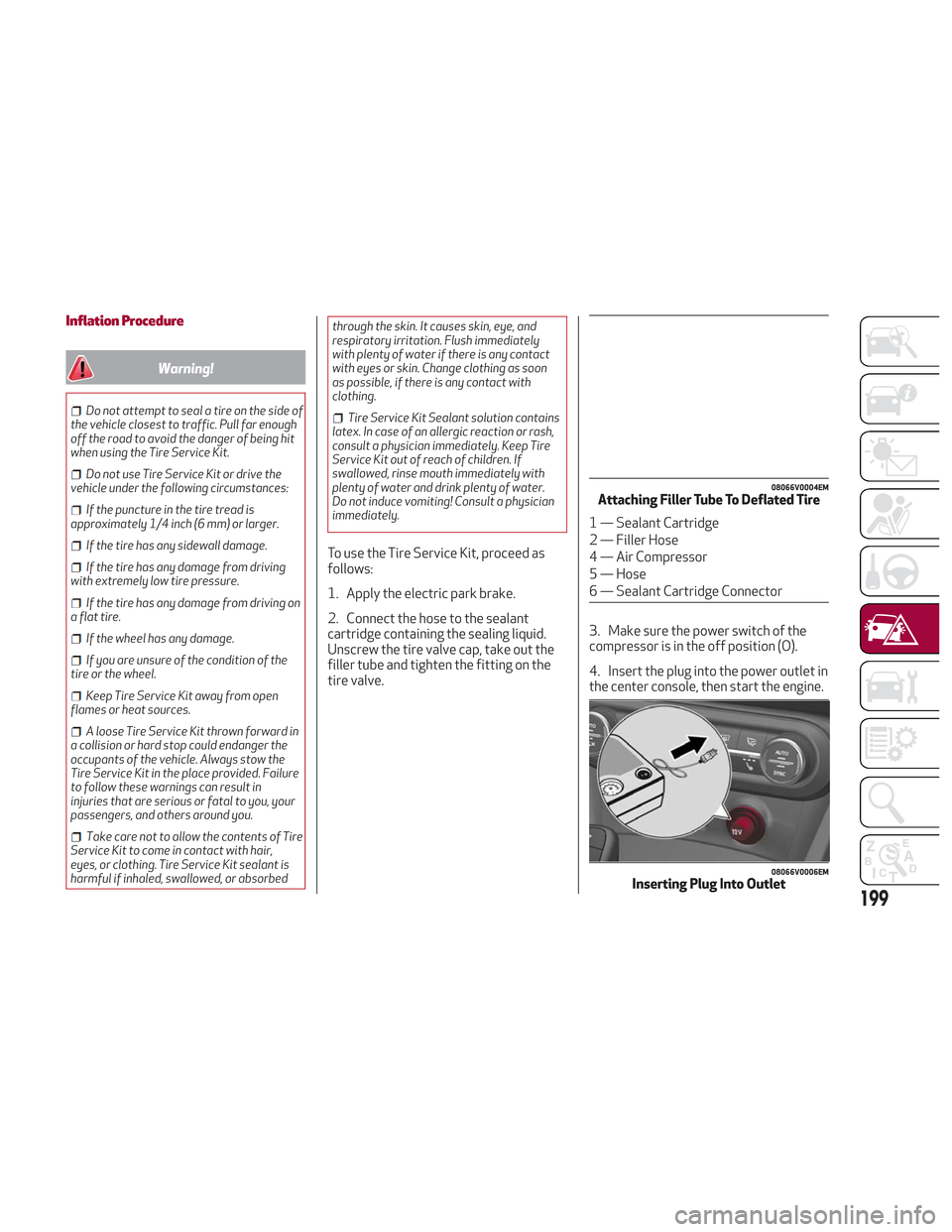

2. Connect the hose to the sealant

cartridge containing the sealing liquid.

Unscrew the tire valve cap, take out the

filler tube and tighten the fitting on the

tire valve. 3. Make sure the power switch of the

compressor is in the off position (O).

4. Insert the plug into the power outlet in

the center console, then start the engine.

08066V0004EMAttaching Filler Tube To Deflated Tire

1 — Sealant Cartridge

2 — Filler Hose

4 — Air Compressor

5 — Hose

6 — Sealant Cartridge Connector

08066V0006EMInserting Plug Into Outlet

199

Page 202 of 276

5. Start the compressor by placing the

power switch in the on position (I).

6. Inflate the tire to a pressure of at

least 32 psi (2.2 bar). Refer to “Tires” in

“Servicing And Maintenance” for more

information. In order to obtain a more

precise reading, check the pressure value

on pressure gauge with the compressor

off.

7. If the pressure is not at least 26 psi

(1.8 bar) after 15 minutes, disengage the

compressor from the valve and power

outlet. Then, move the vehicle forwards

approximately five tire turns in order to

distribute the sealing fluid inside the tire

evenly, and then repeat the inflation

operation.8. Drive the vehicle for about 5 miles

(8 km), stop, engage the electric park

brake, and recheck the tire pressure.

9. If the pressure is less than 19 psi

(1.3 bar),

DO NOTdrive the vehicle, and

see an authorized dealer.

10. If a pressure value of at least 19 psi

(1.3 bar) is detected, restore the correct

pressure (with engine running and

electric park brake engaged), and drive

immediately with great care to an

authorized dealer.

Warning!

Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired

or replaced after using Tire Service Kit. Do

not exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious

or fatal to you, your passengers, and others

around you. Have the tire checked as soon as

possible at your authorized dealer.

11. Apply the adhesive label from the

sealant bottle where it can be easily seen

by the driver as a reminder that the tire

has been treated with a Tire Service Kit,

as well as not to exceed the speed

restriction for the treated tire.

Warning!

Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to the

padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere the

sticker to areas where warning lights or the

speedometer cannot be viewed.

Note: Only use original sealant

cartridges, which can be purchased at an

authorized dealer.

Checking And Restoring Tire Pressure

The compressor can also be used to

check and, if necessary, restore the tire

pressure.

Proceed as follows:

1. Make sure that the power switch is in

the O (off) position.

2. Connect the hose directly to the valve

on the tire to be inflated.

3. Insert the plug into the socket in the

passenger compartment or in the cargo

area and start the engine.

4. Start the compressor by putting the

power switch to I (on). As soon as the

correct pressure is reached, put the

power switch to O (off).

08066V0005EMAir Compressor

7 — Power Switch

8 — Pressure Gauge

200

IN CASE OF EMERGENCY

Page 203 of 276

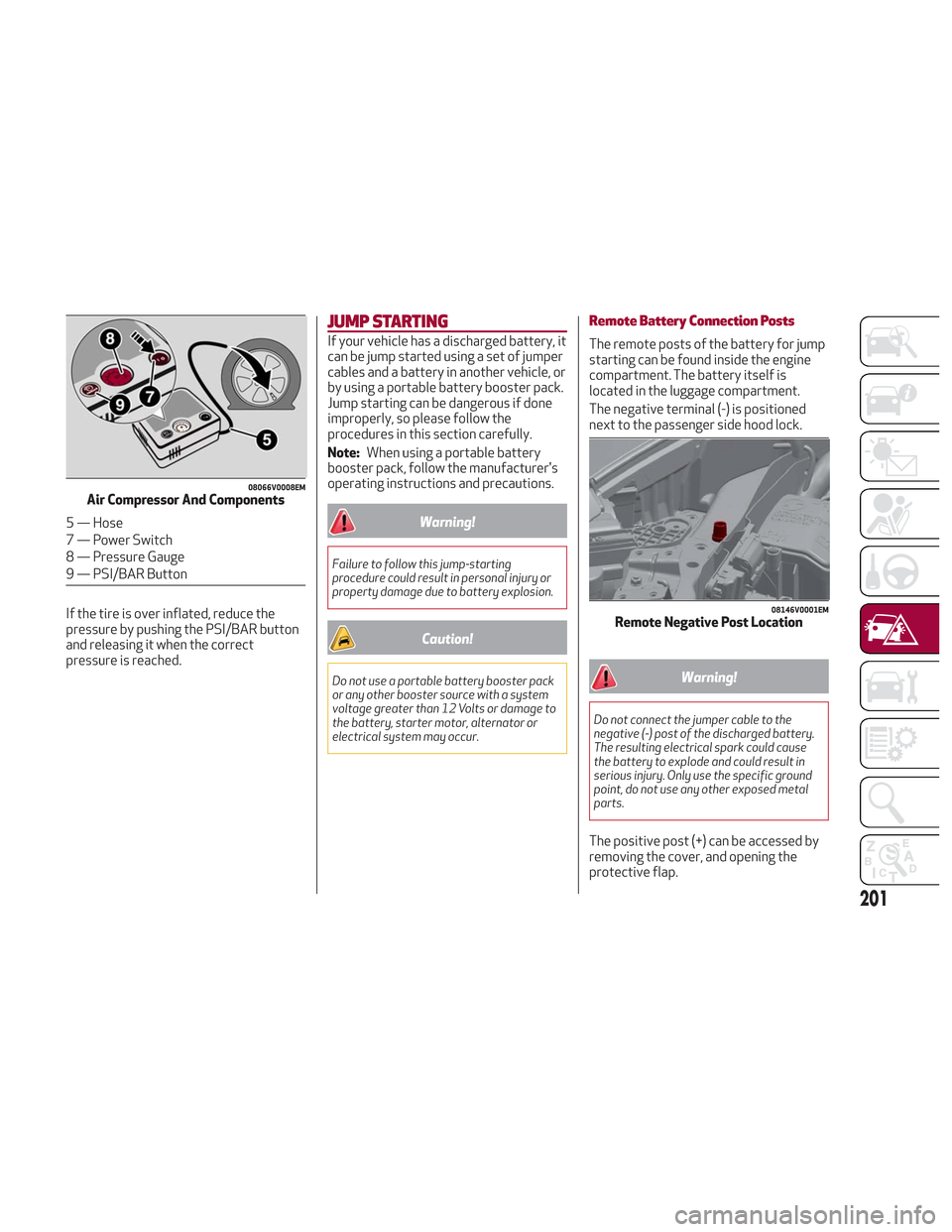

If the tire is over inflated, reduce the

pressure by pushing the PSI/BAR button

and releasing it when the correct

pressure is reached.

JUMP STARTING

If your vehicle has a discharged battery, it

can be jump started using a set of jumper

cables and a battery in another vehicle, or

by using a portable battery booster pack.

Jump starting can be dangerous if done

improperly, so please follow the

procedures in this section carefully.

Note:When using a portable battery

booster pack, follow the manufacturer's

operating instructions and precautions.

Warning!

Failure to follow this jump-starting

procedure could result in personal injury or

property damage due to battery explosion.

Caution!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

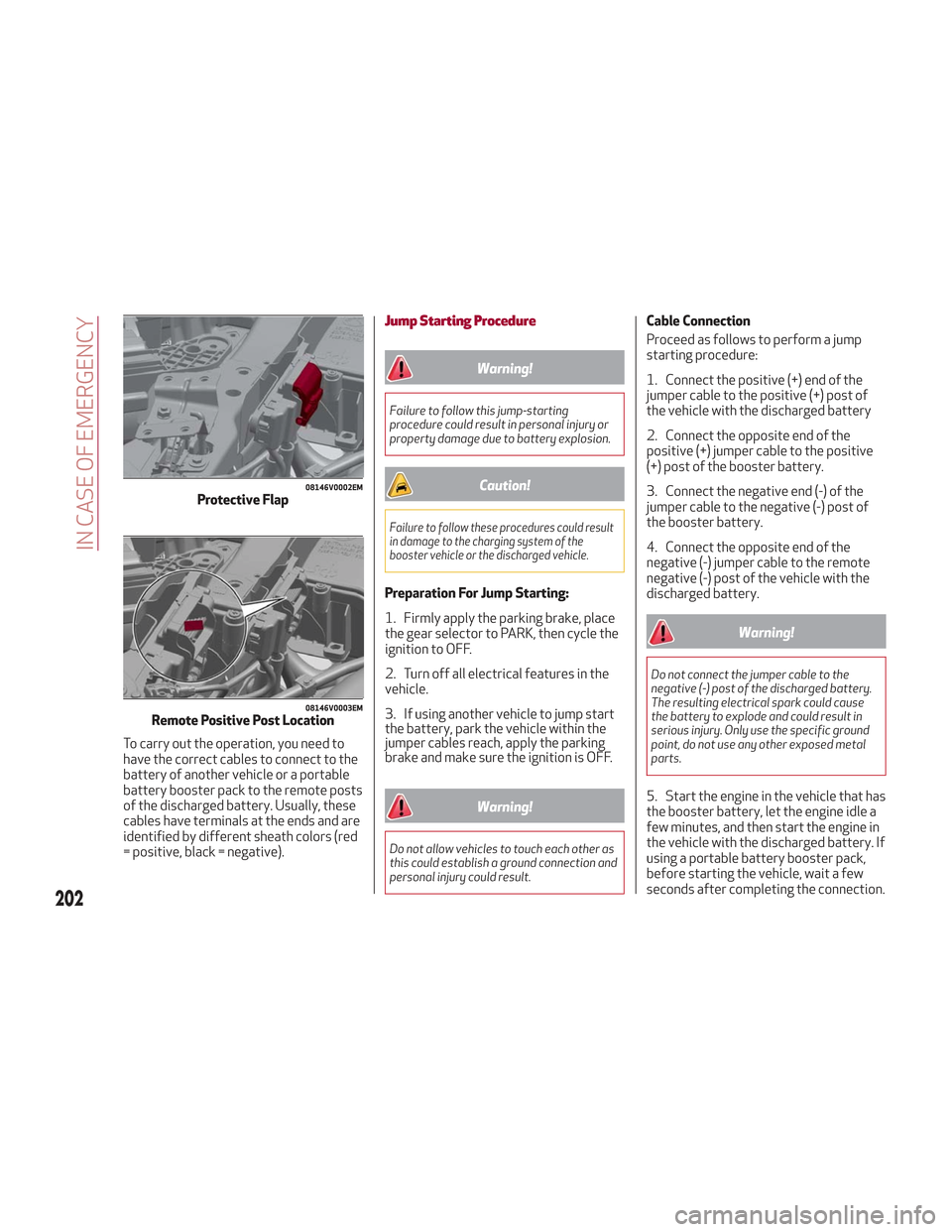

Remote Battery Connection Posts

The remote posts of the battery for jump

starting can be found inside the engine

compartment. The battery itself is

located in the luggage compartment.

The negative terminal (-) is positioned

next to the passenger side hood lock.

Warning!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

serious injury. Only use the specific ground

point, do not use any other exposed metal

parts.

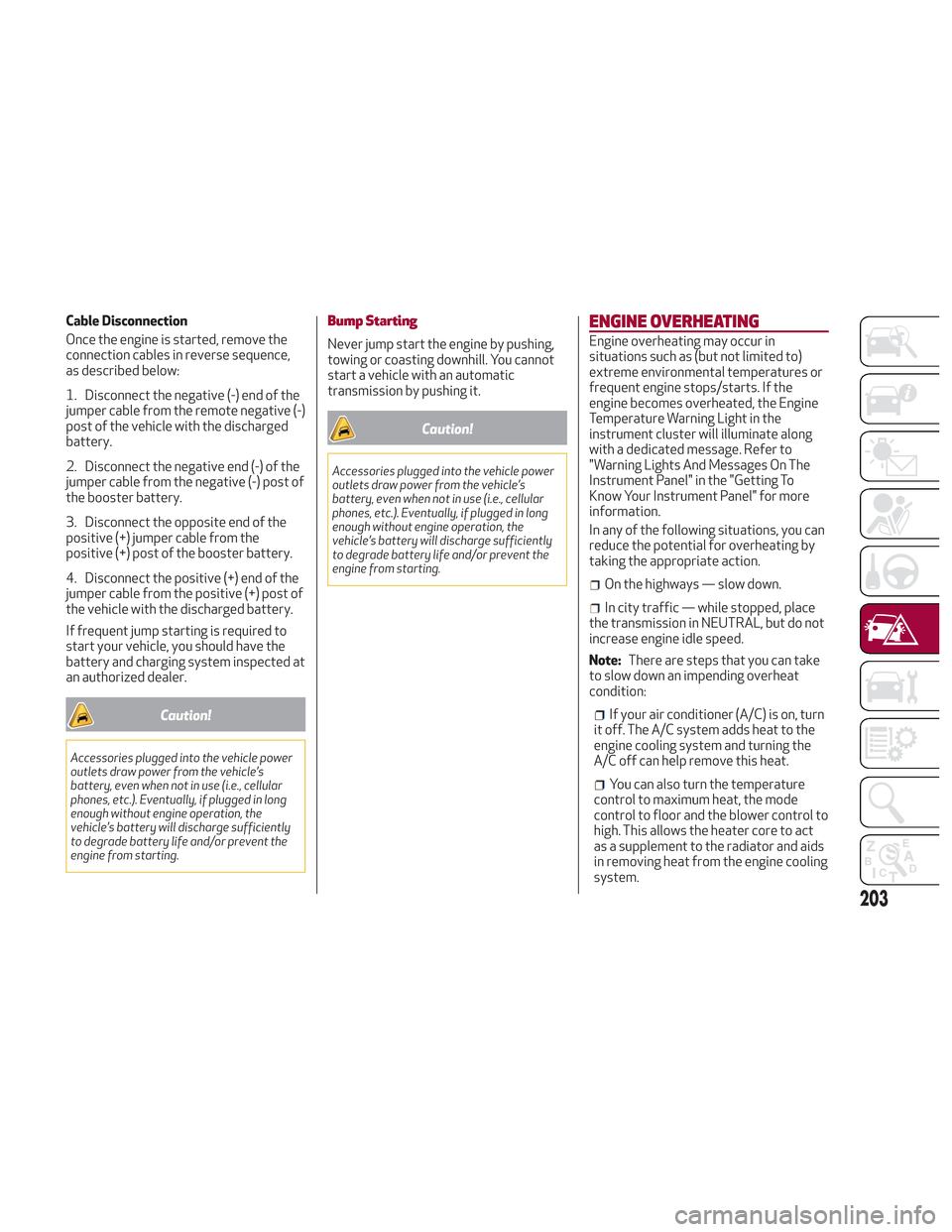

The positive post (+) can be accessed by

removing the cover, and opening the

protective flap.

08066V0008EMAir Compressor And Components

5 — Hose

7 — Power Switch

8 — Pressure Gauge

9 — PSI/BAR Button

08146V0001EMRemote Negative Post Location

201

Page 204 of 276

To carry out the operation, you need to

have the correct cables to connect to the

battery of another vehicle or a portable

battery booster pack to the remote posts

of the discharged battery. Usually, these

cables have terminals at the ends and are

identified by different sheath colors (red

= positive, black = negative).

Jump Starting Procedure

Warning!

Failure to follow this jump-starting

procedure could result in personal injury or

property damage due to battery explosion.

Caution!

Failure to follow these procedures could result

in damage to the charging system of the

booster vehicle or the discharged vehicle.

Preparation For Jump Starting:

1. Firmly apply the parking brake, place

the gear selector to PARK, then cycle the

ignition to OFF.

2. Turn off all electrical features in the

vehicle.

3. If using another vehicle to jump start

the battery, park the vehicle within the

jumper cables reach, apply the parking

brake and make sure the ignition is OFF.

Warning!

Do not allow vehicles to touch each other as

this could establish a ground connection and

personal injury could result.

Cable Connection

Proceed as follows to perform a jump

starting procedure:

1. Connect the positive (+) end of the

jumper cable to the positive (+) post of

the vehicle with the discharged battery

2. Connect the opposite end of the

positive (+) jumper cable to the positive

(+) post of the booster battery.

3. Connect the negative end (-) of the

jumper cable to the negative (-) post of

the booster battery.

4. Connect the opposite end of the

negative (-) jumper cable to the remote

negative (-) post of the vehicle with the

discharged battery.

Warning!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

serious injury. Only use the specific ground

point, do not use any other exposed metal

parts.

5. Start the engine in the vehicle that has

the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery. If

using a portable battery booster pack,

before starting the vehicle, wait a few

seconds after completing the connection.

08146V0002EMProtective Flap

08146V0003EMRemote Positive Post Location

202

IN CASE OF EMERGENCY

Page 205 of 276

Cable Disconnection

Once the engine is started, remove the

connection cables in reverse sequence,

as described below:

1. Disconnect the negative (-) end of the

jumper cable from the remote negative (-)

post of the vehicle with the discharged

battery.

2. Disconnect the negative end (-) of the

jumper cable from the negative (-) post of

the booster battery.

3. Disconnect the opposite end of the

positive (+) jumper cable from the

positive (+) post of the booster battery.

4. Disconnect the positive (+) end of the

jumper cable from the positive (+) post of

the vehicle with the discharged battery.

If frequent jump starting is required to

start your vehicle, you should have the

battery and charging system inspected at

an authorized dealer.

Caution!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s

battery, even when not in use (i.e., cellular

phones, etc.). Eventually, if plugged in long

enough without engine operation, the

vehicle’s battery will discharge sufficiently

to degrade battery life and/or prevent the

engine from starting.

Bump Starting

Never jump start the engine by pushing,

towing or coasting downhill. You cannot

start a vehicle with an automatic

transmission by pushing it.

Caution!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s

battery, even when not in use (i.e., cellular

phones, etc.). Eventually, if plugged in long

enough without engine operation, the

vehicle’s battery will discharge sufficiently

to degrade battery life and/or prevent the

engine from starting.

ENGINE OVERHEATING

Engine overheating may occur in

situations such as (but not limited to)

extreme environmental temperatures or

frequent engine stops/starts. If the

engine becomes overheated, the Engine

Temperature Warning Light in the

instrument cluster will illuminate along

with a dedicated message. Refer to

"Warning Lights And Messages On The

Instrument Panel" in the "Getting To

Know Your Instrument Panel" for more

information.

In any of the following situations, you can

reduce the potential for overheating by

taking the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place

the transmission in NEUTRAL, but do not

increase engine idle speed.

Note: There are steps that you can take

to slow down an impending overheat

condition:

If your air conditioner (A/C) is on, turn

it off. The A/C system adds heat to the

engine cooling system and turning the

A/C off can help remove this heat.

You can also turn the temperature

control to maximum heat, the mode

control to floor and the blower control to

high. This allows the heater core to act

as a supplement to the radiator and aids

in removing heat from the engine cooling

system.

203

Page 206 of 276

Warning!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open the

hood until the radiator has had time to cool.

Never try to open a cooling system pressure

cap when the radiator or coolant bottle is

hot.

Caution!

Driving with a hot cooling system could

damage your vehicle. If temperature gauge

reads “H”, pull over and stop the vehicle. Idle

the vehicle with the air conditioner turned

off until the pointer drops back into the

normal range. If the pointer remains on the

“H”, turn the engine off immediately, and call

for service.

Note:

If the cooling fan does not operate

while the engine is running, the engine

temperature will increase. Stop the

engine and contact an authorized dealer.

If the engine continues to overheat or

frequently overheats, have the cooling

system inspected. The engine could be

seriously damaged unless repairs are

made. Contact an authorized dealer.

TOWING A DISABLED VEHICLE

This section describes procedures for

towing a disabled vehicle using a

commercial towing service.

Caution!

The vehicle should be transported with all

four wheels OFF the ground on the flatbed

of a roadside assistance vehicle. Avoid

towing with only the front (or rear) wheels

lifted. When towing with only the front (or

rear) wheels lifted, in addition to damaging

the body, it could damage the transmission.

Do not use sling-type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flatbed

truck, do not attach to front or rear

suspension components. Damage to your

vehicle may result from improper towing.

Ensure that the Electric Park Brake is

released, and remain released, while being

towed.

Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

Note: If your vehicle is equipped with a

Anti-Lift Protection system, you will need

to disable the system prior to towing by

pushing the button located on the

overhead console. Refer to “Anti-Lift

Protection — If Equipped” in “Getting To

Know Your Vehicle” for further

information.

The operators of the assistance vehicle

must be informed with regard to the

vehicle's minimum height from ground in

order to avoid contact between the ends

of the bumpers with the equipment of the

breakdown truck.

The following image illustrates the front

and rear attachment corners of the

vehicle, to be taken into consideration

when loading the vehicle on the

commercial towing vehicle.

204

IN CASE OF EMERGENCY